Forging method of roller

A roll and forging technology, applied in manufacturing tools, forging/pressing/hammer devices, heating/cooling equipment, etc., can solve problems such as poor forgeability and surface cracking, reduce processing time, improve production efficiency, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

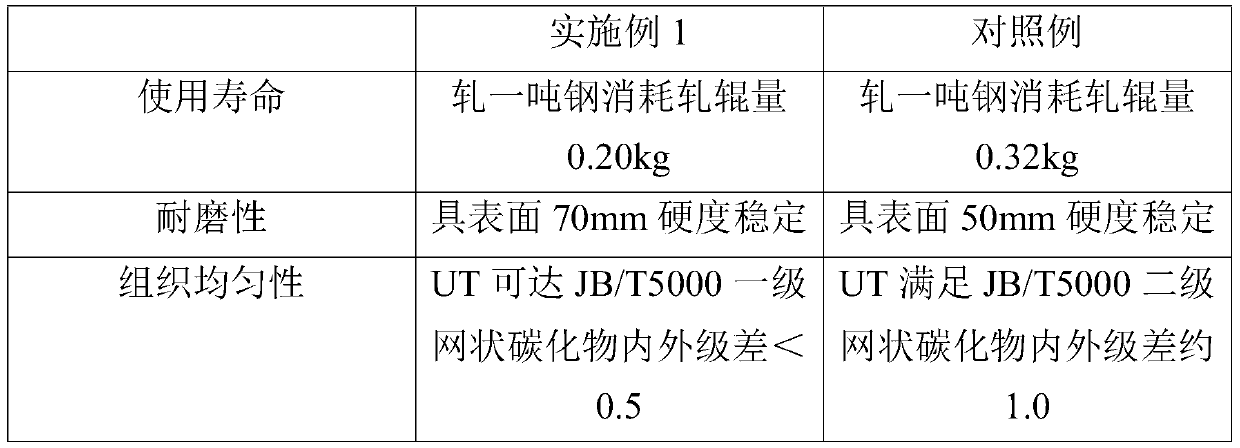

Examples

Embodiment 1

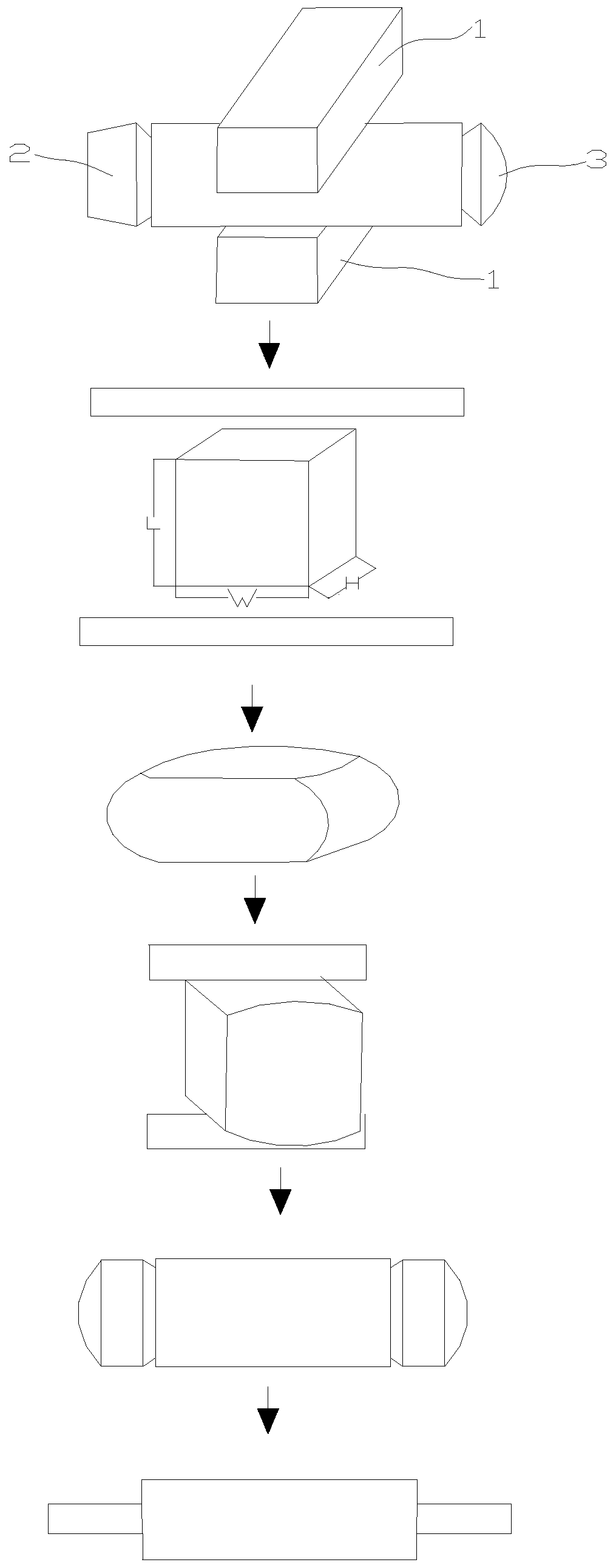

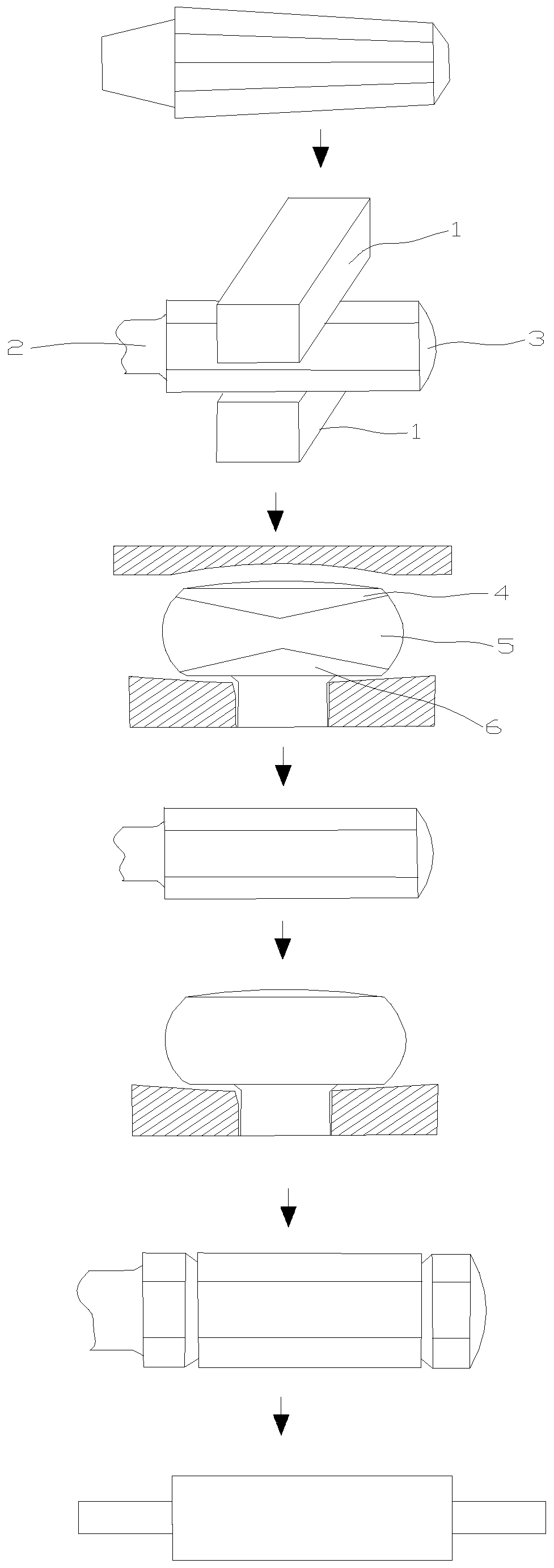

[0023] The whole process is attached figure 1 As shown, the specific steps are as follows

[0024] S1: Heat the steel ingot to 1180°C, squeeze the steel ingot from both sides with an anvil, remove the riser 2 and the nozzle 3, and the length of the pressed steel ingot (marked by the letter L in the attached drawing), width (in the attached drawing Marked by the letter W) and the height (marked by the letter H in the drawings) ratio is 3:1.5:1; the whole process of the above is as attached figure 1 As shown in the first small figure in;

[0025] S2: Raise the temperature of the steel ingot to 1230°C, squeeze the steel ingot from both sides in the length direction, and flatten the length of the steel ingot to half of the original length, and the surface of the steel ingot in the width direction and the surface in the height direction are both in the shape of Arc-shaped; the whole process is as attached figure 1 As shown in the second picture in , the shape of the ingot after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com