Patents

Literature

191results about How to "Reduce environmental disposal costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

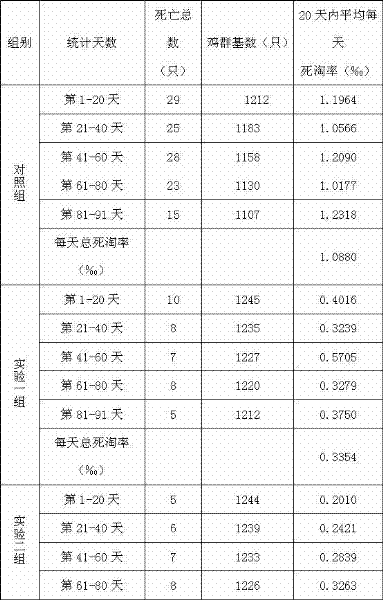

Fermented feed additive, preparation method and application

ActiveCN102550815ASlow down digestionPromote digestion and decompositionFood processingAnimal feeding stuffMonosodium glutamateBacillus licheniformis

The invention discloses a fermented feed additive, a preparation method and application thereof. The fermented feed additive is prepared by fermenting mixed strains and mixed auxiliary materials consisting of monosodium glutamate protein, bean pulp, bran, cottonseed meal, corn fibers, rice bran and powdered rice hulls, wherein the mixed strains are obtained by mixing activated strains of lactobacillus acidophilus, lactobacillus planetarium, lactobacillus casei, saccharomyces cerevisiae, bacillus subtilis and bacillus licheniformis in a proportion of (1-5): (1-5): (1-5): (1-5): (1-5): (1-5); and the dosage of the fermented feed additive is 5 to 100 percent of the weight of the animal feed when used for the animal feed. According to the fermented feed additive, the bean pulp, the bran, the cottonseed meal and other raw auxiliary materials are sufficiently utilized, so that the food consumption in the animal feeding process is reduced; the fermented feed additive can be used to partiallyor completely replace the animal feed, and antibiotic medicaments can be reduced or prevented from being used; and no medicament is left, so that the feeding cost of farmers is reduced.

Owner:WEIFANG ZHONGKEJIAYI BIO FODDER TECH

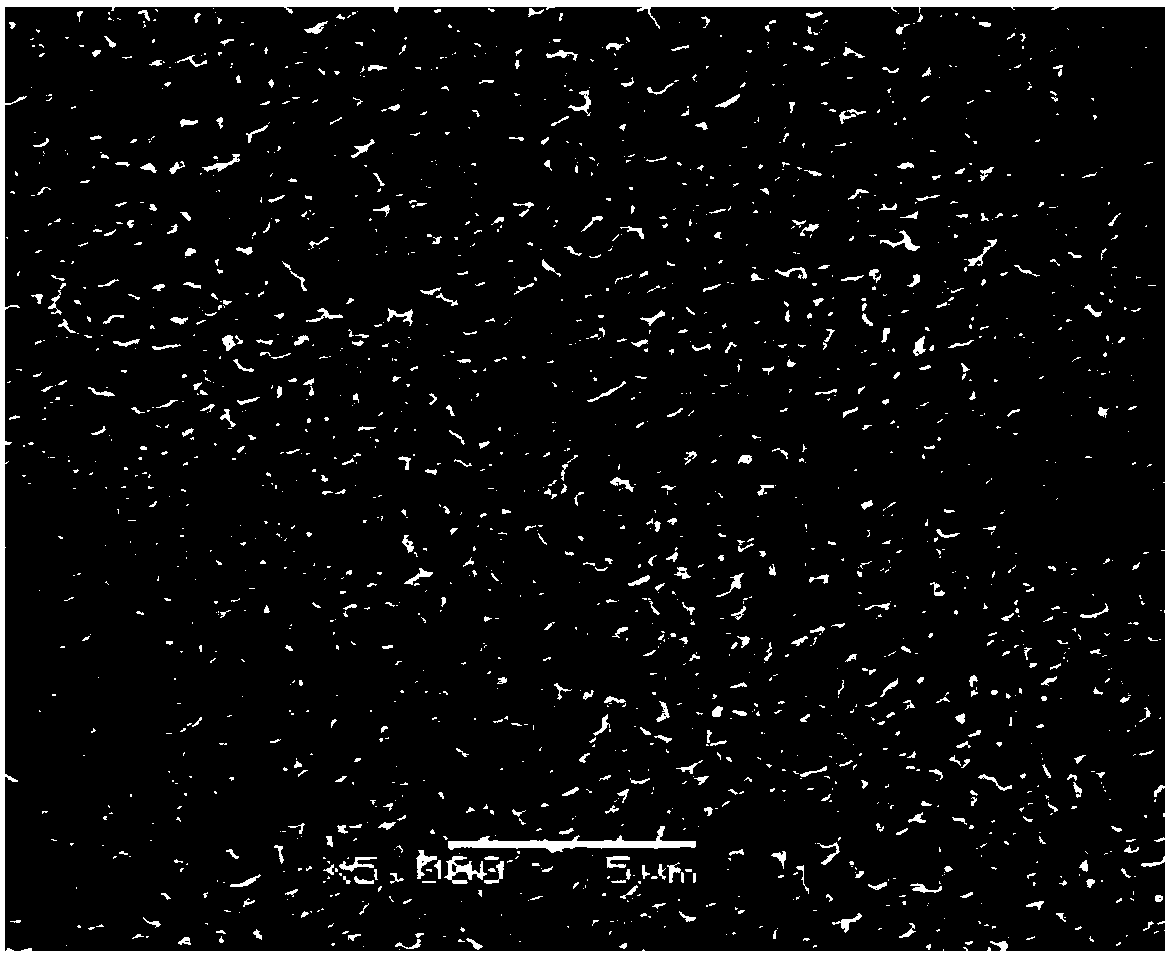

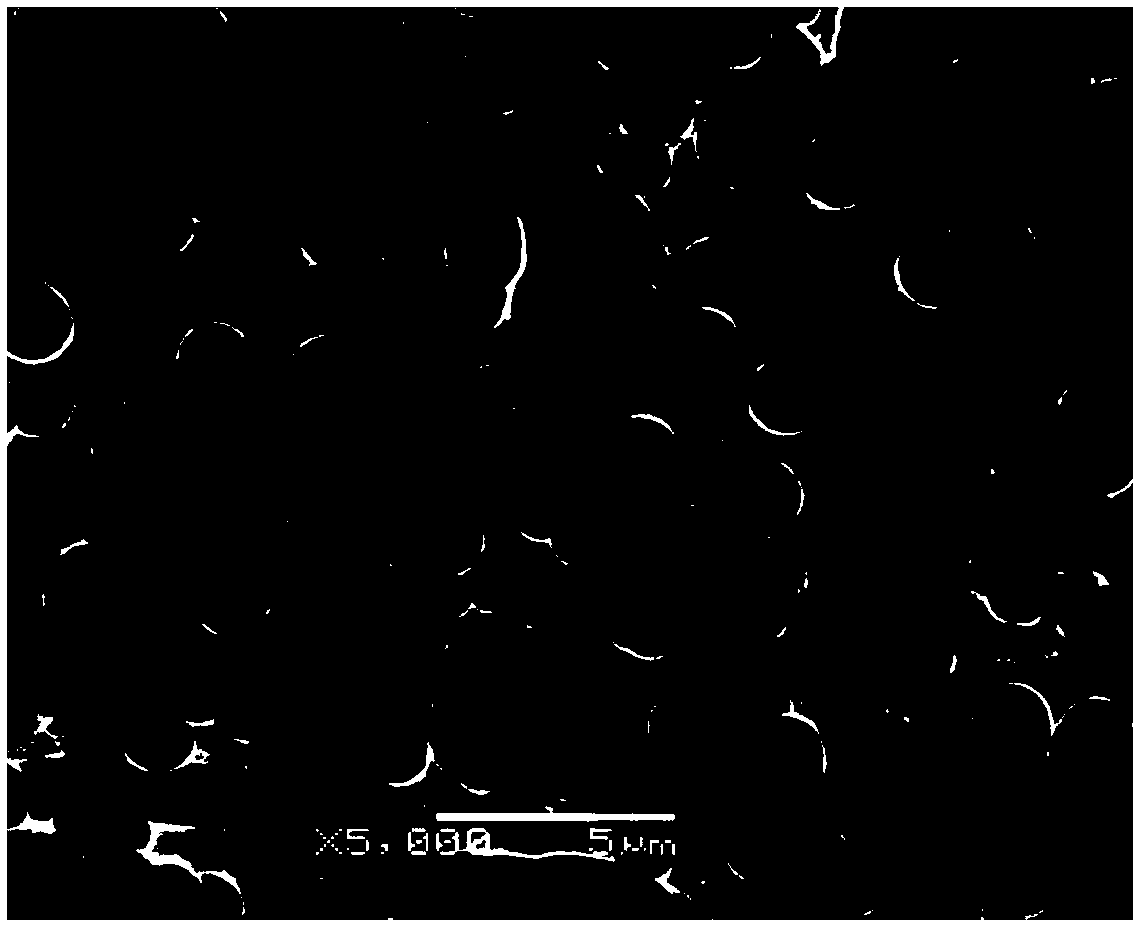

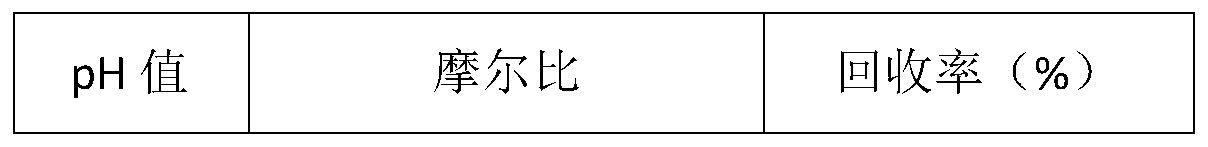

Texturing method for polysilicon wafer cutting by diamond wire

InactiveCN107658221AReduce reflectivityReduce dosageSemiconductor/solid-state device manufacturingPhotovoltaic energy generationCrystalline siliconMaterials science

The invention belongs to the texturing field of a crystalline silicon solar cell, and specifically relates to a texturing method for polysilicon wafer cutting by a diamond wire. The texturing method comprises the following steps of 1, preparing a corrosion liquid, putting a silicon wafer into the corrosion liquid to be reacted at a temperature of 20-80 DEG C for 4-15min to form a porous structureon the surface of the silicon wafer; 2, performing water washing on the silicon wafer processed in the first step, and then cleaning the silicon wafer by a demetalization cleaning liquid at a normal temperature to remove solid metal granules from the silicon wafer, wherein the cleaning time is 2-8min; and 3, performing water washing on the silicon wafer processed in the second step for 30-100S; and performing correction on the porous structure on the surface of the silicon wafer by adopting a texturing correction liquid. By cutting the polysilicon surface by the diamond wire, the texturing structure with uniform dimensions, hole diameter of 400nm-1.5mm, hole depth of 200-500nm and low reflectivity can be obtained, thereby improving photoelectric conversion efficiency effectively.

Owner:NANJING NAXIN NEW MATERIAL

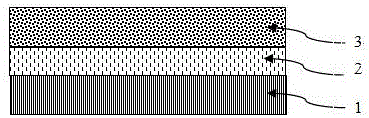

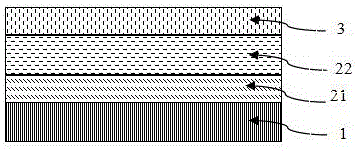

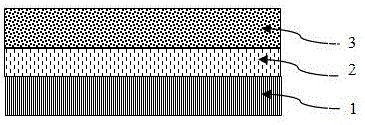

Photoelectric thin film capable of strengthening adhesive force and application of photoelectric thin film

InactiveCN106098806ANo obvious sheddingGood adhesionSemiconductor devicesChemical platingSilicon oxide

The invention discloses a photoelectric thin film capable of strengthening the adhesive force. A thin film structure comprises a substrate, one, two or multiple interface modification layers and a metal thin film layer, wherein the interface modification layers are the same or different in material; the substrate is a glass, quartz, lead-containing glass, ceramic, zirconium oxide, aluminum oxide, silicon wafer, mica or plastic substrate; the interface modification layers are made of silicon oxide, aluminum oxide, zirconium oxide, titanium oxide or a compound of two or more of the silicon oxide, the aluminum oxide, the zirconium oxide and the titanium oxide; and the metal thin film layer is made of aluminum, silver, copper, gold and various metal alloys. Each interface modification layer is prepared by CVD, PVD or a chemical method such as a sol-gel method; and the metal thin film layer is prepared by the methods of PVD, CVD or chemical plating and the like. After the interface modification layers are adopted, the adhesion properties of the substrate and the metal thin film layer are obviously improved; the disadvantage that the metal thin film layer easily falls off on the substrate is well overcome; and the photoelectric thin film can be applied to the fields of a photoelectric device electrode, a light reflector or an anti-electromagnetic interference protective layer and the like.

