Patents

Literature

151results about How to "Reduce surface cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

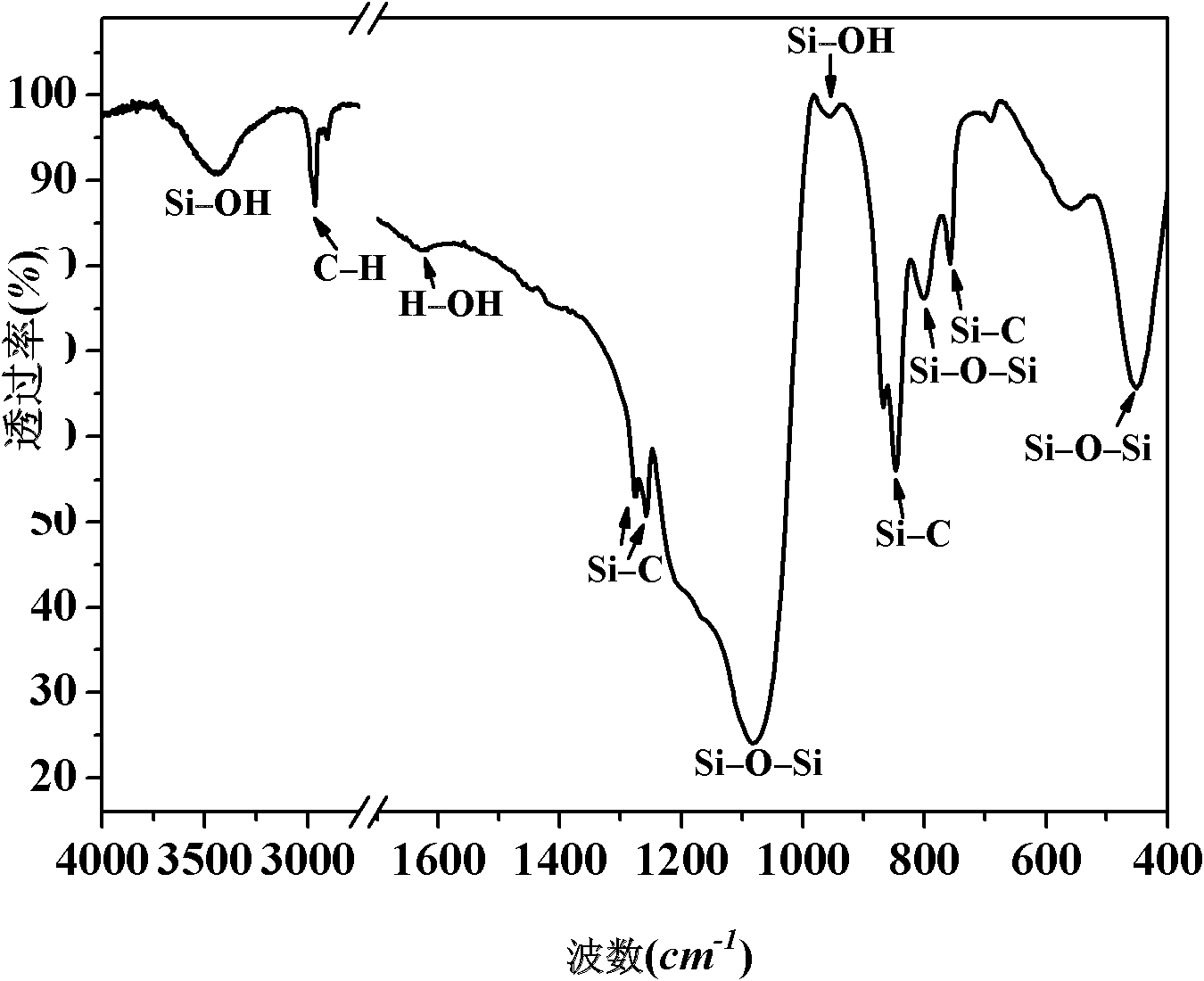

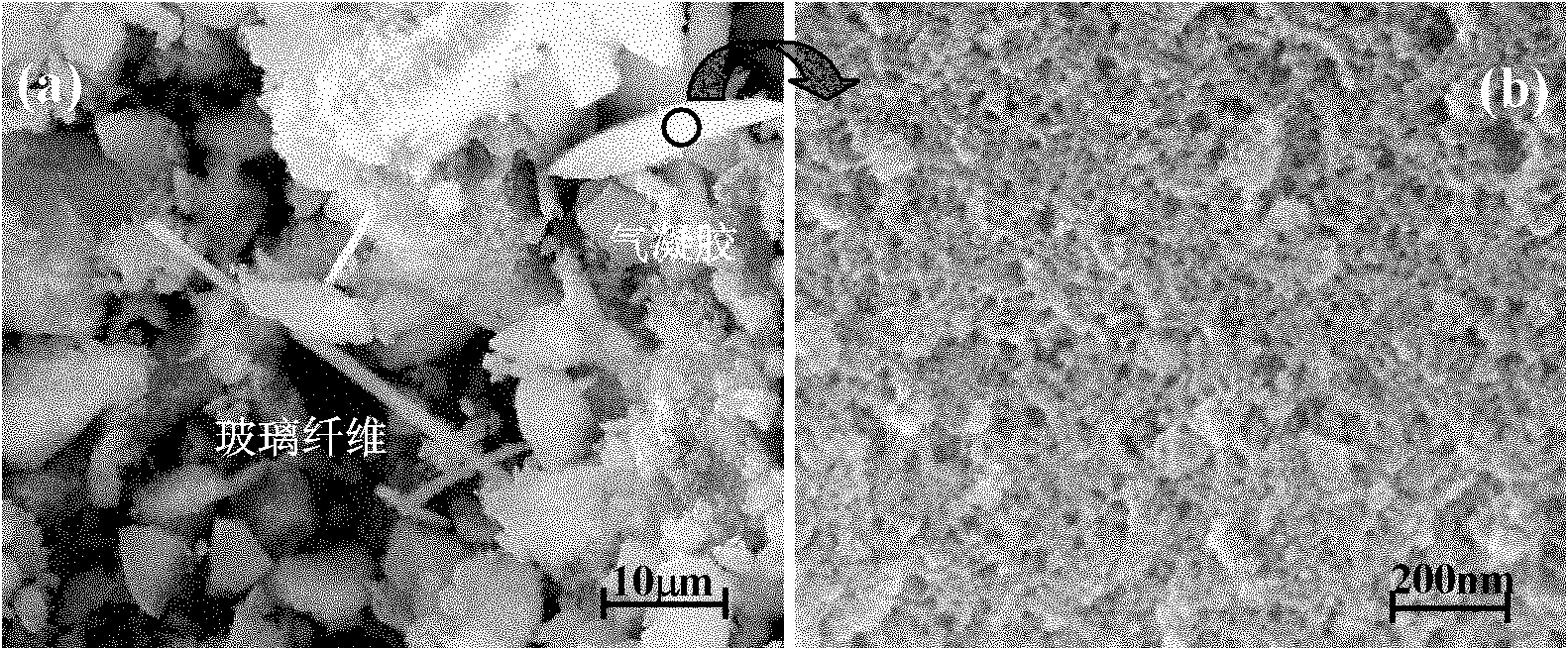

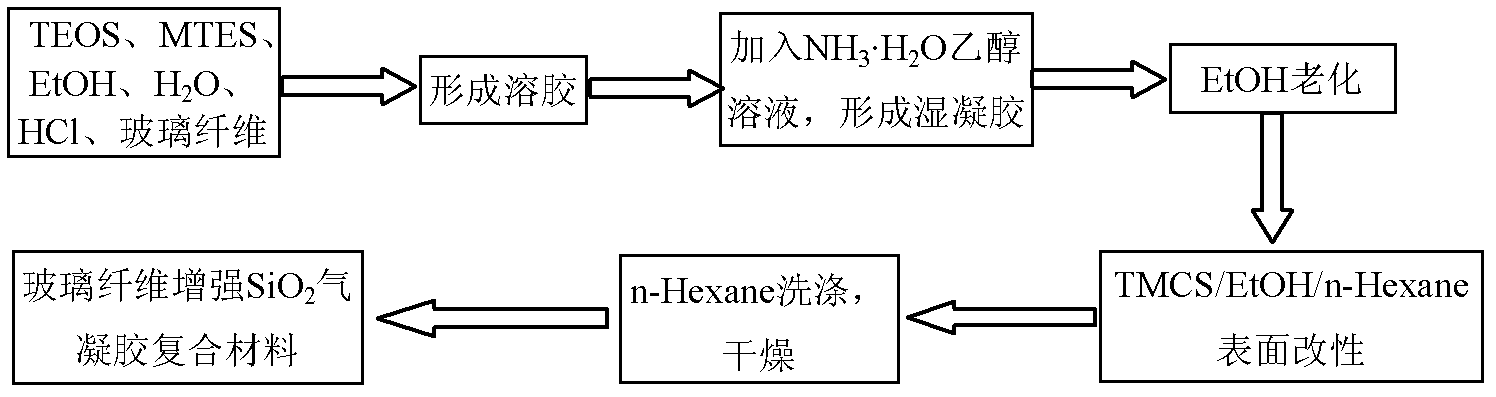

Glass fiber reinforced silicon dioxide aerogel composite material and preparation method thereof

