Patents

Literature

647 results about "Ethyl oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

At room temperature, ethylene oxide is a flammable colorless gas with a sweet odor. It is used primarily to produce other chemicals, including antifreeze. In smaller amounts, ethylene oxide is used as a pesticide and a sterilizing agent.

Encapsulated fragrance chemicals

InactiveUS7125835B2Increase depositionCosmetic preparationsOrganic detergent compounding agentsPersonal careFlavor

A polymeric encapsulated fragrance is disclosed which is suitable for use in personal care and cleaning products. In a preferred embodiment of the invention, the fragrance is encapsulated by a first polymer material to form a fragrance encapsulated polymer, the polymer encapsulated shell is then coated with a mixture of cationic polymers, in a preferred embodiment the coating polymers are a reaction product of polyamines and (chloromethyl) oxirane or (bromomethyl) oxirane.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Encapsulated fragrance chemicals

InactiveUS7196049B2Increase depositionCosmetic preparationsOrganic detergent compounding agentsPersonal careFlavor

A polymeric encapsulated fragrance is disclosed which is suitable for use in personal care and cleaning products. In a preferred embodiment of the invention, the fragrance is encapsulated by a first polymer material to form a fragrance encapsulated polymer, the polymer encapsulated shell is then coated with a mixture of cationic polymers, in a preferred embodiment the coating polymers are a reaction product of polyamines and (chloromethyl) oxirane or (bromomethyl) oxirane.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Alkylene oxide catalyst and use thereof

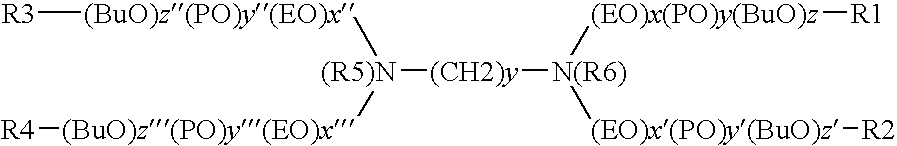

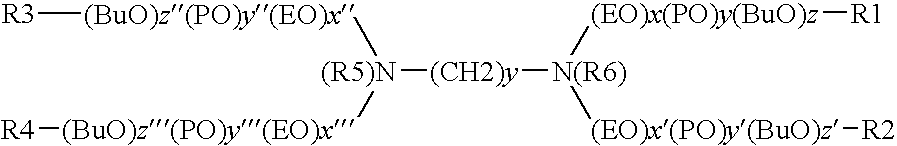

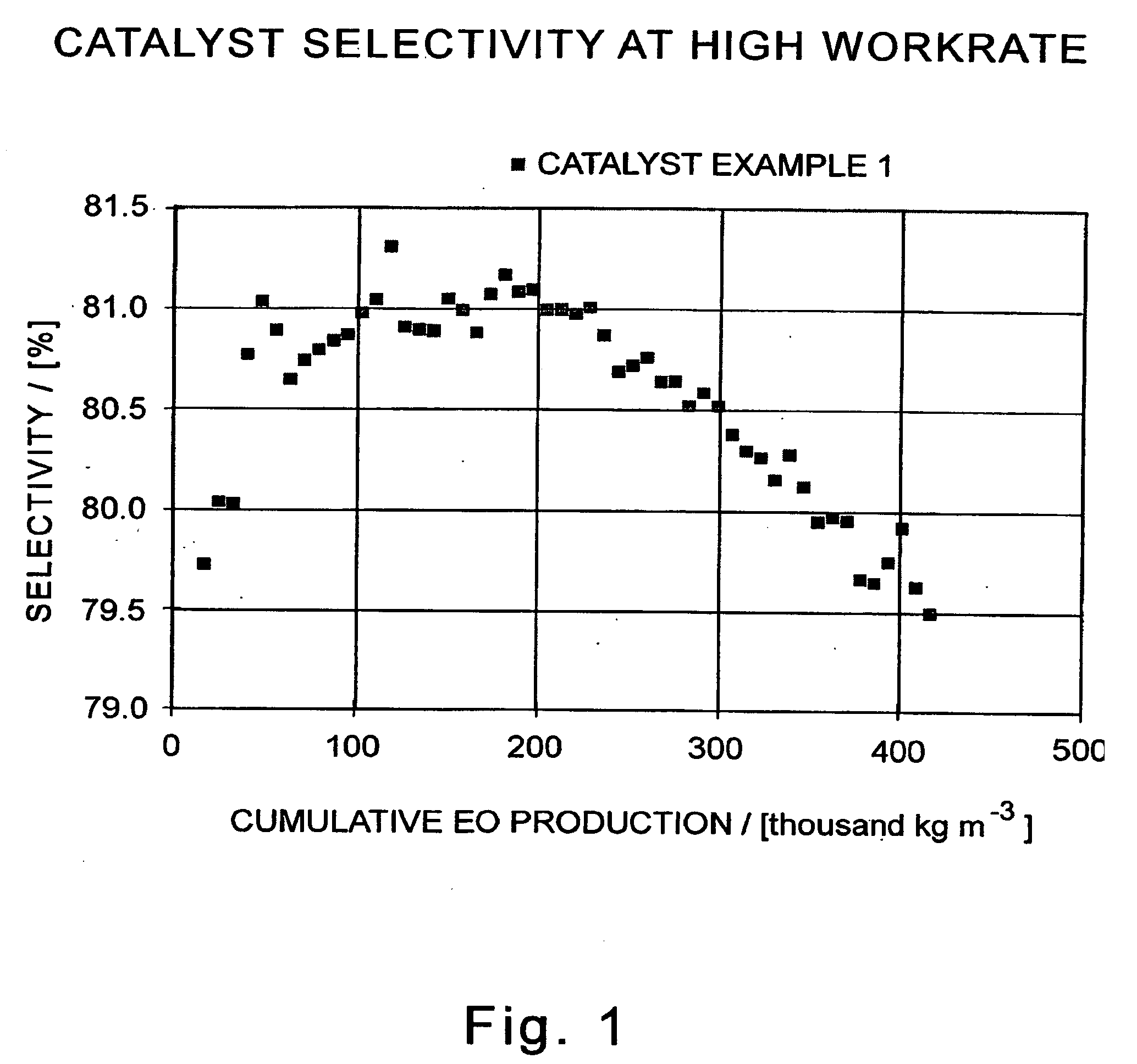

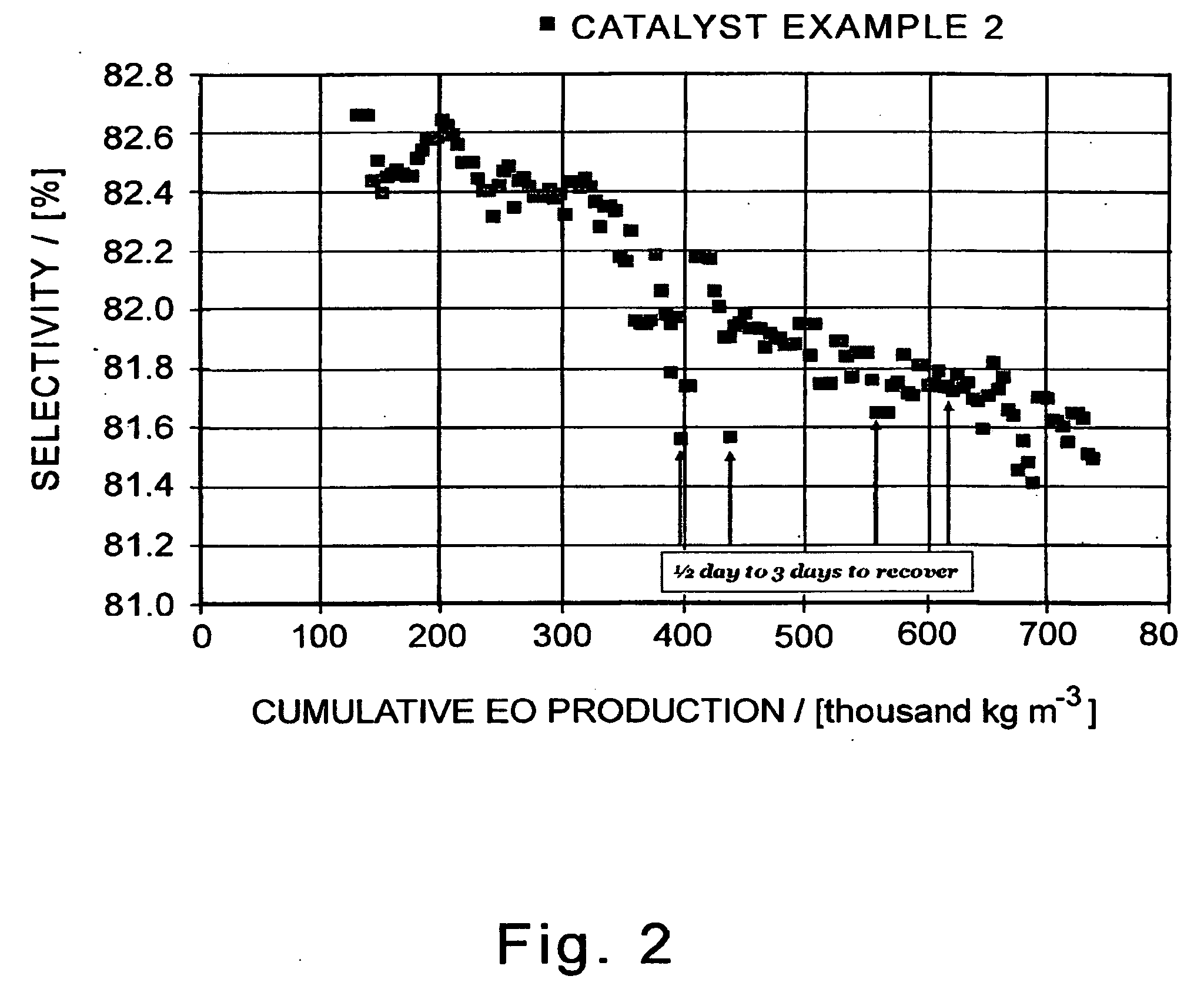

InactiveUS20090177000A1Selectivity towards ethylene oxide formation is optimalGood choiceOrganic chemistryCatalyst activation/preparationOxygenEthylene

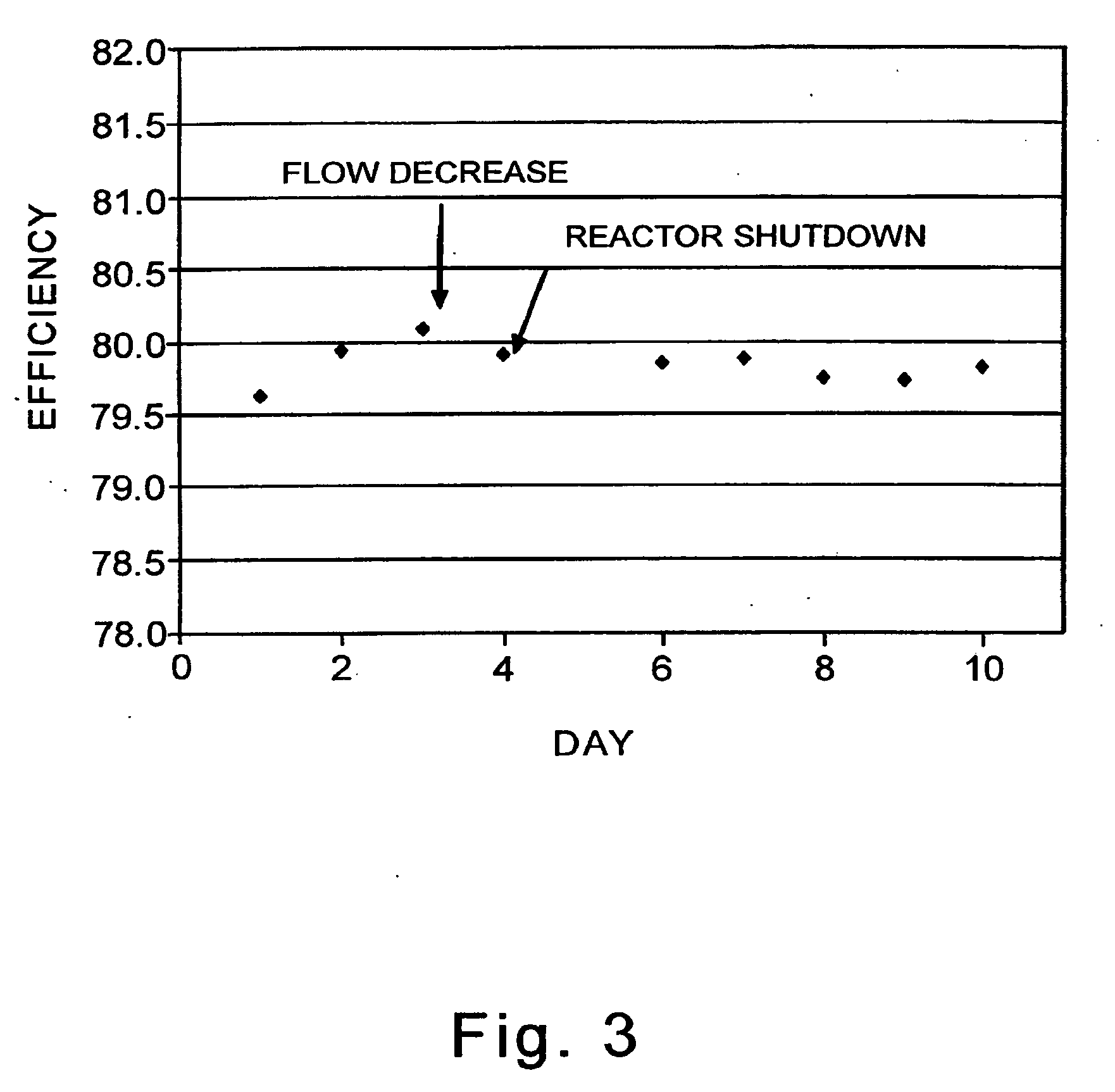

A supported silver catalyst and use thereof in a process for producing an alkylene oxide, such as ethylene oxide, by the direct oxidation of an alkylene with oxygen or an oxygen-containing gas, wherein the catalyst provides improved stability and improved resilience to reactor upsets and timely recovery to substantially pre-upset levels of catalyst activity and / or efficiency. In some embodiments, the catalyst also exhibits improved activity. A catalyst capable of producing ethylene oxide at a selectivity of at least 87 percent while achieving a work rate of at least 184 kg / h / m3 at a temperature of no greater than 235° C. when operated in a process where the inlet feed to a reactor containing the catalyst comprises ethylene, oxygen, and carbon dioxide, wherein the concentration of carbon dioxide in the inlet feed is greater than or equal to 2 mole percent.

Owner:DOW GLOBAL TECH LLC

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

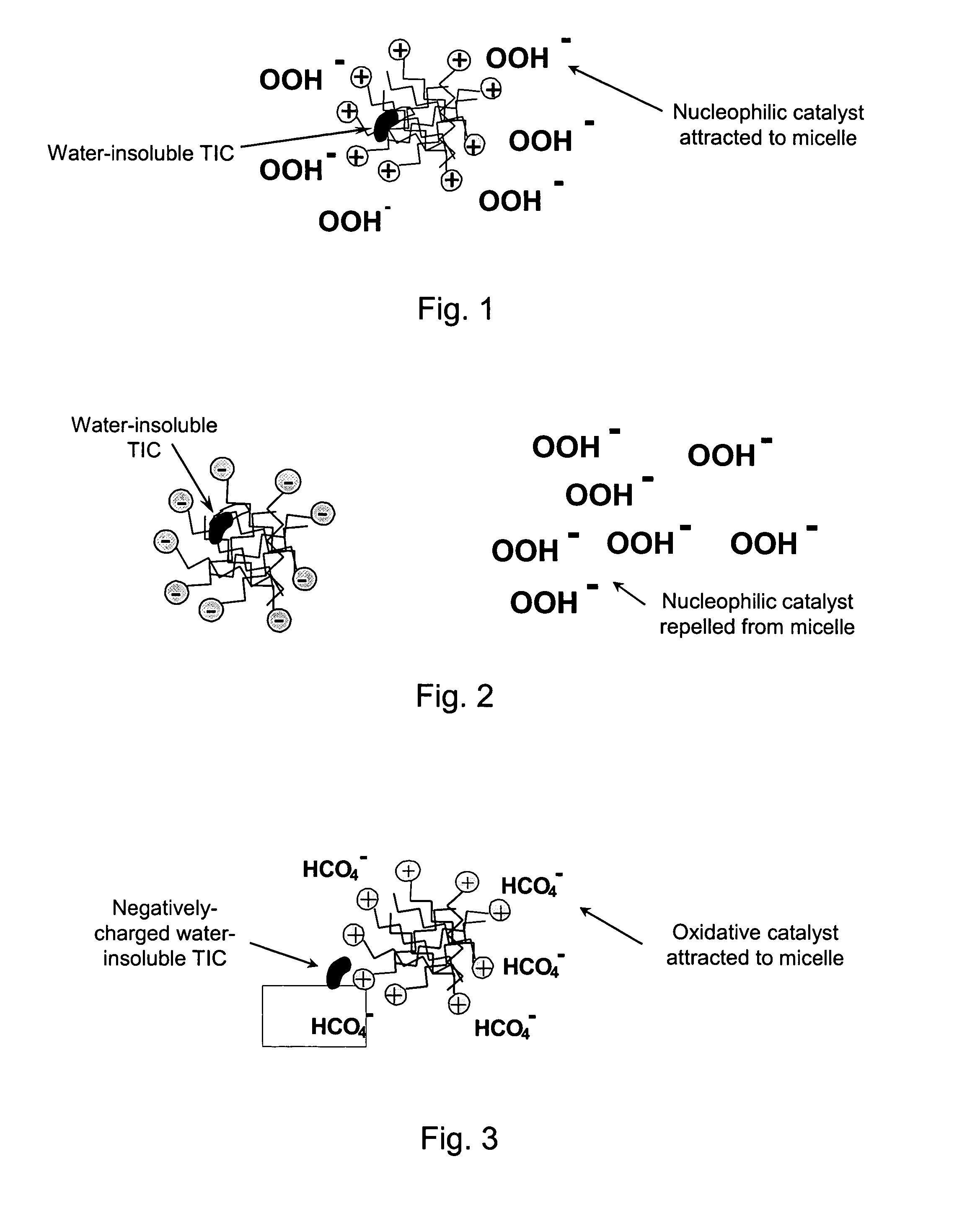

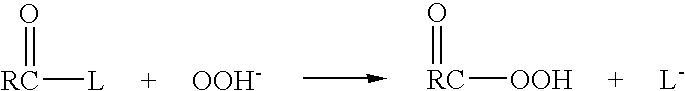

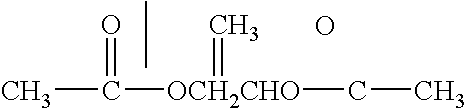

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Anti-Settling and Thickening Compositions and Methods for Using Same

