Patents

Literature

100results about How to "Meet production standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

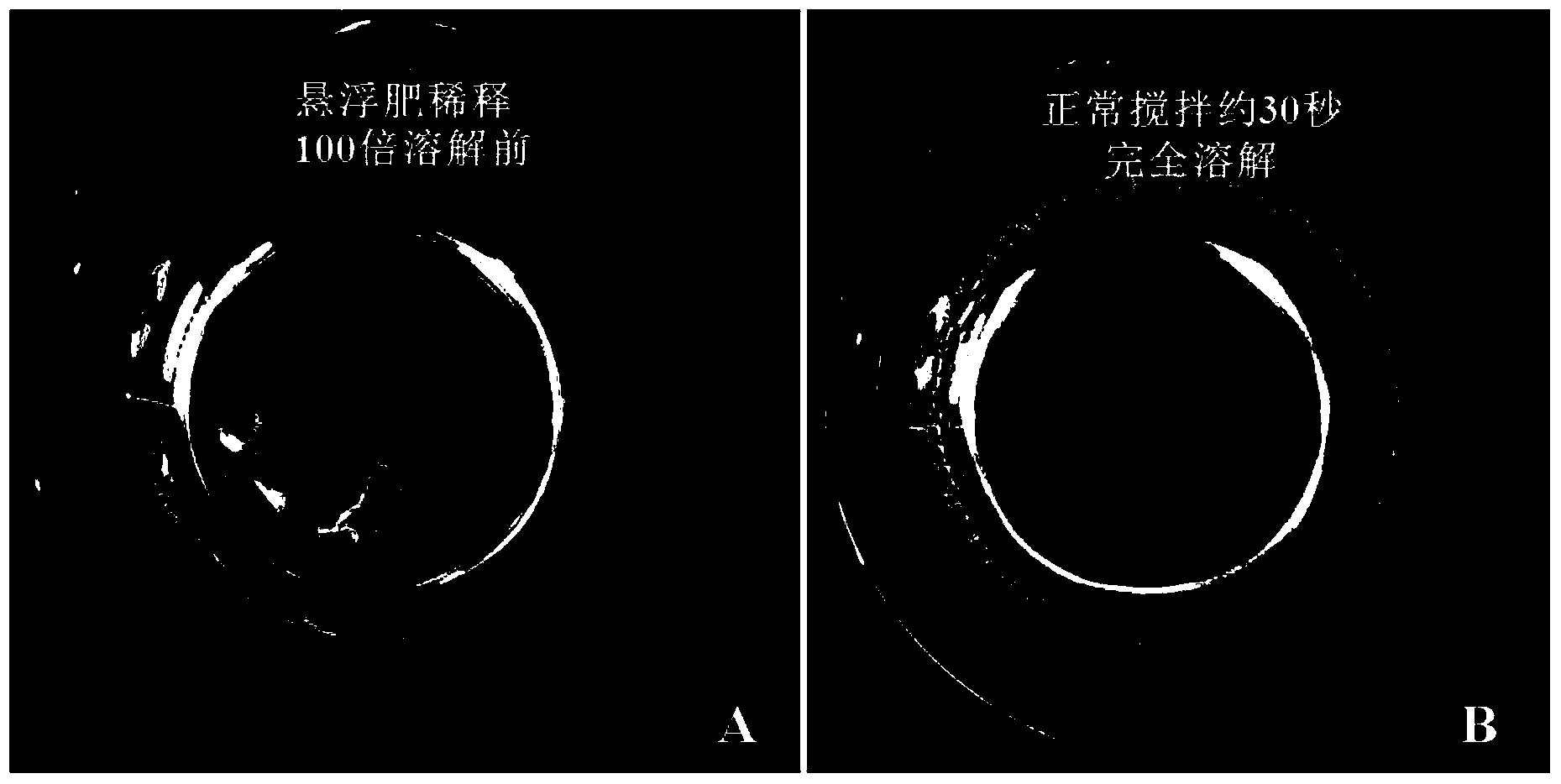

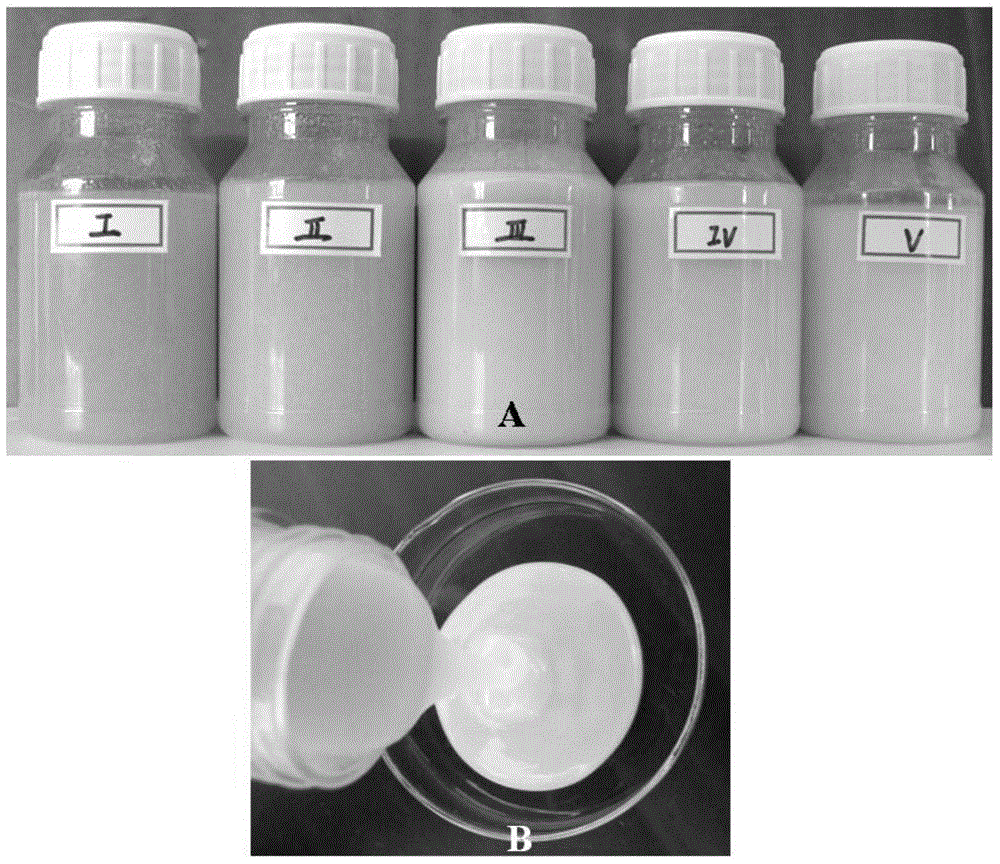

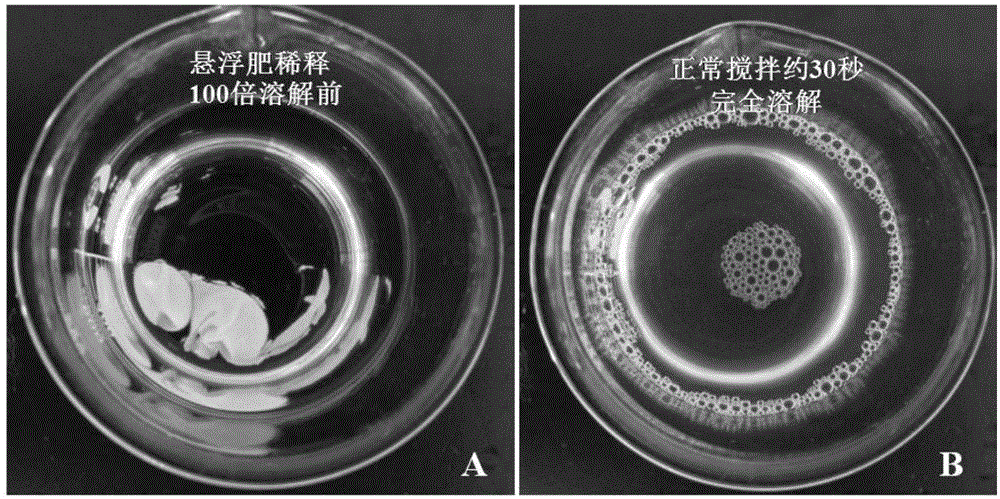

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

Technology for organically cultivating and harvesting net house vegetables green sword bean, sweet corn and broccoli successively in one year

InactiveCN101779559AReduce viral illnessReduce the occurrence and harm of pests and diseasesPlant protectionSoil-working methodsMicroclimateWeed

The invention relates to technology for organically cultivating and harvesting net house vegetable green sword bean, sweet corn and broccoli successively in one year. The technical scheme of the invention comprises the following steps: (1) land parcel selection; (2) construction technology for an organic vegetable net house; (3) selection of breeds and arrangement of crops for rotation; (4) fertilization technology; (5) control technology for pests and weeds; and (6) harvesting technology. The technology has the following advantages that: the research on the technology for organically cultivating and harvesting the green sword bean, the sweet corn and the broccoli successively in one year is carried out, dependable crops and high quality can be achieved, and the production standard for the organic vegetables is met; a microclimate principle of the pests is changed and disturbed on the ecological environment, so the occurrence and damage of the plant diseases and insect pests are reduced; excessive absorption for a certain element in the soil is reduced, so imbalance of soil nutrient is avoided; and the soil is also fully utilized so as to create higher yield.

Owner:东营市农业科学研究所

Beverage capable of lowering and preventing high blood sugar

The beverage capable of lowering blood sugar and preventing hyperglycemia contains birch down extract, kudzu vine root isoflavone, ginsenoside and other natural functional medicine-food components. The beverage can regulate and lower blood sugar, promote the recovery of diabetics, lower the medicine dosage of diabetics and prevent hyperglycemia.

Owner:武斌

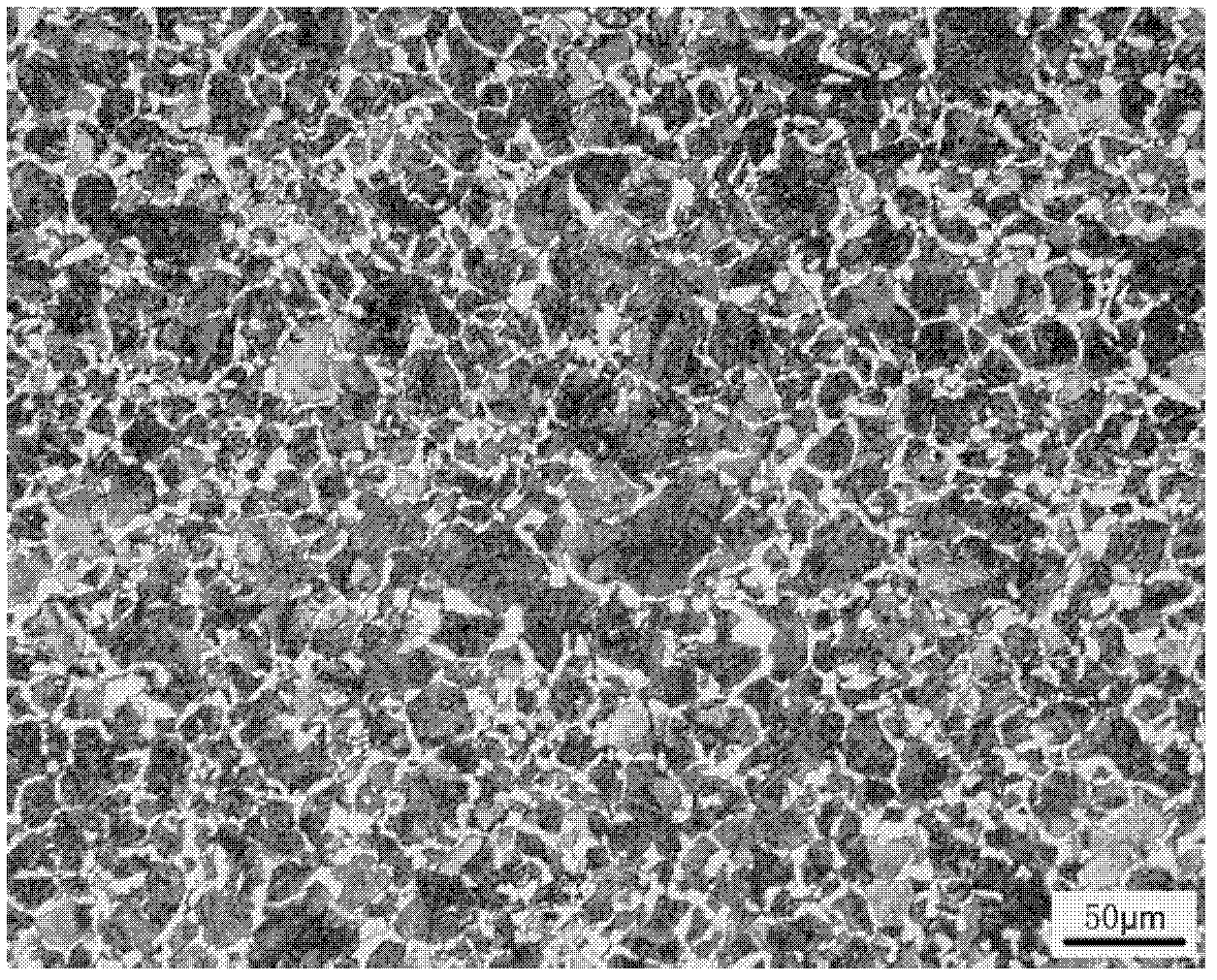

Method for producing Nb-containing high-speed train wheel steel

InactiveCN102534396AHigh strengthImproves the toughness of steel under high-strength conditionsMetallic materialsPearlite

The invention relates to a method for producing Nb-containing high-speed train wheel steel, and belongs to the field of metal materials. The wheel steel comprises the following components in percentage by weight: 0.40 to 0.70 percent of C, 0.70 to 0.80 percent of Mn, 0.30 to 0.60 percent of Si, 0.015 to 0.110 percent of Nb, 0.20 to 0.35 percent of Cr, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S and the balance of Fe and inevitable elements. The method comprises the following steps of: smelting, forging to obtain a steel billet, performing normalization and heat preservation at the temperature of between 850 and 900 DEG C for 1 hour, performing air cooling or water spray cooling to room temperature, and ensuring that cooling speed is controlled in therange of 1 to 15 DEG C / s and a room temperature structure is ferrite and pearlite. The high-speed train wheel steel produced by the method has the tensile strength of 740 to 900MPa, the yield strength of 450 to 570MPa, the breaking elongation of 15 to 25 percent and the low temperature (-20 DEG C) impact work (Akv) of 15 to 20J, and a uniform structure with 10 to 25 percent of ferrite can be obtained at room temperature. The Nb-containing high-speed train wheel steel has mechanical properties of high strength and toughness, and overcomes the defect of a low toughness value of the conventionalhigh and medium carbon wheel steel.

