Method for treating citric acid-containing solution

A technology of citric acid solution and treatment method, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of high production cost, large amount of waste liquid, and high consumption of raw materials and auxiliary materials, and achieves reduction of environmental protection treatment costs and improvement of Purity and concentration, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

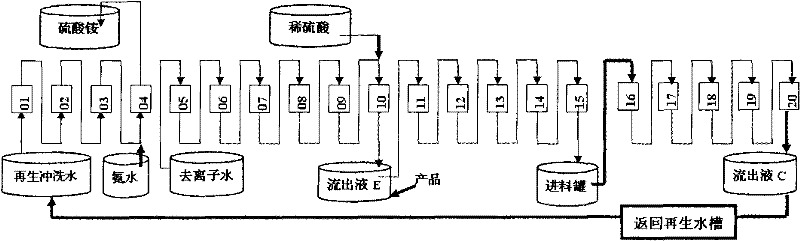

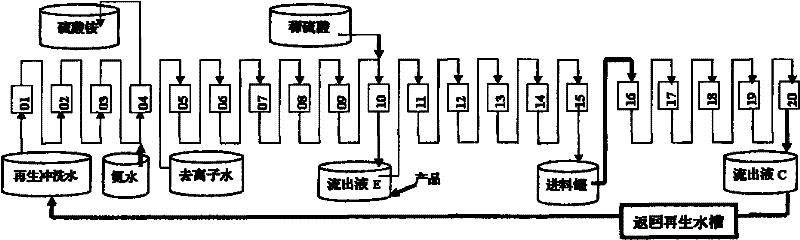

Image

Examples

Embodiment 1

[0050] (1) Removal of cations: 1000L of centrifugation qualified (control index turbidity less than 10NTU), content is 16.0% by weight of citric acid clear liquid (wherein, iron ion content is 1.0ppm) by 1.8 times column volume / hour Flow rate passes through the exchange column that cation exchange resin (as 001 * 7) is housed to remove cation therein, obtains the effluent A1 of 1120L, and citric acid content is 14.15% by weight in the effluent A1, and iron ion content is 0.25ppm, and cation The working temperature of the exchange resin is 35°C;

[0051] (2) decolouring: the effluent A1 that step (1) is obtained enters the decolorization process by the GH-15 carbon column at a flow rate of 1.8 times column volume / hour, and the content of citric acid in the effluent B1 and the effluent B1 of 1200L is obtained is 13.0% by weight, the light transmittance of the effluent B1 is 85%, and the temperature during the decolorization treatment is 50°C;

[0052] (3) Ion-exchange chromatog...

Embodiment 2

[0066] (1) Remove cations: 710L qualified by centrifugal separation, content is 15.5% by weight of citric acid supernatant (wherein, iron ion content is 1.2ppm) and the citric acid mother liquor that obtains in 54L embodiment 1 mixes, by 1.5 times The flow rate of column volume / hour passes through the exchange column that cation exchange resin (as 001 * 7) is housed to remove cation therein, obtains the effluent A2 of 850L, and the citric acid content is 17.88% by weight in the effluent A2, iron ion content is 0.3ppm, and the working temperature of the cation exchange resin column is 40°C;

[0067] (2) decolorization: the effluent A2 that step (1) is obtained enters the decolorization process by the GH-11 carbon column at a flow rate of 1.5 times of column volume / hour, and the content of citric acid in the effluent B2 and the effluent B2 of 920L is obtained is 16.3% by weight, the light transmittance of the effluent B2 is 82%, and the working temperature during decolorization ...

Embodiment 3

[0075] (1) Remove cations: 1000L qualified by centrifugal separation, content is 15.0% by weight of citric acid supernatant (wherein, iron ion content is 1.5ppm) and the citric acid mother liquor that obtains in 60L embodiment 2 mixes, by 2.0 times The flow velocity of the column volume / hour is passed into an exchange column equipped with a cation exchange resin (such as 001×7) to remove cations therein to obtain 1150L of effluent A3, and the citric acid content is 16.56% by weight in the effluent A3, and the iron ion content is 0.35ppm, and the working temperature of the cation exchange resin column is 30°C;

[0076] (2) decolorization: the effluent A3 that step (1) is obtained enters decolorization process by GH-15 charcoal column by the flow rate of 2.0 times column volume / hour, obtains the content of citric acid in the effluent B3 of 1250L, effluent B3 is 15.05% by weight, the light transmittance of the effluent B3 is 83%, and the working temperature during decolorization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com