Patents

Literature

189 results about "Acid oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Periodic Acid Oxidation. Periodic acid is the highest oxoacid of iodine, in which the iodine exists in oxidation state VII. Like all periodates it can exist in two forms: orthoperiodic acid, with the chemical formula H 5IO 6 and metaperiodic acid, which has the formula HIO 4.

Controllable preparation method of non-noble metal monatomic catalyst

InactiveCN107096536AIncrease profitImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOxygenAqueous solution

The invention discloses a controllable preparation method of a non-noble metal monatomic catalyst and aims at solving the problem of absence of a preparation method of the non-noble metal monatomic catalyst in the prior art. The cost of the catalyst is reduced, the atom utilization rate is improved, and the prepared monatomic catalyst has the advantages of high catalytic activity and high stability. According to the technical scheme, the controllable preparation method comprises the following steps of (1) an oxygen-containing functional group is prepared on a porous carrier material by using a mixed acid oxidation method; (2) an oxidized porous carrier dispersion is mixed with a water solution of a non-noble metal salt, non-noble metal cations and the oxygen-containing functional group on a porous carrier are subjected to fixed-point reaction and loaded to the porous material; and (3) the non-noble metal cations loaded on the porous material are subjected to in-situ reduction by adopting a reducing agent to prepare the non-noble metal monatomic catalyst.