Owner:UNIV OF SCI & TECH BEIJING

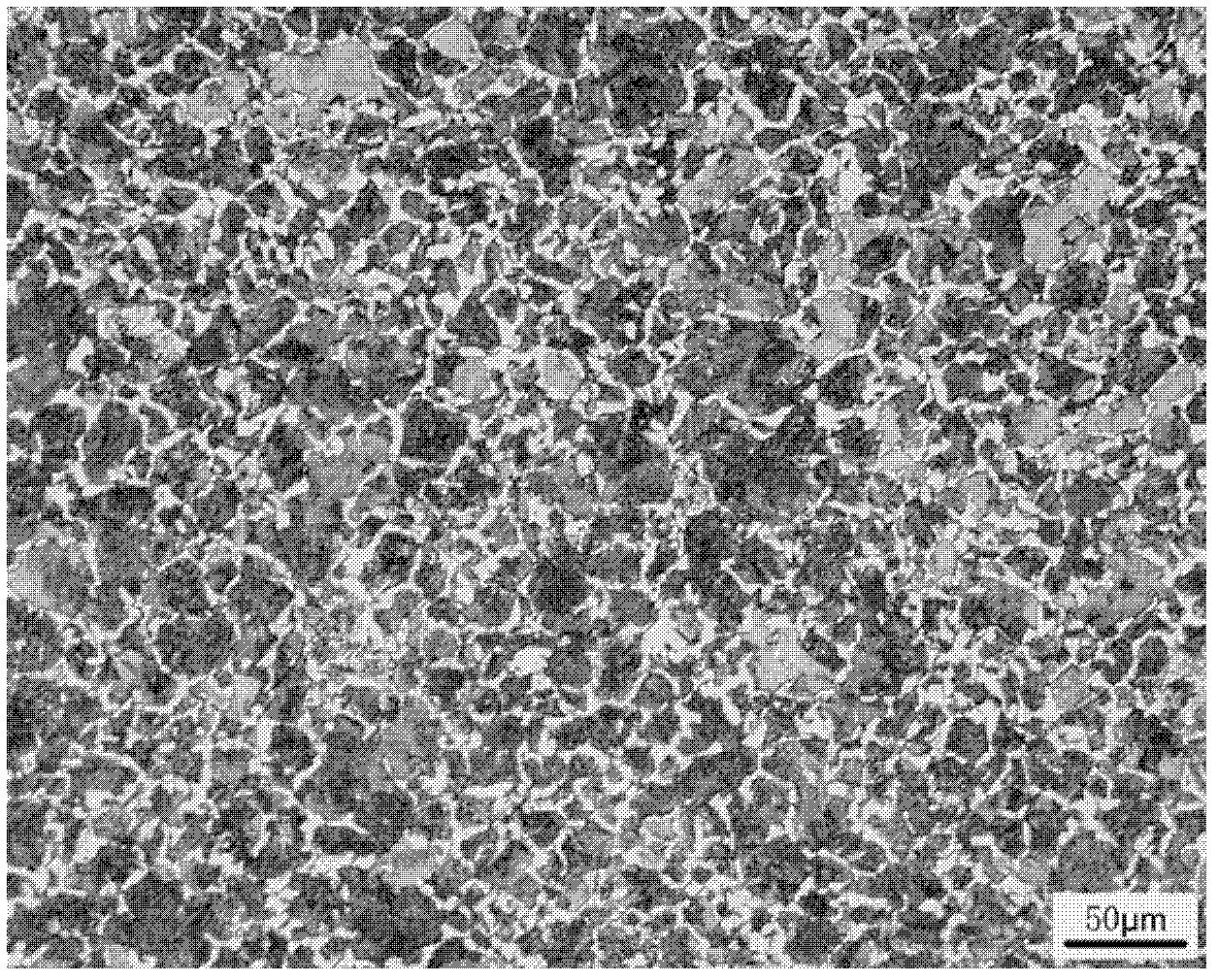

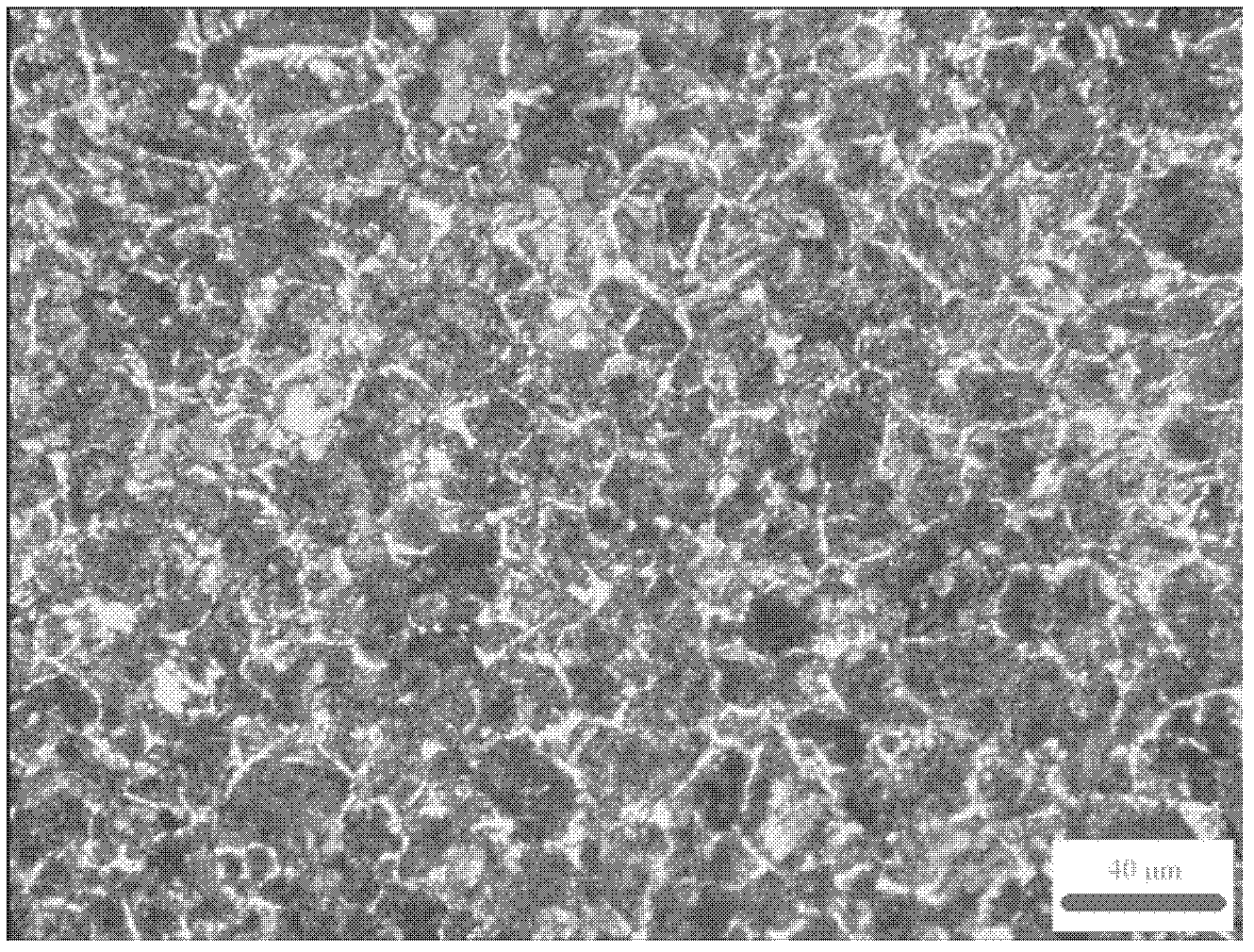

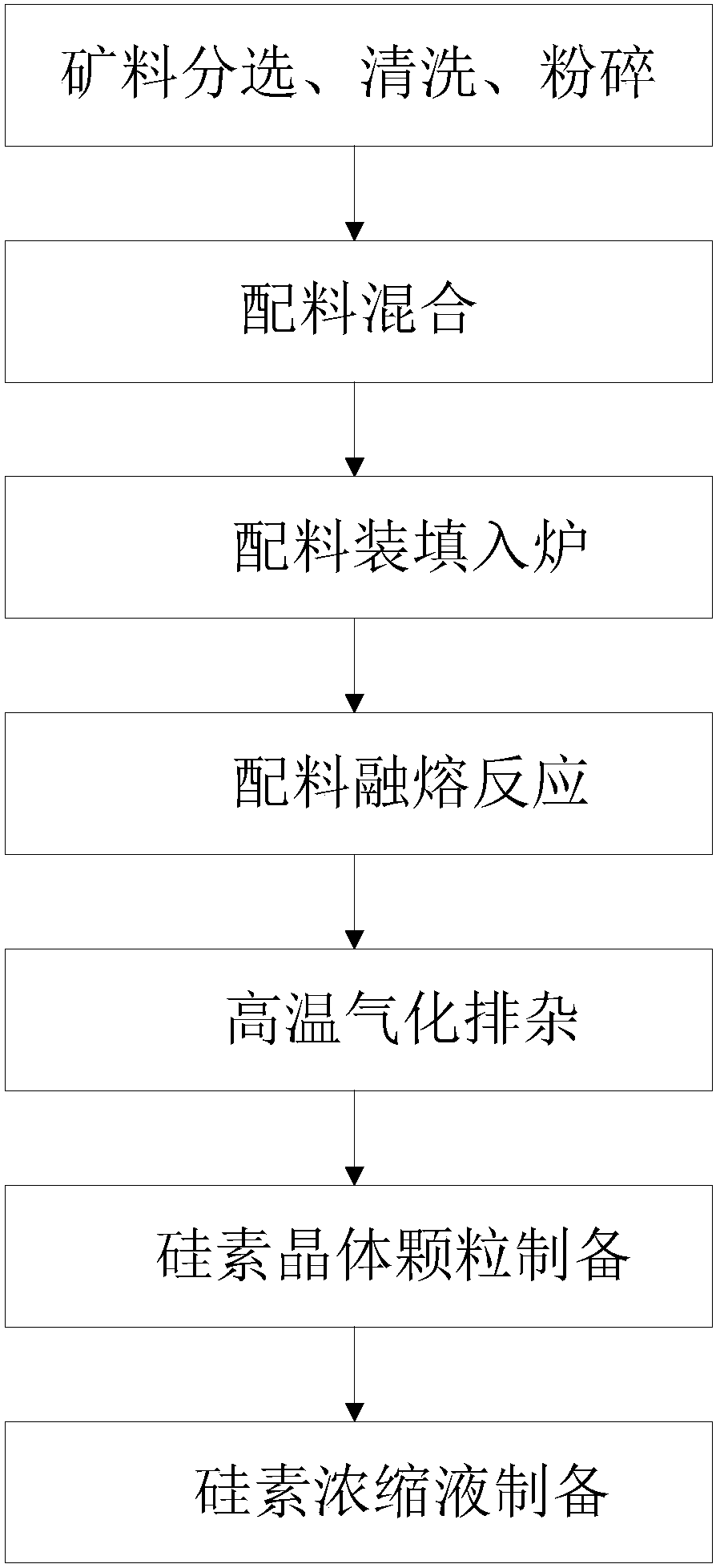

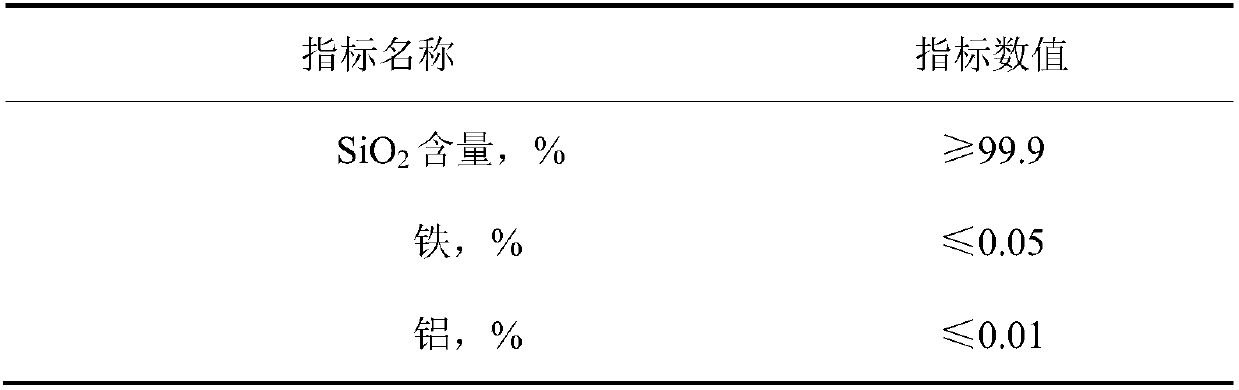

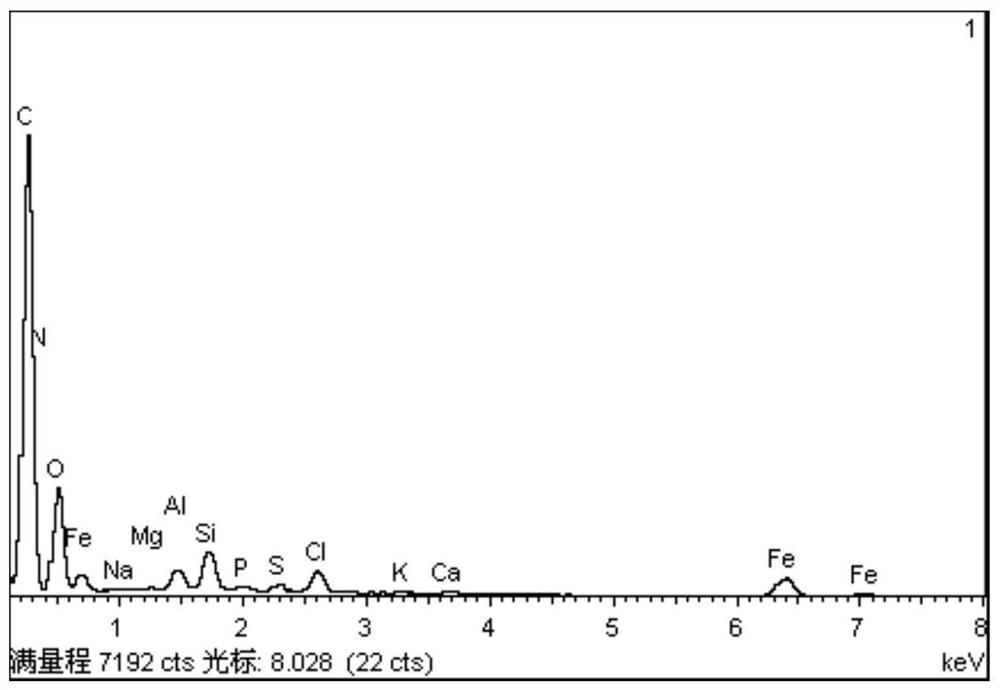

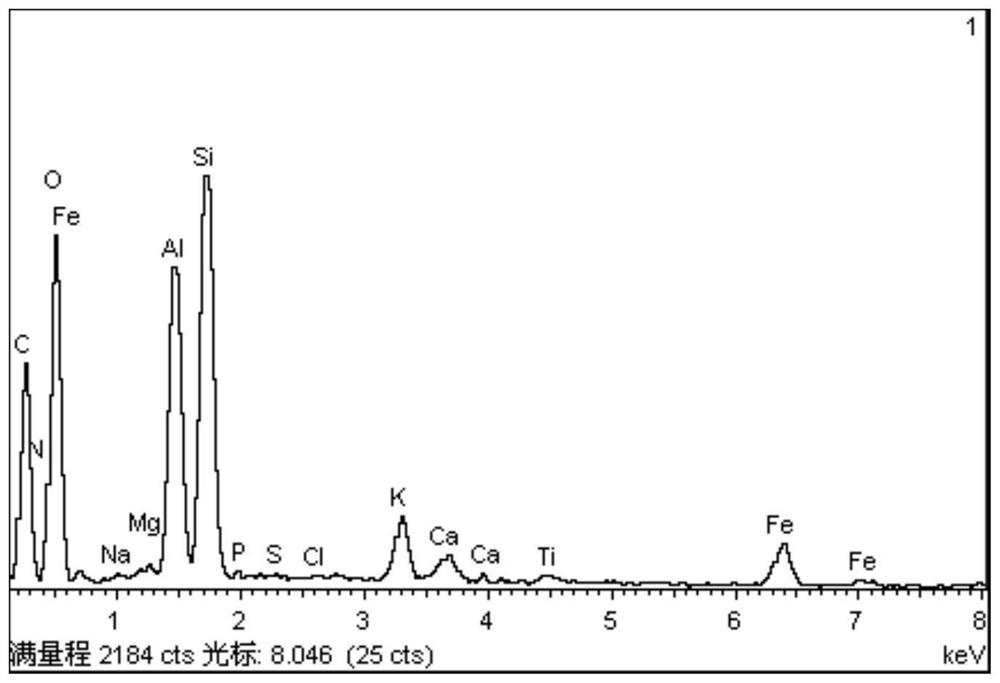

Food-grade silicon production method

InactiveCN107625133AMeet production standardsGood for healthSilicon oxidesFood scienceProcess equipmentMixed materials

The present invention discloses a food-grade silicon production method, which comprises: sorting a mineral material, washing, and crushing; mixing materials; loading the mixed materials into a furnace; carrying out a melting reaction on the materials; carrying out high temperature gasification and impurity removing; preparing silicon crystal particles; and preparing a silicon concentrated liquid.According to the present invention, with the food-grade silicon production method, the production environment, the production process equipment requirements and the finished product detection standardrequirements are simultaneously determined; the silicon produced through the method does not contain harmful heavy metal components and toxic substances, and can be dissolved in water, such that thewater body is alkaline, and is instantaneously rich in a large amount of metasilicic acid beneficial to human body and a variety of mineral elements required by human body; and the obtained food-gradesilicon can be used as food, health product additives or human body trace element supplements.

Owner:GUANGZHOU HANNATER HEALTH PROD CO LTD

Water insoluble dietary fiber prepared from red alga plant gracilaria agar residue and preparation method thereof

The invention relates to a water insoluble dietary fiber prepared from red alga plant gracilaria agar residue and a preparation method thereof. The water insoluble dietary fiber is prepared from residue obtained by processing red alga plant gracilaria agar as a raw material through the procedures of washing treatment and acid treatment, bleaching treatment, drying and pulverizing on water soluble dietary fiber. The water insoluble dietary fiber has powdery appearance and light yellow color, the water holding capacity is 4.325, and the expansion force is 3.93 ml / g. The preparation method has short reaction time, simple and practical technology and low investment and quick effect taking in actual production and is applicable to popularization and application.

Owner:GUANGDONG OCEAN UNIVERSITY

Process for preparing emulsion breaker of sulfated oil

InactiveCN1754943AReduce moisture contentDehydration fastHydrocarbon oil dewatering/demulsificationDemulsifierPolymer science

The preparation method of demulsifier for acidified oil comprises three demulsifers of A, B, and C with weight proportion as 0.5-2:0.5-2:1-5, all belonged to block polymer reacted by ethylene oxide, propylene oxide and diisocyanate with different initiators. With this invention, at 60-70Deg, it is rapid to dewater, and the water content of crude oil is less than 0.5%.