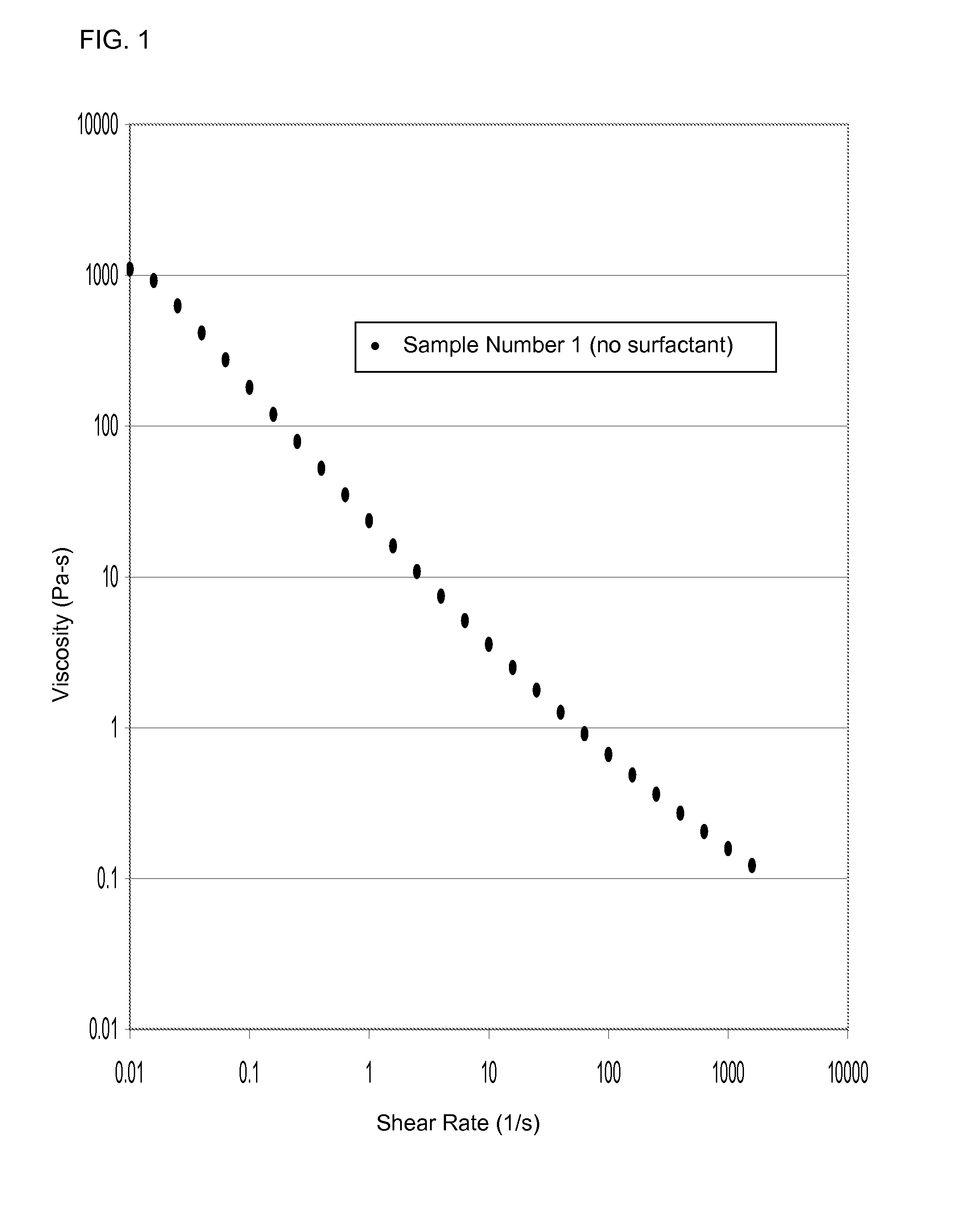

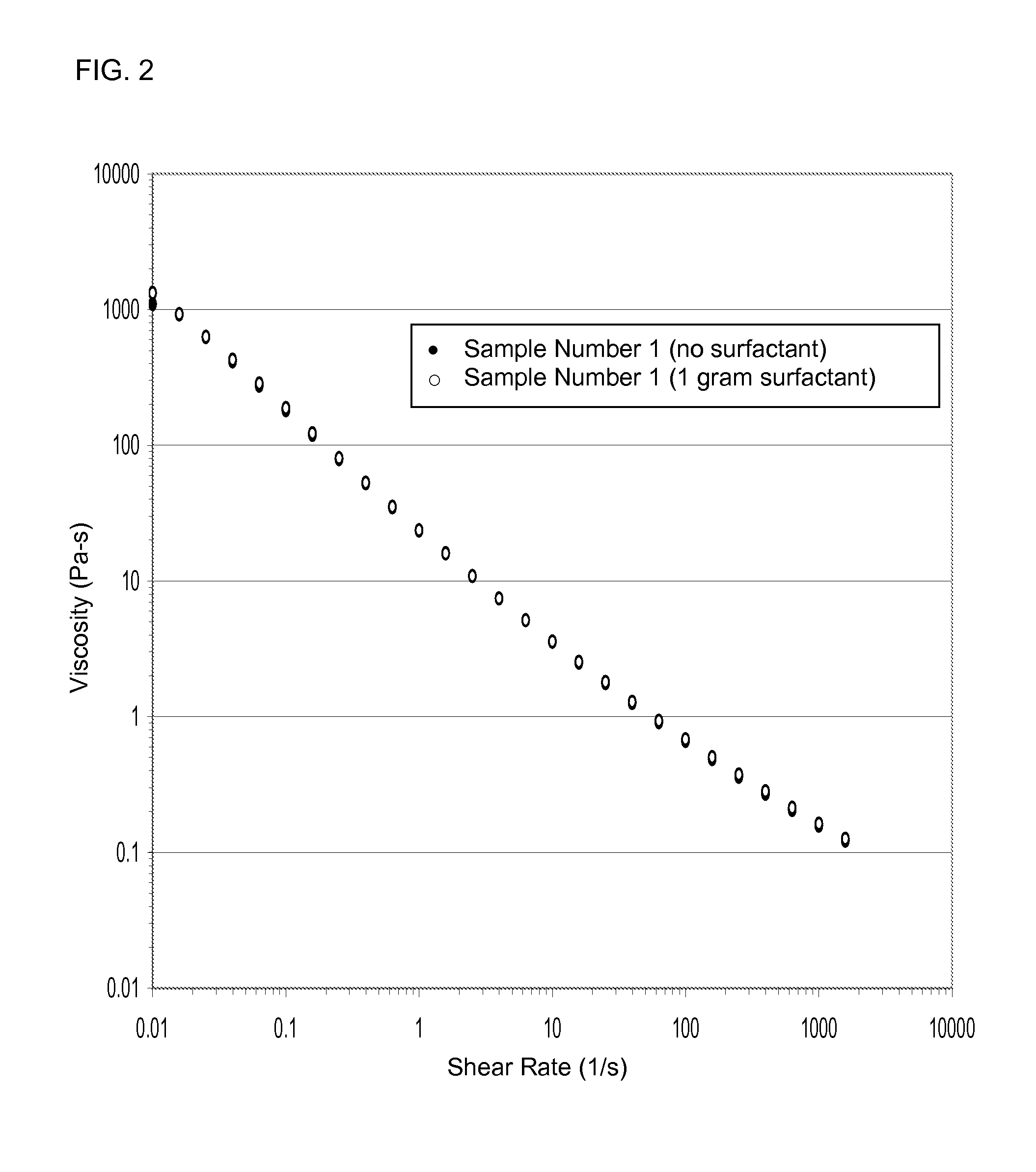

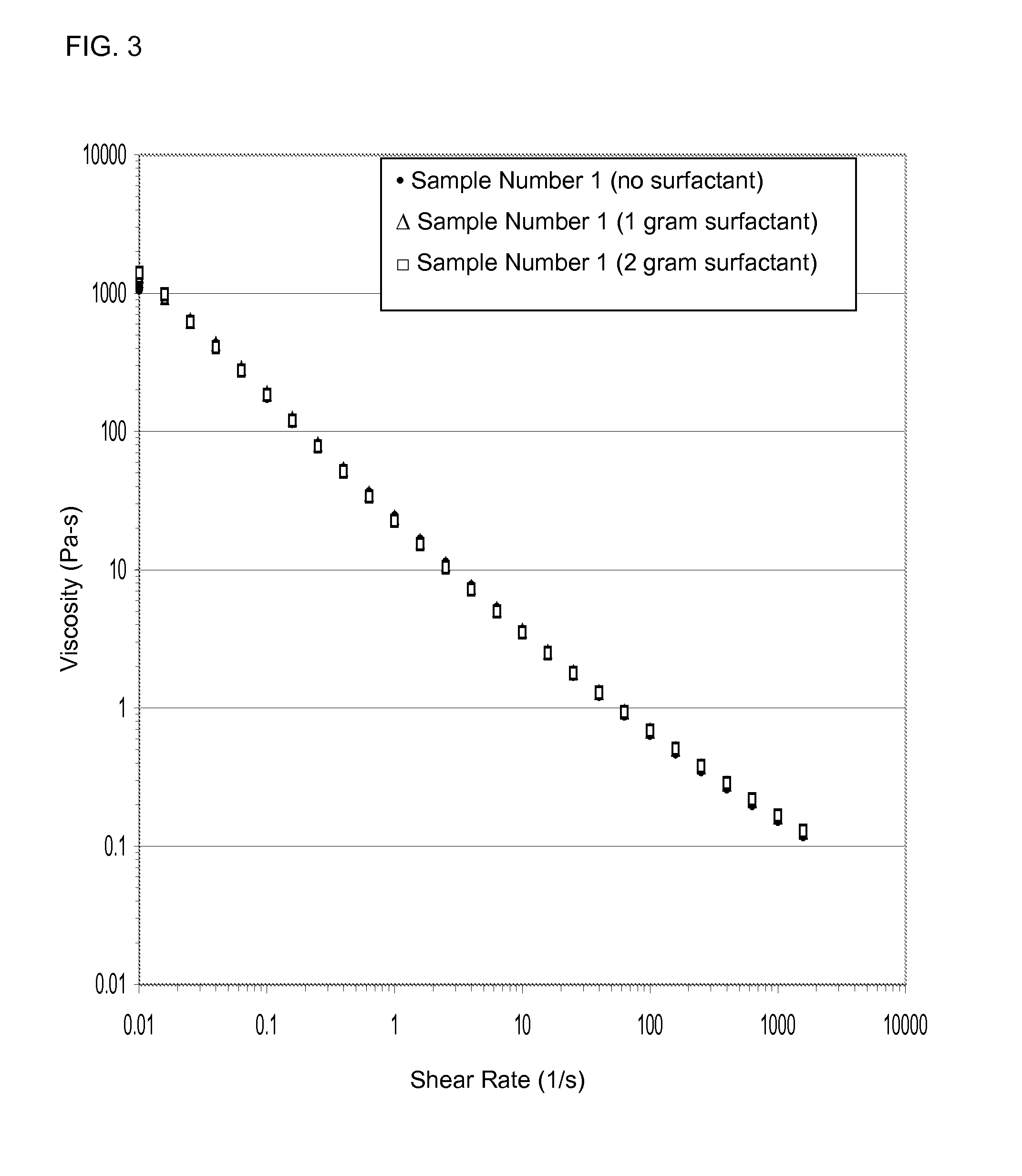

InactiveUS20140178325A1Little viscosityHigh viscosityCosmetic preparationsOrganic detergent compounding agentsSURFACTANT BLENDMonomer

An anti-settling additive, composition containing the anti-settling additive, and methods for use in coating compositions or formulations. A HASE thickener with improved resistance to surfactants and anti-sag properties, compositions containing the thickener and methods for use of the thickener in coating compositions or formulations and the like. The anti-settling additive and the thickener being a polymer synthesized using a specialized associative monomer that contains C1-C4 alkyl, propylene oxide, ethylene oxide and a polymerizable group.

