Patents

Literature

531results about "Hydrocarbon oil dewatering/demulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

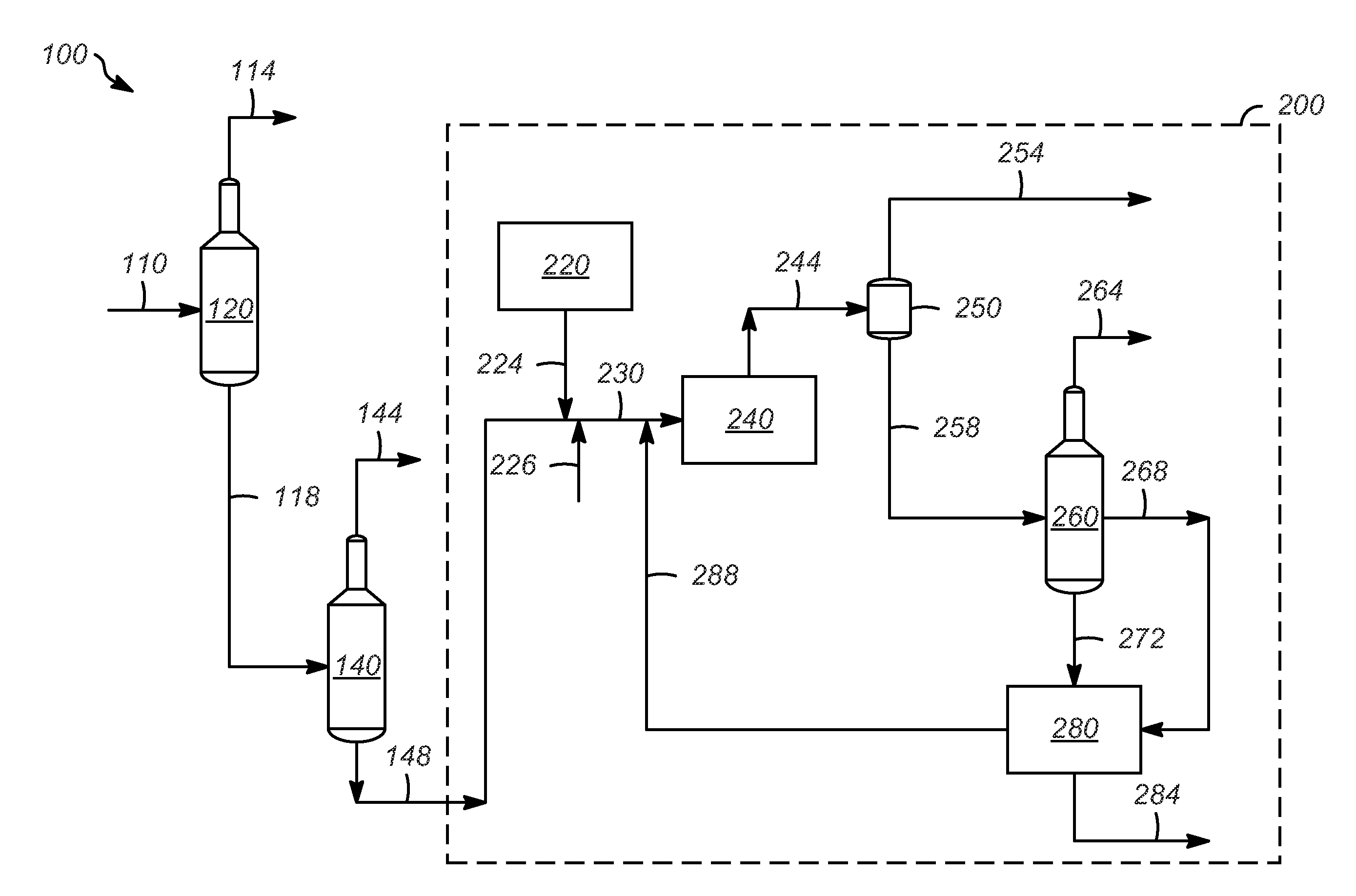

Process to produce aromatics from crude oil

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

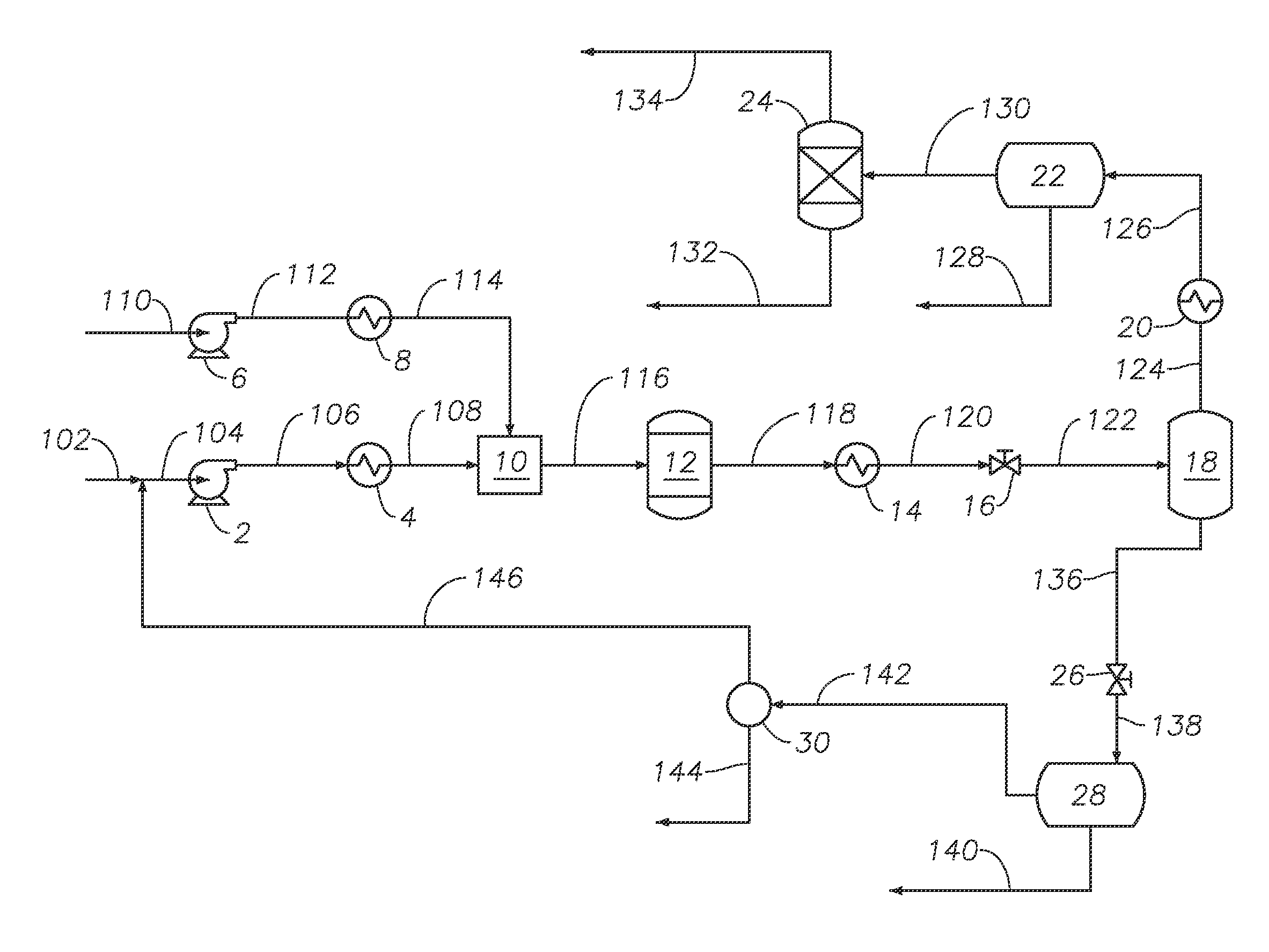

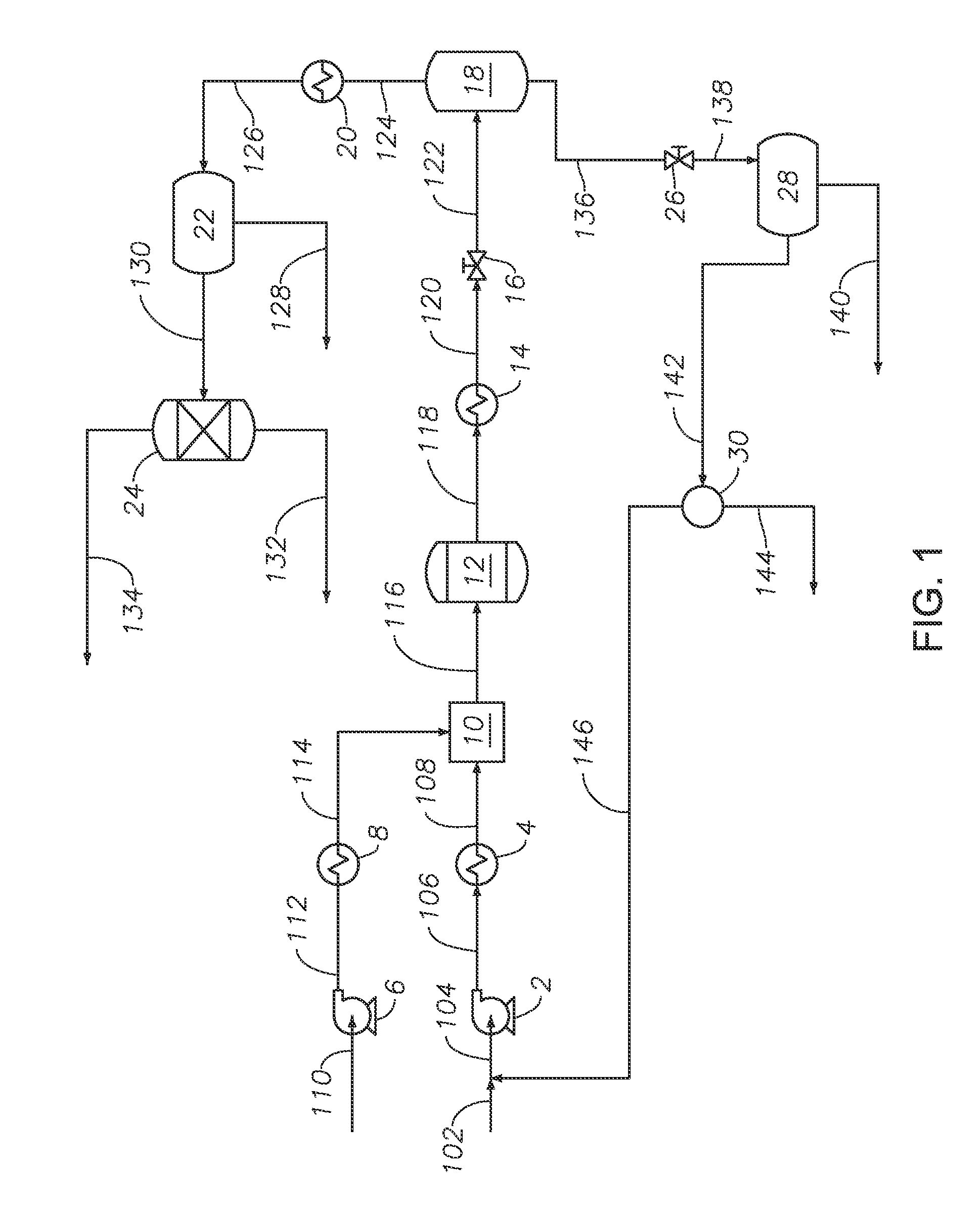

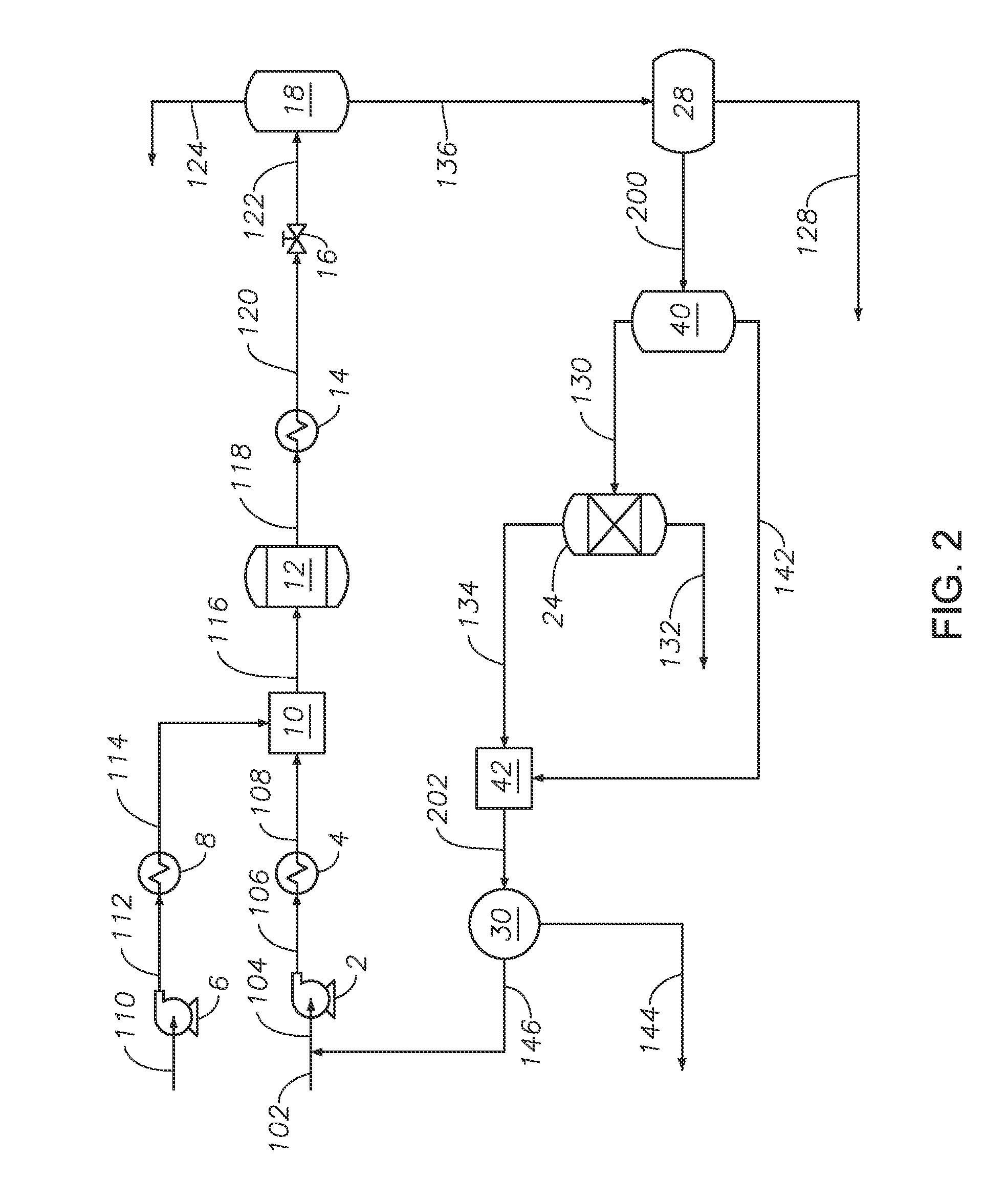

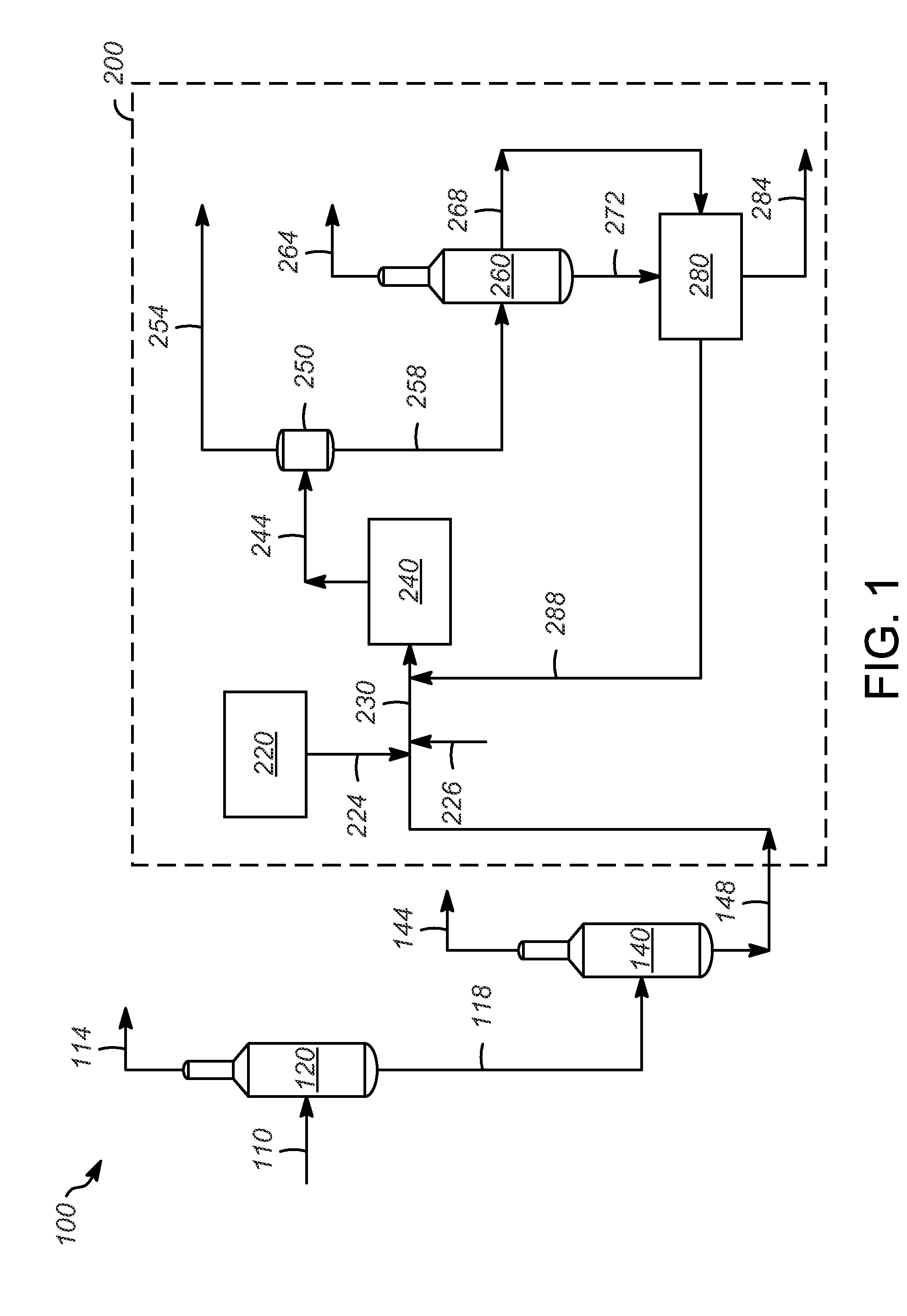

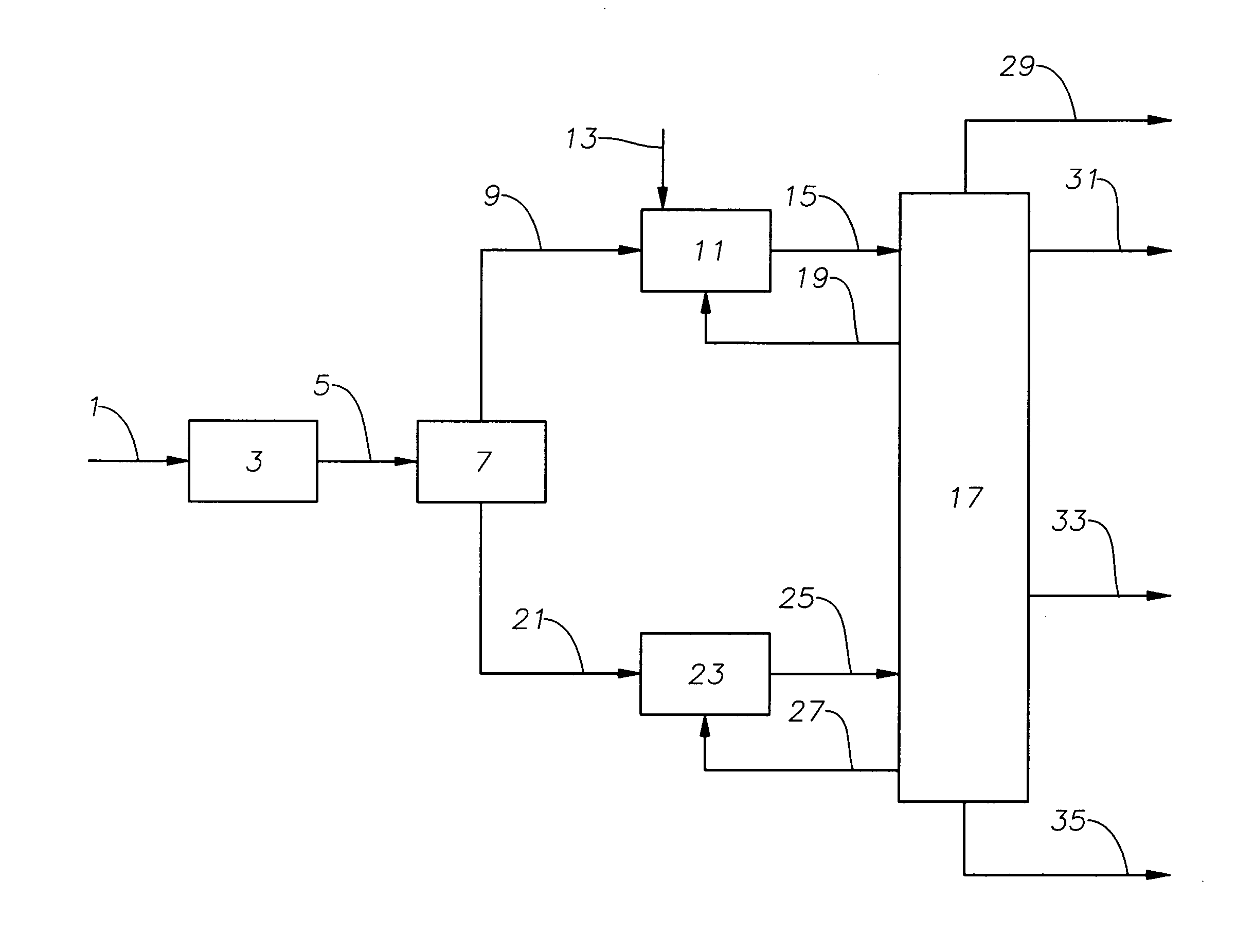

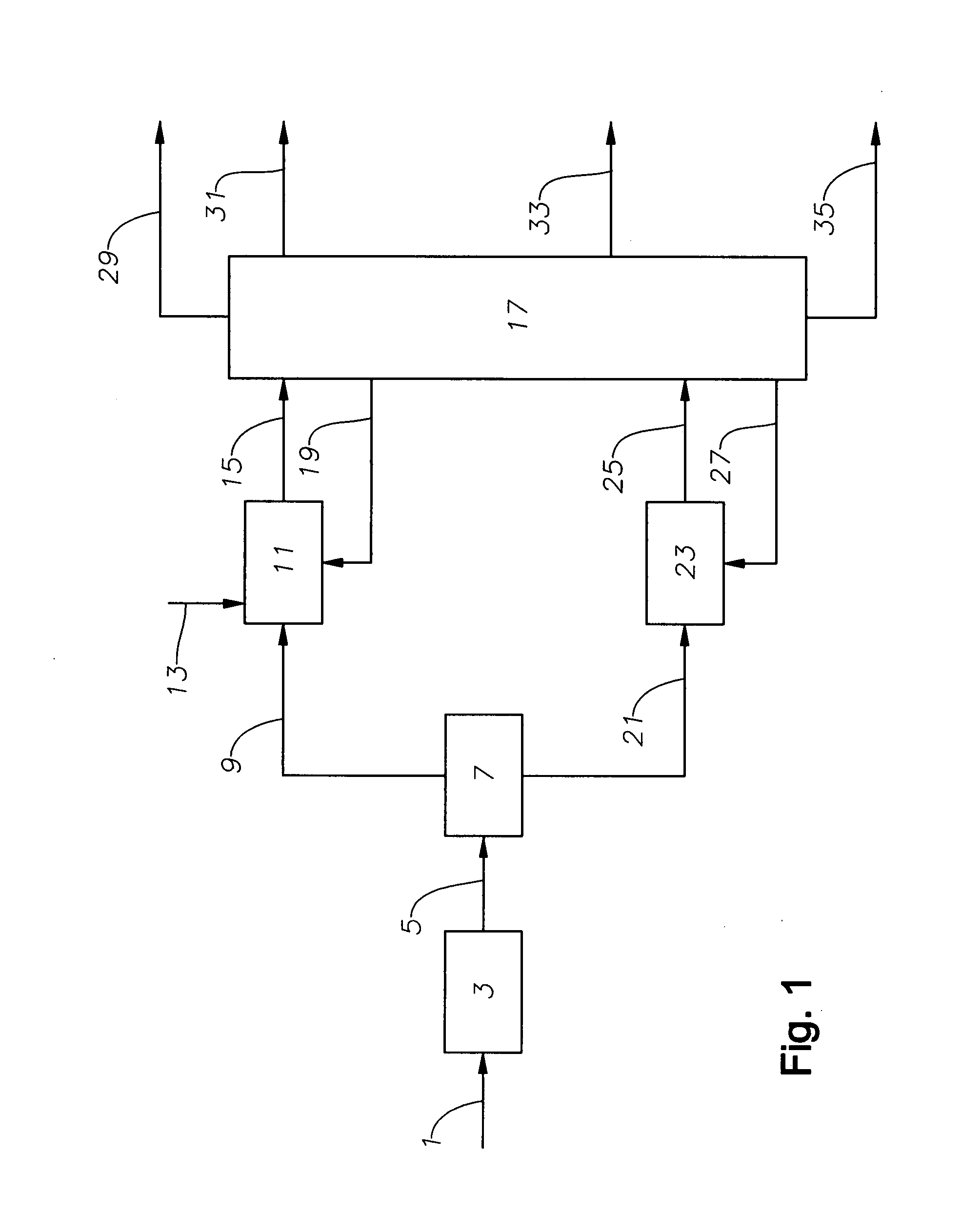

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

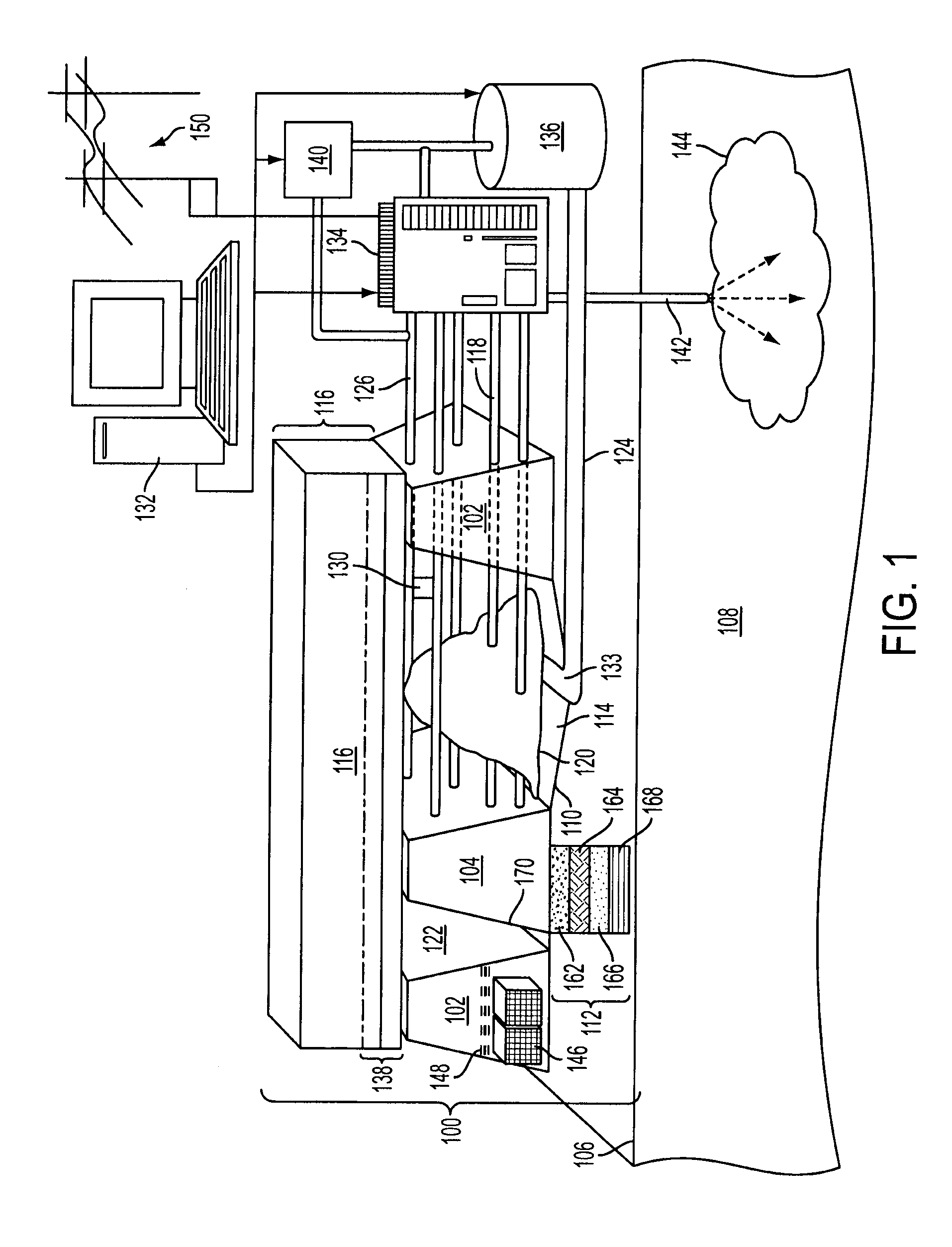

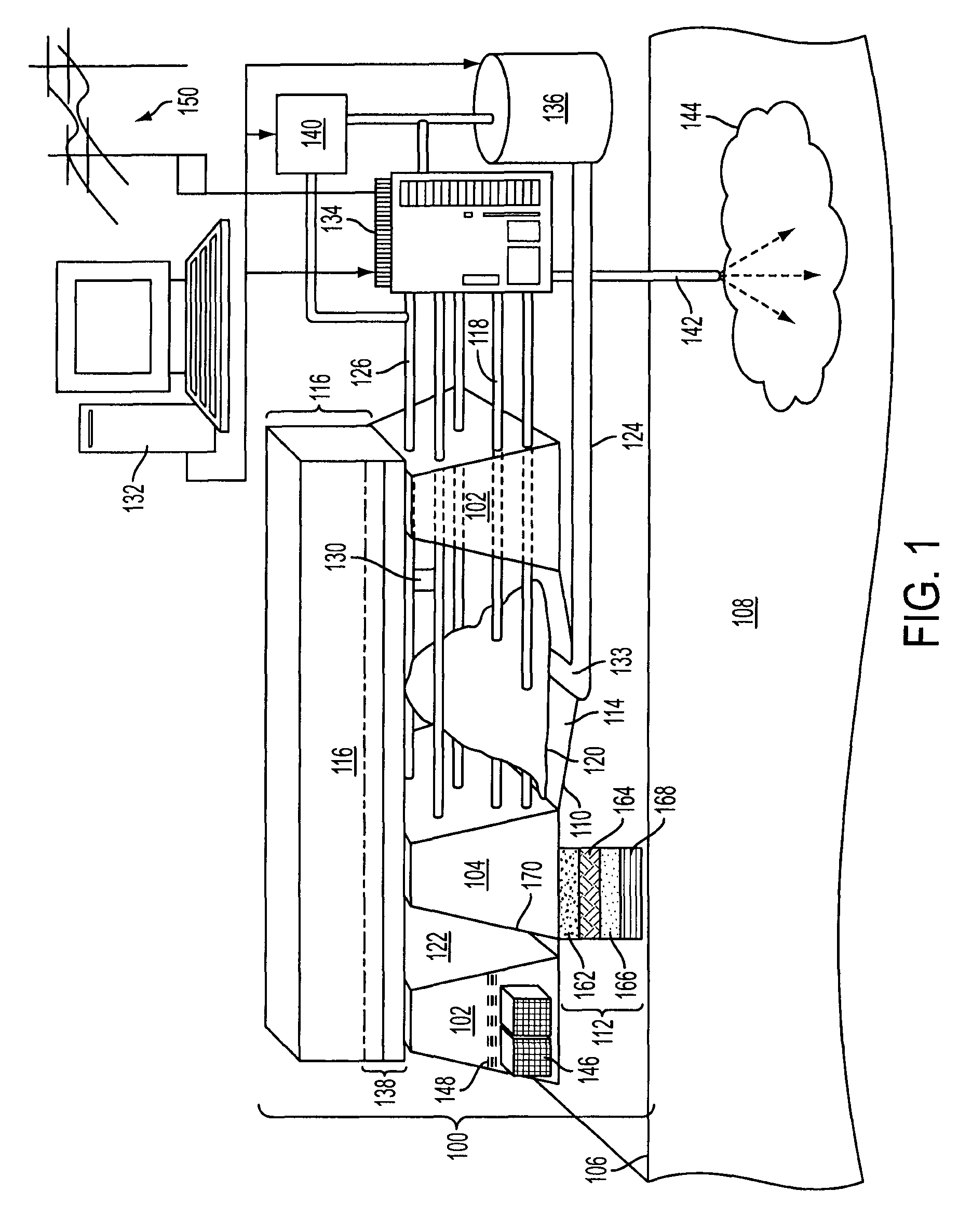

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190818A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