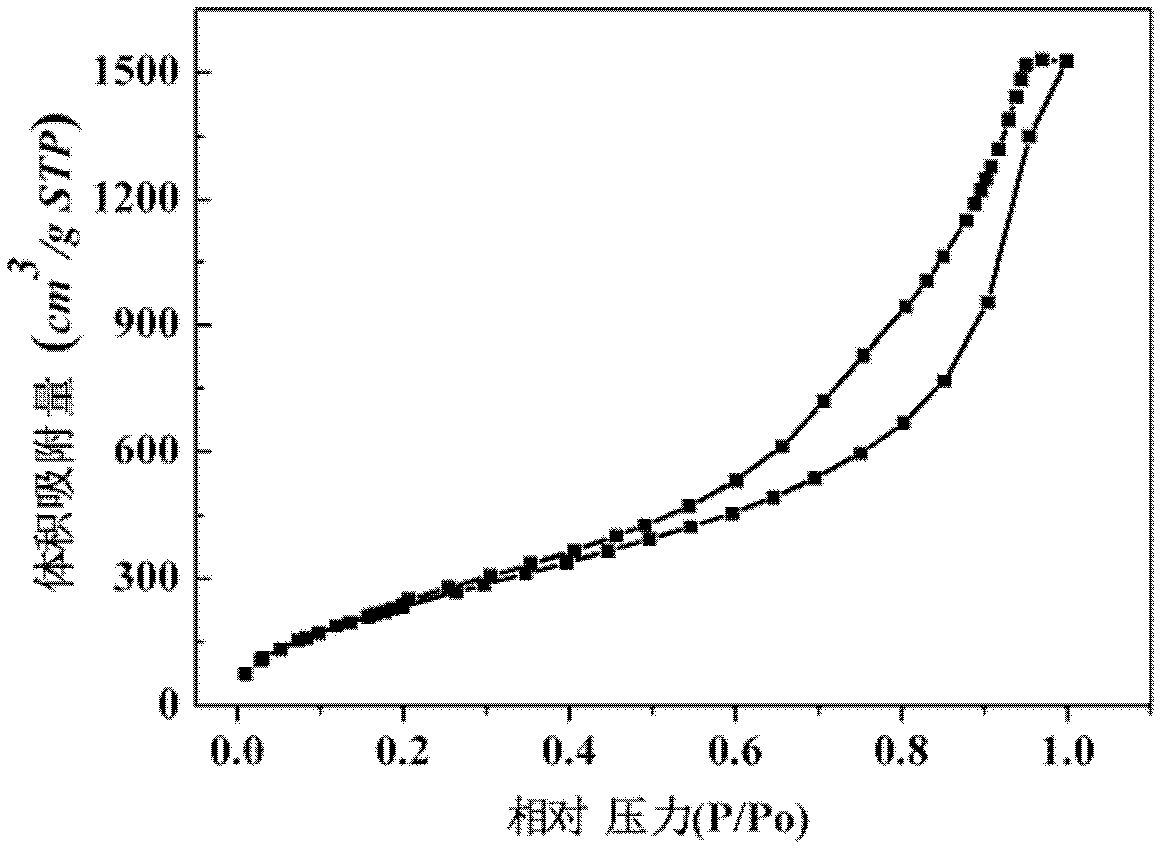

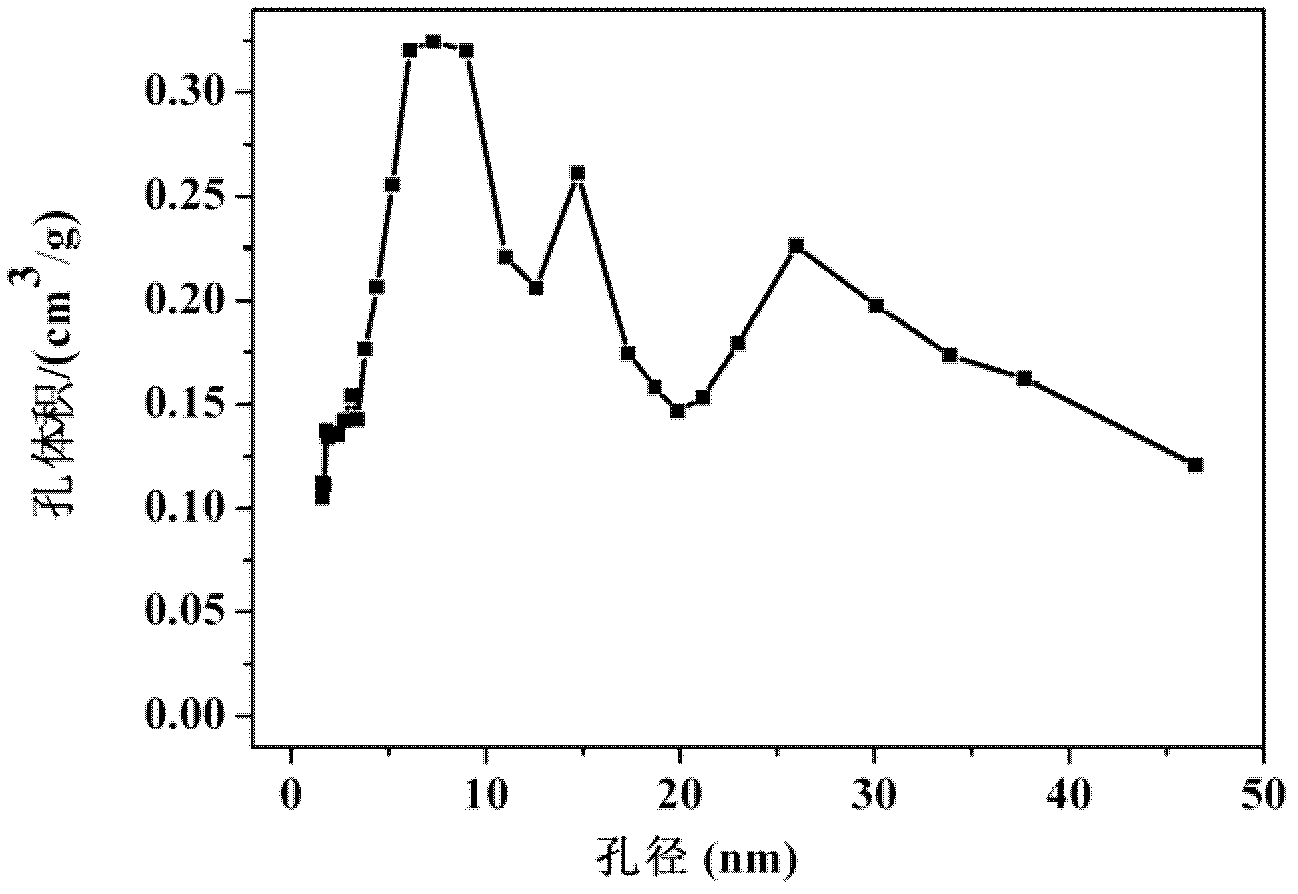

The invention relates to an aerogel composite material, in particular to a glass fiber reinforced silicon dioxide aerogel composite material and a preparation method thereof. The excellent properties of aerogel are maintained, the mechanical properties of the aerogel are reinforced, and the glass fiber reinforced silicon dioxide aerogel composite material has good integrity and certain strength. The glass fiber reinforced silicon dioxide aerogel composite material is prepared by compounding glass fiber and silicon dioxide aerogel, wherein the glass fiber is a reinforcement, and the content ofthe glass fiber accounts for 1-15% total mass of a sample; the silicon dioxide aerogel is a matrix, tetraethoxysilane is a silicon source material, and methyltrimethoxysilane or methyltriethoxysilaneis used as a silicon source co-precursor. The preparation method comprises the following steps of: firstly, pretreating the glass fiber; then, preparing glass fiber reinforced silicon dioxide composite wet gel; and finally, aging, secondarily modifying and drying the silicon dioxide composite wet gel.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

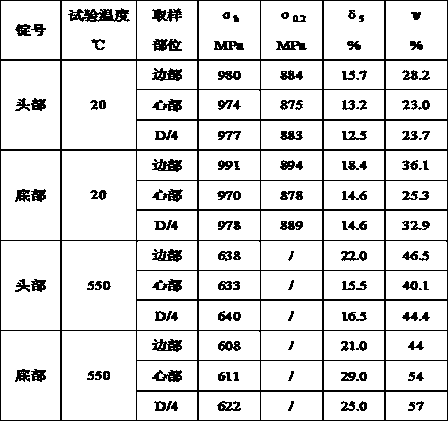

Manufacturing method of stainless steel large forging for thermonuclear fusion reactor

ActiveCN104174796AReduce surface cracksSmall crack depthMetal-working apparatusSS - Stainless steelIngot

The invention discloses a manufacturing method of a stainless steel large forging for a thermonuclear fusion reactor. The manufacturing method comprises the following steps: (1) preprocessing of a steel ingot; (2) heating of the steel ingot; (3) forging of the steel ingot; (4) twice upsetting forging and twice drawing out of the ingot; (5) shaping of the finished product; (6) heating processing of finished product forgings, wherein the finally obtained the stainless steel large forging is 300-1000 mm in thickness, 300-1800 mm in width and 500-2200 mm in length. The manufacturing method realizes that the grain size of the stainless steel large forging is greater than or equal to the second level, the depth of surface cracks of the stainless steel large forging is less than 1 mm, and the stainless steel large forging satisfies the quality requirement of the thermonuclear fusion reactor (the ITER Plan included).

Owner:NORTHEASTERN UNIV +1

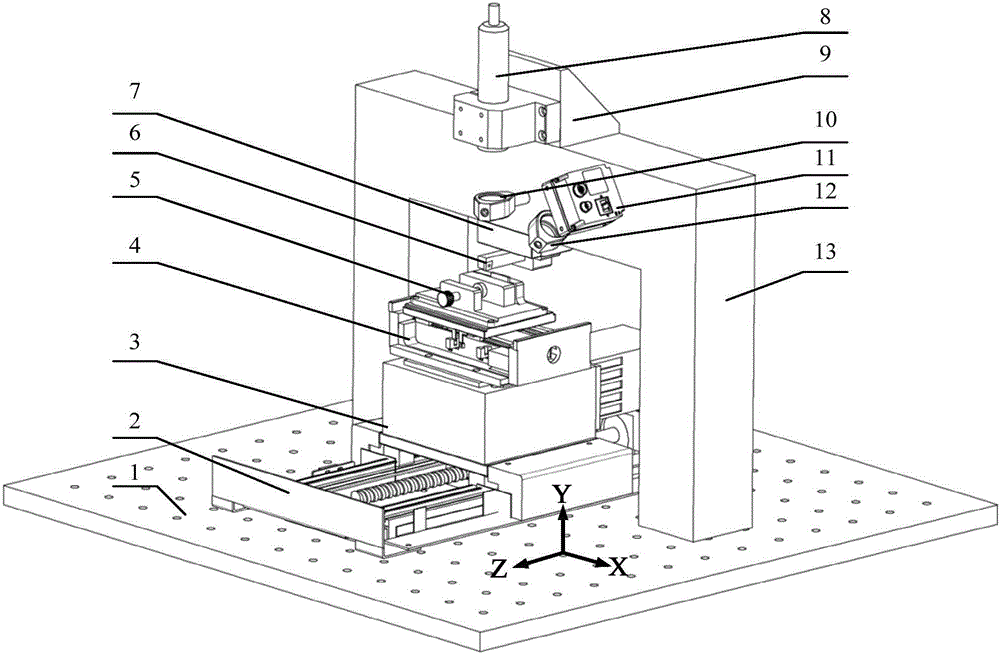

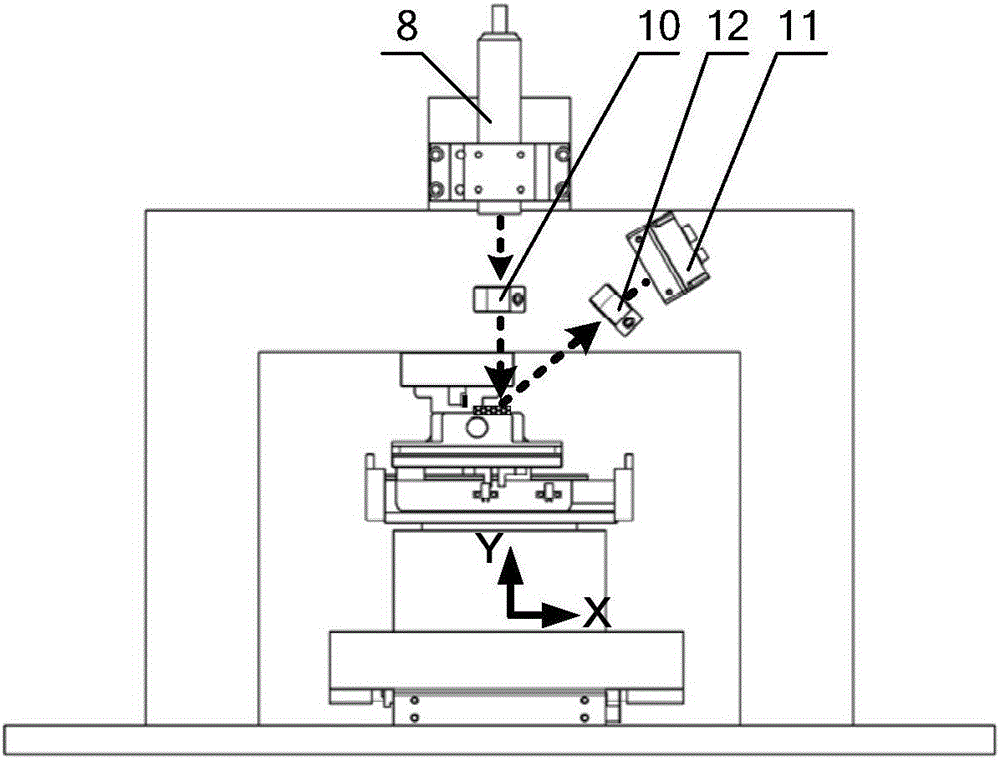

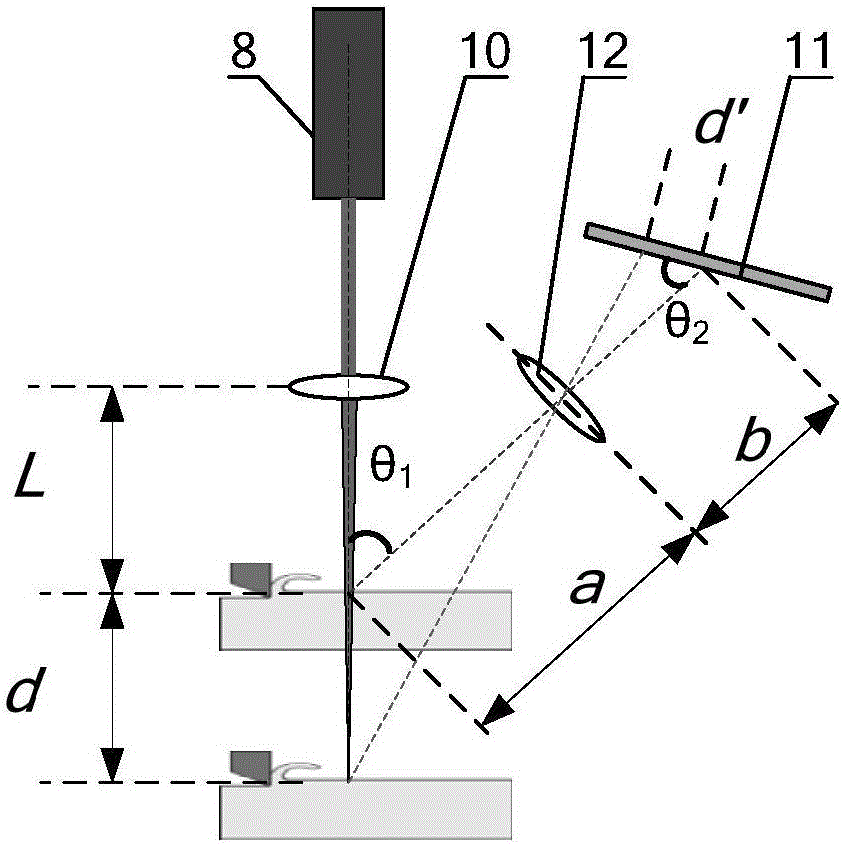

Laser-assisted orthogonal micro-cutting device and method having automatic laser focus following function

ActiveCN106312567AIncreased durabilityExtend your lifeOther manufacturing equipments/toolsLaser beam welding apparatusMachined surfaceLight beam

The invention discloses a laser-assisted orthogonal micro-cutting device and method having an automatic laser focus following function, belongs to the technical field of machining equipment and aims to solve the problem that height changes of to-be-machined surfaces cannot be monitored in real time in laser-assisted micro-cutting processes in the prior art. A motion unit and a laser-assisted machining unit of the device are mounted on a shock-absorbing platform; an optical automatic following unit is arranged on the laser-assisted machining unit and comprises a lens A, a lens B and a linear array charge coupled device (CCD) sensor; laser emitted by a laser light source of the laser-assisted machining unit irradiates a to-be-machined surface via the lens A, and a laser beam reflected by the to-be-machined surface is focused on the linear array CCD sensor via the lens B; and the to-be-machined surface is mounted on the motion unit, and a computer control unit adjusts displacement of the to-be-machined surface in the direction X, the direction Y and the direction Z in real time by the aid of the motion unit according to the laser action range fed back by the linear array CCD sensor.

Owner:CHANGCHUN UNIV OF SCI & TECH

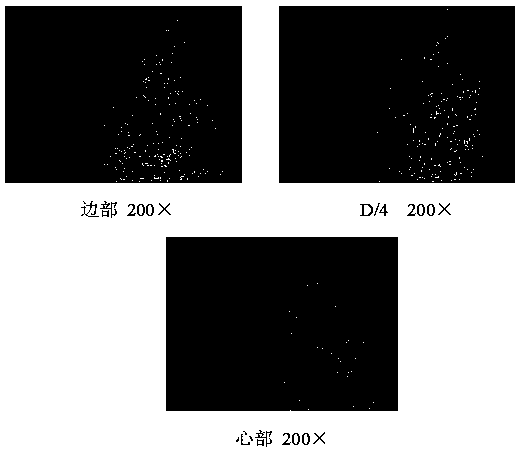

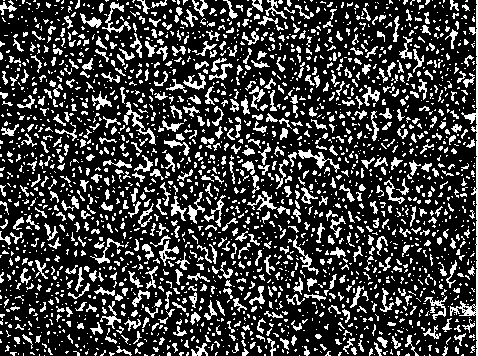

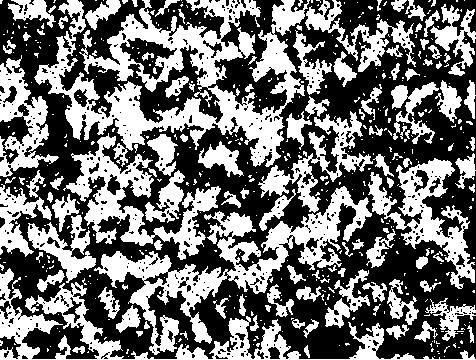

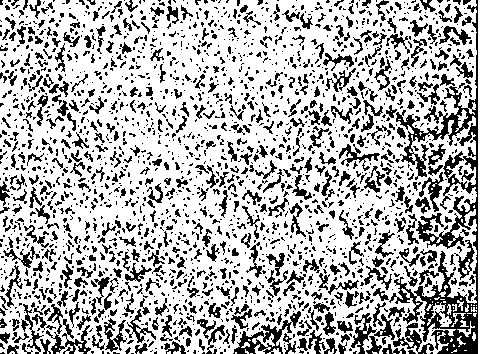

Forging method of Ti55 titanium alloy large-size bar

ActiveCN107824731AReduce surface crackingImprove forgeabilityMetal-working apparatusForgingTitanium alloy

The invention discloses a forging method of a Ti55 titanium alloy large-size bar. The forging method comprises the steps of billet forging, intermediate forging and finished product forging. Accordingto the forging method, on the basis of a traditional single-phase area and two-phase area upsetting-drawing deformation process, a high-low-high-low alternate forging process is adopted for carryingout forging deformation of a billet, so that original beta grains are remarkably refined, and forging penetration of the large-size bar is improved; and the Ti55 titanium alloy large-size bar is obtained, wherein the core and the side of the Ti55 titanium alloy large-size bar are each of a thin and uniform equiaxed structure, the strength anisotropy of the Ti55 titanium alloy large-size bar is small, and the size of the Ti55 titanium alloy large-size bar is phi 300 mm-phi 450 mm or above.