Owner:SHANDONG NORMAL UNIV

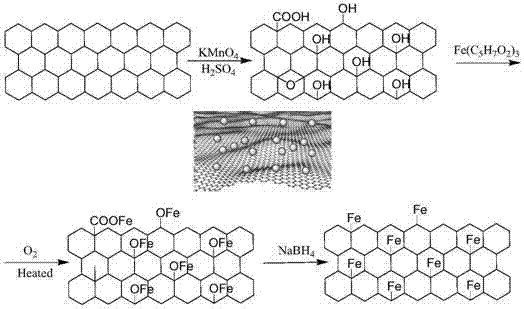

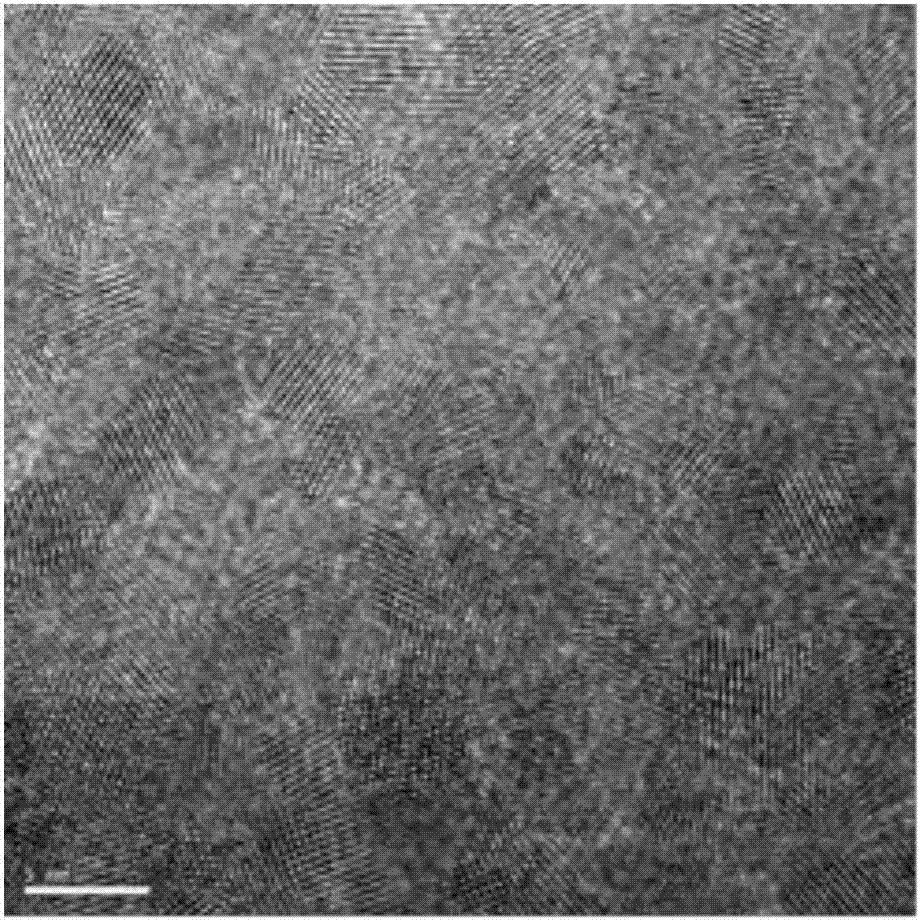

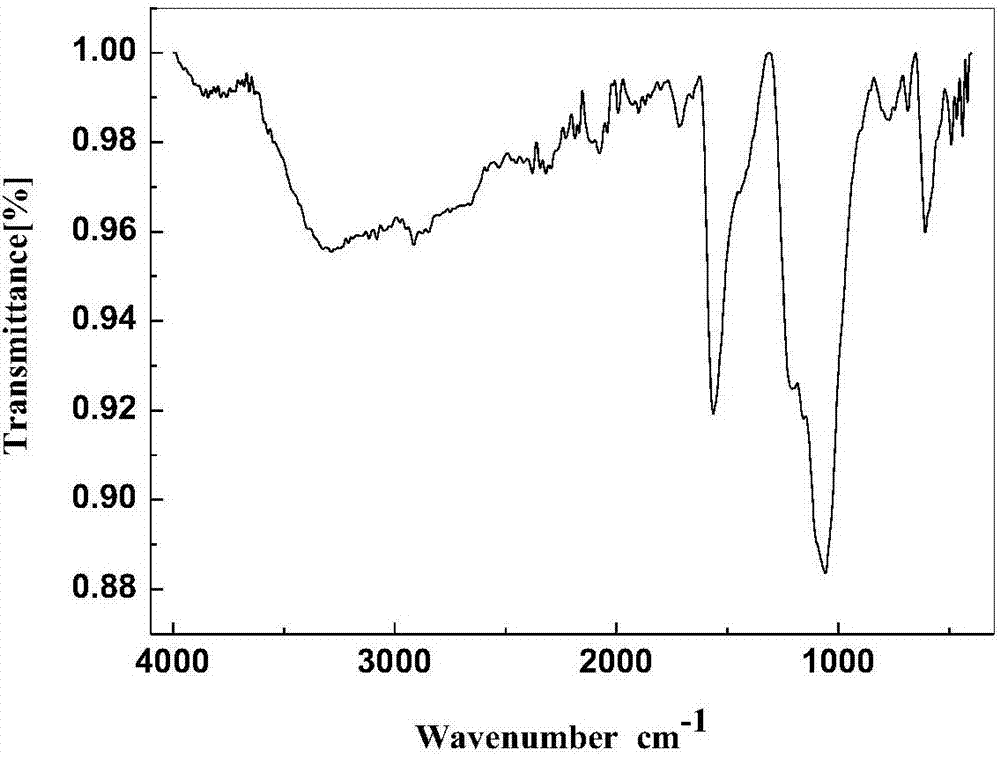

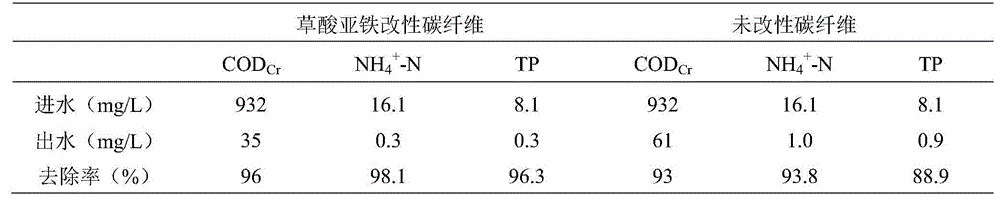

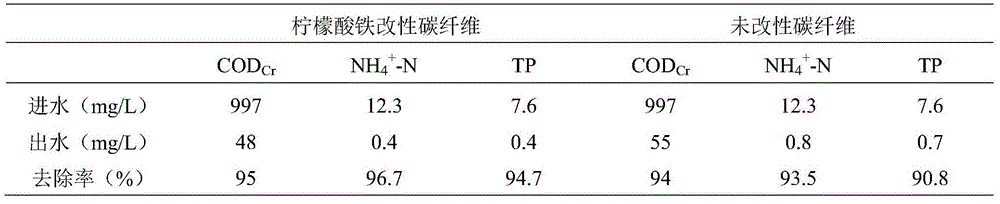

Excellent and efficient carbon fiber biofilm carrier modification method

InactiveCN104803471AGood biocompatibilityGood flexibilitySustainable biological treatmentBiological water/sewage treatmentFiberCarbon fibers

The invention discloses an excellent and efficient carbon fiber biofilm carrier modification method and aims to improve water treatment performance of carbon fibers used as biofilm carrier materials. A basic raw material is the carbon fibers; the modification method mainly comprises steps as follows: firstly, acid oxidation treatment is performed on the carbon fibers, so that surfaces of the carbon fibers are ensured to have sufficient functional groups for preparation for iron carrying; then an organic iron solution is used as a modifying agent, surface modification is performed