Installation structure body for main reducer of roller mill and application method thereof

A technology of reducer and structure body, applied in the field of structure body, can solve the problems that the reducer is difficult to achieve smoothness, the deformation of the base plate is not easy, the adjustment cannot be adjusted, etc., and achieves the effects of scale change, short processing time, and reduced processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

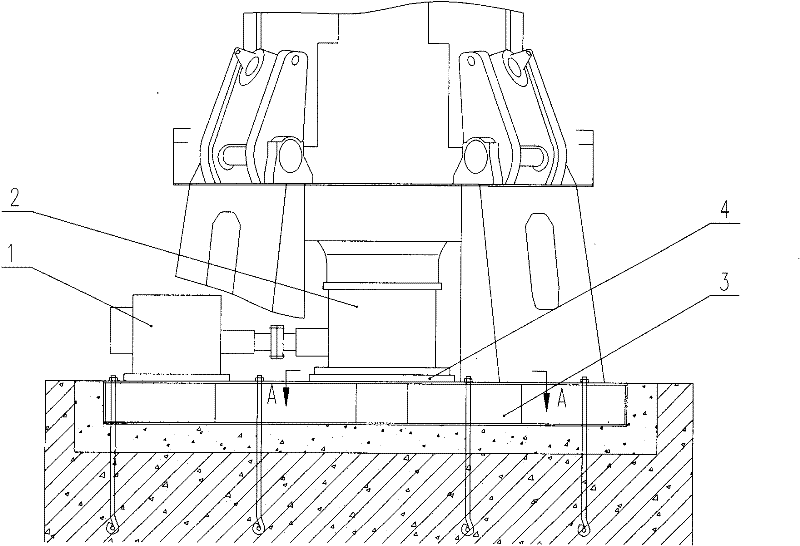

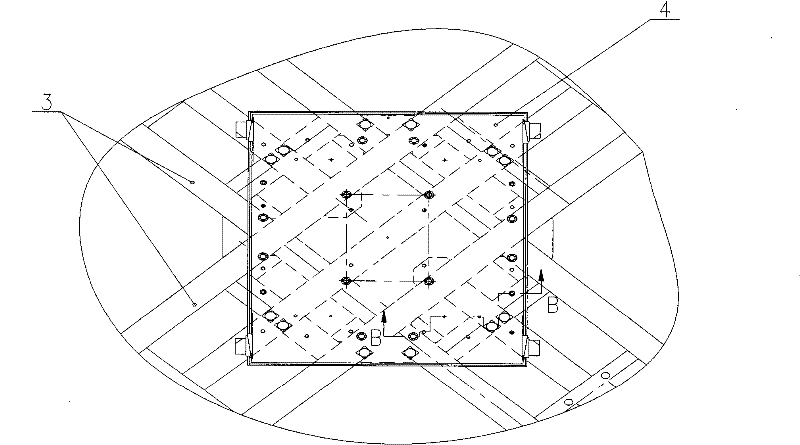

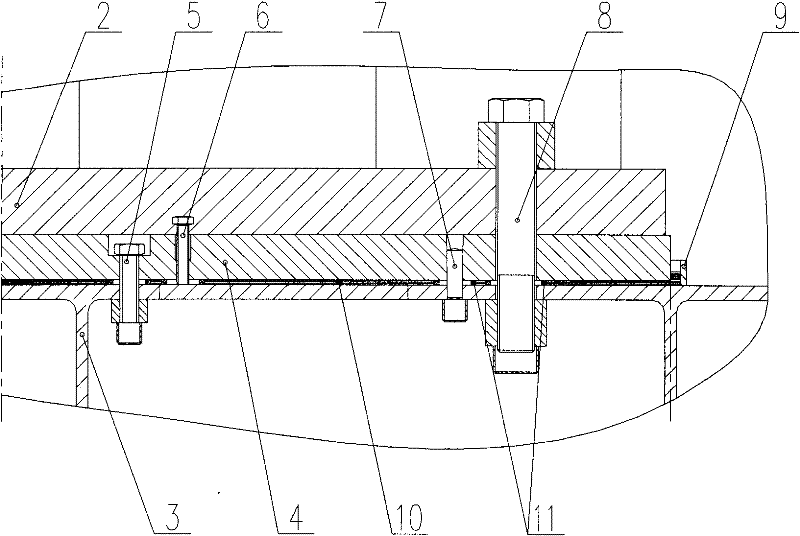

[0029] Such as Figure 1~3 As shown, a roller mill main reducer installation structure and its application method, the structure includes a mill reducer 2, a reducer base plate 4, and a mill base frame 3 connected in sequence.

[0030] A plug 10 with a thickness of 10 mm is provided between the base plate 4 of the reducer and the base frame 3 of the mill. The stopper 10 is an epoxy resin layer. Epoxy resin is currently widely used in marine propellers, engines and auxiliary equipment, bearing housings and various pump systems, and replaces steel pads or cast iron block pads by taking the role of pad plugs. Epoxy resins harden with the action of specific curing agents to become extremely strong and durable solids. The present invention pours this type of epoxy resin in the 10mm gap space between the reducer base plate 4 and the mill base frame 3 . It is recommended to use the CHOCKFAST ORANGE variety of epoxy resin. This variety of epoxy resin has a very large reputation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com