Method for preparing multifunctional deemulsifying agent of crude oil and products thereof

A crude oil demulsifier and multi-functional technology, which is applied in the fields of hydrocarbon oil dehydration/demulsification, petroleum industry, etc., can solve the problem that the decalcifier has no demulsification function and cannot effectively remove alkaline earth metals, etc., and achieves efficient demulsification and dehydration. performance, good compatibility, strong surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Propylene oxide (PO), ethylene oxide (EO) block copolyether

[0017] In a 500ml autoclave equipped with an electric stirrer, add 23.0g of diethylenetriamine and 80ml of mixed xylene, and add 0.2g of potassium hydroxide as a catalyst. Under the condition of heating and stirring, 70.0g of PO and 15.0g of EO are successively introduced, and the reaction temperature The range is 120-140°C, and the reaction pressure is 0.45MPa. After the absorption is complete, the xylene is distilled off under reduced pressure to obtain the desired polyether.

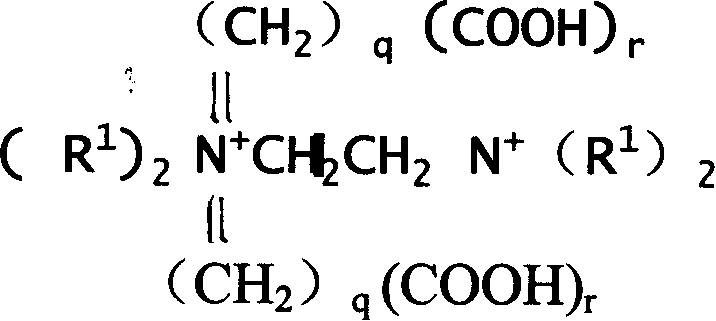

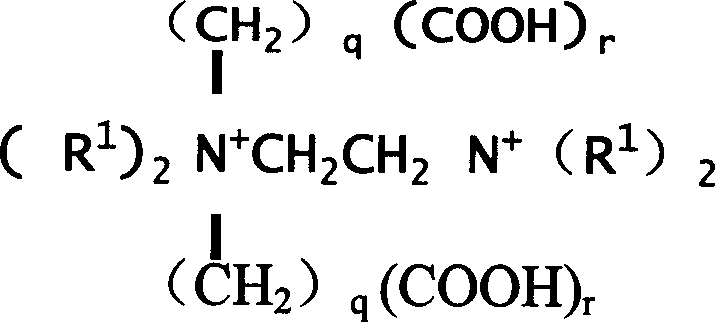

[0018] 2. Synthesis of betaine-type crude oil demulsifier

[0019] In a 500ml three-necked flask with stirring, thermometer, and condenser, add 54.0g of polyether 1 and 220ml of 95% ethanol, carefully add 36.0g of α-haloacetic acid in three batches, reflux for 3 hours after the addition, and remove the white solid in the solution by hot filtration , and then evaporate the ethanol in the filtrate to obtain the product which is the...

Embodiment 2

[0022] The block copolyether was prepared by the method of Example 1. In an autoclave equipped with an electric stirrer, 23.0 g of triethylenetetramine and 80 ml of mixed xylene were added, and 0.2 g of sodium hydroxide was added as a catalyst. Under the condition of heating and stirring, 70.0gPO and 15.0gEO are sequentially introduced, the reaction temperature range is 90-120°C, and the reaction pressure is 0.45MPa. After the absorption is complete, the xylene is evaporated under reduced pressure to obtain the desired polyether.

[0023] In a three-neck flask equipped with stirring, a thermometer, and a condenser, add 54.0 g of the polyether of Example 1 and 200 ml of 95% ethanol, heat to 50° C., and slowly add 49.0 g of α-chloropropionic acid dropwise. After the dropwise addition, the reactant was refluxed for about 2.5 hours to complete the reaction. Remove the white solid by filtration, remove the solvent under reduced pressure and cool the unreacted matter to room tempera...

Embodiment 3

[0028] In a 500ml autoclave equipped with an electric stirrer, add 23.0g of ethylenediamine and 80ml of mixed xylene, and add 0.2g of potassium hydroxide as a catalyst. Under the condition of heating and stirring, 70.0g of PO and 15.0g of EO are successively introduced. The reaction temperature range 130-150°C, the reaction pressure is 0.15MPa, after the absorption is complete, distill the xylene under reduced pressure to obtain the desired polyether.

[0029] In a 500ml three-necked flask with stirring, thermometer, and condenser, add 54.0g of polyether and 220ml of 95% ethanol, carefully add 36.0g of α-halogenated succinic acid in three batches, reflux for 3 hours after the addition, and remove the white color in the solution by hot filtration. solid, and then distill off the ethanol in the filtrate to obtain the finished product. The demulsifier of the invention has good demulsification and demetallization effects, and the demulsifier dosage is 100ppm, which is more economi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com