on the carbon fibers with a liquid phase impregnation method, and an organic-iron-modified carbon fiber biofilm carrier material with the surface containing the iron element is prepared. The preparation method is simple and easy to implement, prepared organic-iron-modified carbon fibers can keep original excellent performance of the carbon fibers, the surface roughness and the hydrophilicity are significantly improved, the film colonization cycle is short, the microbial activity is improved, time required for water treatment is short, removal rates of COD, ammonia nitrogen and total phosphorus are obviously increased, the outgoing water quality is good in stability, and the reuse rate is higher.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

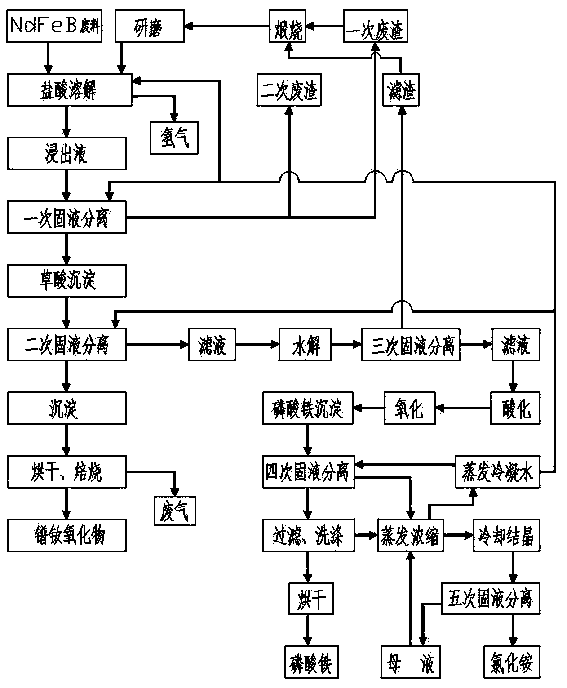

Method for separating and utilizing neodymium iron boron waste materials

ActiveCN103773966AReliable separation and recoveryReduce the cost of separation and recoveryIron compoundsProcess efficiency improvementOXALIC ACID DIHYDRATEPhosphate