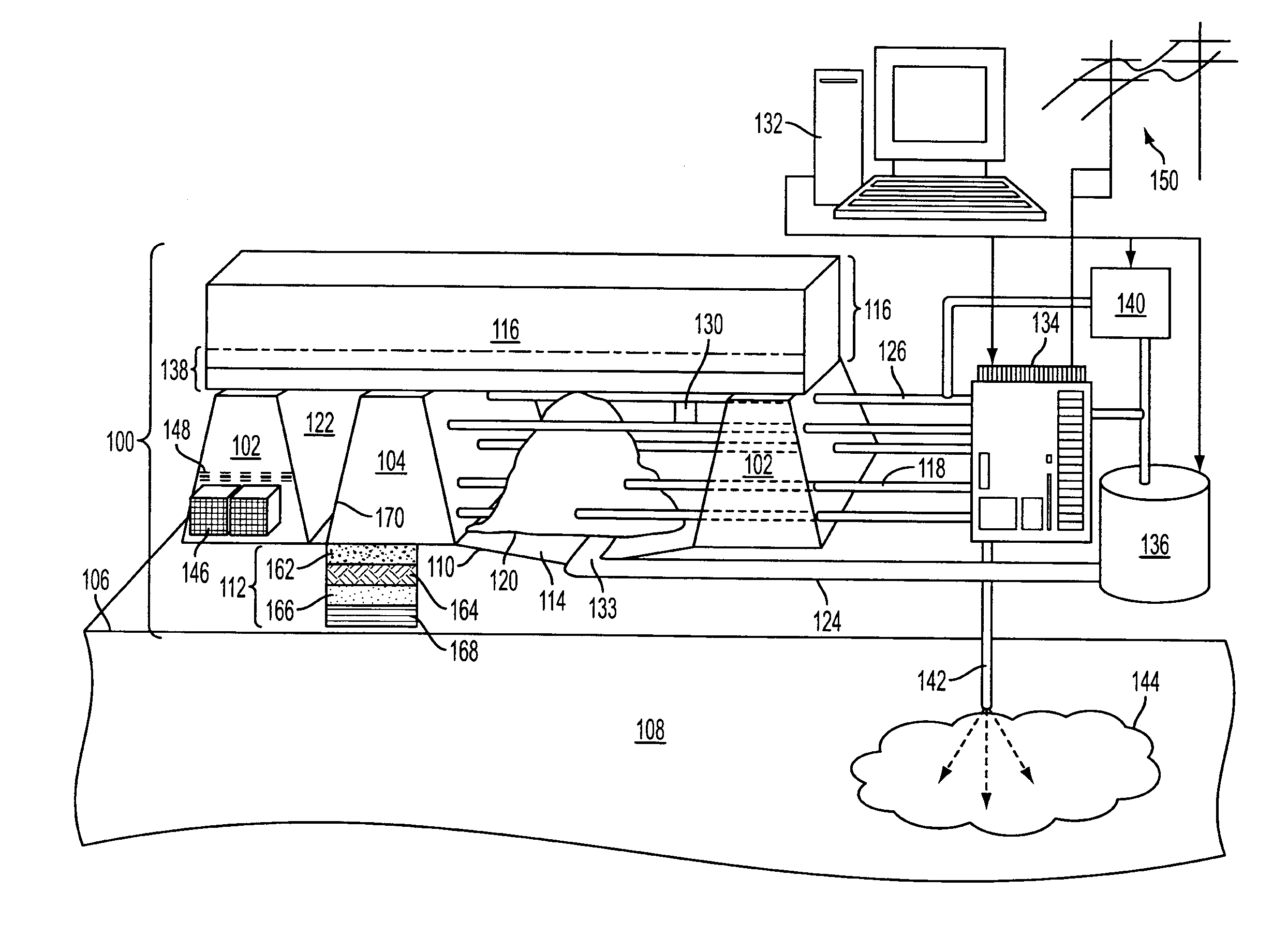

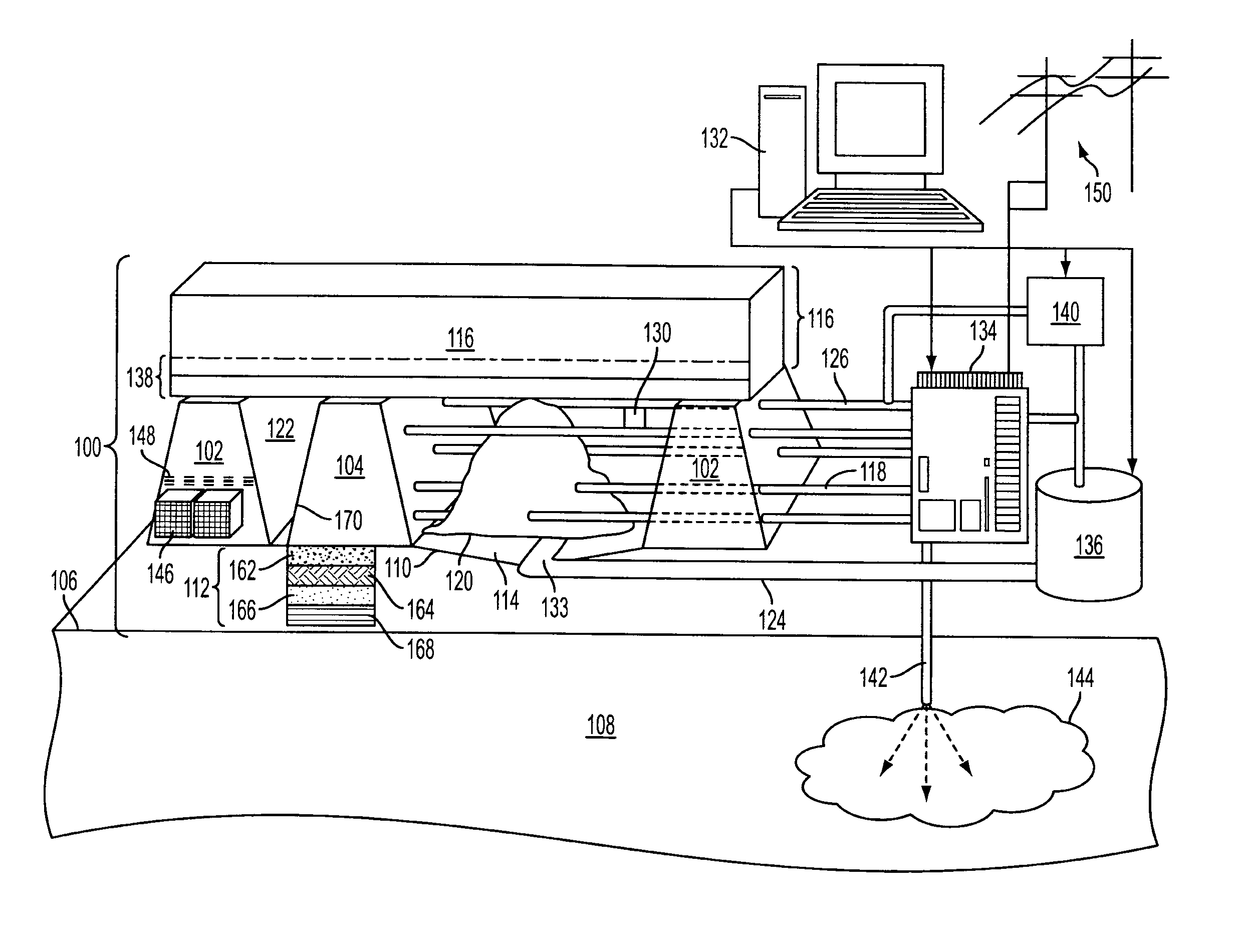

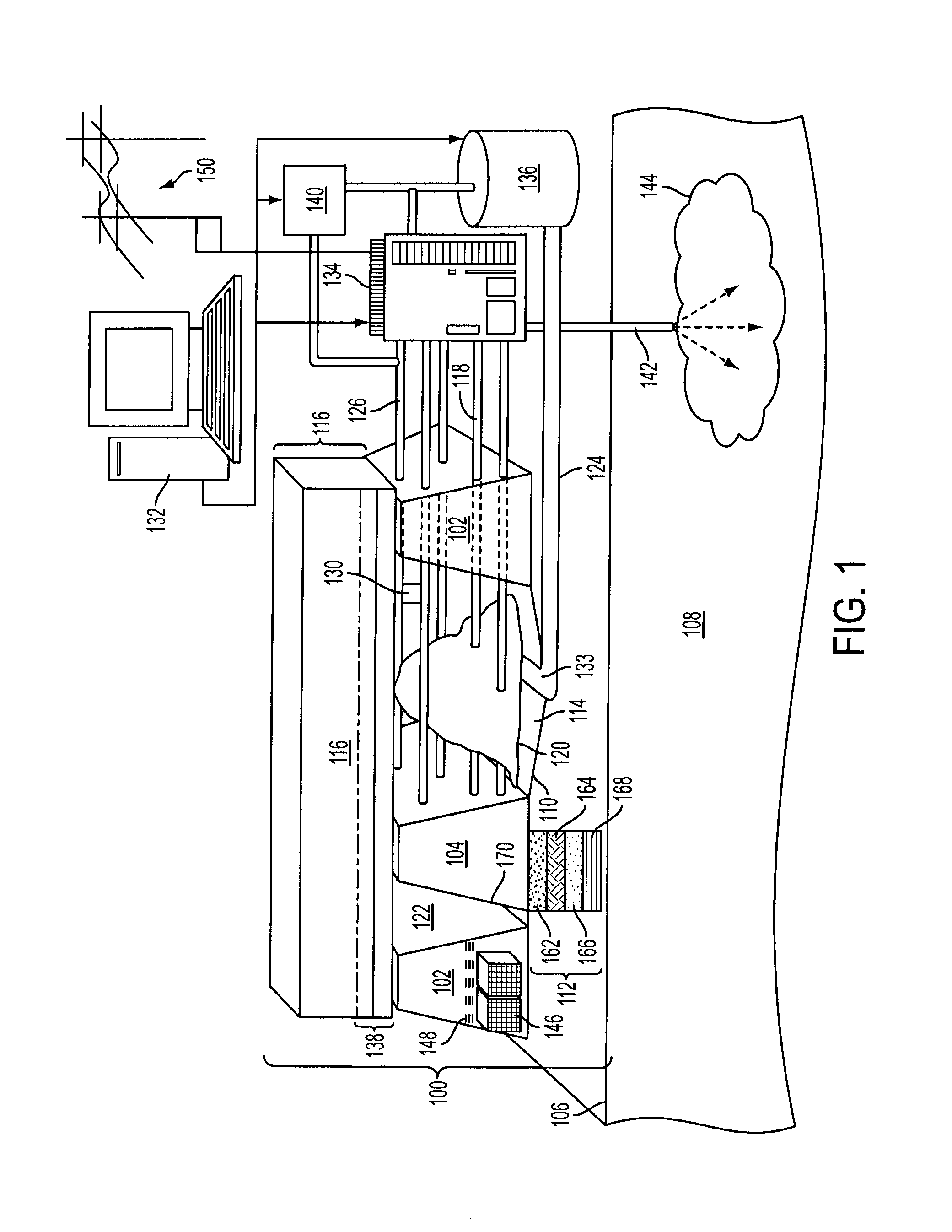

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

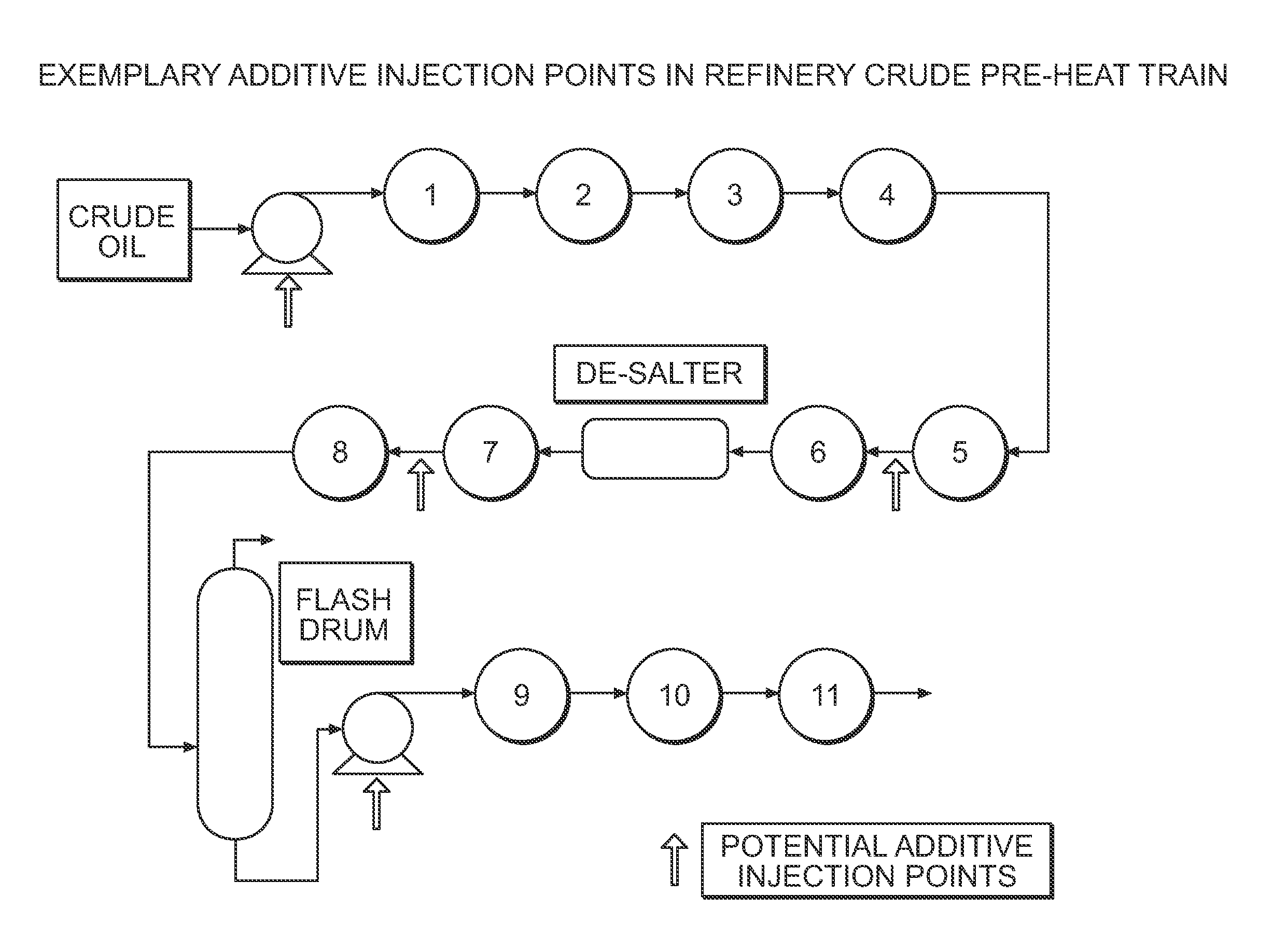

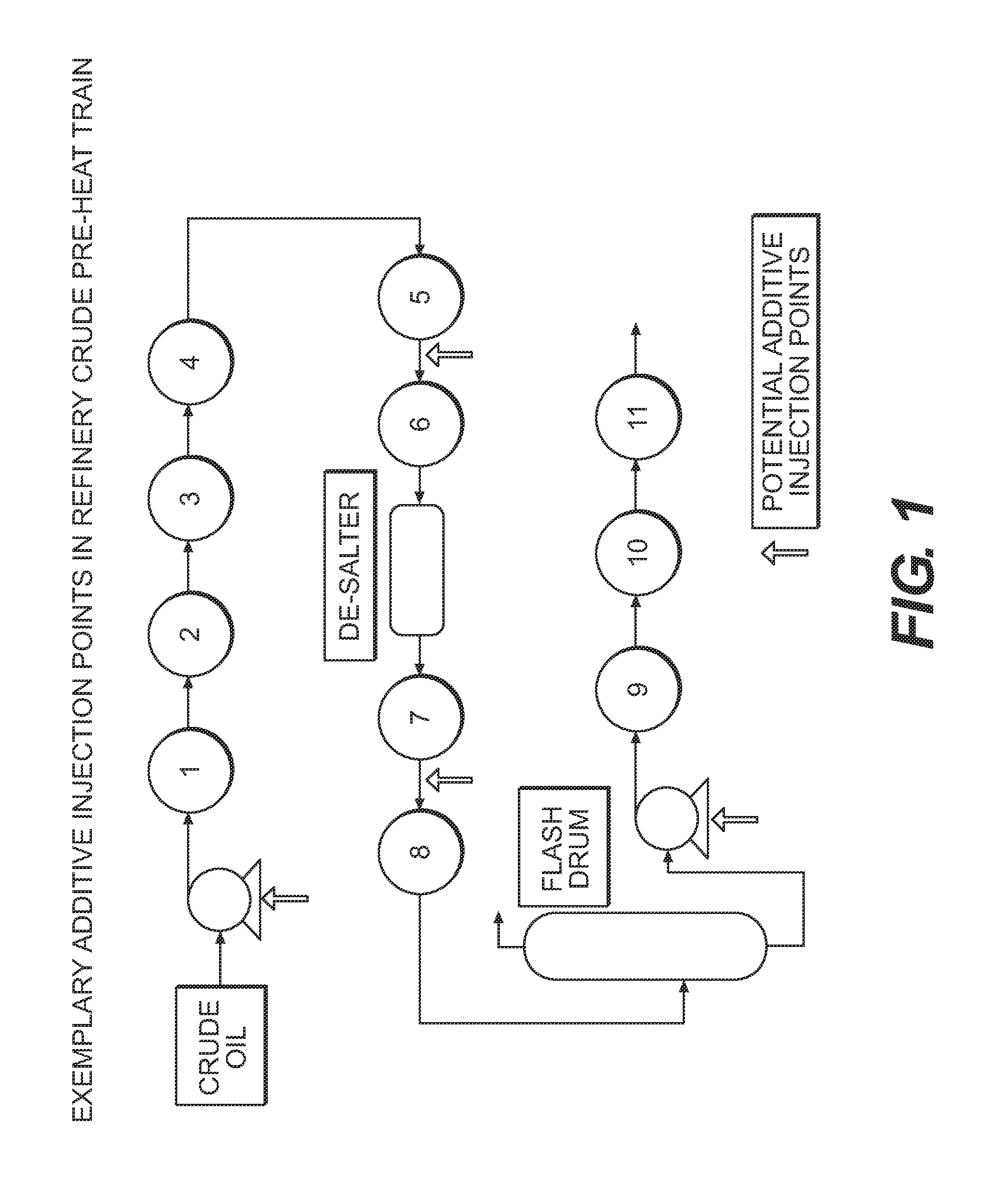

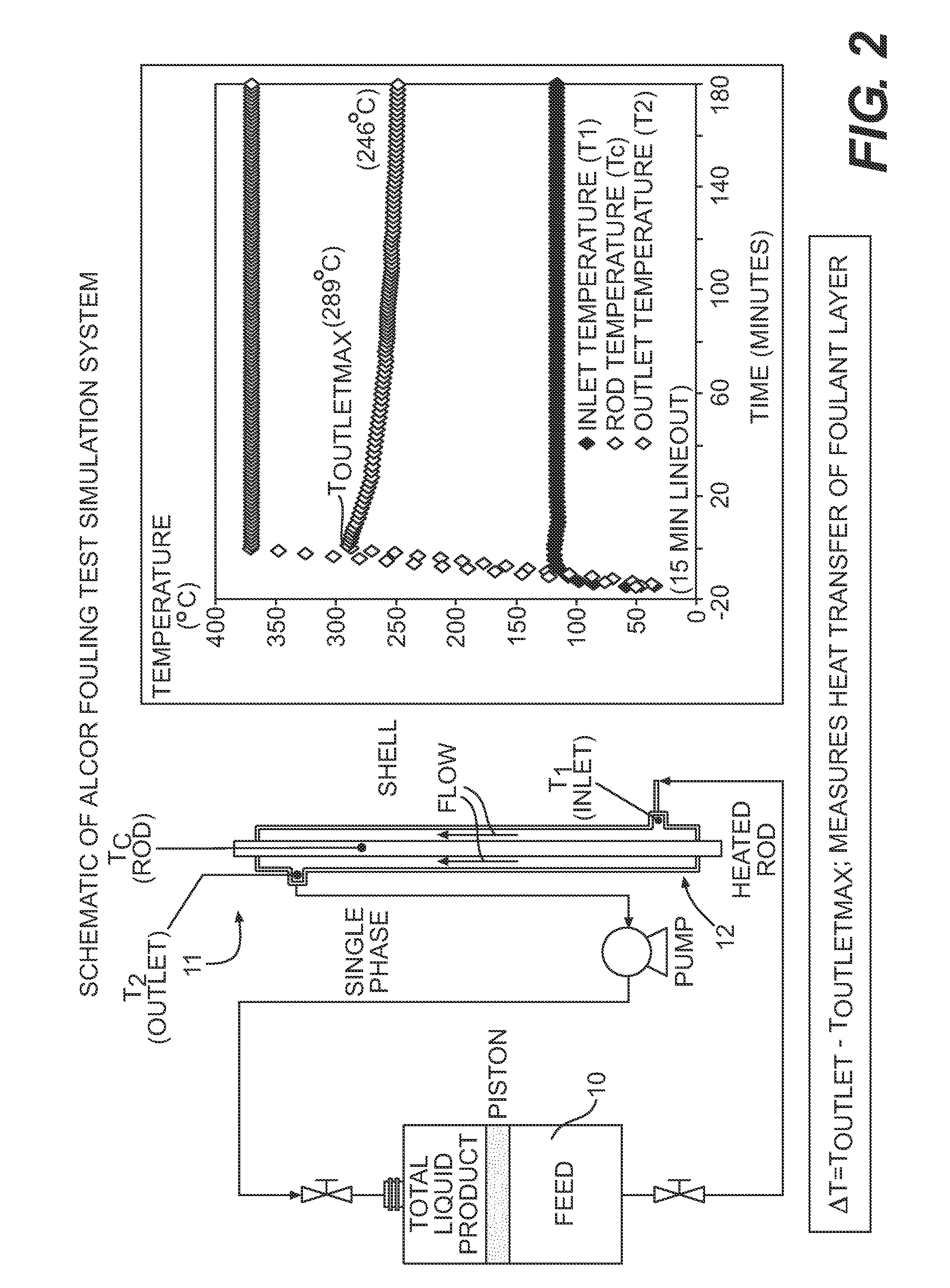

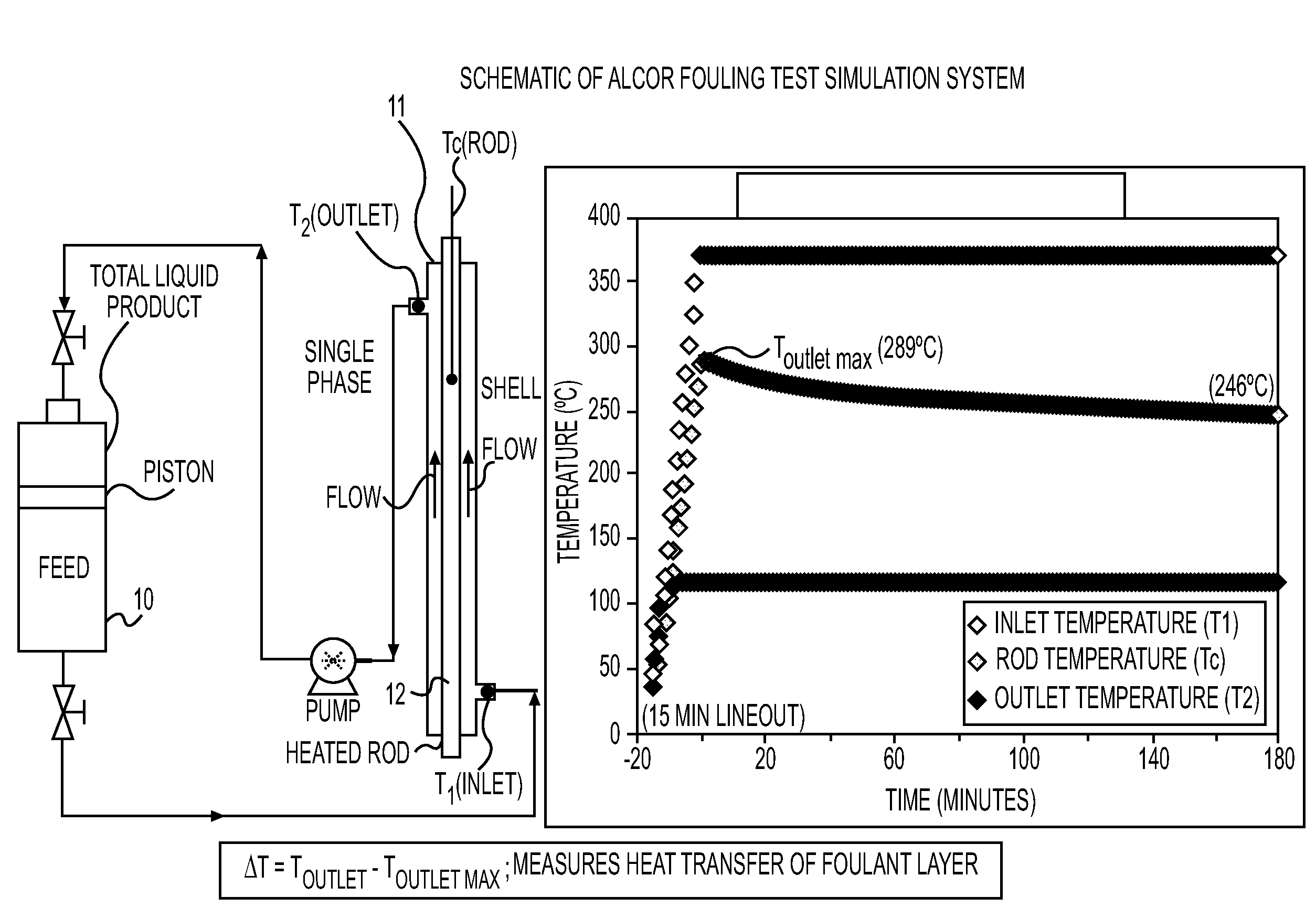

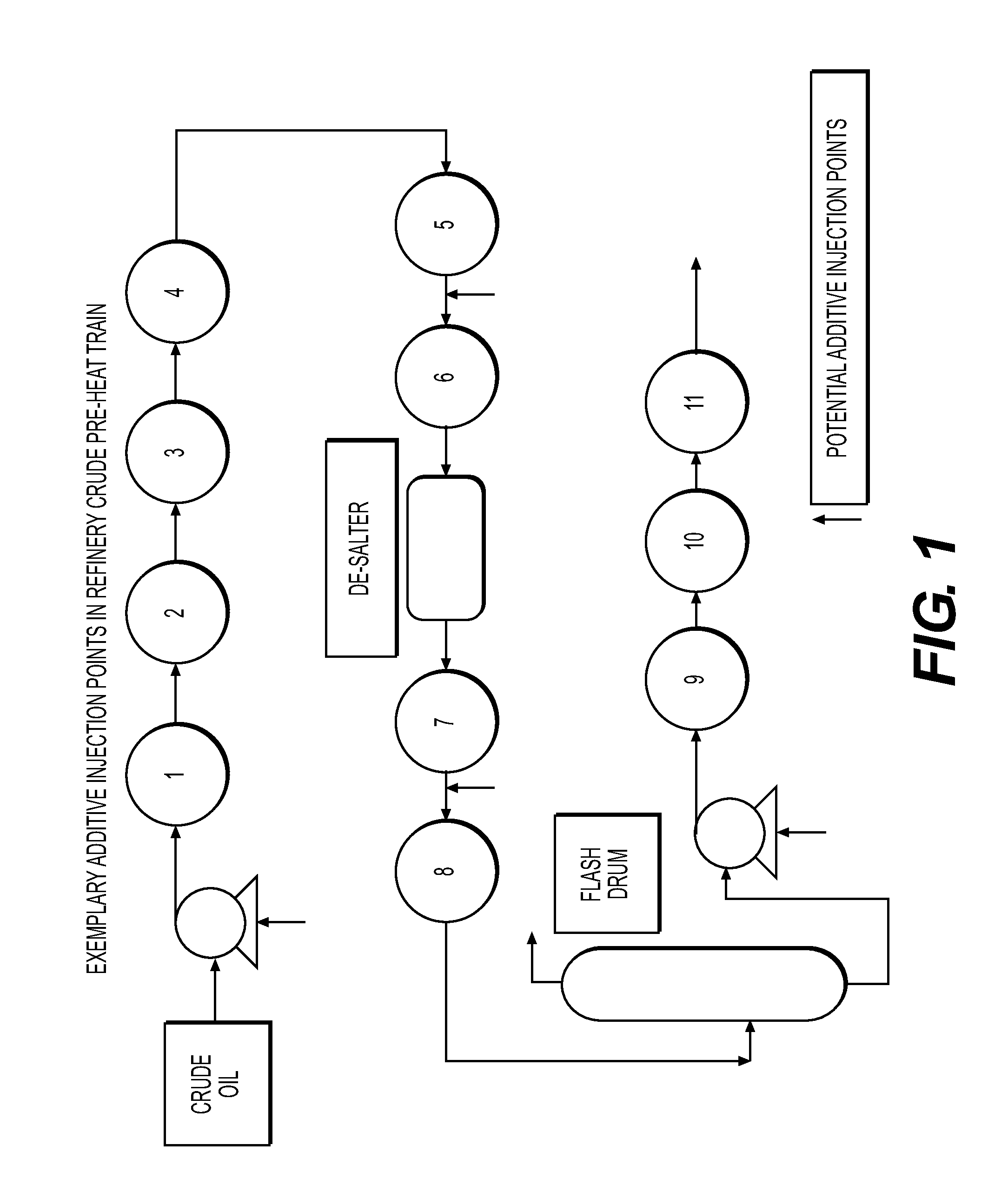

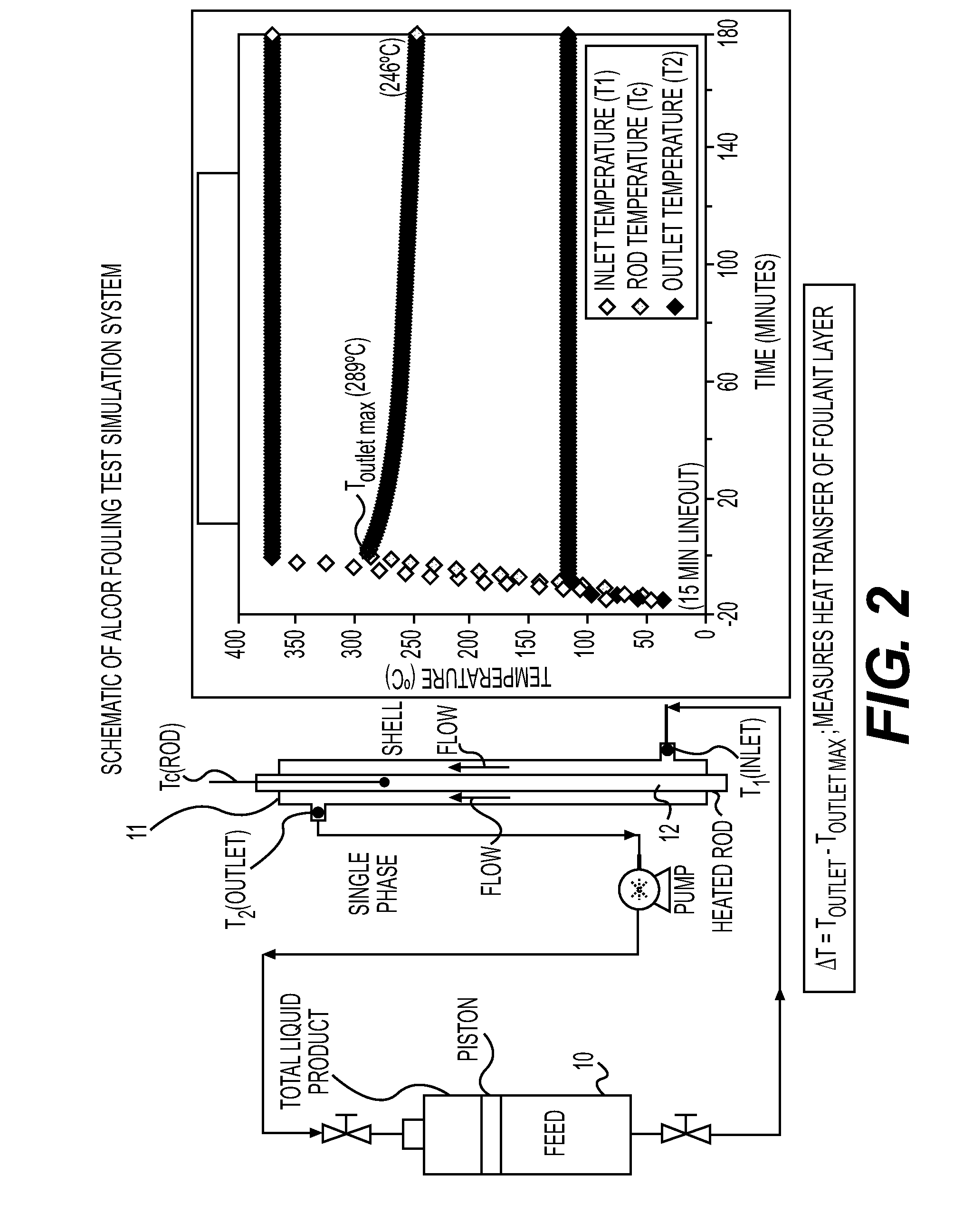

Polyalkyl succinic anhydride derivatives as additives for fouling mitigation in petroleum refinery processes

InactiveUS20100170829A1Thermal non-catalytic crackingOrganic chemistryParticulatesFouling mitigation

The present invention provides a method for reducing fouling, including particulate-induced fouling, in a hydrocarbon refining process including the steps of providing a crude hydrocarbon for a refining process; adding at least one polyalkyl succinic anhydride derivative additive disclosed herein. The additive can be complexed with a boronating agent, such as boric acid, to yield a boron-containing polyalkyl succinic anhydride derivative.