Owner:湖南湘投金天钛业科技股份有限公司

Self-connecting type and high-strength seamless steel tube for rope coring drill rod, as well as manufacturing method thereof

InactiveCN103276297AIntrinsic Quality GuaranteeReduce surface cracksDrilling rodsMetallic material coating processesCoringSteel tube

The invention relates to a self-connecting type and high-strength seamless steel tube for a rope coring drill rod. The seamless steel tube is characterized by comprising components in percentage by weight as follows: 0.38%-0.43% of C, 0.17%-0.35% of Si, 0.70%-0.90% of Mn, P smaller than or equal to 0.015%, S smaller than or equal to 0.010%, 090%-1.10% of Cr, 0.15%-0.25% of Mo. Cu smaller than or equal to 0.10%. Ni smaller than or equal to 0.10%, AS smaller than or equal to 0.015%, Sn smaller than or equal to 0.015%, Sb smaller than or equal to 0.010%, Pb smaller than or equal to 0.008%, Bi smaller than or equal to 0.010%, and the balance of Fe. The seamless steel tube has high strength. The invention further relates to a manufacturing method of the seamless steel tube.

Owner:浙江新纪元管业科技有限公司

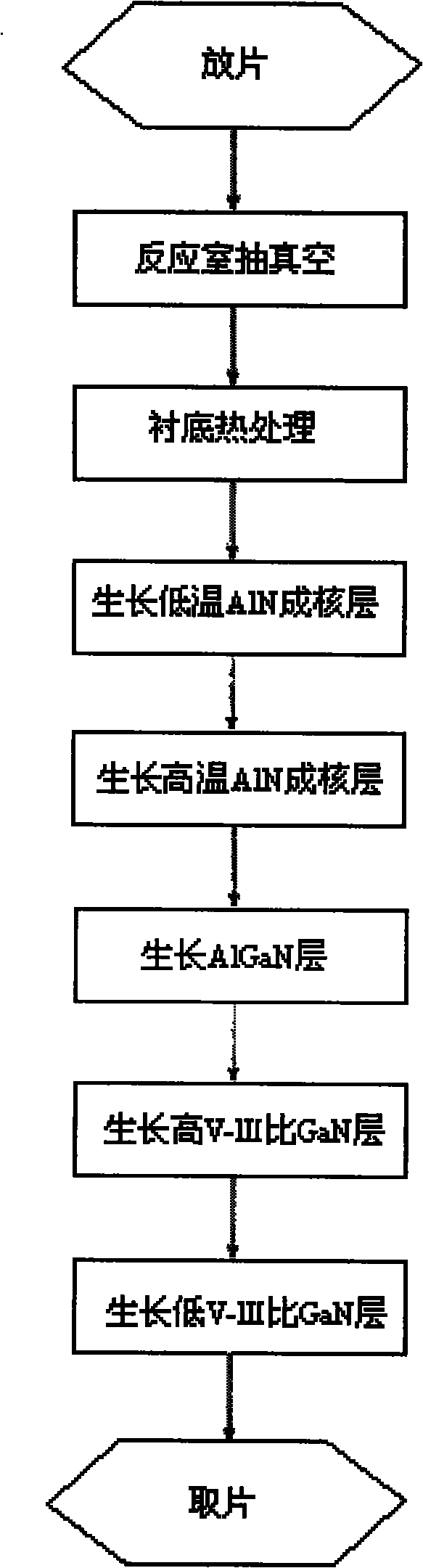

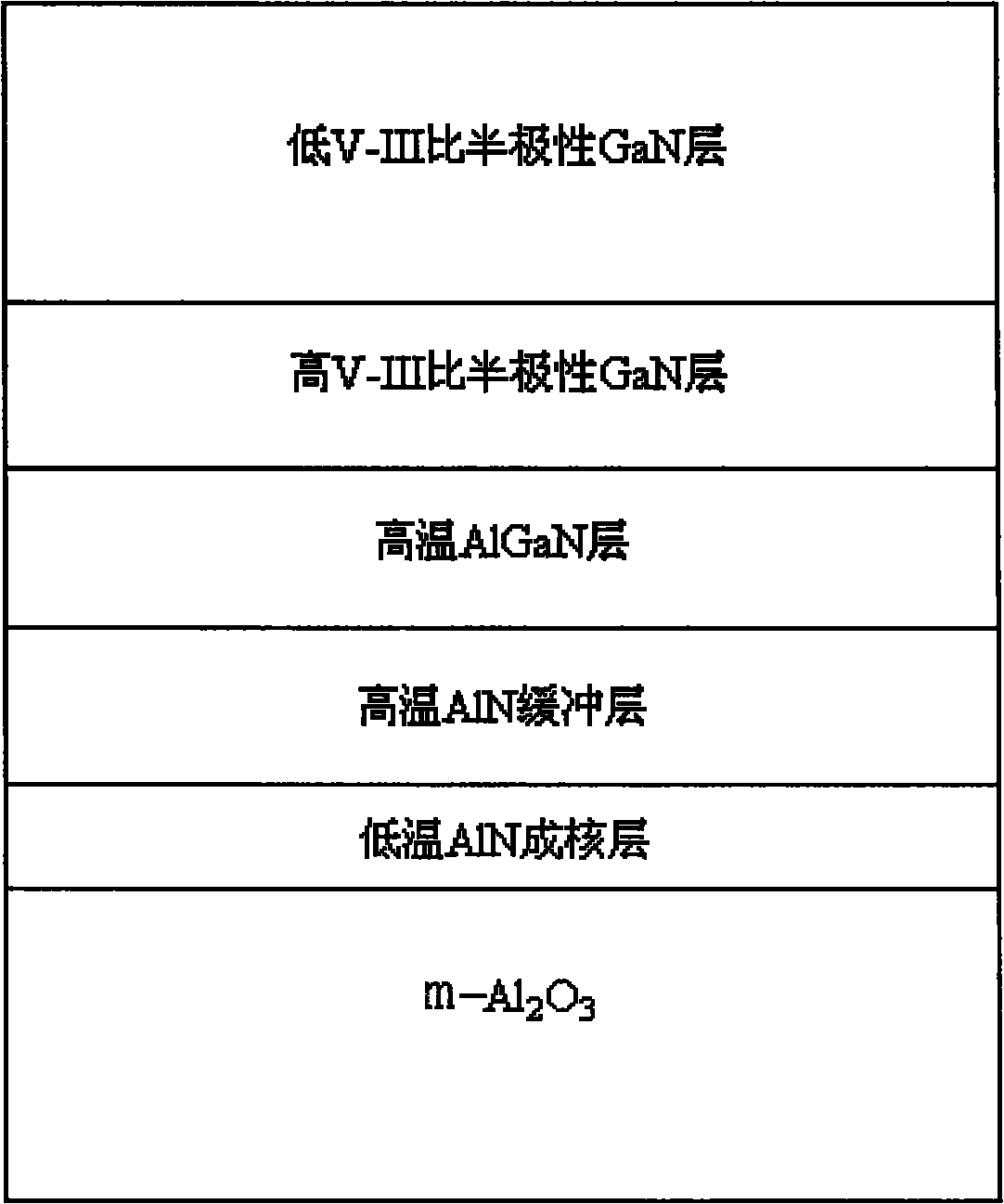

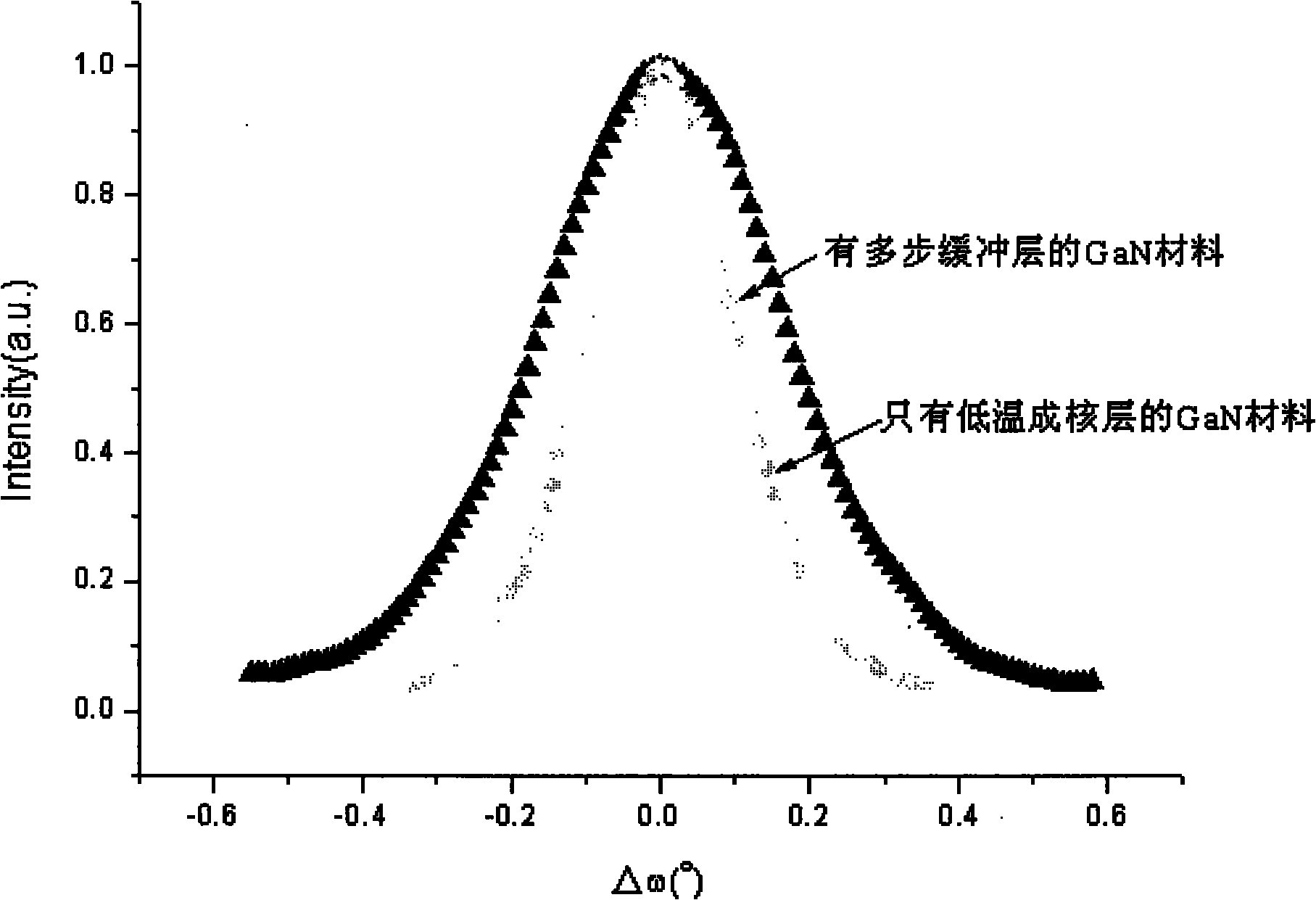

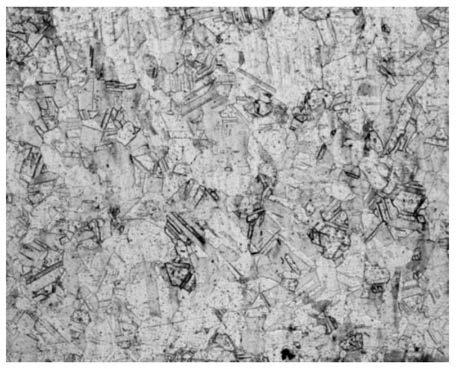

Method for growing semi-polar GaN based on Al2O3 substrate with m sides

ActiveCN101847578AImprove efficiencySimple stepsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingLight-emitting diodeMixed gas

The invention discloses a method for growing a semi-polar GaN membrane based on an Al2O3 substrate with m sides and mainly solves the problems that the conventional semi-polar material has poorer quality and non-attractive surface appearance. The method comprises the following steps of: (1) arranging an Al2O3 substrate with m sides in to an MOCVD (Metal Organic Chemical Vapor Deposition) reaction chamber, introducing the mixed gas of hydrogen and ammonia to the reaction chamber, and thermally processing the substrate; (2) growing a low-temperature AlN (Aluminium Nitride) layer with thickness of 20 to 200 nm and temperature of 500 to 650 DEG C on the Al2O3 substrate with m sides; (3) growing a high-temperature AlN layer with thickness of 50 to 200 nm and temperature of 1000 to 1150 DEG C on the low-temperature AlN layer; (4) growing a high-temperature AlGaN layer with thickness of 50 to 500 nm and temperature of 1000 to 1150 DEG C on the high-temperature AlN layer; (5) growing a semi-polar GaN layer with high V-III ratio, the thickness of 50 to 1000 nm and the temperature of 1000 to 1150 DEG C on the high-temperature GaN layer; and (6) growing a semi-polar GaN layer with low V-III ratio, the thickness of 1000 to 10000 nm and the temperature of 1000 to 1150 DEG C on the semi-polar GaN layer with high V-III ratio. The invention has the advantages of simple process and little fault, and is applied to manufacturing the semi-polar GaN light-emitting diodes and the lasers.

Owner:云南凝慧电子科技有限公司

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

High-nitrogen vanadium-nitrogen alloy VN18 and production method thereof

The invention discloses a high-nitrogen vanadium-nitrogen alloy VN18 and a production method thereof, which aim at solving the problems of poor quality, low nitrogen content, higher production cost and instable product quality in the prior art. The high-nitrogen vanadium-nitrogen alloy VN18 comprises the following components: vanadium oxide, carbon powder, a catalyst, a guiding agent, a nitrogen fixating agent, a densifying agent and a binding agent according to the weight ratio of (70-80):(15-25):(4-6):(0.5-2):(0.2-1):(0.6-0.8):(2-6). The invention further provides a production method of the high-nitrogen vanadium-nitrogen alloy VN18. The high-nitrogen vanadium-nitrogen alloy VN18 is high in nitrogen content, large in density, high in vanadium yield, and low in production cost.