Owner:天津市慧珍科技有限公司

Spent bleaching clay-based organic fertilizer, and preparation method and application thereof

InactiveCN108558580AImprove the situationPromote growthBio-organic fraction processingExcrement fertilisersEcological environmentPoultry manure

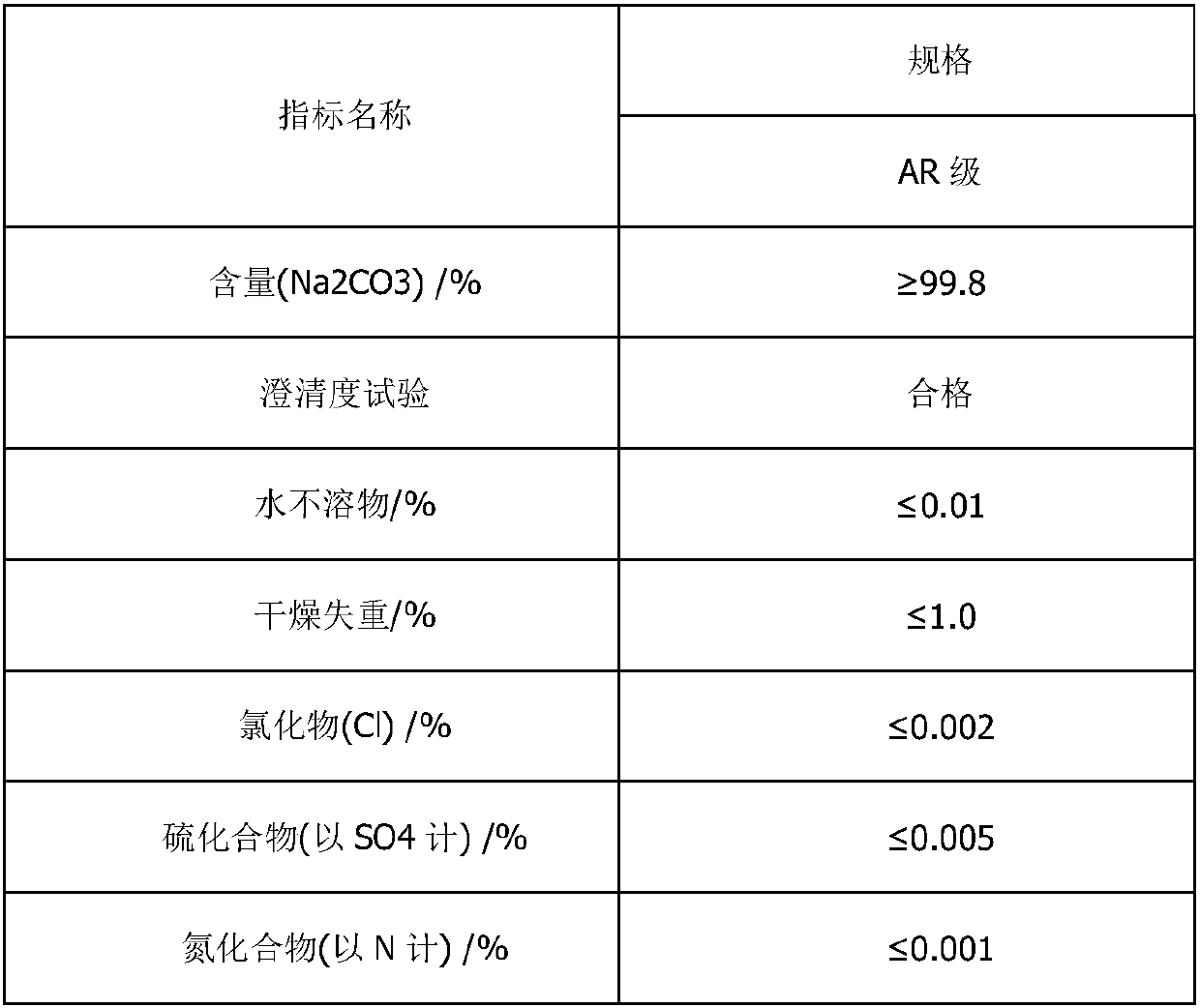

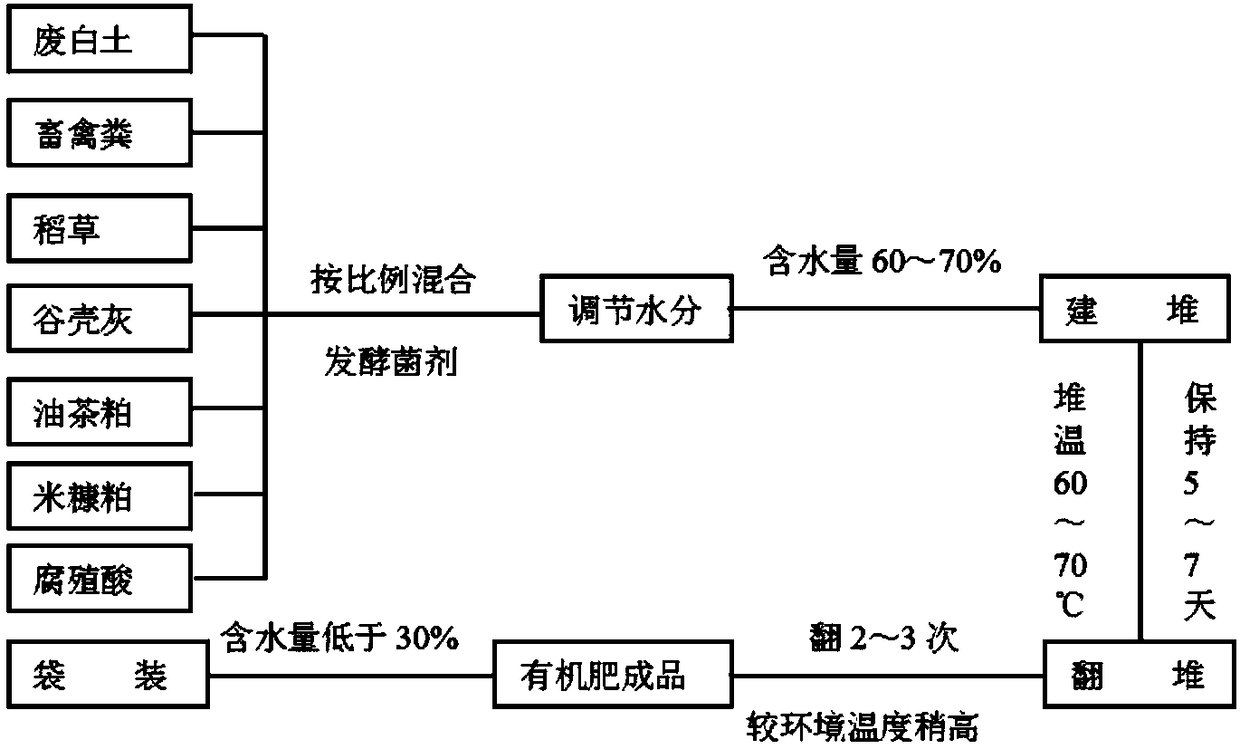

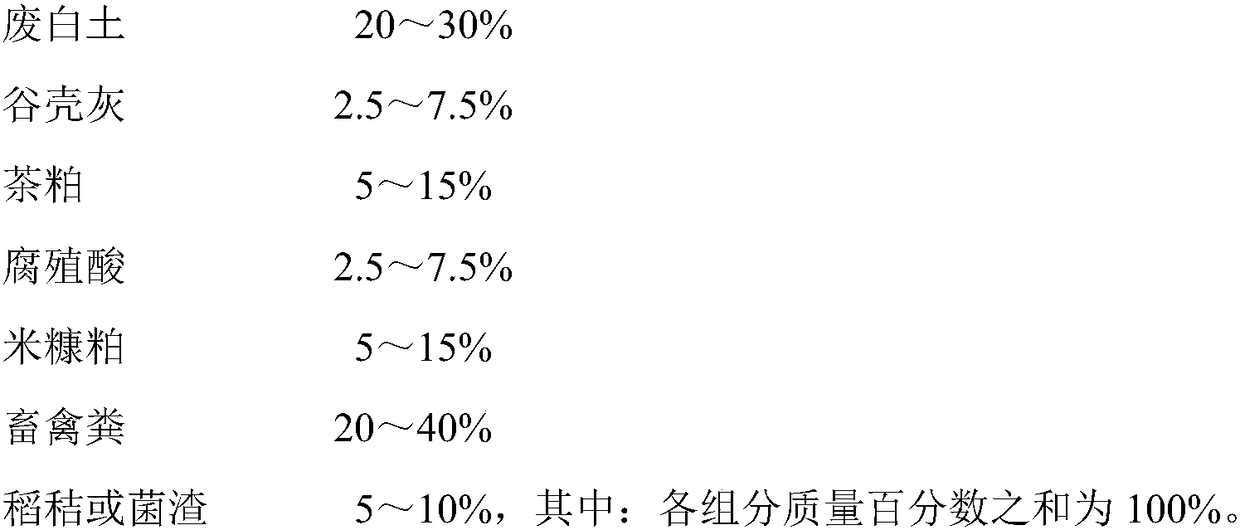

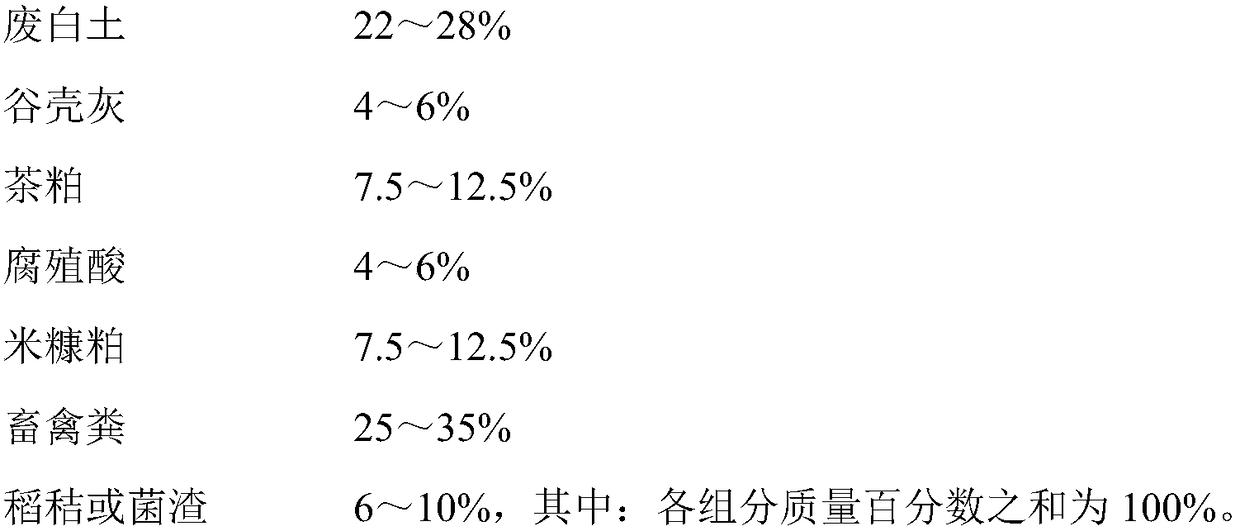

The invention relates to a spent bleaching clay-based organic fertilizer, and a preparation method and an application thereof, and belongs to the technical field of organic fertilizers. The organic fertilizer is prepared from 20-30% of spent bleaching clay, 2.5-7.5% of rice husk ash, 5-15% of tea seed meal, 2.5-7.5% of humic acid, 5-15% of rice bran, 20-40%of livestock and poultry manure, and 5-10% of rice straws or fungus residues. The organic fertilizer can effectively improve the conditions of soil, improve the water retention and fertilizer conservation capacity of the soil, promote the growth of crops, increase the yield and increase the income. The organic fertilizer is prepared from the spent bleaching clay, livestock and poultry manure, rice straws and other wastes, so the problemof recycling of various agricultural wastes is solved. The organic fertilizer can be applied to the production of green agricultural products, reduces pollution, protects the ecological environment, and improves the production efficiency and the economic benefit of an enterprise, so the organic fertilizer has a very broad development prospect.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

Cultivation method of organic ginseng

ActiveCN103125248AMeet production standardsReduce generationHorticultureBiotechnologyMedicinal herbs

The invention relates to a cultivation method of traditional Chinese medicinal materials, and provides a cultivation method of organic ginseng. The cultivation method comprises the following steps: (1) selecting a proper land and environment; (2) preparing soil and making a cultivation bed to reduce diseases; (3) further applying organic fertilizers to keep nutrition balanced; (4)selecting a disease-resistant variety which is high-quality, multiple in resistance and long in stem; (5)increasing seed growing power for natural sprout; (6) planting and cultivating strong plants densely; (7) constructing a shed to reasonably adjust illumination; (8) manually weeding and cleaning the surface of the cultivation bed to reduce the environment where diseases occur; (9) adjusting and controlling water content to reduce the environment where diseases occur; (10) reasonably preventing and controlling plant diseases and insect pests; and (11) harvesting with a pollution controlling method. The cultivation method of the organic ginseng can achieve stable yield and high quality of the organic ginseng, enables the organic ginseng product to meet an organic ginseng production standard, can solve the problems that pesticide residue content and heavy metal content exceed the standard in a traditional ginseng cultivation process, and ensures quality of product of ginseng original medicinal materials.

Owner:通化百泉参业集团有限公司

Soilless half-hydroponic planting method of organic Chinese chives

InactiveCN105900662AAchieving anniversary plantingImprove qualityPlant cultivationCultivating equipmentsChemical treatmentSymbiotic bacteria

The invention discloses a soilless half-hydroponic planting method of organic Chinese chives, and belongs to the field of facility agriculture cultivation. Disinfection treatment is conducted on non-transgenic Chinese chive seeds which are not subjected to chemical treatment, and in the whole process, organic fertilizers such as fermented and decomposed straw and chicken mature are utilized for matrix cultivation and leaching agent irrigation; seedling is conducted in the earlier stage of 3 months to 4 months; transplanting is conducted in the middle stage of 6 months to 18 months for half-hydroponic cultivation; in the later stage, hydroponic cultivation is conducted by combining an order, and cyclic fertilizer supply and timely liquid fertilizer recycling are adopted; a cultivation mode that the Chinese chives are managed in different periods and stages is combined. The invention further provides an organic matrix for planting vegetables and organic liquid fertilizer and a making method thereof. Earlier fermentation, post decomposition and continuous retting are conducted on straw, chicken manure and the like which serve as the raw materials by means of the characteristic of symbiotic bacteria; continuous extracting and leaching agent supplementing are conducted, and the organic liquid fertilizer is obtained after collecting is conducted; nutrients are comprehensive, the fertilizer efficiency is balanced, and plant absorption is promoted; the soilless half-hydroponic planting method of the organic Chinese chives is an efficient, practical and low-cost planting method.

Owner:SHANDONG UNIV OF TECH

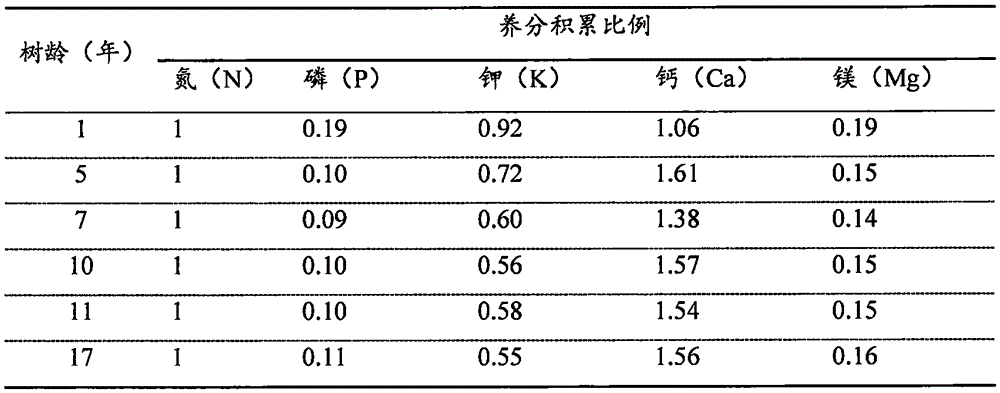

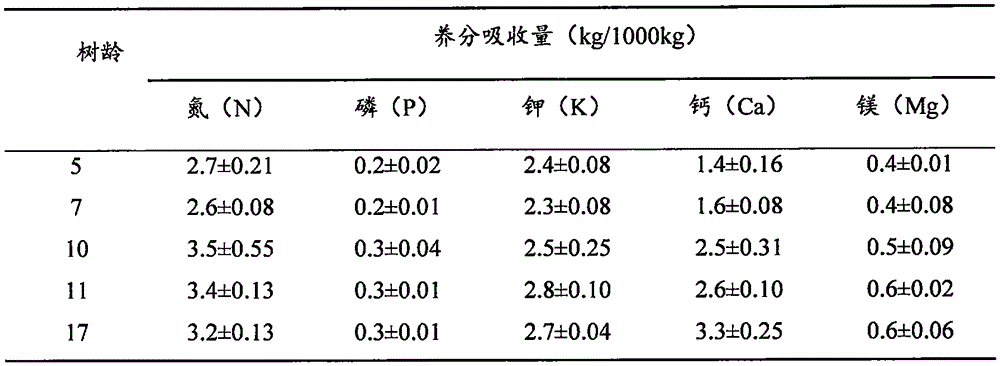

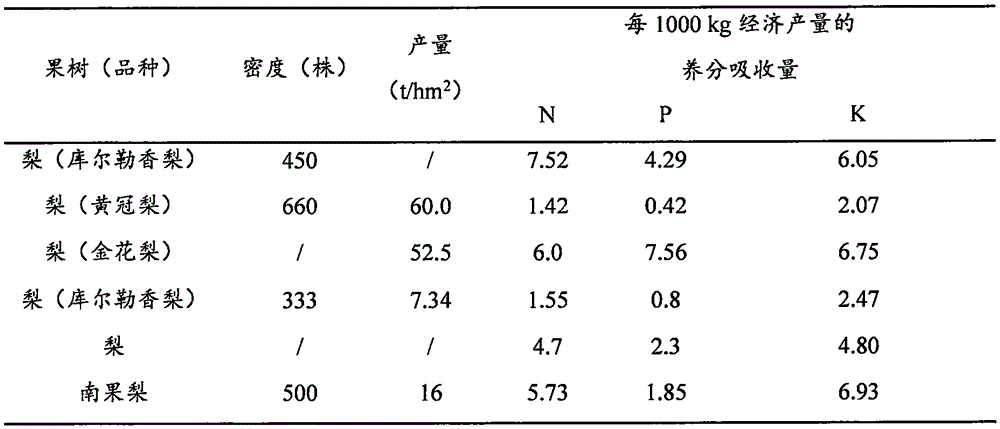

Formula fertilizer for production of green pear products as well as preparation method and application method of formula fertilizer

InactiveCN105523871APromote flowering and fruit settingStable outputAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPEARPotassium

The invention provides formula fertilizer for production of green pear products. The formula fertilizer comprises nitrogenous fertilizer, phosphate fertilizer, potassium fertilizer as well as secondary element and microelement fertilizer containing Ca, Mg, B, Zn and Fe; in percentage by mass, the content of nitrogen in the formula fertilizer is 15%-18%, phosphorus pentoxide 6%-12%, potassium oxide 6%-18%, calcium oxide 0.5%-3%, magnesium oxide 0-2%, B 0.1%-0.5%, Zn 0.1%-0.2% and Fe 0.1%-1%. The formula fertilizer is mainly based on the soil fertility characteristic and the pear feature variety of pear orchards, the reasonable and accurate formula fertilizer is adopted, the fertilizer utilization rate is high, blooming and fruit setting of pears are facilitated, the product yield is stable, and the product quality is greatly improved.