Owner:EXXON RES & ENG CO

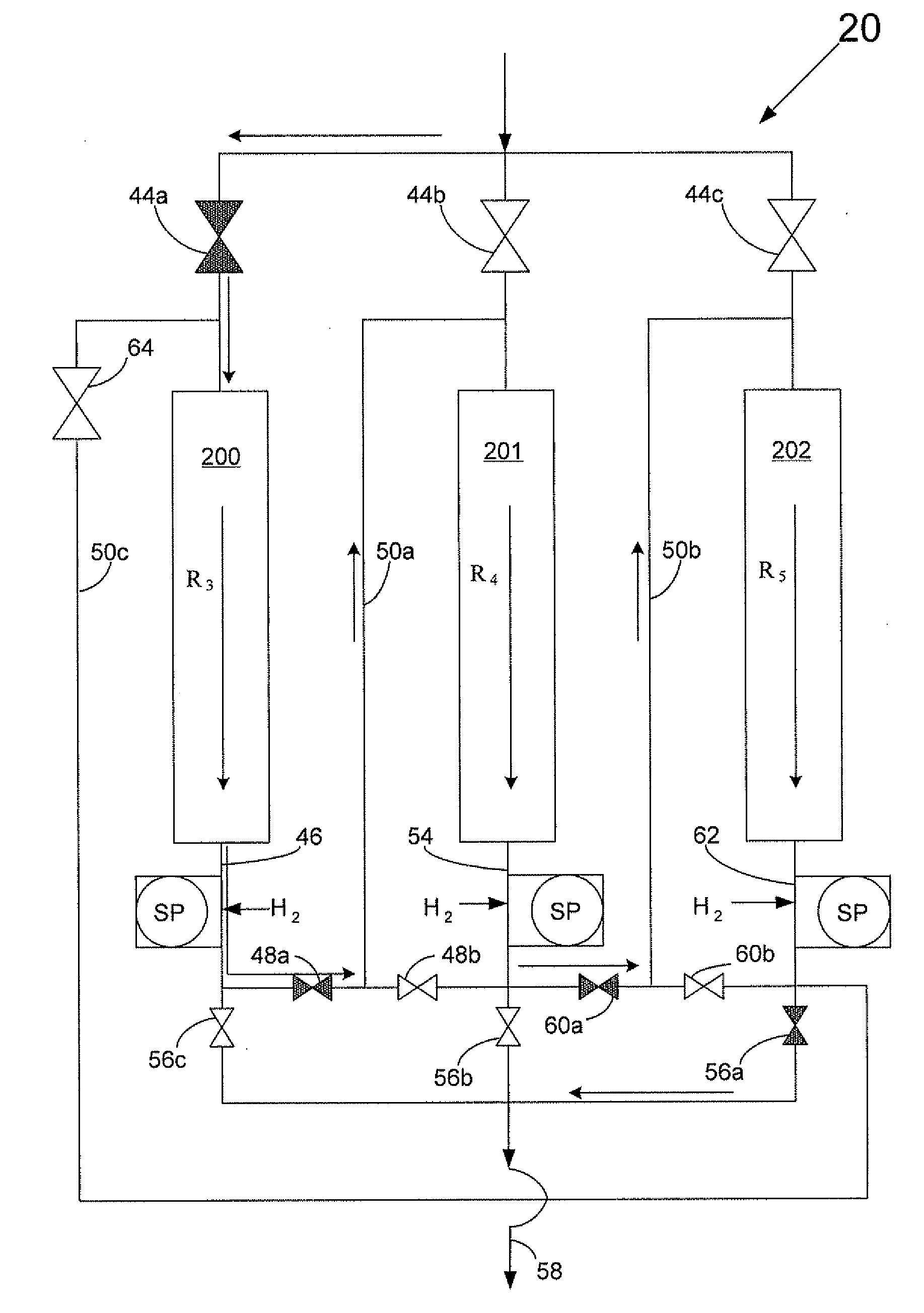

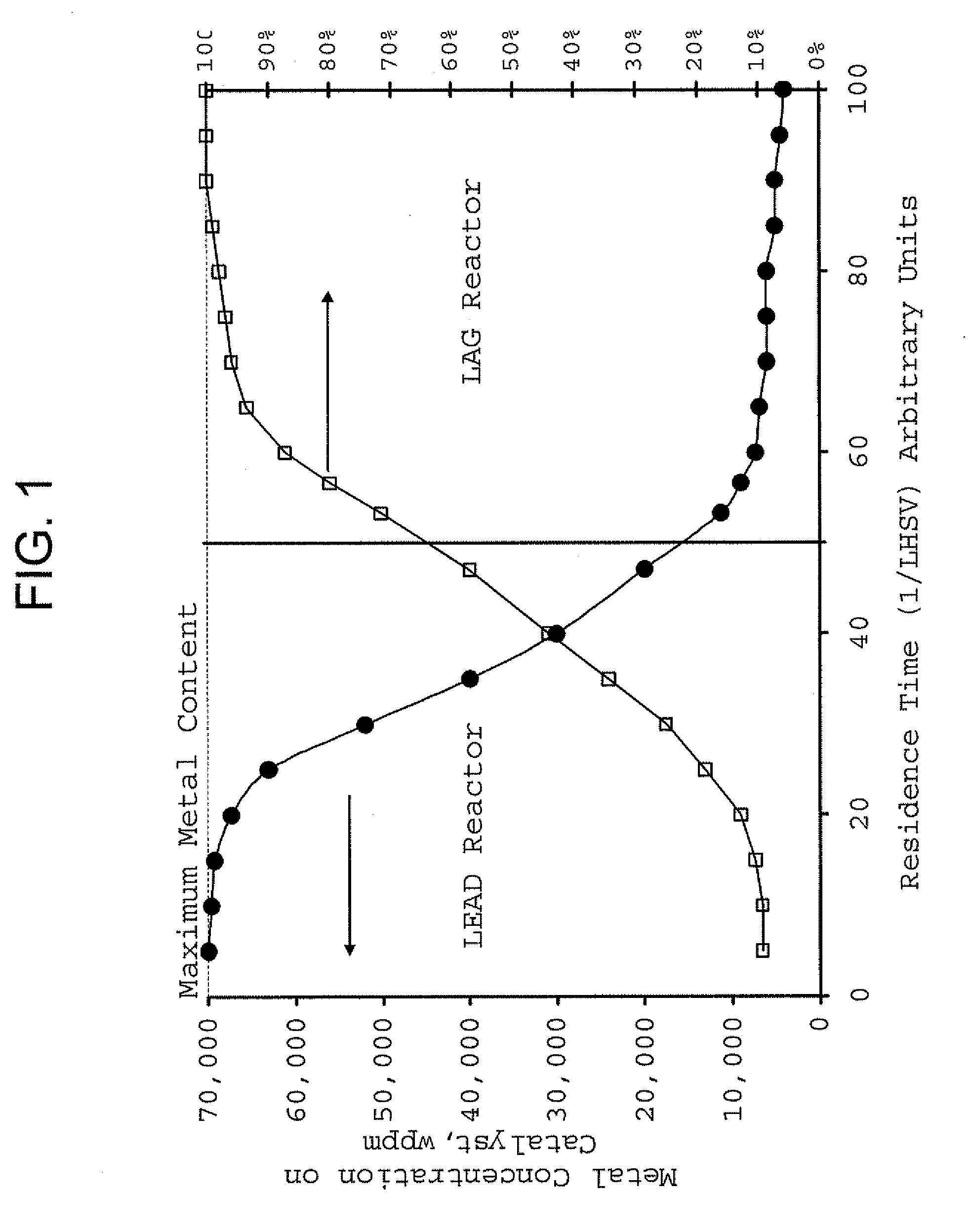

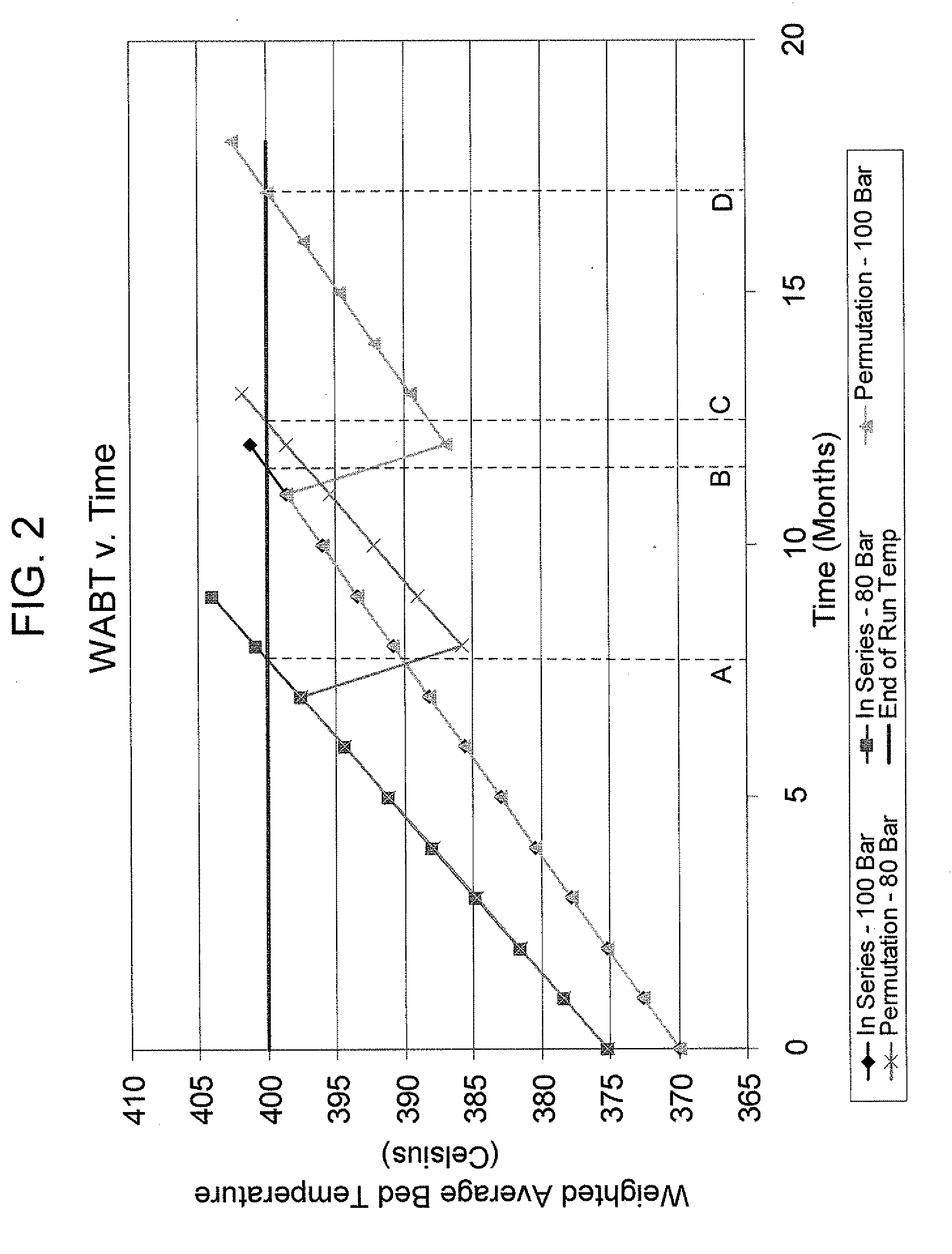

Process for catalytic hydrotreating of sour crude oils

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

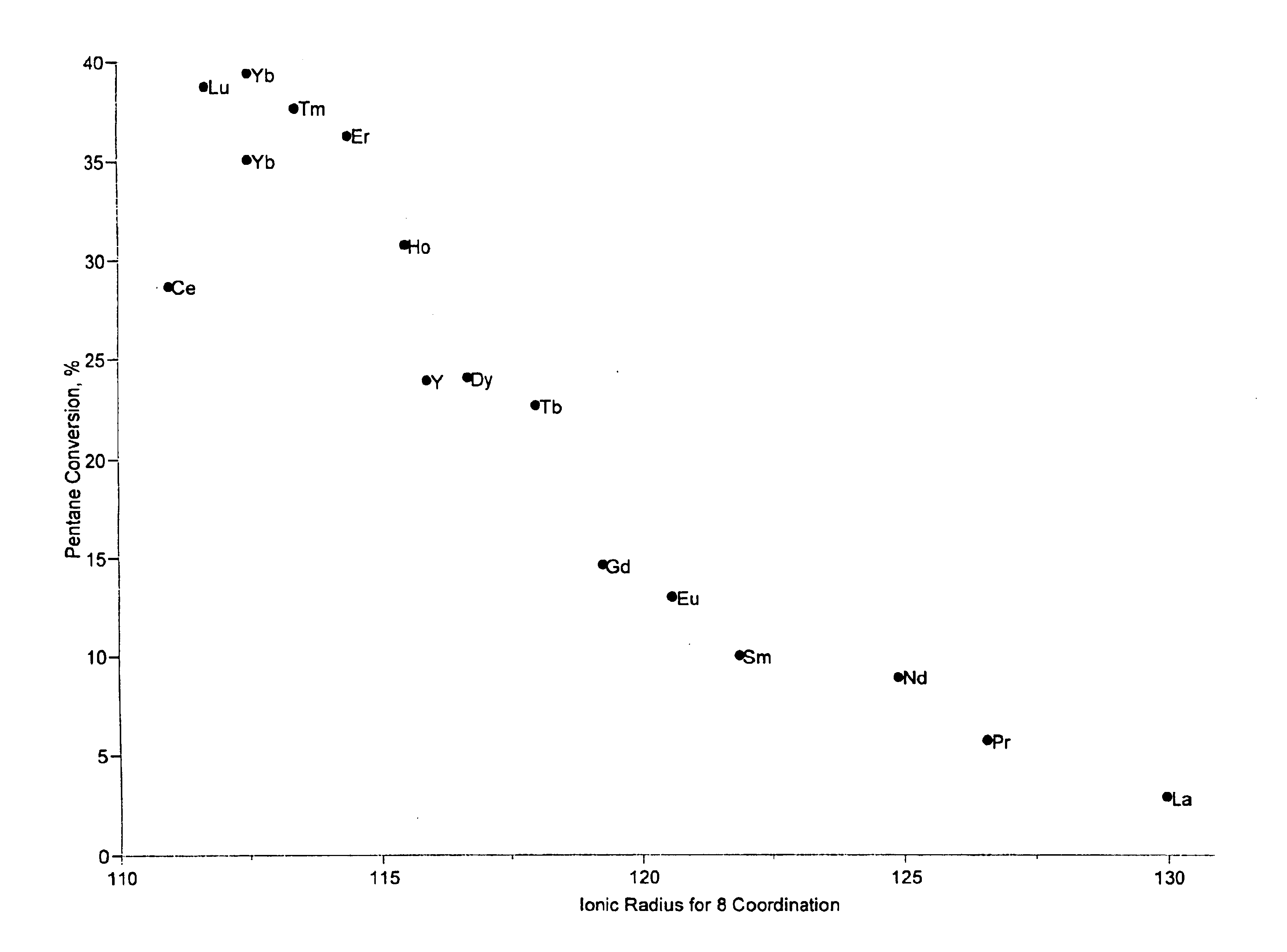

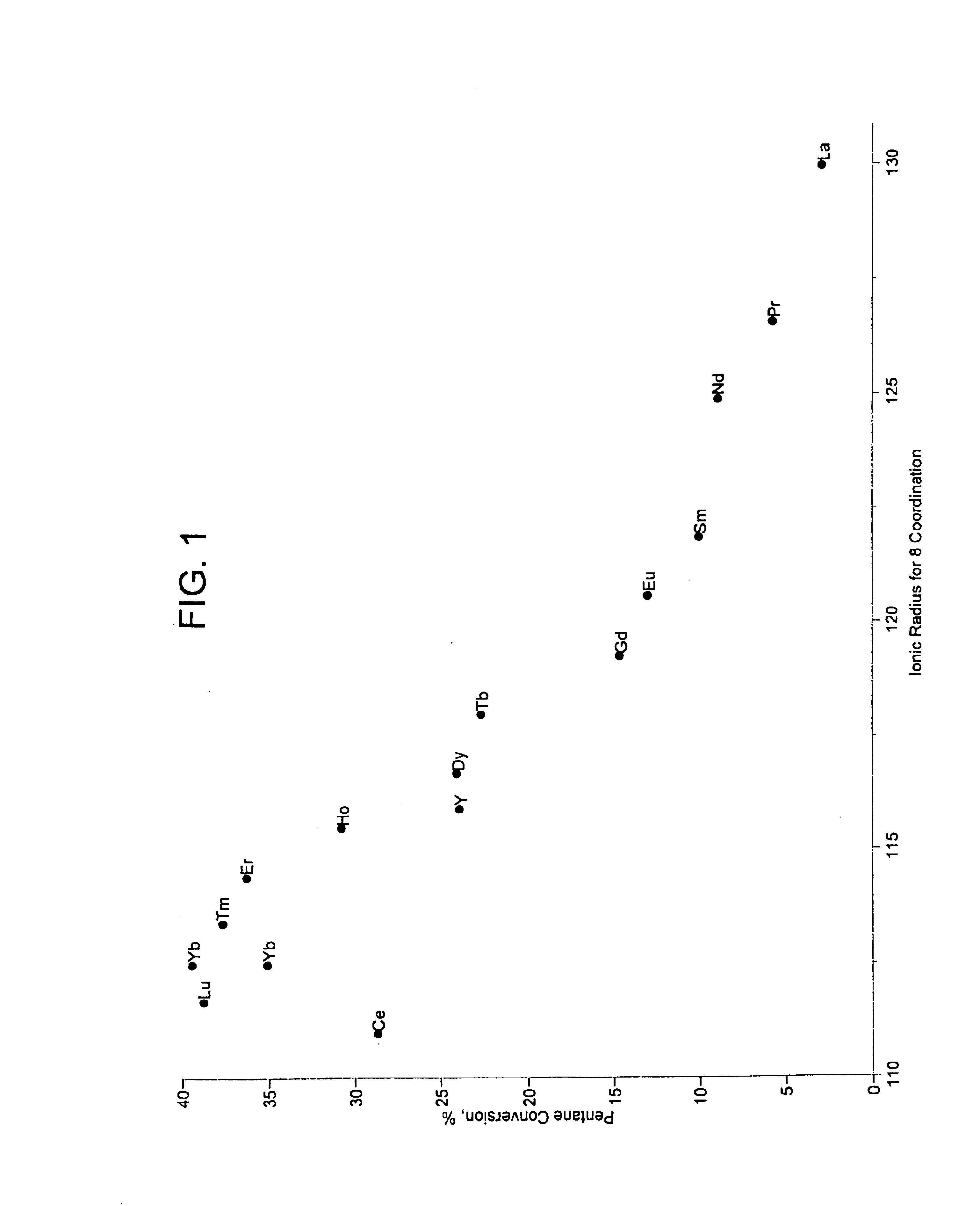

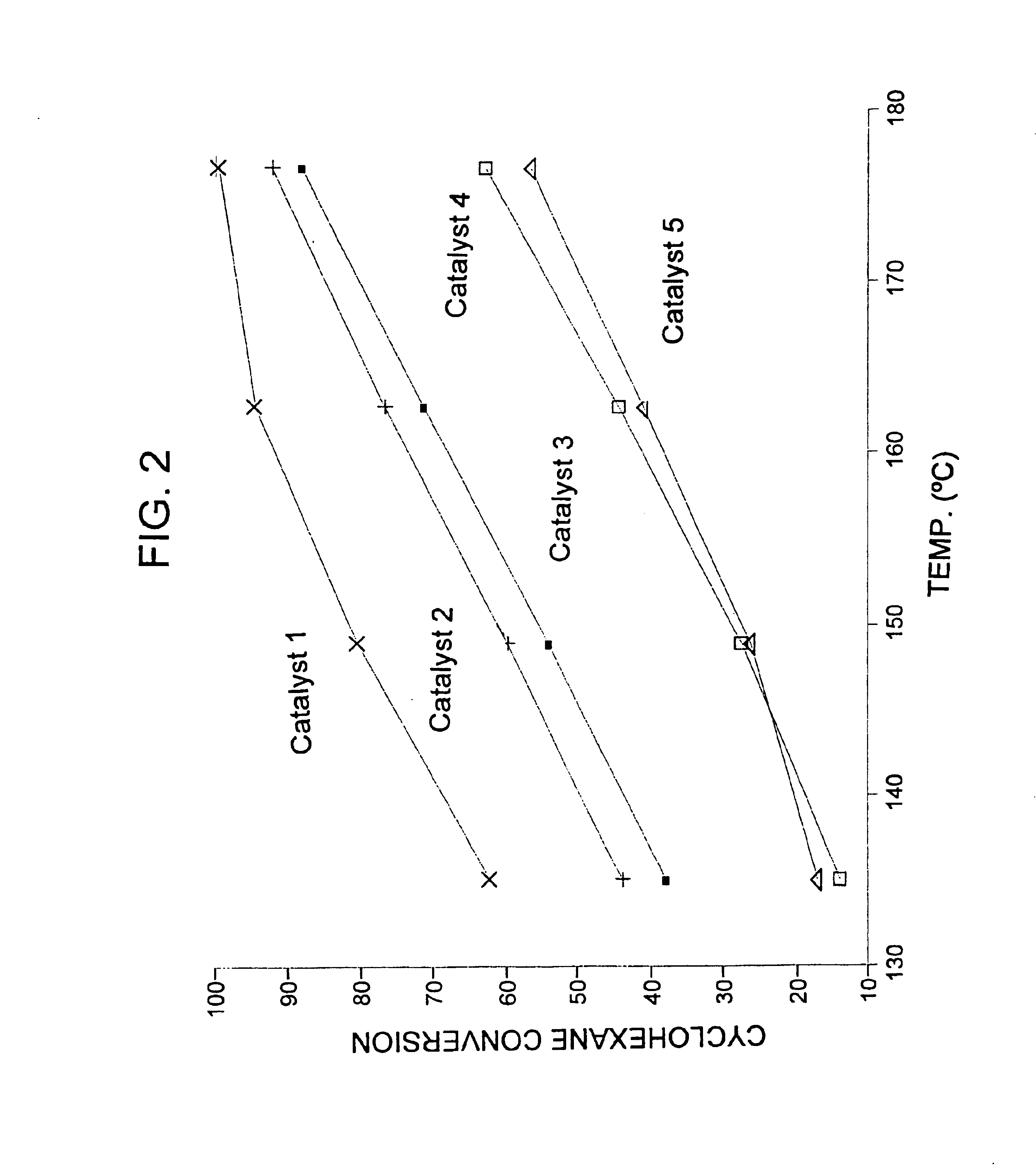

High-activity isomerization catalyst and process

InactiveUS6881873B2Improve performanceImprove stabilityThermal non-catalytic crackingHydrocarbon by isomerisationAlkaneSulfation

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component of at least one lanthanide element or yttrium component, which is preferably ytterbium, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

