Amphiphilic acetochlor magnetic molecularly imprinted polymer and preparation method and application thereof

A technology of imprinted polymer and acetochlor, which is applied in the field of separation and analysis, achieves the effects of amphiphilicity, high specific selectivity, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Amphiphilic Acetochlor Magnetic Molecularly Imprinted Polymer:

[0038] (1) material preparation

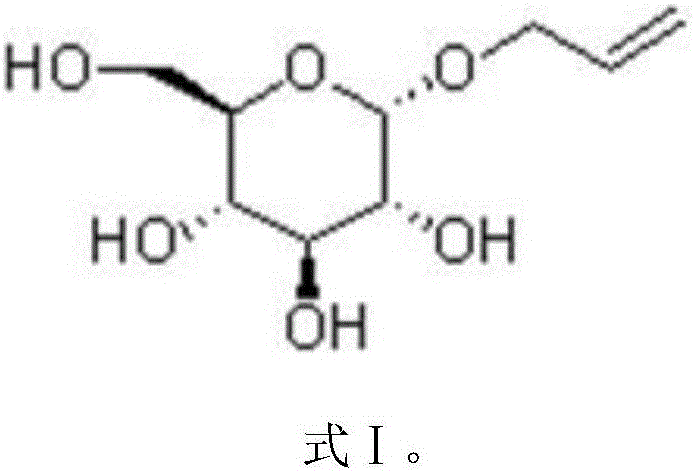

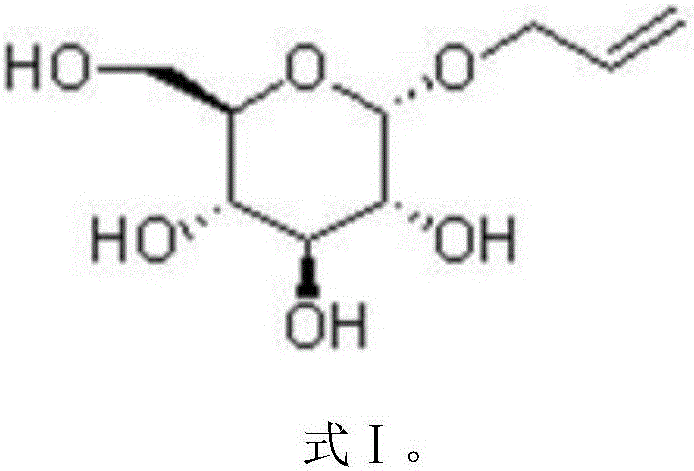

[0039] Each raw material component is formulated according to the following dosage ratio: 0.91 g of ferric oxide, 0.91 g of template acetochlor, 0.91 g of alkenyl glycoside type functional monomer (structural formula shown in formula I), 1.98 g of divinylbenzene, Cross-linking agent N,N-methylenebisacrylamide 16.17g, initiator azobisisobutyronitrile 0.08g, pore-forming agent ethanol 55.31g;

[0040] (2) Preparation of molecularly imprinted polymers with template molecules

[0041] Add the above-mentioned prepared reactants into the reaction kettle and mix evenly, ultrasonically degas for 15 minutes, then fill with nitrogen and deoxygenate for 15 minutes, seal and polymerize in a constant temperature oil bath at 60°C for 24 hours to obtain a polymer with template molecules;

[0042] (3) Preparation of molecularly imprinted polymers that remove template mole...

Embodiment 2

[0047] Preparation of Amphiphilic Acetochlor Magnetic Molecularly Imprinted Polymer:

[0048] (1) material preparation

[0049] Each raw material component is formulated according to the following dosage ratio: 0.91 g of ferric oxide, 0.91 g of template acetochlor, 0.91 g of alkenyl glycoside type functional monomer (structural formula shown in formula I), 1.98 g of 4-vinylpyridine , crosslinking agent ethylene glycol dimethacrylate 16.17g, initiator azobisisovaleronitrile 0.08g, pore forming agent ethanol 55.31g; (2) Preparation of molecularly imprinted polymer with template molecules

[0050]Add the above-mentioned prepared reactants into the reaction kettle and mix evenly, ultrasonically degas for 15 minutes, then fill with nitrogen and deoxygenate for 15 minutes, seal and polymerize in a constant temperature oil bath at 40°C for 18 hours to obtain a polymer with template molecules;

[0051] (3) Preparation of molecularly imprinted polymers that remove template molecules ...

Embodiment 3

[0056] Preparation of Amphiphilic Acetochlor Magnetic Molecularly Imprinted Polymer:

[0057] (1) material preparation

[0058] Each raw material component is formulated according to the following dosage ratio: 0.91 g of ferric oxide, 0.91 g of template acetochlor, 0.91 g of alkenyl glycoside type functional monomer (structural formula shown in formula I), 1.98 g of vinylbenzene, Joint agent ethylene glycol dimethacrylate 16.17g, initiator azobisisovaleronitrile 0.08g, pore-forming agent ethanol 55.31g;

[0059] (2) Preparation of molecularly imprinted polymers with template molecules

[0060] Add the above-mentioned prepared reactants into the reaction kettle and mix evenly, ultrasonically degas for 15 minutes, then fill with nitrogen and deoxygenate for 15 minutes, seal and polymerize in a constant temperature oil bath at 50°C for 20 hours to obtain a polymer with template molecules;

[0061] (3) Preparation of molecularly imprinted polymers that remove template molecules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com