Forging method of Ti55 titanium alloy large-size bar

A large-scale, titanium alloy technology, applied in the field of titanium alloy material processing, can solve the problems of low yield, difficulty in forging deformation processing, easy cracking, etc., achieve the effects of small strength anisotropic difference, reduce blank loss, and reduce surface cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

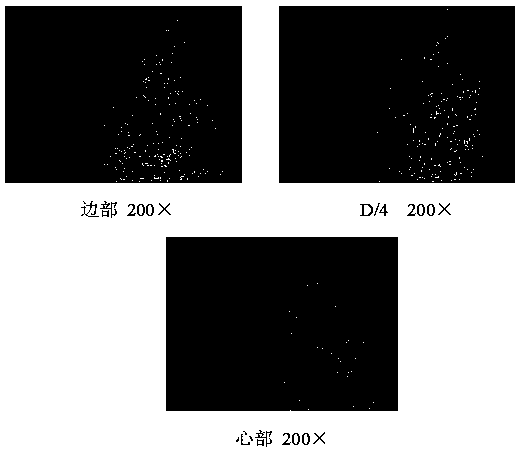

Image

Examples

Embodiment 1

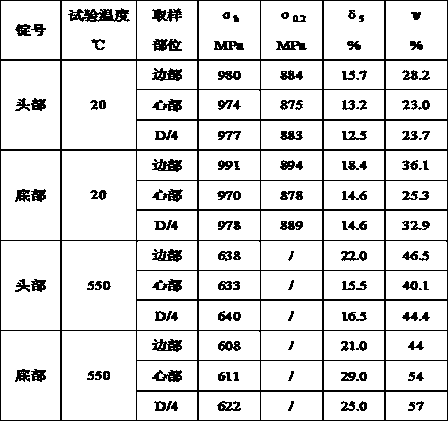

[0025] Example 1 (Φ400㎜ specification bar)

[0026] Step 1, blank forging:

[0027] Select a Ti55 ingot with a specification of Φ780 and about 1.75 tons. The β phase transition temperature is 1000°C, put it into a heating furnace with a temperature of 800°C, preheat it for 1-2 hours, and slowly raise the temperature to 1150°C for 4-6 hours. Fire forging with two upsetting and two drawing forging to a square billet □ 580mm, the deformation of upsetting and drawing is controlled at 40~45%, after forging, it is air-cooled and the cracks are cleaned;

[0028] Step 2, intermediate forging:

[0029] Step 2.1. Put the forged billet completed in step 1 into a heating furnace with a temperature of 800°C, preheat for 2-4 hours, slowly raise the temperature to 1080°C and keep it for 4-6 hours, then carry out 2 times of upsetting and drawing forging, each time of 2 times Upsetting and two-drawing forging to square billet □ 580mm, the deformation of single-fire upsetting and drawing is c...

Embodiment 2

[0040] Example 2 (Φ300㎜ specification bar)

[0041] Step 1, blank forging:

[0042] Select Φ680 specifications, about 1.5 tons of Ti55 ingot, β transformation temperature is 1000 ℃, put it into a heating furnace with a temperature of 800 ℃, preheat for 1-2 hours, slowly raise the temperature to 1150 ℃ and keep it for 4-6 hours, then carry out two headings Two-drawing forging to a square billet □560mm, the amount of upsetting and drawing deformation is controlled at 40~45%, air-cooled after forging, and the cracks are cleaned;

[0043] Step 2, intermediate forging:

[0044] Step 2.1. Put the forged billet completed in step 1 into a heating furnace with a temperature of 800°C, preheat for 2-4 hours, slowly raise the temperature to 1080°C and keep it for 4-6 hours, then carry out 2 times of upsetting and drawing forging, each time of 2 times Upsetting and two-drawing forging to square billet □ 560mm, single-shot upsetting and drawing deformation is controlled at 38~42%, air-coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com