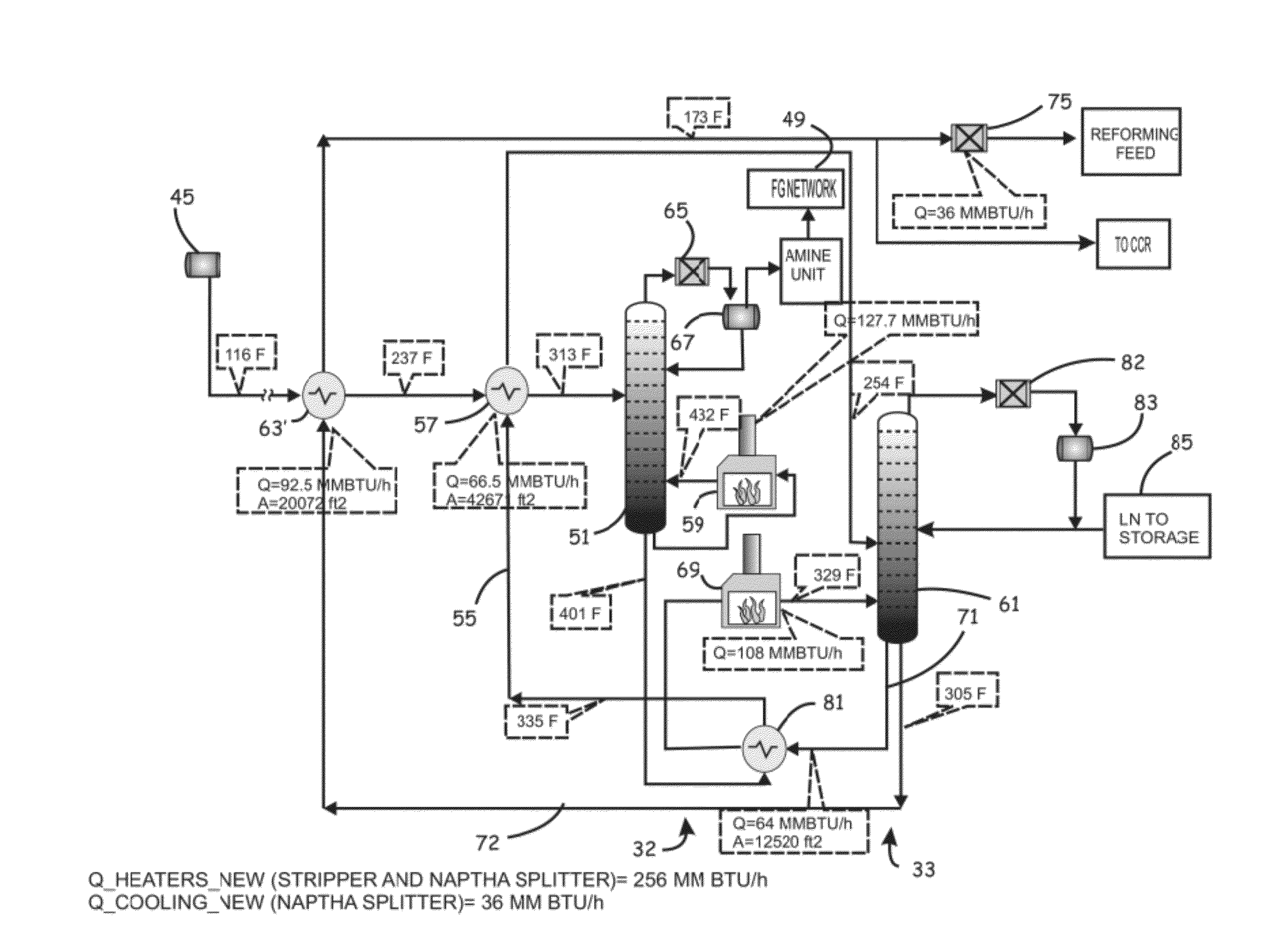

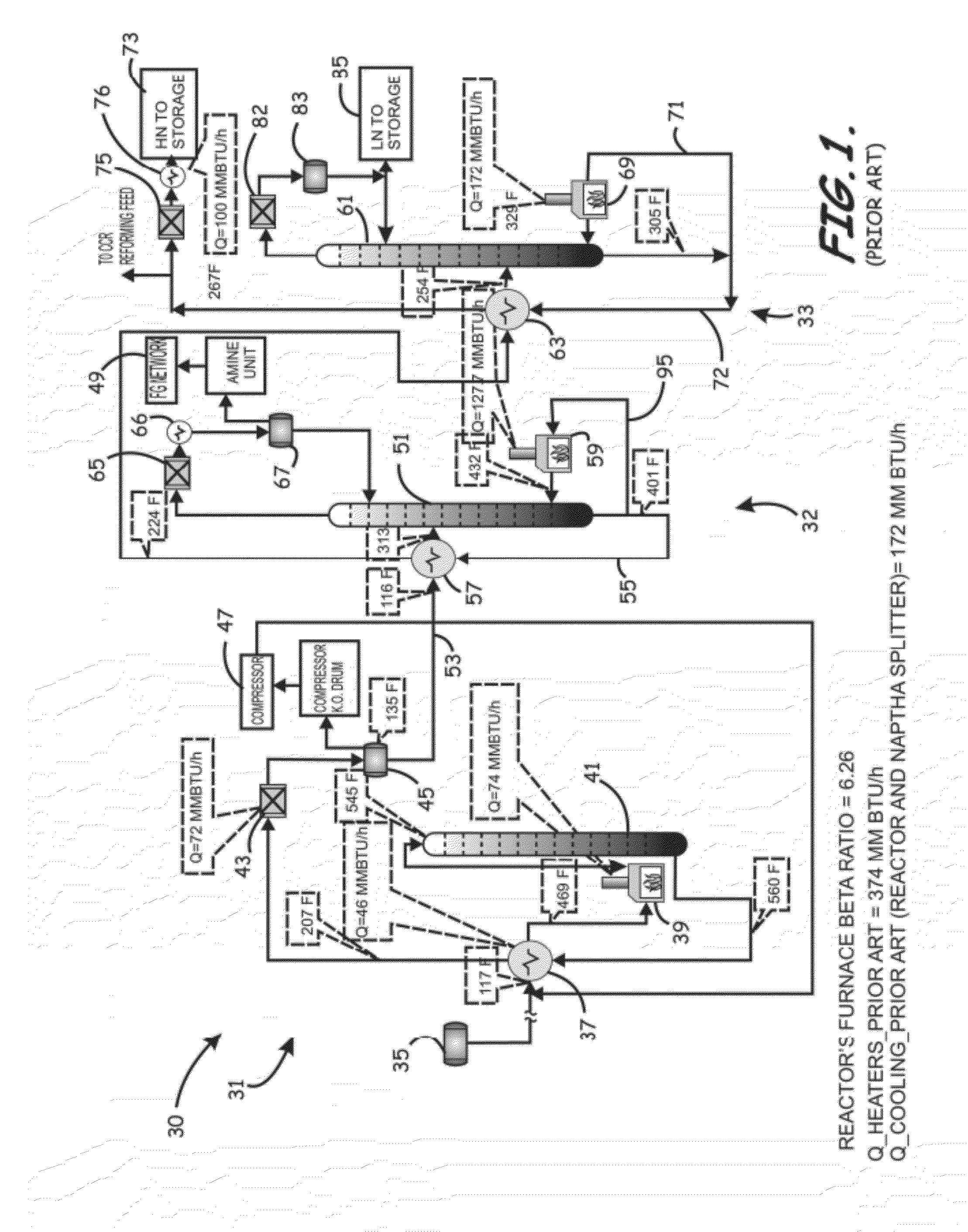

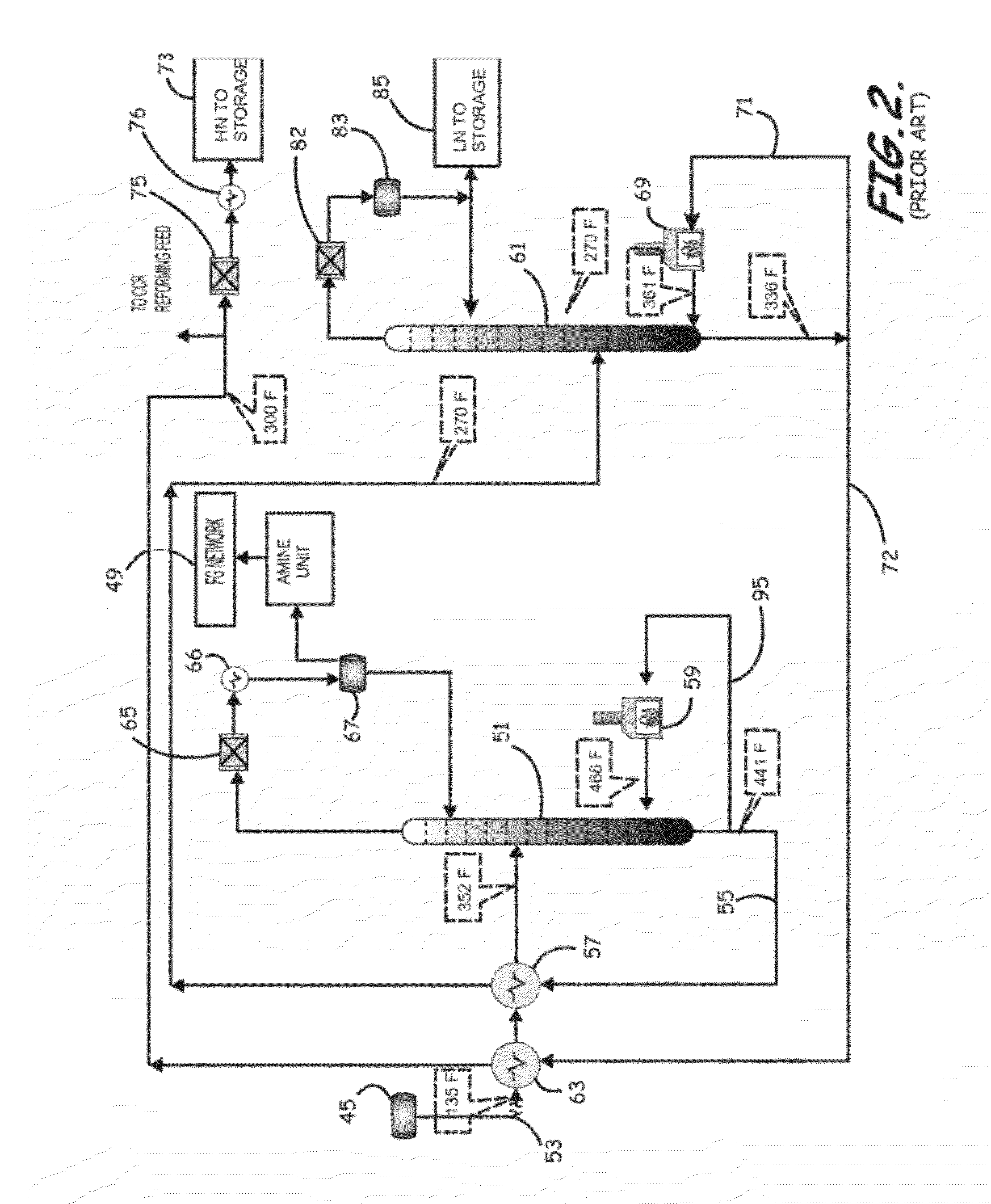

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

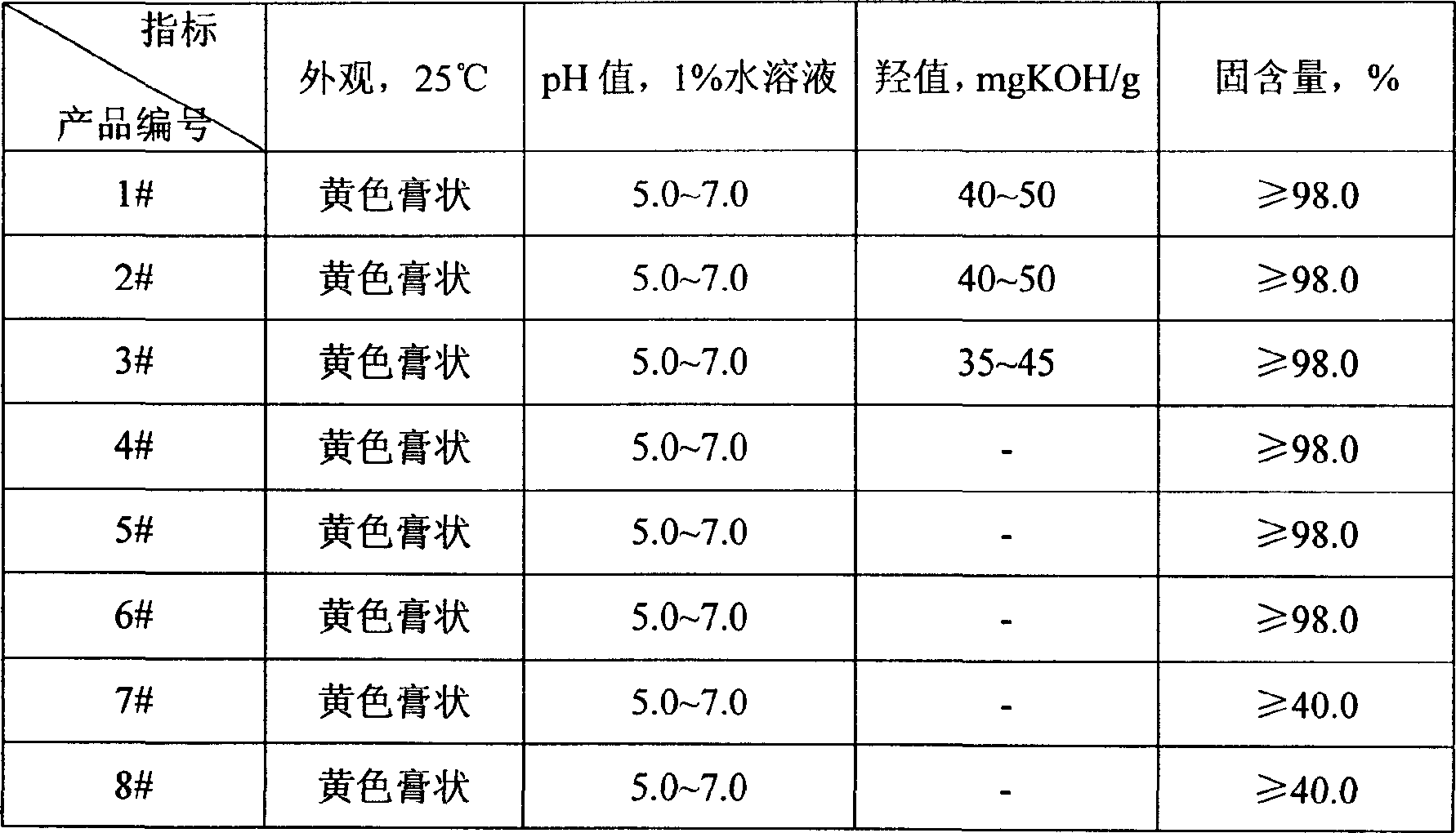

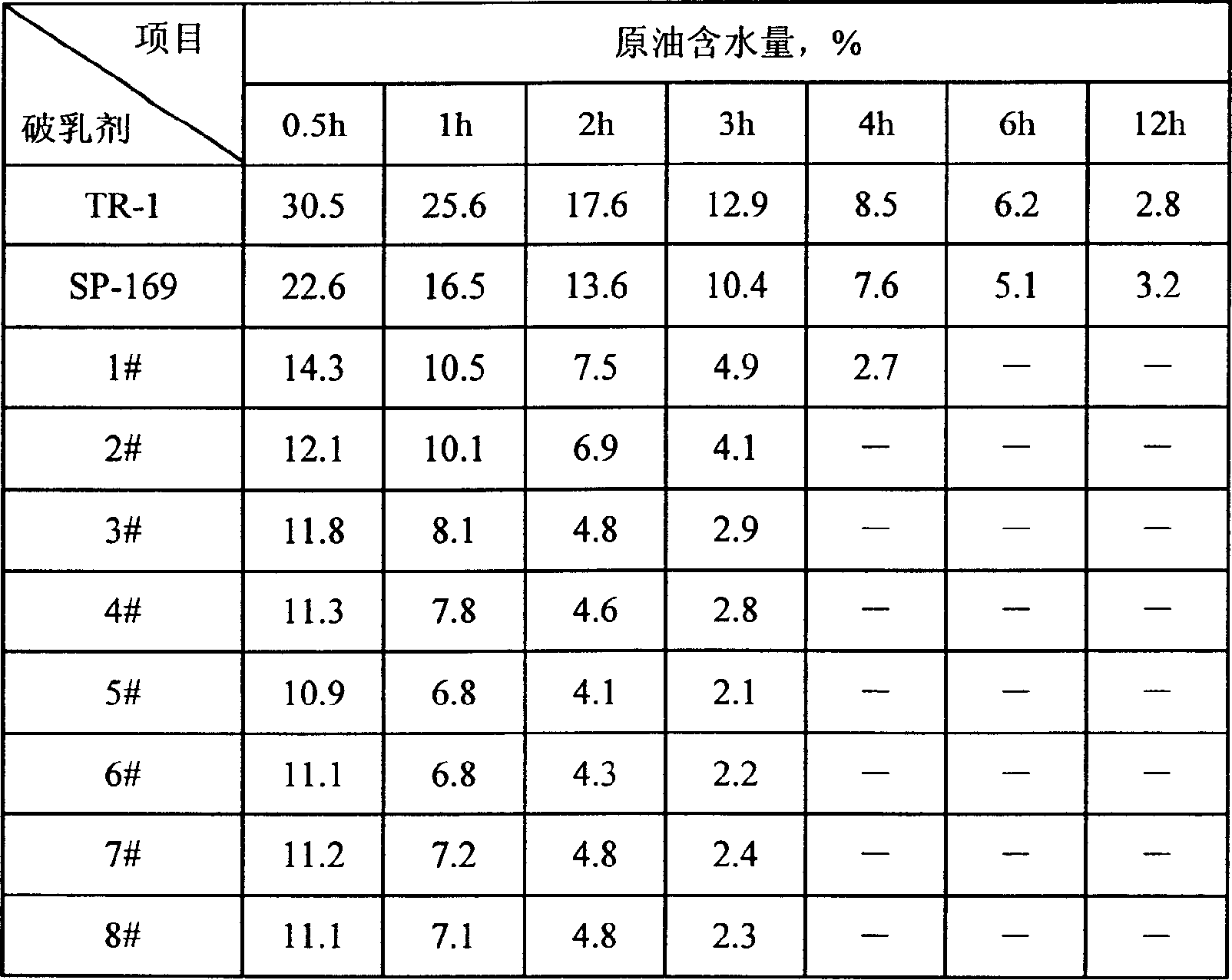

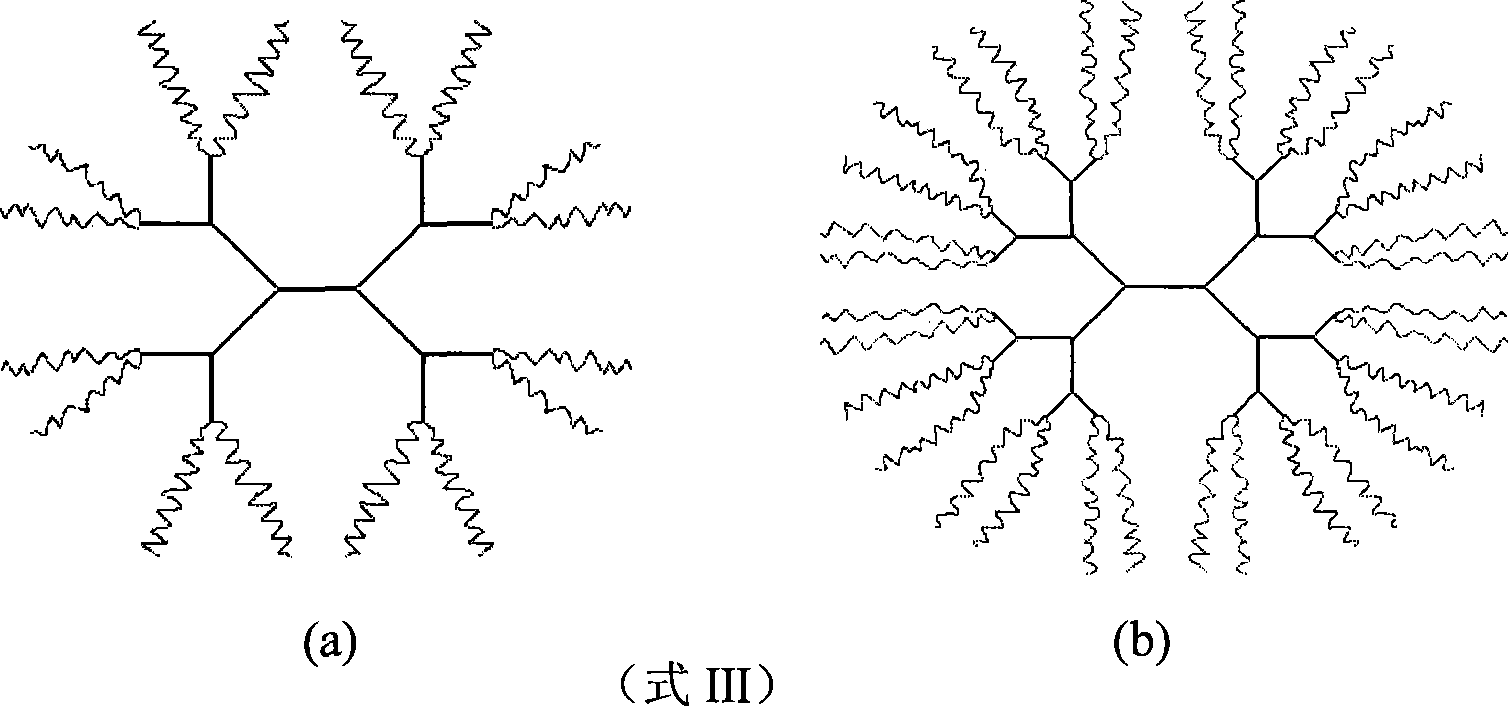

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

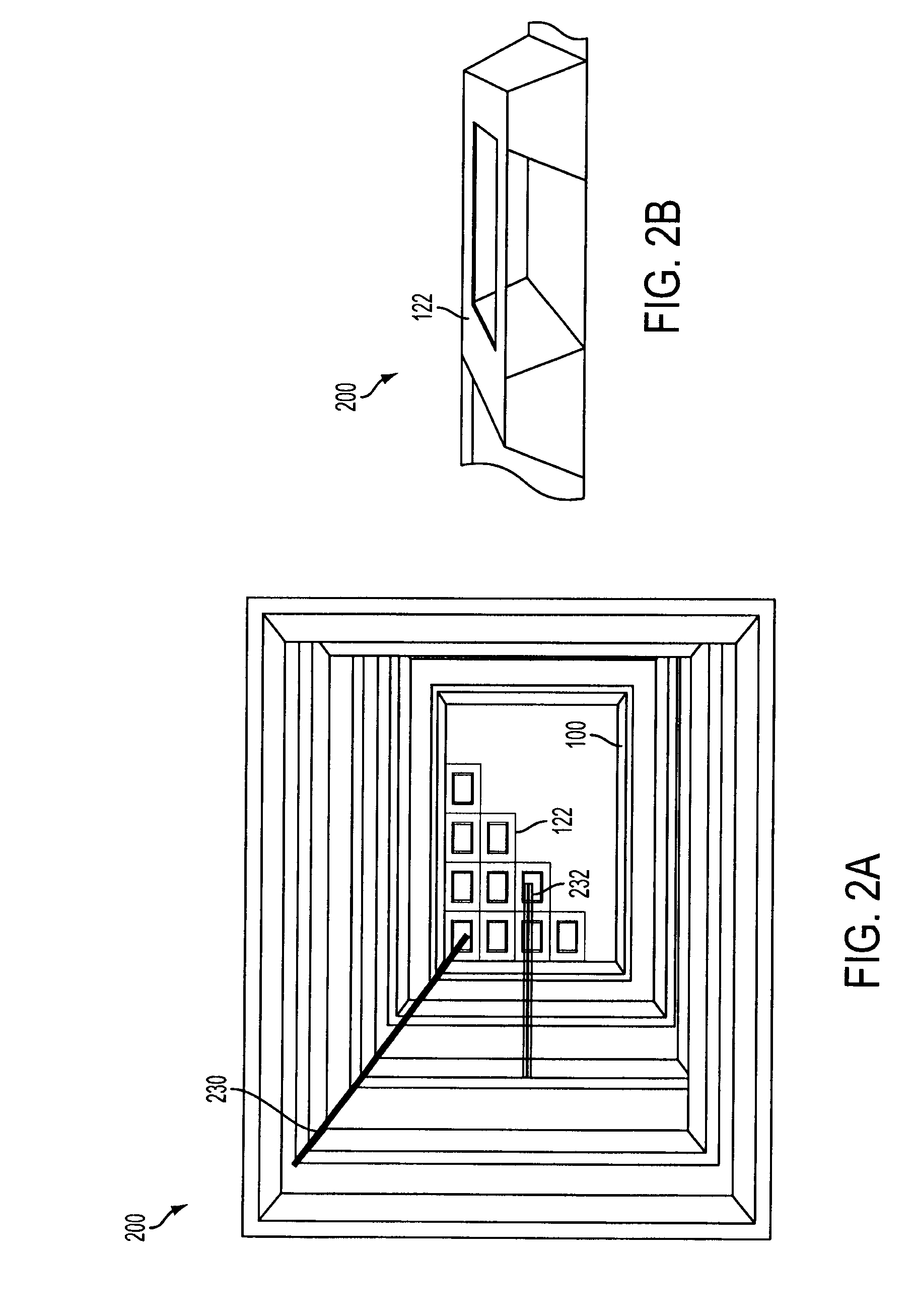

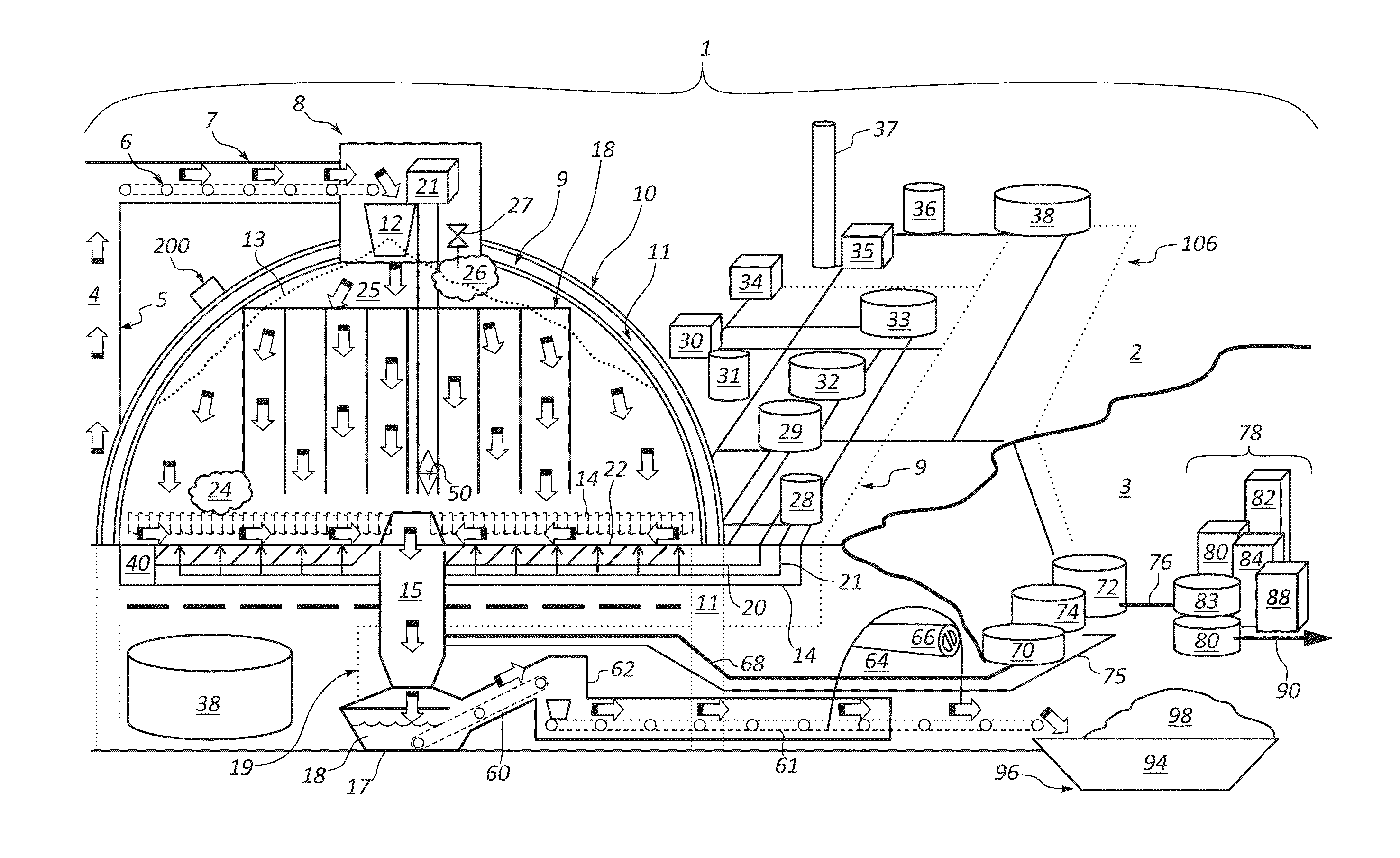

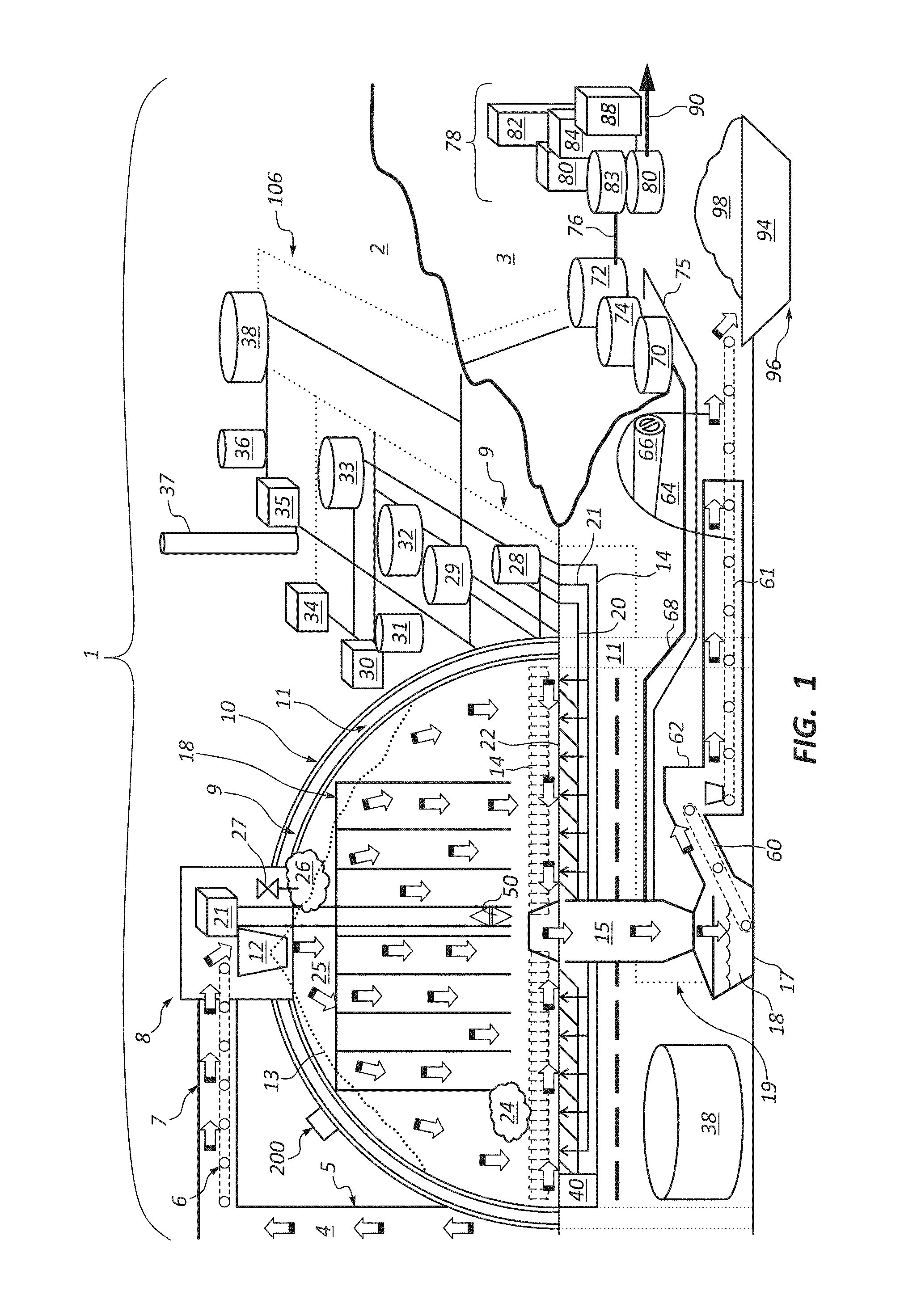

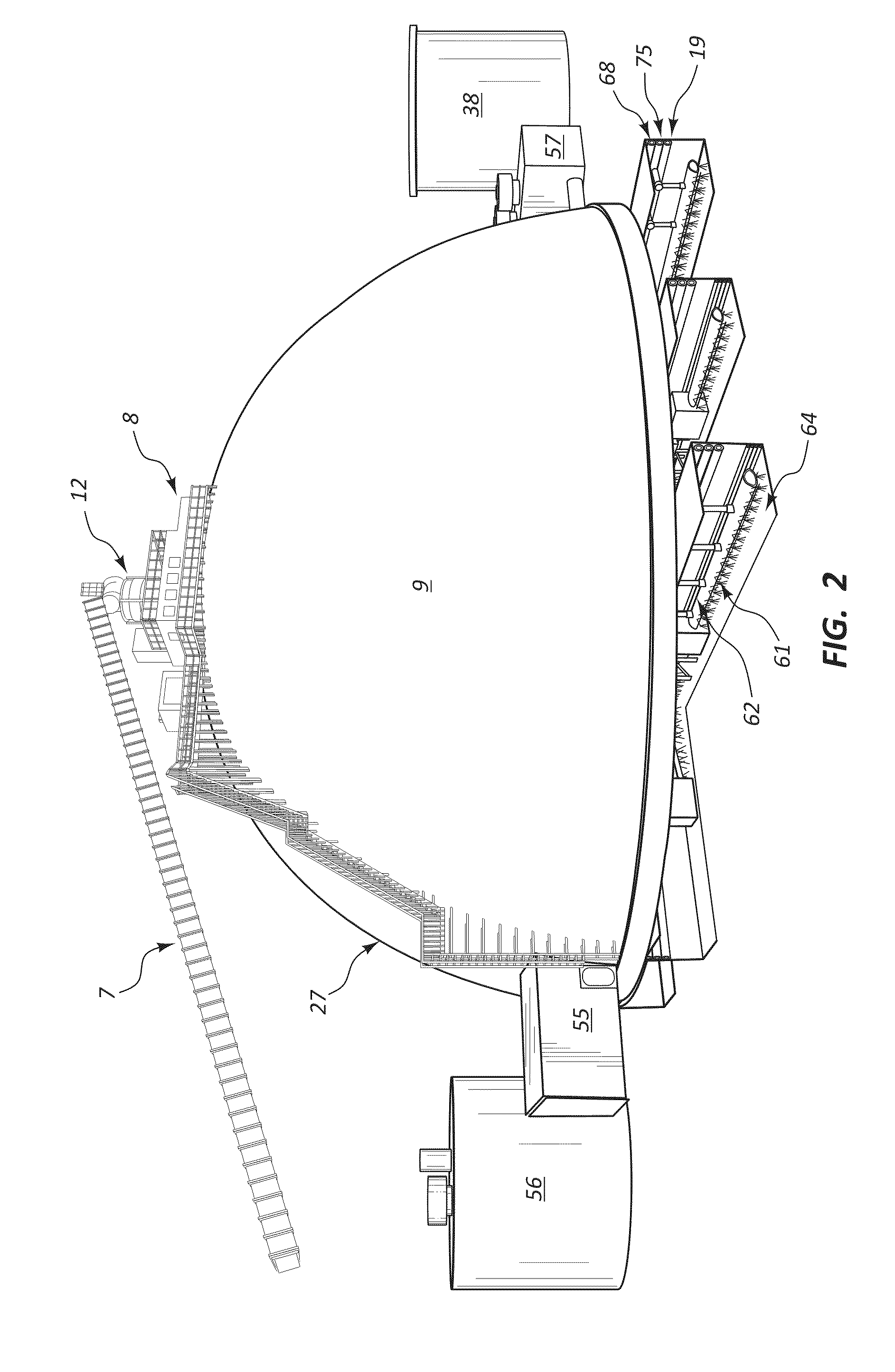

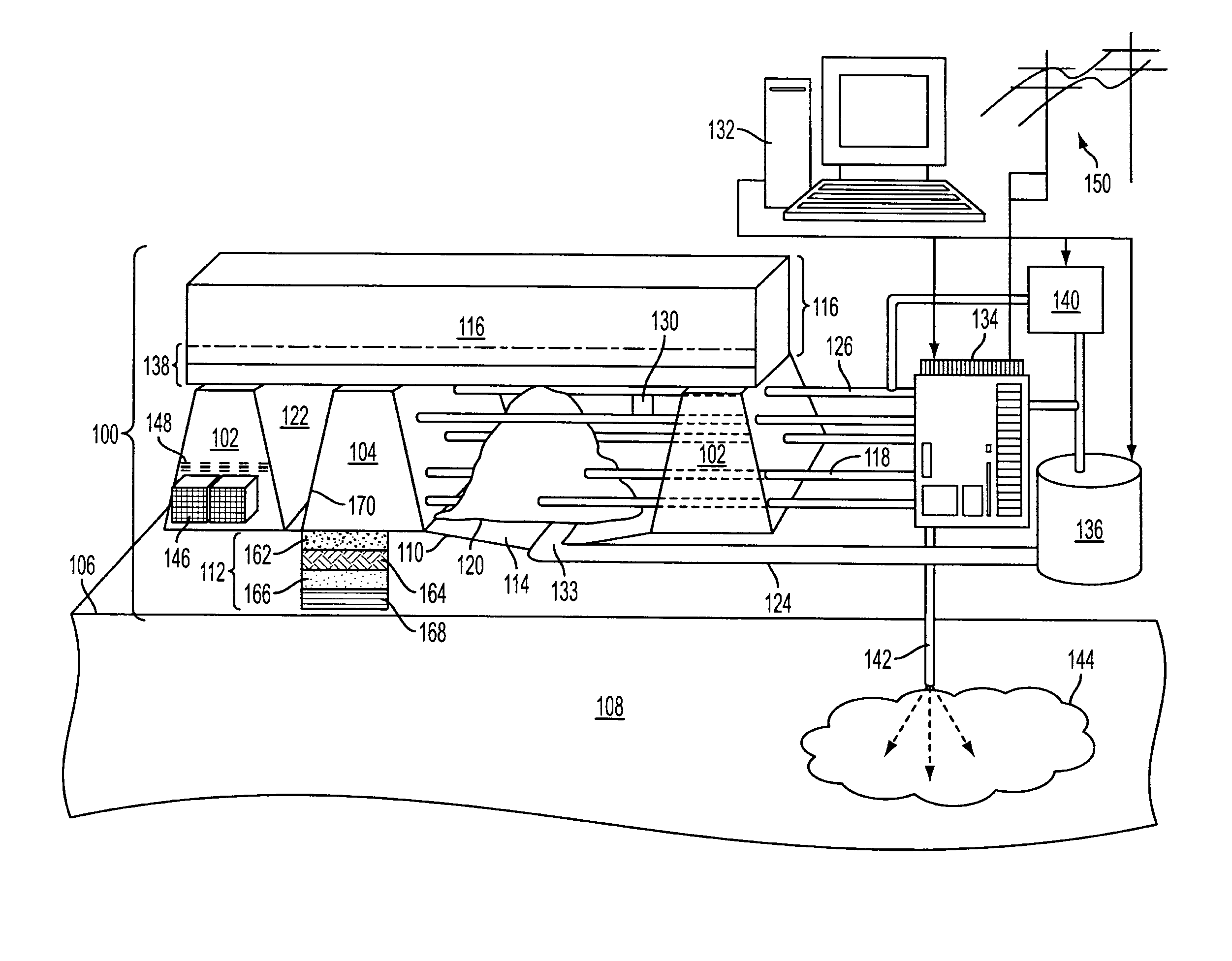

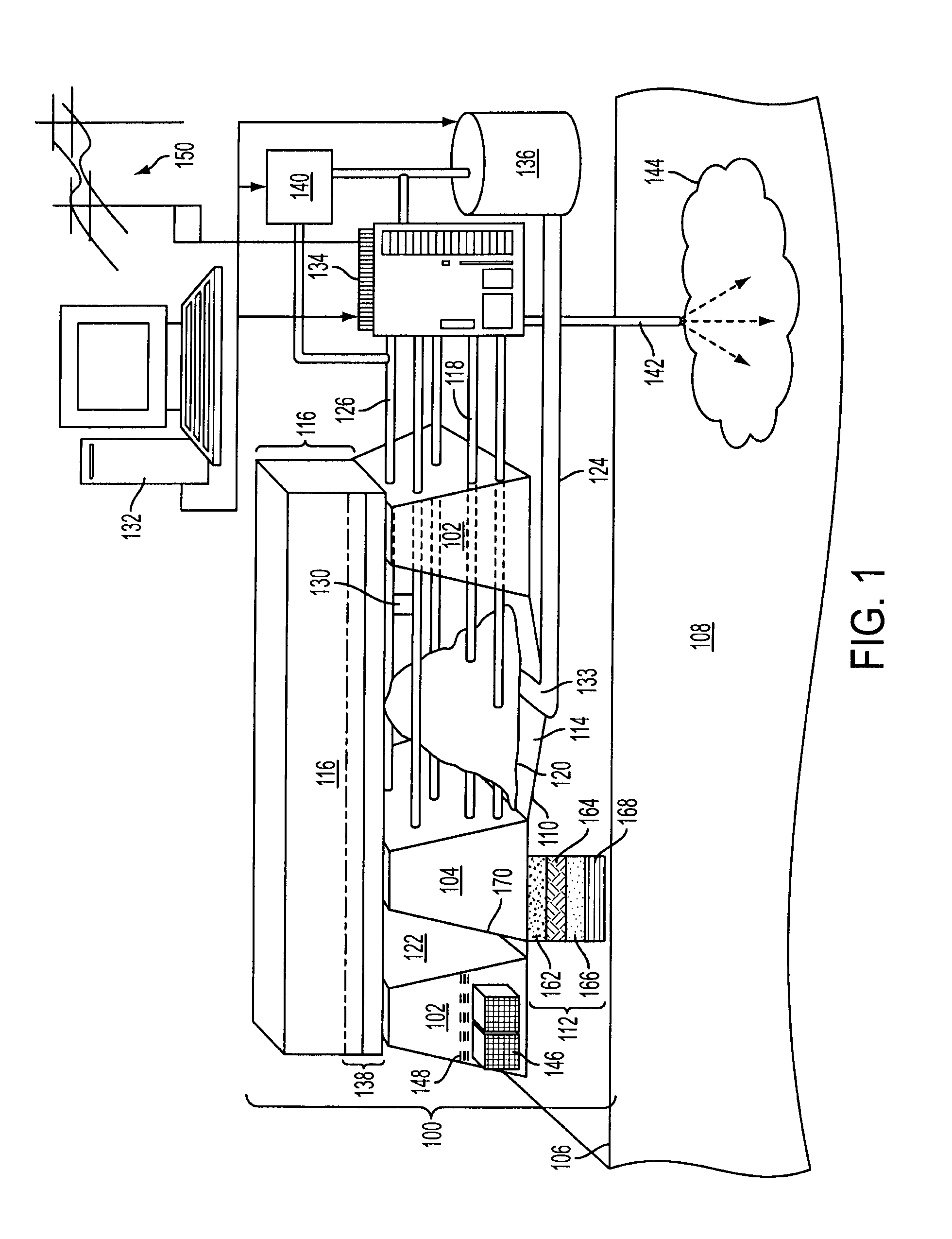

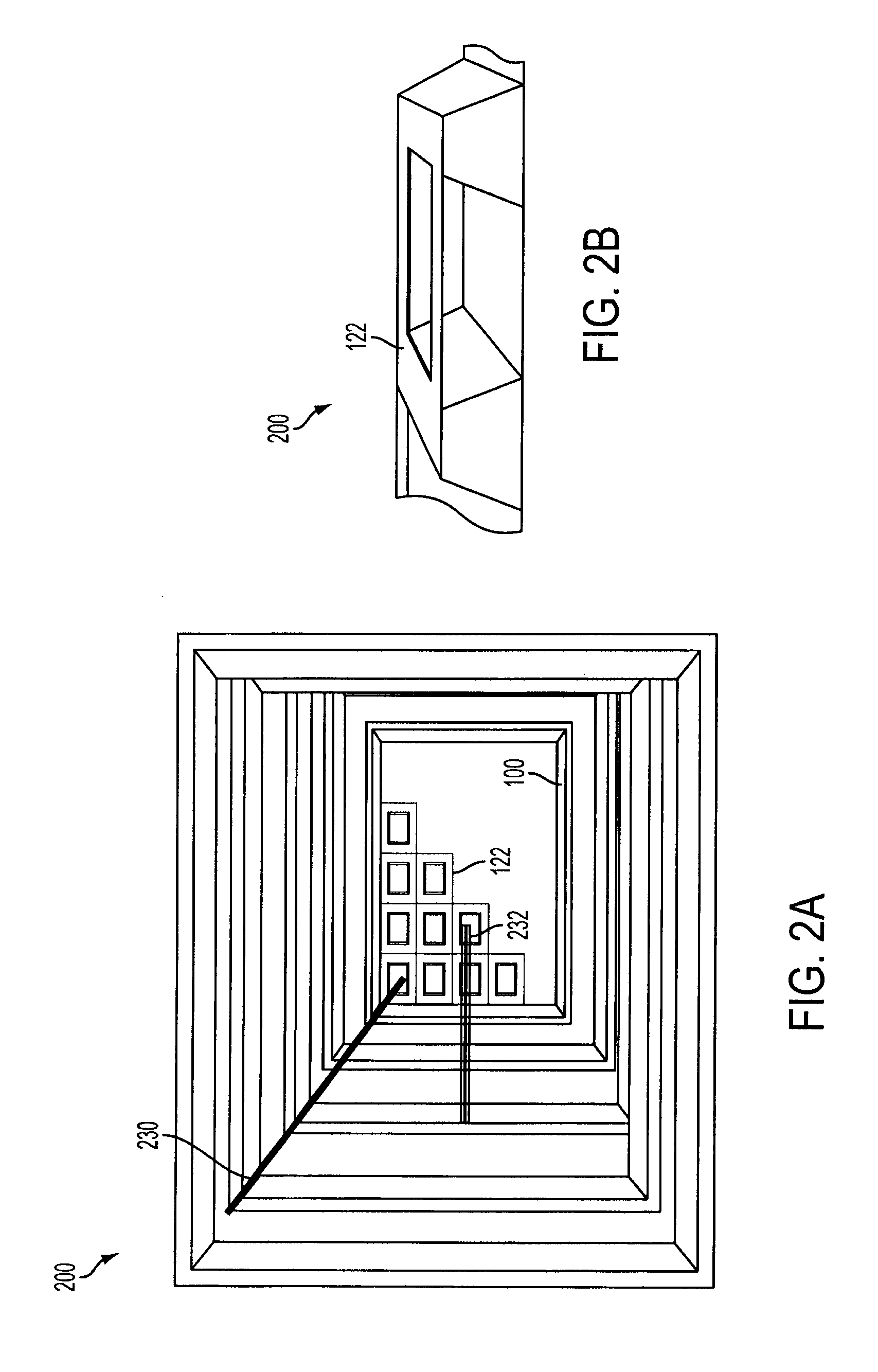

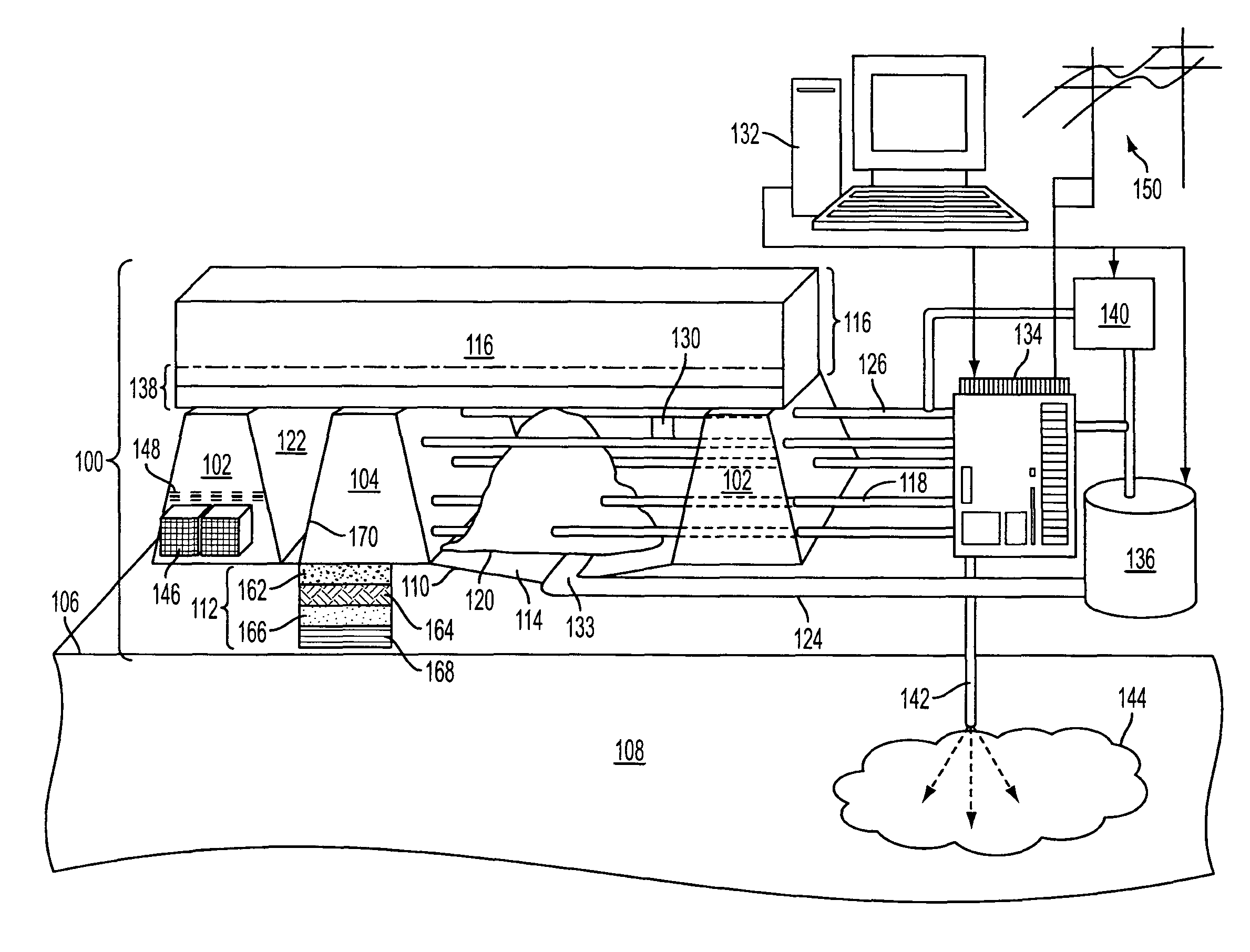

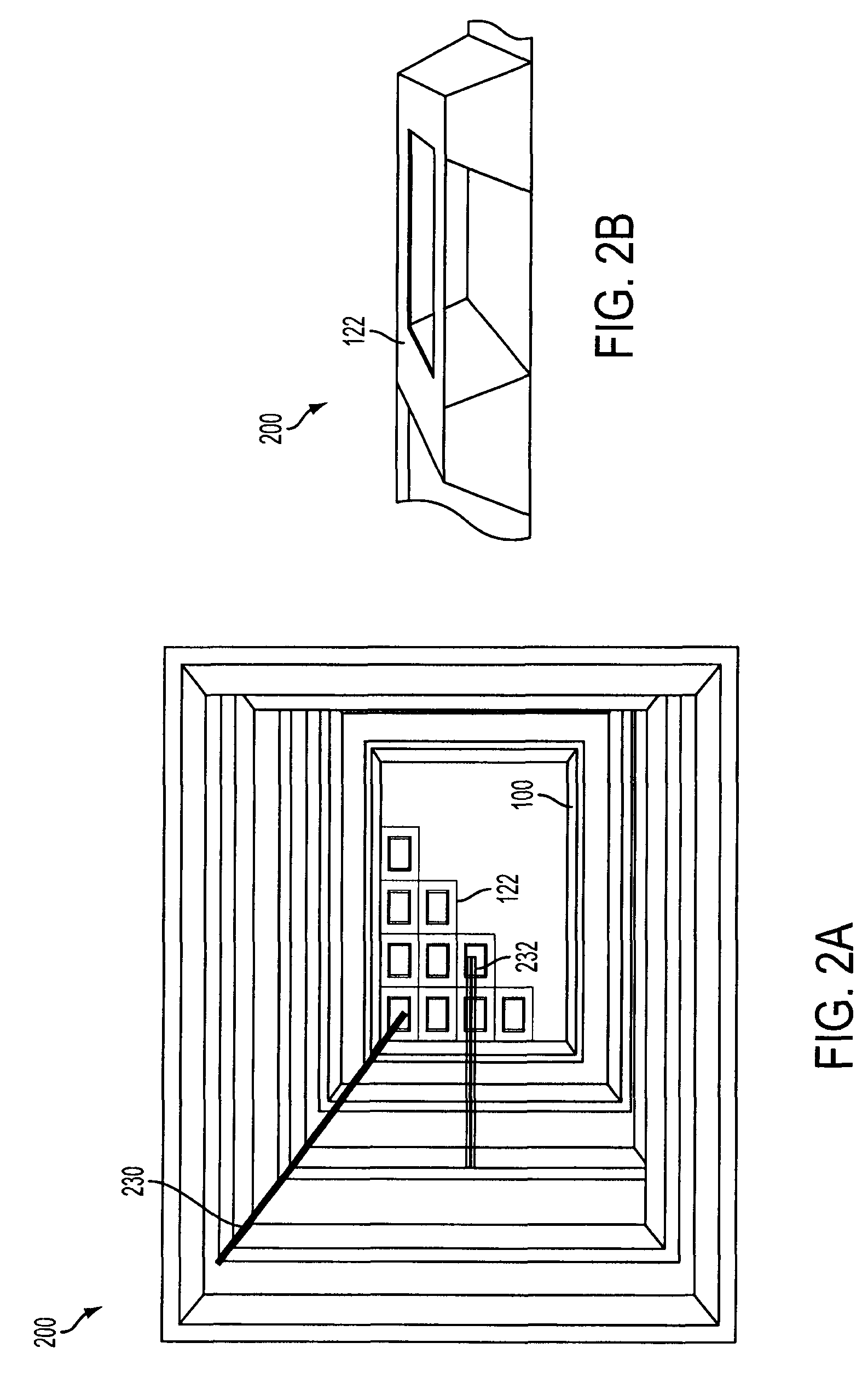

Systems, Apparatus and Methods of a Dome Retort

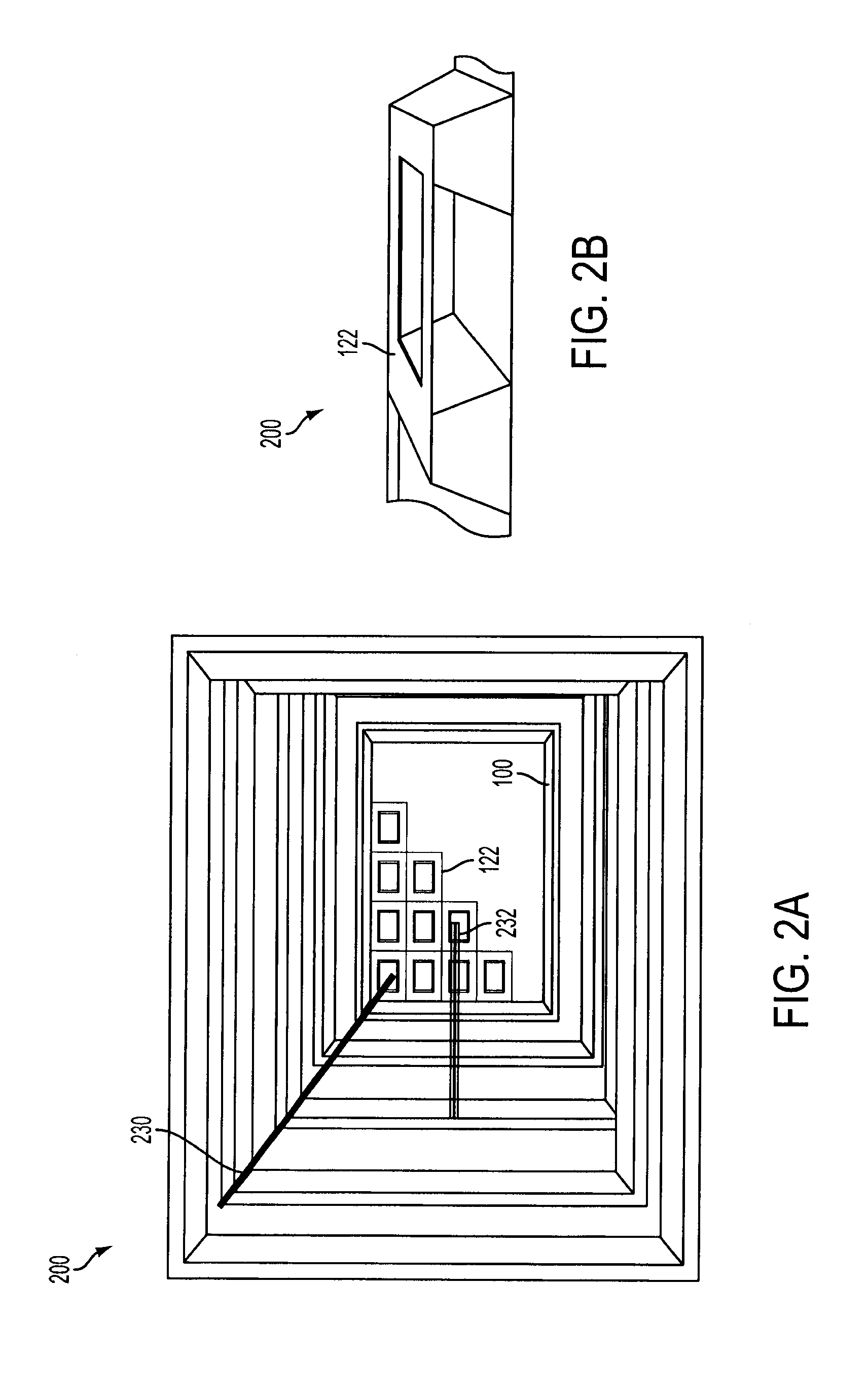

InactiveUS20110313218A1Increased material throughputLower cost of capitalPressurized chemical processDirect heating destructive distillationBasementControl system

A system, apparatus and method for hydrocarbon extraction from feedstock material that is or includes organic material, such as oil shale, coal, lignite, tar sands, animal waste and biomass. A retort system including at least one retort vessel may include a monolithic dome structure surrounded by a process isolation barrier, the dome structure being sealingly engaged with the process isolation barrier. The dome structure and the process isolation barrier define a retort chamber, at least a portion of which may comprise a subterranean chamber. A lower end of the dome retort structure provides an exit for collected hydrocarbons and spent feedstock material. Systems may include a plurality of such dome retort structures. A control system may be used for controlling one or more operating parameters of a retorting process performed within such a dome retort structure for extraction and collection of hydrocarbons.

Owner:DANA TODD C

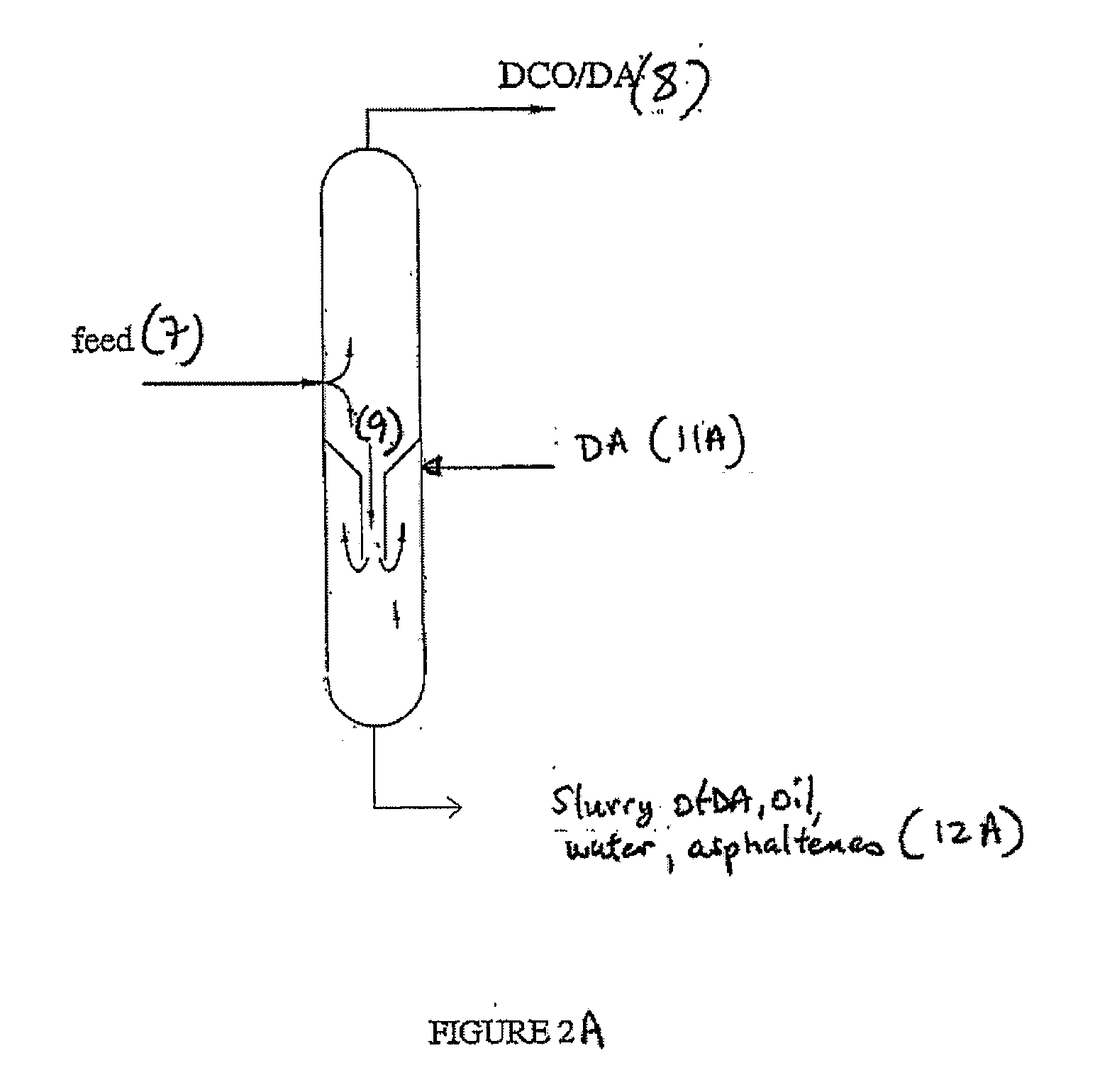

Slurry hydrocracking apparatus or process

InactiveUS20110303580A1Easy to separateAvoid disintegrationWorking-up pitch/asphalt/bitumenHydrocarbon oil crackingSlurryProcess engineering