Owner:辽宁省果树科学研究所

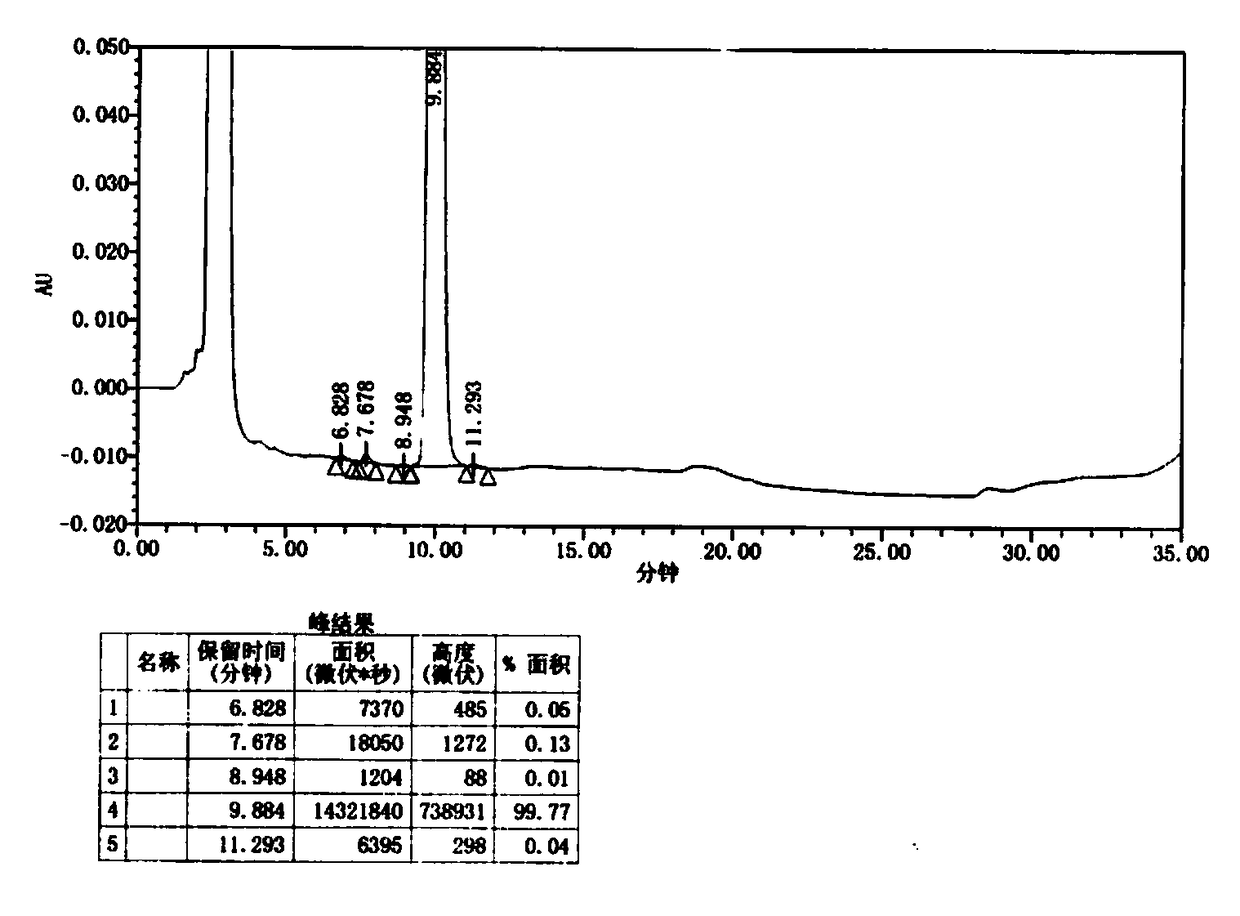

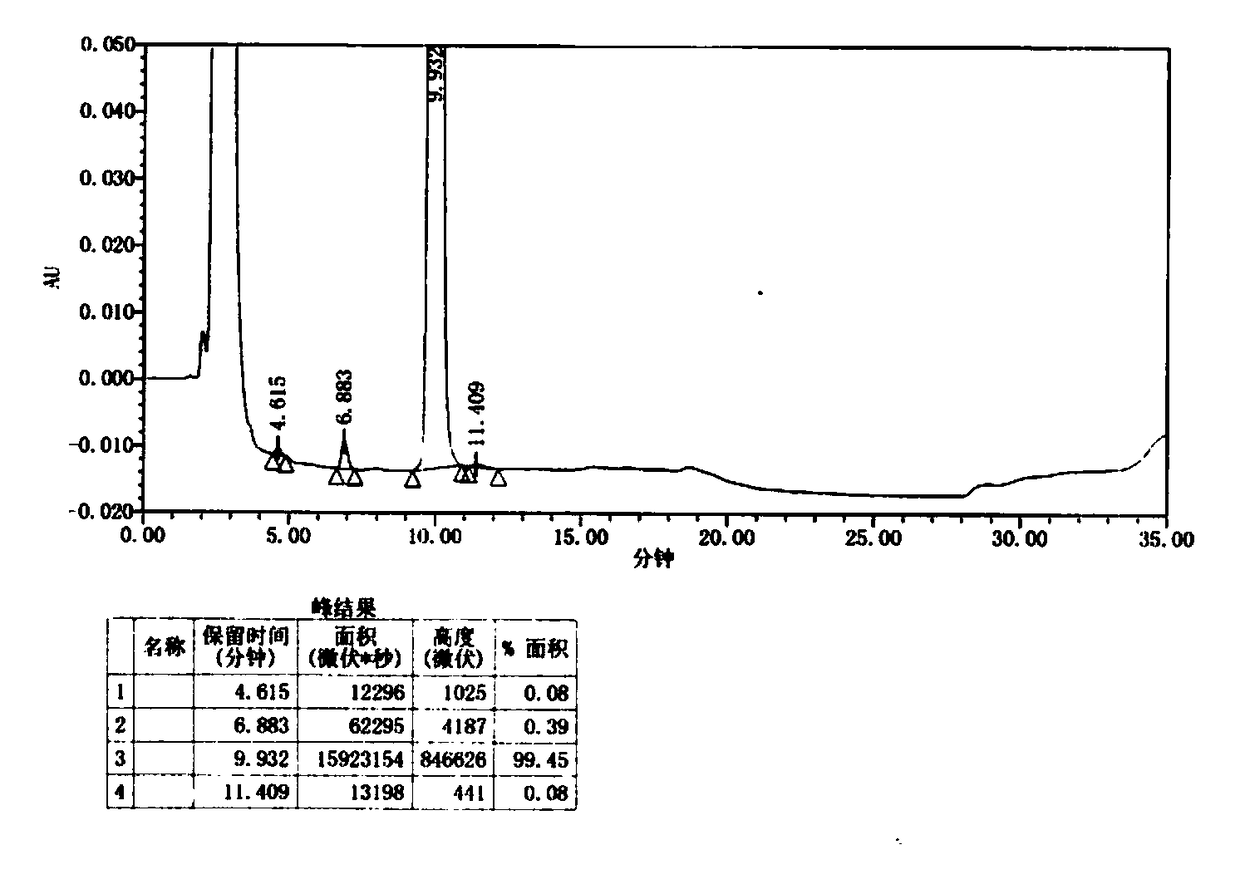

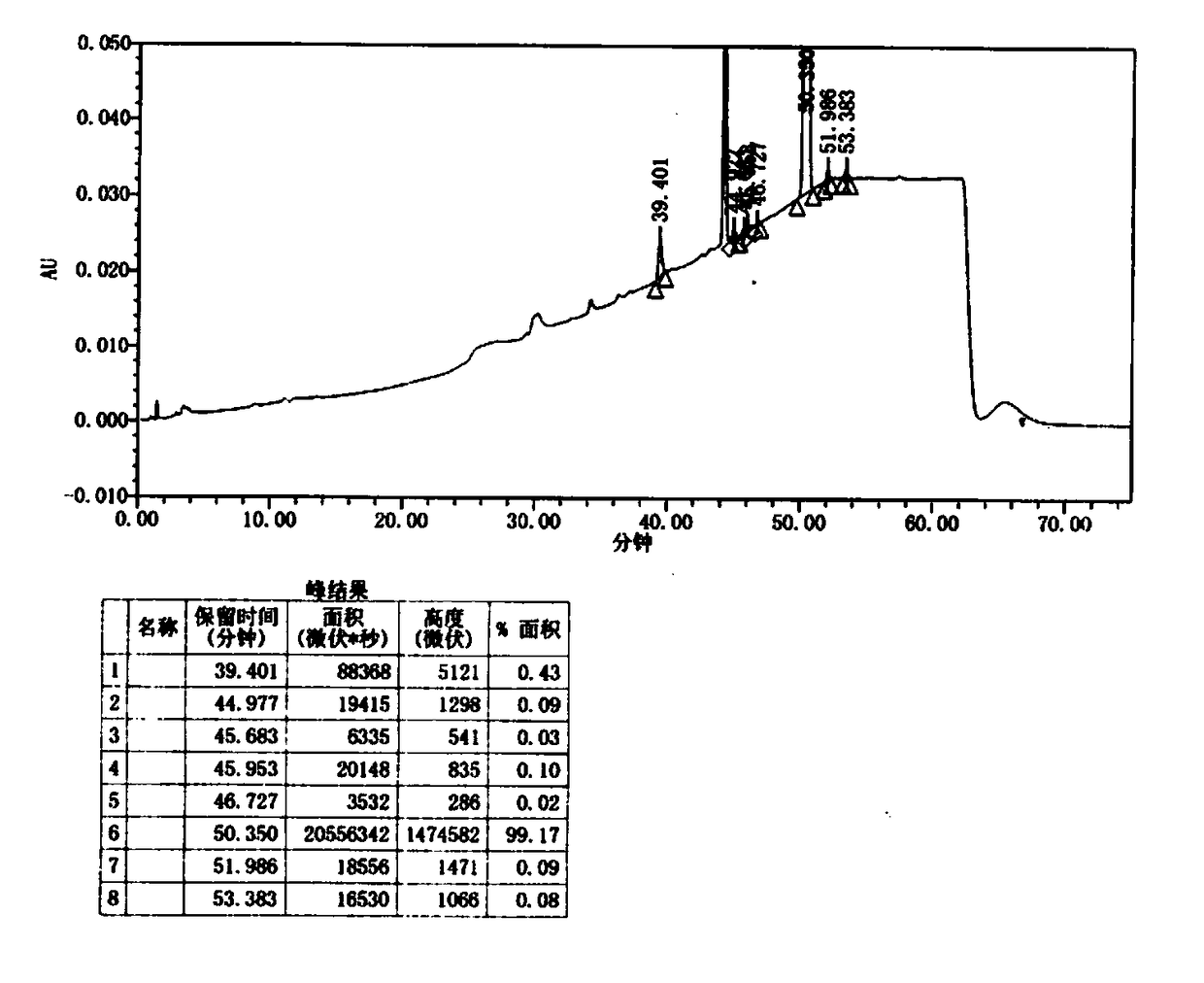

Preparation method and product of palbociclib

The invention discloses a preparation method of palbociclib. The preparation method comprises the following steps: 1) dissolving 4-(6-aminopyridine-3-yl)-piperazine-1-tertiary butyl carboxylate into asolvent A, adding an alkali reagent, activating at 0-20 DEG C, adding 6-bromine-2-chlorine-8-cyclopentyl-5-methyl-pyridino-[2,3-D]-pyrimidine-7(8H)-ketone, adjusting the solution to acid after a reaction is completed, cooling and filtering, taking filter cakes, and drying the filter cakes to obtain an intermediate I; 2) in the presence of an inert atmosphere, dissolving the intermediate I and butyl vinyl ether into a solvent B, catalyzing with a catalyst at 95-105 DEG C, cooling and separating a crystal after the reaction is completed, filtering, and taking the filter cakes, and drying the filter cakes to obtain an intermediate II; 3) dissolving the intermediate II into a solvent C, adding an acid, adjusting the solution to acid after the reaction is completed, filtering, and taking and centrifuging filtrate to obtain a target product, namely palbociclib. By adjusting reaction parameters and optimizing preparation process procedures, the preparation method is high in product yield, good in purity, simple and mild in process conditions and applicable to industrial large-scale production.

Owner:CHONGQING SANSHENG IND CO LTD

Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

The invention discloses a compound liquid fertilizer with high suspension degree, and a preparation method and an application thereof, and belongs to the liquid fertilizer industry field. The preparation method comprises the steps: adding macromolecule organic sugar into a clay material to be used as a basal suspending agent I, and carrying out first suspension chelation of a major element and a trace element at the temperature of 40-60 DEG C; followed by controlling the temperature at 20-30 DEG C, slowly adding a plant growth regulator and a surface active material, fully mixing uniformly, finally adding macromolecule cellulose and an analog thereof as a suspending agent II, carrying out second suspension chelation, and fully stirring to obtain the compound liquid fertilizer with high suspension degree. The prepared compound liquid fertilizer with high suspension degree has comprehensive nutrients, high content, low cost, good liquidity, good stability and good dissolvability, and is beneficial for crops to efficiently absorb and utilize. The preparation method is simple in process and easy to implement. The compound liquid fertilizer is an ideal fertilizer source for water and fertilizer integration for drip irrigation, sprinkler irrigation, water flushing and the like.

Owner:SOUTH CHINA AGRI UNIV +1

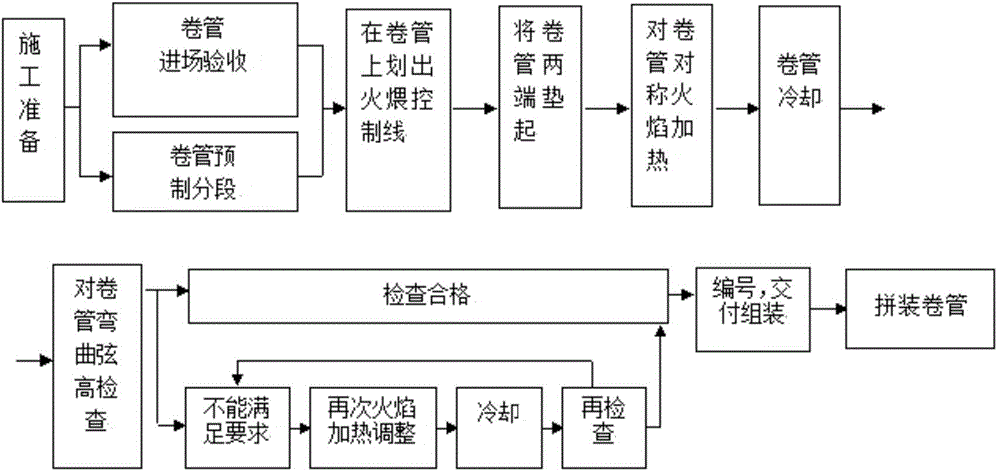

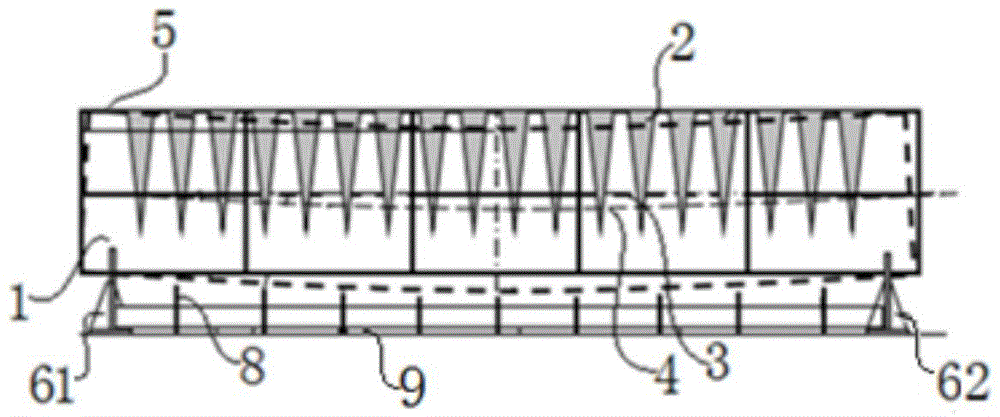

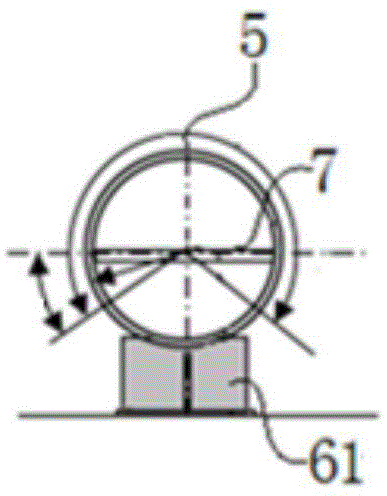

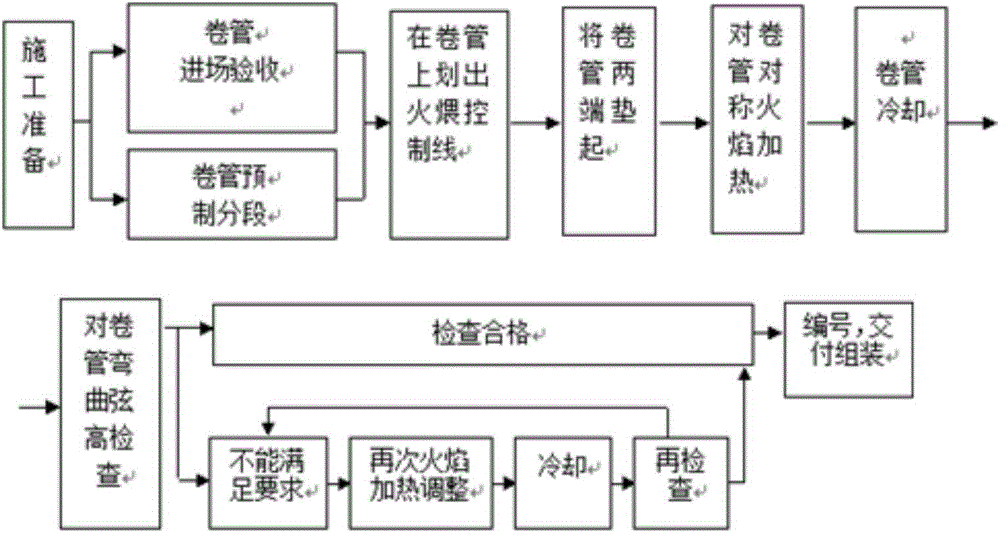

Method for manufacturing large bent steel members on basis of fire bending

ActiveCN104138942AAchieve the purpose of simmeringSimplify construction proceduresMetal working apparatusEngineeringPipe support