Owner:绵竹三人禾科技发展有限责任公司

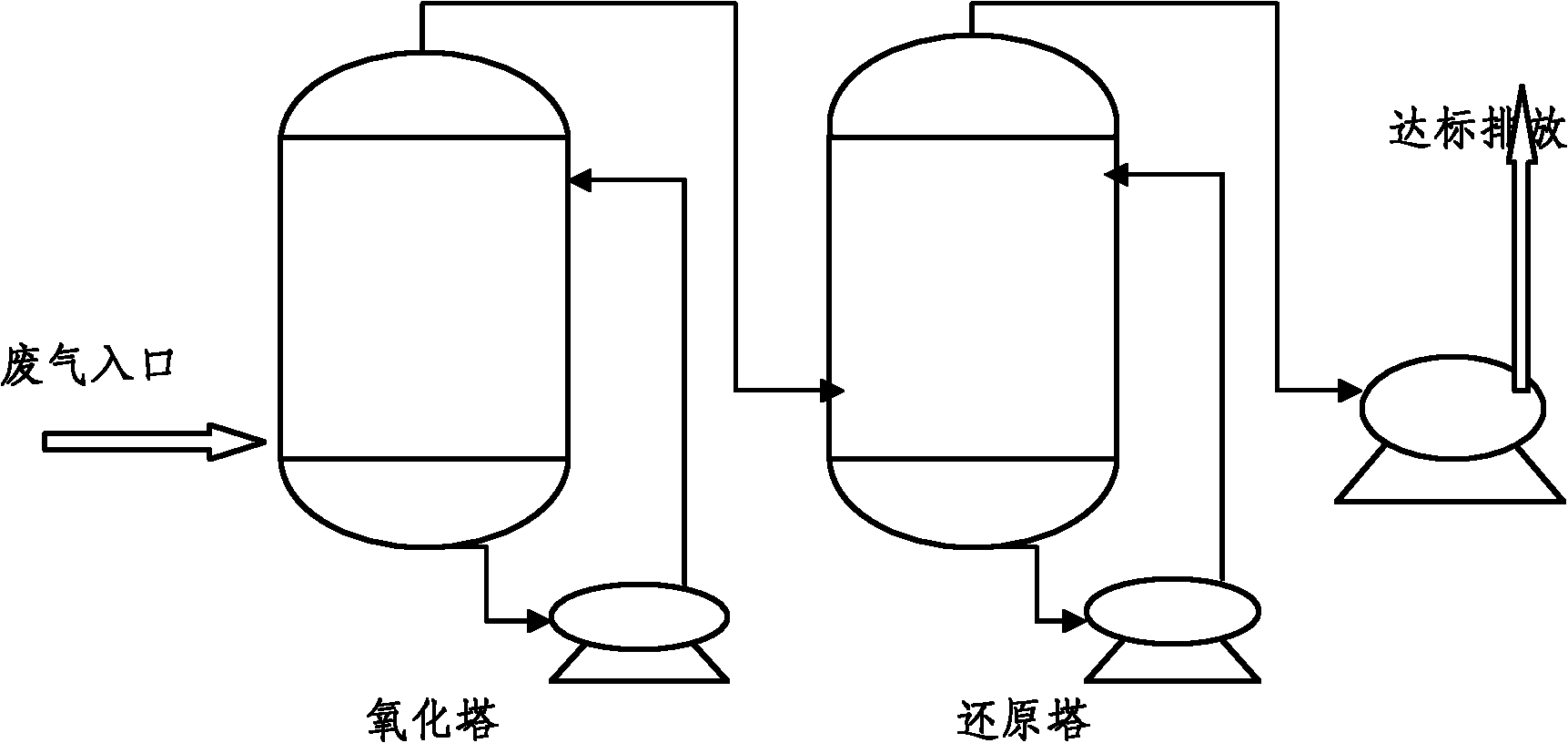

Purification process for acid oxidation and alkaline reduction of waste gas containing nitrogen oxide

The invention discloses a purification process for acid oxidation and alkaline reduction of waste gas containing nitrogen oxide and belongs to the field of treatment processes of the waste gas containing the nitrogen oxide by using an acid oxidation and alkaline reduction purification process. The process comprises the following steps of: washing the waste gas containing the nitrogen oxide in an acid oxidizing agent solution by using composite tower equipment, and carrying out absorption and oxidizing reaction to improve the degree of oxidization (the molar ratio of nitrogen dioxide (NO2) to nitric oxide (NO)) of the nitrogen oxide in the waste gas; and re-washing in an alkaline reducing agent solution, and carrying out absorption and reduction reaction to make the nitrogen oxide in the waste gas reduced into nitrogen and water, so that the nitrogen oxide in the waste gas is thoroughly removed, the aim of purifying the waste gas containing the nitrogen oxide is fulfilled, and the process contributes to environmental protection.