One exemplary embodiment can include a slurry hydrocracking process. The process can include combining one or more hydrocarbons and a slurry hydrocracking catalyst as a feed to a slurry hydrocracking reaction zone, fractionating an effluent from the slurry hydrocracking reaction zone, separating the pitch from at least a portion of the slurry hydrocracking catalyst, and recycling the suspension to the slurry hydrocracking reaction zone. The slurry hydrocracking catalyst may include a support. Fractionating the effluent may provide a light vacuum gas oil, a heavy vacuum gas oil, and a mixture comprising a pitch and the slurry hydrocracking catalyst. Generally, the separated slurry hydrocracking catalyst is comprised in a suspension.

Owner:UOP LLC

Methods of recovering hydrocarbons from hydrocarbonaceous material with reduced non-carbonaceous leachate and co2 and associated systems

ActiveUS20080190816A1Avoid insufficient heatingInhibition formationThermal non-catalytic crackingUnderground chambersLeachateMaterials science

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a stationary permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom within a temperature range which is sufficient to substantially avoid formation of carbon dioxide or non-hydrocarbon leachates. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

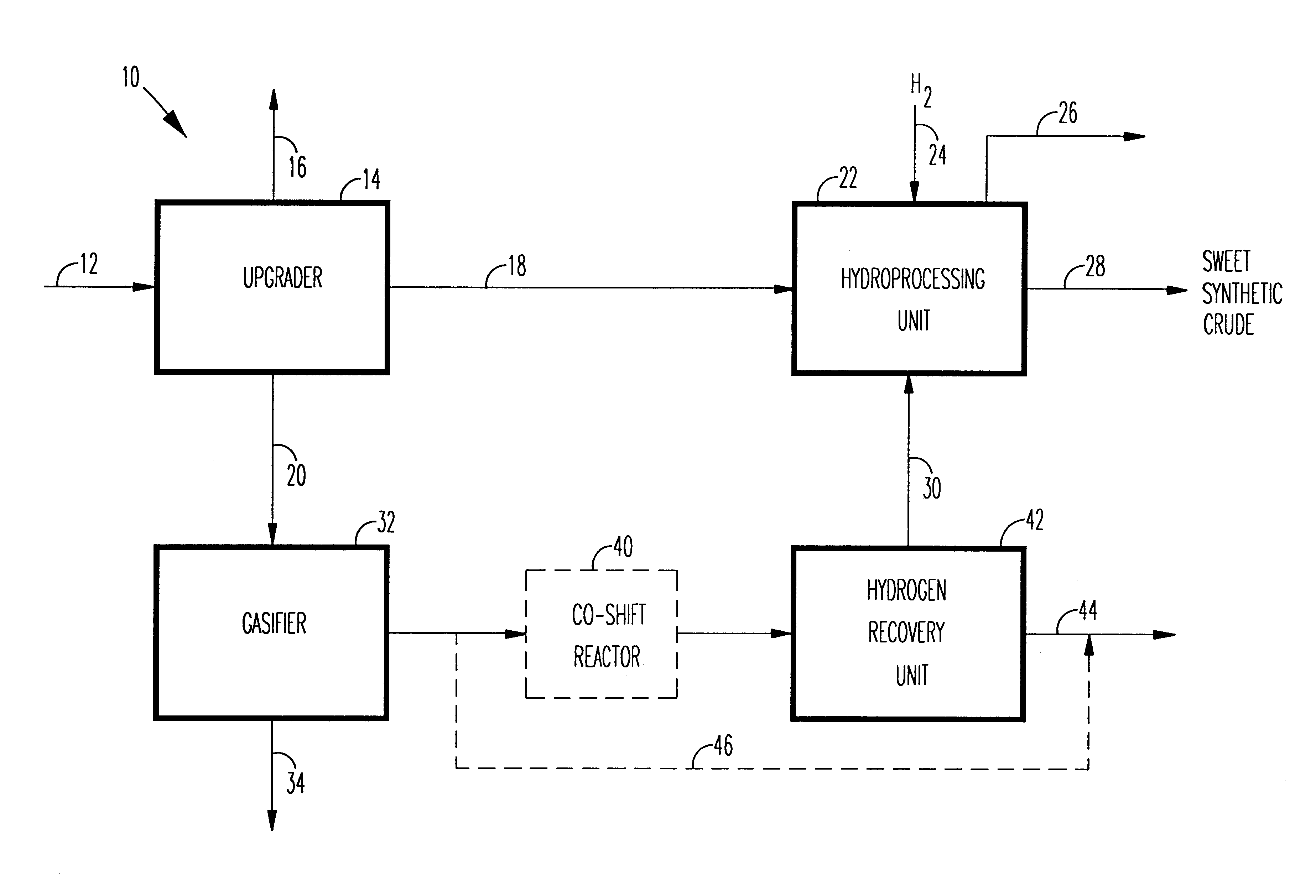

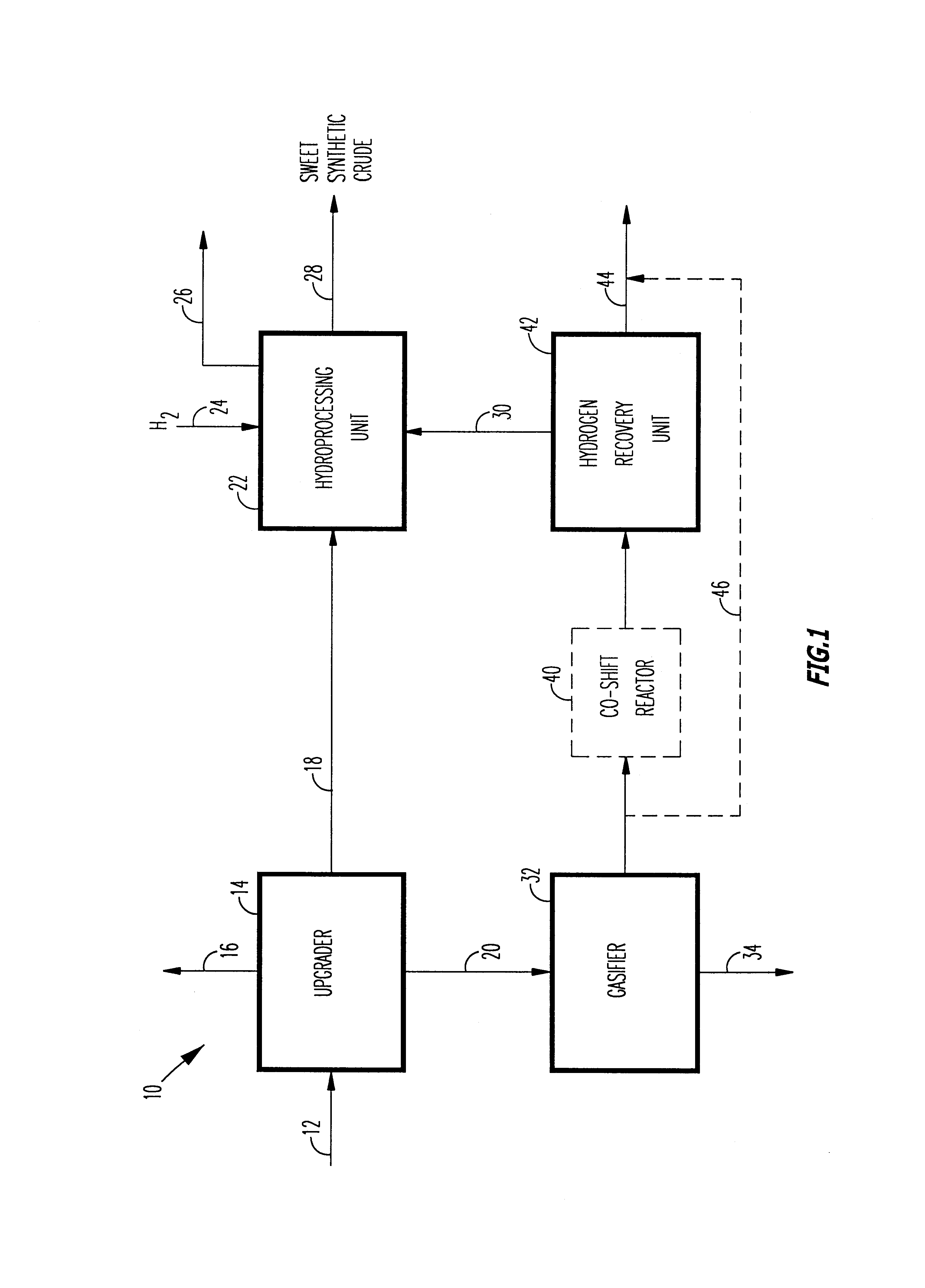

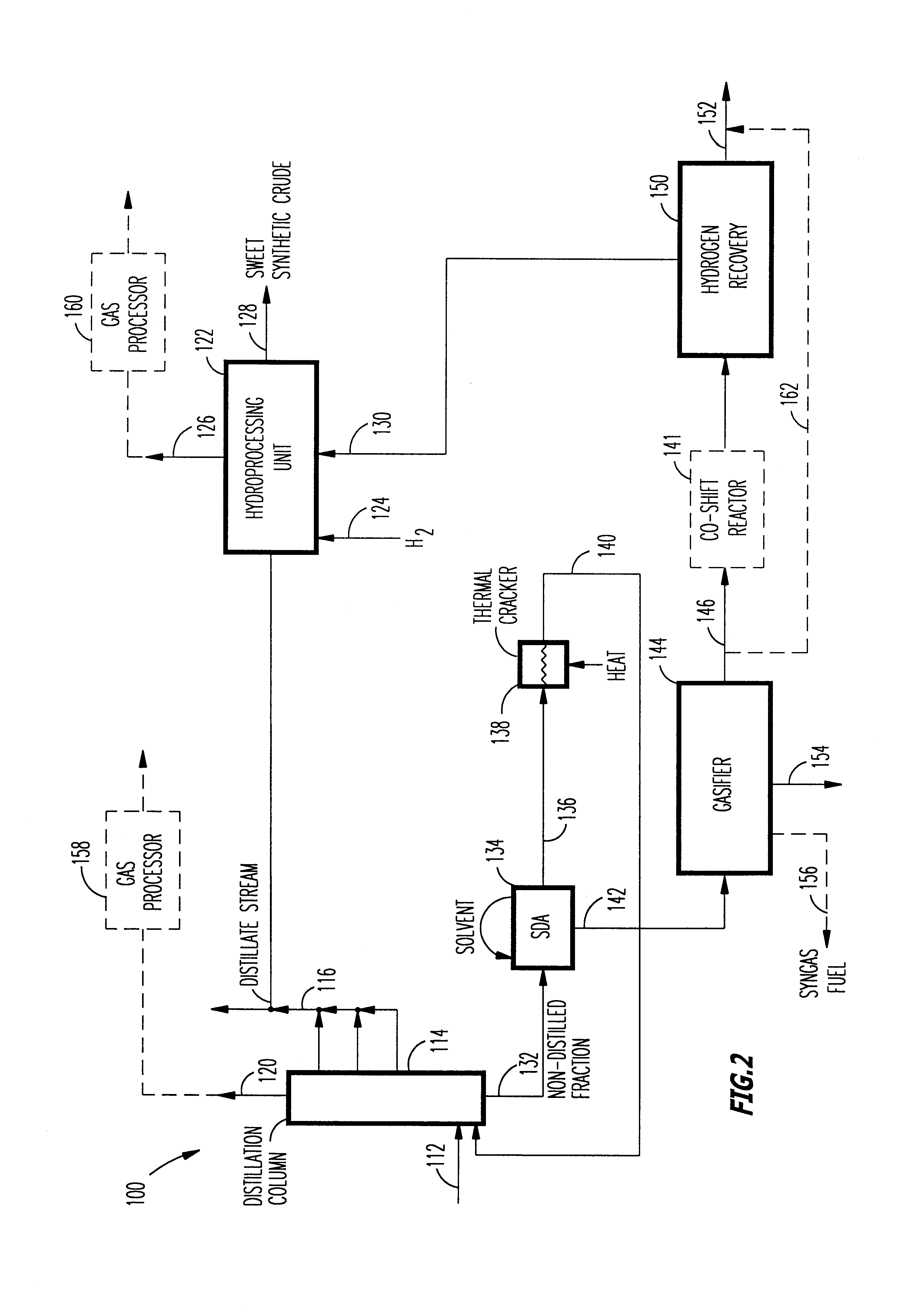

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

Apparatus and process for treating a hydrocarbon stream

InactiveUS20100243532A1Minimizes inventoryQuantity minimizationLiquid degasificationSolvent extractionBoiling pointIonic liquid

One exemplary embodiment can be an apparatus for treating a hydrocarbon stream having one or more compounds with a boiling point of about 140-about 450° C. The apparatus can include an extraction zone and a regeneration zone. The extraction zone can include at least one settler. Each settler can have a height and a length. Typically the length is greater than the height. Also, the settler can form a boot, which can be adapted to receive a feed at one end. The regeneration zone may include a regenerator for an ionic liquid. The regenerator can include a column adapted to provide a regenerated ionic liquid to the extraction zone.