Owner:高波

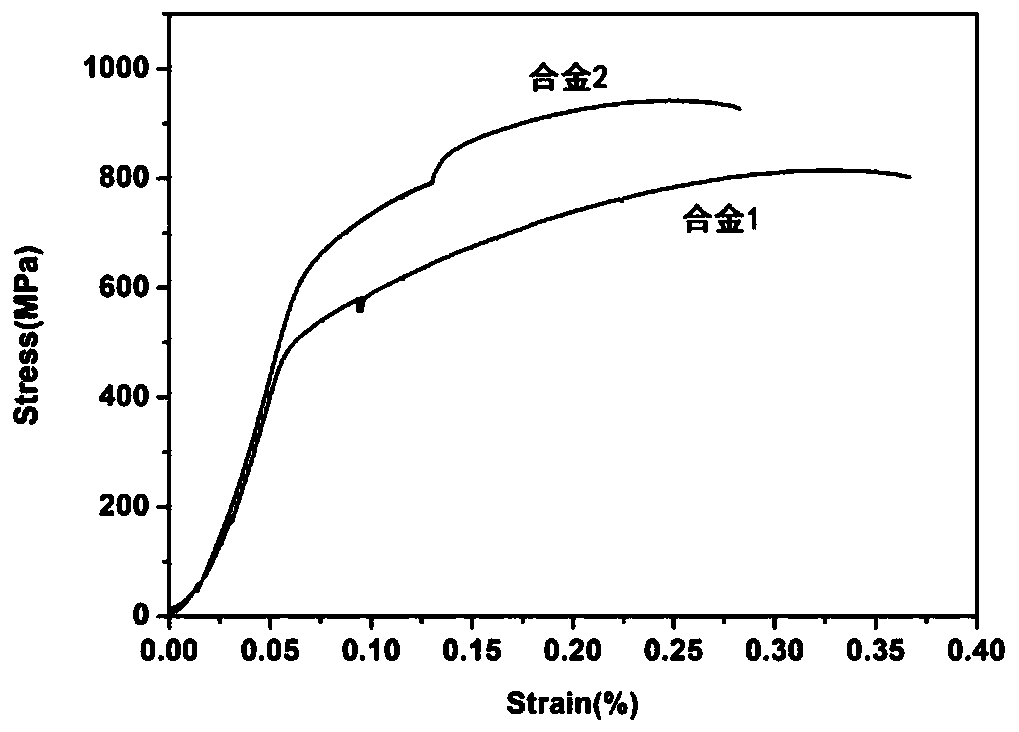

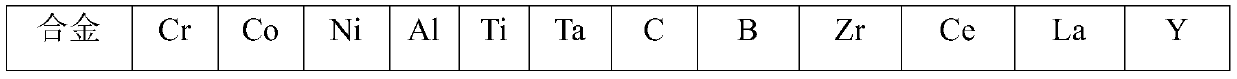

High-toughness medium entropy high temperature alloy and preparing method thereof

ActiveCN111500917AHigh strengthImprove high temperature mechanical propertiesIndustrial gasManufactured material

The invention discloses a high-toughness medium entropy high temperature alloy and a preparing method thereof. The alloy comprises chemical components including, by weight percent, 28.5 to 32.5% of Cr, 31.5 to 33.4% of Co, 32 to 35% of Ni, 0.5 to 6% of Al, 0 to 6% of Ti, 0 to 3% of Ta, 0.02 to 0.12% of C, 0.002 to 0.015% of B, 0.005 to 0.12% of Zr, 0.005 to 0.15% of RE, and larger than or equal to2% and smaller than or equal to 6% of Al+Ti+Ta, wherein Re is one of Ce, La and Y. The preparing method of the alloy comprises the steps that the raw materials are burdened and smelted according to the proportion, an electrode bar is forged and subjected to remelting, forging is carried out, an alloy bar is prepared, and the alloy bar is subjected to solid solution and aging heat treatment. The alloy is provided with a reasonable component ratio, a wide heat machining window and a heat processing system, the prepared alloy bar has the higher temperature strength, good heat machining and oxidation resistance properties, and the alloy is a candidate material of aero-engine and industrial gas turbine heat end parts.

Owner:UNIV OF SCI & TECH BEIJING +1

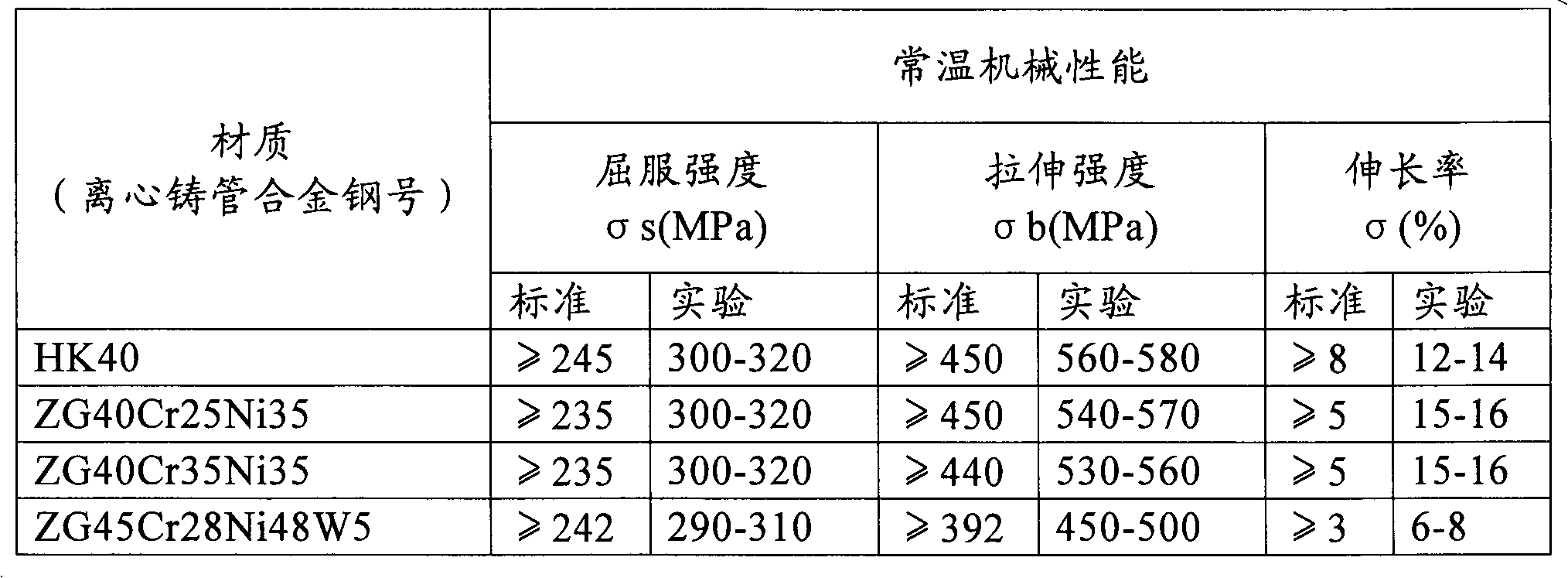

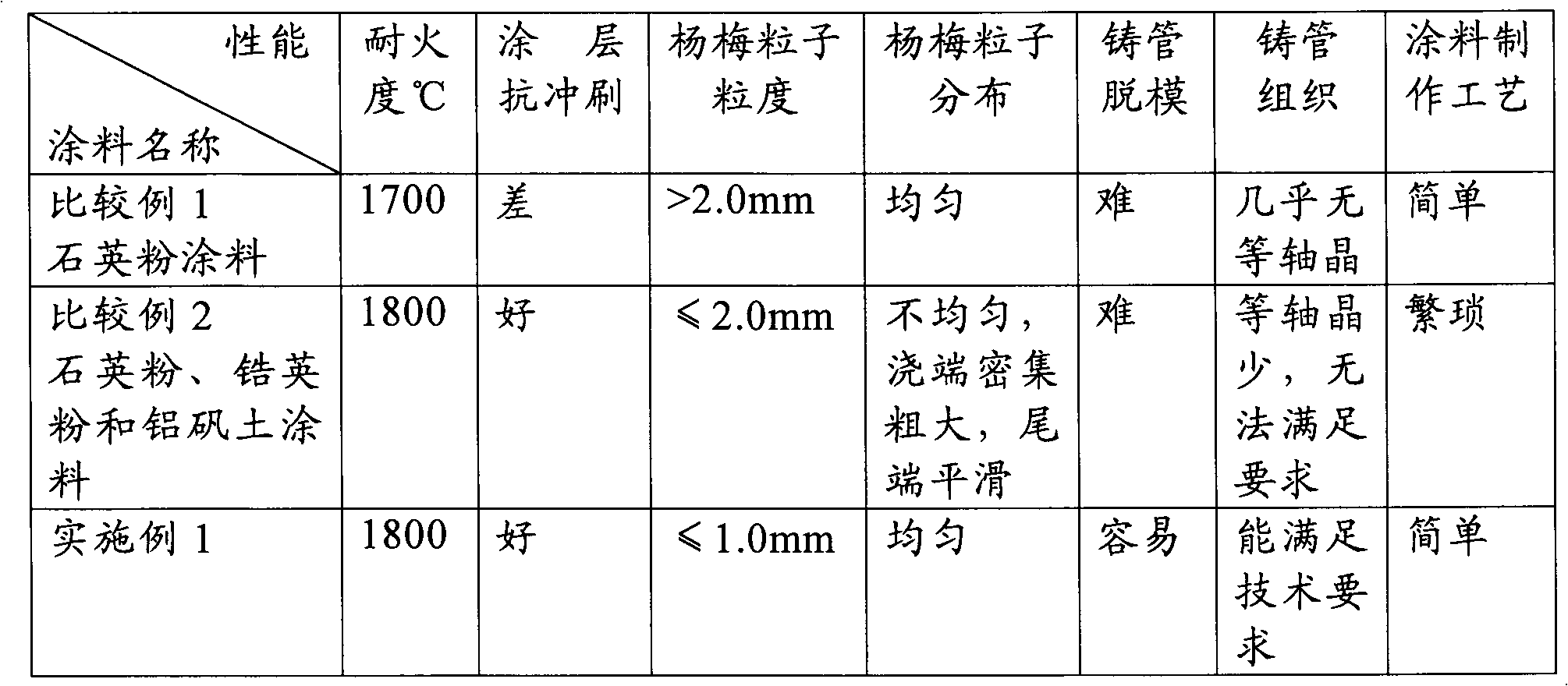

Composite coating for heat-resisting alloy centrifugal casting tube

InactiveCN101648802AStable and uniform use requirementsEasy to operateFoundry mouldsFoundry coresSuspending AgentsAlloy

The invention discloses a composite coating for a heat-resisting alloy centrifugal casting tube, which comprises the following components by weight part: 20-60 parts of quartz powder, 20-70 parts of zircon powder, 0.4-1.5 parts of suspending agent, 0.3-0.8 part of binding agent, 20-40 parts of carrier, 0.1-0.3 part of magnesium oxide and 0.1-0.3 part of activating agent. In the invention, the centrifugal casting tube which has favorable appearance and evenly-distributed waxberry particles is obtained as the composite coating containing quartz powder and zircon powder is adopted; meanwhile, theinherent quality of tube sections is improved, the heat transferring effect of furnace tubes while in use is enhanced; and the composite coating is mainly used in coating processes of reformer tubesand ethylene cracking furnaces in petrochemistry.