Owner:RHODIA OPERATIONS SAS

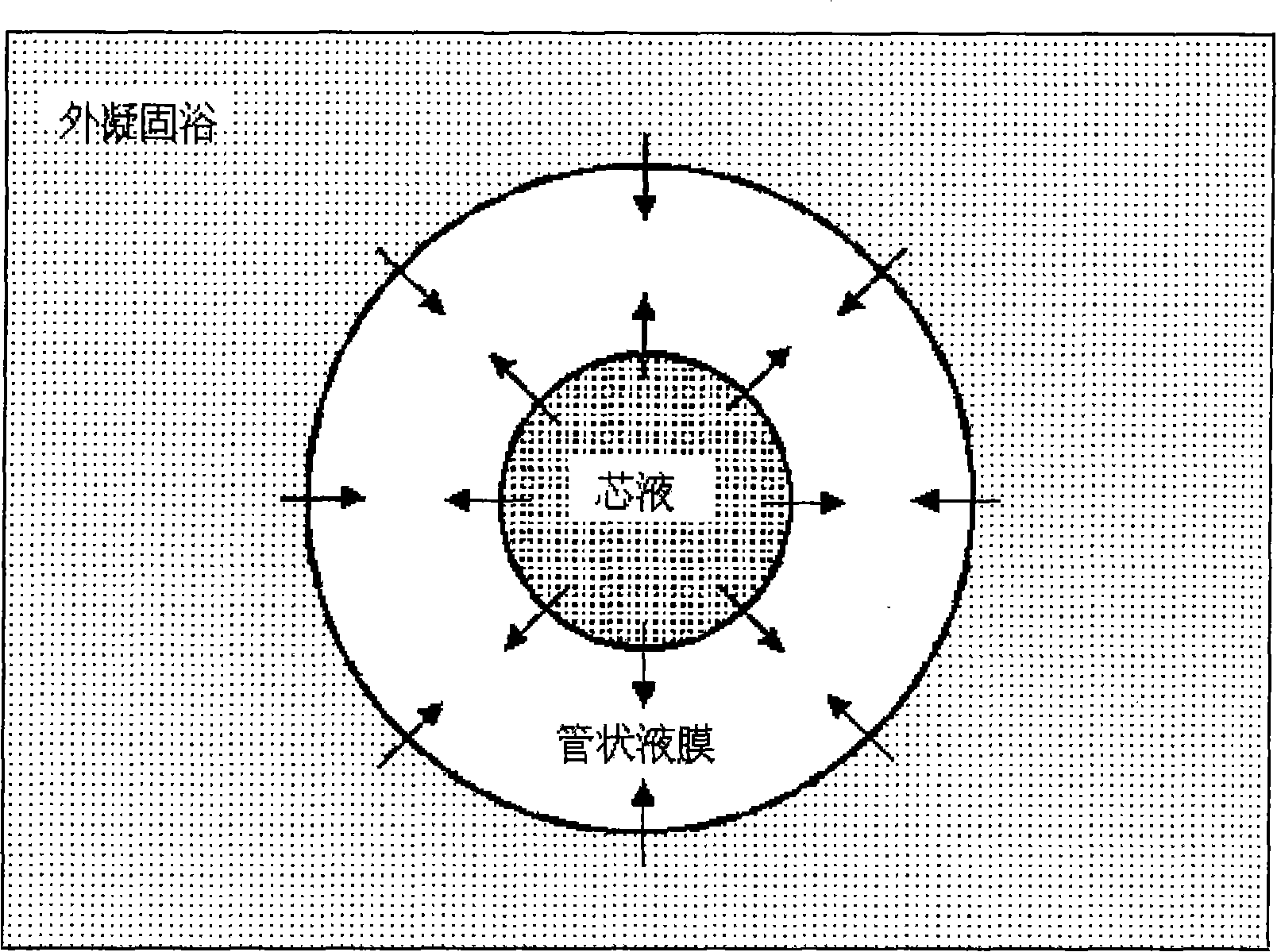

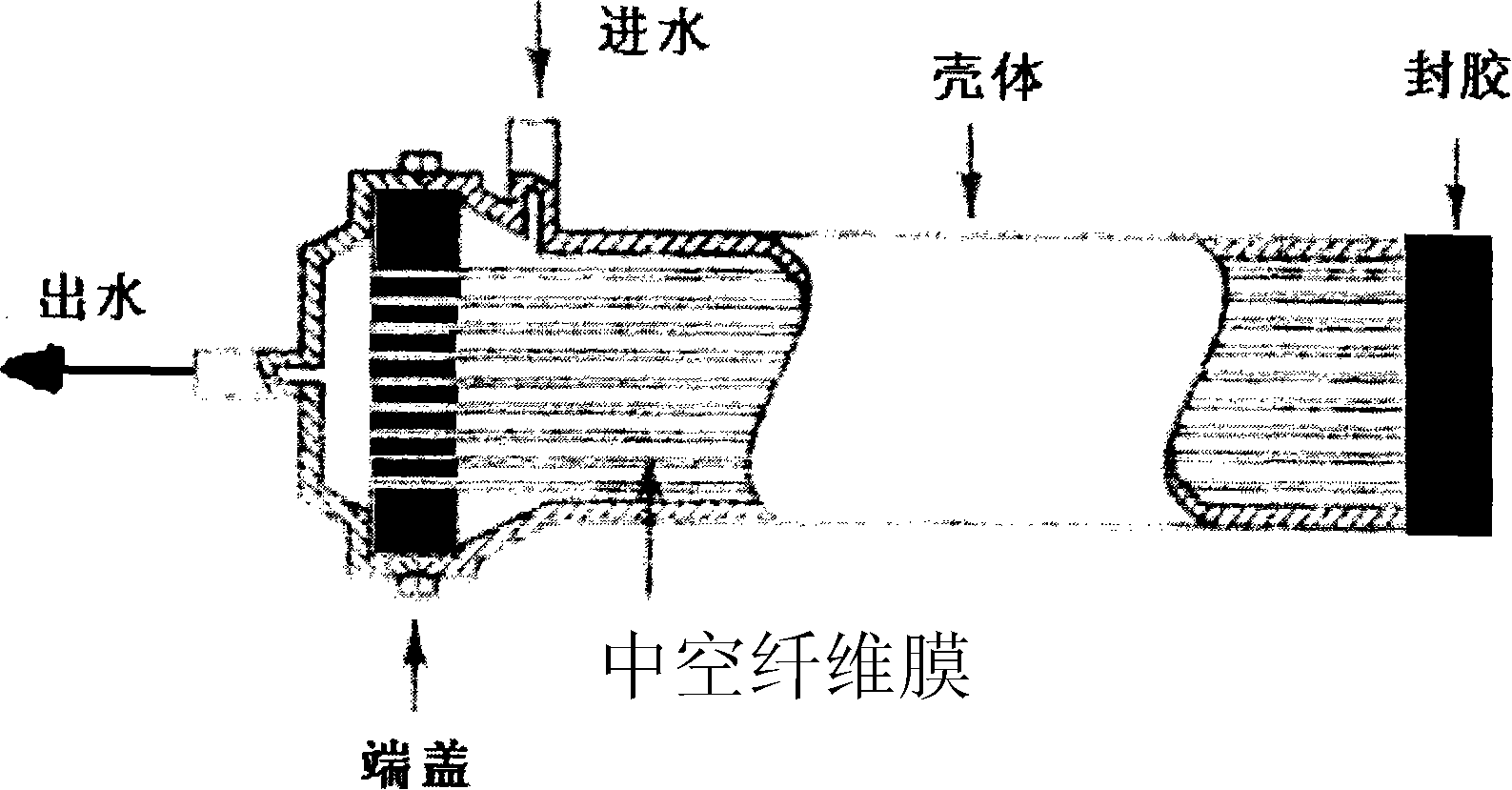

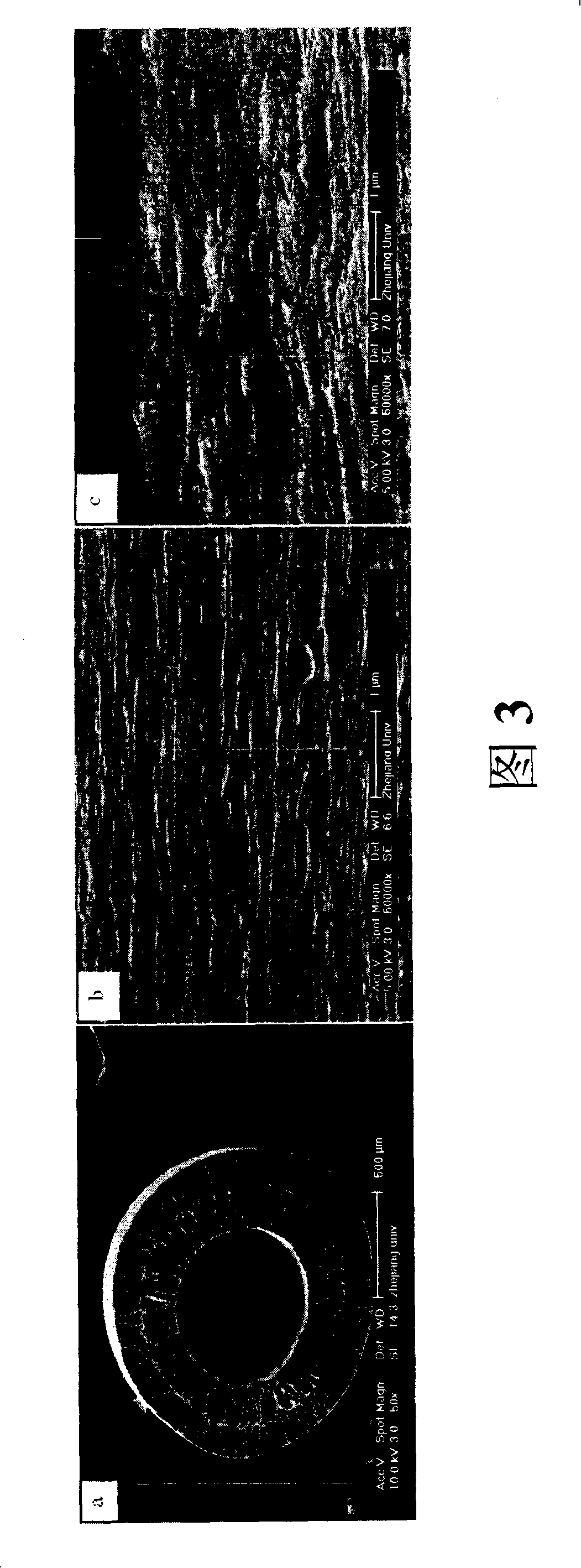

Hydrophilicity kynoar hollow fiber microporous membrane and preparation method thereof

ActiveCN101190401AImprove anti-pollution performanceAvoid adsorptionSemi-permeable membranesHollow fibrePorosity

The invention discloses a hydrophilic polyvinylidene fluoride hollow fiber microporous membrane and the preparation method thereof. The main composition and the mass content of the membrane are 70% to 90% of polyvinylidene fluoride, amphiphilic poly-(propylene oxide-oxirane), 5% to 29% of poly-(methacrylic acid- acrylic acid) or poly-(methacrylic acid methyl ester-vinyl alcohol) copolymer and 1% to 5% of nano-silicon dioxide. The membrane preparation method is that all the components are mixed and dissolved with aperture regulator, thickener and solvent to obtain the membrane preparation liquid; after that, the hollow fiber forming is carried out through a dry-wet spinning technique, and finally cleaning and drying are implemented. The obtained membrane has adjustable internal diameter and external diameter, 60% to 80% of porosity and the aperture ranging from 0.01micron to 0.2micron. As a water disposal separating membrane material with excellent performance, the invention has the advantages of being able to be fully humid, organic adsorption resistance and great water flux, etc.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

Easily adhesive polyamide film

InactiveUS6352762B1High bonding strengthStrong adhesionLiquid surface applicatorsFilm/foil adhesivesWater basedPolyamide

An easily adhesive polyamide film has been created from unstretched or uniaxially stretched non-heated polyamide film coated with a water-base coating mixture, whose main constituents are (A) water polyurethane resin containing acetylene glycol in which each carbon atom immediately adjacent to the triple-bonded carbon atom is replaced with a hydroxyl group and a methyl group, and / or an ethylene oxide addition product of the acetylene glycol; (B) a water-soluble polyepoxy compound; and (C) particles with an average diameter between 0.001 and 1.0 mum, of which the solid-content weight ratio is 98-30 / 2-70 / 0.1-10, the coating amount after stretching is between 0.005 and 0.030 g / m2, and the film is stretched in at least one direction and then heated. This newly invented film possesses good blocking resistance and excellent adhesiveness with print ink, laminate, and other coating mixtures, and is especially suitable for boiling sterilization, retort sterilization, and packaging of liquids.

Owner:KOHJIN CO LTD

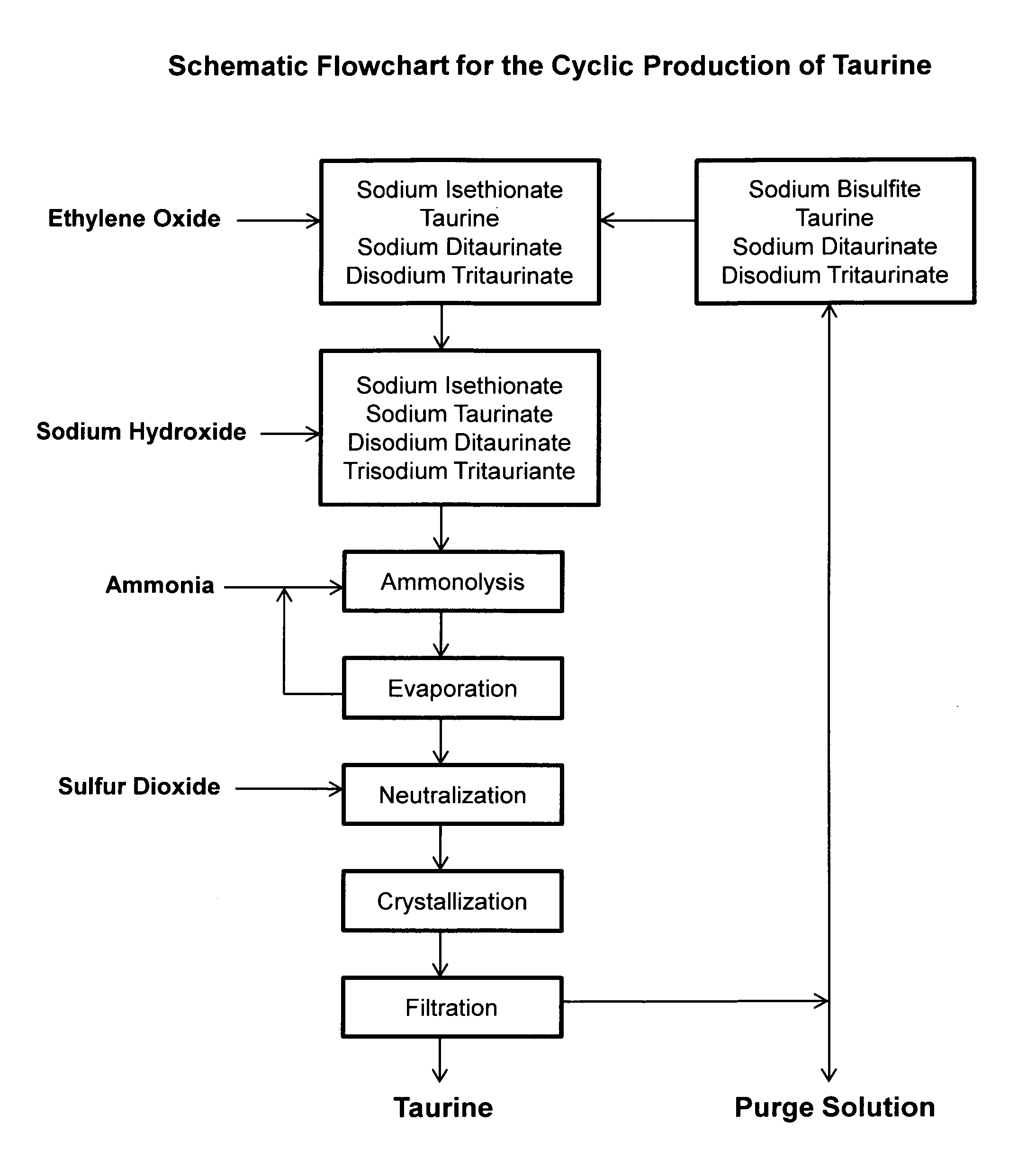

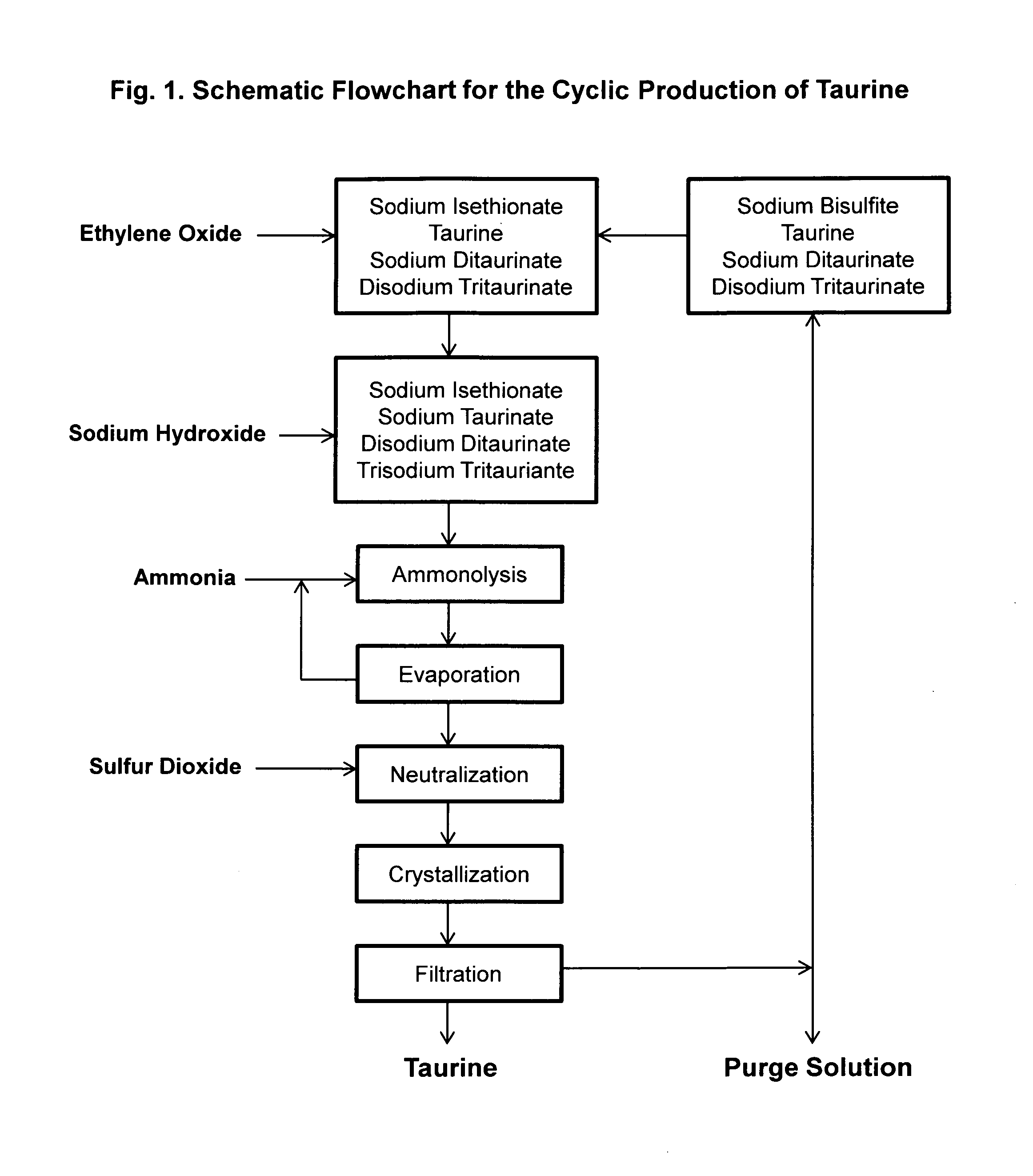

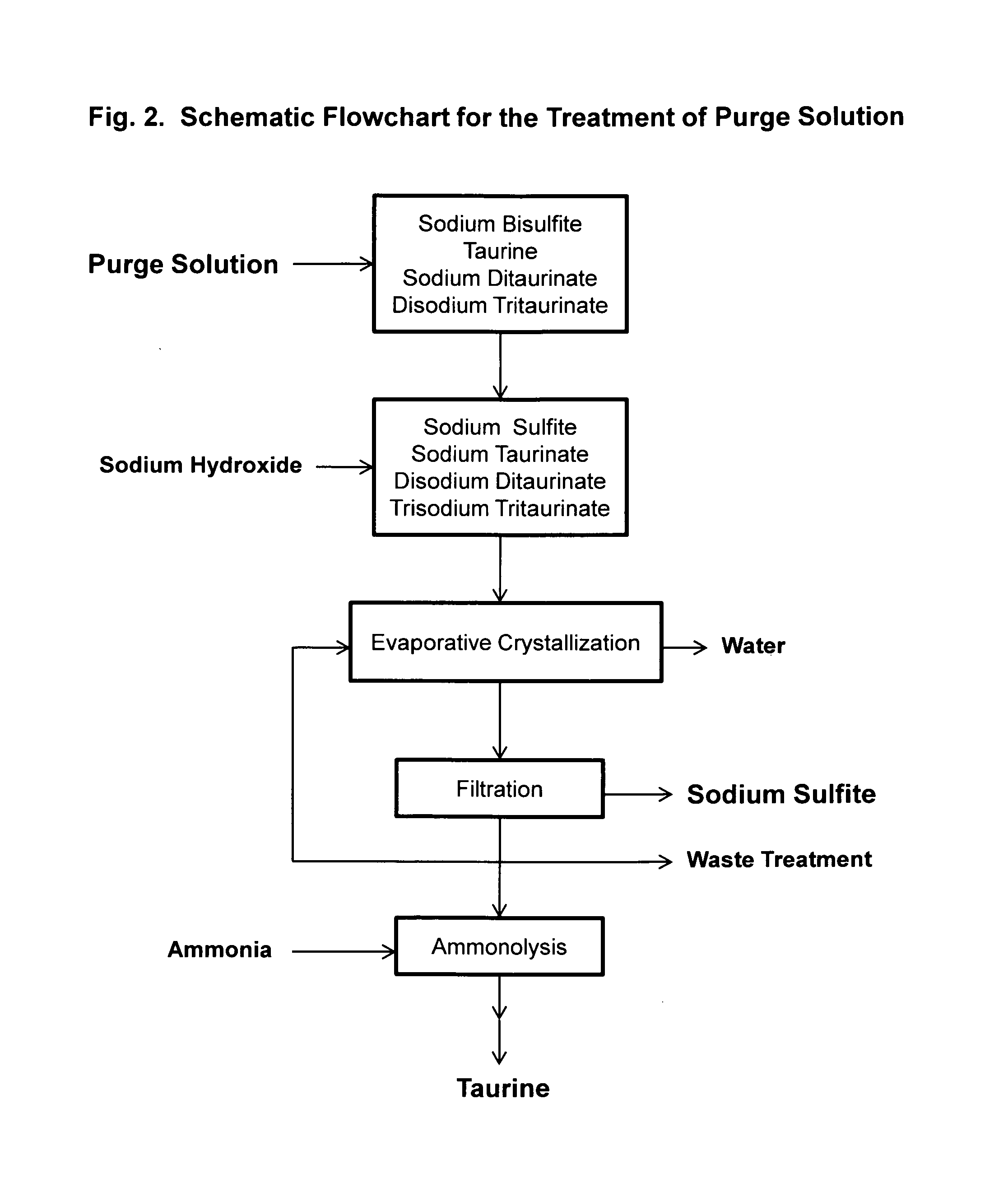

Cyclic process for the production of taurine from ethylene oxide

ActiveUS9061976B1Organic compound preparationSulfonic acids salts preparationCyclic processSodium dithionite

The present invention discloses a cyclic process for the production of taurine from ethylene oxide in a high yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. The cyclic process is completed by using sulfur dioxide or sulfurous acid to neutralize sodium taurinates to recover taurine and to regenerate sodium bisulfite, which is then reacted with ethylene oxide.