Owner:UOP LLC

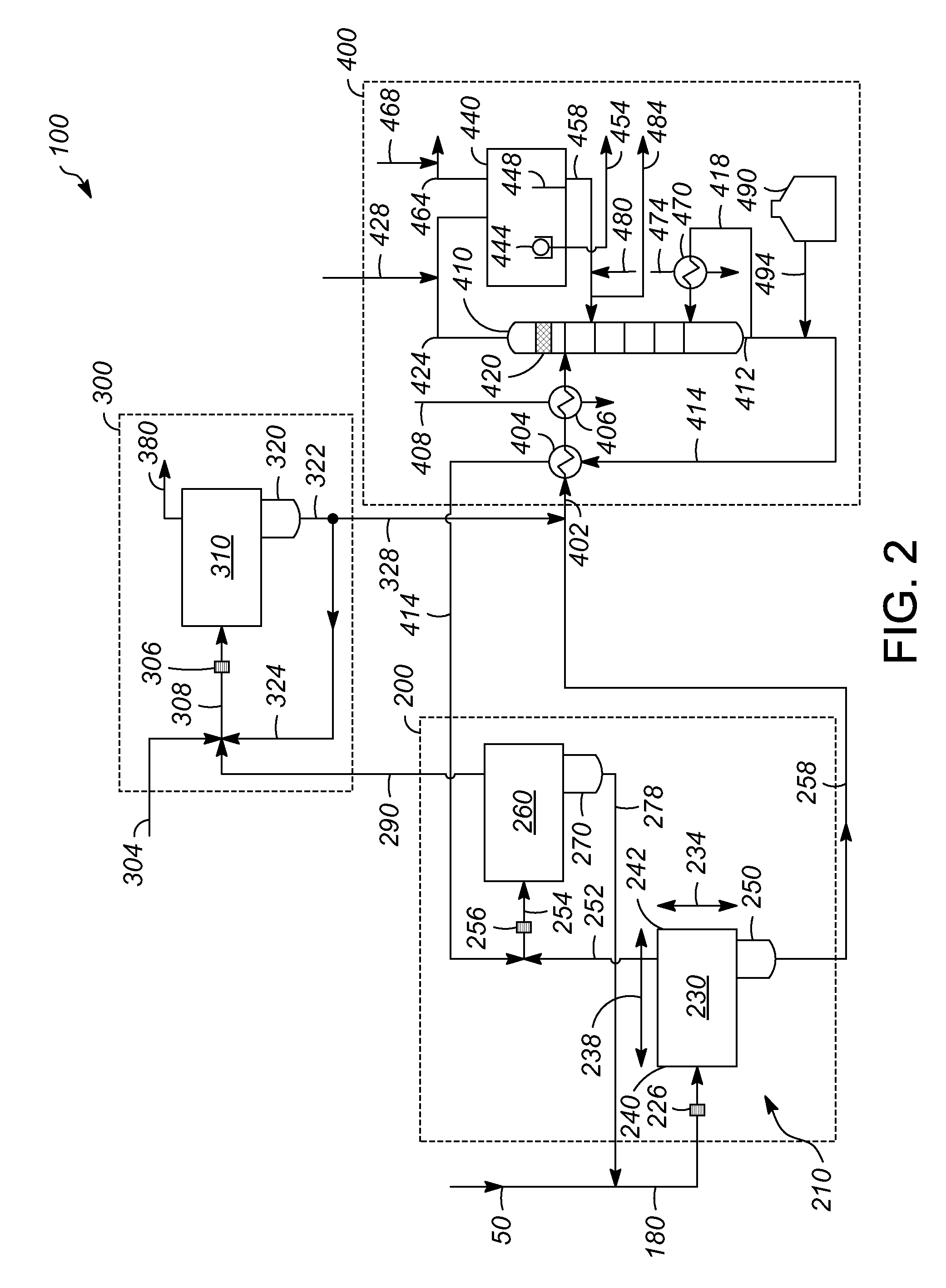

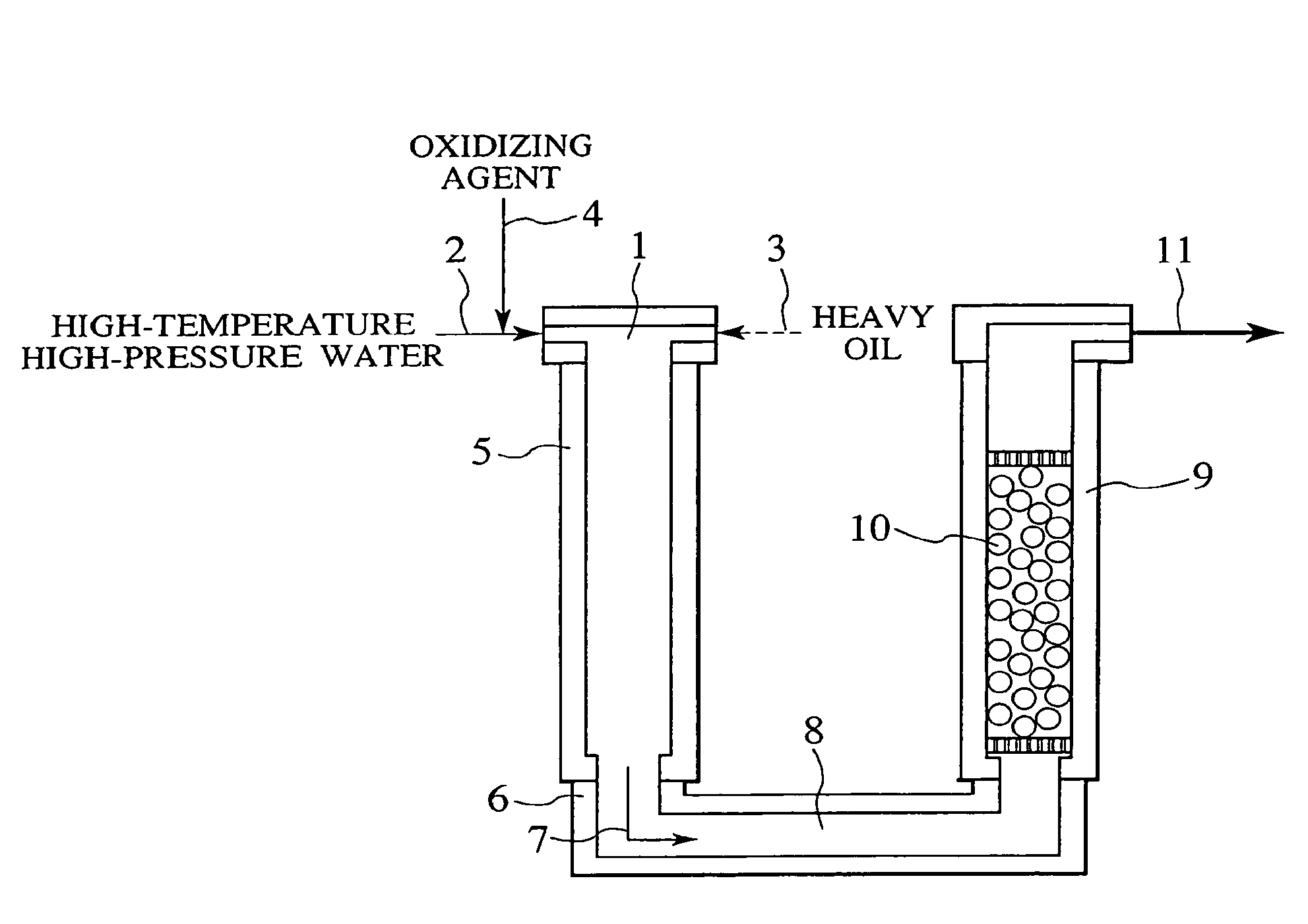

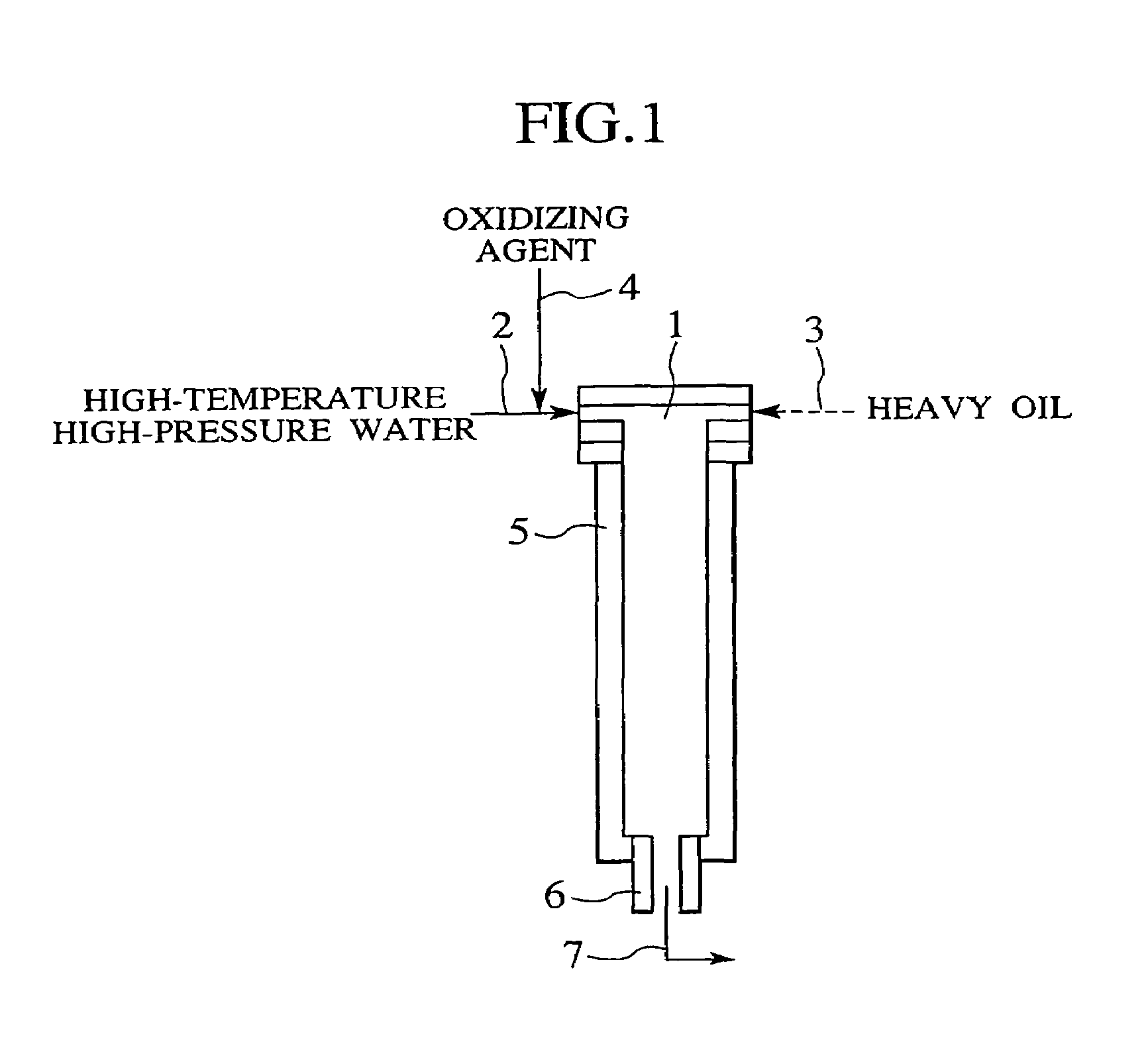

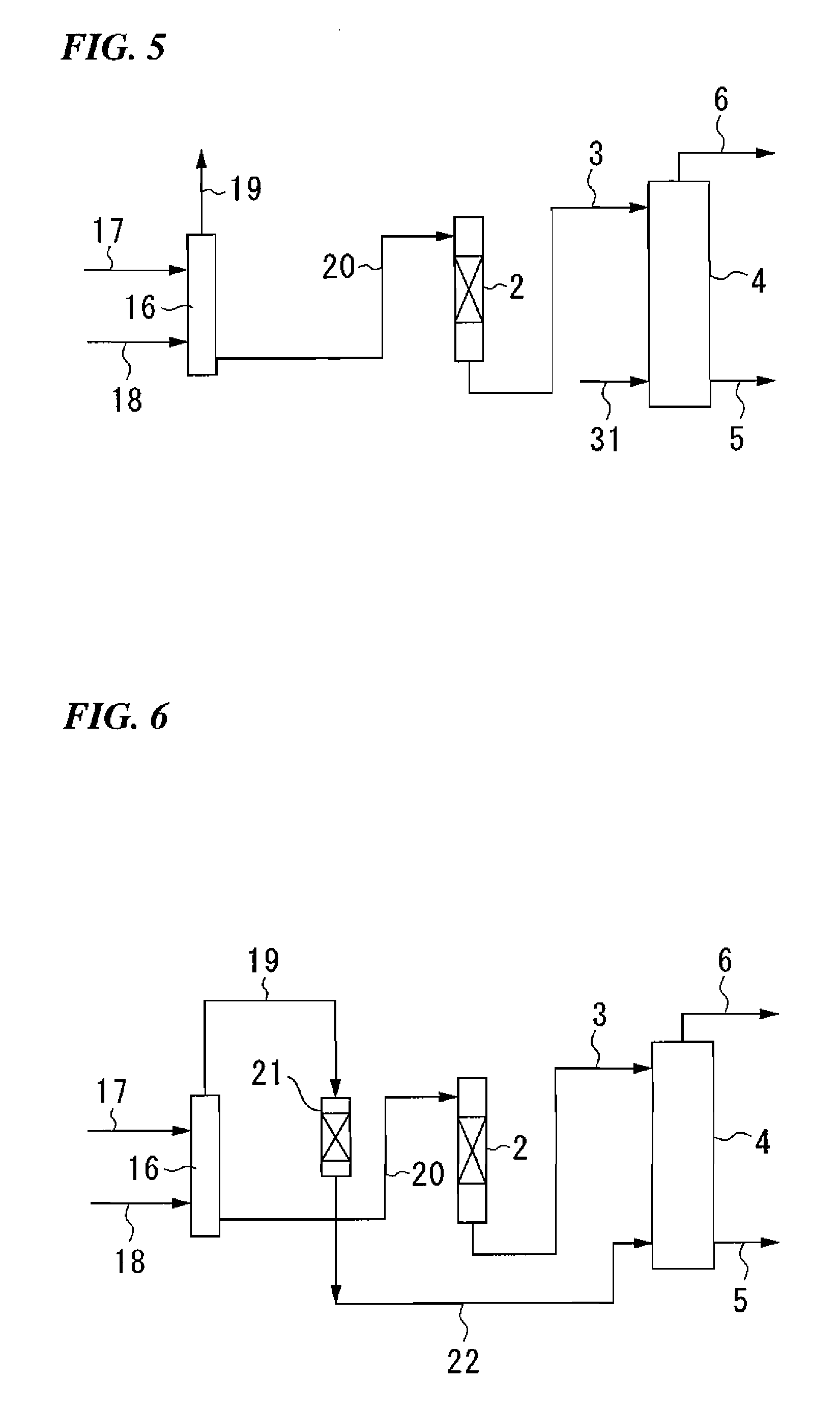

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure having permeable walls and associated systems

ActiveUS20080190815A1Easy to produceLarge movementThermal non-catalytic crackingUnderground chambersHydrocotyle bowlesioidesEngineering

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume having substantially permeable side walls and a substantially impermeable cap. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom without contamination or substantial leaching of materials outside of the impoundment. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS7862705B2Low costHigh outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

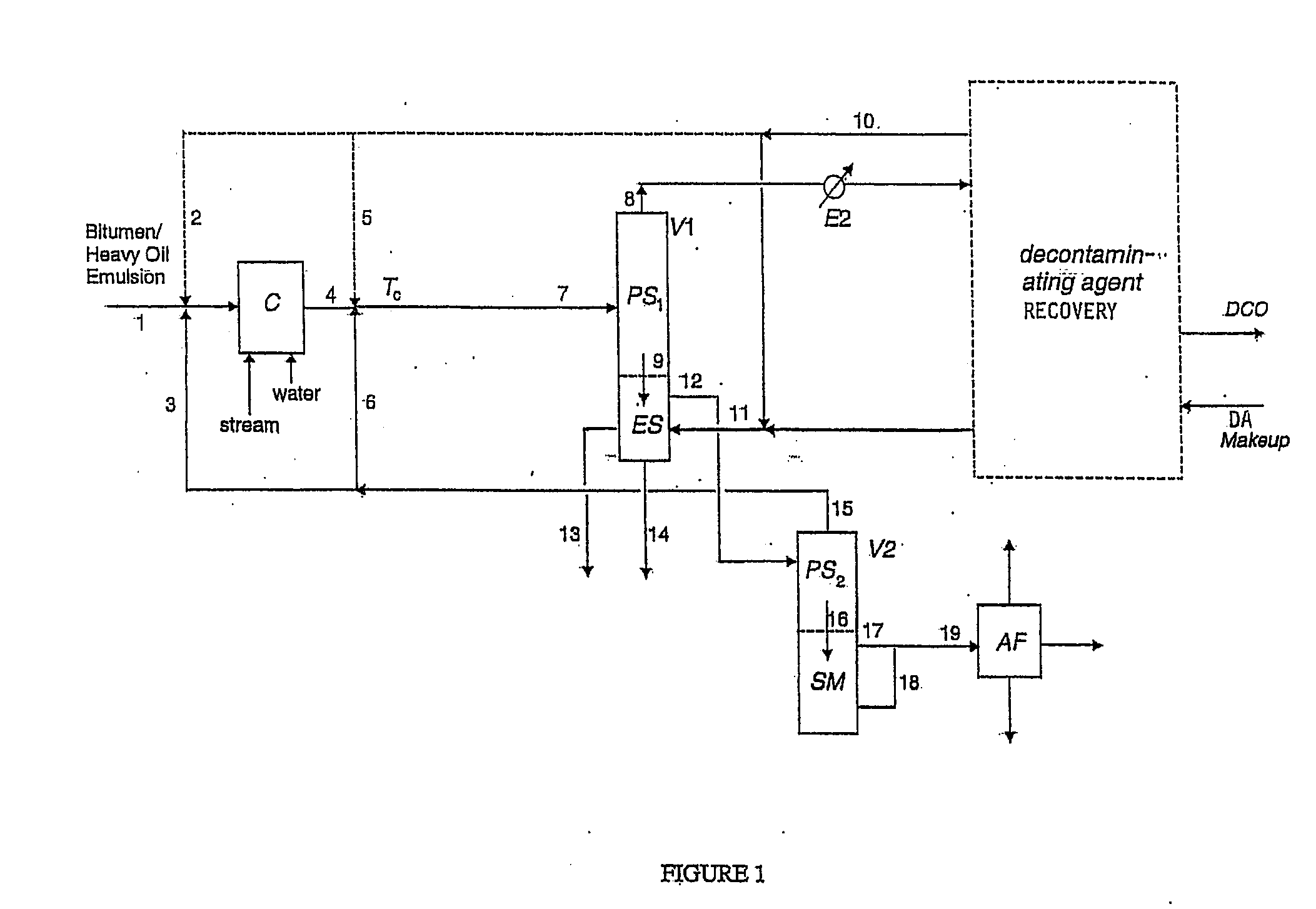

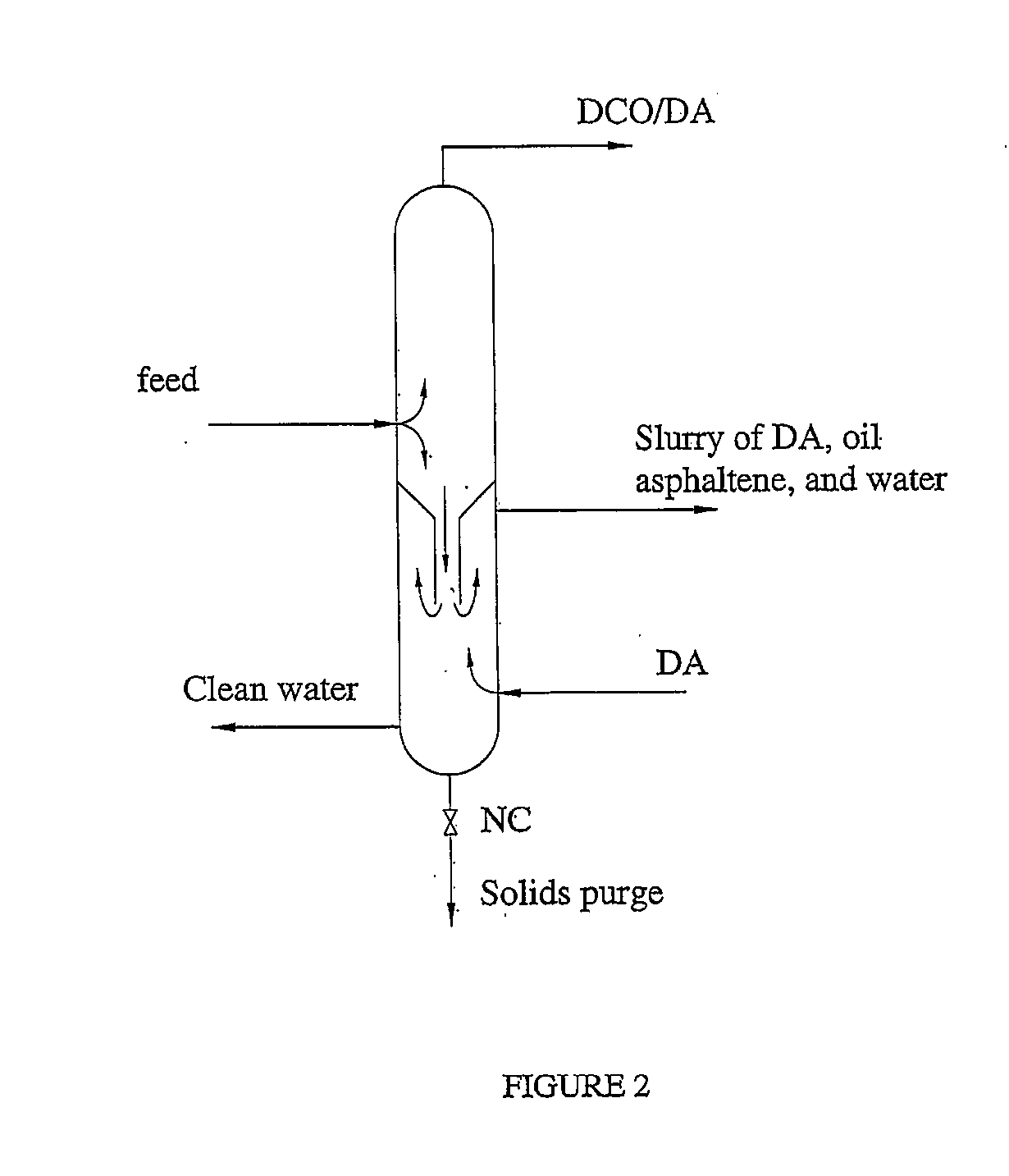

Decontamination of asphaltic heavy oil and bitumen

ActiveUS20060260980A1Distillation regulation/controlHydrocarbon distillationPetroleum productFuel oil

Owner:VALUE CREATION +1

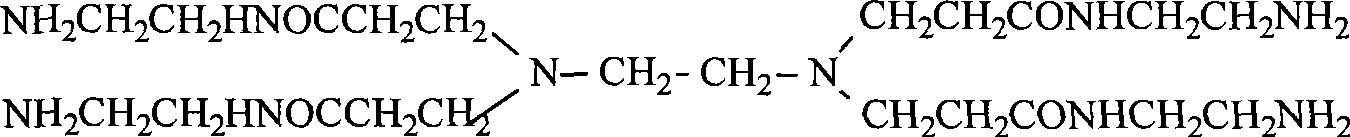

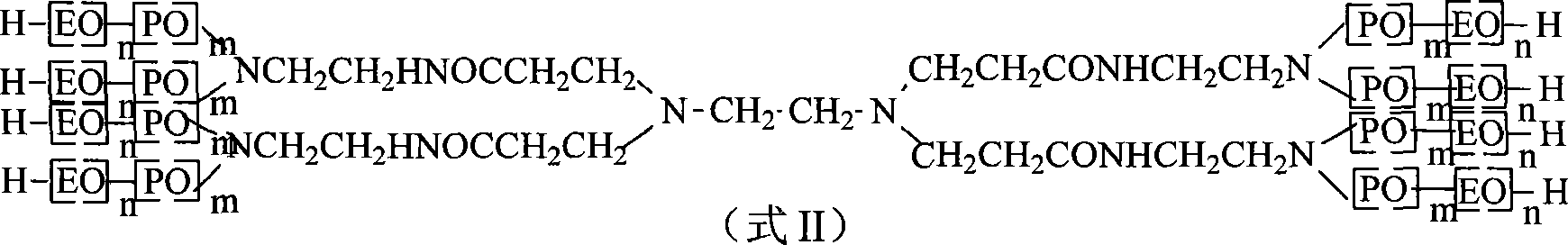

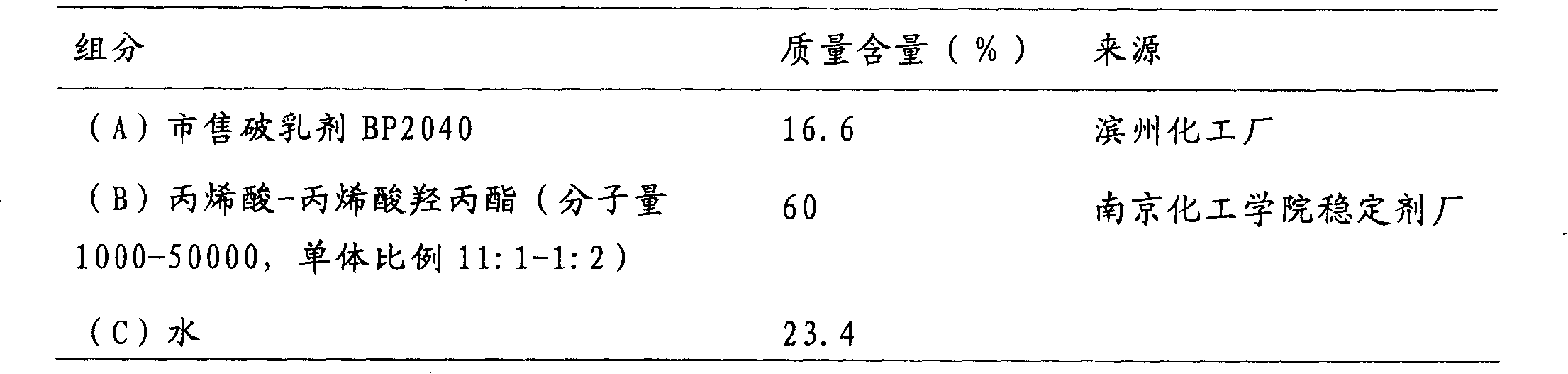

Crude de-emulsifier and its preparing process

InactiveCN101418230AHigh molecular weightImprove surface propertiesHydrocarbon oil dewatering/demulsificationEpoxyEmulsion

The invention discloses a de-emulsifying agent and a method for preparing the same. The de-emulsifying agent is a polyether compound prepared by alkoxylation reaction of poly (amidoamine) (PAMAM) and epoxy compounds. The invention adopts the PAMAM with a dendritic multi-branch structure as an initiator for synthesis the de-emulsifying agent. The obtained de-emulsifying agent has the characteristics of a plurality of branched and large molecular weight. The de-emulsifying agent has good interfacial activity, infiltrability, good crude oil emulsion de-emulsifying performance, and wide applications in crude oil exploration, oil refining and other fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

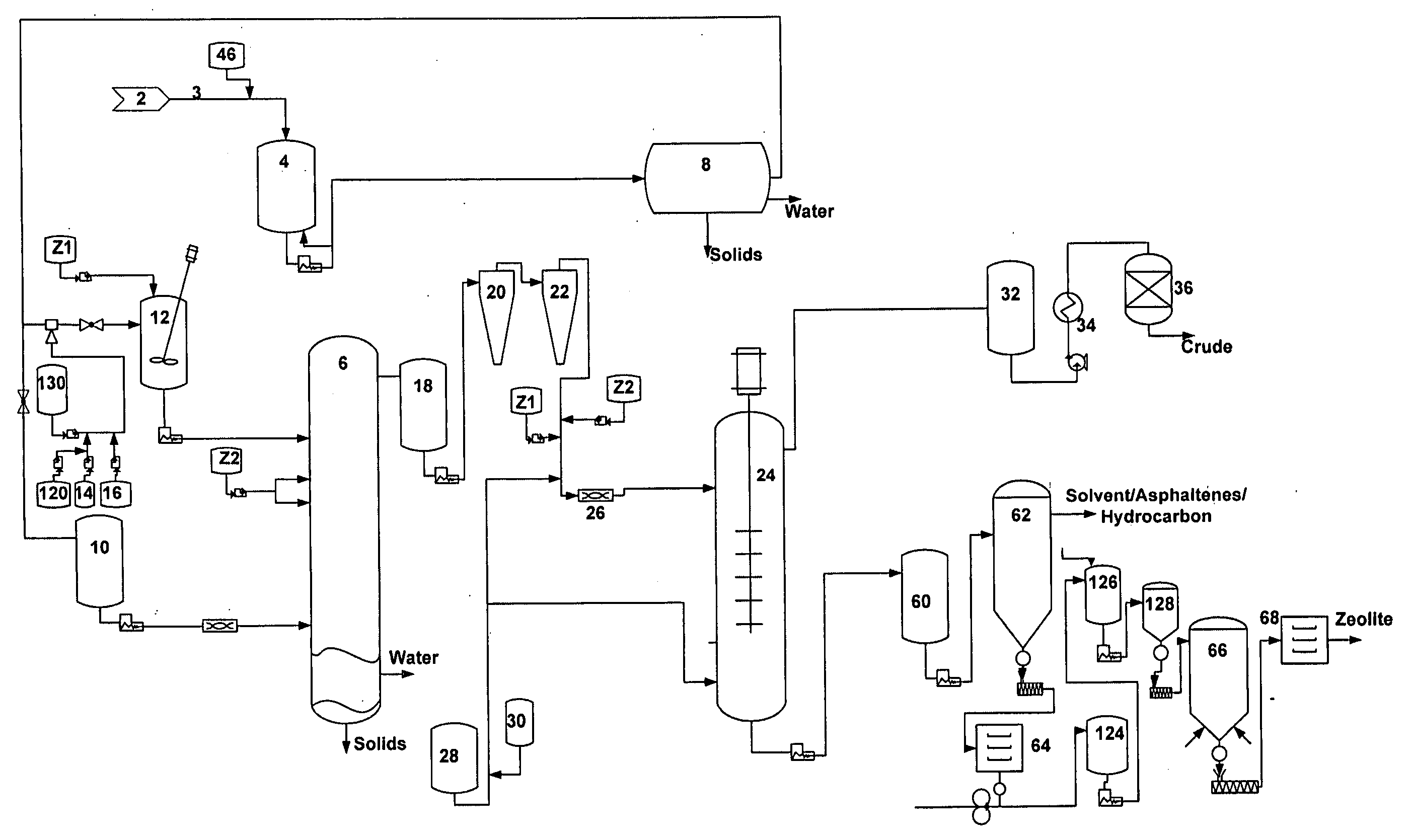

Processing unconventional and opportunity crude oils using zeolites

InactiveUS20060272983A1Hydrocarbon oil dewatering/demulsificationHydrocarbon oils refiningImpurityOil sands

The disclosed process removes or reduces impurities such as asphaltenes, solids (especially solid fines), sulfur, metals, chlorides, water, salts, and acids from bitumen, oil sands, and crude oils with a wide range of gravities. A crude source composition is contacted with one or more zeolite materials to remove asphaltenes, solids, sulfur, NSO, metals, chlorides, water, salts, and / or acids from the composition. The crude source is typically diluted with a hydrocarbon solvent such as naphtha before contacting the zeolite(s). The disclosed processes represent an improvement over prior and presently available processes because the disclosed processes are capable of processing emulsions.