The invention discloses a method for manufacturing large bent steel members on the basis of fire bending and belongs to the technical field of pipeline machining. The method comprises the step of construction preparation, wherein quality detection and algorithm quantification are carried out on reel pipes; the step of reel pipe marking, wherein the reel pipes are supported by a reel pipe supporting device, and heating areas are marked on the reel pipes; the step of fire bending, the heating areas marked well are bent along the zigzag path, and the time duration for bending is decided according to colors generated when the reel pipes are heated; the step of cooling detection, wherein after the reel pipes are cooled, whether the distance between the lower bottoms of the bent reel pipes and the upper end of a detection board is within 3 mm or not is detected, and the reel pipes are qualified if the distance is within 3 mm; the step of secondary processing, wherein when deviation between the actual reel pipe bending chord height H1 and the theoretical reel pipe bending chord height H is large, adjustment is carried out through a gas welding baking handle; the step of reel pipe splicing, wherein the reel pipes reaching the bending standard are welded through a structural steel platform. The method solves the problem that a large instrument is needed when the large bent steel members are manufactured, and no external force needs to be applied.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

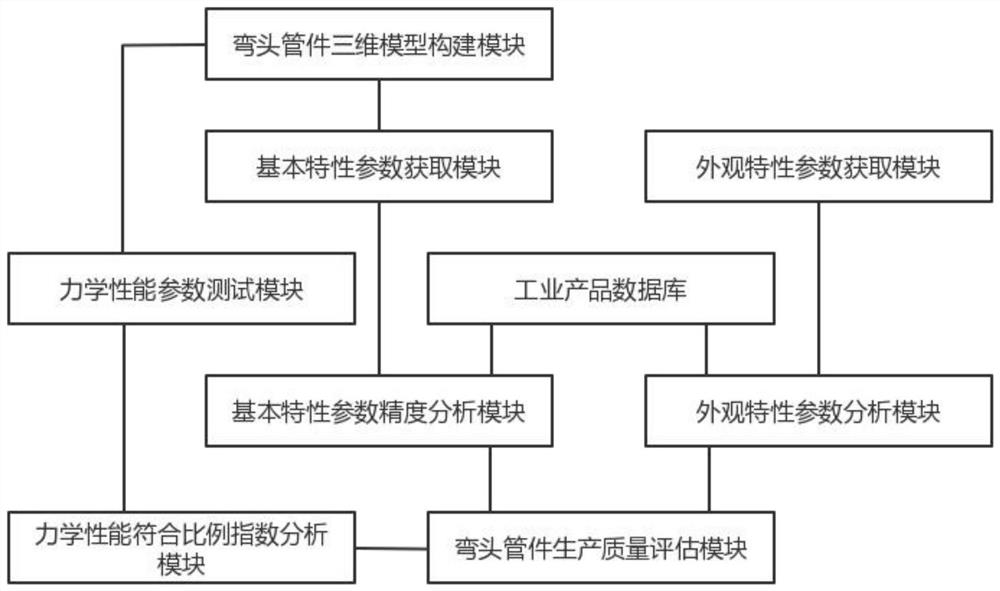

Industrial product production quality monitoring and analyzing system based on big data

ActiveCN114862266ARealize automated monitoringEasy to useResourcesManufacturing computing systemsPipe fittingProcess engineering

The invention discloses an industrial product production quality monitoring analysis system based on big data, and the system comprises the steps: obtaining a three-dimensional model and an appearance image of each to-be-monitored elbow pipe fitting, and obtaining basic characteristic parameters and appearance characteristic parameters of each to-be-monitored elbow pipe fitting; the basic characteristic parameter precision conforming proportion index and the appearance characteristic parameter influence proportion index of each to-be-monitored elbow pipe fitting are analyzed, meanwhile, mechanical property testing is conducted on each to-be-monitored elbow pipe fitting, mechanical property parameters of each to-be-monitored elbow pipe fitting are obtained, the mechanical property conforming proportion index of each to-be-monitored elbow pipe fitting is analyzed, and the mechanical property conforming proportion index of each to-be-monitored elbow pipe fitting is obtained. And the comprehensive production quality coefficient of each to-be-monitored elbow pipe fitting is evaluated, so that multi-dimensional analysis on the production quality of the elbow pipe fitting is realized, the problems of over one-sidedness and limitation of an existing mode are avoided, the error of an analysis result of the production quality of the elbow pipe fitting is effectively reduced, and the overall use quality of a later-stage pressure pipeline is improved to a great extent.

Owner:多彩贵州印象网络传媒股份有限公司

Compound fertilizer for producing green fruits and vegetables and preparation method of compound fertilizer

InactiveCN106116892APromote flowering and fruit settingStable outputCalcareous fertilisersAlkali orthophosphate fertiliserFruit setBacillus sp. ET

The invention provides a compound fertilizer for producing green fruits and vegetables and a preparation method of the compound fertilizer. The compound fertilizer is prepared from nitrogen fertilizer, potash fertilizer, phosphate fertilizer, trace element fertilizer and a bacillus inoculum. The compound fertilizer is comprehensive in formula, outstanding in effect and beneficial to ensuring flowering and fruit setting of fruits and vegetables, stabilizing the yield and improving the quality.