Owner:EAST CHINA NORMAL UNIV

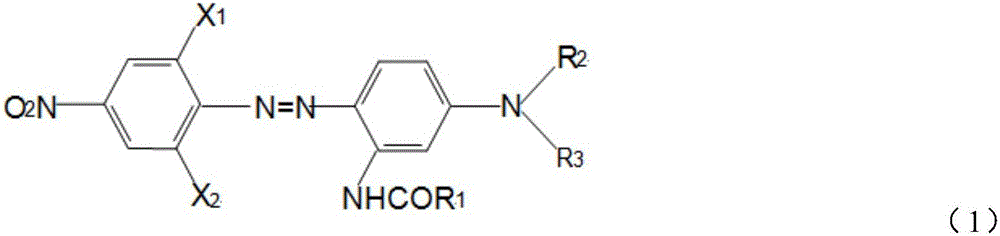

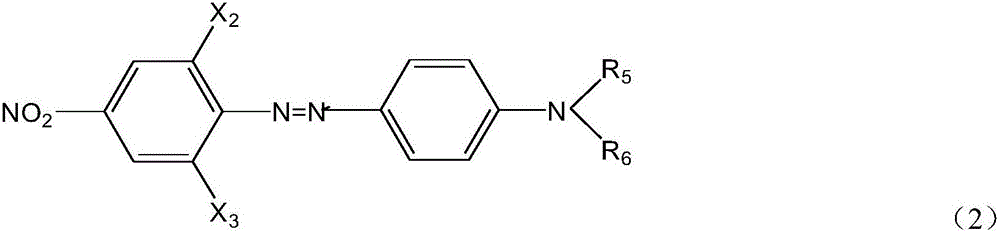

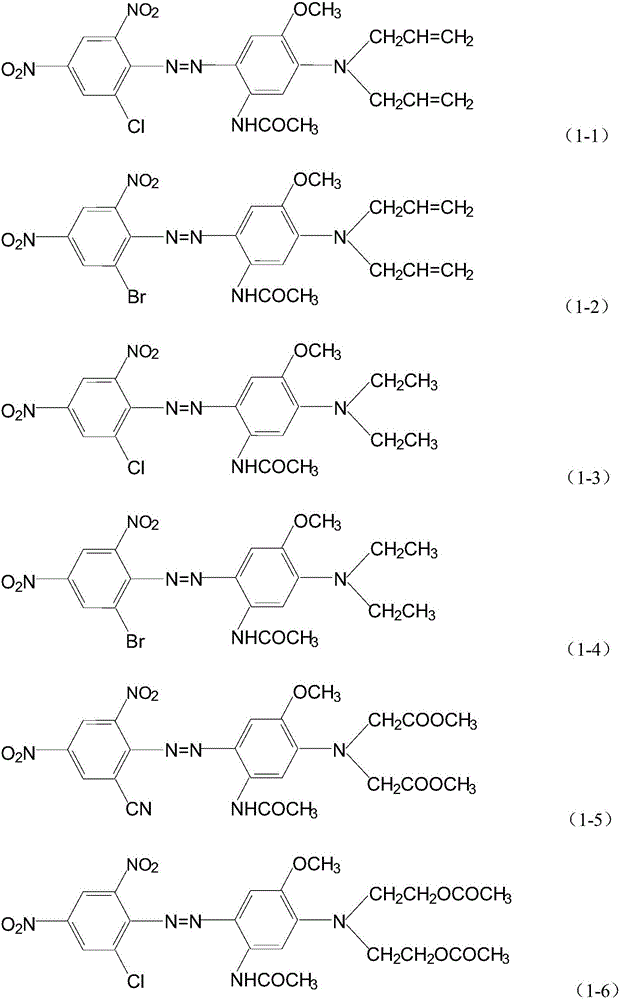

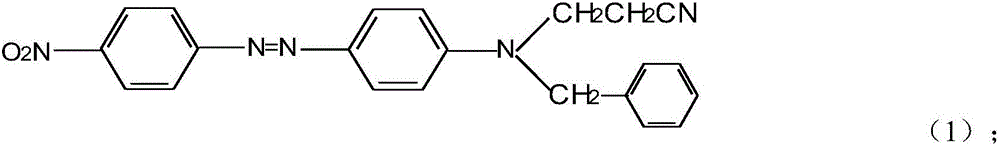

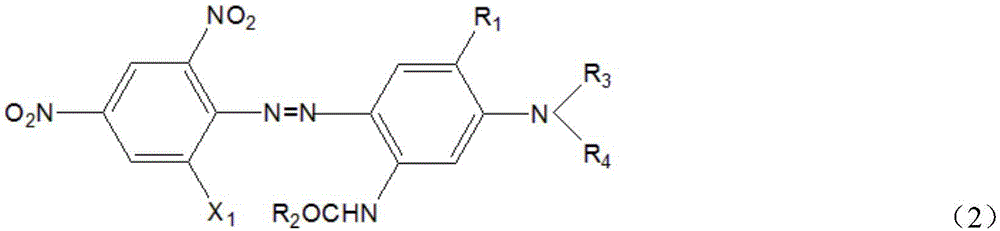

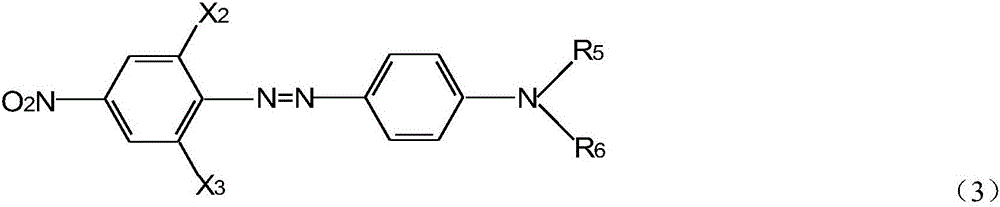

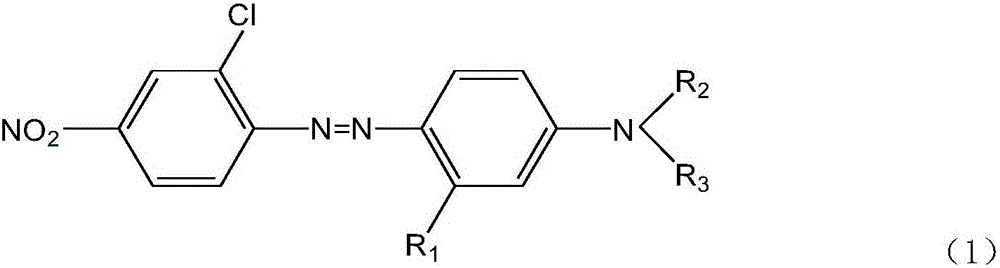

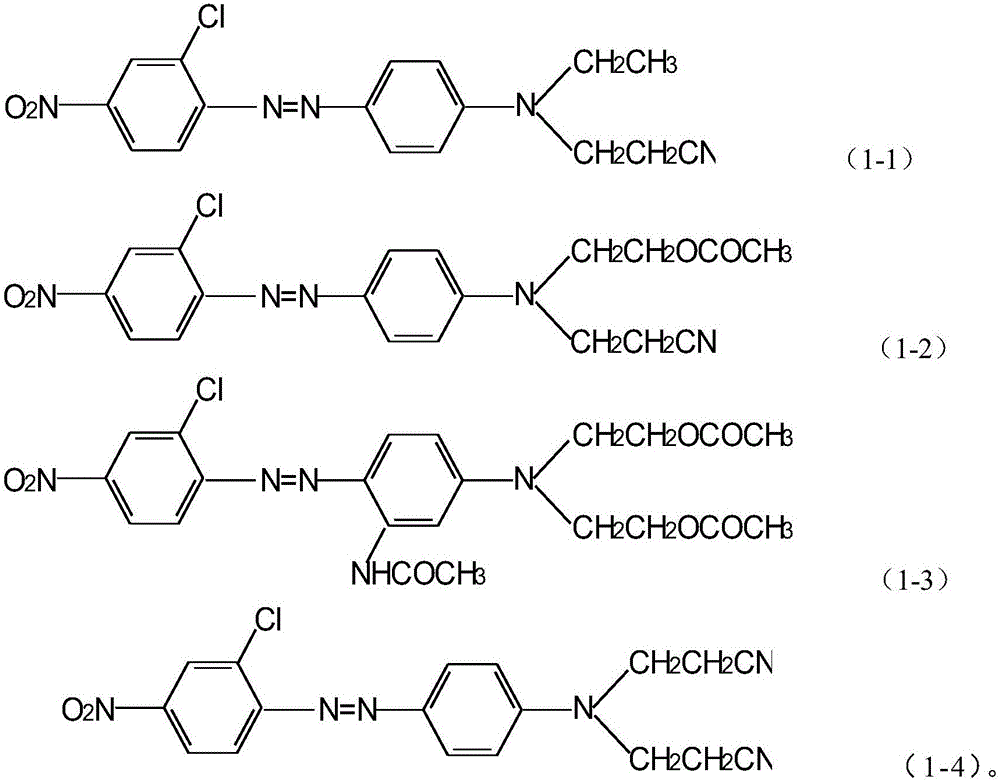

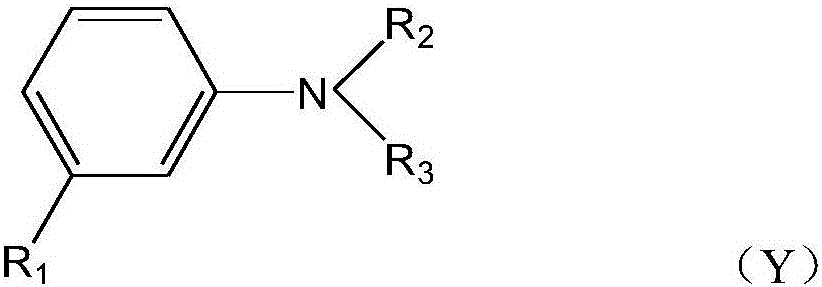

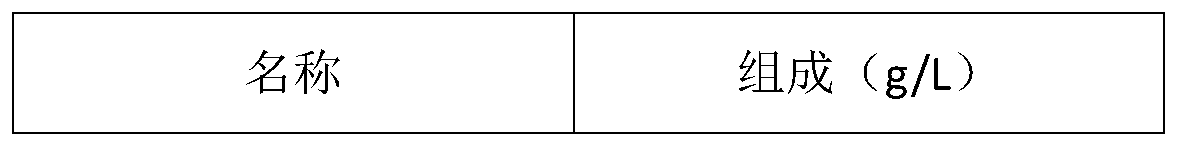

Disperse dye composition, and preparation method and application thereof

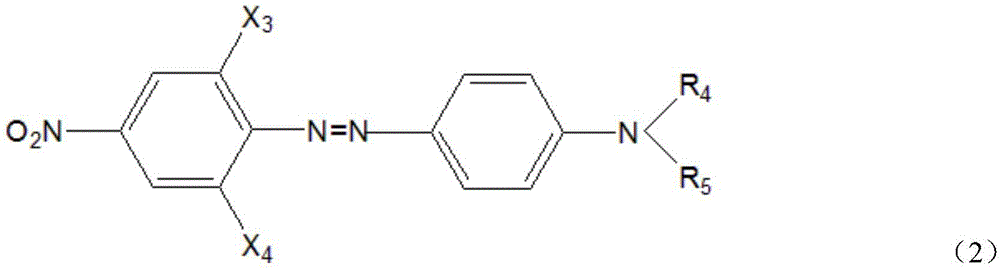

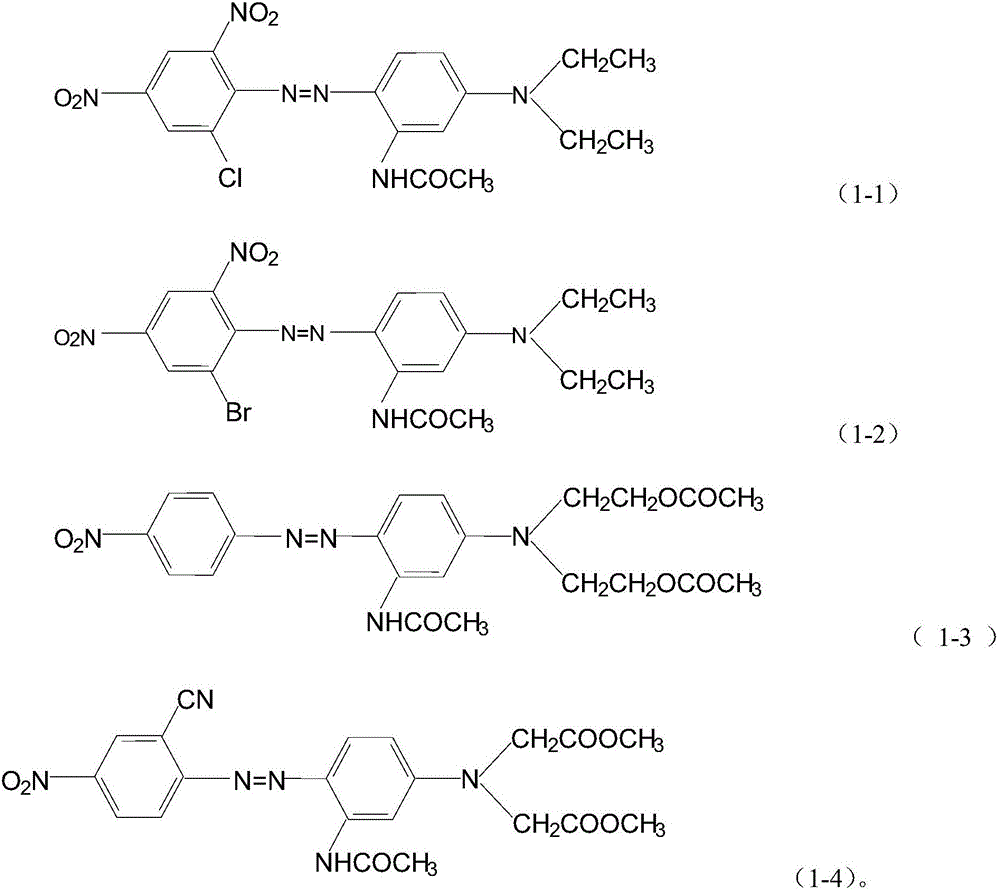

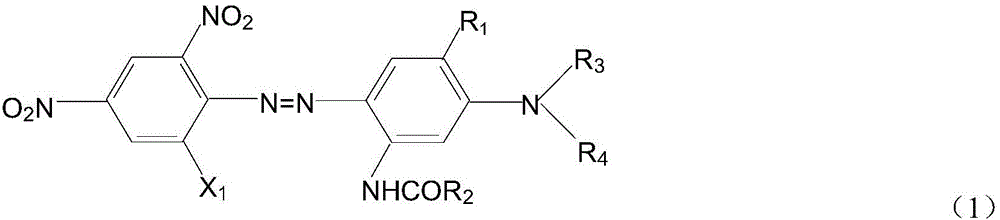

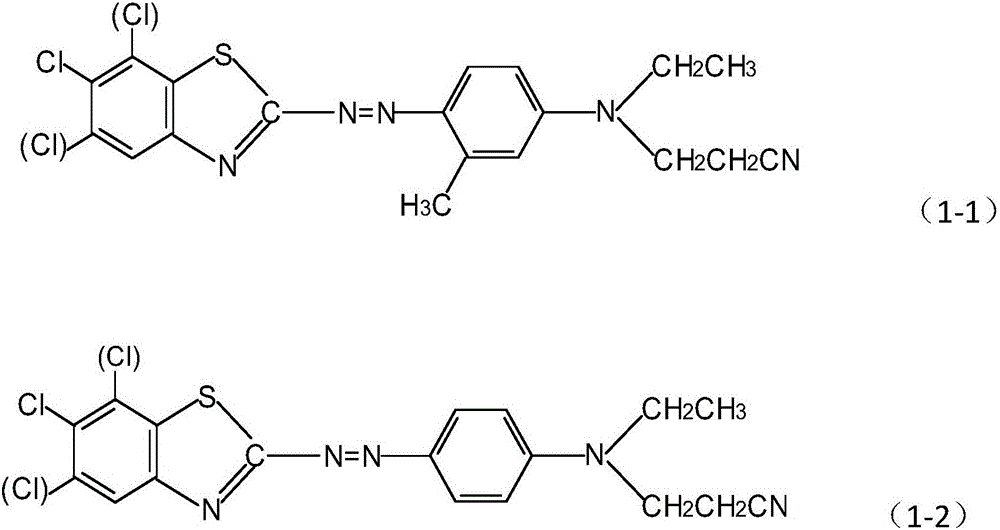

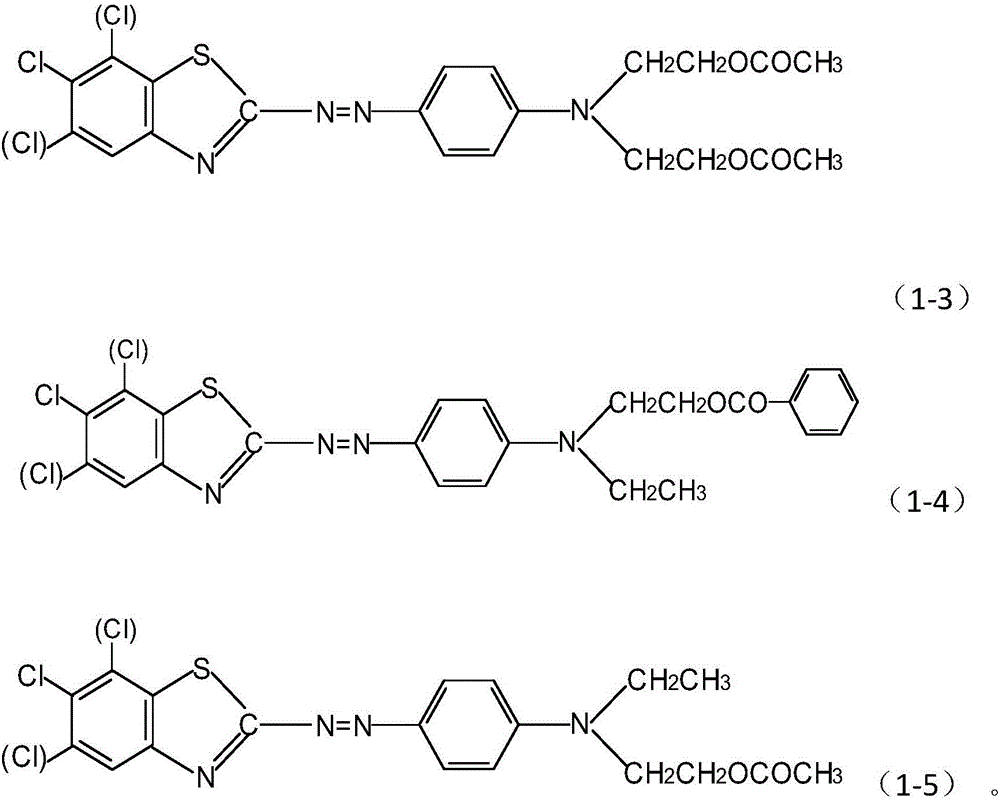

Disclosed are a disperse dye composition, and a preparation method and application thereof. The disperse dye composition comprises a component A composed of one or more of compounds shown as a formula (1) (please see the specifications for the formula), a component B composed of one or more of compounds shown as a formula (2) (please see the specifications for the formula), forbidden aromatic amine compounds, chlorinated phenols, chlorobenzene and chlorotoluene, optional auxiliaries, and other unavoidable impurities. The total content of the forbidden aromatic amine compounds is 10 ppm or below, the respective content of the various chlorinated phenols is 0.5 ppm or below, and the total content of the chlorobenzene and chlorotoluene is 1 ppm or below. The various environment protection indexes of the disperse dye composition meet the requirements of Oeko-Tex Standard 100(2016). In addition, after fabric is dyed through the disperse dye composition, the dyed fabric meets the baby level requirements of Oeko-Tex Standard 100(2016).

Owner:ZHEJIANG RUNTU INST +1

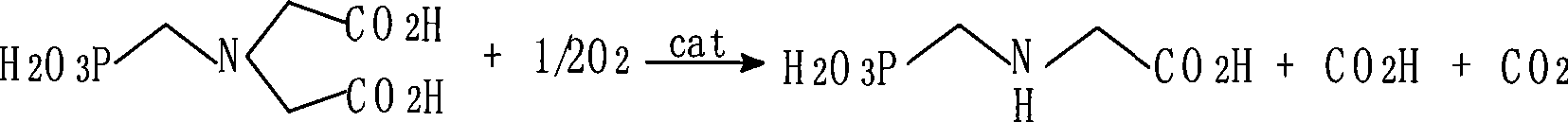

Method for preparing glyphosate

ActiveCN101531677AReduce manufacturing costEliminate generationBiocidePhysical/chemical process catalystsHigh concentrationIminodiacetic acid