Owner:VITAWORKS IP LLC

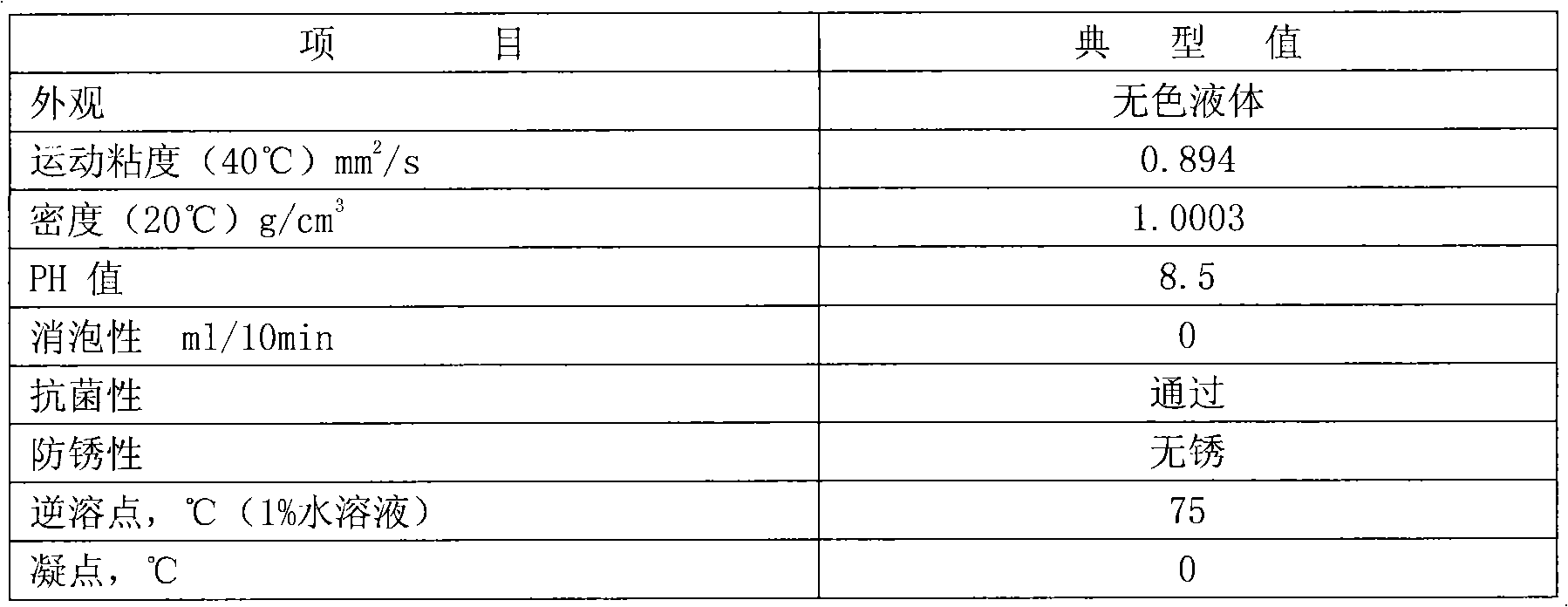

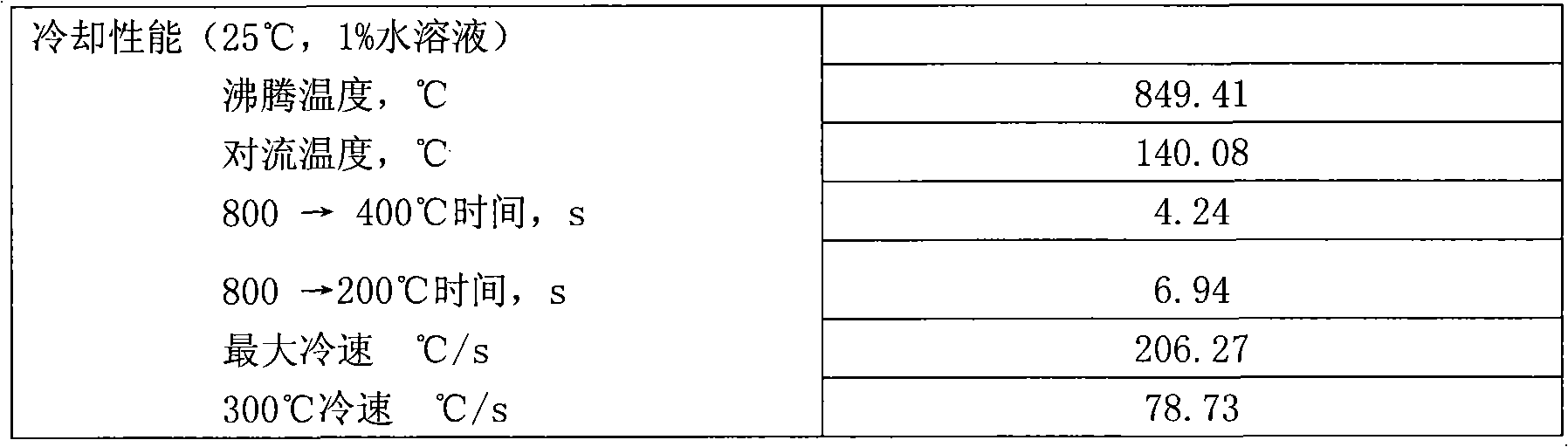

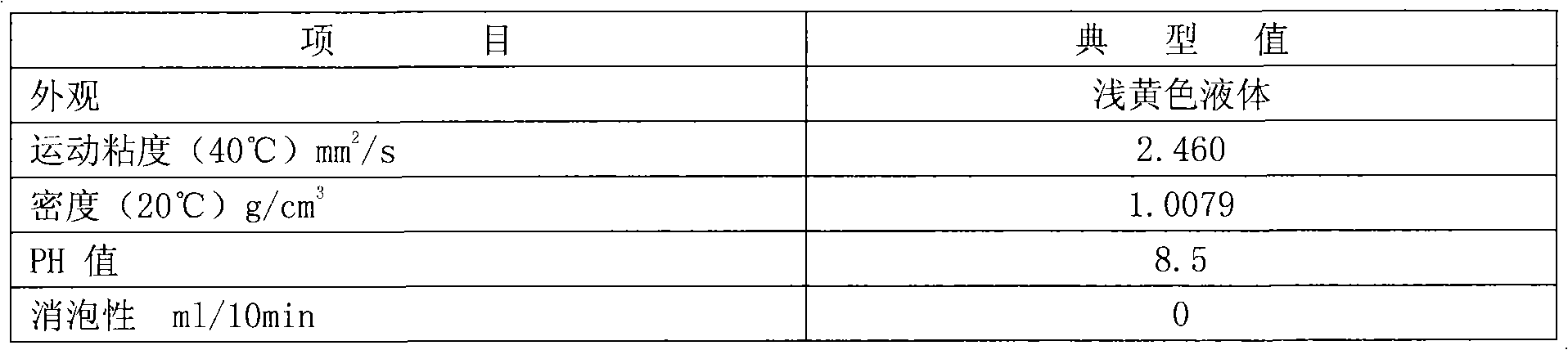

Water soluble polyether quenching medium

ActiveCN101660027AOvercome the easy-to-growth bacteria fromOvercome the smelly problemQuenching agentsQuenchingDefoaming Agents

The invention relates to a water soluble polyether quenching medium for quenching a metal material, which comprises the following components in percentage by weight: 1 to 30 percent of water soluble polyether, 0.1 to 1.0 percent of antirusting agent, 100 to 500ppm of defoaming agent, 0.1 to 1.0 percent of composite germicide, 0.2 to 2 percent of pH regulator and the balance of water, wherein the water soluble polyether is a condensation compound of ethylene oxide and propylene epoxide and a number-average molecular weight is less than 20,000. The water soluble polyether quenching medium is characterized by solving the problems of insufficient hardness of oil quenched workpieces and cracking and deformation of water quenched workpieces, reducing fire hazards in quenching, improving production safety, avoiding oily fume discharge, reducing environment pollution, improving working environment, contributing to the body and mind health of workers, along with readily available raw materials,simple production process, low price, excellent antirusting, defoaming and antibacterial performance, wide quenching cooling speed range and cooling speed ranging from oil quenching cooling speed andwater quenching cooling speed.

Owner:PETROCHINA CO LTD

Lithographic printing plate developing compositions

InactiveUS20100216067A1Solve the real problemDiluted working strength developersSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusCarboxylic acidFatty alcohol

A concentrated developer can be prepared with less than 60 weight % water and still remain in a single phase with little or no haze or precipitation. This developer concentrate also includes a water-soluble or water-miscible organic solvent, one or more alkyl ether carboxylic acid, coconut oil alkanolamine, coconut fatty alcohol polyglycol ether, β-naphtholethoxylate, and block propylene oxide-ethylene oxide in an amount of at least 0.1 and up to 50 weight % solids, and optionally an alkyl naphthalene sulfonate in an amount of up to 40 weight % solids. The developer concentrate can be diluted up to 80:1 or greater with water and used to process imaged lithographic printing plate precursors.

Owner:EASTMAN KODAK CO

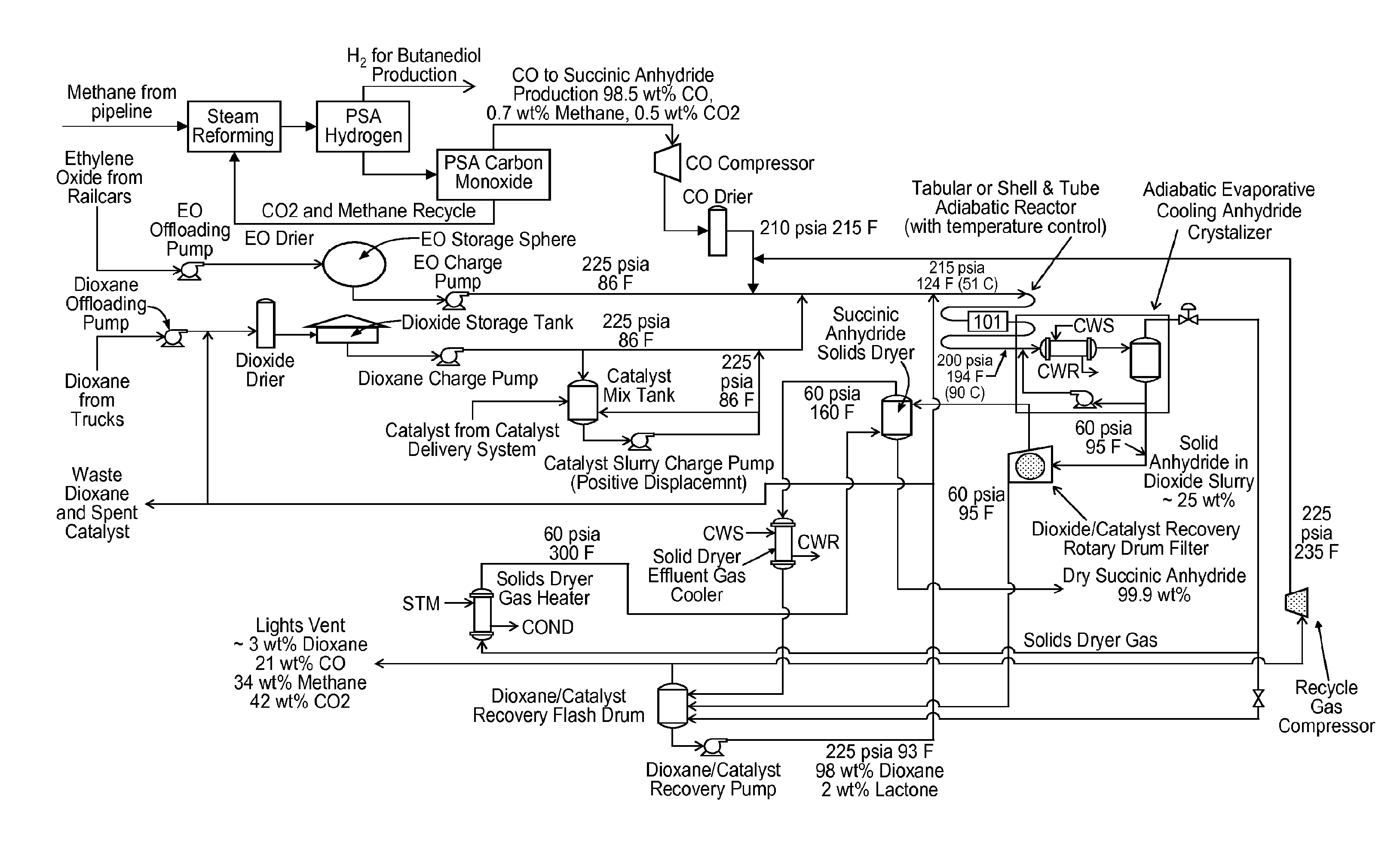

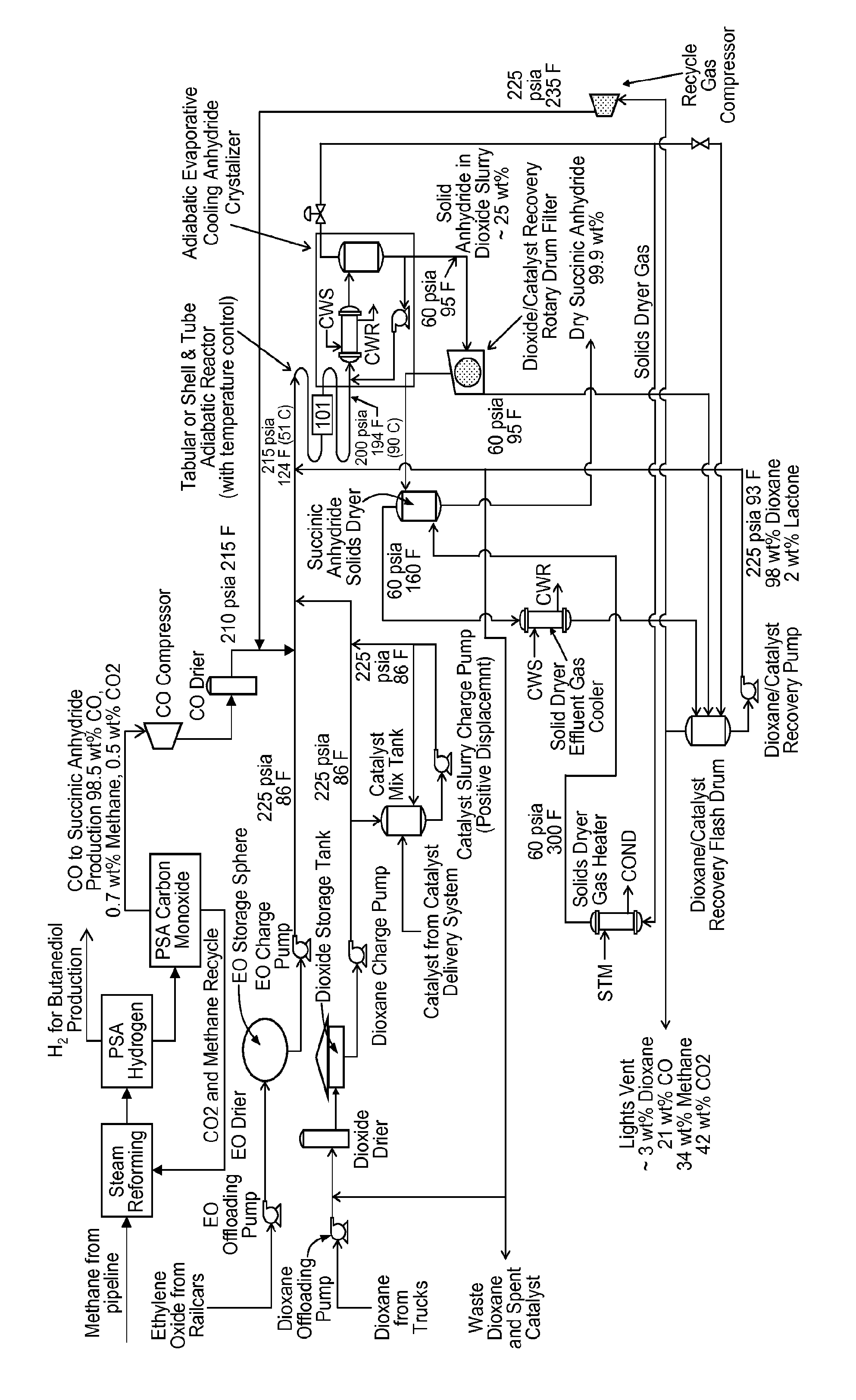

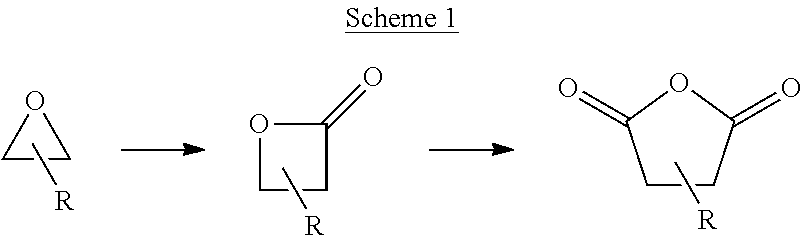

Succinic anhydride from ethylene oxide

ActiveUS9156803B2Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthylene oxideContinuous flow