Owner:浦杰

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

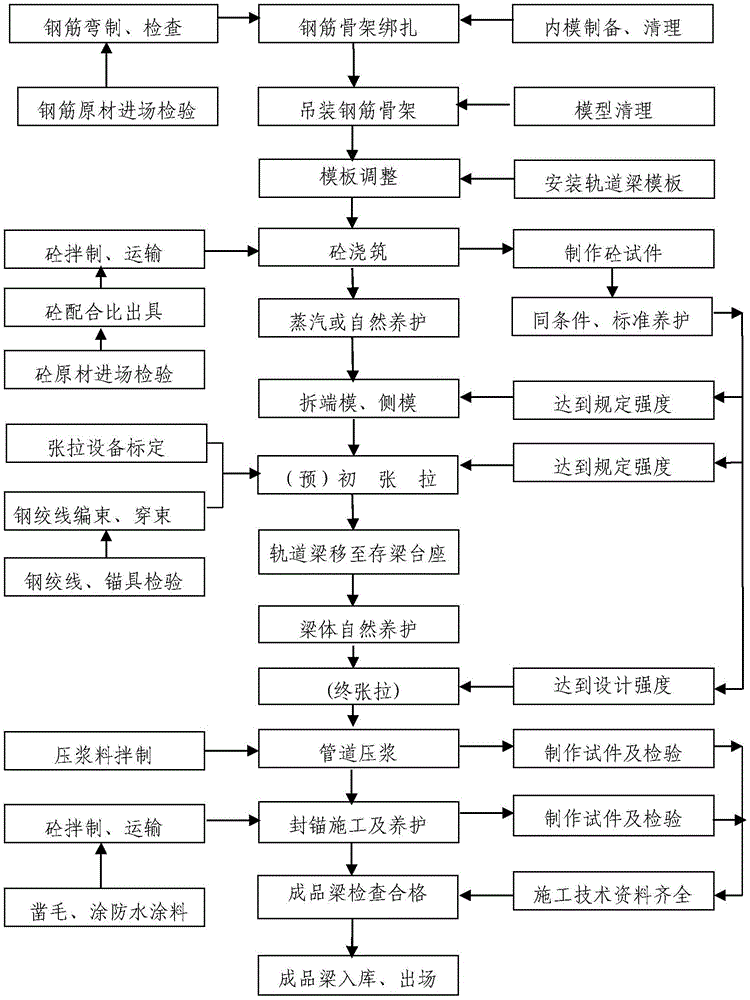

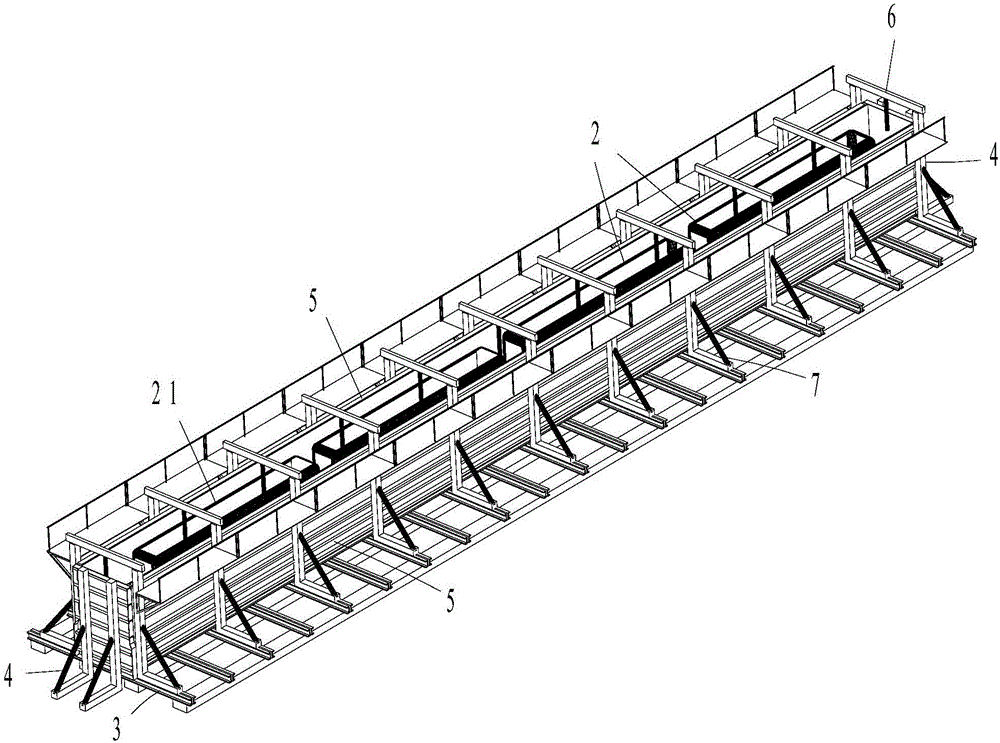

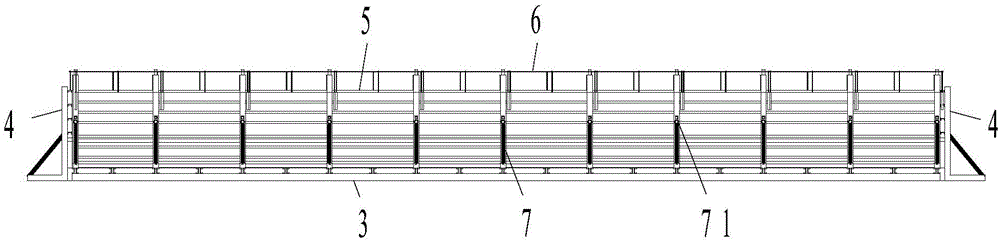

Manufacture method for maglev track beam

ActiveCN105014786AImprove prefabrication efficiencyHigh adjustment accuracyMouldsRailway tracksEngineeringVertical displacement

The invention discloses a manufacture method for a maglev track beam. The manufacture method comprises the following steps: tying a framework of steel reinforcement, manufacturing an internal mold, putting the internal mold in the framework of steel reinforcement, mounting a formwork of track beam, and regulating the formwork of track beam so as to meet the required linearity. The lateral displacement relative to the track beam and the perpendicularity relative to a bottom mold of the side mold of the formwork of track beam can be regulated through a regulating component, and a translating component arranged outside end molds is used for regulating the longitudinal movement relative to the side mold of each end mold. The manufacture method has the advantages of being easy to operate, high in regulating precision and simple to assemble and disassemble the molds. A control component can respectively regulate the transverse displacement, the longitudinal displacement and the vertical displacement of the track beam, the linearity precision can achieve the range of + / -5, and the precast quality of a curved track beam is ensured. The intelligent control can realize high regulating precision, high efficiency and good reliability of a formwork system, and the manufacture method is particularly applicable to precasting of medium-low-speed maglev linear or curved track beams.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

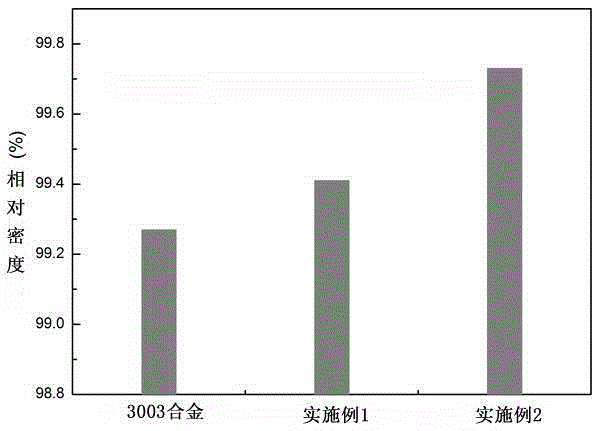

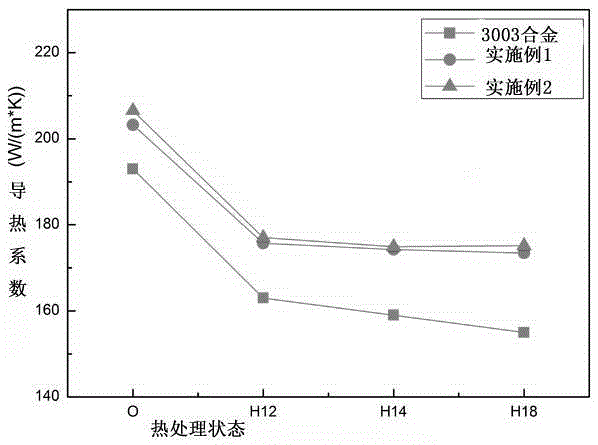

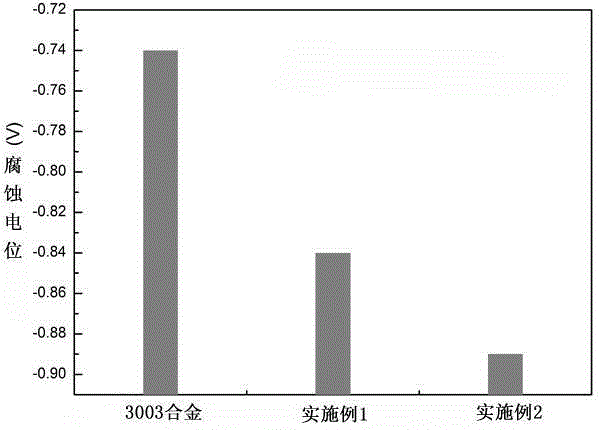

Rare earth aluminum alloy and preparation method thereof

The invention relates to a rare earth aluminum alloy and a preparation method thereof, and belongs to the technical field of alloy synthesis. The rare earth aluminum alloy is prepared through vacuum suction casting of an aluminum basal body and a rare earth source; and the rare earth aluminum alloy is obtained by performing primary smelting on the aluminum basal body, refining, adding the rare earth source into a refined product, and performing impurity removal for vacuum suction casting molding. The rare earth aluminum alloy is applied to the processing of rare earth aluminum alloys and radiator section bars, and has such advantages as high compactness, good wear resistance, good weldability and high heat conductivity.

Owner:绍兴市质量技术监督检测院

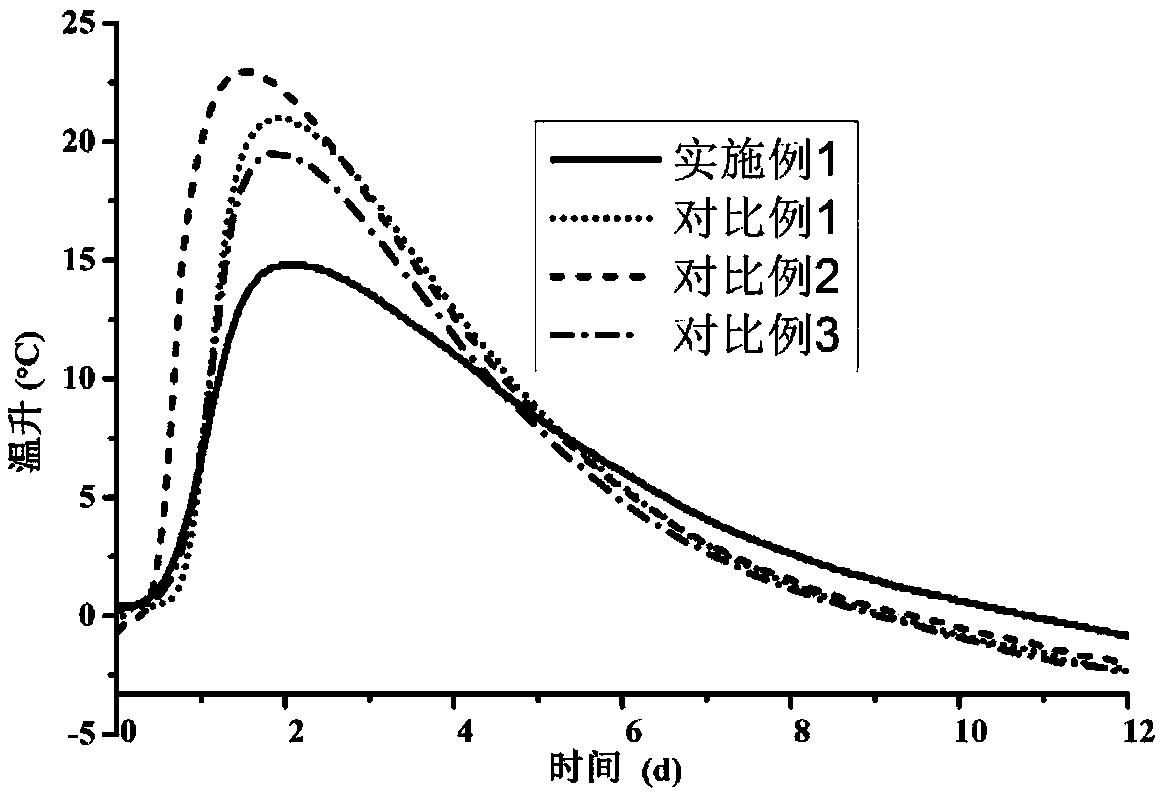

Mass concrete hydration temperature rise inhibitor as well as preparation method and application thereof

InactiveCN111377652AReduce temperature rise rateReduce temperature peakBarium hydroxide octahydrateHydration reaction

The invention discloses a mass concrete hydration temperature rise inhibitor and a preparation method thereof. The inhibitor is composed of porous ceramsite, a phase change material and a starch-basedhydration heat regulation and control material; the particle size of the porous ceramsite is 1-25 mm, and the surface pore diameter of the porous ceramsite is 10-300 [mu] m; the phase change materialis one or a mixture of two of paraffin and barium hydroxide octahydrate in any proportion. By utilizing the characteristics of porous structure and relatively closed gaps of concrete, porous ceramsite is used as a carrier to load a phase change material and absorb heat generated by hydration of large-volume concrete, and a hydration heat regulation and control technology is combined to reduce thehydration heat release rate of cement, delay the temperature rise rate of the large-volume concrete and reduce the temperature peak of the large-volume concrete; meanwhile, the phase-change energy storage material adopted in the technology plays a role in heat compensation in the temperature drop stage of the mass concrete, the temperature difference between the inner surface and the outer surface of a concrete structure can be reduced, and the non-penetrating surface cracking phenomenon is reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

Method for preparing reconstituted bamboo floor through efficient glue dipping technique

InactiveCN106003344ALower requirementStrong glueRadiation/waves wood treatmentWood treatment detailsElastic modulusEngineering

The invention relates to a method for preparing a reconstituted bamboo floor through an efficient glue dipping technique. The method for preparing the reconstituted bamboo floor through the efficient glue dipping technique comprises the following steps of A, material selecting; B, cutting-off; C, shredding; D, two times of drying; E, glue dipping; F, pressing; G, dividing; and H, post-treatment. The elasticity modulus of the floor is not smaller than 7855 MPa, the static bending strength of the floor is not smaller than 96 MPa, and the glue stripping rate of the floor in boiling water is zero. By the adoption of the method for preparing the reconstituted bamboo floor through the efficient glue dipping technique, the problems that when an ordinary floor is manufactured, material limitation exists, and the service life is short can be solved.

Owner:FUJIAN GOLDEN BAMBOO IND

Preparation method of silicon dioxide aerogel composite material

The invention relates to preparation and a method of a silicon dioxide aerogel composite material. The silicon dioxide aerogel composite material takes tetraethyl orthosilicate as a silicon source and industrially-produced glass fibers or fiber cotton materials as a reinforcing body. Firstly, composite wet gel is prepared by adopting a fiber surface acid treatment process or an acid treatment and coupling agent crosslinking common treatment process and a sol-gel method, then, the composite wet gel is aged, solvent-replaced and modified, and finally, the silicon dioxide aerogel composite material is prepared under the normal-pressure drying. The prepared silicon dioxide aerogel composite material has the characteristics of high porosity, high specific surface area, low density, low dielectric constant, low thermal conductivity and the like and also has good formability, and functional materials with different properties and structures can be prepared as required. The preparation and the method have the advantages of simple synthesis process, low raw material cost and low equipment requirements; and the prepared composite aerogel has a certain mechanical property, is enlarged in the application field and can be taken as building heat-insulation and sound-insulation materials, transportation pipeline energy conservation and environmental protection material and fire protection and heat insulation materials.

Owner:厦门纳美特新材料科技有限公司

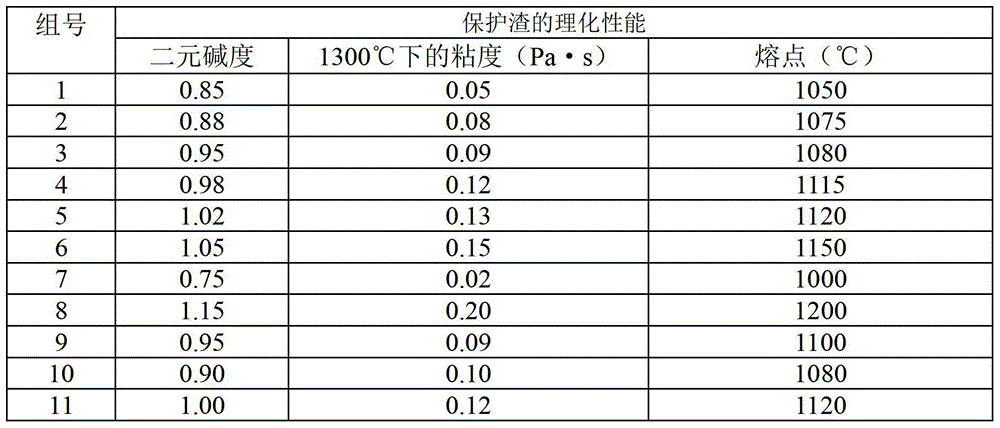

Continuous casting process for boiler pipe steel resistant to sulphuric acid dew point corrosion

The invention relates to a continuous casting process for boiler pipe steel resistant to sulphuric acid dew point corrosion. A full-protecting pouring mode is adopted during continuous casting. A long nozzle argon sealing protecting casting mode is adopted from a steel ladle to a tundish. An integrated built-in submersed nozzle protecting casting mode is adopted from the tundish to a crystallizer. Molten steel in the tundish uses molten steel covering agents. Continuous temperature measurement is carried out on the tundish. Full-automatic liquid surface detection is carried out on the liquid surface of the crystallizer in the continuous casting process. The continuous casting pulling rate is automatically controlled according to the superheat degree of the tundish. Automatic water distribution is carried out for the crystallizer and secondary cooling. The crystallizer uses special casting powder for the boiler pipe steel resistant to sulphuric acid dew point corrosion in the casting process. By means of the continuous casting process for the boiler pipe steel resistant to sulphuric acid dew point corrosion, the surface cracks of rolled metal can be largely reduced, and the flaw detection rate and yield are greatly increased.