The invention discloses a method for preparing glyphosate. N- (Phosphonomethyl) iminodiacetic acid is in the oxygenation reaction with oxygen in the water medium in the presence of catalyzer such as activated carbon, the solid-liquid separation is performed after the reaction to obtain the crystal with glyphosate and the filter cake with activated carbon, the reaction mother liquor is in the later process; the filter cake is added in the glyphosate saturated solution, after heating and dissolving the activated carbon is separated from the glyphosate solution, the glyphosate solution is cooled and crystallized, after separation the solid glyphosate product and the filter solution are obtained, the filter cake is made into the glyphosate saturated solution; the reaction mother liquor passes through a barrier separation device, the glyphosate in the mother liquor is separated from the by-product such as formaldehyde, the glyphosate mother liquor is recycled in the oxygenation reaction, or used as the glyphosate saturated solution. The invention provides the low-cost method for preparing glyphosate by the catalytic oxidation of high-concentration N- (Phosphonomethyl) iminodiacetic acid by the cyclic utilization of the reaction mother liquor, improving the yield of solid glyphosate and solving the environmental protection problem caused by the byproduct such as formaldehyde.

Owner:捷马化工股份有限公司

Disperse dye composition as well as preparation method and application thereof

ActiveCN106800798AImprove washing fastnessEasy to useMonoazo dyesDyeing processDisperse dyeChlorobenzene

The invention discloses a disperse dye composition as well as a preparation method and an application thereof. The disperse dye composition comprises a component A consisting of one or more of compounds shown by formula (1), a component B consisting of one or more compounds shown by formula (2), forbidden aromatic amine compound, chlorinated phenol, chlorobenzene, chlorotoluene, optional accessory and other unavoidable impurities, wherein the total content of the forbidden aromatic amine compound is below 10ppm, the total content of chlorinated phenol of each kind is below 0.5ppm, and the total content of chlorobenzene and chlorotoluene is below 1ppm. The environmental protection indexes of the disperse dye composition meet the requirements of Oeko-Tex Standard 100 (2016); and the properties such as washing fastness after dyeing are excellent. Moreover, by adopting the disperse dyeing composition disclosed by the invention for dyeing, the dyed fabric meets the baby-level requirements of Oeko-Tex Standard 100 (2016).