Owner:BEIJING UNIV OF CHEM TECH +1

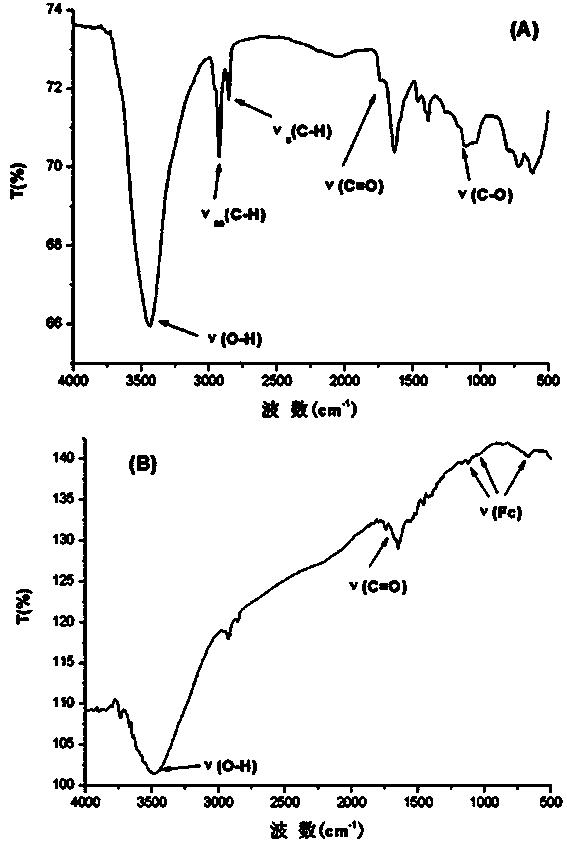

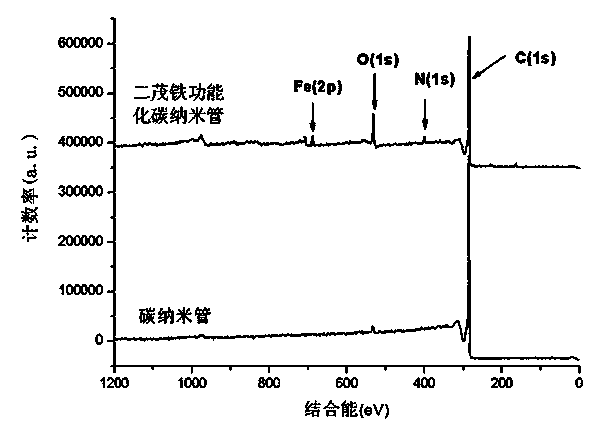

Method for preparing ferrocene functionalized carbon nanotube composite material

ActiveCN103466595AOvercome easy fall offOvercome stabilityMaterial nanotechnologyCarbon compoundsChemical reactionCarbon nanotube

Owner:FUZHOU UNIV

Method for preparing modified composite biological filler

InactiveCN106867607AImprove stabilityGood effect of hanging filmGaseous fuelsBiological water/sewage treatmentPolyvinyl chlorideGrowth promoting

The invention discloses a method for preparing a modified composite biological filler and belongs to the technical field of environmental protection. According to the method, polyvinyl chloride polyhedral hollow spheres serve as a carrier, are subjected to compound-acid oxidation and then are subjected to acrylic acid grafting modification; through introducing oxo polar groups, the surface roughness and microbial film hanging performance are improved, the specific surface area and microbial attachment area are increased; due to adsorption removal capability of zeolite, vermiculite and activated charcoal to wastewater, luffa cylindrica is subjected to carbonizing treatment and then is compounded with the zeolite and the vermiculite, and FeAl precipitates are adsorbed; FeAl oxide doped composite powder is prepared through high-temperature calcination, so as to further improve the adsorption removal capability; meanwhile, due to biological film growth promoting action of Fe, the film hanging time is shortened; and finally, the composite powder is stuck to surfaces of the modified polyvinyl chloride polyhedral hollow spheres treated with polyvinyl alcohol, so as to prepare the modified composite biological filler. The prepared modified composite biological filler has the advantages that the stability is good, the specific surface area is large, the surface is rough, and biological films are difficult in falling-off.