Owner:NANJING IRON & STEEL CO LTD

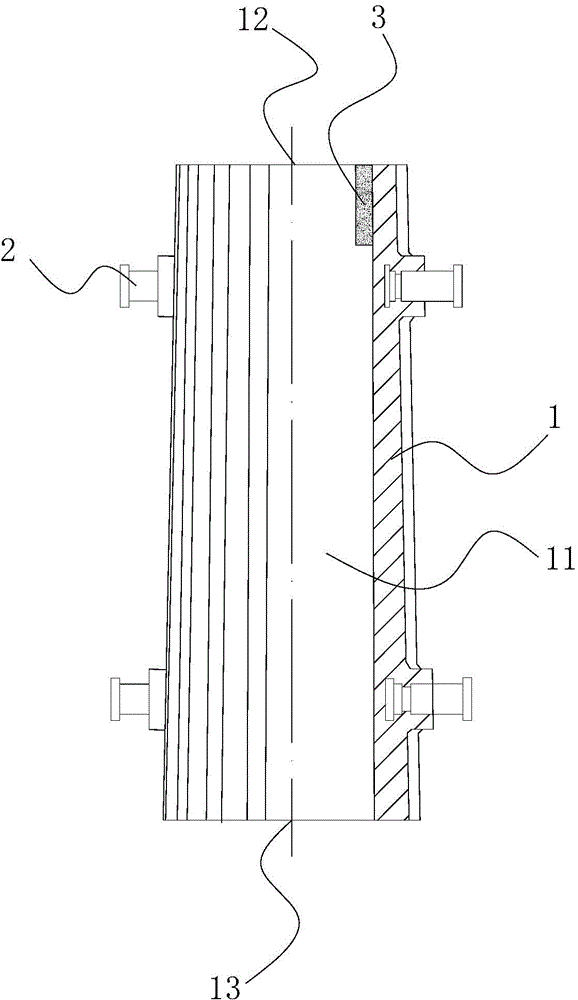

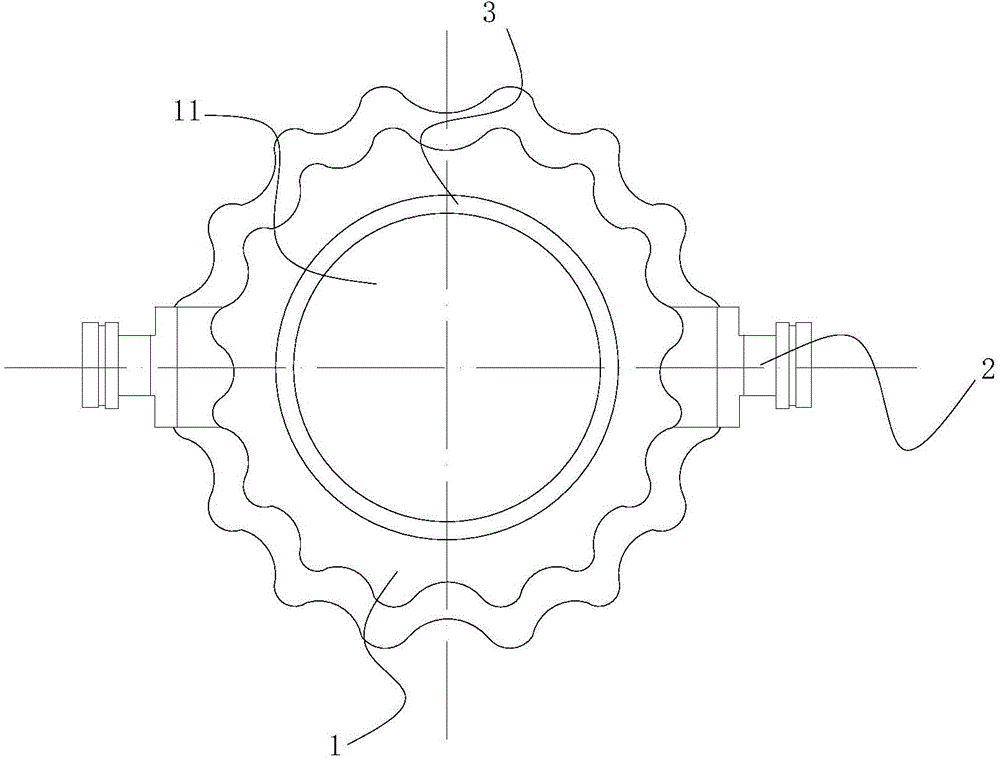

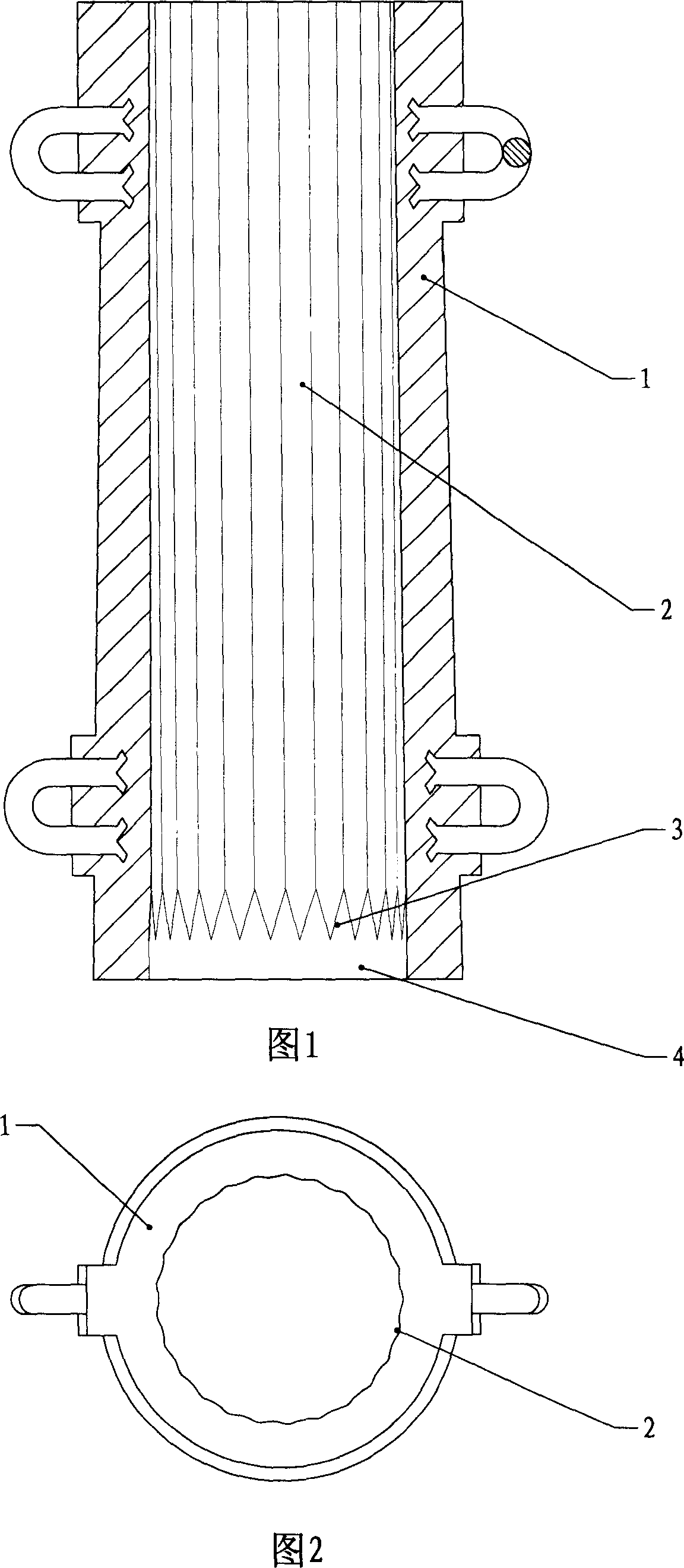

Round ingot die and round ingot manufacturing method

The invention relates to the technical field of casting of ingots, and provides a round ingot die. The round ingot die comprises a die body, a lug and an insulation board; an inner cavity is formed in the die body; the cross section of the outer side surface of the die body is polygonal wave shaped. According to the round ingot die, the radiating area of the side surface of the ingot is increased; hot melt at the outermost layer can be quickly cooled to form a chilling layer; the thickness increase of the chilling layer is sped up; therefore, static pressure in pouring of hot melt can be borne; crack can be prevented; the difficulty at pouring of the round ingot can be greatly reduced; meanwhile, the size precision of the outer side surface of the round ingot die cannot influence the size precision of the round ingot, so that the requirement on the processing precision of the outer side surface of the round ingot die is reduced, the process and working houses are decreased, and the cost can be saved. The invention further provides a round ingot manufacturing method. The method is that the degree of superheat of hot melt is 40 to 55 DEG C; the linear speed of pouring of an ingot body is 80 to 220mm / min; the linear speed of filling and pouring of a dead head of the insulation board is 35 to 90mm / min. The method can properly reduce the casting temperature and speed; the round ingot can be quickly radiated; therefore, the surface cracks can be decreased.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