Owner:ZHEJIANG RUNTU INST +1

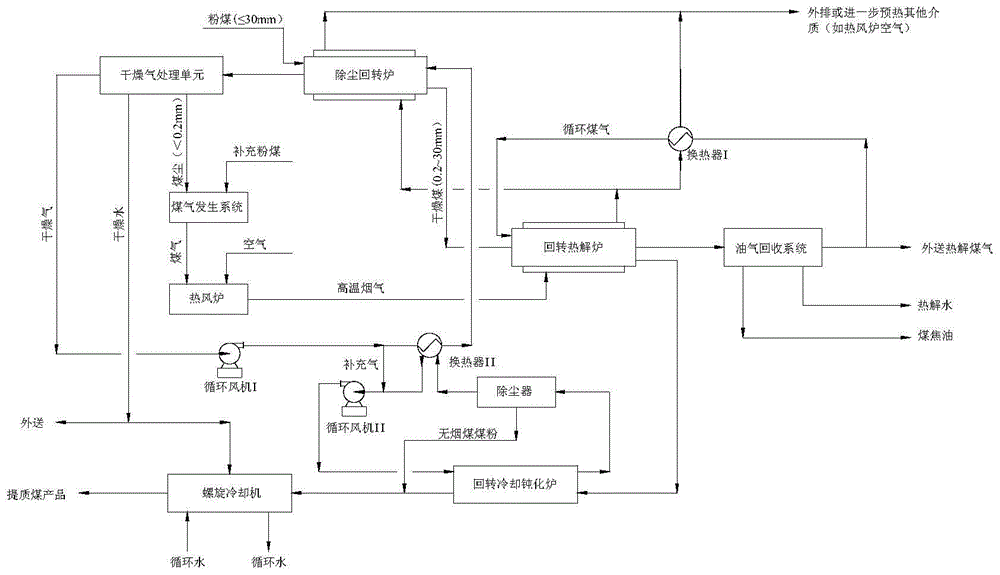

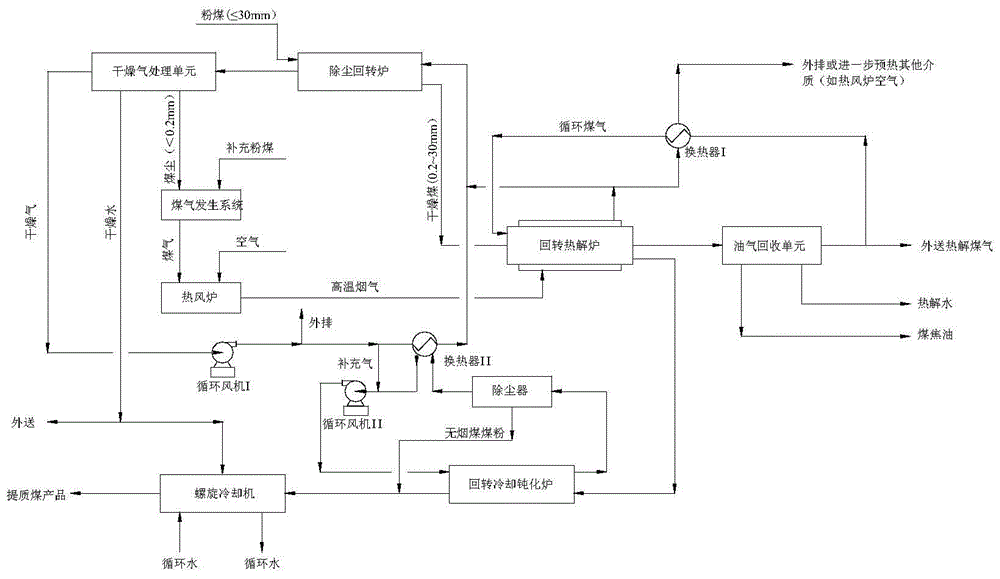

Gas-circulating method for pyrolysis production of anthracite in coal powder rotary furnace

ActiveCN104789244AHigh yieldReduce consumptionIndirect heating destructive distillationSpecial form destructive distillationCoal dustAnthracite

The invention provides a method for pyrolysis production of anthracite in a coal powder rotary furnace. The method relates to a coal powder dust removing rotary drying furnace system, an external-heating rotary furnace pyrolysis system with a coal gas circulation function, a rotary cooling passivation system with a heat recovery function, and an oil gas recovering system, wherein the coal powder dust removing rotary drying furnace system is used for heating coal powder to 110 to 280 DEG C and removing coal dust of which the particle size is smaller than 0.2 mm; drying water is recovered and fed to a downstream spiral cooling machine to be used for anthracite cooling and humidification; the coal dust obtained after separation is fed to a coal gas generating system to generate fuel, namely coal gas; after dust removing, coal is sent to a downstream rotary pyrolysis system for pyrolysis; high-temperature anthracite is generated, and cooled; the cooled anthracite is passivated at a middle-low temperature; the passivated anthracite is cooled in the spiral cooling machine; water is sprayed on the cooled passivated anthracite for humidification; the humidified anthracite is sent out; high-temperature oil gas produced in the process enters the oil gas recovering system to obtain coal tar, pyrolyzed water and coal gas. Part of the produced pyrolyzed coal gas returns to the pyrolysis furnace after preheating in a circulating manner, while the other part of the produced pyrolyzed coal gas is sent out.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

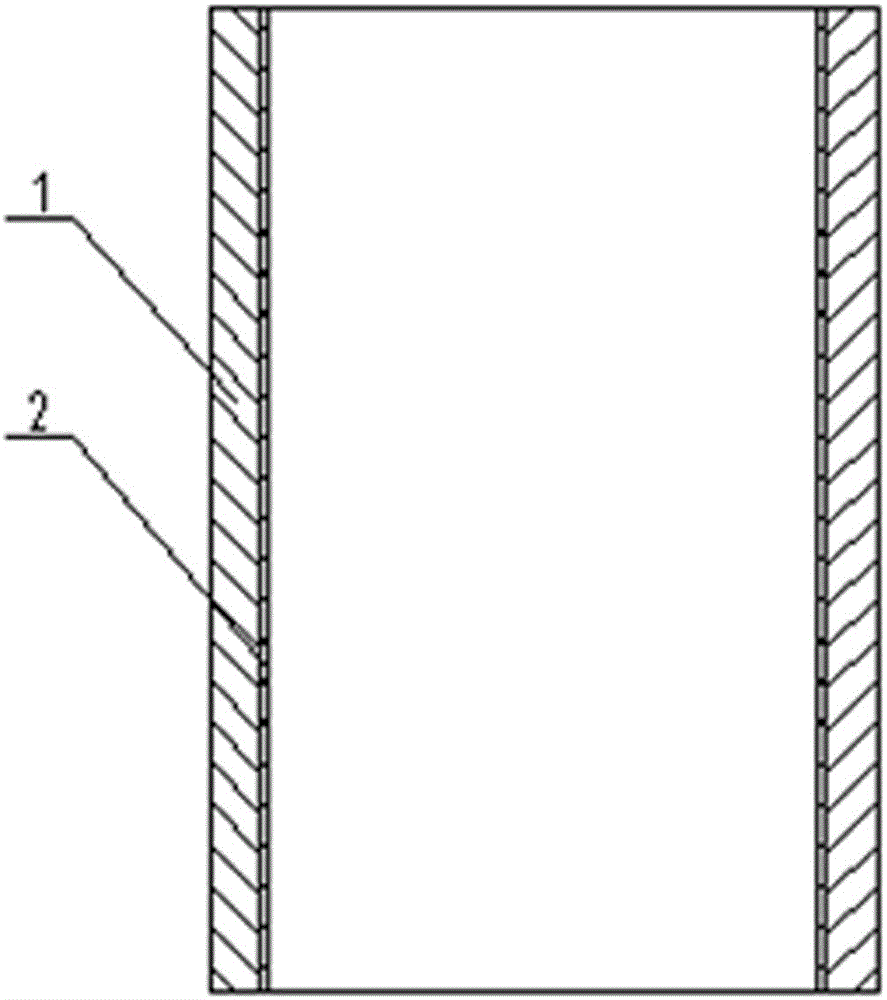

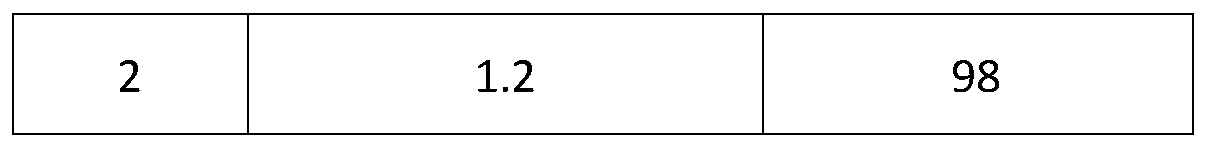

Electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe

ActiveCN103982142AExtended service lifeIncreased microhardnessDrilling rodsCorrosion preventionWear resistantAcid washing

The invention relates to an electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe, and belongs to the field of oil field oil pipes. The inner surface of the oil pipe is electroplated with an amorphous state nickel-based alloy corrosion-resistant wear-resistant protection layer. The thickness of the protection layer is 20-50 microns. The protection layer is electroplated by the steps of oil removing, water washing, acid washing, water washing, activating, deionized water cleaning, electroplating, water washing and thermal treatment. Treatment is performed in oil removing liquid for 5-10 minutes; in acid washing, an oxide film is removed from a sulfur solution till the natural color of metal is exposed; in electroplating, nickel alloy electroplating liquid is adopted, the PH value is adjusted to 2-6 by using nickel carbonate, the temperature is more than or equal to 60 DEG C, the current density is 2-8 A / dm<2>, and the electroplating time is 2 hours; in thermal treatment, the temperature is kept at 200-300 DEG C for 1.5 hours. The oil pipe has the advantages of high microhardness, resistance to acid and alkali corrosion, high wear resistance and long service life.

Owner:胜利油田金岛实业有限责任公司

Prepn process of malonic ester

InactiveCN101066921AReduce usageReduce dosageOrganic compound preparationCarboxylic acid esters preparationAcetic acidChloroacetic acids

The present invention provides preparation process of malonic ester. Malonic ester is prepared with chloroacetic acid as material and through a neutralization reaction, a cyanidation, an acidification, a dewatering step, a hydrolysis and twice esterification. The preparation process with twice esterification has total malonic ester yield as high as 90 %, obviously reduced consumption of extractant toluene, high apparatus utilizing rate and lowered production cost.

Owner:CHONGQING UNISPLENDOUR CHEM

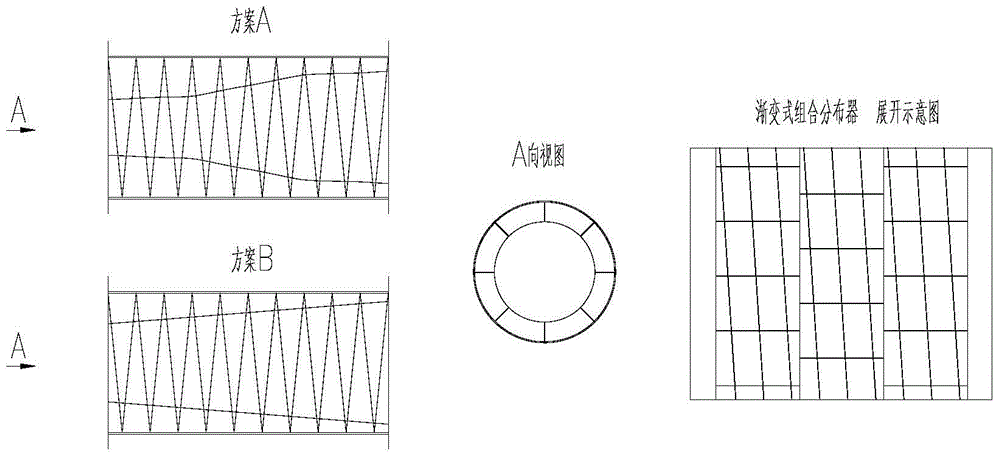

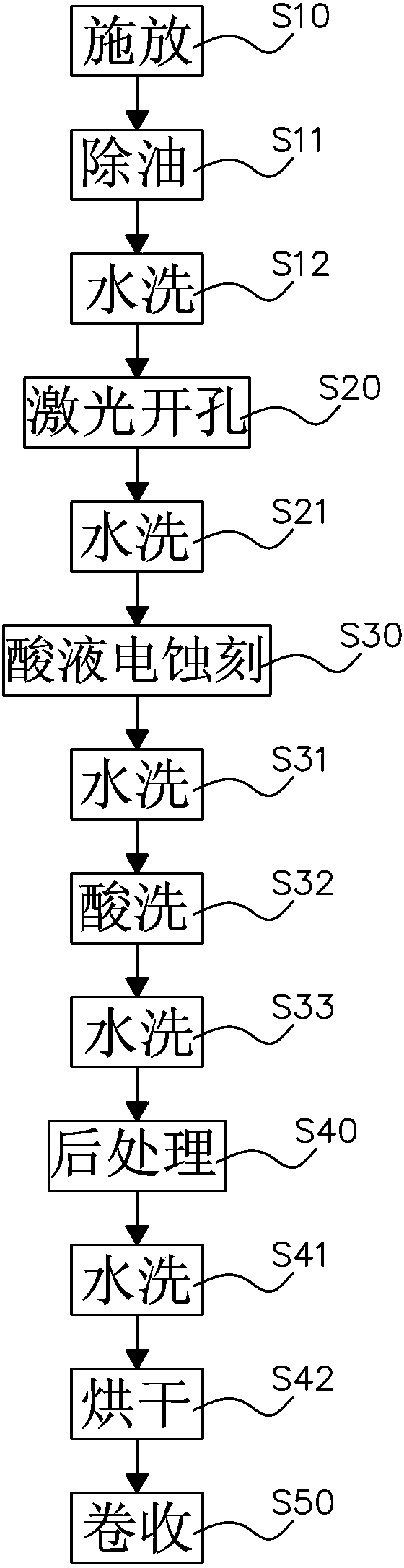

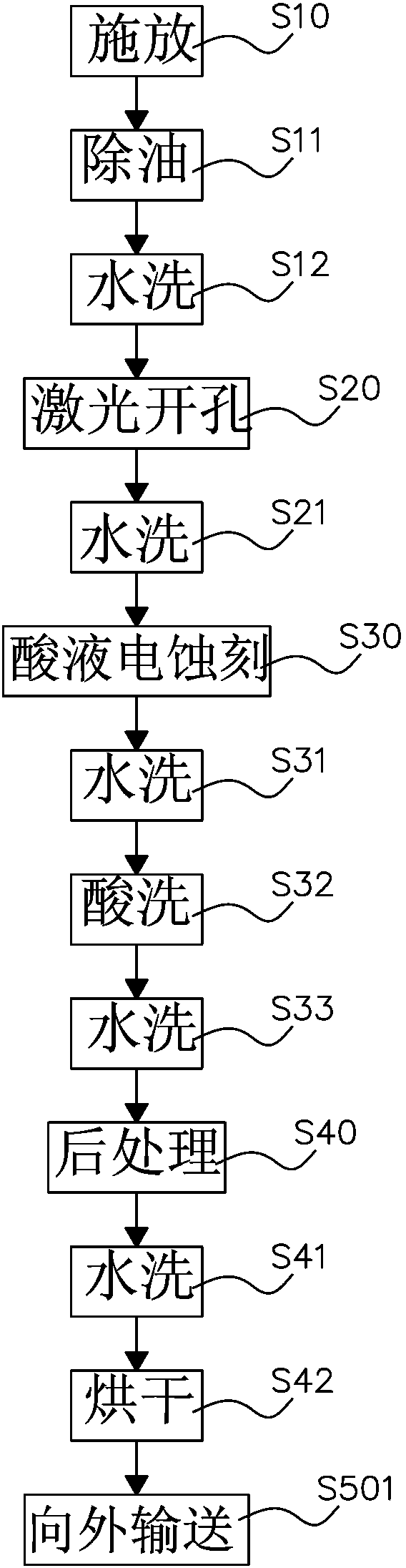

Porous current collector metal material continuous processing method

InactiveCN103972513AEasy to respond to needsEasy to processElectrode carriers/collectorsHybrid capacitor current collectorsGalvanometerMetallic materials