Owner:CHANGZHOU UNIV

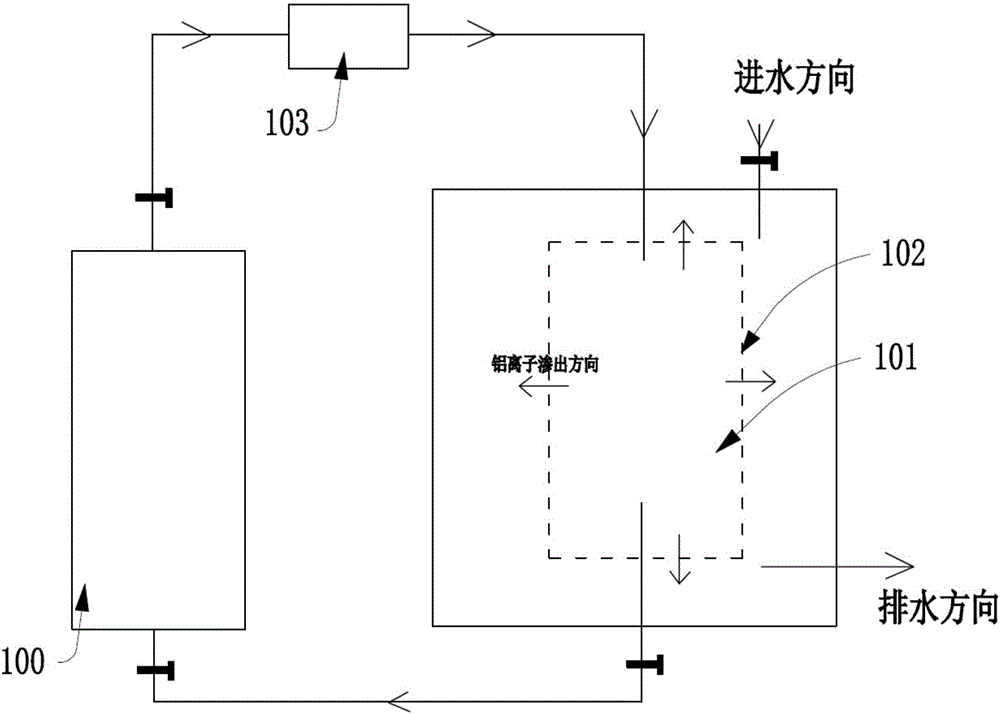

Oxidation energy-saving method for recycling aluminium ions and sulphuric acid of oxidation tank and improving current density

ActiveCN106757255AReduce the amount of dissolutionHigh densityCellsAnodisationHigh current densityEvery Hour

The invention discloses an oxidation energy-saving method for recycling aluminium ions and sulphuric acid of an oxidation tank and improving current density. The method comprises an oxidation solution circulating cooling step, an aluminium ion crystal product recycling step, a sulphuric acid oxidation solution recycling step, a gas stirring step, a defrosting step and a current density adjusting step; the current density adjusting step comprises the following steps: adjusting the flow of a variable frequency pump to be that the oxidation solution is circulated not more than six times every hour; adjusting the current density in an anodic oxidation tank. The invention provides an oxidation energy-saving method for recycling the aluminium ions and the sulphuric acid of the oxidation tank and improving the current density, the oxidation current density is improved, the oxidation time is shortened, the dissolving amount of oxidation films is reduced, and the oxidation energy consumption is reduced for the first time on the premise of blowing cold an oxidation film interface by fully utilizing a cathode cooling pipe.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