Owner:DROUGHTON CHARLOTTE R +1

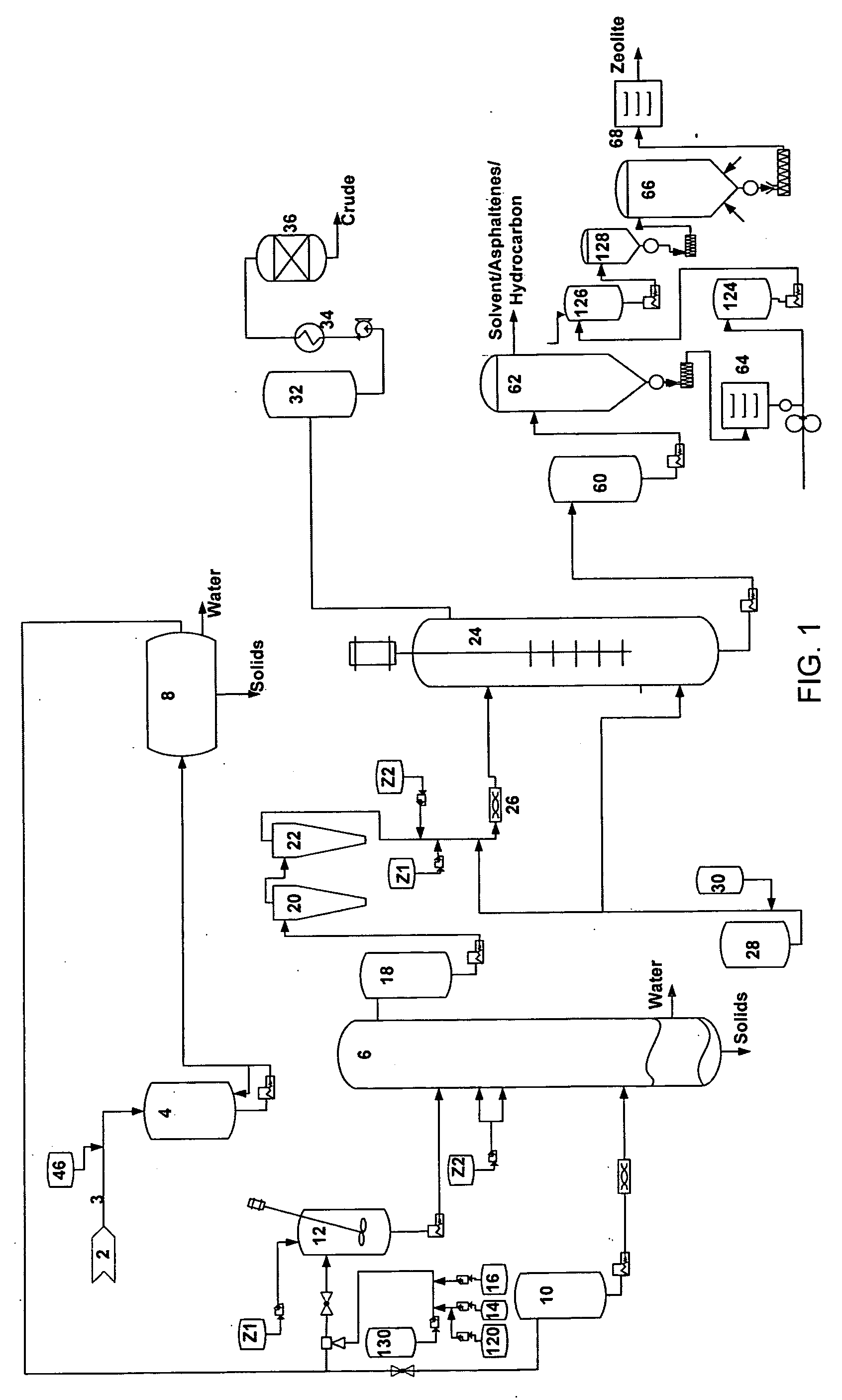

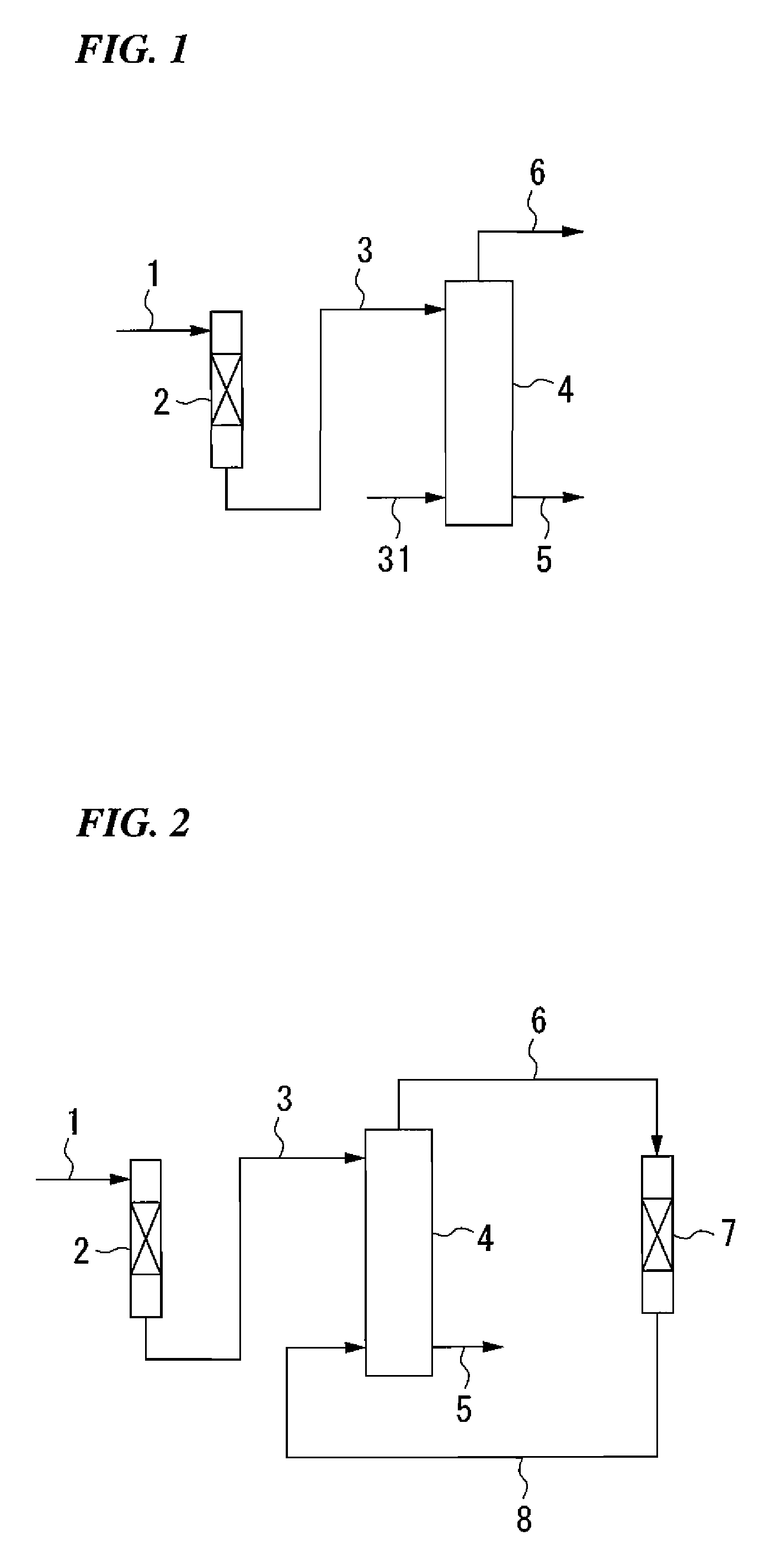

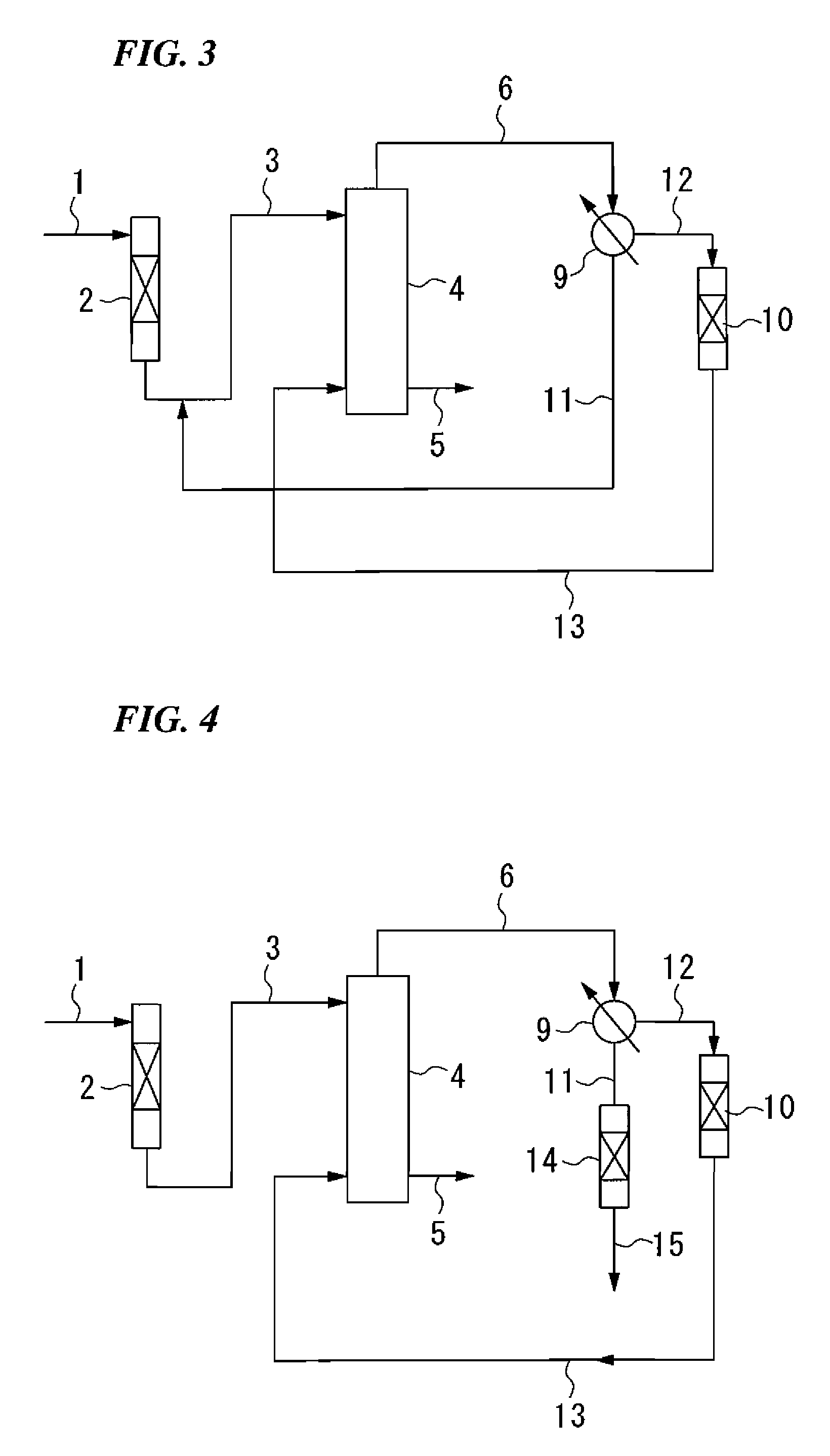

Mercury removal apparatus for liquid hydrocarbon

InactiveUS20100025184A1Easy to useComponent can be removedPhysical/chemical process catalystsUsing liquid separation agentLiquid stateLiquid hydrocarbons

A mercury removal apparatus for a liquid hydrocarbon of the present invention includes a conversion device 2 which converts a mercury component in a raw liquid hydrocarbon into elemental mercury to obtain a first liquid hydrocarbon containing the elemental mercury; and a first stripping device 4 which brings the first liquid hydrocarbon into counter-current contact with a first stripping gas, thereby transferring the elemental mercury in the first liquid hydrocarbon to the first stripping gas to obtain a second liquid hydrocarbon in which the amount of the elemental mercury decreases and a first gaseous hydrocarbon containing the elemental mercury.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD +1

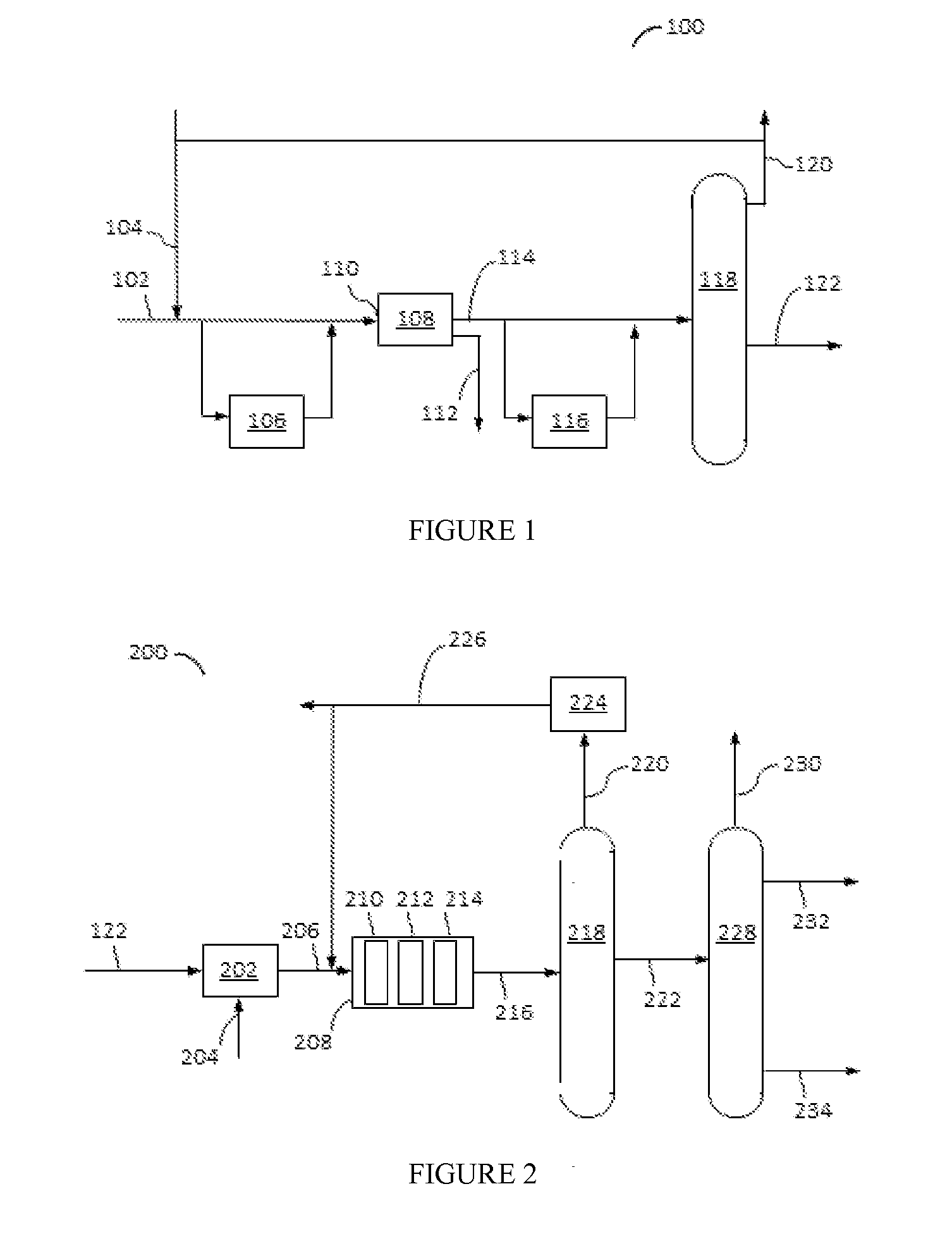

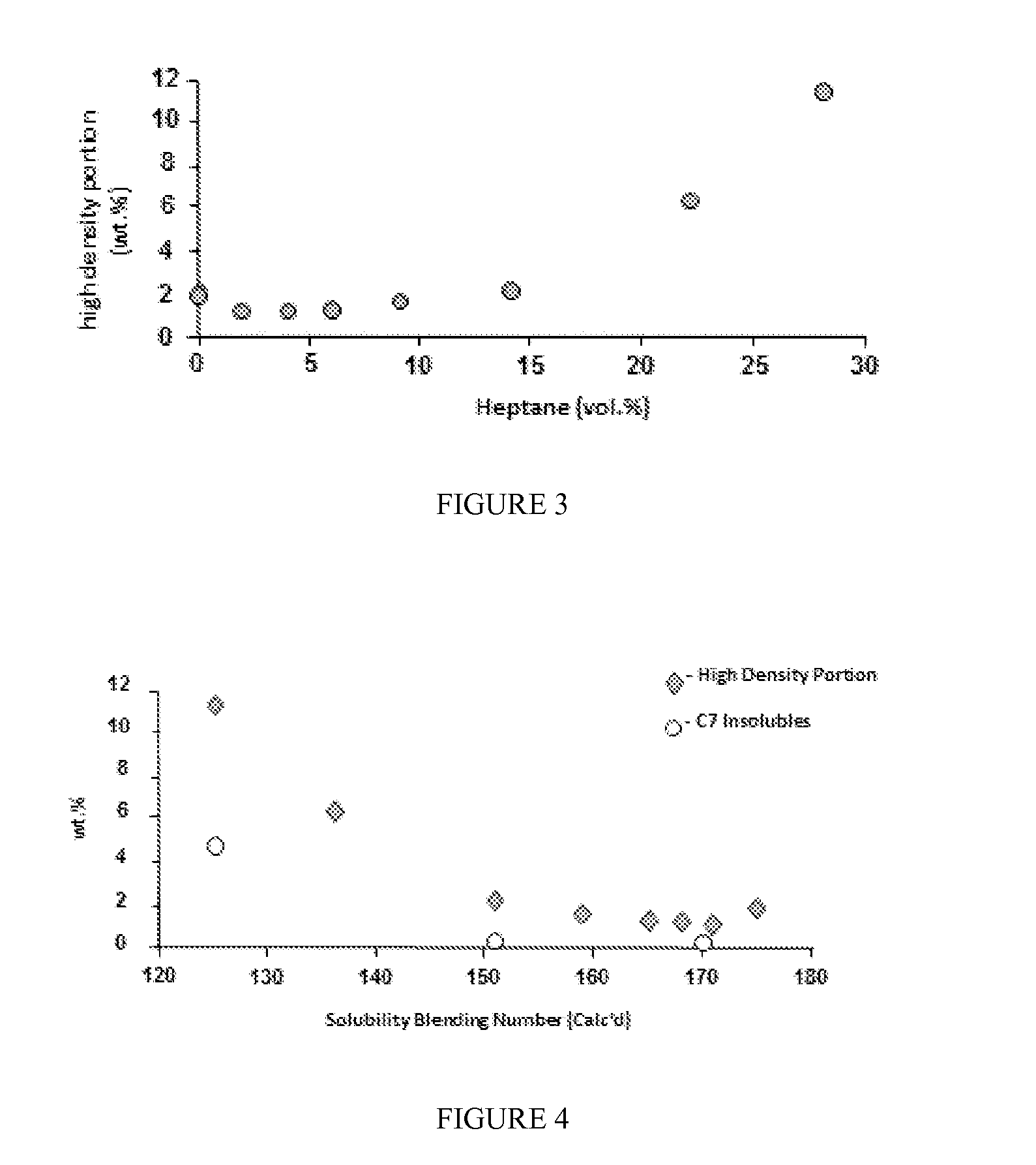

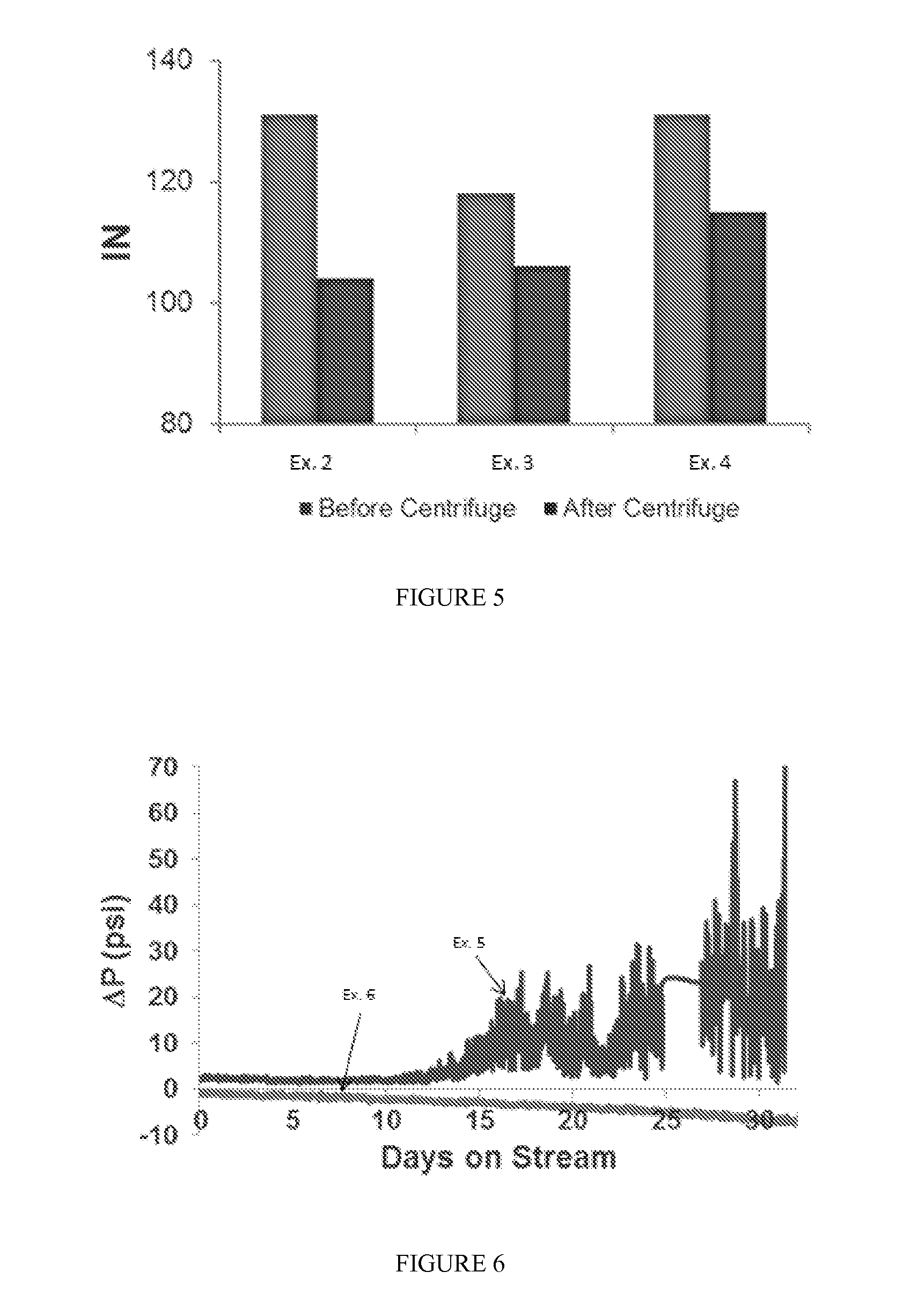

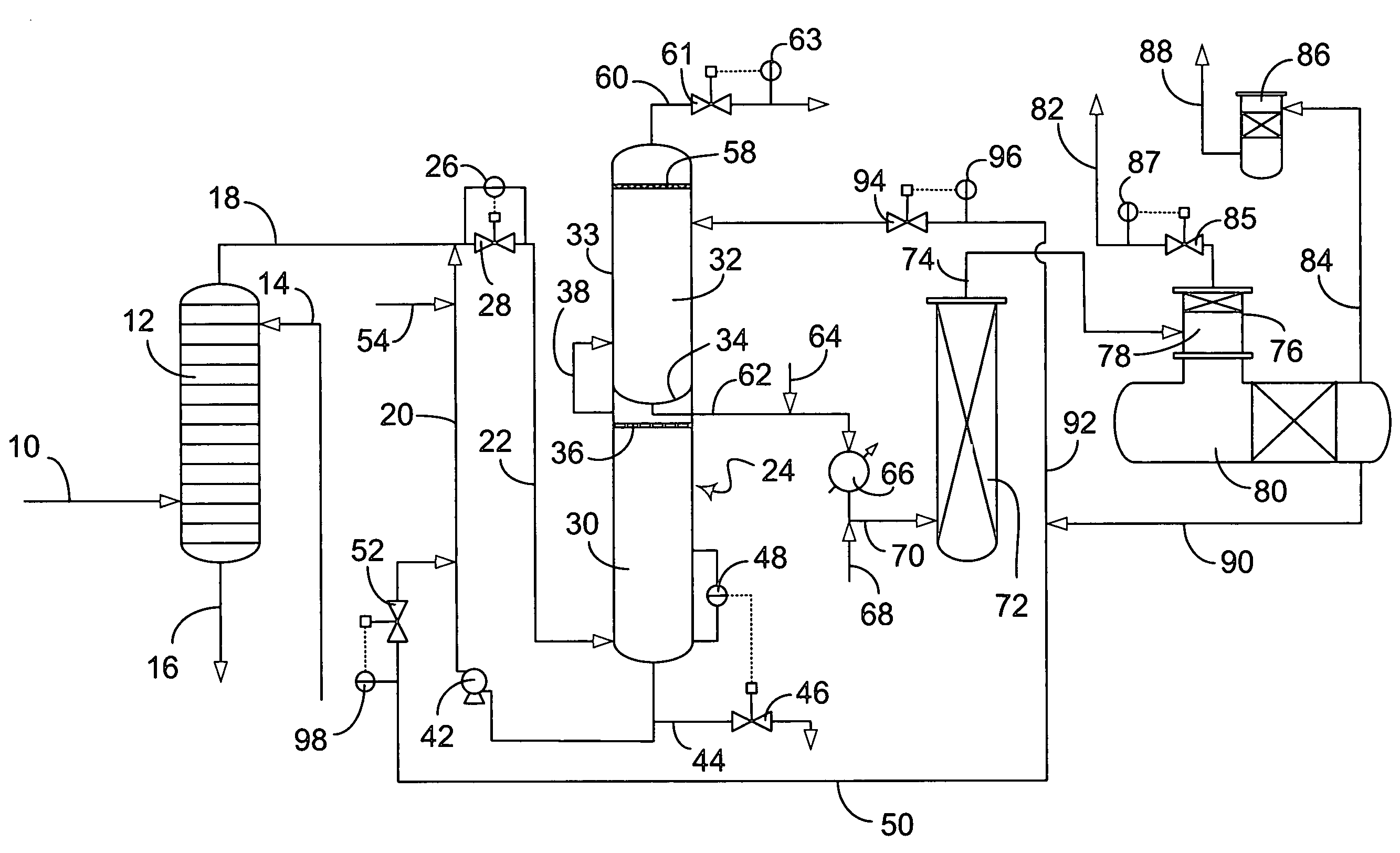

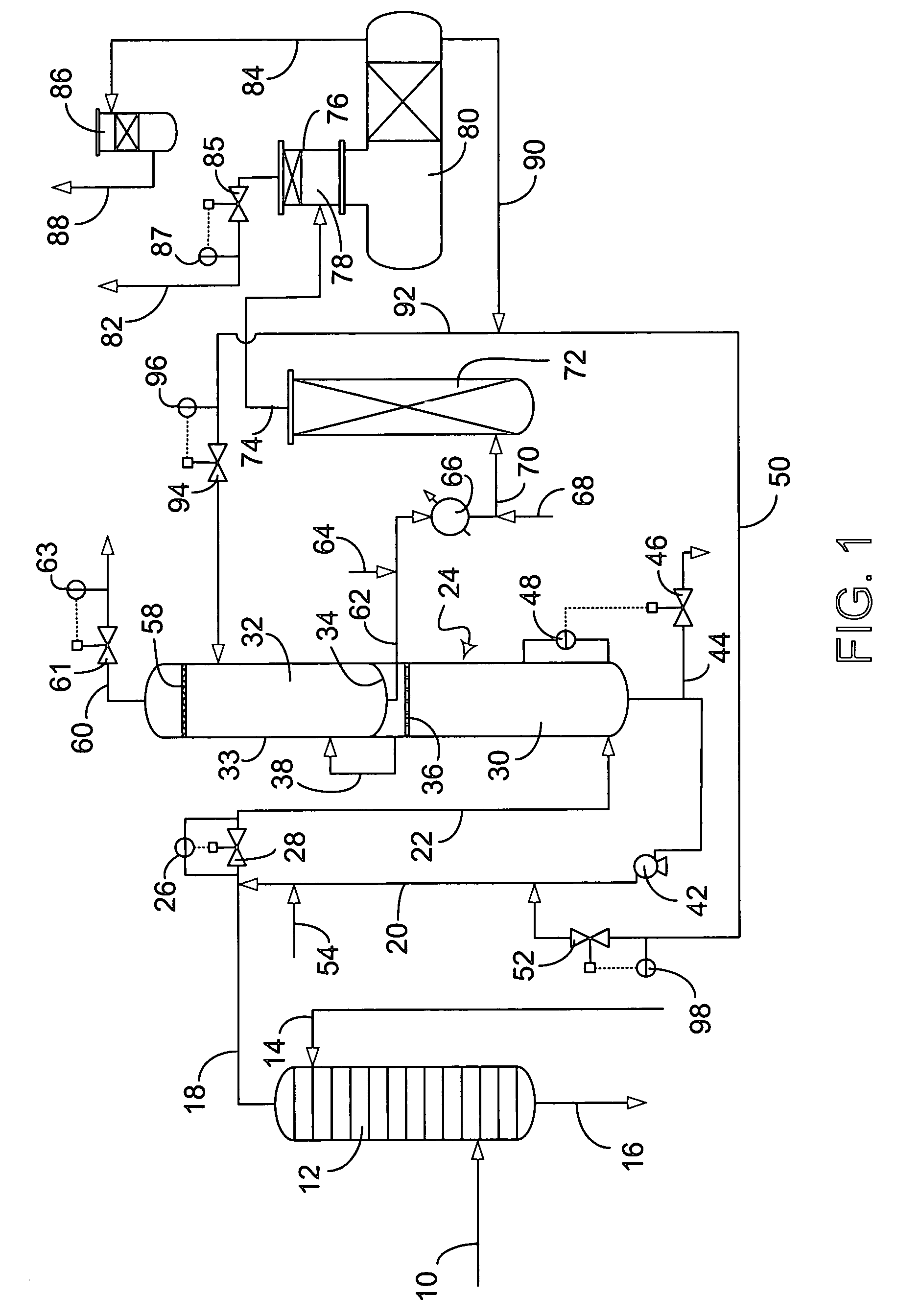

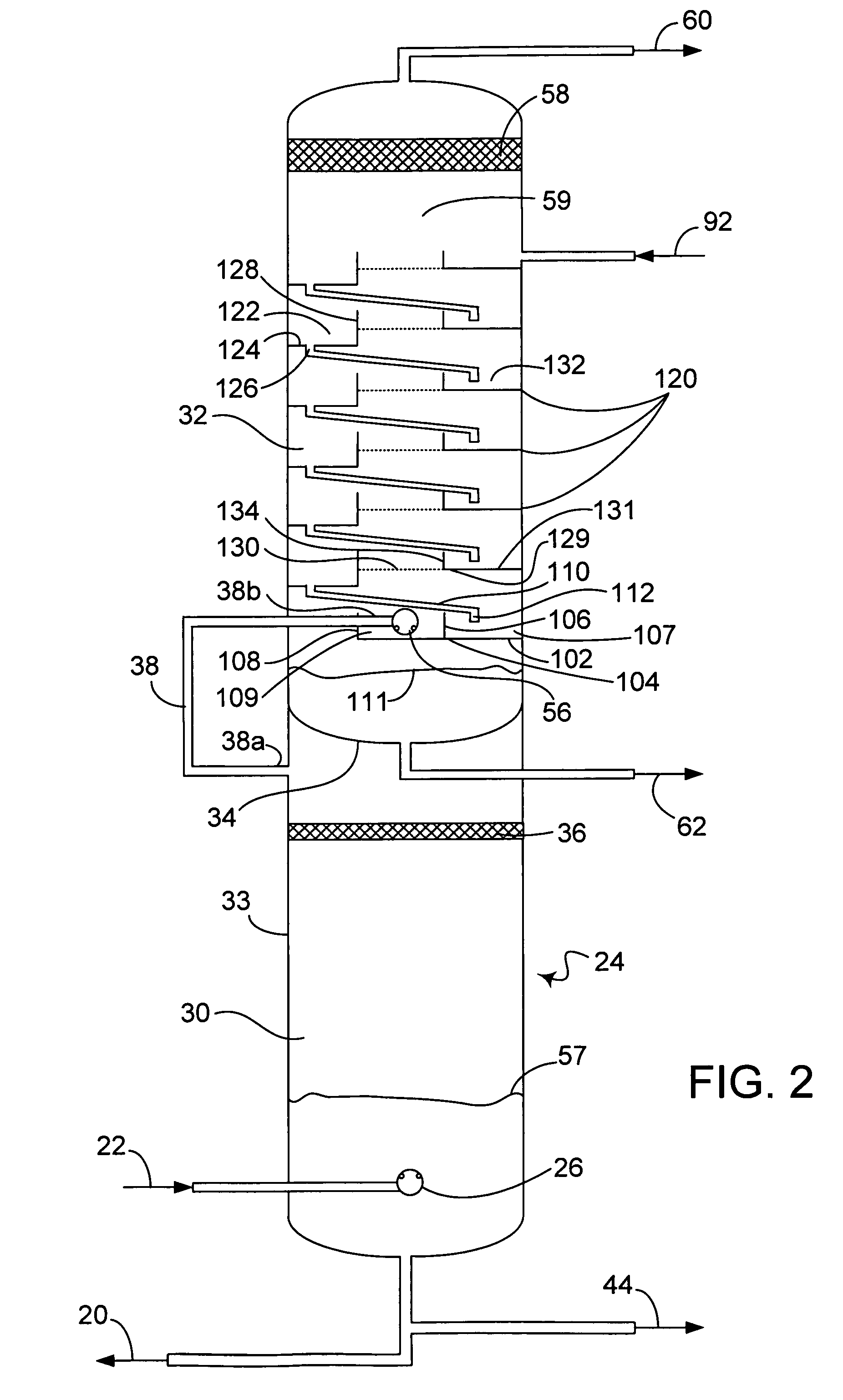

Method and Apparatus for Improving A Hydrocarbon Feed

ActiveUS20150361354A1Improve compatibilityImprove scalabilityTreatment with plural serial stages onlyRotary centrifugesHigh densityVolumetric Mass Density

Methods for upgrading a hydrocarbon feed are disclosed. The methods include a hydrocarbon feed having an insolubility number, Ifeed, with at least a first fluid to form a fluid-feed mixture; and inducing a centrifugal force to the fluid-feed mixture sufficient to form at least a higher density portion and a lower density portion, said lower density portion having an insolubility number, ILD, wherein ILD / Ifeed≦0.95. Methods and apparatus for hydroprocessing the treated feed and blending with a fuel oil blend-stock are also described.

Owner:EXXONMOBIL CHEM PAT INC

Apparatus for prewashing a hydrocarbon stream containing hydrogen sulfide

Disclosed is an apparatus for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic prepares the hydrocarbon stream for extraction. Spent alkali is continuously withdrawn and regenerated alkali is continuously added to the prewash section.