A porous current collector metal material continuous processing method comprises a to-be-processed long-strip flexible sheet-shaped metal material is allowed to maintain a continuous conveying state in a specific time; an optical fiber laser is utilized to cooperate with galvanometer operation, so that preset positions on the metal material can be controlled to be subjected to perforation processing; followed by, the metal material after perforation is allowed to pass through an acid solution to be subjected to electroetching processing, so that a roughening structure is formed on the surface of the metal material; then the surface of the metal material is subjected to antioxidant processing, so that a coating layer for preventing oxidation is formed and then dried; and finally, the metal material with the surface having the active material is directly rolled up or conveyed to a next procedure.

Owner:伦扬高科(韶关)有限公司

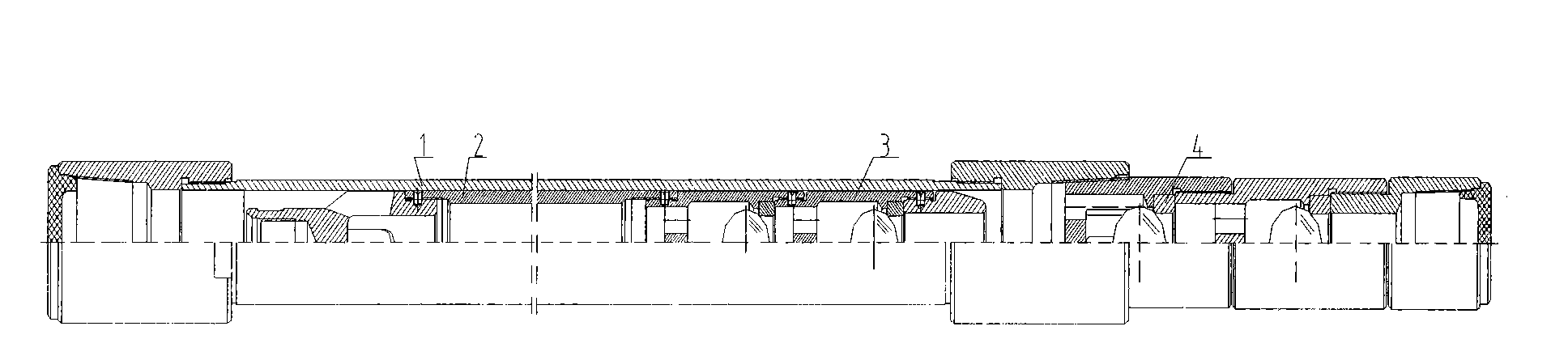

Electroplating amorphous ferrum-nickel-tungsten alloy corrosion-resistant wear-resistant oil pump

InactiveCN101666302AExtended service lifeCompact structurePumpsPositive-displacement liquid enginesEtchingWear resistant

The invention relates to an electroplating amorphous ferrum-nickel-tungsten alloy corrosion-resistant wear-resistant oil pump comprising a pump barrel, a plunger piston, an oil inlet valve and an oiloutlet valve, wherein the internal surface of the pump barrel is plated with an amorphous ferrum-nickel-tungsten corrosion-resistant wear-resistant protective layer, and the thickness of the protective layer is at least 75 mu m. The method for plating the protective layer comprises the following steps: electrolyzing to remove oil, washing with clear water, etching, washing with deionized water, electroplating, washing with weater and heat-treating. The electrolyzing to remove oil is realized by treating in an oil removing solution at 65-75 DEG C for 5-10 minutes, and the current density is 5-10 A / dm<2>. The etching is realized by removing oxidation films in a NaNO3 solution with the current density of 5-10 A / dm<2> until the natural color of the metal is exposed. The electroplating is realized in such as way that: a tungsten alloy plating solution is adopted, sodium hydroxide or ammonia is used for regulating the pH value to 7-8, the temperature for the electroplating is at least 70 DEGC, the current density is 5-10 A / dm<2>, and the electroplating time is 3-4 hours. The heat treatment is realized by keeping the temperature at 500-600 DEG C for 1.5 hours. The oil pump has the advantages of high microhardness, acid resistance, corrosion resistance, favorable wear resistance and long service life.

Owner:胜利油田金岛实业有限责任公司 +1

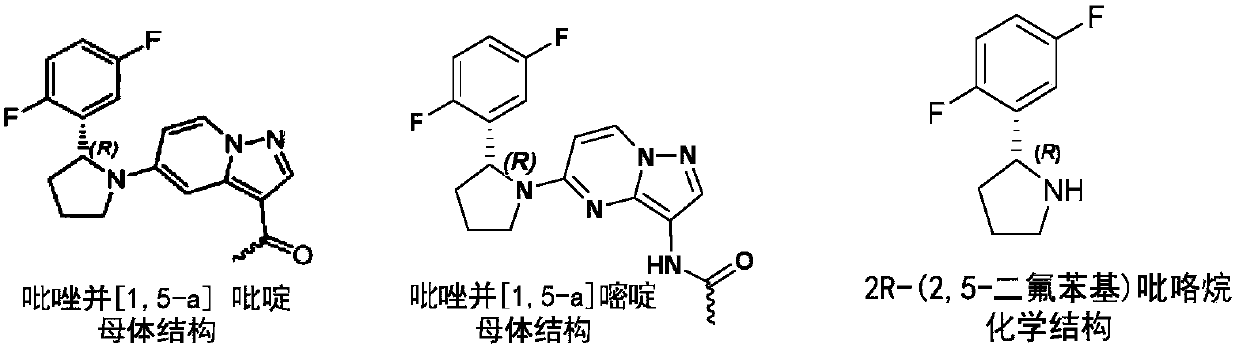

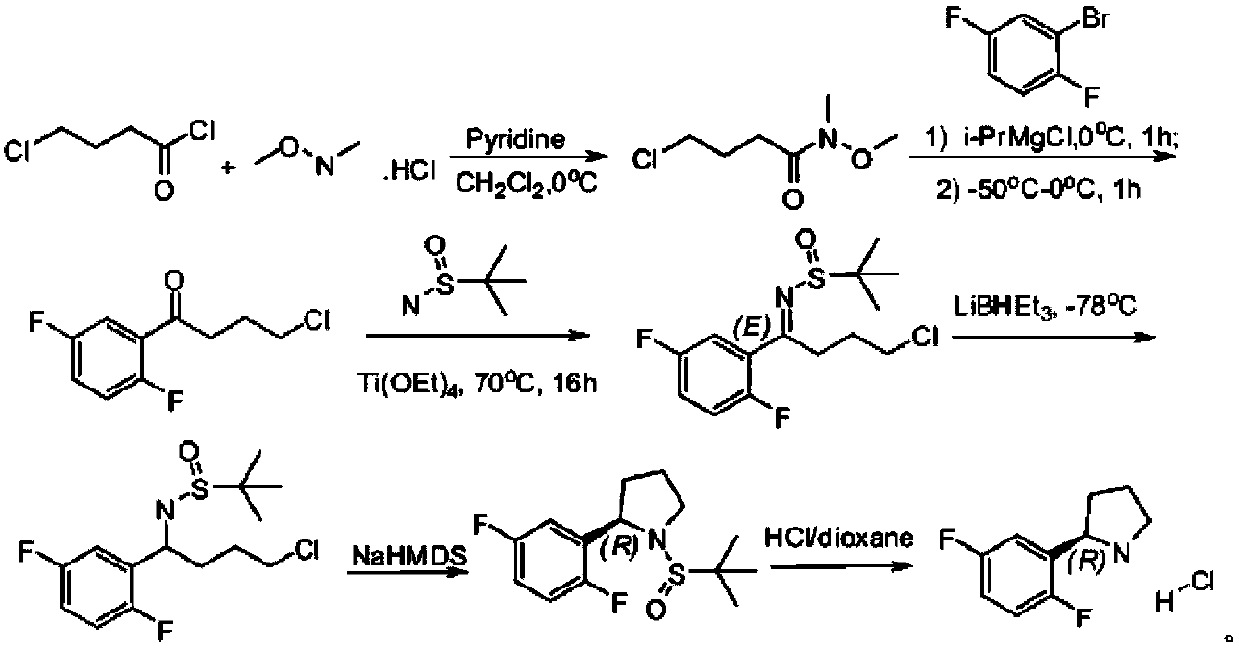

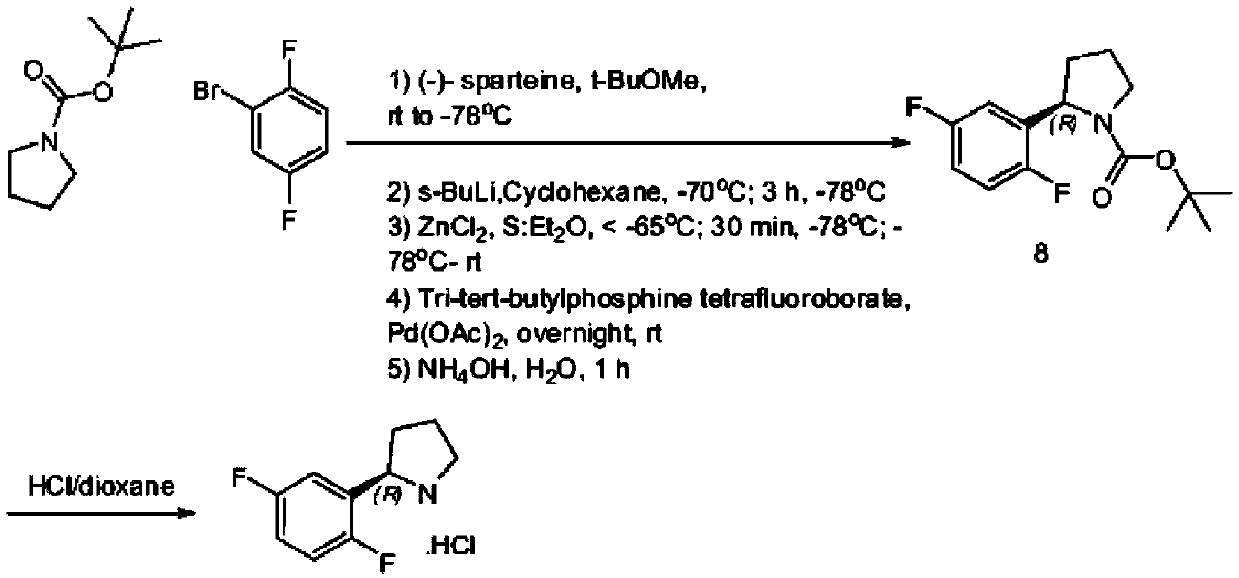

Preparation method of (R)-2-(2,5-difluorophenyl)pyrrolidine or salt thereof

InactiveCN109593803ASignificant technological progressImprove stabilityFermentationLoop closingChlorobenzene

The invention provides a preparation method of (R)-2-(2,5-difluorophenyl)pyrrolidine or salt thereof. N-protected pyrrolidone and 1,4-difluoro-chlorobenzene are subjected to a Grignard reaction to obtain a compound shown in formula 3; the compound shown in the formula 3 is subjected to deportection and loop closing under an acid condition to obtain a compound shown in formula 4 or salt of the compound; the compound shown in the formula 4 or salt of the compound selectively reduce and synthesize an optical pure compound (R)-2-(2,5-difluorophenyl)pyrrolidine or salt thereof under catalysis ofenzyme, wherein enzyme is recombinant imine reductase and coenzyme circulation is performed by glucose and glucose dehydrogenase. The enzyme is used to replace a chemical chiral reagent, and the problem that chiral inducers are needed in the prior art is solved; compared with metal catalysis, the enzyme catalytic reaction has the characteristics that the cost is low, reaction selectivity is good,the conversion rate and optical purity of the product are high and the reaction process is simple to operate and environmentally friendly, and is applicable to mass industrial production.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

Disperse dye composition and preparation method and application thereof

ActiveCN106752080AHigh strengthGood sublimation fastnessOrganic dyesDyeing processChlorinated phenolsEthyl Chloride

The invention relates to a disperse dye composition and a preparation method and application thereof. The disperse dye composition comprises a component A as shown in formula (1), a forbidden aromatic amine compound, chlorinated phenol, chlorobenzene, chlorotoluene, any auxiliary materials and other unavoidable impurities. According to the disperse dye composition, the total content of the forbidden aromatic amine compound is 10ppm or lower, the total content of each chlorinated phenol is 0.5ppm or lower, and the total content of chlorobenzene and chlorotoluene (COCs) is 1ppm or lower. Various environment-protective indexes of the disperse dye composition conform to the requirement of Oeko-Tex Standard 100 (2016), and various performance such as the fold strength, sublimation fastness and the like is excellent. Furthermore, after the disperse dye composition of the invention is used for dyeing a fabric, the dyed fabric conforms to the requirements of a baby level of the Oeko-Tex Standard 100 (2016). (Shown in the description).