Owner:LANHE SHANGHAI BIOTECH CO LTD

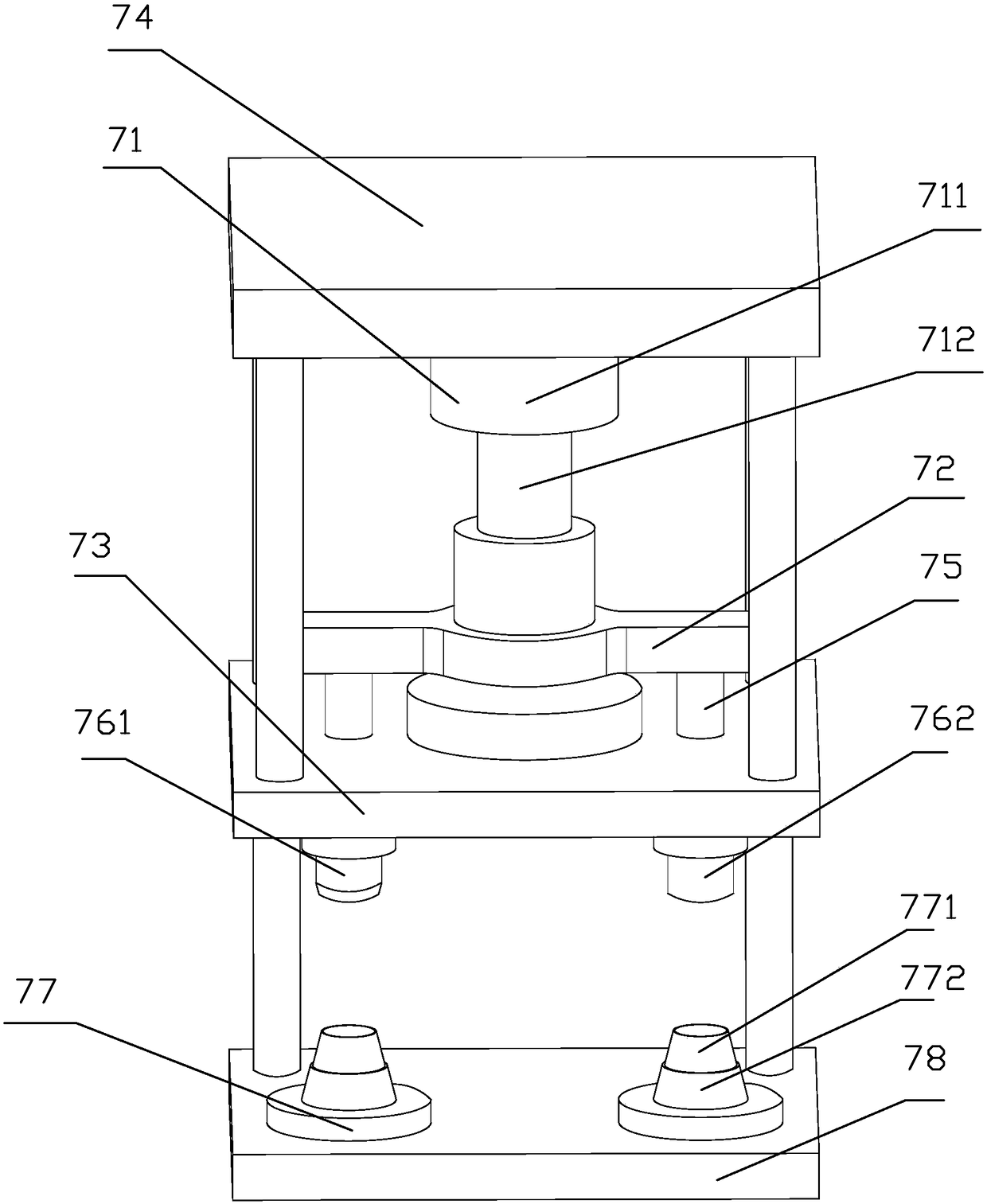

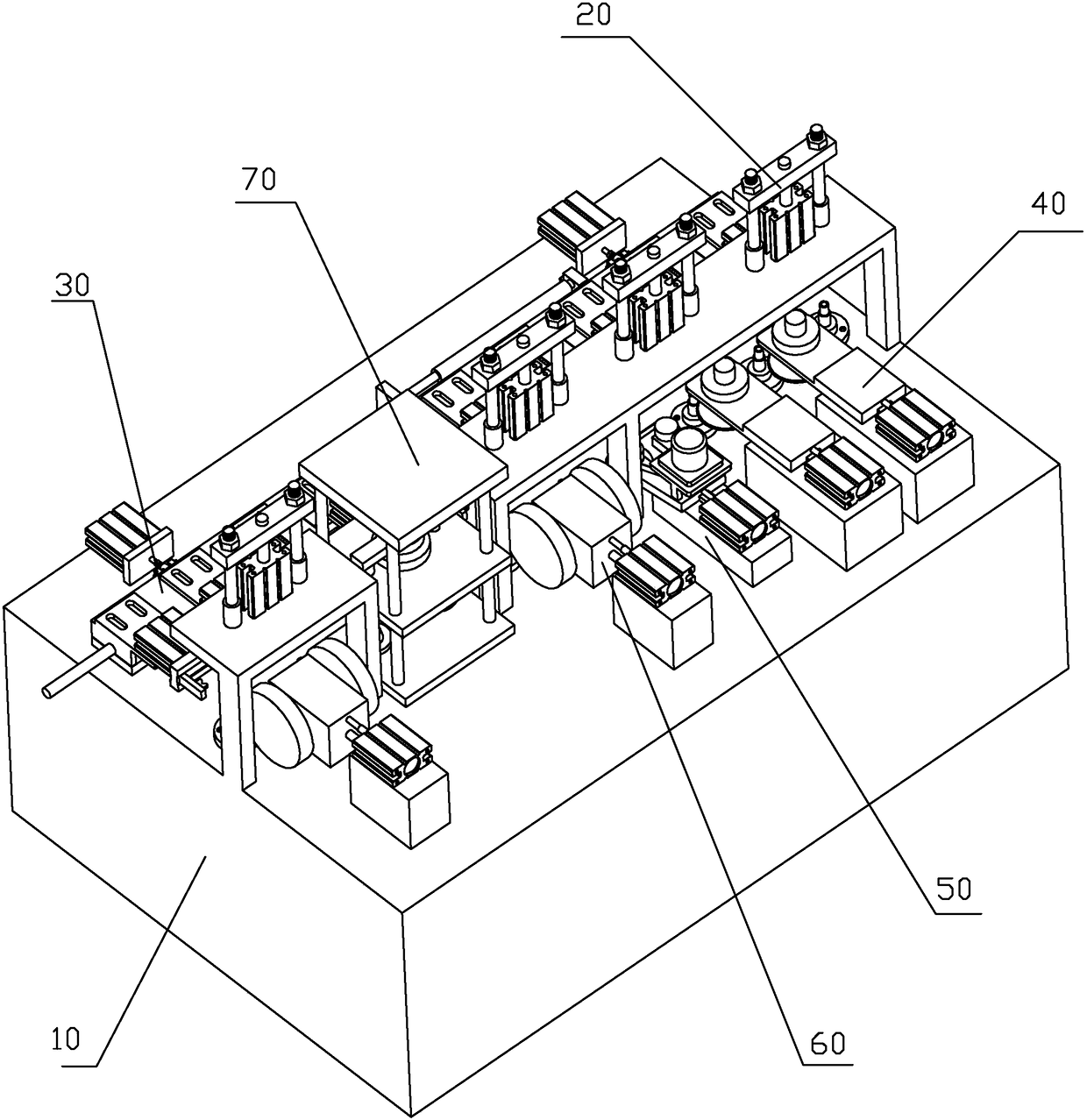

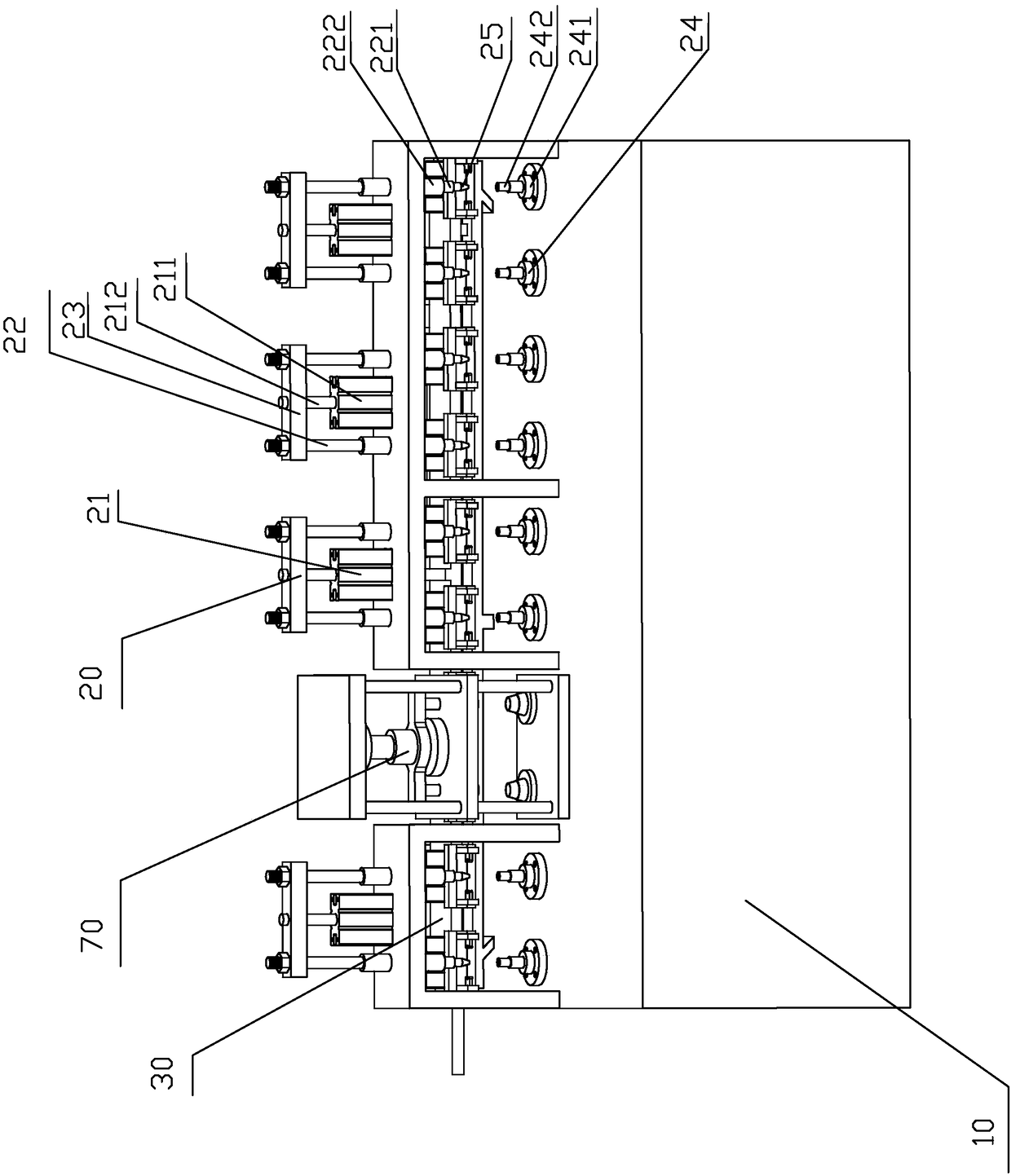

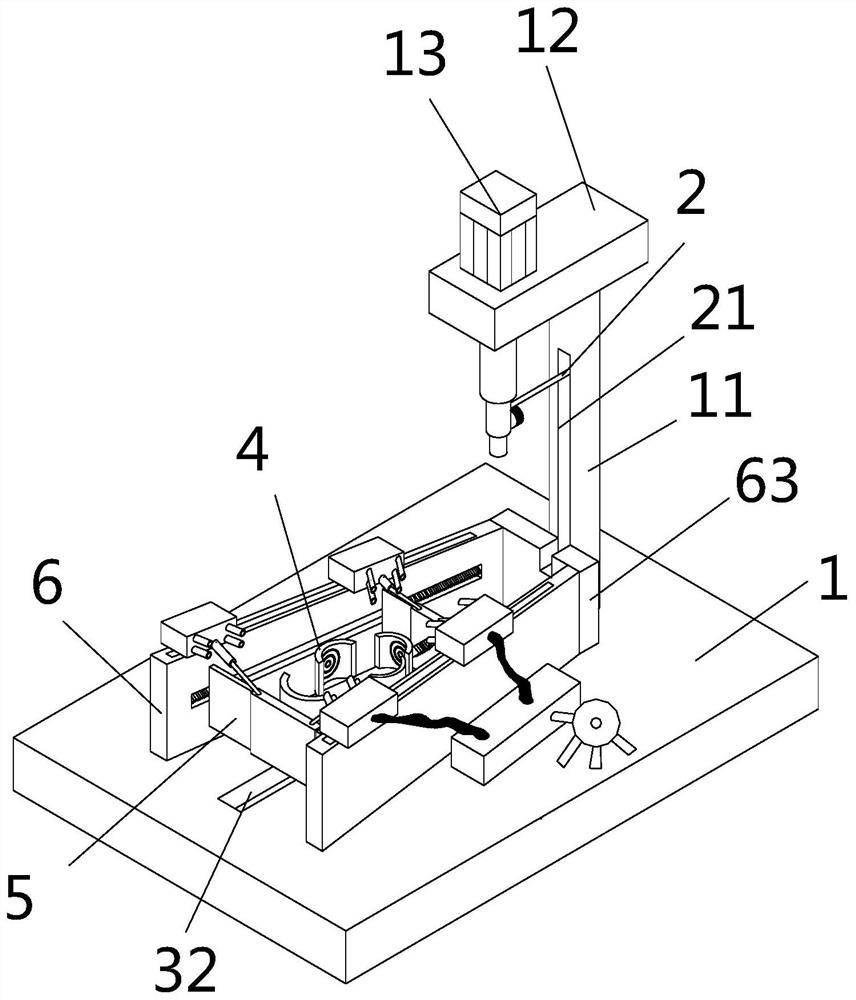

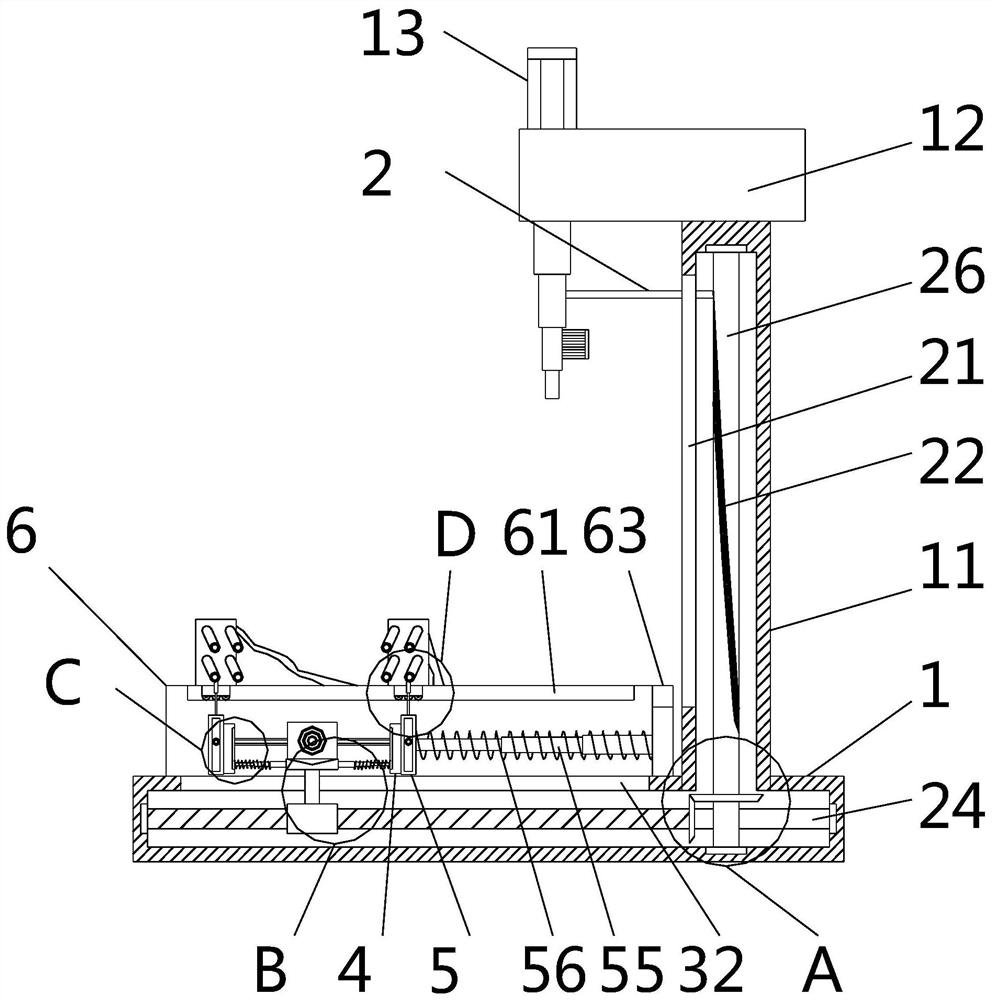

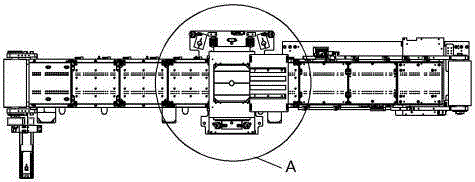

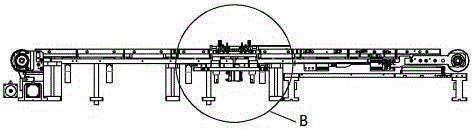

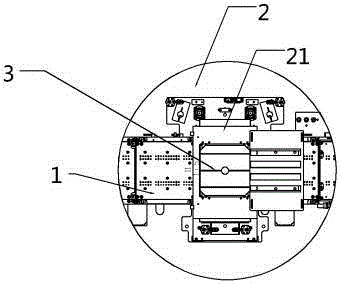

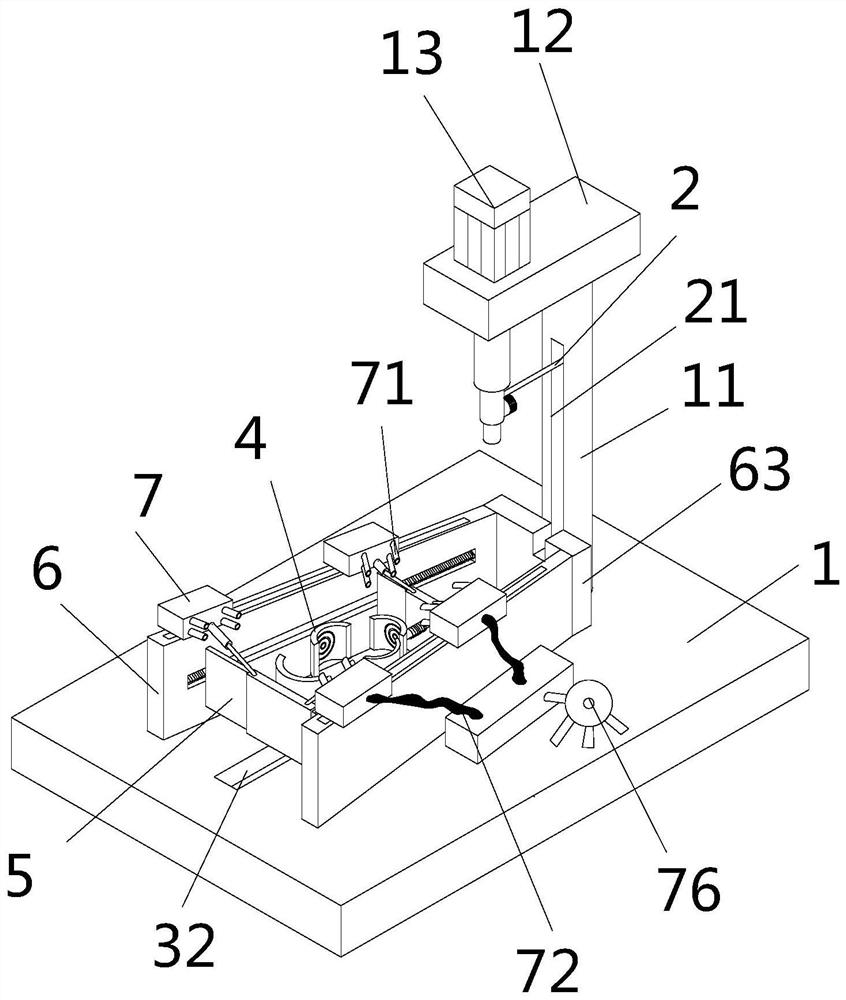

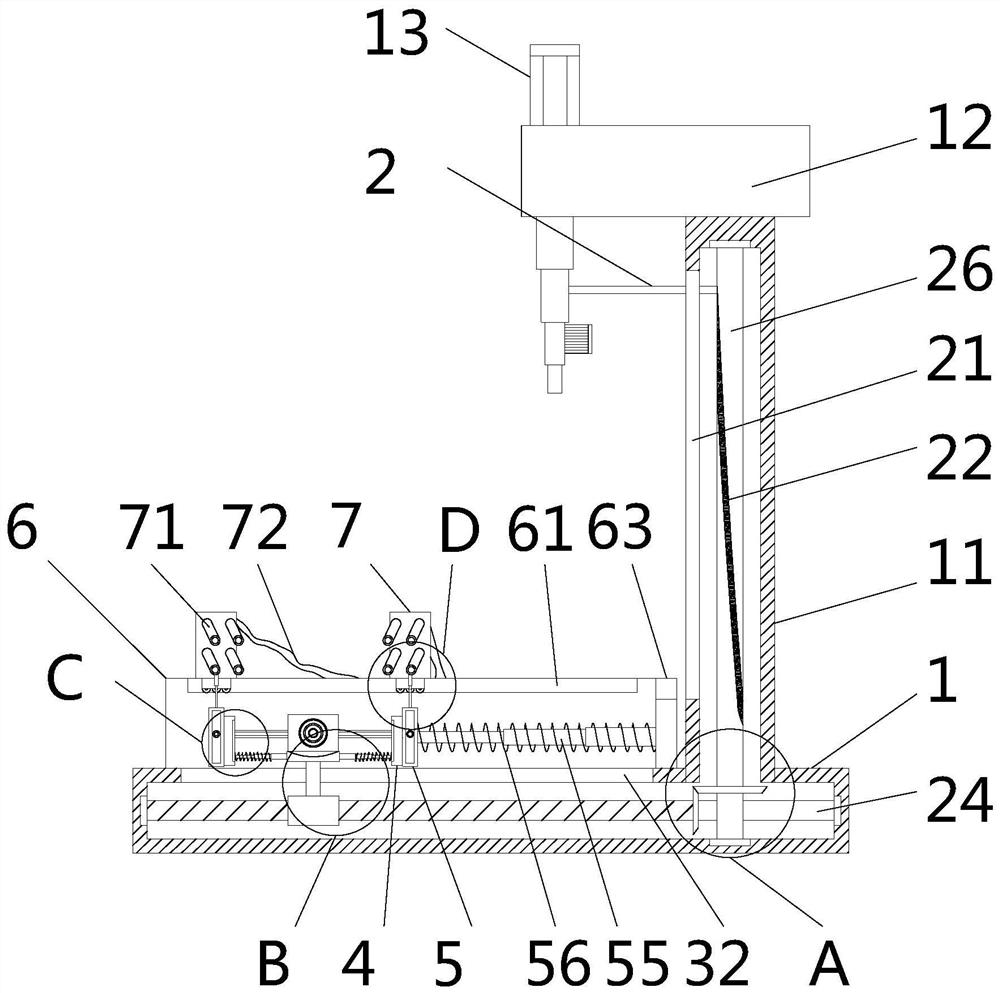

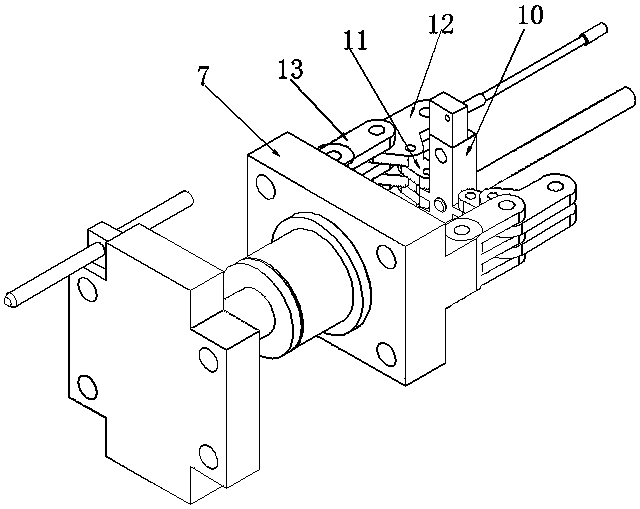

Commutator processing device

PendingCN108134300AMeet production standardsIncrease productivityDynamoelectric machine connectorsCommutators manufactureEngineering

The present invention relates to a commutator processing device. The device comprises a pedestal, a putting device configured to perform axial and radial positioning of a commutator and perform rotational motion putting of the commutator along the circumference, a transmission device configured to drive the commutator to perform transposition, a bending device configured to perform bending of commutator bars of the commutator on the putting device, a chamfer deburring device configured to perform deburring of a commutator chamfer on the putting device, an interdeep deburring device configuredto perform deburring of interdeeps between the commutator bars of the commutator on the putting device and an outer surface deburring device configured to perform deburring of the outer surface of thecommutator on the putting device. The production efficiency is high.

Owner:瑞安市龙星机电配件厂(普通合伙)

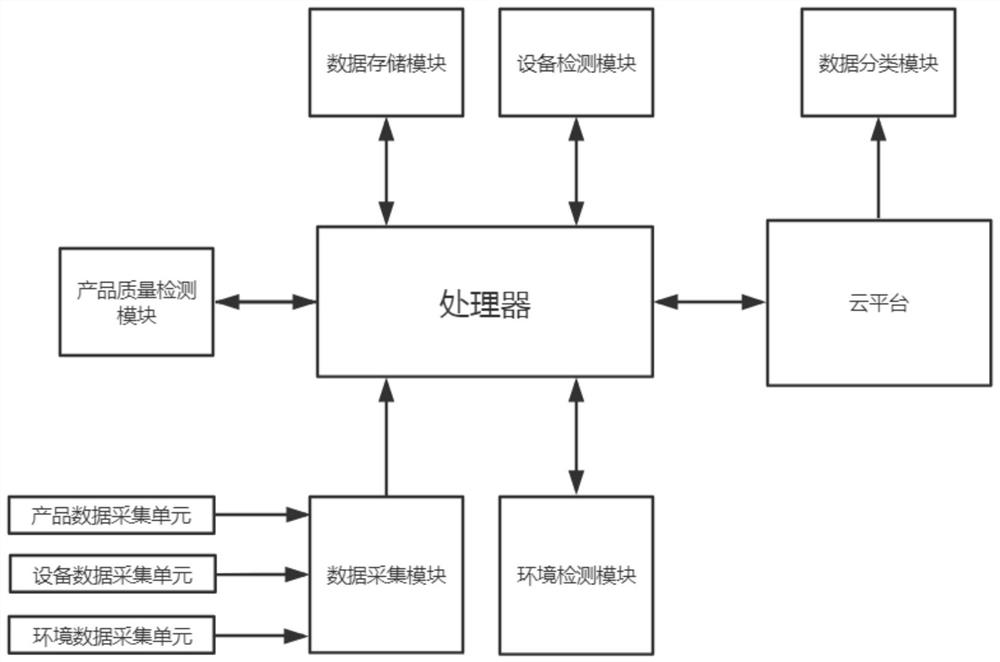

Data mining service platform based on cloud computing

ActiveCN112749893AGuaranteed accuracyAvoid invalid detectionDigital data information retrievalResourcesAmbient dataData acquisition

The invention belongs to the field of data mining, and relates to a cloud computing technology, in particular to a data mining service platform based on cloud computing, which comprises a processor, and the processor is in communication connection with a data acquisition module, a data storage module, a product quality detection module, an equipment detection module, an environment detection module and a cloud platform. The cloud platform is in communication connection with a data classification module, the data acquisition module comprises a product data acquisition unit, an equipment data acquisition unit and an environment data acquisition unit, and the equipment data acquisition unit is used for acquiring a processing platform surface image of processing equipment; the product data can be deeply analyzed through the arranged data classification module, and after unqualified products are removed, the remaining qualified products are subjected to data classification, so that the data processing time is shortened, and the data classification efficiency is improved.