Owner:NOVOMER INC

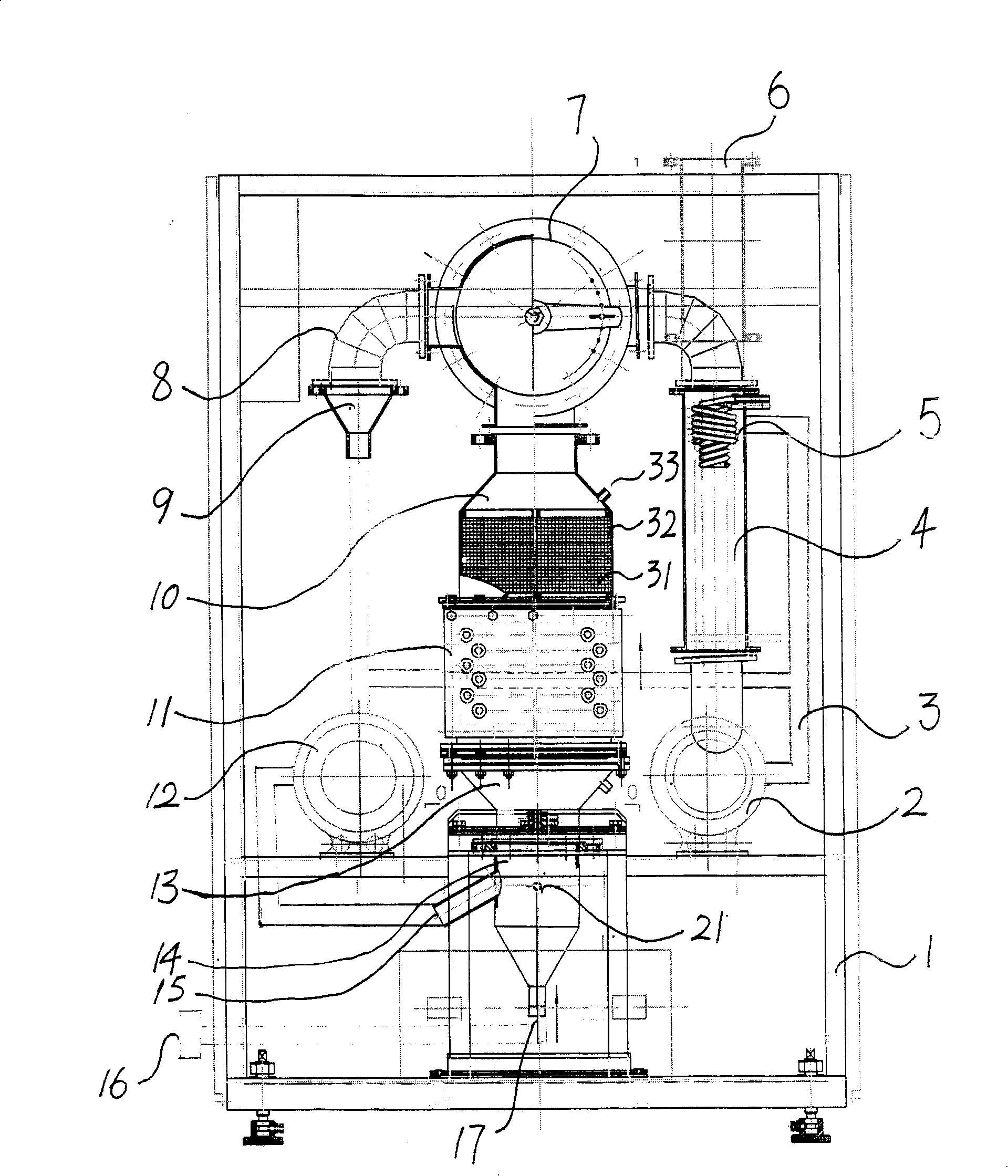

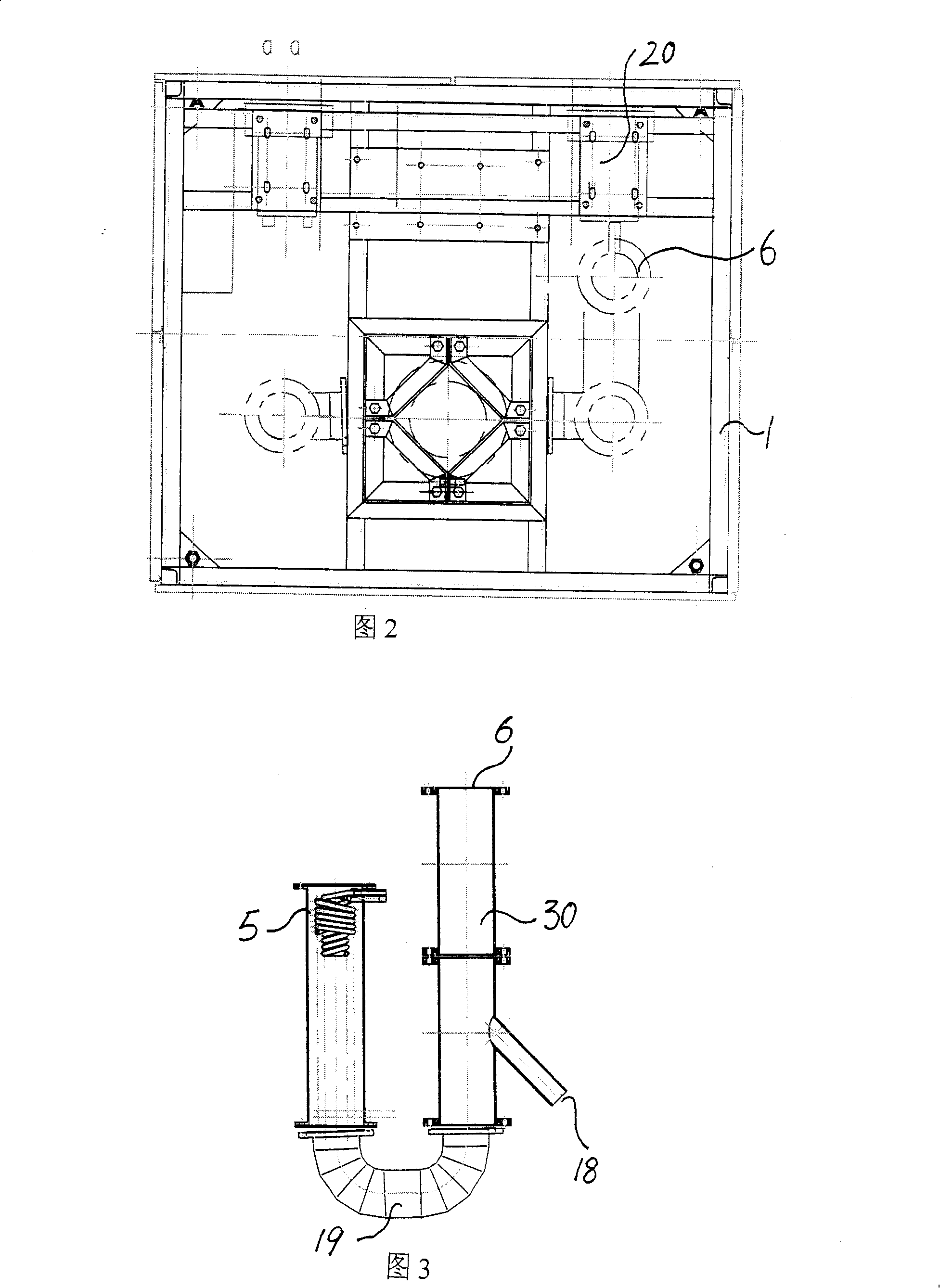

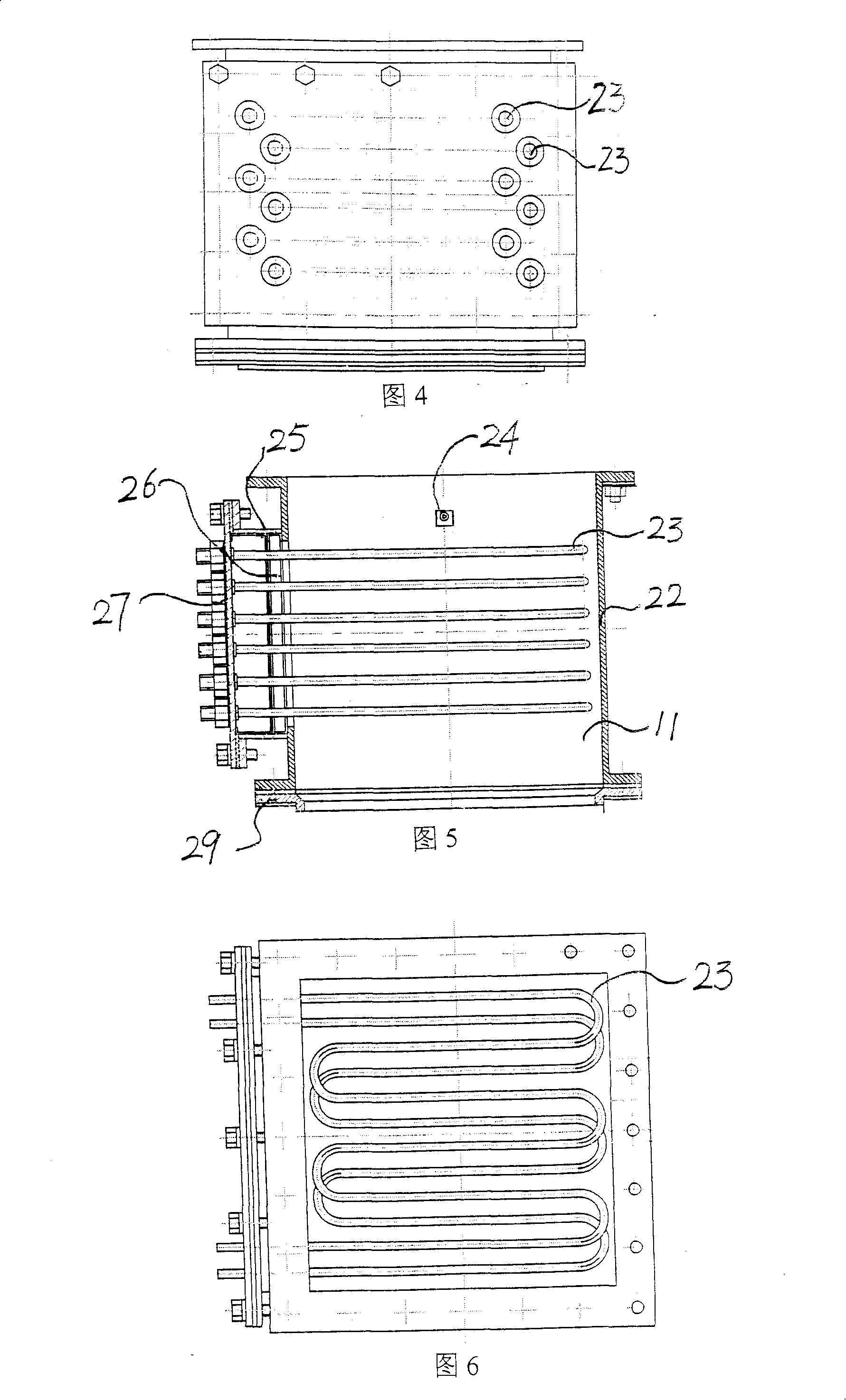

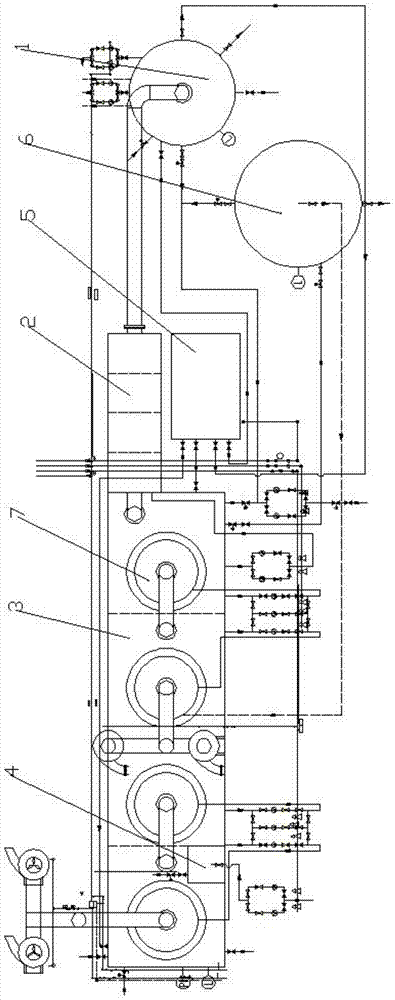

Ethylene oxide exhaust gas processor

InactiveCN101224381AReduce concentrationSave energyDispersed particle separationIncinerator apparatusCombustion chamberEthylene oxide

The invention relates to an ethylene oxide exhaust gas processor. A pre-mixing chamber, a pre-heating chamber, a firebox, an adsorption chamber, a gas-distributing regulator and a cooling chamber which are mutually communicated are sequentially arranged upwards from an inlet of ethylene oxide exhaust gas. The gas-distributing regulator is communicated with the cooling chamber and is also communicated with a circulation fan. A jet circulation air intake and a vacuumizing port are arranged on the pre-mixing chamber. Heating pipes are arranged in the firebox and are interlaced orderly into layers, and the firebox is communicated with the adsorption chamber. A plurality of adsorbing layers are arranged in the internal part of the adsorption chamber, and a porous clapboard is respectively arranged between two layers, and the upper part of the adsorption is communicated with the gas-distributing regulator which can regulate the flow of high temperature purifying gas and circulation hot gas. The invention not only can lead the sterilized ethylene oxide gas to be thoroughly decomposed into carbon dioxide and water and lead the concentration of disposed and purified ethylene oxide nearly to be 0ppm which is further less than 1ppm regulated by the international standard, but also can lead the hot air to be recycled so as to conserve energy. The operation of the invention is convenient, and can be carried out together with sterilizing so as to avoid the secondary pollution.

Owner:吕延利

High moisture vapor transmission hot melt moisture cure polyurethane adhesive with excellent hydrolysis resistance

InactiveUS6133400AGood moisture permeabilityImprove washabilityAdhesive articlesSynthetic resin layered productsPolyesterMoisture cure polyurethane

This invention relates to a hot melt moisture cure polyurethane composition which is the reaction product of a polyether polyol formed from a compound selected from the group consisting of ethylene oxide, propylene oxide, 1,2-butylene oxide, 1,4-butylene oxide and mixtures thereof; a low molecular weight polyalkylene glycol having from 3 to 7 carbon atoms; a crystalline polyester polyol having a melting point from about 40 DEG C. to about 120 DEG C.; and at least one polyfinctional isocyanate component wherein said composition has a moisture vapor transmission rate of greater than about 100 g / m2 / day film thickness of from about 450 to about 500 g / m2, and hydrolysis resistance.

Owner:HB FULLER CO

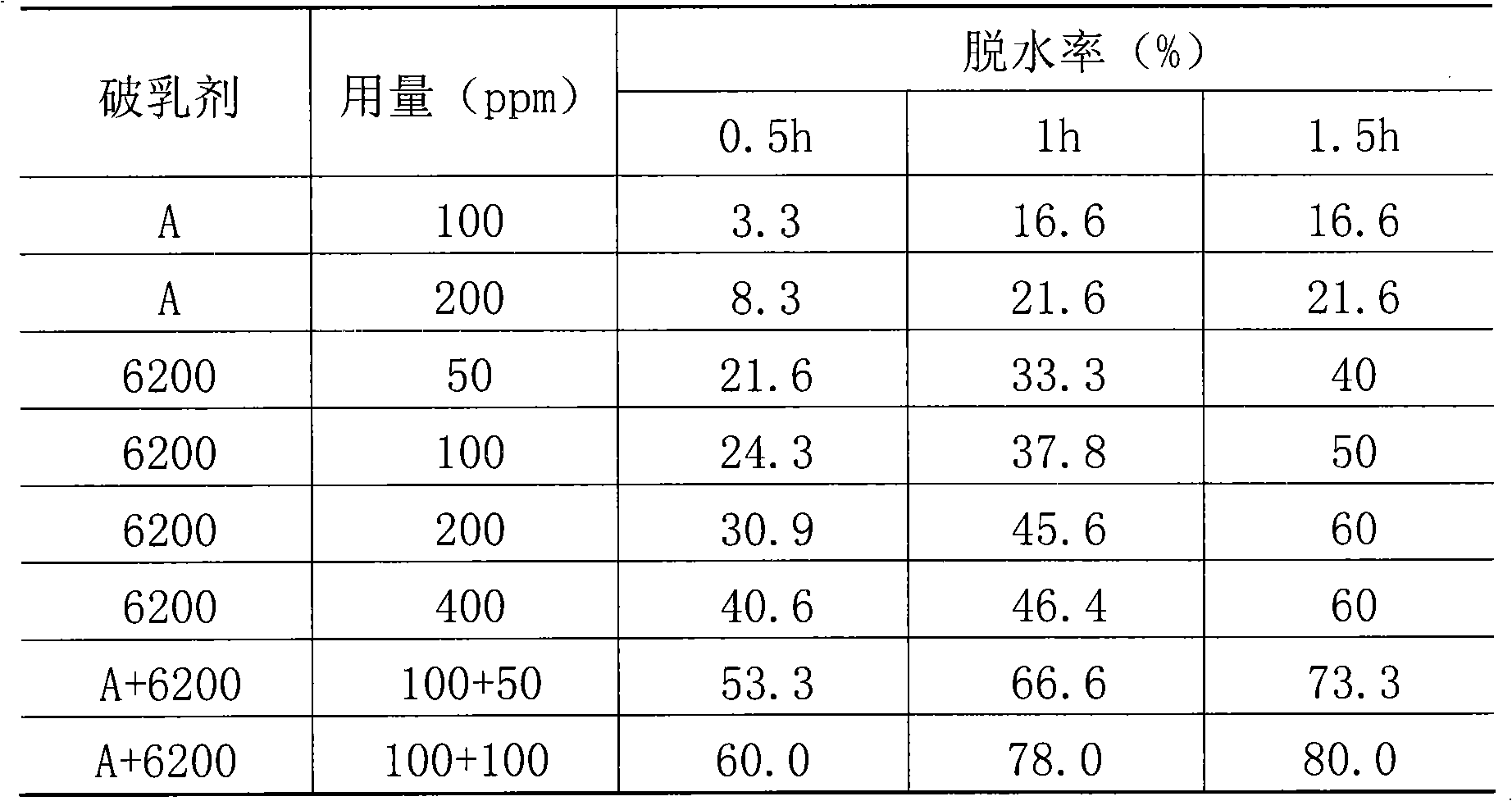

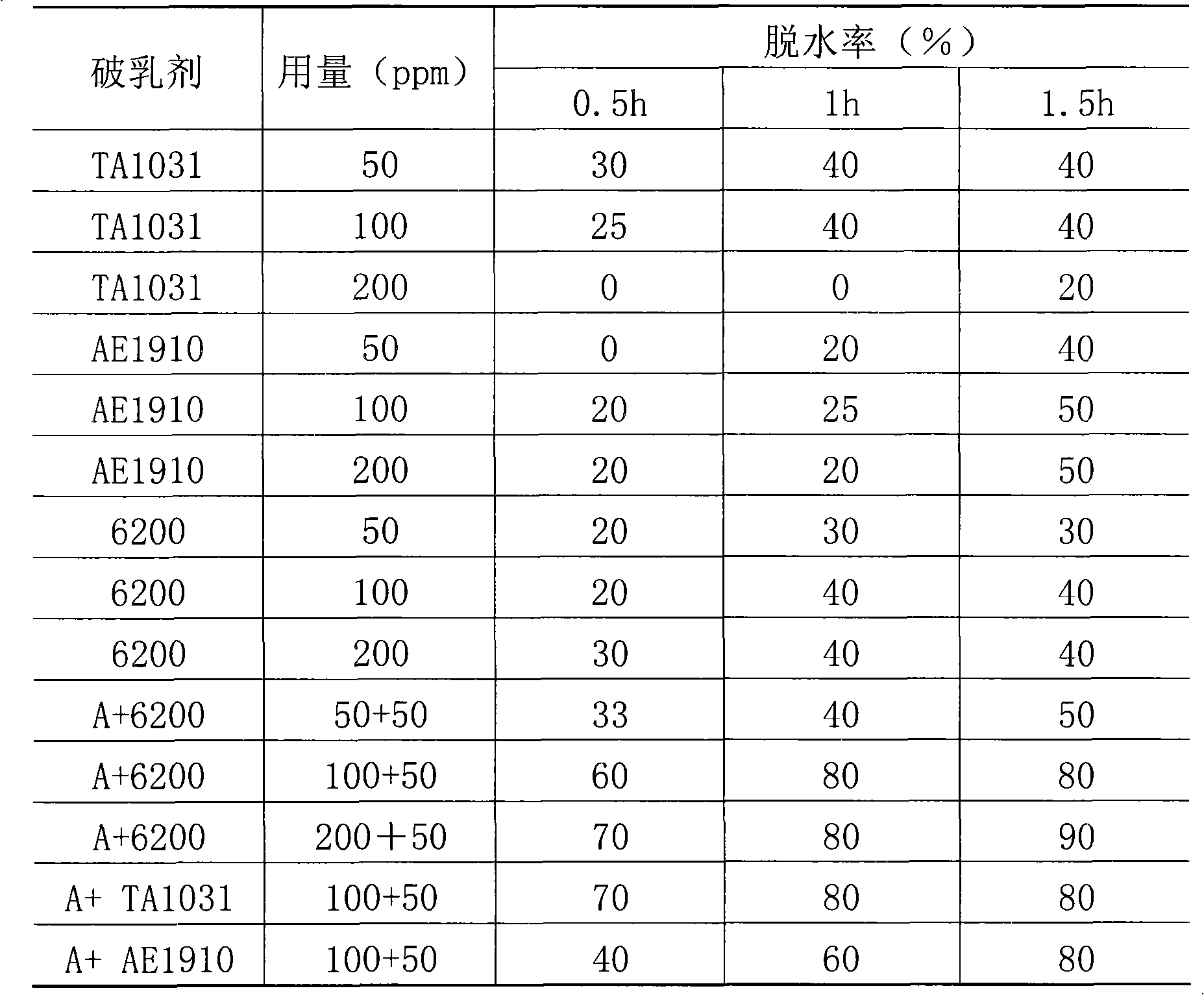

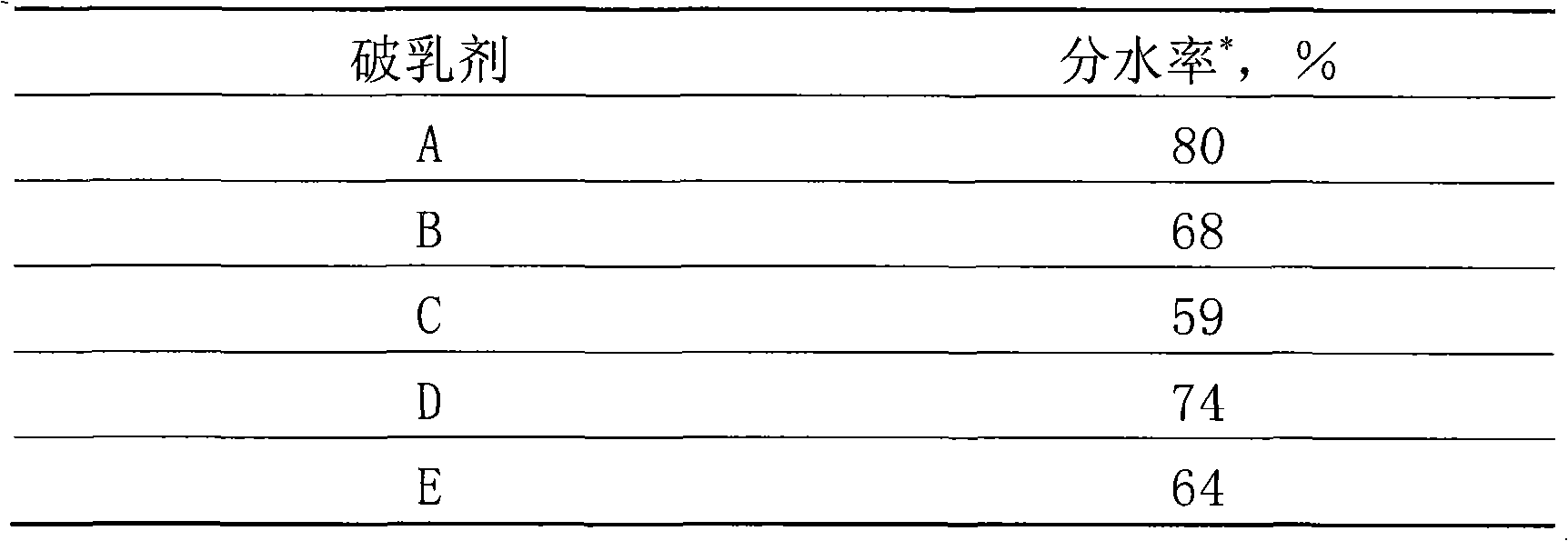

Preparing method of oil field demulsifier

ActiveCN102030878AHigh molecular weightGood broad spectrumDewatering/demulsification with chemical meansDemulsifierCarboxylic acid