Owner:ZHEJIANG RUNTU INST +1

Method for improving distribution uniformity of reinforced phase in silver metal oxide electric contact material

InactiveCN108950257AImprove uniformityIncrease the concentration of vacanciesElectricitySmelting process

The invention discloses a method for improving distribution uniformity of a reinforced phase in a silver metal oxide electric contact material. A reinforced phase element is prepared into powder, a powder spraying device sprays the reinforced phase element powder into a silver solution through inert gas, vacancy concentration of the reinforced phase element is improved, the relative motion velocity of the reinforced phase element and the silver solution is increased, melting and diffusion velocities of the reinforced phase element in the silver solution can be increased effectively, and distribution uniformity of the reinforced phase in the silver substrate in the silver metal oxide electric contact material is finally improved. The technology can be applied to the production process of all silver metal oxide electric contact materials adopting internal oxidation technology or atomization technology, compared with the traditional internal oxidation technology and atomization technology, the method can significantly shorten uniformization time of the silver alloy smelting process, the volatilization amount of the low-melting-point reinforced phase element in the smelting process isreduced, and environment protection treatment cost is lowered.

Owner:FUDA ALLOY MATERIALS

Preparation method of (R)-2-(2,5-difluorophenyl) pyrrolidine or salt thereof

ActiveCN109593802ASignificant technological progressImprove stabilityFermentationGrignard reagentGrignard reaction

The invention provides a preparation method of (R)-2-(2,5-difluorophenyl) pyrrolidine or salt thereof. N-protected pyrrolidone and a 2,5-fluorophenyl magnesium chloride Grignard reagent are subjectedto a Grignard reaction, and a compound represented as the formula 3 is obtained; the compound represented as the formula 3 is subjected to deprotection and ring closure under the acidic condition, anda compound represented as the formula 4 or salt of the compound is obtained; under enzyme catalysis, formic acid or formate is utilized as a hydrogen donor, a cofactor is adopted, cofactor cycle is realized, and the compound represented as the formula 4 or the salt of the compound is selectively reduced to synthesize an optically pure compound, namely, (R)-2-(2,5-difluorophenyl) pyrrolidine or the salt thereof; enzyme is a combination of recombinant imine reductase and formate dehydrogenase, and the cofactor is oxidized / reduced type nicotinamide adenine dinucleotide phosphate or oxidized / reduced type nicotinamide adenine dinucleotide. The method is safe in process and simple to operate, and yield and optical purity of a product are both higher.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

Composite flocculating agent and method for processing maize soaking water

InactiveCN102730811AGood flocculation effectGood synergyWater/sewage treatment by flocculation/precipitationFlocculationChemical oxygen demand

The invention provides a composite flocculating agent which comprises the ingredients as follows: sodium polyacrylate, carboxymethyl chitosan, montmorillonite and diatomaceous earth. The invention further provides a method for processing maize soaking water by applying the composite flocculating agent. The method comprises the following steps: under flocculation condition, mixing and standing the maize soaking water with the composite flocculating agent; and conducting solid and liquid separation to the flocculated mixture. The composite flocculating agent is used for processing the maize soaking water to be capable of well recycling protein in the maize soaking water, protein content of feed manufactured by the solid part obtained after processing is higher, the COD (chemical oxygen demand) value of the liquid obtained after processing is greatly reduced, the environment friendliness processing difficulty is lowered, and better environment protection is achieved.

Owner:COFCO BIOTECHNOLOGY CO LTD

Multifunctional crude oil tank farm treating agent

ActiveCN103275753AReduce contentReduce dirty oil contentDewatering/demulsification with chemical meansDiethylene glycol monobutyl etherSolubility

The invention relates to a multifunctional crude oil tank farm treating agent which is prepared by the following raw materials in percentage by weight: 55%-65% of a modified polyether demulsifying agent, 10%-15% of a synergist, 3%-5% of a dispersant and 20%-30% of a solvent, wherein the modified polyether demulsifying agent is one or a plurality of nonyl phenolic resin polyether, nonyl phenol aldehyde resin polyether, tertiary butyl phenolic resin polyether and tertiary butyl phenol amine aldehyde resin polyether polymerized by nonyl phenol, m-dinonylphenol or p-tert-butylphenol as an initiator, or a condensation product of the nonyl phenol, the m-dinonylphenol, the p-tert-butylphenol, vinylamines and methanal as the initiator with propylene epoxide and ethylene oxide; the synergist is a non-ionic surface active agent; the dispersant is polyacrylic acid or polyacrylamide; and the solvent is one or a plurality of diethylene glycol monobutyl ether, terpene or naphtha. The multifunctional crude oil tank farm treating agent is suitable for pretreating of various types of temporary stored or long-term stored crude oil entering the tank farm. A product has oil solubility, and the usage amount is low.

Owner:沈红新 +1

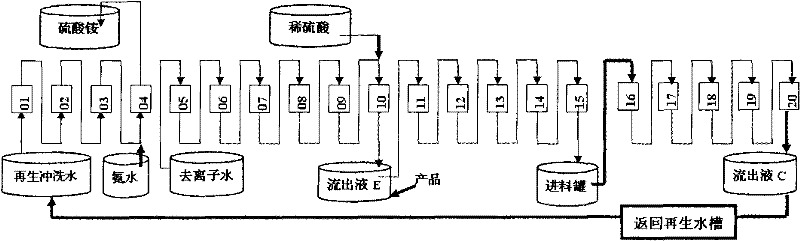

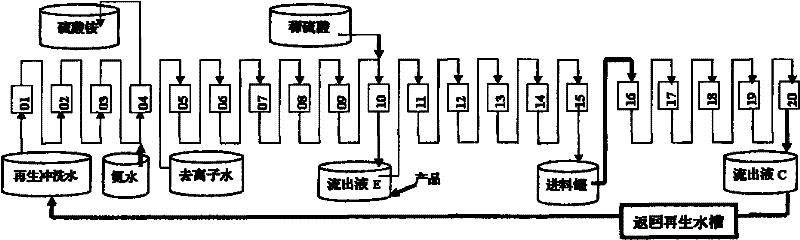

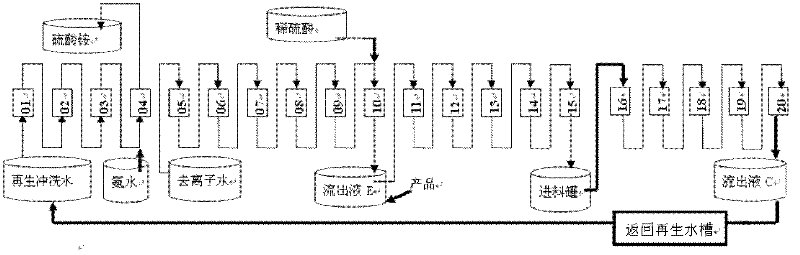

Method for treating citric acid-containing solution

ActiveCN102190579AReduce consumptionEmission reductionCarboxylic compound separation/purificationIon exchangeElution

The invention provides a method for treating citric acid-containing solution, which is characterized by comprising the following steps of: (1) making the acid-containing solution flow through a cation exchange resin column and contacted with cation exchange resin therein to obtain effluent liquid A; (2) making the effluent liquid A flow through an active carbon column and contacted with active carbon therein to obtain effluent liquid B; and (3) contacting the effluent liquid B with a plurality of anion exchange resin column groups for ion exchange chromatography, wherein each anion exchange resin column group circularly passes through an adsorption area, a purification area, an elution area and a regeneration area in turn so as to be circularly subjected to exchange adsorption, purification, elution and regeneration in turn. By the method for treating the citric acid-containing solution, high-purity and high-yield citric acid can be obtained in unit time, and the method is energy-saving and environment-friendly.

Owner:COFCO BIOTECHNOLOGY CO LTD

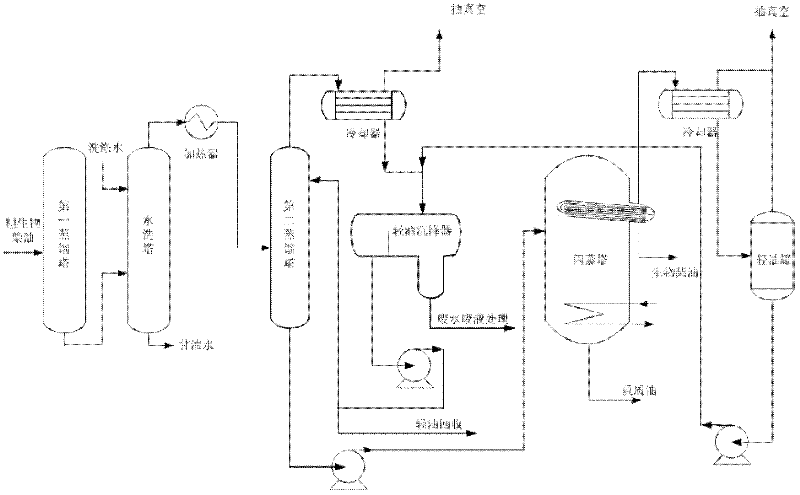

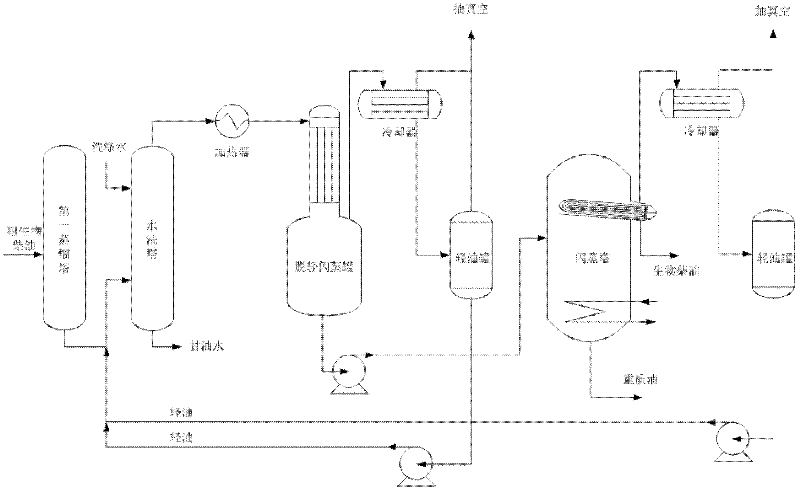

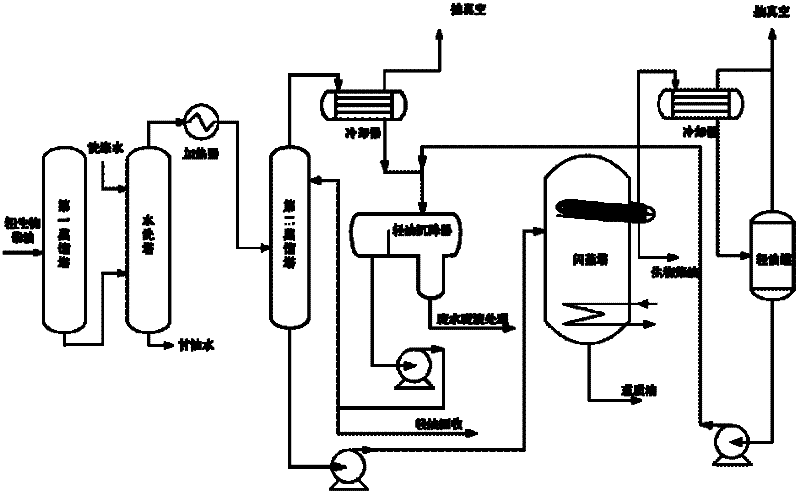

Refining method for biodiesel coarse product

Owner:CHINA NAT OFFSHORE OIL CORP +2

A kind of processing method containing citric acid solution

ActiveCN102260167AReduce consumptionEmission reductionCarboxylic compound separation/purificationIon exchangeElution

The invention provides a treatment method of a citric acid contained solution, wherein the method comprises the following steps of: (1) enabling the citric acid contained solution to flow through an active carbon column and contact active carbon in the active carbon column so as to obtain an effluent liquid A, wherein the light transmission rate of the effluent liquid A is more than 60% through the contacting condition; (2) regulating the pH value of the effluent liquid A obtained in the step (1) to be 2-5 so as to obtain a solution B; and (3) enabling the effluent liquid B to contact multiple anion exchange resin column groups so as to carry out ion exchange chromatography separation, wherein each anion exchange resin column group passes through an adsorption area, a purification area, an elution area and a regeneration area in sequence in circulation so that the anion exchange resin column group is exchanged, adsorbed, purified, eluted and regenerated in sequence in circulation. The citric acid contained solution is treated by using the method provided by the invention so that citric acid with high purity and high yield can be obtained within a unit time in an environment friendly and energy saving way.