Owner:SHANGHAI UNIV +1

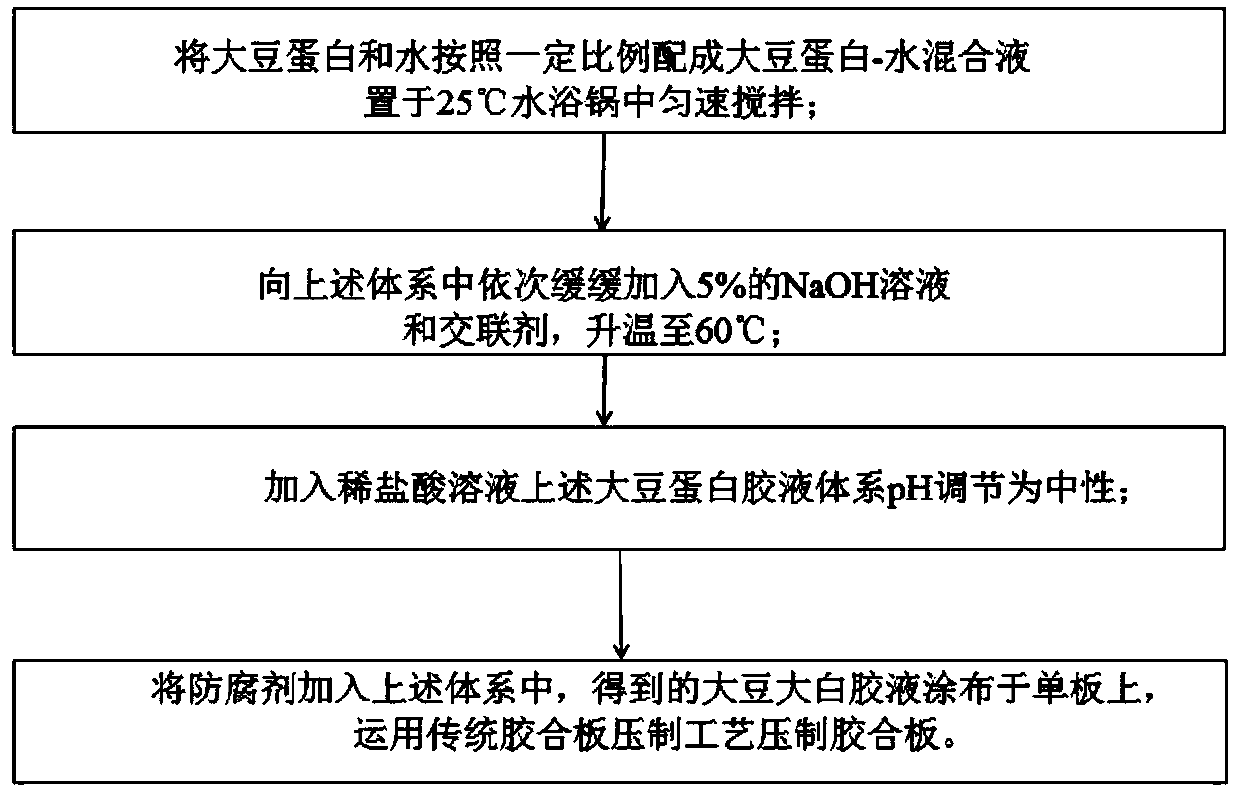

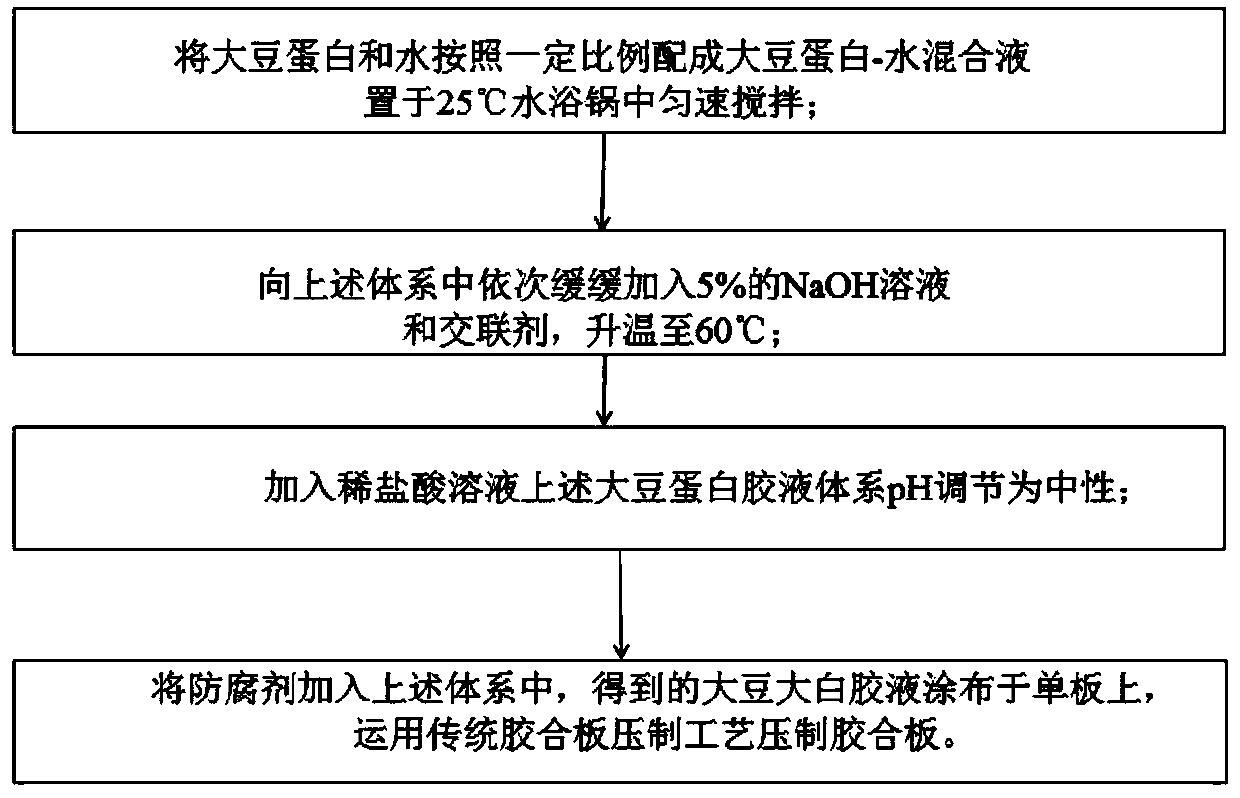

Plywood aldehyde-free soybean protein glue and preparation method thereof

InactiveCN109913170AUniform natureModerate viscosityNon-macromolecular adhesive additivesProtein adhesivesPreservativePolyamide

The invention discloses plywood aldehyde-free soybean protein glue and a preparation method thereof. The aldehyde-free soybean protein glue is prepared from following components: 25 parts of separatedsoybean protein powder, 200-300 parts of deionized water, 25-35 parts of 5% of a sodium hydroxide solution by mass, 20-25 parts of a PAE crosslinking agent for polyamide polyamine epichlorohydrin resin and 5-10 parts of a preservative. The aldehyde-free soybean protein glue is non-poisonous and harmless, low in cost and better in adhesive property. By pressing of the plywood with the aldehyde-free soybean protein glue, the adhesive property of obtained plywood can meet the national standard requirement.

Owner:NANJING UNIV OF SCI & TECH

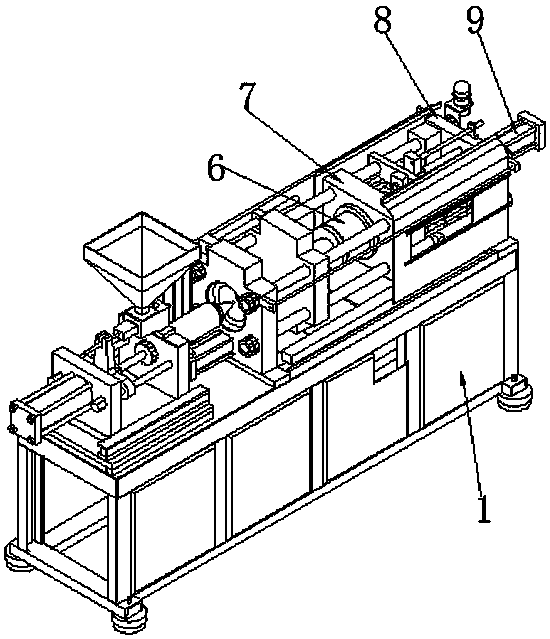

Drilling equipment for stainless steel ball production

ActiveCN112059244AGuaranteed cleanlinessReduce labor intensityFeeding apparatusPositioning apparatusDrill holeEnvironmental geology

The invention relates to the technical field of stainless steel production and processing, and discloses drilling equipment for stainless steel ball production. The drilling equipment comprises a base, a connecting sleeve is fixedly mounted at the top of the right side of the base, a top plate is fixedly mounted at the top end of the connecting sleeve, an electric telescopic rod is arranged at theleft end of the top plate, and a linkage rod is arranged at the output end of the electric telescopic rod. According to the drilling equipment for stainless steel ball production, the integrated process of automatic feeding, automatic positioning, automatic discharging and synchronous movement dust collection of steel balls is achieved, through driving of the electric telescopic rod assisting a power source, mutual cooperative use of automatic feeding, automatic discharging and synchronous dust collection is achieved, the structures are used in a mutual cooperative manner, the structures supplement each other, and high innovativeness is achieved; and the accurate drilling effect on the steel balls is guaranteed, the cleanliness degree generated after steel ball drilling is guaranteed, thelabor intensity of workers is reduced, the production and machining efficiency of the steel balls is improved, the enterprise production standard is met, and the drilling equipment is suitable for large-scale popularization.

Owner:淄博环亚钢球有限公司

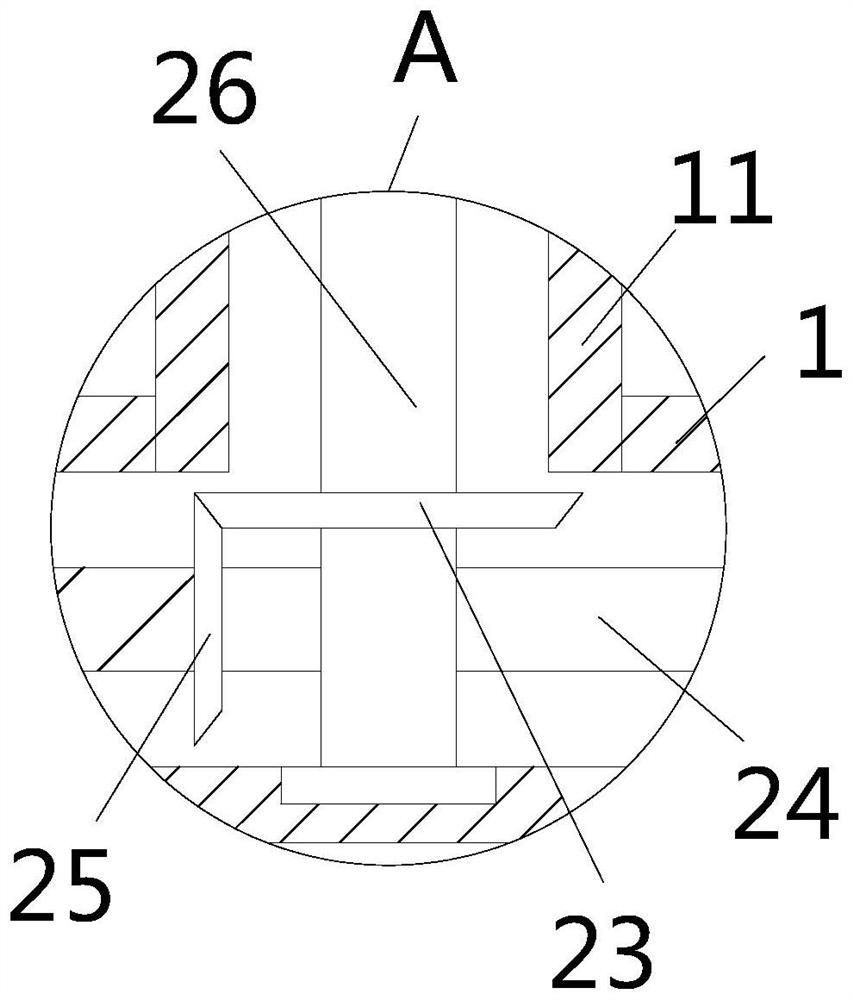

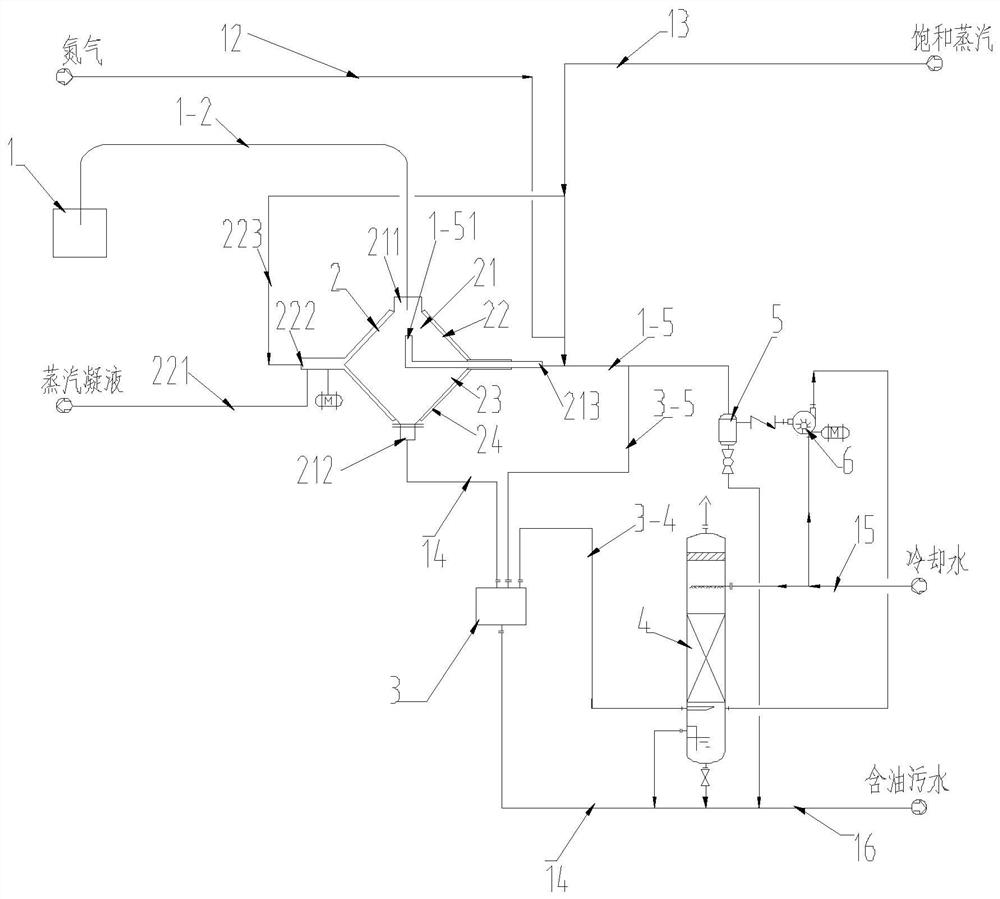

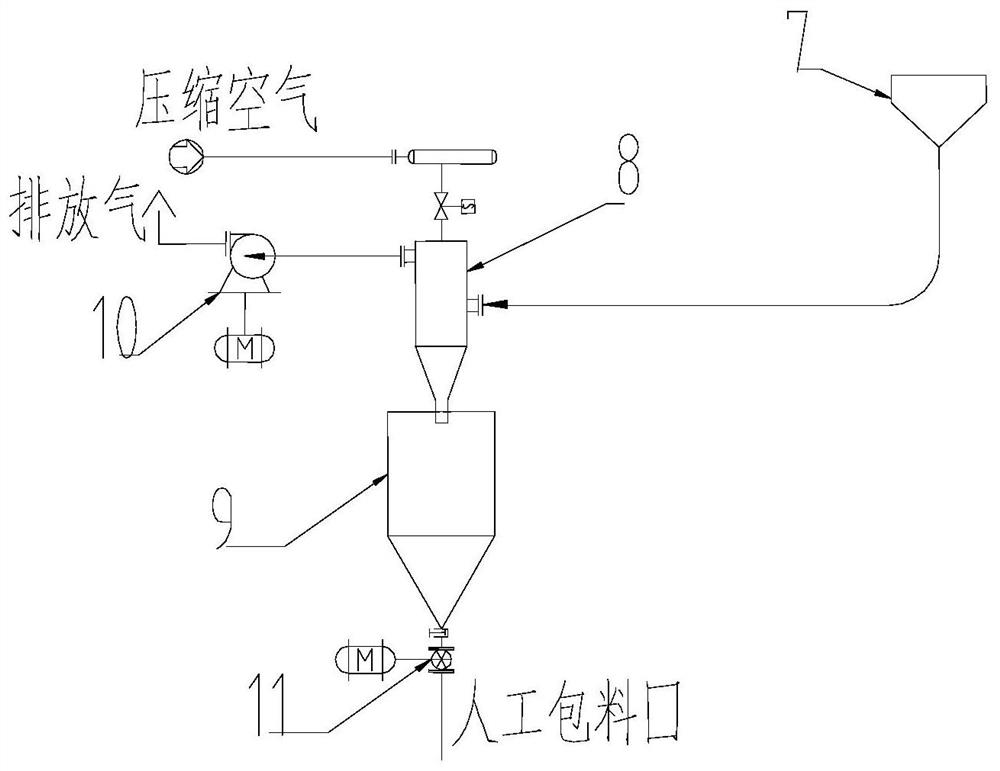

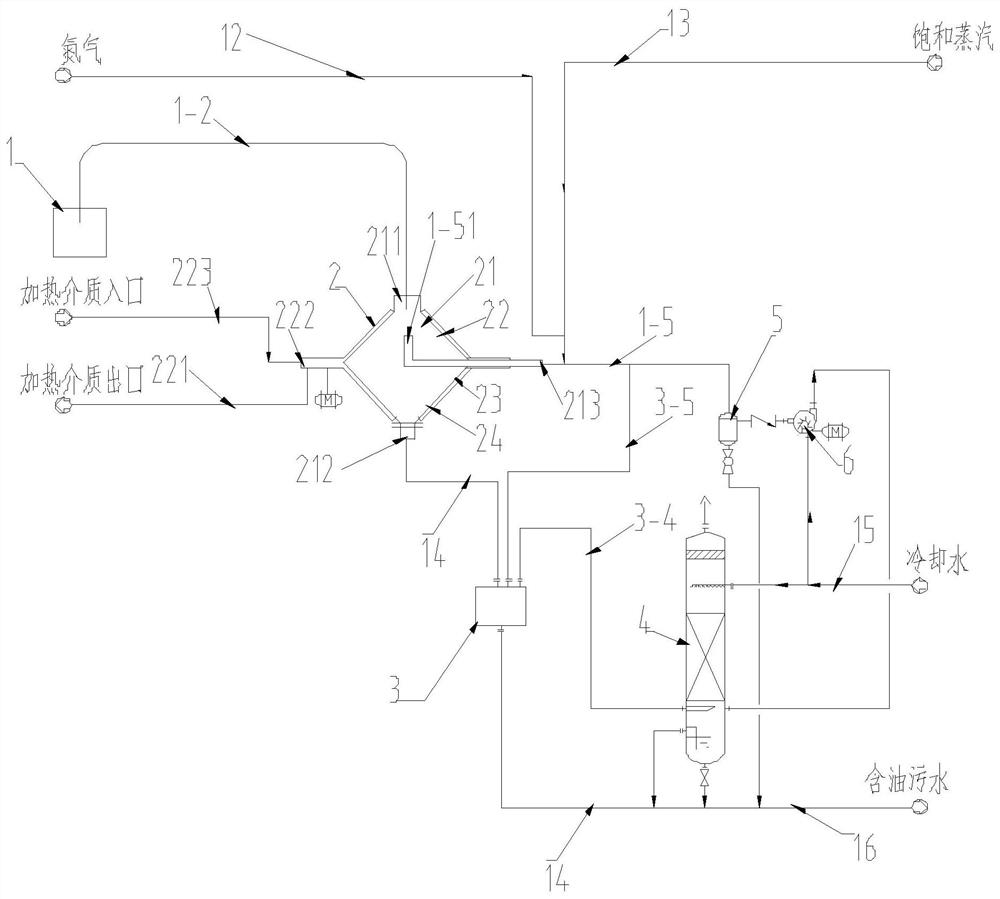

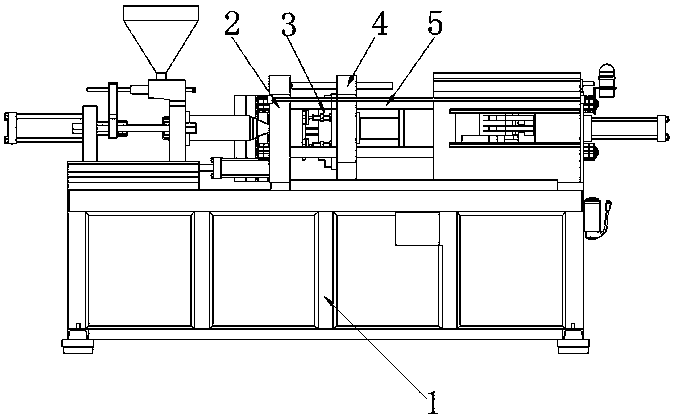

System and method for deeply removing VOC from polypropylene material and drying polypropylene material

