Method for preparing glyphosate

A technology of glyphosate and glyphosate mother liquor, applied in botany equipment and methods, chemical instruments and methods, chemicals for biological control, etc., can solve high production costs, no description of treatment methods, and high pressure on environmental protection and other issues, to achieve the effect of reducing environmental protection treatment costs, improving atomic economy, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

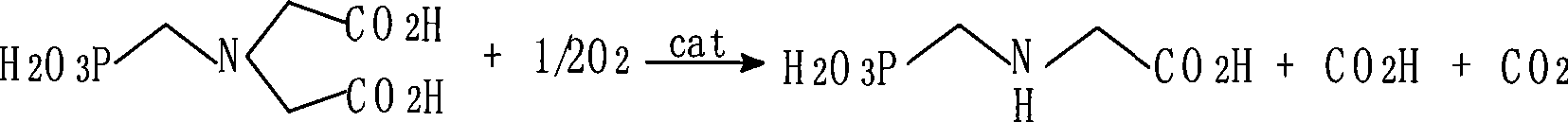

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 100g of bisglyphosate with a mass fraction of 98.6%, 5g of activated carbon catalyst and 400g of water into a reactor with agitation, air inlet and air outlet, and under the condition of 0.5Mpa pressure and 55°C, feed oxygen to catalyze Oxidation reaction, after the reaction, solid-liquid separation, to obtain 396g reaction mother liquor, wherein the mass fraction of glyphosate is 1.2%, and the mass fraction of formaldehyde is 2.5%. Add the filter cake containing glyphosate crystals and activated carbon into 800g glyphosate saturated solution, raise the temperature to dissolve the glyphosate crystals, separate the activated carbon and glyphosate solution within 30 minutes through the solid-liquid separation device, and collect the activated carbon The catalyst is returned to the catalytic oxidation reaction system for recycling.

[0023] Freeze the glyphosate solution to 5°C to fully crystallize the glyphosate, separate and obtain 65.6g of glyphosate solid, the mass...

Embodiment 2

[0026] 100g mass fraction is 98.6% bisglyphosate, 10g active carbon catalyst and 200g glyphosate solution (reaction mother liquor after membrane separation removes formaldehyde in embodiment 1) drop into the reactor that has stirring, air inlet and gas outlet Inside, under the conditions of 0.8Mpa pressure and 80°C, oxygen was introduced to carry out catalytic oxidation reaction. After the reaction, solid-liquid separation was carried out to obtain 204g reaction mother liquor, wherein the mass fraction of glyphosate was 1.4%, and the mass fraction of formaldehyde was 3.8%. Add the filter cake containing glyphosate crystals and activated carbon into 1200g glyphosate saturated solution, raise the temperature to dissolve the glyphosate crystals, separate the activated carbon and glyphosate solution through the solid-liquid separation device, collect the activated carbon catalyst and return to the catalytic It can be recycled in the oxidation reaction system.

[0027] Freezing gly...

Embodiment 3

[0030] Put 100g of bisglyphosate with a mass fraction of 98.6%, 20g of activated carbon catalyst and 100g of water into a reactor with stirring, air inlet and air outlet, and under the conditions of 1.2Mpa pressure and 110°C, feed oxygen to catalyze Oxidation reaction. After the reaction, solid-liquid separation was carried out to obtain 102 g of reaction mother liquor, wherein the mass fraction of glyphosate was 1.8%. The filter cake containing glyphosate crystals and activated carbon is joined in 1300g glyphosate saturated solution and 200g glyphosate solution (reaction mother liquor that 2 membrane separations remove formaldehyde in the embodiment), temperature rises and dissolves glyphosate crystal, through solidification The liquid separation device separates the activated carbon and the glyphosate solution, collects the activated carbon catalyst and returns it to the catalytic oxidation reaction system for recycling.

[0031] Freeze the glyphosate solution to below 5°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com