Owner:COFCO BIOTECHNOLOGY CO LTD

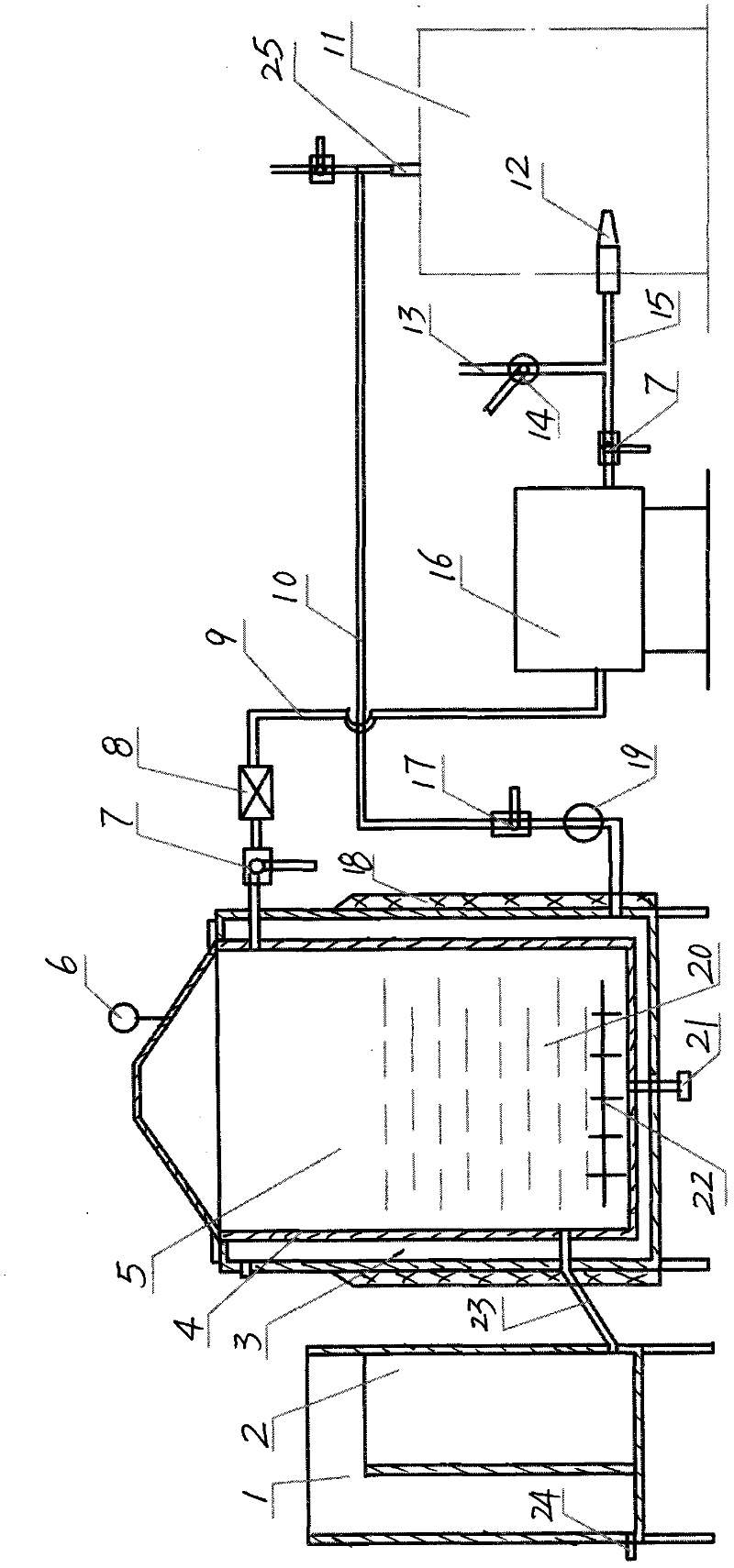

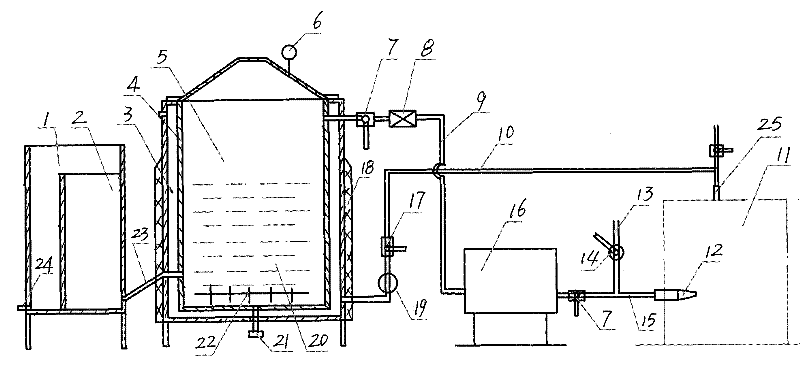

Method and device for applying methane to industrial hating furnace

InactiveCN102162000AEnsure usabilityEnsure requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsAir compressionProcess engineering

The invention discloses a method and device for applying methane to an industrial hating furnace. The device comprises a methane tank (4) and a heating chamber (3), wherein the methane tank is communicated with a bucket (2); the methane tank is connected with a methane storeroom (16) through a delivery pipe (9); the methane storeroom is connected with a flame gun (12) positioned in the industrial heating furnace through an output pipe (15); the output pipe is connected with an air compression pipe (13); and the heating chamber is connected with a hot air discharging pipe (25) in the industrial heating furnace through a hot air pipe (10). By utilizing the device, a fermentation material is filled in the methane tank firstly, the methane tank is heated to 50-80 DEG C so that the fermentation material is fermented and decomposed at high temperature to generate methane, then the methane is stored and delivered to the industrial heating furnace so as to be ignited, and then compressed air is introduced to the methane so that the methane sufficiently combusts in the industrial heating furnace after being mixed with the compressed air. By utilizing the method and device provided by the invention, the quality of the combusted product can be ensured, the gas cost can be greatly reduced, energy sources are saved, waste materials are sufficiently utilized, and the environmental pollution is reduced.

Owner:刘达苏

Disperse dye composition and preparation method and use thereof

A disperse dye composition and a preparation method and use thereof are disclosed, the disperse dye composition comprises a component A, a banned aromatic amine compound, chlorinated phenol, chlorobenzene, chlorotoluene, optional accessories, and other inescapable impurities, the component A comprises one or more compounds of compounds shown as formula (1), the total content of the prohibited aromatic amine compound is 10ppm or below, the total content of various types of the chlorinated phenol is respectively 0.5ppm or below, and the total content of the chlorobenzene and the chlorotoluene is 1ppm or below. All environmentally-friendly indicators of the disperse dye composition meet the requirements of Oeko-Tex Standard 100 (2016). In addition, after a fabric is dyed with the disperse dye composition, and the dyed fabric meets the baby level requirements of the Oeko-Tex Standard 100 (2016).

Owner:ZHEJIANG RUNTU INST +1

Preparation method of di-tert-butyl dicarbonate

The invention relates to a preparation method of di-tert-butyl dicarbonate and belongs to the technical field of synthesis of pharmaceutical intermediates. The preparation method comprises the following steps: adding metal sodium into xylol; heating to obtain sodium sand; then dropwise adding tert-butyl alcohol and carrying out pumping filtration to obtain sodium tert-butoxide; dissolving the sodium tert-butoxide into petroleum ether; introducing carbon dioxide and reacting to obtain a monoester sodium salt solution; adding a catalyst and slowly dropwise adding diphosgene to react; after reacting, standing and carrying out the pumping filtration; and washing with water, drying, distilling, cooling and crystallizing to obtain the di-tert-butyl dicarbonate. According to the preparation method, the sodium tert-butoxide is prepared from the metal sodium and the di-tert-butyl dicarbonate is prepared from the sodium tert-butoxide; a pumping filtration method is used for replacing a previous distillation method, so that the process is simpler and more energy is saved; the petroleum ether is used for replacing n-hexane and toluene, so that the production cost is reduced and a product is easier to purify; and finally, after the reaction, the pumping filtration is carried out and then water washing is carried out, so that the amount of wastewater is reduced and the environment-friendly treatment cost is reduced.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

Preparation method of citrate

ActiveCN102417452AReduce dosageReduce utilizationOrganic compound preparationCarboxylic acid esters preparationAlcoholCitric acid fermentation

The invention provides a preparation method of citrate. The method comprises the following step of: undergoing a contact reaction on citric acid and monohydric alcohol in the presence of a catalyst to obtain citrate, wherein the citric acid is citric acid containing one or more of Fe<3+>, Al<3+> and Cu<2+> prepared with at least one of the following methods: in a method I, a clear citric acid zymotic fluid is separated and purified with a calcium salt method to obtain the citric acid containing one or more of Fe<3+>, Al<3+> and Cu<2+>; and in a method II, a clear citric acid zymotic fluid is separated and purified with a chromatography to obtain the citric acid containing one or more of Fe<3+>, Al<3+> and Cu<2+>. By adopting the method disclosed by the invention for preparing the citric acid, the procedure can be simplified, the dosage of a catalyst can be reduced, and the yield and purity of the citrate are increased.

Owner:COFCO BIOTECHNOLOGY CO LTD

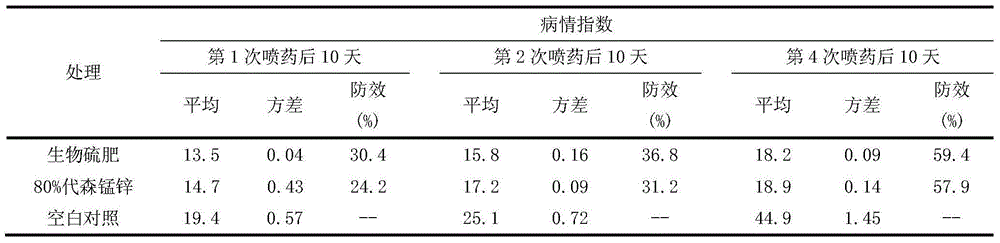

Biological sulfur fertilizer and preparation method thereof

ActiveCN104628488AImprove qualityReduce environmental disposal costsFertilizer mixturesHigh concentrationPreservative

The invention discloses a biological sulfur fertilizer which consists of 80 to 99 wt% of elemental sulfur suspension, 0.02 to 2 wt% of dispersant, 0.08 to 1.5 wt% of antiseptic, and 0.9 to 16.5 wt% of surfactant. The elemental sulfur in biological sulfur fertilizer is in a good suspension state under a high concentration condition, and can prevent fertilizer from greening and deterioration by inhibiting microbe growth. The biological sulfur fertilizer can increase the crop output and prevent the diseases, is an ideal elemental sulfur fertilizer, and is capable of achieving comprehensive wastewater treatment and utilization.