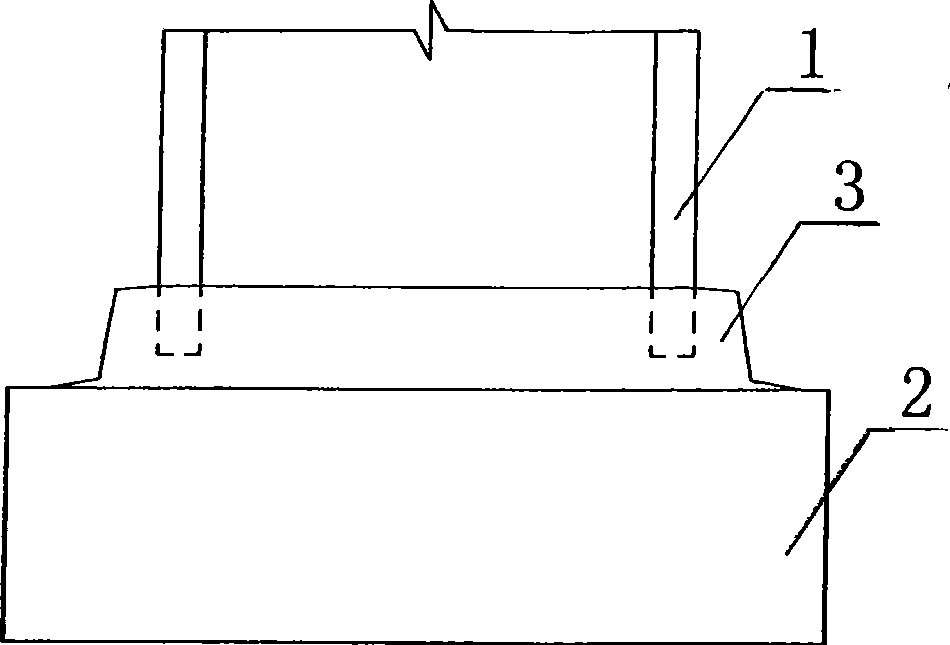

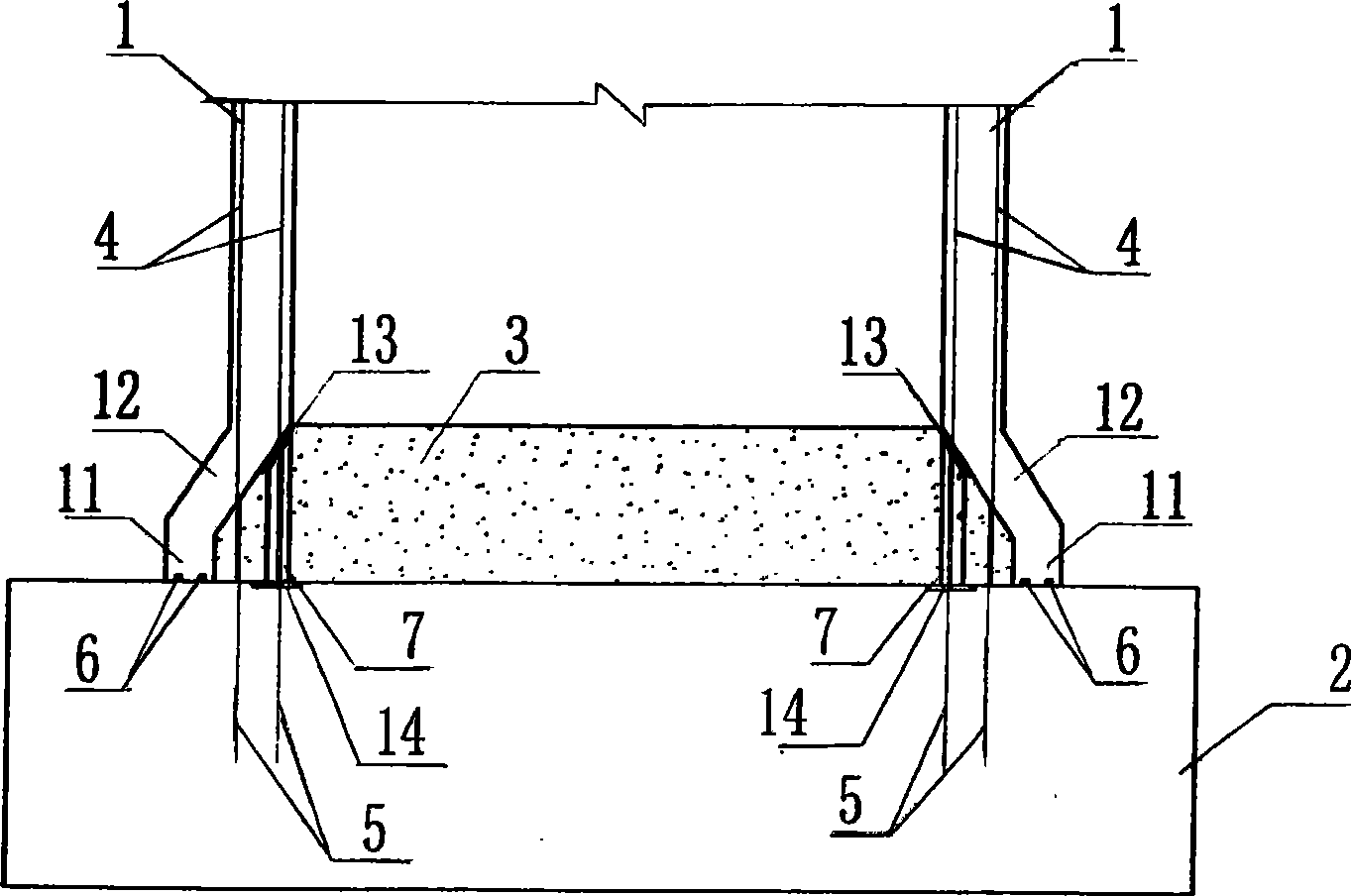

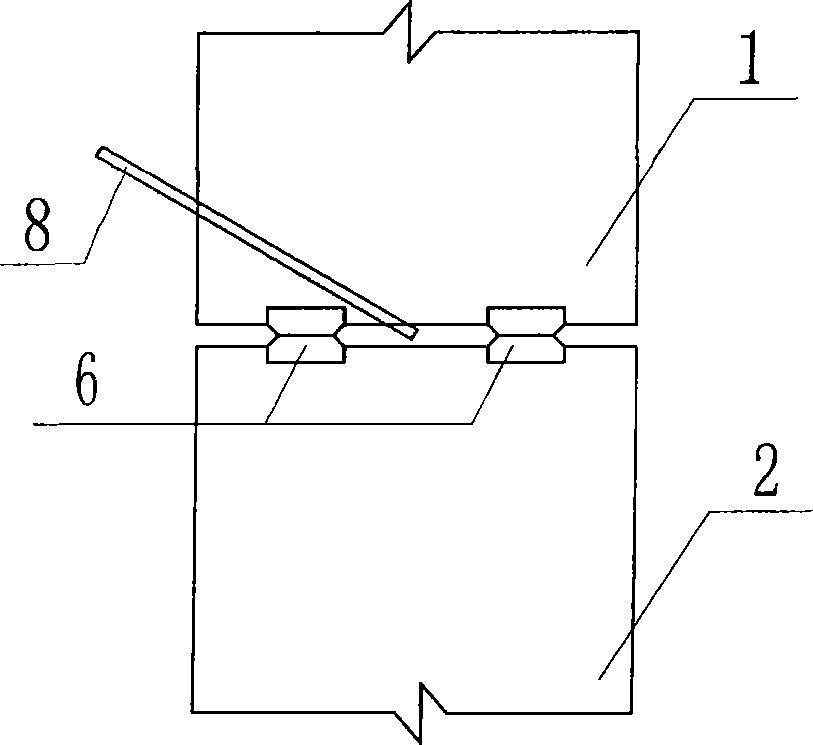

Highly-permanent connection mode for prefabricated pier body and cushion cap of cross-sea bridge

InactiveCN101509259AImprove your durabilityExtended service lifeBridge structural detailsFoundation engineeringRebarCorrosion prevention

A high-durability connecting method of a prefabricated pier shaft with a cushion cap of a bridge spanning the sea, relates to a big bridge pier with high-durability connecting between the prefabricated pier shaft and foundation in the sea corrosion environment; wherein, the prefabricated pier shaft, the cushion cap are connected with wet connector concrete in the middle, the under-part of the prefabricated pier shaft is provided with a flaring transition section and a straight line section, the reservation steel bars of the prefabricated pier shaft in the middle of the wet connector concrete are connected with the reservation steel bars of the cushion cap by double side welding, and a water-seal rubber strip is arranged between the prefabricated pier shaft and the cushion cap. The wet connector concrete is isolated with the sea corrosion environment by a prefabricated pier shaft wall, which puts an end to the situation that the injurious ingredient in the sea invades into the inner of the wet connector; the body of the prefabricated pier shaft is prefabricated in a land factory, therefore, the quality can be controlled effectively and the probability of the surface crack occurrence is lowered; employing the corrosion prevention system can greatly improve the self-durability of structure and effectively block corrosion channels, therefore, the service life of structure can be extended.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

Continuous casting method for low-alloy steel wide and thick slabs

The invention discloses a continuous casting method for low-alloy steel wide and thick slabs. The continuous casting method comprises the following steps: pouring molten steel from a tundish into a crystallizer; in the crystallizer, adding casting powder on the liquid level of molten steel; enabling the molten steel to form casting blanks with liquid cores through the vibration of the crystallizer and the cooling action of the wide surface and the narrow surface of the crystallizer, and then continuously pulling out the casting blanks with the liquid cores from the outlet of the crystallizer at a pulling speed Vc to pass through a secondary cooling zone so as to obtain completely solidified casting blanks. The continuous casting method is characterized in that the crystallizer is composed of a copper plate, the flow speed of cooling water in cooling water seams of the copper plate is 8.8-9.3m / s, and the specific value of the narrow surface heat flow and the wide surface heat flow of the crystallizer is 0.85-0.95. As the cooling schedule of the crystallizer is reasonably controlled, the continuous casting method can reduce the surface cracks of the produced wide and thick slabs and optimize the product quality.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vanadium-nitrogen alloy production method

ActiveCN102936678APrevent collision with each otherHigh apparent densityIron powderPositive pressure

The invention relates to a vanadium-nitrogen alloy production method which belongs to the technical field of metallurgy. The method comprises the steps of: stirring and uniformly mixing vanadium-containing raw material powder, iron powder, carbon powder and bonder for briquetting and forming, sending the mixture and rice husk into a calcining kiln according to a volume ratio of 1: 1 for dry distillation in the absence of oxygen at a temperature of 600-650 DEG C for 6-7h, heating to 1300-1500 DEG C, sending high-purity nitrogen into the calcining kiln from different gas inlets under micro-positive pressure for 2-4h, carrying out carbonization and nitrogenization on the formed material briquette, and cooling and discharging to obtain a vanadium nitride product. According to the method, the discharge problem of the gas generated in the reaction and the penetration problem of the reaction participation gas are solved through changing a reaction environment of the formed material briquette in the calcining kiln, so that the carbonization and the nitrogenization are promoted and the aims of improving the nitrogen content of the vanadium-nitrogen alloy, homogenizing and stabilizing the product quality, shortening the reaction time, improving the output and reducing the production cost are finally achieved.

Owner:HUNAN ZHONGXIN NEW MATERIALS TECH

High-hardness, high-strength and high-toughness aluminium alloy, preparation method of aluminium alloy, and preparation method of synchronizer toothed ring

The invention discloses a high-hardness, high-strength and high-toughness aluminium alloy which comprises the components: 7.36-10.21wt% of zinc, 2.18-3.56wt% of magnesium, 1.9-2.8wt% of copper, 0.15-0.40wt% of zirconium, 0.12-0.36wt% of iron, 0.05-0.45wt% of silicon, 0.01-0.03wt% of erbium / lanthanum / cerium, and the balance aluminum and unavoidable impurities. The invention also relates to a preparation method of the high-hardness, high-strength and high-toughness aluminium alloy and a preparation method of a high-hardness, high-strength and high-toughness synchronizer toothed ring. Through the improvement on smelting and heat treatment technologies, the prepared aluminium alloy has excellent mechanical properties such as high hardness, high tensile strength and high yield strength; and when the aluminium alloy is used to prepare the synchronizer toothed ring, the surface strength and the abrasive resistance of the prepared synchronizer toothed ring are improved greatly, and the quality and service life of the synchronizer toothed ring can be improved and increased.

Owner:FUJIAN DEYEXI LIGHT ALLOY TECH CO LTD

Shortening sweetheart pastry and production method thereof

InactiveCN108378108AFully fermentedFully absorbedDough treatmentBakery productsCooking & bakingFilling materials

The present invention discloses a shortening sweetheart pastry and a production method thereof. The production method comprises steps of sweetheart pastry filling material manufacturing, bakery shortening manufacturing and water-oiled crust manufacturing; the sweetheart pastry filling material comprises the following raw materials in mass percentages: 60-80 parts of glutinous rice flour, 60-80 parts of soft white sugar, 100-120 parts of water, 20-40 parts of white sesame seeds, 50-60 parts of non-hydrogenated margarine and 30-40 parts of lard. During the manufacturing and production processesof the water-oiled crust, multiple still-putting is conducted, so that dough is fully fermented and conducts absorption to reduce surface cracking phenomena during baking processes; at the same time,the lard is used to manufacture the bakery shortening, so that water-oiled crust dough wrapped with the filling material is subjected to multiple lamination and shortening effects of the product during the baking are improved; and before the baking, opening is conducted on the surface of the product, so that hot gas inside can be released during the baking. The shortening sweetheart pastry is goodin the shortening effects, rich in aroma, thin in crusts and thick in filling, moist, soft and smooth in filling heart, sweet but not greasy in taste, fragrant, crisp and tasty.

Owner:北京味多美食品有限责任公司

High-performance cobalt-based high-temperature alloy brush wire material

The invention discloses a high-performance cobalt-based high-temperature alloy brush wire material. The high-performance cobalt-based high-temperature alloy brush wire material is characterized in that the brush wire material comprises, by mass percent, 0.02%-0.1% of C, 1%-1.5% of Al, 0.5%-2% of Ti, 0.003%-0.01% of B, 10%-14% of W, 9%-11% of Cr, 17%-25% of Ni and the balance Co and inevitable impurities. The material has high-temperature-resistance wear resistance, high-temperature-resistance corrosion resistance and oxidization resistance, in addition, high strength is achieved, in other words, a proper alloy component ratio, a corresponding processing and preparing technology and a corresponding heat treatment technology are selected, and due to the fact that alloy strengthening elements are properly added and the processing and preparing technology is improved, the alloy performance is greatly strengthened, the tissue evenness is improved, grains are refined, defects are lowered, impurities are reduced, and the yield of alloys is increased. Meanwhile, the comprehensive performance of the alloys should be improved as much as possible on the premise that plasticity of the alloys is not changed.

Owner:江苏鑫信润科技股份有限公司

Building garbage resource treatment method

The invention discloses a building garbage resource treatment method, and belongs to the field of building. The technical scheme comprises: manual sorting, magnetic separation, primary screening, primary breaking, air separation, surface modification, slurry preparation, curing molding and other steps. According to the present invention, with the method, building garbage can be converted into usable resources; and the method is used in the recovery treatment of building garbage.

Owner:BEIJING SHOUGANG CONSTR GROUP

Machining method for improving plate shape of TA5-A titanium alloy wide medium-thickness plate

The invention discloses a machining method for improving a plate shape of a TA5-A titanium alloy wide medium-thickness plate. The method comprises the following steps: (1) a TA5-A titanium alloy plateblank is heated and forged at a temperature higher than a phase change point; then, the three-heating-number hot rolling is performed; and primary straightening is performed; (2) the TA5-A titanium alloy plate blank is heated and secondarily straightened in sequence after primary straightening to obtain a TA5-A titanium alloy wide and large medium-thickness plate with unevenness not more than 8 mm / m; and the size (thickness*width*length) of the TA5-A titanium alloy wide medium-thickness plate is (10-30 mm)*(2000-2500 mm)*(5000-7000 mm). The method combines high-temperature large deformation hot rolling with reversing hot rolling, reasonably distributes the rolling reduction and the rolling gates, improves the rolling efficiency, reduces the anisotropy of the plate blank, improves the nonuniform deformation phenomenon of the plate blank in the rolling process, effectively reduces the unevenness of the plate blank, and finally obtain the TA5-A titanium alloy wide medium-thickness platewith the excellent plate shape.

Owner:WESTERN TITANIUM TECH

Environment-friendly nano modified halogen-free flame retardant polypropylene and preparation method thereof

The invention discloses environment-friendly nano modified halogen-free flame retardant polypropylene and a preparation method thereof. The environment-friendly nano modified halogen-free flame retardant polypropylene comprises the following raw materials in parts by weight: 66 parts of polypropylene matrix, 20 parts of halogen-free expanded flame retardant, 2 parts of conductive packing, 1-3 parts of nano modified particles, 1-3 parts of additive, 5 parts of compatilizer, 1 part of an antioxidant and 2 parts of a lubricating agent. The preparation method comprises the following steps: evenly mixing the polypropylene matrix, the compatilizer, the antioxidant and the lubricating agent by virtue of a high-speed mixer, and then putting the mixed material into a precision open mill; after the mixed material is melted, adding the halogen-free expanded flame retardant and the conductive packing, melting and mixing; and then adding the nano modified particles and the additive; and mixing in the precision open mill, thus obtaining polypropylene. According to the environment-friendly nano modified halogen-free flame retardant polypropylene, the nano modified particles and hollow glass beads are adopted as flame retardant synergists, so that the flame retardant property of the polypropylene can be improved, the viscosity of polypropylene polymer melt can also be significantly reduced, the processability is improved, the heat stability is improved, and the environment-friendly nano modified halogen-free flame retardant polypropylene is excellent in yellowing resistance, good in impact resistance and good in bending strength.