Owner:UOP LLC

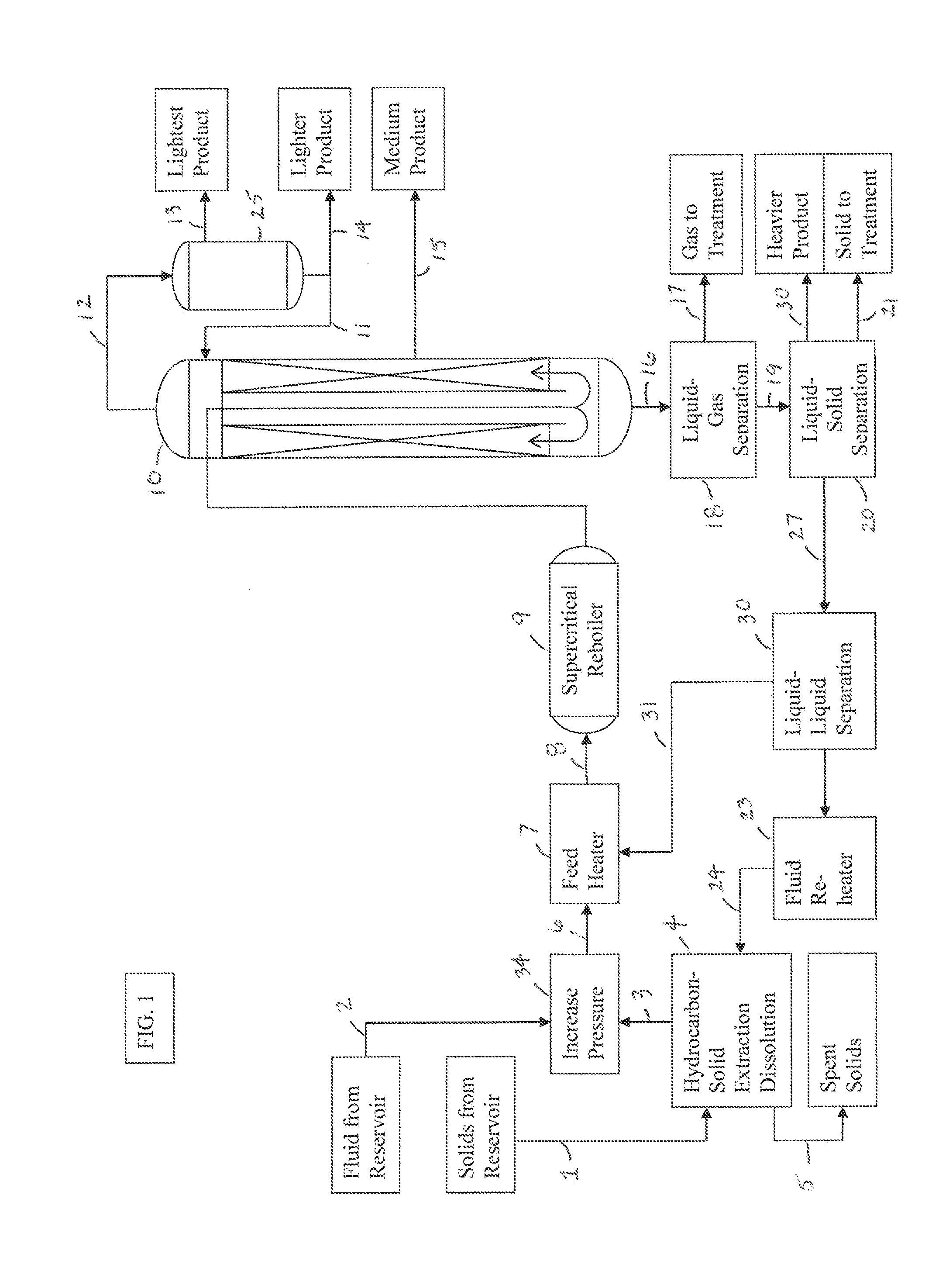

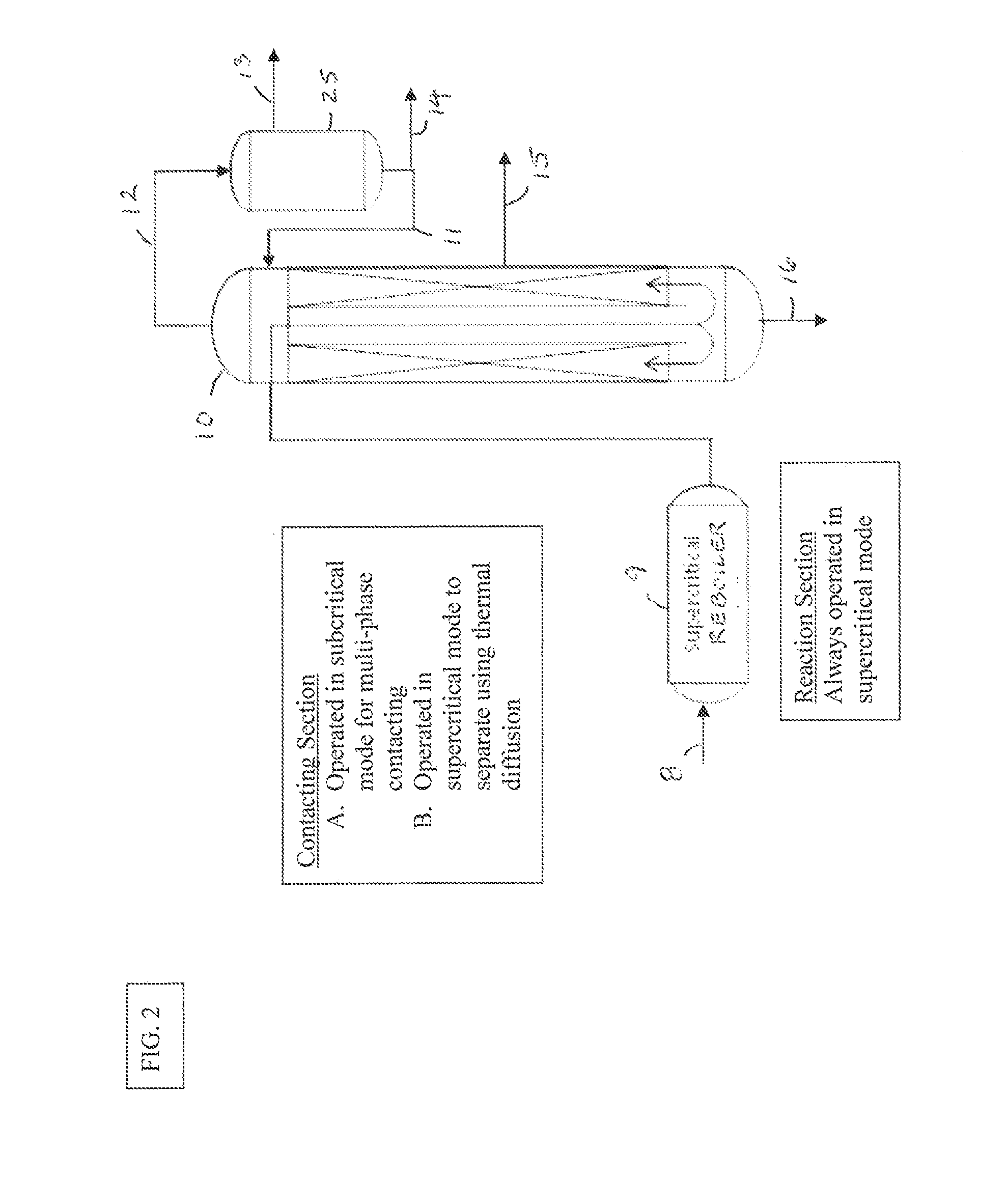

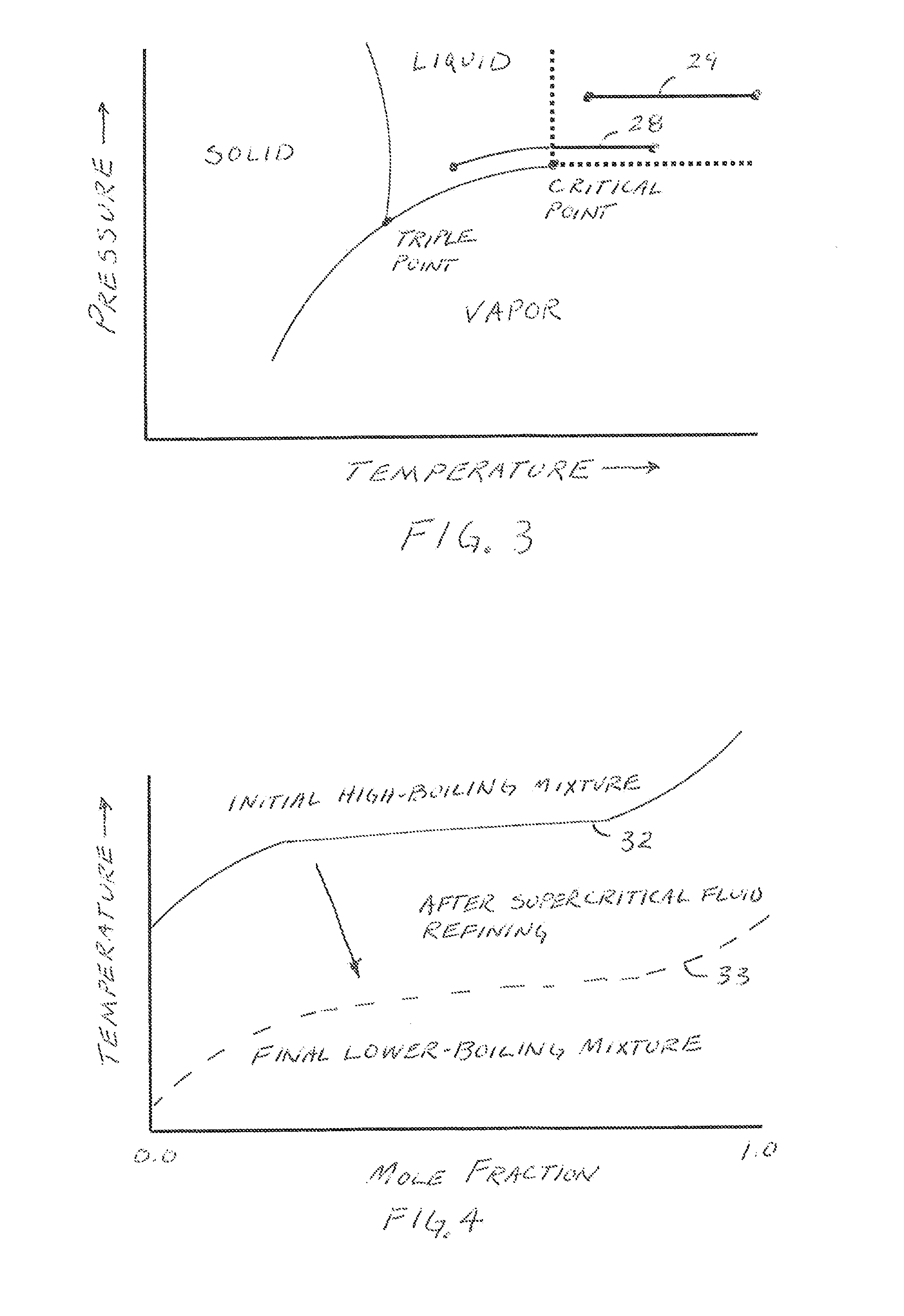

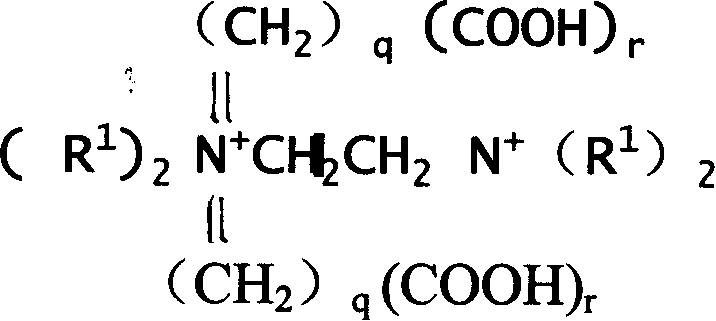

Using supercritical fluids to refine hydrocarbons

ActiveUS20110163011A1Light weightImprove securityRefining by water treatmentLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesAPI gravity

This is a method to reactively refine hydrocarbons, such as heavy oils with API gravities of less than 20° and bitumen-like hydrocarbons with viscosities greater than 1000 cp at standard temperature and pressure using a selected fluid at supercritical conditions. The reaction portion of the method delivers lighter weight, more volatile hydrocarbons to an attached contacting device that operates in mixed subcritical or supercritical modes. This separates the reaction products into portions that are viable for use or sale without further conventional refining and hydro-processing techniques. This method produces valuable products with fewer processing steps, lower costs, increased worker safety due to less processing and handling, allow greater opportunity for new oil field development and subsequent positive economic impact, reduce related carbon dioxide, and wastes typical with conventional refineries.

Owner:HEAVY OIL SOLUTIONS INC

Cryogenic dewatering demulsifier of crude-oil extract

A low-temperature crude-oil extract dewatering demulsifier consists of polyamines polyoxytrimethylene polyethenoxy ether 10-15wt%, alkyl phenolic resin polyoxytrimethylene polyethenoxy ether 30-40wt%, polyethyl-polyamines polyoxytrimethylene polyethenoxy ether 10-15wt%, FC-NO1 fluorocarbon surface active agent 0.05-0.2wt%, methanol 20-25wt% and water 15-22wt%. The crude-oil dewatering temperature is between 25-35degree, additive amount is between 50-80mg / l, water content is <0.2% and oil content of sewage is <500mg / l.

Owner:PETROCHINA CO LTD

Base oildeemulsifier in high performance

ActiveCN101050380ASimple processMild operating conditionsHydrocarbon oil dewatering/demulsificationDemulsifierProton

This invention discloses a method for synthesizing a high-efficiency crude oil demulsifier from cornstarch and conventional polyether demulsifier by graft copolymerization. The method comprises: (1) adding solvent and cornstarch into a reaction kettle with a stirrer, slowly adding proton acid (20-80 wt.% of cornstarch), and stirring for 1-4 h; (2) adding polyether demulsifier and solvent, and refluxing under heating for 2-8 h; (3) adding NaOH solution for neutralization, ending NaOH addition when the pH value is 6.5-8.0, and reacting for 1-3 h until the solution is transparent. The demulsifier has such advantages as simple process, mild operation conditions, wide applications, and good demulsification effect.

Owner:DAQING HUAYING CHEM IND

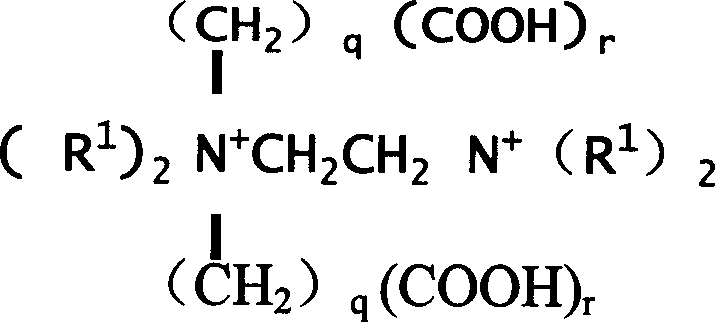

Method for preparing multifunctional deemulsifying agent of crude oil and products thereof

InactiveCN1600835AImprove surface activityImprove wettabilityHydrocarbon oil dewatering/demulsificationEpoxyAlkaline earth metal

This invention provides a method for preparing crude oil demulsification agent for crude oil pretreatment in refinery plant. Said multi-functional demulsification agent has betaine structure, being of amphoteric-ion surfactant. Organic amine is used as initiator, and epoxy propane and epoxy ethane are polymerized to produce polyether, then reacting with alpha-halogenated carboxylic acid to produce said betaine structure product. This produced has advantages of: excellent emulsification ability and dewater ability, on the molecule there are quaternary amido and carboxy group, so having excellent wetting function, and having good complexation stability to alkaline earth metals in crude-oil, being of calcium-disperser, and having excellent function for removing magnesium and iron.

Owner:PETROCHINA CO LTD

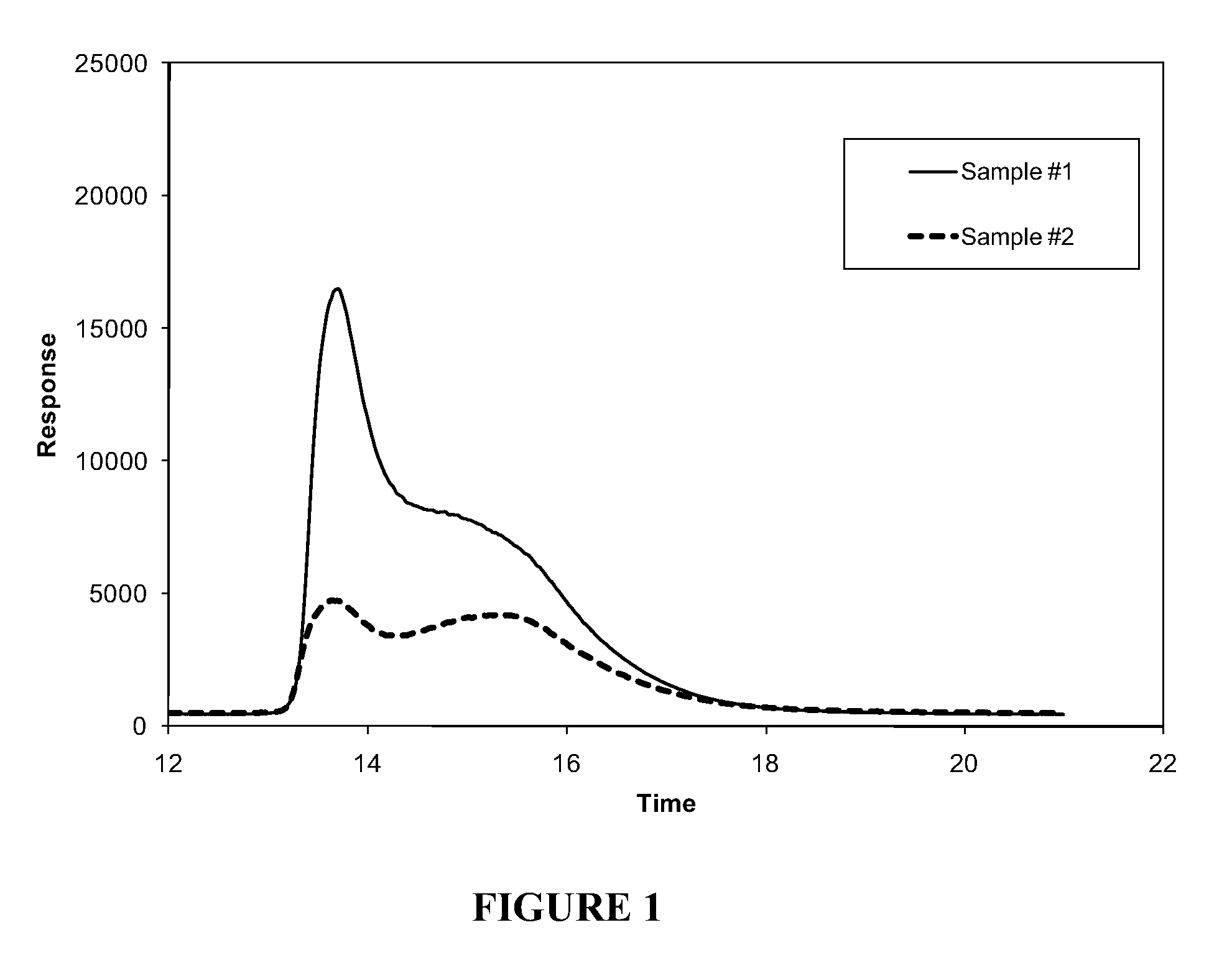

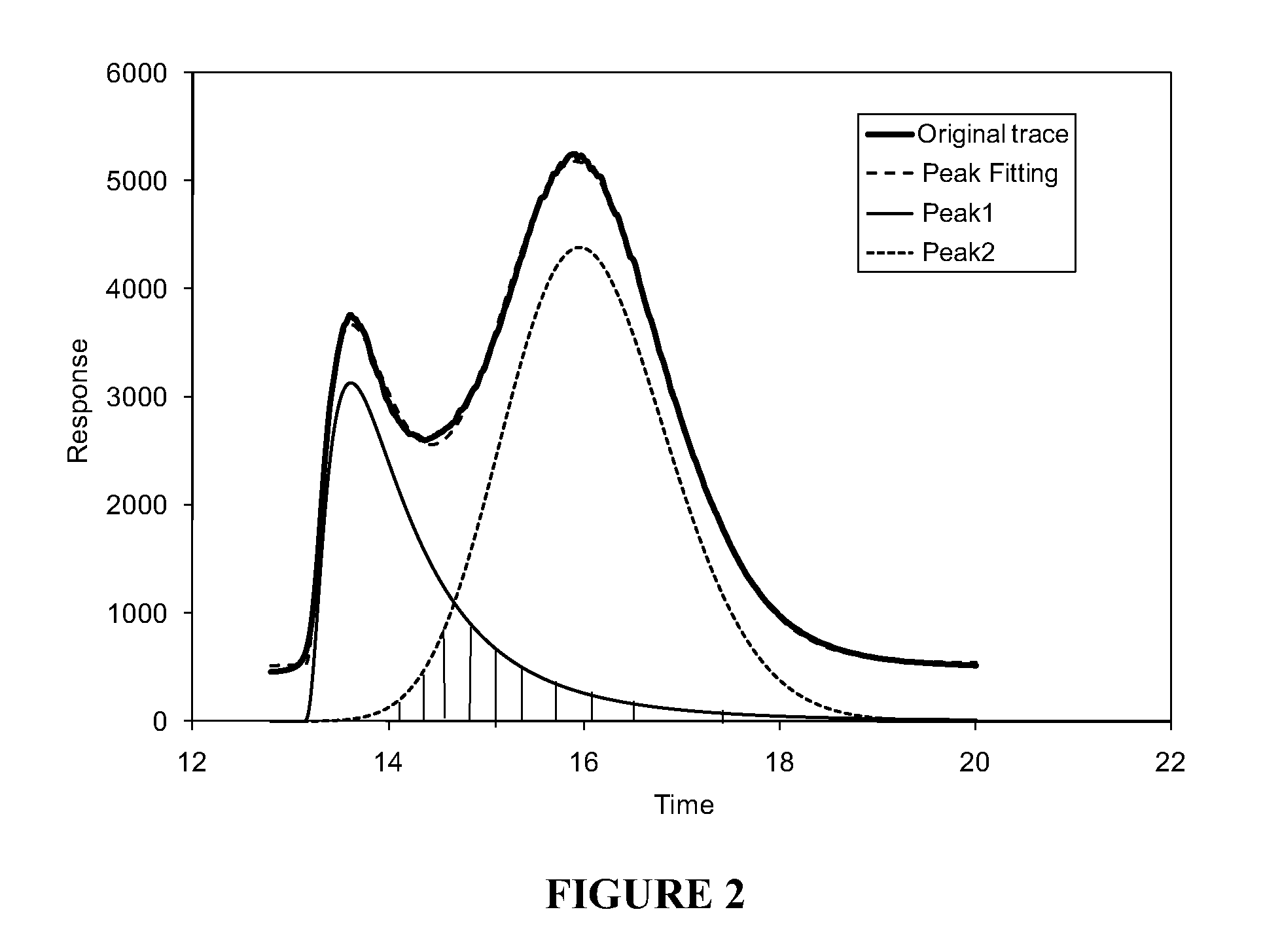

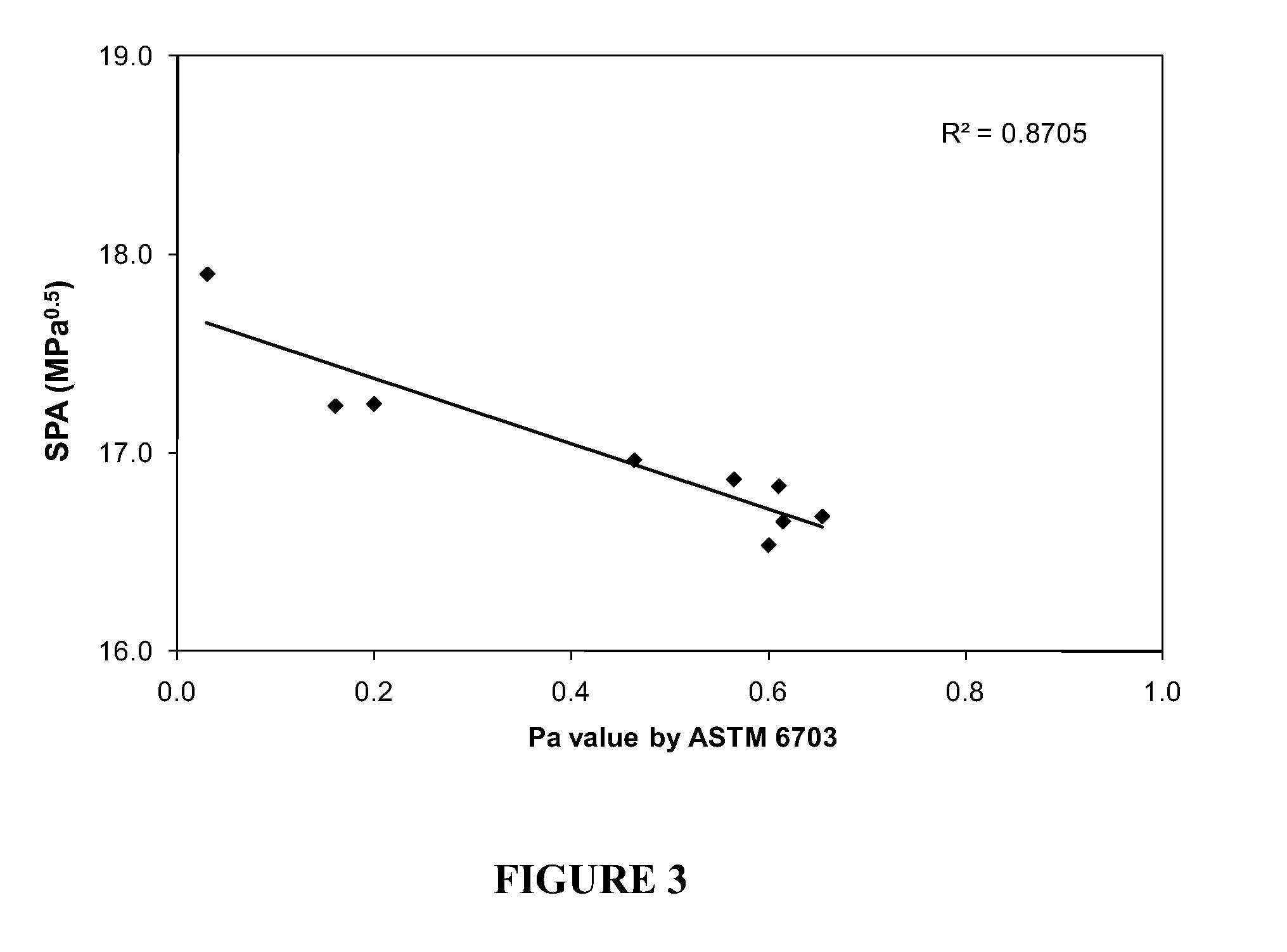

Method for determining asphaltene stability of a hydrocarbon-containing material

InactiveUS20110062058A1Low costWell representedThermal non-catalytic crackingData processing applicationsAlkaneSolubility

A method for determining asphaltene stability in a hydrocarbon-containing material having solvated asphaltenes therein is disclosed. The method involves the steps of: (a) precipitating an amount of the asphaltenes from a liquid sample of the hydrocarbon-containing material with an alkane mobile phase solvent in a column; (b) dissolving a first amount and a second amount of the precipitated asphaltenes by gradually and continuously changing the alkane mobile phase solvent to a final mobile phase solvent having a solubility parameter at least 1 MPa0.5 higher than the alkane mobile phase solvent; (c) monitoring the concentration of eluted fractions from the column; (d) creating a solubility profile of the dissolved asphaltenes in the hydrocarbon-containing material; and (e) determining one or more asphaltene stability parameters of the hydrocarbon-containing material.

Owner:CHEVROU USA INC

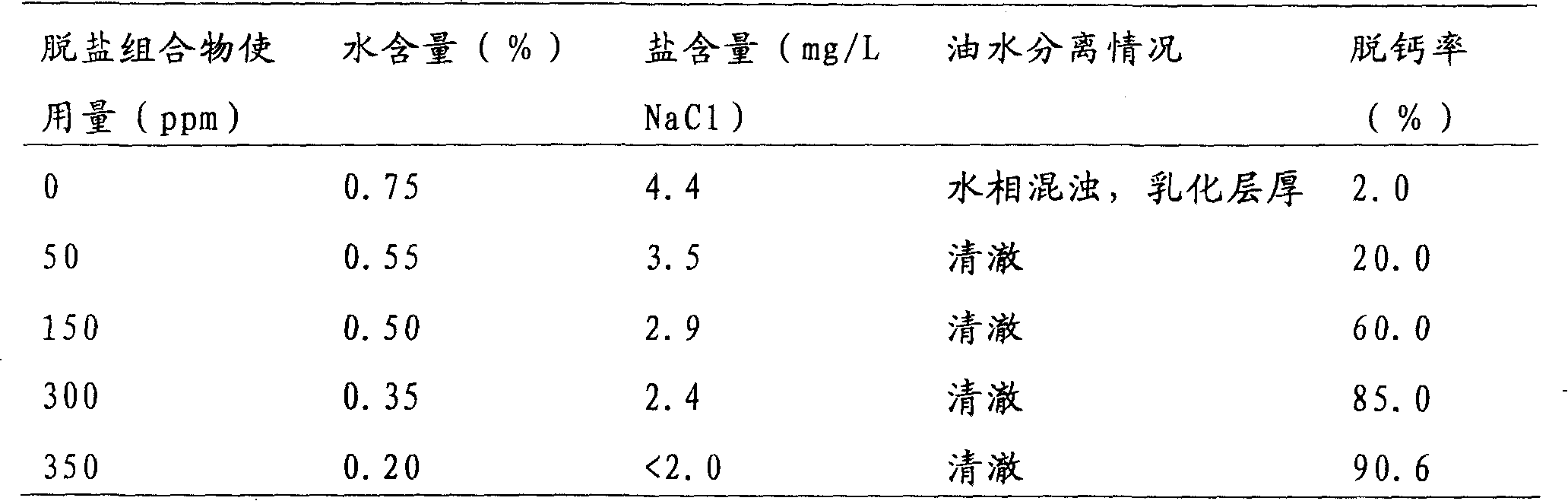

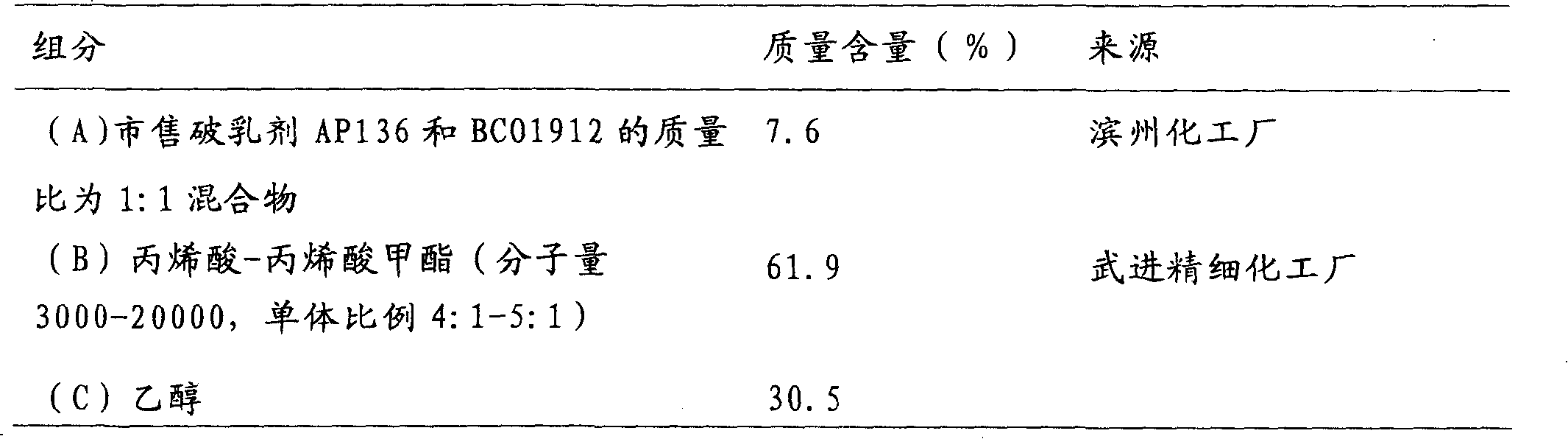

Crude oil desalting composition and method of use thereof

ActiveCN101205482AGood metal removal effectDestabilizingHydrocarbon oil dewatering/demulsificationHydrocarbon oils refiningSolventCrude oil

The invention provides a crude oil desalinization compound, comprising the following components by weight percent: 0 to 95 percent of emulsifying agent, 1 to 90 percent of one or more than one carboxylic acid plymer, or one or more than one organic phosphine compound or the mixture of the organic phosphine compound and 4 to 94 percent of solvent. The invention also provides a method of desalinating the crude oil, particular the acid containing crude oil, by using the desalinization compound. The invention is suitable for the desalinization of the crude oil, particular the acid containing crude oil and the inferior high acid number and high salt crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-temperature quick deemulsifying agent for water-containing wax-containing erude oil and its preparation method

InactiveCN1537924AFast dehydrationGood demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationEpoxyOil processing

Owner:SHANDONG UNIV

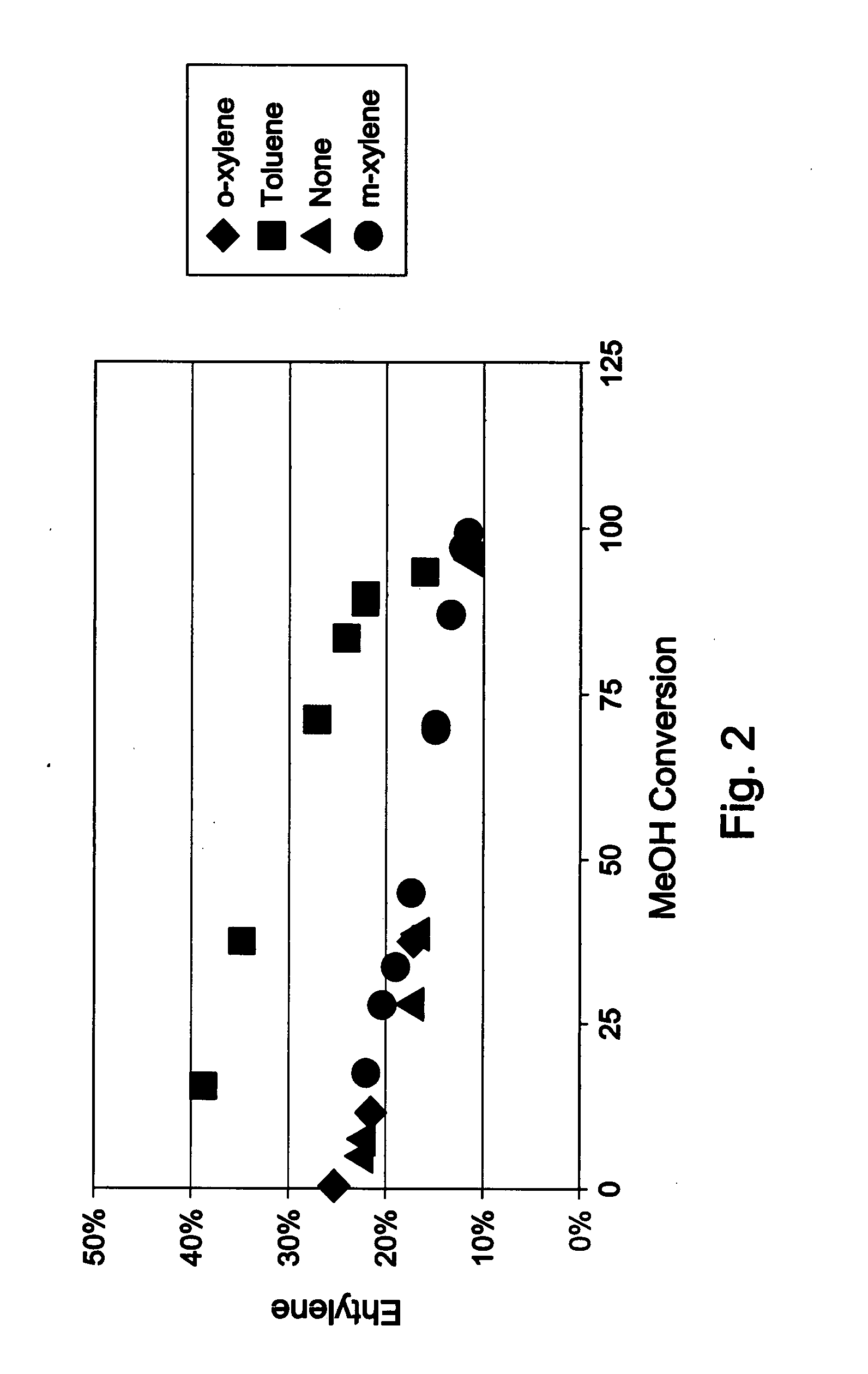

Process of manufacturing para-xylene

InactiveUS20090000988A1Reduce diffuseCatalytic naphtha reformingHydrocarbon from oxygen organic compoundsMolecular sieveMethylating Agent

This disclosure relates to a process of manufacturing para-xylene, comprising (a) contacting a pygas feedstock and methylating agent with a catalyst under reaction conditions to produce a product having para-xylene, wherein the product has higher para-xylene content than the para-xylene content of the pygas feedstock; and (b) separating the para-xylene from the product of the step (a), wherein the catalyst comprises a molecular sieve having a Diffusion Parameter for 2,2-dimethylbutane of about 0.1-15 sec−1 when measured at a temperature of 120° C. and a 2,2-dimethylbutane pressure of 8 kPa-a and the pygas comprises from about 1 to about 65 wt % benzene and from about 5 to 35 wt % toluene.

Owner:EXXONMOBIL CHEM PAT INC

Polyalkylene epoxy polyamine additives for fouling mitigation in hydrocarbon refining processes

InactiveUS20110147275A1Reduce dirtHydrocarbon oil dewatering/demulsificationHydrocarbon oils refiningEpoxyParticulates

The present invention provides a method for reducing fouling, including particulate-induced fouling, in a hydrocarbon refining process including the steps of providing a crude hydrocarbon for a refining process and adding an antifouling agent containing a polymer base unit and a polyamine group to the crude hydrocarbon. The antifouling agent can be obtained by reacting an epoxidation reagent with a vinyl-terminated polymer, such as polypropylene or poly(ethylene-co-propylene), to form a terminal epoxy group, followed by reacting a polyamine with the epoxy group.

Owner:EXXON RES & ENG CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com