The invention discloses a preparing method of an oil field demulsifier. The preparing method adopts ethyleneamine as a raw material, and the oil field demulsifier is prepared by crosslinking modification of the ethyleneamine, ethylene oxide, and propylene epoxide. The method comprises the following steps of: with the ethyleneamine as an initiator, enabling the ethyleneamine to react with propylene oxide and ethylene oxide to prepare an ethyleneamine type polyether demulsifier under the existence of a basic catalyst; carrying out self-crosslinking reaction on the polyether demulsifier A by adopting polycarboxylic acid under the action of a catalyst to prepare a product B; and finally carrying out self-crosslinking reaction on the polyether demulsifier A and the product B in a solvent by adopting toluene diisocynate to prepare a high performance demulsifier as a final product. The demulsifier prepared by the preparing method has the advantages of higher relative molecular weight, favorable dehydration effect and favorable broad spectrum, and can be used for demulsification and dehydration of the crude oil in the oil field. The dehydrated water is clear, and the dosage of the demulsifier is less.

Owner:JURONG NINGWU CHEM

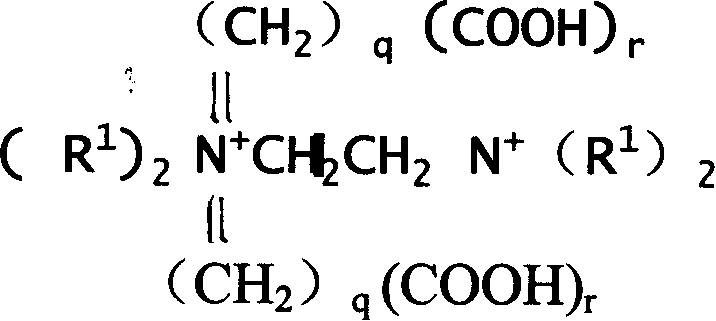

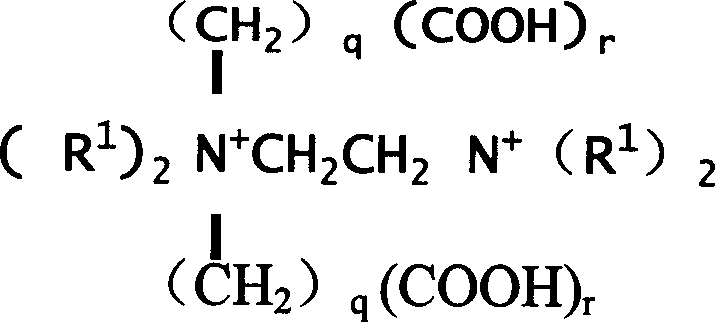

Method for preparing multifunctional deemulsifying agent of crude oil and products thereof

InactiveCN1600835AImprove surface activityImprove wettabilityHydrocarbon oil dewatering/demulsificationEpoxyAlkaline earth metal

This invention provides a method for preparing crude oil demulsification agent for crude oil pretreatment in refinery plant. Said multi-functional demulsification agent has betaine structure, being of amphoteric-ion surfactant. Organic amine is used as initiator, and epoxy propane and epoxy ethane are polymerized to produce polyether, then reacting with alpha-halogenated carboxylic acid to produce said betaine structure product. This produced has advantages of: excellent emulsification ability and dewater ability, on the molecule there are quaternary amido and carboxy group, so having excellent wetting function, and having good complexation stability to alkaline earth metals in crude-oil, being of calcium-disperser, and having excellent function for removing magnesium and iron.

Owner:PETROCHINA CO LTD

Low-temperature quick deemulsifying agent for water-containing wax-containing erude oil and its preparation method

InactiveCN1537924AFast dehydrationGood demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationEpoxyOil processing

Owner:SHANDONG UNIV

Transparent anti-fog anti-splash coating compositions

The present invention is directed to an anti-fogging / anti-splash composition that can be used for anti-fog / anti-splash applications. When applied to the surface of a transparent or reflective substrate, the composition dries relatively clear and comprises a solution of a non-toxic, fast drying solvent or alcohol and a surface active agent containing sodium lauryl ether sulfate, and either a block ethylene oxide / polyethylene oxide copolymer, an ethoxylated amine, an ethoxylated acetylenic alcohol, sodium sulfosuccinate, ethoxylated sorbitan ester, random EO / PO polymers on butyl alcohol, or mixtures thereof. When applied to the surface of a substrate, the present invention provides a coating of high transparency which cures rapidly, is sufficiently surface active to be an anti-fog agent when "dry", will persist when "wet" under water spray conditions (such as on a dental mirror) for a period substantial enough to be practicable, and will provide anti-splash benefits throughout the use cycle.

Owner:MACHSON ROGER

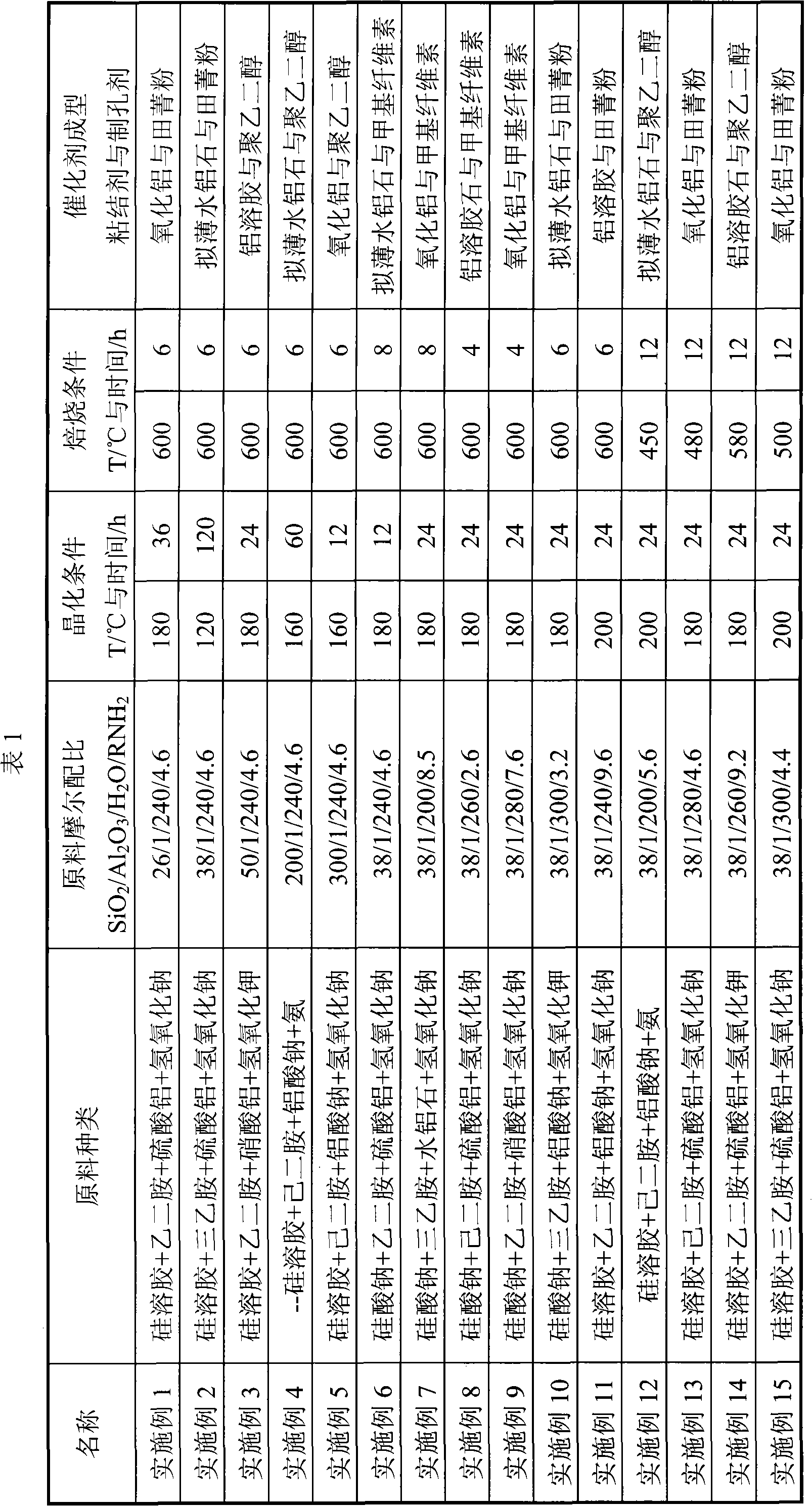

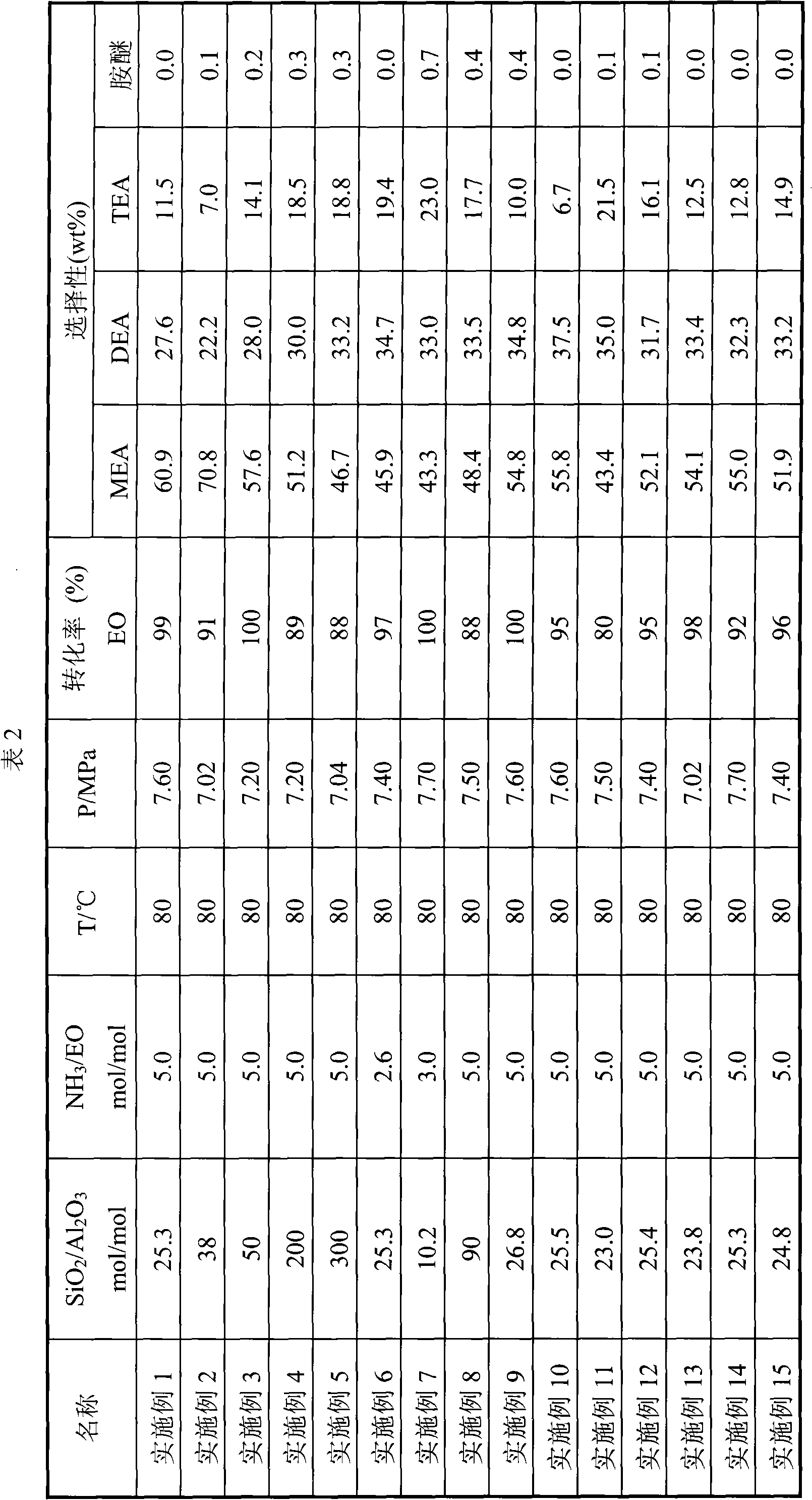

Method for producing ethanolamine

ActiveCN101885686AGood acidity distributionPromote regenerationMolecular sieve catalystsOrganic compound preparationEthylene oxideReaction temperature

The invention relates to a method for producing ethanolamine, mainly solving the technical problem of high reaction temperature and high system pressure in the prior art. The technical problem is well solved by using a technical scheme in which ethylene oxide and ammonia are used as raw materials and ZSM-5 is taken as a catalyst for reaction to produce ethanolamine under the conditions that the mole ratio of ammonia to ethylene oxide is 0.5-15, the reaction temperature is 50-100 DEG C, the system pressure is 4-12 MPa, and liquid-phase space velocity is 0.5-4h<-1>. The method can be used in the industrial production of the ethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

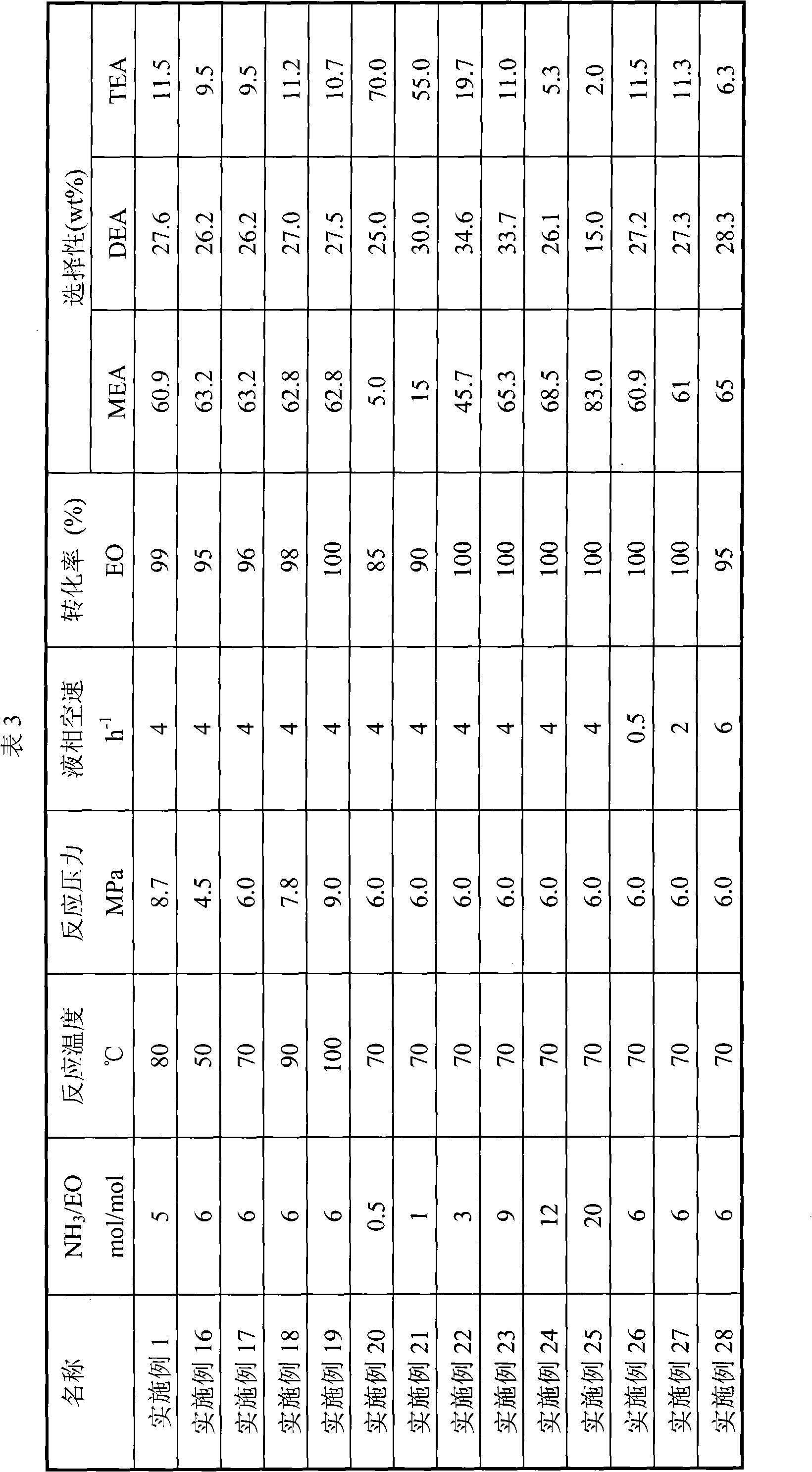

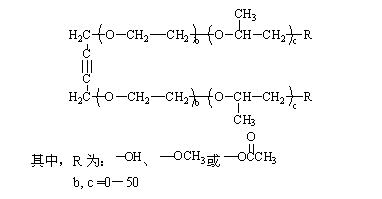

Alkynyl diol ethyl oxide polyether or alkynyl diol propyl oxide polyether co-modified polysiloxane and preparation method thereof

The invention relates to alkynyl diol ethyl oxide polyether or alkynyl diol propyl oxide polyether co-modified polysiloxane, wherein the molecular structure of the alkynyl diol ethyl oxide polyether or alkynyl diol propyl oxide polyether co-modified polysiloxane is shown in the specification. The alkynyl diol ethyl oxide polyether or alkynyl diol propyl oxide polyether co-modified polysiloxane provided by the invention has the advantages of low surface tension, efficient wetting power, low foam / foam inhibition performance and stronger emulsifying property.