Owner:HENAN UNIV OF SCI & TECH

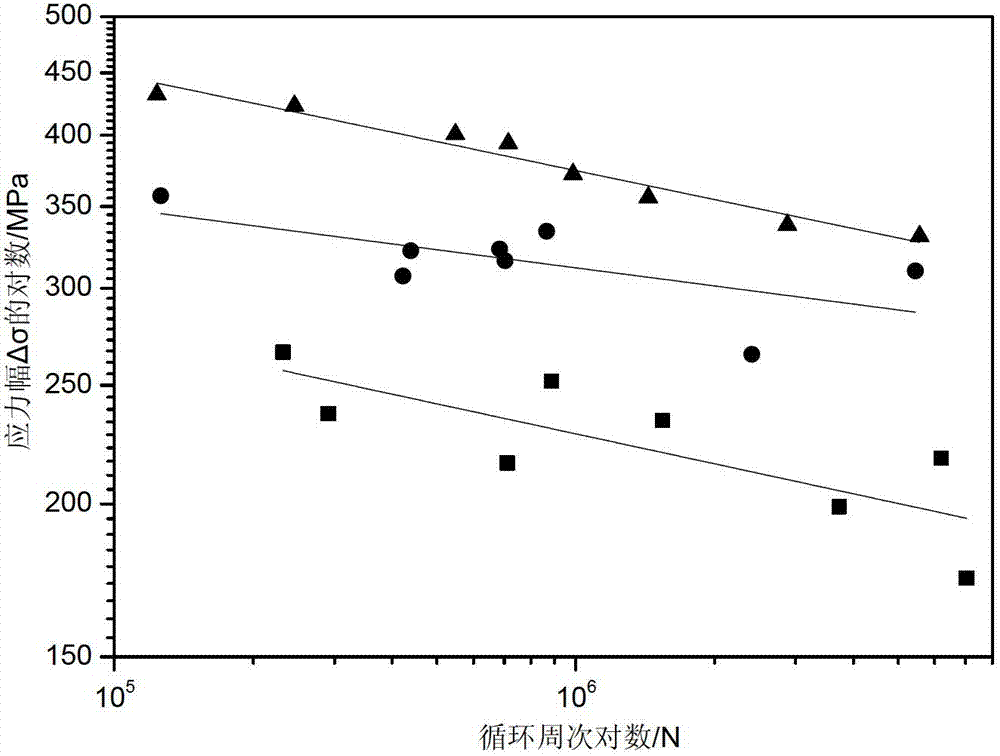

Pretreatment process for reducing defects of surface of ultrasonic impact test piece

The invention discloses a pretreatment process for reducing the defects of a surface of an ultrasonic impact test piece. The process comprises the following steps of carrying out degreasing and decontamination and then carrying out mechanical polishing. Through surface treatment, grease contaminations on the surface are removed, and residual slag and sharp parts on the surface of the test piece are polished off, so that higher surface quality is achieved. The surface conditions of the ultrasonic impact test piece are improved, and the sharpness of the surface is reduced, so that the crack initiation sources are reduced.

Owner:TIANJIN UNIV

Killed steel casting method

A periodic tube rolling machine with slant rolling drill rig is used to generate big caliber thick wall steel blocks, to satisfy the inside and surface quality requirements. Inner cavity working section of the mold is wave shape multilateral cross section shape wave ingot mold, with sulfur content controlled under 0.025% of the steel liquid, casting temperature within 40 to 80DEG C, linear speed 80 to 230mm / min, cracking ratio lower than 5%, pass rate 98.81%, with low consumption of metal, low cost, especially suitable for rolling into seamless steel tubes with multi types and specification and phi> / =426mm.

Owner:攀钢集团成都钢铁有限责任公司

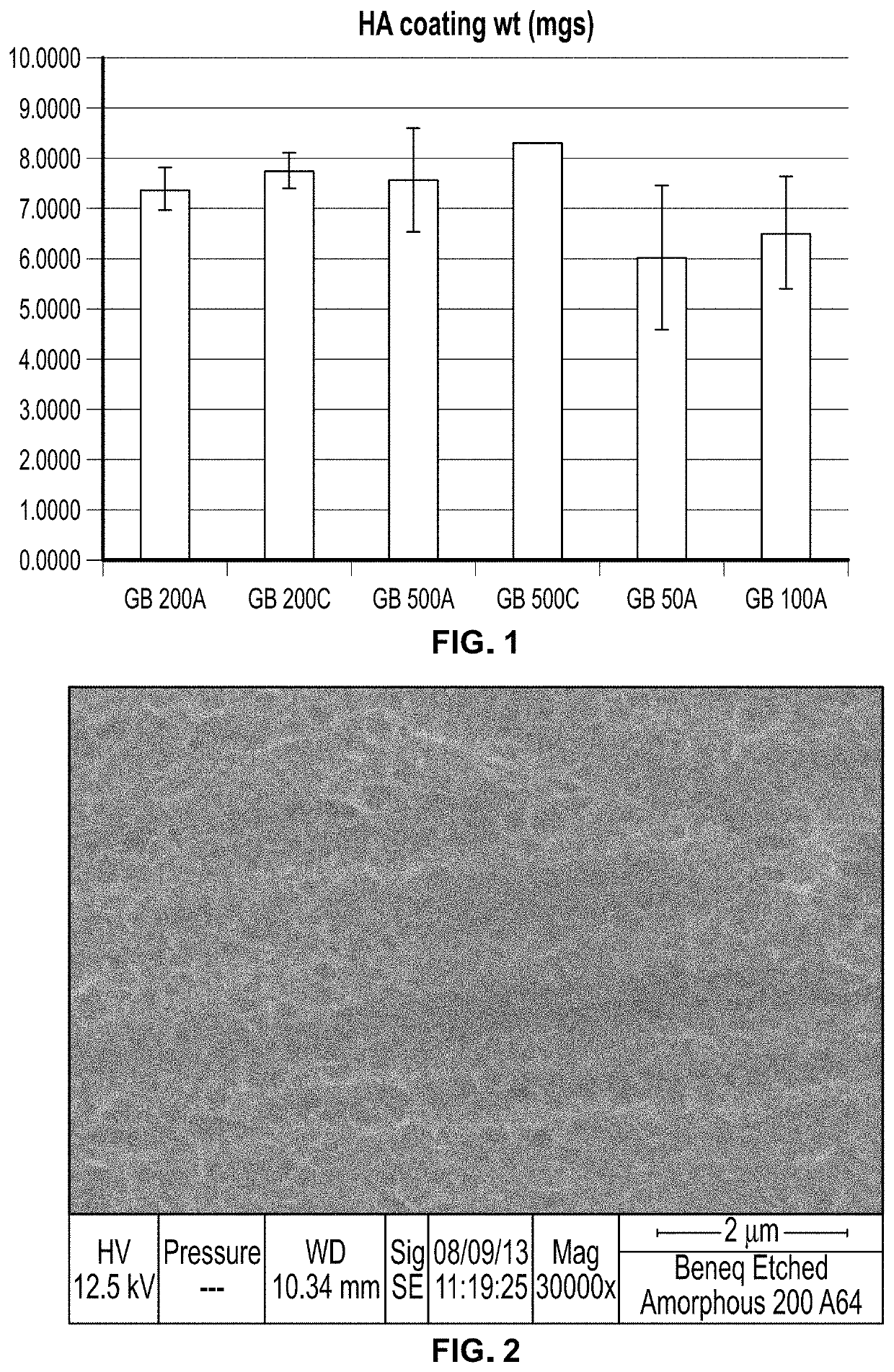

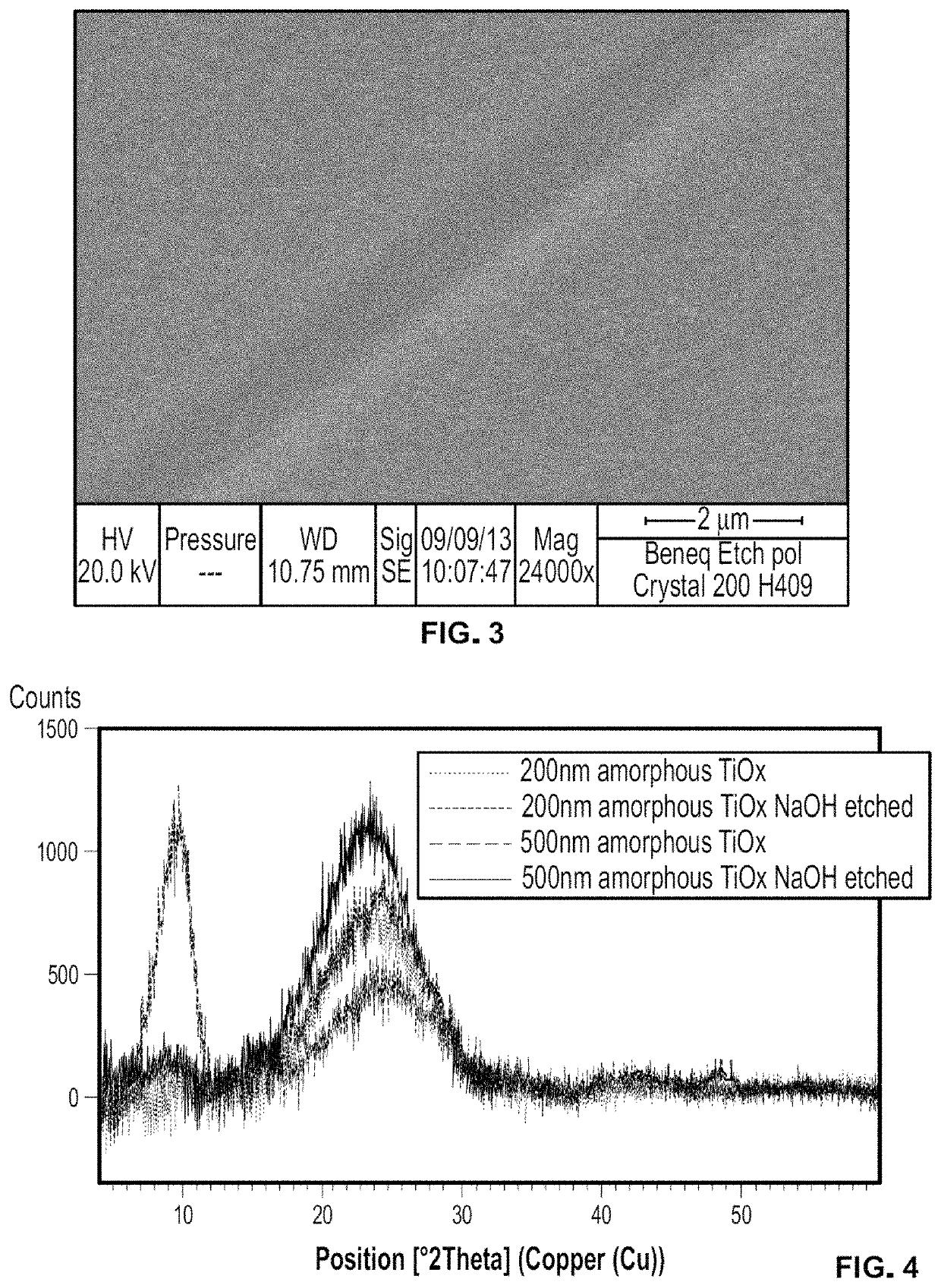

Orthopedic implant having a crystalline calcium phosphate coating and methods for making the same

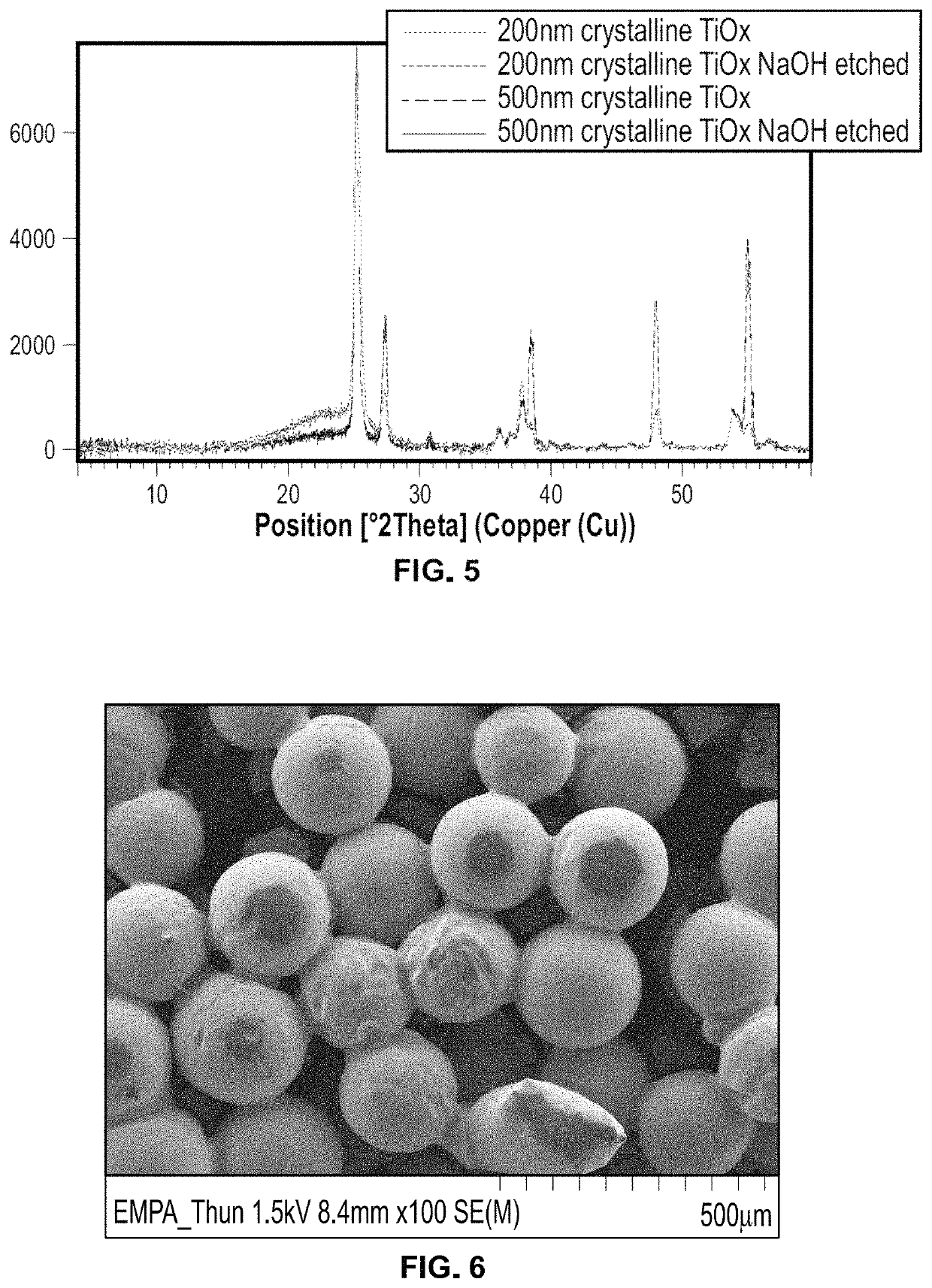

ActiveUS10537661B2Reduce air volumeReduce surface cracksElectrolytic inorganic material coatingPretreated surfacesCalcium phosphate coatingOrthopedic department

An orthopedic implant having a metal surface and a calcium phosphate layer disposed on at least part of the metal surface is described. The calcium phosphate layer has an average crystallite size of less than about 100 nm in at least one direction and dissolves for more than 2 hours in vitro. The calcium phosphate layer is substantially free of carbonate. The coating, which is formed on a sodium titanate surface, has increased shear strength and tensile strength. The coating is formed by a solution deposited hydroxyapatite process under inert conditions. The pH of the solution varies by less than 0.1 pH unit / hour during coating formation.

Owner:DEPUY SYNTHES PROD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com