PendingCN111790317AAvoid oxidation reactionsSmall footprintChemical/physical processesAir quality improvementPolymer sciencePolypropylene

The invention relates to a system for deeply removing VOC from a polypropylene material and drying the polypropylene material. The system comprises a raw material tank for placing a polypropylene material to be treated; a steam reactor, which comprises an inner shell and an outer shell, wherein a space between the inner shell and the outer shell is an interlayer, a space in the inner shell is an inner container, the inner shell is provided with a material inlet / outlet, a condensate outlet and a vacuum interface, the outer shell is provided with a heating medium inlet / outlet, the material inlet / outlet is communicated with the raw material tank through a feeding pipeline, and the heating medium inlet / outlet is communicated with a steam pipeline; a condensate tank, which is communicated withthe condensate outlet of the steaming reactor through a condensate pipeline; a vacuum pump, which is communicated with the vacuum interface of the steam reactor through a vacuum pipeline, wherein thevacuum interface is also communicated with the steam pipeline; and a product bin, which is used for placing the treated polypropylene material. The invention also relates to a method for deeply removing VOC from a polypropylene material and drying the polypropylene material.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

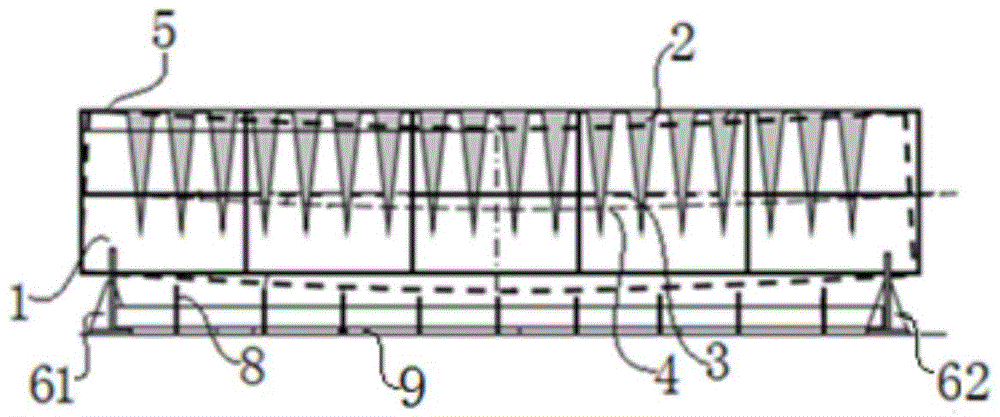

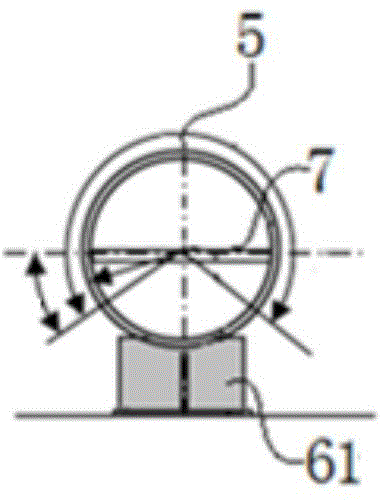

Solar cell welding and pressing device

ActiveCN105215535ASimple structureEasy to maintainMetal working apparatusNon-electric welding apparatusMechanical engineeringSolar cell

A solar cell welding and pressing device comprises a pressing assembly and a high temperature conveying line, and is characterized in that the high temperature conveying line penetrates through the pressing assembly; the pressing assembly comprises a pressing needle, a guide board, tension springs, bearing pedestals, guide shafts, a fixing board and a pressing needle up-and-down air cylinder; the pressing assembly is installed on the high temperature conveying line through the fixing board; the two sides of the fixing board are fixedly provided with the guide shafts through the bearing pedestals; the upper portions of the guide shafts are connected with the guide board through the tension springs; the guide board is connected with the pressing needle. The solar cell welding and pressing device has the beneficial effects that the solar cell welding and pressing device is simple in structure and convenient to maintain and can weld a solder strip and a solar cell at a time, the welding quality is good and stable and meets the production standard of products, the production efficiency is improved, and the production cost is reduced effectively.

Owner:SUZHOU CHENZHENG SOLAR ENERGY EQUIP CO LTD

Organic pelletized preparation for cabbage seeds and preparation method thereof

InactiveCN108294054ALow costImprove the quality of cabbageBiocideNematocidesSodium carboxymethylcelluloseChemistry

The invention provides an organic pelletized preparation for cabbage seeds. The organic pelletized preparation comprises following substances in percentage by weight: 10 to 20% of chitin, 5 to 20% ofcorn starch, 20 to 40% of pyrethrum plant fiber and paper pulp, 20 to 30% of bio-carbon, 1 to 10% of sodium carboxymethyl cellulose, 1 to 10% of castor seed oil residue, 1 to 3% of rare earth nitrate,1 to 3% of soil conditioner, 0.2 to 2% of biological antiseptic (sodium alginate), 0.2 to 0.5% of potassium sorbate, and coloring agent (0.025g / kg). The ratio of water to biogas slurry is 1:1, and water and biogas slurry are mixed for use. The provided pelletized preparation is applied to plantation of organic cabbage, and can be used to control underground insects, nematode, and above ground insects. The synergistic effect is obvious. The preventive effect is good, and the lasting period is long. The preparation can promote the growth of crop roots and plants, increases the yield and improves the quality of crops.

Owner:SHANDONG UNIV OF TECH

Drilling equipment for spherical articles

ActiveCN112170892APrecise drilling effectGuaranteed cleanlinessFeeding apparatusPositioning apparatusEngineeringSteel ball

The invention relates to the technical field of stainless steel production and processing, and discloses drilling equipment for spherical articles. The drilling equipment comprises a base, wherein a connecting sleeve is fixedly arranged on the top of the right side of the base; a top plate is fixedly arranged on the top end of the connecting sleeve; an electric telescopic rod is arranged at the left end of the top plate; and a linkage rod is arranged at the output end of the electric telescopic rod. The drilling equipment for the spherical articles realizes the integrated process of automaticfeeding, automatic positioning, automatic discharging of steel balls and and synchronous movement dust collection; the mutual cooperative use of automatic feeding, automatic discharging and synchronous dust collection is achieved through driving of the electric telescopic rod of an auxiliary power source; the structures of the drilling equipment are cooperatively used, and supplement each other; the drilling equipment has relatively strong creativity, and the advantages of guaranteeing the accurate drilling effect on the steel balls and the cleanliness of the drilled steel balls, reducing thelabor intensity of workers, improving the production and machining efficiency of the steel balls, meeting the production standards of enterprises and being suitable for large-scale popularization.

Owner:宣城慧哲生产力促进中心有限公司

Single-ingredient polyurethane adhesive for automobile as well as production process and application thereof

InactiveCN108624277AMeet production standardsSimple processPolyureas/polyurethane adhesivesPrepolymerPolyurethane adhesive

The invention discloses a single-ingredient polyurethane adhesive for an automobile. The single-ingredient polyurethane adhesive is prepared by the following steps of obtaining prepolymers through reaction on the single-ingredient polyurethane adhesive through modified isocyanate, polyisocyanate and polyalcohol under the catalysis condition, and then controlling the prepolymers through catalysts and polymerization inhibitors, wherein the mass ratio of polyalcohol to the modified isocyanate to polyisocyanate is 1:(3.5 to 4.5):(0.2 to 0.4). The invention also discloses a production process and apurpose of the single-ingredient polyurethane adhesive for the automobile.

Owner:吉林省盛达实业有限公司

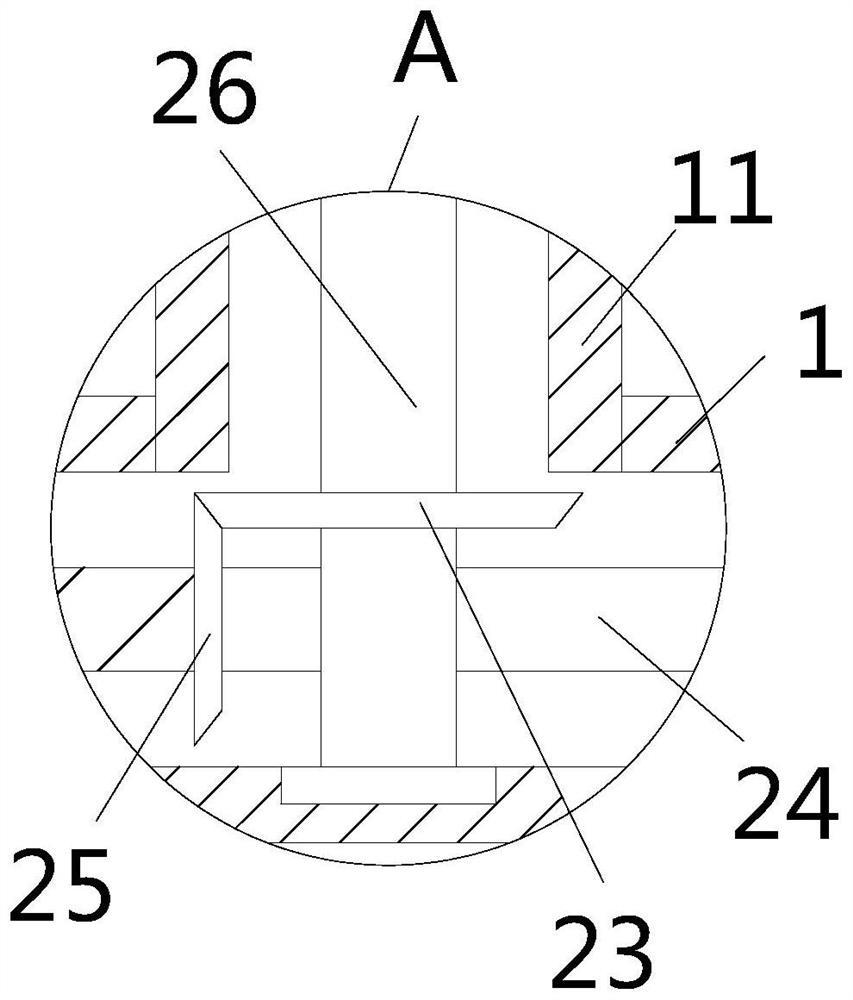

Mold closing device for injection molding machine and mold closing method of mold closing device

ActiveCN111361092AEnsure electrical connectionMeet production standardsControl engineeringHydraulic pump

The invention discloses a mold closing device for an injection molding machine. The mold closing device comprises a bottom frame, a fixed seat, a clamping mechanism, a sliding seat, sliding rods, a push seat, a buffer connecting seat and a mounting seat, wherein the fixed seat is installed at one end of the top of the bottom frame, the mounting seat is installed at the other end of the top of thebottom frame, the sliding rods are installed on the periphery between the fixed seat and the mounting seat, and the sliding seat and the buffer connecting seat are installed on the outer sides of thesliding rods in a sliding mode. According to the mold closing device for the injection molding machine, when a mold is placed on a fixed limiting block and the bottom of the mold makes contact with afixed plate, an induction block is completely compressed into a containing groove at the moment, a second spring is compressed into a telescopic groove, a movable contact at the bottom of a second limiting sliding block makes contact with a fixed contact at the top of a supporting rod at the moment, and electric connection between a storage battery and a PLC is kept; and then a hydraulic pump is controlled by the PLC to clamp the mold, it is guaranteed that the bottom side of the mold makes contact with the fixed seat and the sliding seat, and it is guaranteed that subsequently-produced injection molding parts meet the production standard.

Owner:QINGDAO LET FLEXITANK CO LTD

Method for preparing biochar from bottom mud and garden waste and application of biochar

ActiveCN113171750APrevent eutrophicationReduce the amount of fertilizerOther chemical processesWater contaminantsEnvironmental engineeringBiochar

The invention provides a method for preparing biochar from bottom mud and garden waste and application of the biochar. The preparation method comprises the following steps: cleaning and drying bottom mud and garden waste, crushing for later use, taking the bottom mud and the garden waste according to a mass ratio of 1:(0.25-4), adding water, uniformly mixing, drying to obtain a mixture A, pyrolyzing the mixture A at 300-700 DEG C for 1-5 hours to obtain a mixture B, adding water into NaOH or FeCl3 serving as a modifier, uniformly mixing with the mixture B, and drying to obtain the biochar. The biochar can adsorb nitrogen and phosphorus in a water body to be used by landscape plants, and nutrients are provided for the plants to reduce the fertilizing amount of the plants, so that waste recycling is achieved, the problems that bottom mud and garden waste are difficult to dispose, and the concentration of phosphorus in the water body is high are effectively solved, a virtuous circle of multiple substances in the water body environment is formed, and the maintenance cost of the water body environment is greatly reduced.

Owner:GUANGDONG UNIV OF TECH

Organic granulating and planting method for seeds of Solanum nigrum L

InactiveCN108353937AImprove qualityImprove planting efficiencyBiocidePlant growth regulatorsDiseaseCastor Seed

The invention provides an organic granulating and planting method for the seeds of Solanum nigrum L, wherein the preparation comprises, by weight, 10-20% of chitin, 5-20% of corn starch, 20-40% of Pyrethrum cinerariifolium plant fiber and paper pulp, 20-30% of biochar, 1-10% of carboxymethyl cellulose sodium, 1-10% of castor seed oil residue, 1-3% of rare earth nitrate, 1-3% of a soil improver, 0.2-2% of a biological preservative sodium alginate, 0.2-0.5% of potassium sorbate, and 0.025 g / kg coloring agent, and water and biogas slurry are subjected to mixed use according to a ratio of 1:1. According to the present invention, the granulation preparation is suitable for the planting of organic Solanum nigrum L; the organic granulating and planting method can be used for preventing and controlling underground pests, nematodes and above-ground pests and diseases of Solanum nigrum L, has good economic benefits, and can promote the development of the lateral root of Solanum nigrum L and thegrowth of the plant; and the growth of Solanum nigrum L in spring is accelerated and the growth of weeds is controlled by using the seedling culture technology, and the yield and the quality of Solanum nigrum L are improved by using the row-staggered planting through different managements on the staggered rows.

Owner:SHANDONG UNIV OF TECH

Method for bending large-diameter pipelines through fire

ActiveCN104138941ASimplify construction proceduresReduce construction costsShaping toolsPipe supportEngineering

The invention discloses a method for bending large-diameter pipelines through fire and belongs to the technical field of pipeline machining. The method comprises the step of construction preparation, wherein quality detection and algorithm quantification are carried out on reel pipes; the step of reel pipe marking, wherein the reel pipes are supported by a reel pipe supporting device, and heating areas are marked on the reel pipes; the step of fire bending, the heating areas marked well are bent along the zigzag path, and the time duration for bending is decided according to colors generated when the reel pipes are heated; the step of cooling detection, wherein after the reel pipes are cooled, whether the distance between the lower bottoms of the bent reel pipes and the upper end of a detection board is within 3 mm or not is detected, and the reel pipes are qualified if the distance is within 3 mm; the step of secondary processing, wherein when deviation between the actual reel pipe bending chord height H1 and the theoretical reel pipe bending chord height H is large, adjustment is carried out through a gas welding baking handle. The method solves the problem that a large instrument is needed when the large-diameter pipelines are bent through fire, bending is carried out by utilization of gravity of the pipelines and characteristics of the pipelines, requirements for sites and instruments are not high, and the method is applicable to various construction environments.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Non-granular environment-friendly brick and preparation method thereof

The non-granular environment-friendly brick is prepared from the following raw materials in parts by weight: 60 to 70 parts of quartz sand mud, 21 to 25 parts of building solid waste broken stones andgravels, 10 to 14 parts of 425 # ordinary Portland cement, 1 to 3 parts of a liquid admixture and 1 to 3 parts of water. The invention further provides a preparation method of the non-granular environment-friendly brick. In the invention, the quartz sand mud has fine characteristics, is easy to harden and is easy to disperse and decompose when meeting water, so that the quartz sand mud should beobserved and fully stirred and ground into powder in the stirring process, gravels and cement are added in proportion and stirred, and then the liquid admixture is added and stirred to be pressed. Andthe molded product has no obvious cracks on the surface, has a compact structure and is non-granular in shape, and the appearance conforms to the production standard. And the compression resistance is 21.6 MP.

Owner:安徽省希泰环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com