Owner:ANGELYEAST CO LTD

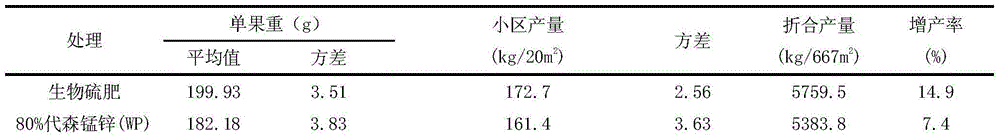

Method of circulation utilizing phenol containing waste water in novolac epoxy preparing process

ActiveCN1927731AReduce manufacturing costIncrease profitWater/sewage treatment by heatingWastewaterTower

The present invention discloses method of cyclically utilizing phenol containing waste water in phenolic epoxy resin production. Phenol containing waste water produced in the phenolic aldehyde condensation reaction during phenolic epoxy resin production is decompression distilled to dewater in the vacuum degree higher than -0.09 MPa; the phenol-water azeotrope distilled out at the kettle temperature higher than 80 deg.c is condensed and reused as partial condensed material; and the phenol-water azeotrope distilled out at the kettle temperature higher than 80 deg.c is condensed and reused as the technological water for the condensation reaction before being rectified in the waste water rectifying tower. The tower top exhausted water contains phenol less than 2000PPM and the tower bottom recovered phenol solution has concentration of 60-90 %. The method results in lowered phenol consumption, less exhausted waste water and lowered waste water treating cost.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

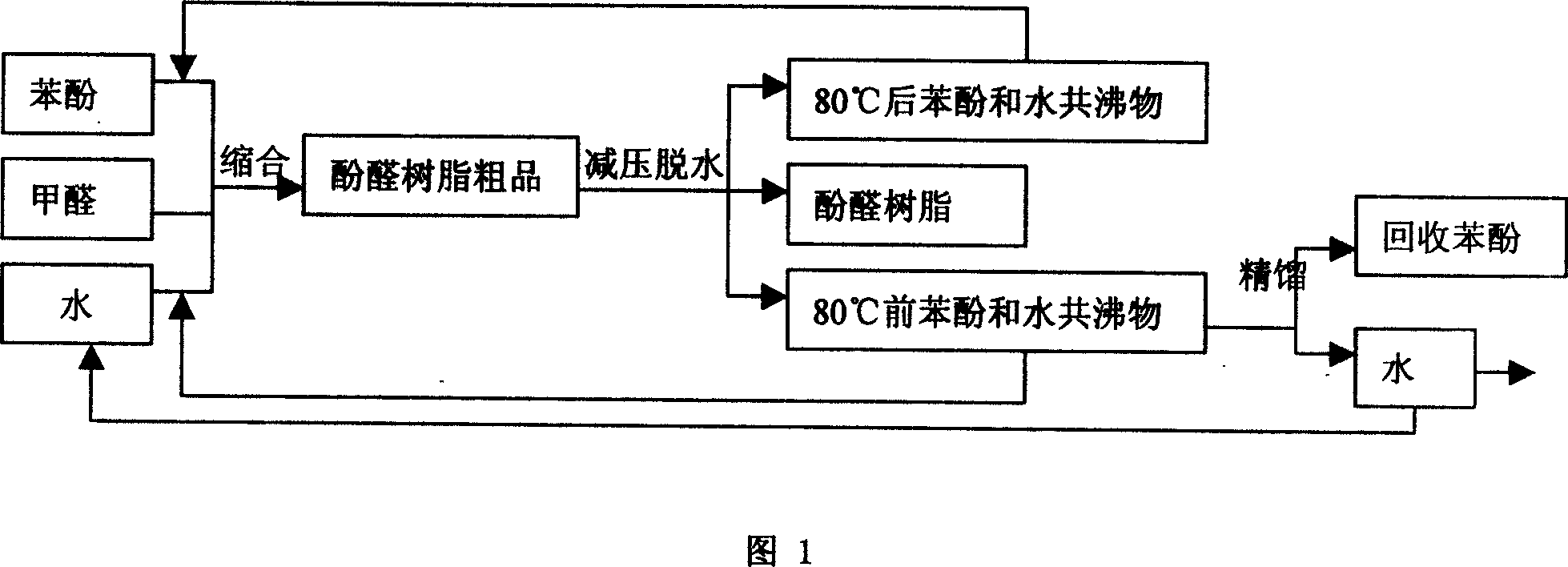

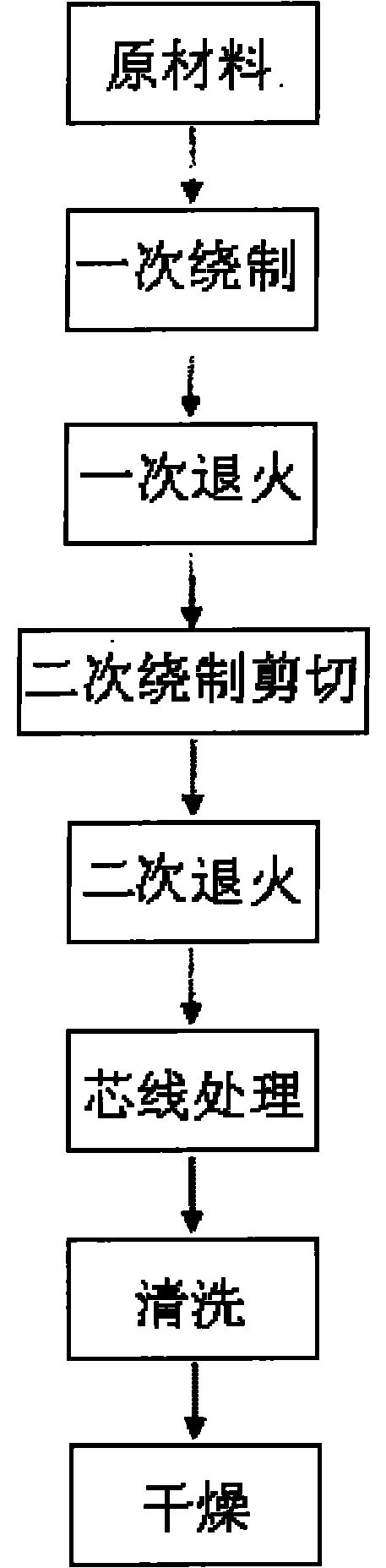

Coreless winding method of coiled-coil filament

InactiveCN102082067AReduce usageEmission reductionCathode heaters manufactureWinding machineWastewater

The invention discloses a coreless winding method of a coiled-coil filament. In the process of secondary winding of the filament, the coreless winding process is adopted, and two-pass molybdenum wires acting as core wires, a coiled-coil filament winding machine and a shearer are not used any more, but the automatic core pulling operation of a coreless filament winding machine is directly used for winding. The method has the following beneficial effects: the process is easy to operate, the usage amount of the rare metal molybdenum for filament production is greatly reduced, and complex equipment is simultaneously reduced, thus reducing the production procedures and saving the raw materials; and in addition, the wastewater discharge is reduced, the disposal costs for environmental protection in the process of production is reduced, and at the same time, the production speed and the product quality are improved.

Owner:ANHUI HUSN HUAGUANG ENERGY SAVING TECH

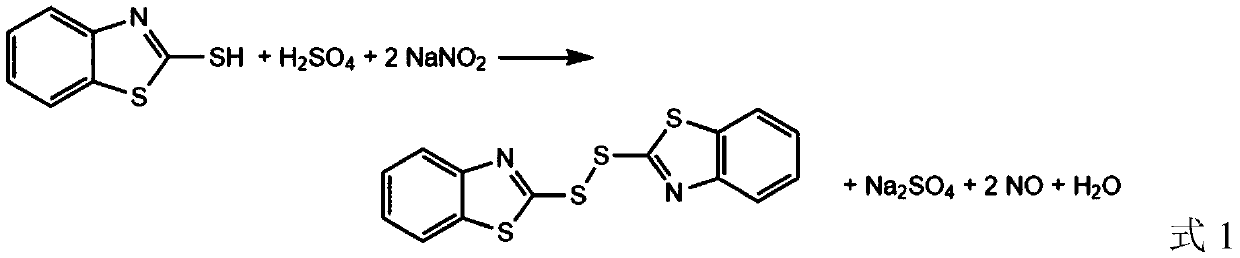

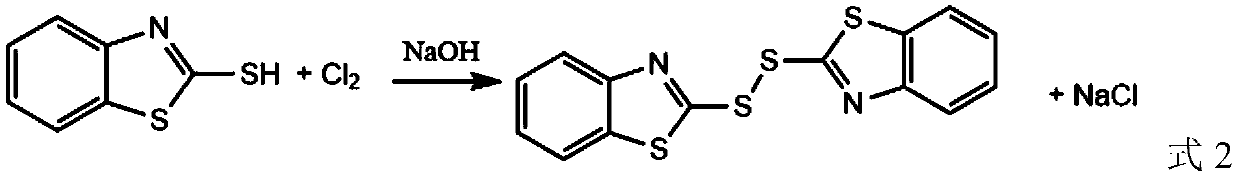

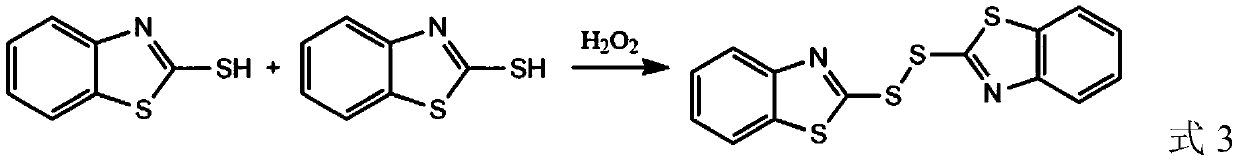

Green synthesis method of dibenzothiazole disulfide as rubber vulcanization accelerator

ActiveCN110590703AReduce generationReduce environmental disposal costsProductsOrganic chemistrySodium bicarbonateVulcanization

The invention discloses a green synthesis method of dibenzothiazole disulfide as a rubber vulcanization accelerator, and belongs to the technical field of chemical engineering. The green synthesis method specifically comprises the following steps: completely dissolving 2-mercaptobenzothiazole in a sodium carbonate aqueous solution, then dropwise adding hydrogen peroxide, feeding carbon dioxide toadjust the pH of a system, and carrying out oxidation to generate dibenzothiazole disulfide and sodium bicarbonate. A sodium carbonate solution formed by heating the obtained sodium bicarbonate solution can be used for dissolving the raw material 2-mercaptobenzothiazole so as to realize circulation of the raw materials. The purity of the product prepared by the method can reach 99% or above. Compared with a traditional mixed acid oxidation method, the green synthesis method has the advantages that a large amount of salt-containing wastewater is reduced, and the process is environmentally friendly.

Owner:TSINGHUA UNIV

Wet harmless extraction process for metal in waste mobile phone circuit board

InactiveCN111172398AAvoid lostHigh recovery rateProcess efficiency improvementNitrogen oxidesSulfur dioxide

The invention provides a wet harmless extraction process for metal in a waste mobile phone circuit board. The wet harmless extraction process solves the problem of metal recovery in the waste mobile phone circuit board in the prior art, and comprises the following steps that the waste mobile phone circuit board is disassembled into an IC chip, a surface mounted device and a light panel, a low-toxicity and environment-friendly leaching agent is developed, tin, copper silver and gold palladium are directionally and selectively leached by adopting a step-by-step method, and then tin, copper silver and gold palladium are reduced and extracted, the recovery rate of gold, silver and palladium reaches 95% or above, a suitable stripping agent is selected for stripping a gold plating on the light panel. According to the wet harmless extraction process, and various process units do not generate pollutants such as nitrogen oxide, sulfur dioxide and other countries strictly controlled by the totalamount, so that environmental pollution is reduced from the source.

Owner:广东华越环保科技有限公司

Disperse dye composition as well as preparation method and application thereof

ActiveCN106833023AMeet environmental protection requirementsEasy to useMonoazo dyesDyeing processEnvironmental resistanceChlorinated phenols

The invention discloses a disperse dye composition as well as a preparation method and application thereof. The disperse dye composition contains a component A, a prohibited aromatic amine compound, chloridized phenol, chlorobenzene and chlorotoluene, optional auxiliaries and other inevitable impurities, wherein the component A contains one or more compounds of formula (1) as shown in the specification. Various environment-friendly indexes meet the requirements of Bluesign, in addition, the single contents of the prohibited aromatic amine compound (AZO), the chloridized phenol (CPs) and the chlorobenzene and chlorotoluene (COCs) and the total content of the chlorobenzene and chlorotoluene in the chemical product of the disperse dye composition are low. In addition, after being dyed, a fabric can meet infant-grade requirements of Oeko-Tex Standard 100 (2016). Sewage generated after dyeing can also meet environment-friendly requirements, and meanwhile, the disperse dye composition can be relatively convenient, rapid and safe to use.

Owner:ZHEJIANG RUNTU INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com