Owner:CHINA RES INST OF DAILY CHEM IND

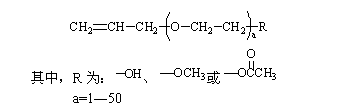

Method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide

ActiveCN101824022AHigh activityReduce lossesOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyAlkaline earth metal

The invention relates to a method for synthesizing ethylene carbonate or propylene carbonate with carbon dioxide and ethylene oxide or propylene oxide. The method adopts continuous circulation reaction; 150g / h ethylene oxide or propylene oxide and 2-4Mpa of carbon dioxide are respectively added from the bottom of a reactor; the reaction pressure is 1.0-5.0Mpa, the reaction temperature is 100-200 DEG C, and the reaction time lasts for 1-5 hours; a catalyzer is compositive catalyzer formed by carbonate and alkyl imidazolium or fxanol ionic liquid; the catalyzer is 7.5g / h, and the weight ratio of the carbonate to the alkyl imidazolium or fxanol ionic liquid ammonia is 1: 6.5; and the carbonate is alkali carbonate or aldaline-earth metal carbonate. The invention has simple process, high activity of the catalyzer and less loss of the catalyzer, the percent conversion of epoxy ethane reaches 96-99 percent, and the selectivity is 97-99 percent.

Owner:PETROCHINA CO LTD

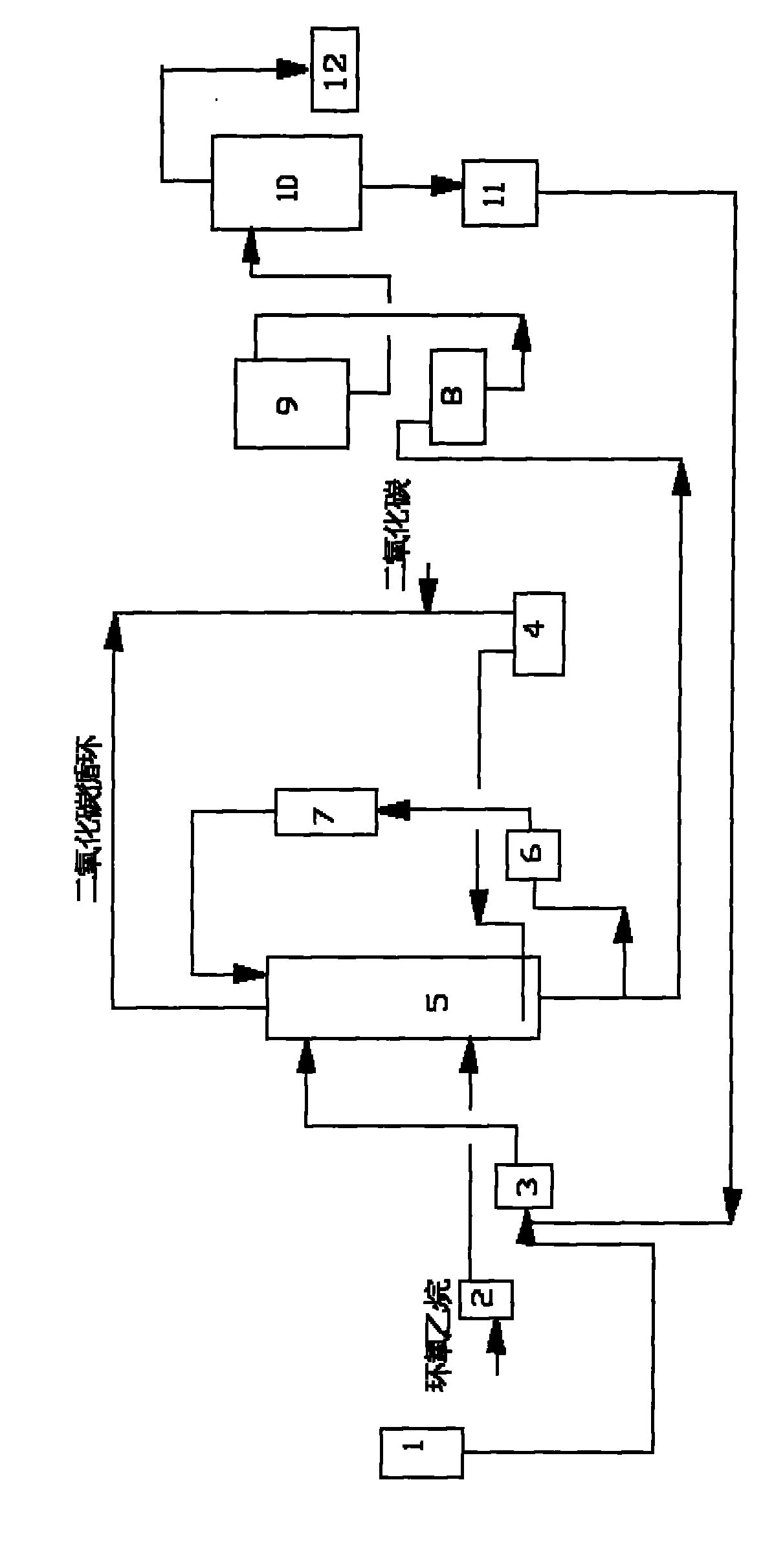

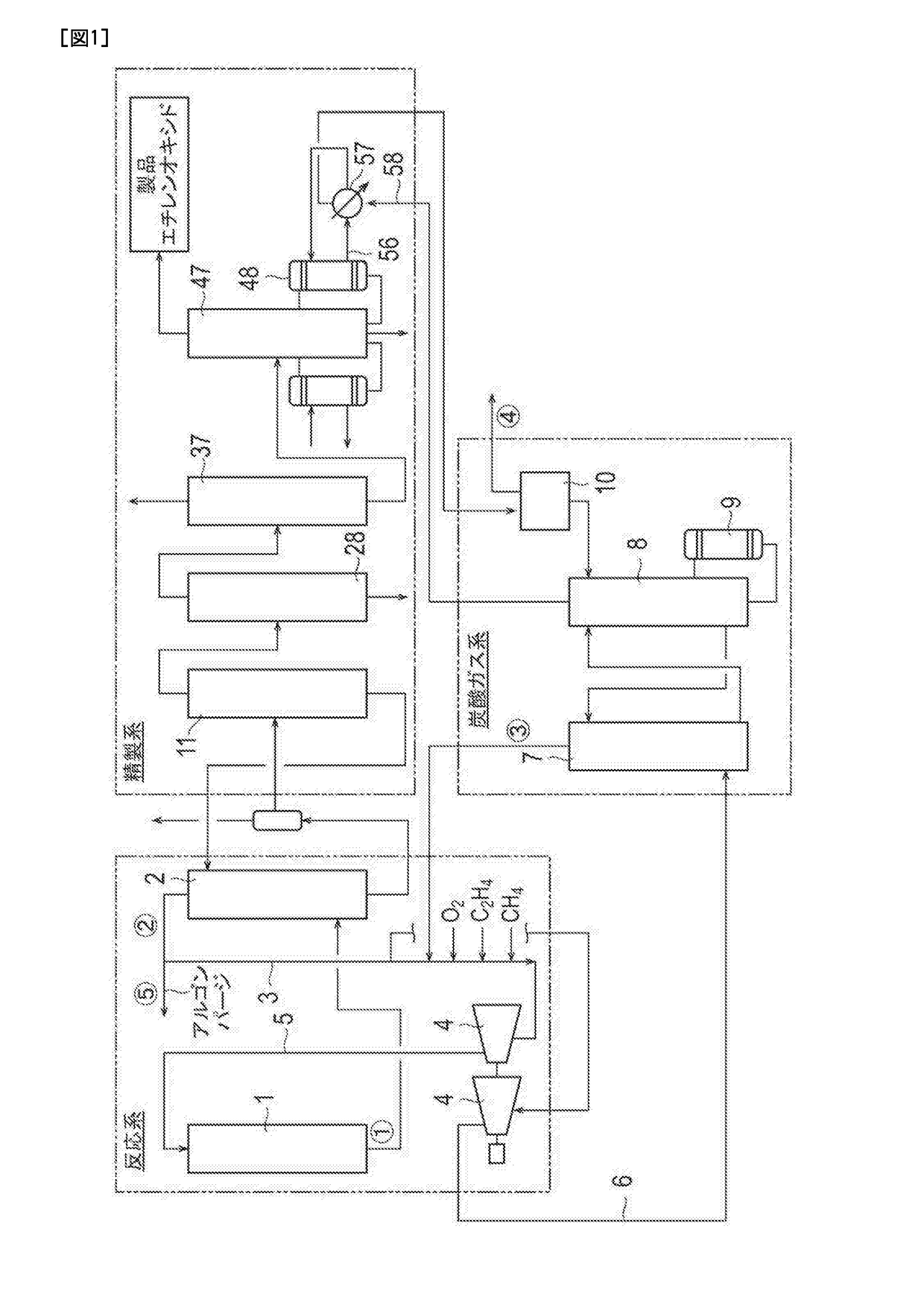

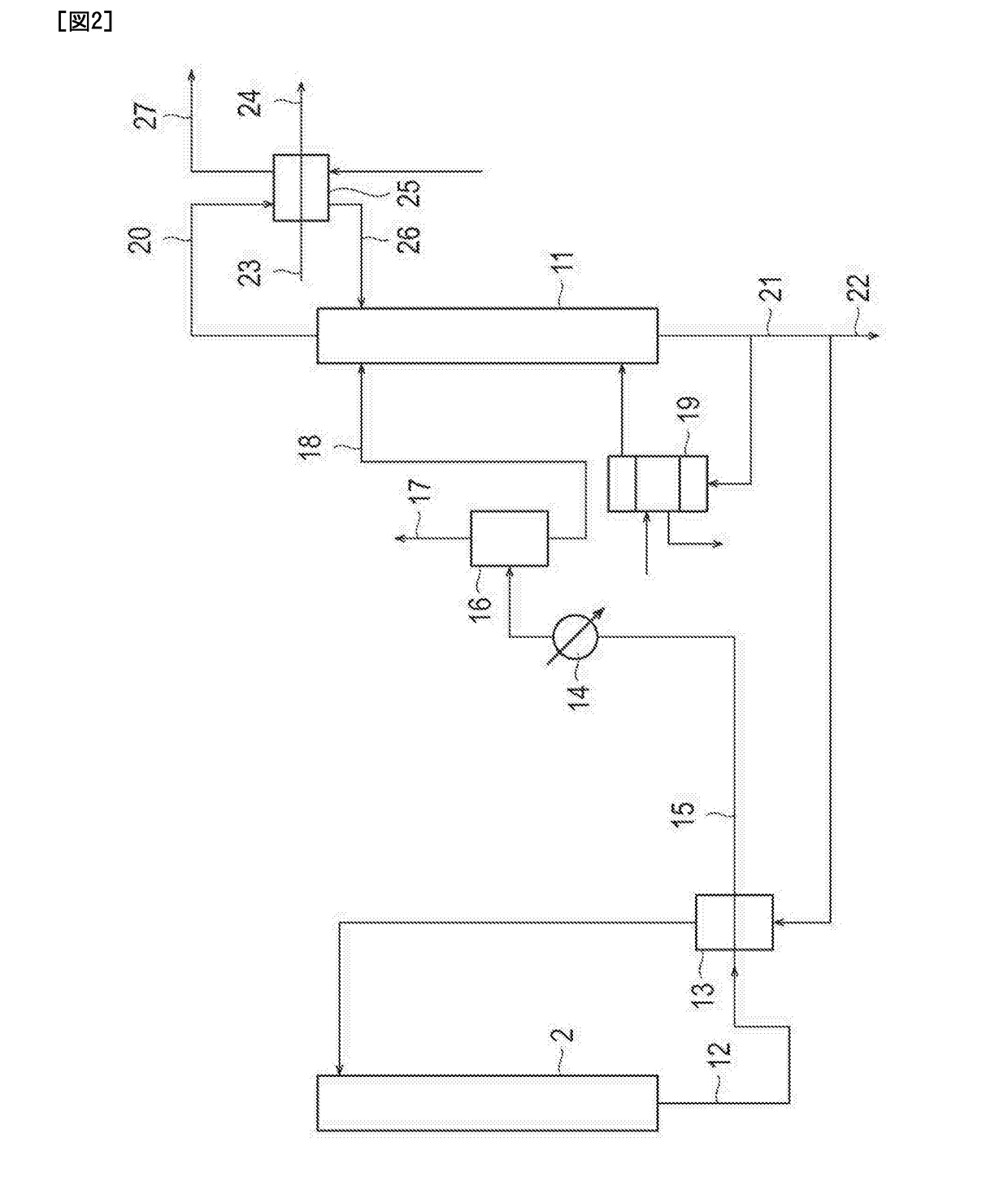

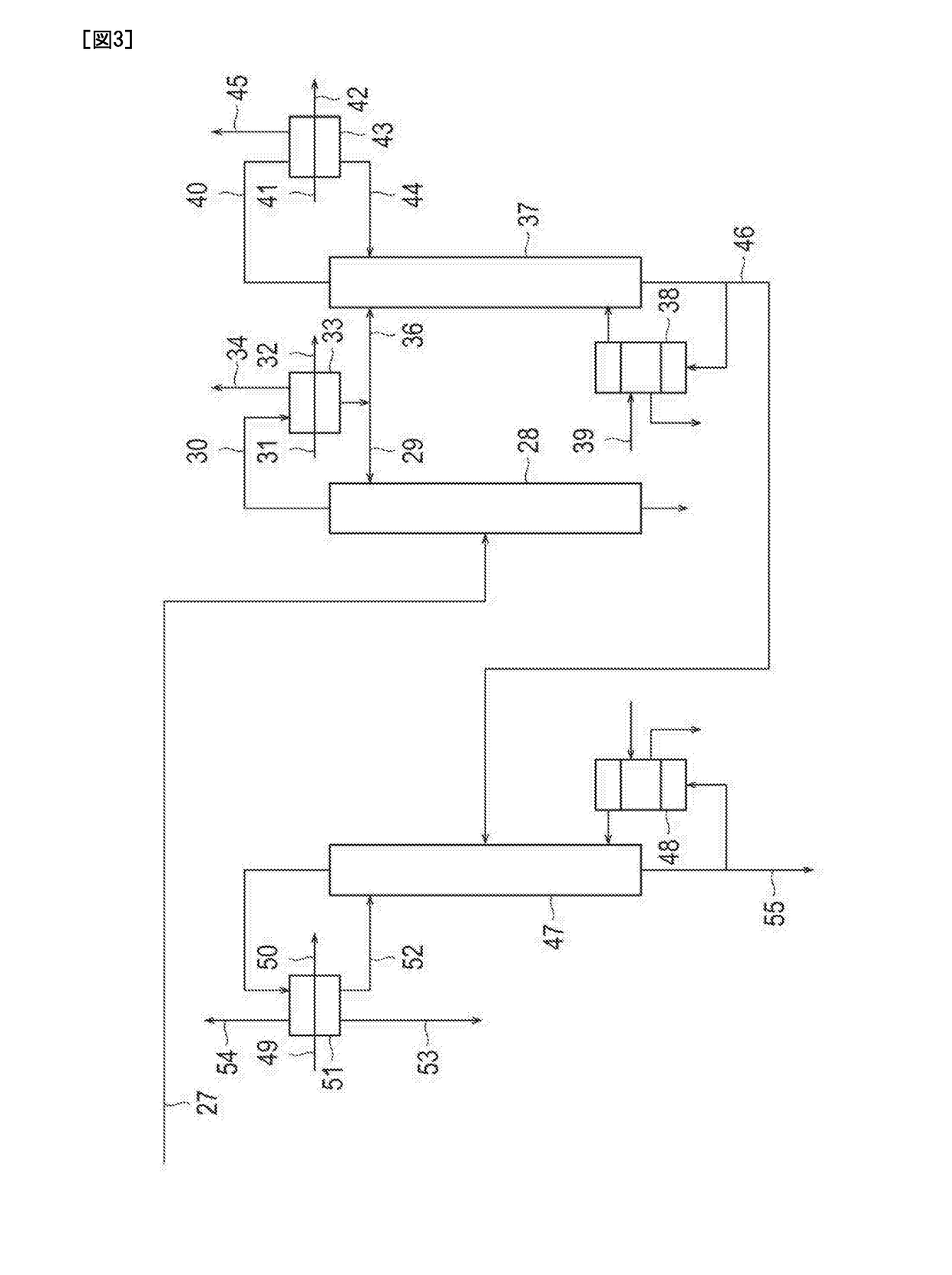

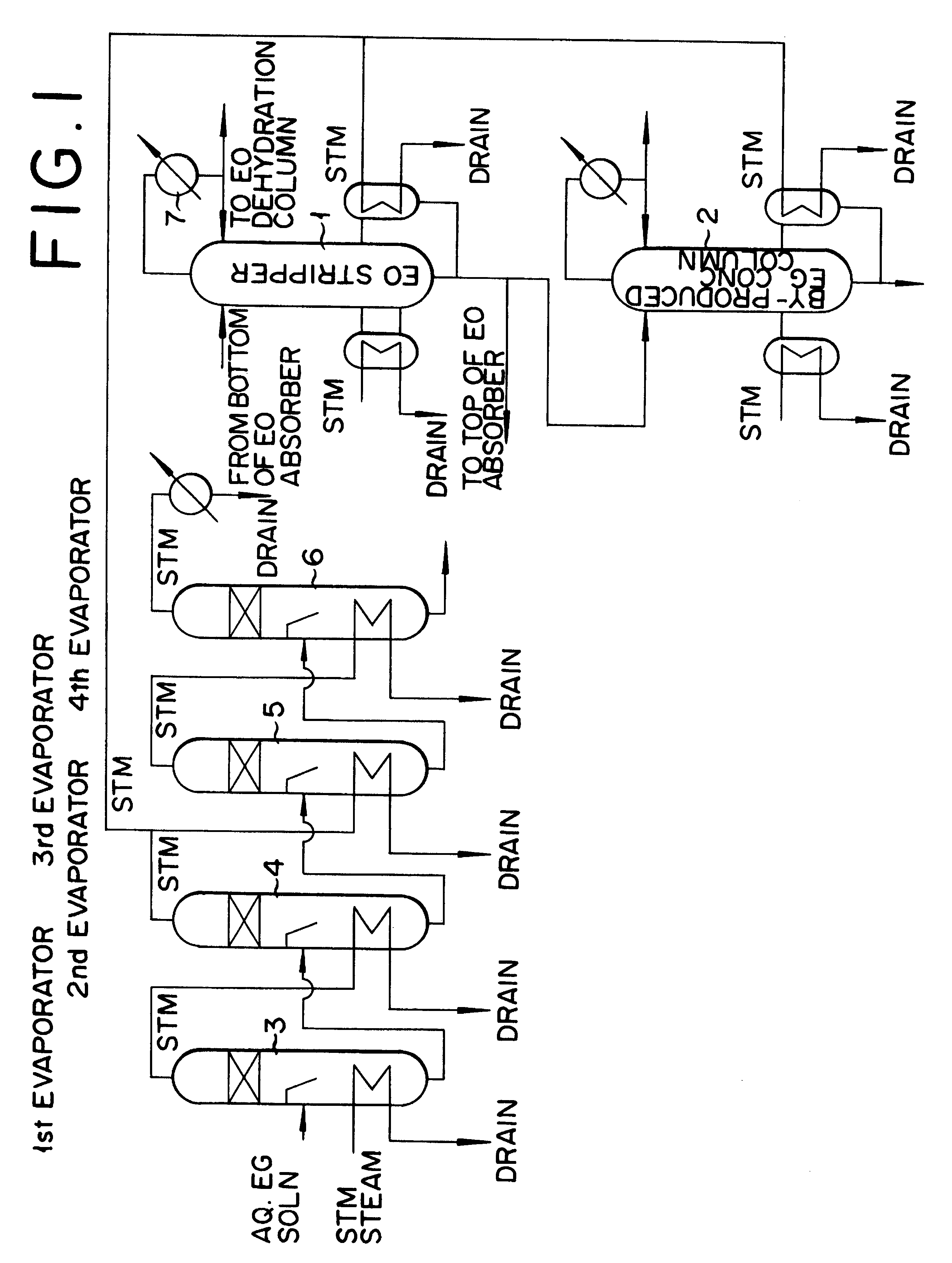

Process for producing ethylene oxide

ActiveUS20170107188A1Reduce decreaseReduce the amount requiredOrganic chemistryGas phaseAbsorption column

To provide a novel technique capable of further reducing the argon purge amount in a process for producing ethylene oxide.A method for producing ethylene oxide, including: a step of supplying an ethylene oxide-containing reaction product gas produced in an ethylene oxidation reaction step in an ethylene oxidation reactor, in which ethylene is subjected to contact gas-phase oxidation using a molecular oxygen-containing gas in the presence of a silver catalyst, to an ethylene oxide absorption column to bring the reaction product gas into contact with an absorption liquid supplied to the ethylene oxide absorption column, supplying an ethylene oxide-containing column bottom liquid of the ethylene oxide absorption column to an ethylene oxide purification system, and purifying ethylene oxide in the ethylene oxide purification system; and a step of supplying at least part of a carbon dioxide gas-containing gas discharged from a column top part of the ethylene oxide absorption column to a carbon dioxide gas absorption column to bring the carbon dioxide gas-containing gas into contact with an absorption liquid, extracting the resulting carbon dioxide gas-rich absorption liquid as a column bottom liquid of the carbon dioxide gas absorption column and supplying the same to an upper part of a carbon dioxide gas stripper column, and stripping a carbon dioxide gas from the carbon dioxide gas-rich absorption liquid and discharging the same from a column top part of the carbon dioxide gas stripper column as an exhaust gas, the concentration of molecular oxygen (O2) in the molecular oxygen-containing gas supplied from outside the system into the system being 99.7% by volume or more.

Owner:NIPPON SHOKUBAI CO LTD

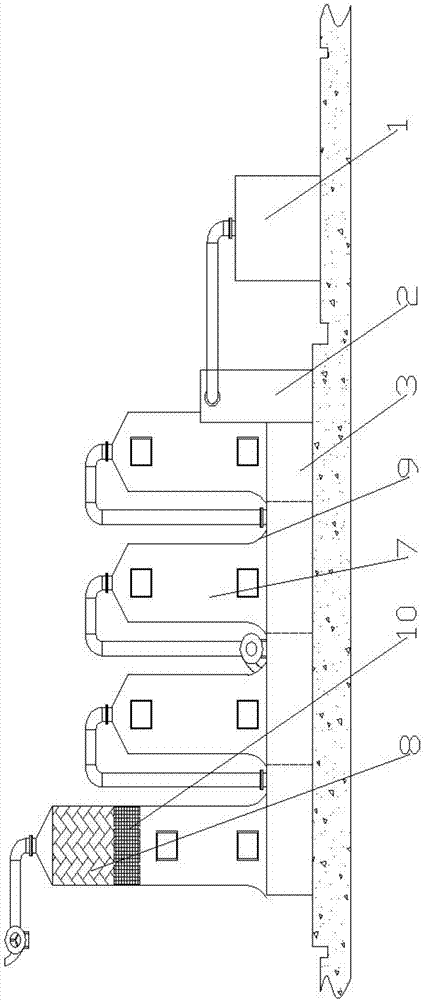

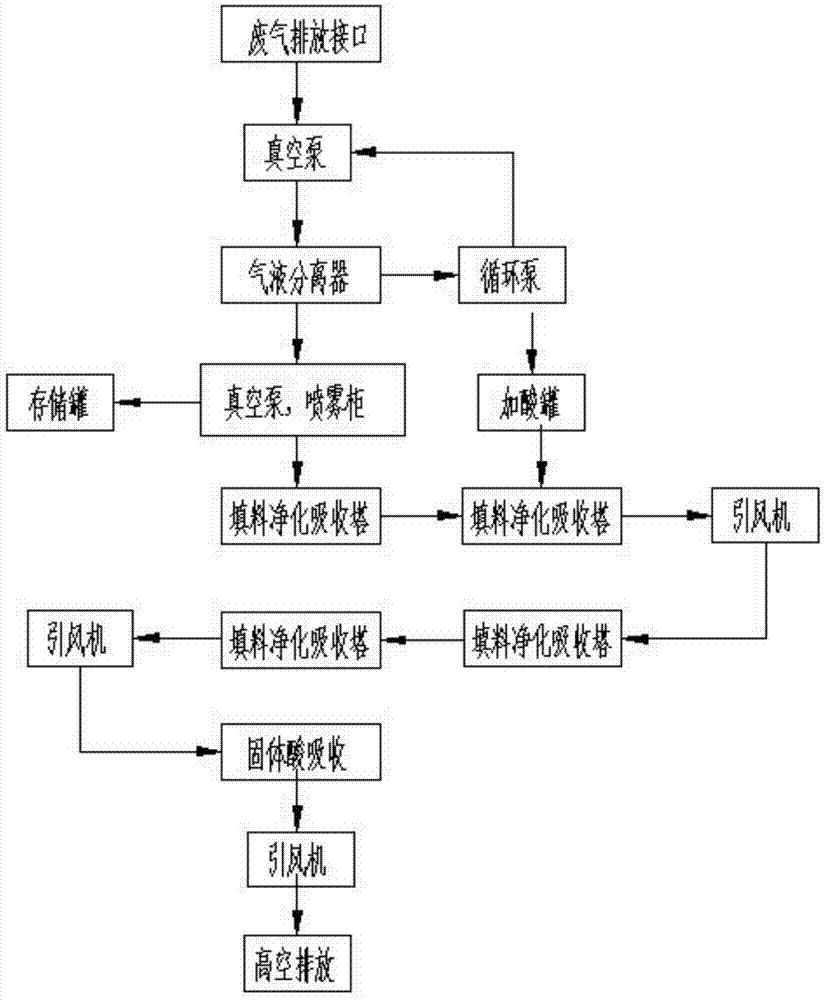

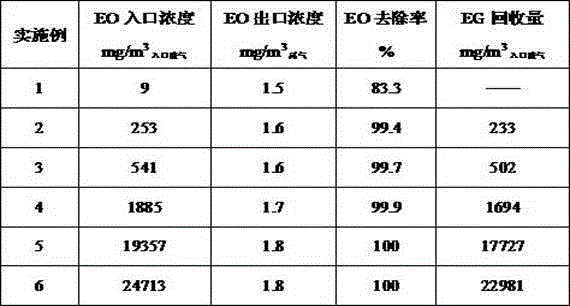

Ethylene oxide waste gas recycling treating system

ActiveCN104275085AGood technical effectEmission reductionDispersed particle separationVapor–liquid separatorEthylene oxide

The invention relates to a waste gas treatment system and in particular relates to an ethylene oxide waste gas recycling treating system. The ethylene oxide waste gas recycling treating system comprises a gas-liquid separator (1), an atomizing cabinet (2) and a water collection tank (3) which are sequentially connected with one another by virtue of a pipeline, wherein N filler purifying absorbing towers (7) used for absorbing ethylene oxide are sequentially arranged inside the water collection tank (3); filler layers are arranged inside the filler purifying absorbing towers (7); pipelines connected with the water collection tank are arranged at the top ends of former N-1 filler purifying absorbing towers (7); an active carbon solid acid layer (8) is arranged at the upper part of the filter layer of the Nth filler purifying absorbing tower (7). According to the ethylene oxide waste gas recycling treating system, the ethylene oxide is cooled firstly and is in relatively well contact with water vapor, then ethylene glycol within a wide application range is generated by the ethylene oxide in a multistage absorbing tower, finally the ethylene oxide is adsorbed and converted again by active carbon solid acid, so that the emission amount of the ethylene oxide is minimized.

Owner:杭州竹影科技有限公司

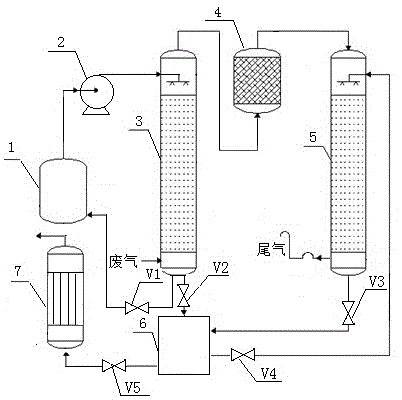

Recycling method of ethylene oxide-containing organic waste gas

InactiveCN104815535AReduce contentReduce environmental disposal costsDispersed particle separationHydration reactionResource utilization

The present invention discloses a recycling method of ethylene oxide-containing organic waste gas. The specific technical scheme comprises that: ethylene oxide in ethylene oxide-containing organic waste gas is subjected to circulation absorbing in a hydrolysis tower by using dilute sulfuric acid with a certain concentration as an absorbent so as to produce a hydration reaction to generate ethylene glycol, the ethylene glycol is conveyed into an ethylene glycol solution storage tank after the ethylene glycol in the solution achieves a certain concentration, a sodium hydroxide solution is added to neutralize, one part of the neutralized ethylene glycol solution is used for the acid gas washing process, the other part is conveyed to the product separation and recovery, the tail gas discharged from the hydrolysis tower enters a reactor to carry out deep oxidation, an acid gas washing treatment is performed, the treated standard tail gas is discharged into the atmosphere, and the absorbing liquid is recycled to the ethylene glycol solution storage tank. According to the present invention, the method has characteristics of short process and simple operation, and with the treatment of the present invention, the ethylene oxide content in the organic waste gas tail gas does not exceed 1 ppm, and a certain amount of the ethylene glycol solution is recovered so as to achieve the resource utilization of the waste gas.

Owner:SHANXI DATONG UNIV

Method for production of ethylene glycol

InactiveUS6417411B2Efficient comprehensive utilizationSmall consumptionOxygen-containing compound preparationOrganic compound preparationGas phaseEthylene oxide

In a composite process for subjecting ethylene to catalytic gas phase oxidation thereby obtaining ethylene oxide and causing this ethylene oxide to react with water thereby obtaining ethylene glycol, a method for producing the ethylene glycol is provided which permits effective utilization of the energy at the step for dehydrating and concentrating the resultant aqueous ethylene glycol solution. In the production of ethylene glycol by the supply of the aqueous ethylene glycol solution to a concentrating treatment at the multi-effect evaporator, the method contemplated by this invention for the production of ethylene glycol comprises utilizing as the source of heating at least one specific step the steam generated in the multi-effect evaporator.

Owner:RECOVERYCARE COM +1

Full-biological degradation nonwoven cloth material

InactiveCN101220534AConjugated synthetic polymer artificial filamentsNon-woven fabricsEpoxyCyclohexene oxide

The invention relates to a total biodegradable non-woven fabric material which is produced by adding 10 to 40 percent of low molecular weight carbon dioxide-cyclohexene oxide copolymer or 10 to 40 percent of high molecular weight poly L-polylactic acid or 10 to 40 percent of poly-hydroxylic butyrate to biodegradable carbon dioxide-propylene oxide or carbon dioxide-epoxy ethane copolymer materials, thus improving the dimensional stability of the carbon dioxide copolymer under high temperature. The number average molecular weight of the carbon dioxide-cyclohexene oxide copolymer is between 4000 and 8000 and the number average molecular weight of the poly L-polylactic acid is above 100,000. By using the carbon dioxide copolymer material of the invention, manufacture can be carried out by adopting a spun-bond method which is commonly used in non-woven fabric manufacturing technique. The obtained non-woven fabrics can maintain dimensional stability at the temperature between 70 DEG C and 75 DEG C, have biodegradation characteristics under the situation of composts or landfill with carbon dioxide and water as degradation end products, and cannot pollute environment when being burnt.

Owner:吉林金源北方科技发展有限公司

Method for preparing metal cyanide catalyst complexes using partially miscible complexing agents

InactiveUS20050065383A1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolyolCyanide

Double metal cyanide catalysts (DMC) are complexed with complexing agents that are miscible in poly(propylene oxide) at higher temperatures and immiscible at lower temperatures. The complexing agent is a poly(ethylene oxide) polymer or a copolymer having a poly(ethylene oxide) block. The catalyst is easily removed from a polyether polyol.

Owner:DOW GLOBAL TECH LLC

Method for preparing ethylene glycol phenyl ether, propylene glycol phenyl ether and butylene glycol phenyl ether

InactiveCN101712600AAvoid many problems caused by distillation processLess investmentEther preparation from oxiranesPolymer sciencePhenyl Ethers

The invention discloses a method for preparing ethylene glycol phenyl ether, propylene glycol phenyl ether and butylene glycol phenyl ether, comprising the following steps: 1) firstly, adding phenyl into a reaction kettle, introducing inert gas and adding catalyst, then adding ethylene oxide or propylene oxide or butylene oxide, reacting under the conditions that the temperature is at 70-140 DEG C and the pressure is less than 1 MPa, thereby generating the crude product of ethylene glycol phenyl ether or propylene glycol phenyl ether or butylene glycol phenyl ether, wherein the mol ratio of the added phenyl to the added ethylene oxide or propylene oxide or butylene oxide is 1:0.6-1; and 2) reducing pressure and distilling the prepared crude benzene under the conditions that the vacuum degree is not less than 0.07MPa and the temperature is at 80-110 DEG C, thereby obtaining the product of ethylene glycol phenyl ether or propylene glycol phenyl ether or butylene glycol phenyl ether. The product of ethylene glycol phenyl ether or propylene glycol phenyl ether or butylene glycol phenyl ether prepared by the invention has a purity more than 99%, and does not need to be rectified and purified; and the method has the advantages of low equipment investment, convenient maintenance, simple operation control, low comprehensive cost and the like, and has considerable economic benefit.

Owner:JIAHUA CHEM

Compound demulsifying agent and method of use thereof

ActiveCN101352666AReduce dosageGood desalination effectTransportation and packagingMixingDemulsifierStyrene-maleic anhydride copolymer

The invention relates to a compound demulsifier and a use method thereof. The compound demulsifier comprises alkyl ester of styrene-maleic anhydride copolymer and ethylene oxide-propylene oxide block polymer, the mass ratio of which is 0.1 to 10: 1. The compound demulsifier of the invention, through compound use of the alkyl ester of styrene-maleic anhydride copolymer and the ethylene oxide-propylene oxide block polymer, can achieve better demulsification effect and is particularly applicable to the demulsification and dehydration of high-asphaltene viscous oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-based demulsifying agent and its use in the treatment of drains bored in oil-based mud

InactiveUS20020055438A1Dewatering/demulsification with chemical meansCleaning apparatusFatty acidPhenol derivative

An oil-based demulsifying formulation which can be used in the treatment of drains bored in oil-based mud, non ecotoxic and optimally compatible with formation fluids, comprises at least one wetting agent selected from the group consisting of anionic surfactants and at least one demulsifier (or "emulsion breaker") selected from the group consisting of copolymers of ethylene oxide and propylene oxide, alcohol or phenol derivatives with alkoxylated or polyalkoxylated chain formations, polyalkyleneglycols, polyamines, alkoxylated or polyalkoxylated derivatives of amines, quaternary ammonium salts, quaternized alkanolamine esters, alkyl esters of fatty acids or natural oils, possibly alkoxylated or polyalkoxylated, and silicated derivatives such as polysiloxanes.

Owner:INST FR DU PETROLE

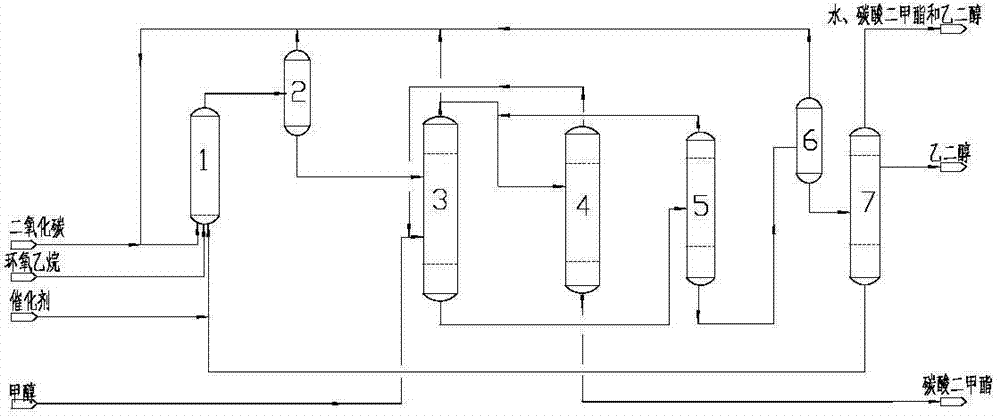

Dimethyl carbonate and ethylene glycol production process

ActiveCN104761429ALow conversion rate per passReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationMethyl carbonateEthylene oxide

The invention relates to a dimethyl carbonate and ethylene glycol production process which is characterized in that the process comprises the following five steps: (a) the carbonylation step for production of ethylene carbonate by catalysis of reaction of ethylene oxide and carbon dioxide by use of an ionic liquid composite catalyst; (b) the step of alcoholysis for ester exchange reaction of the ionic liquid composite catalyst-containing ethylene carbonate solution of the step (a) and methanol in a reaction distillation tower and product separation; (c) the step of purification and refining of dimethyl carbonate from tower top condensate in the reaction distillation tower of the step (b); (d) the step of separation, transformation and refining of ethylene glycol from tower bottom liquid in the reaction distillation tower of the step (b); and (e) the step of circulation cycle of from the ionic liquid composite catalyst in the step (d) to the catalyst in the step (a). The process has the characteristics of high ethylene carbonate one-way conversion rate, simple process flow, small equipment investment, less waste emissions, low energy consumption and the like, and can make companies stronger in competitiveness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com