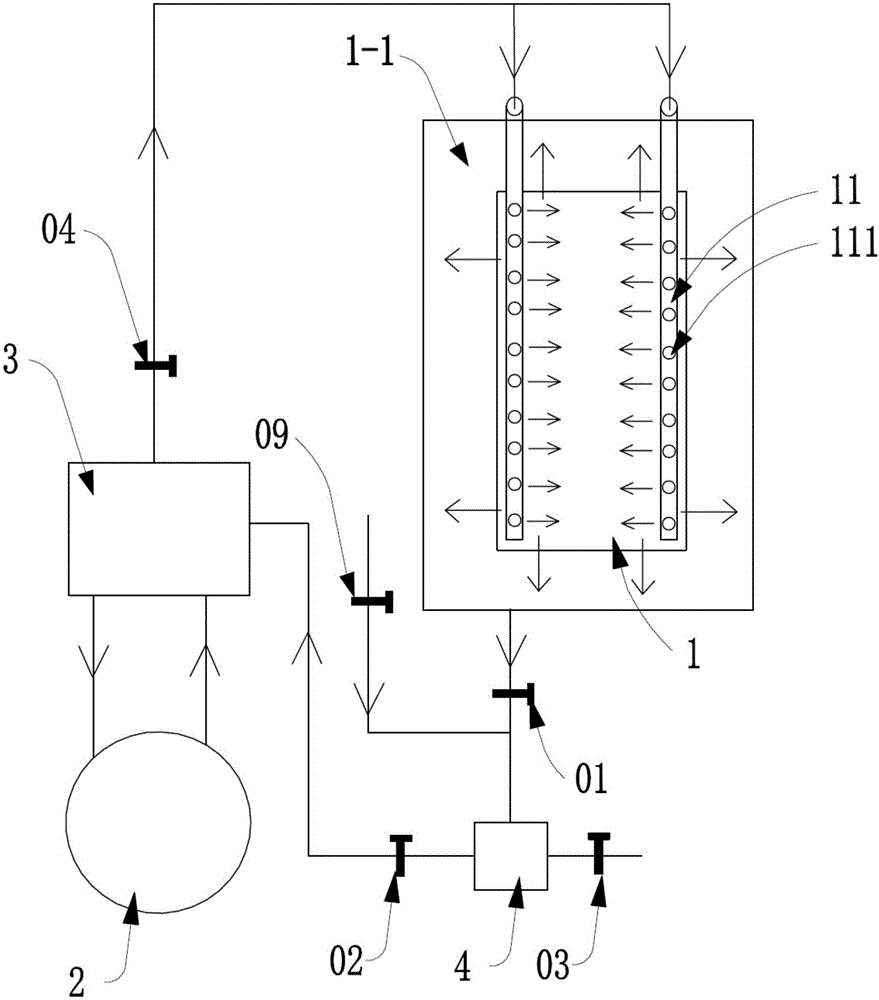

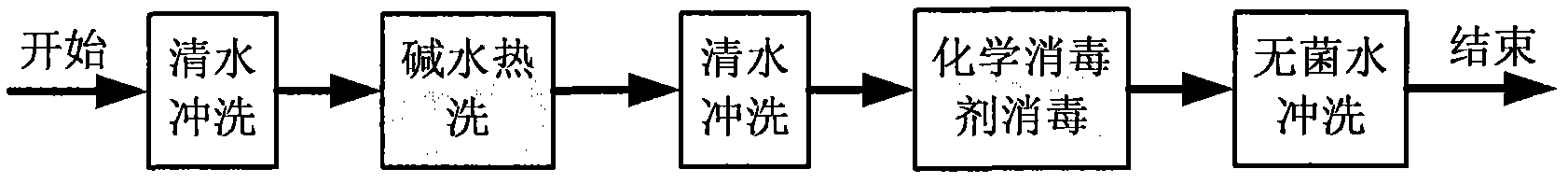

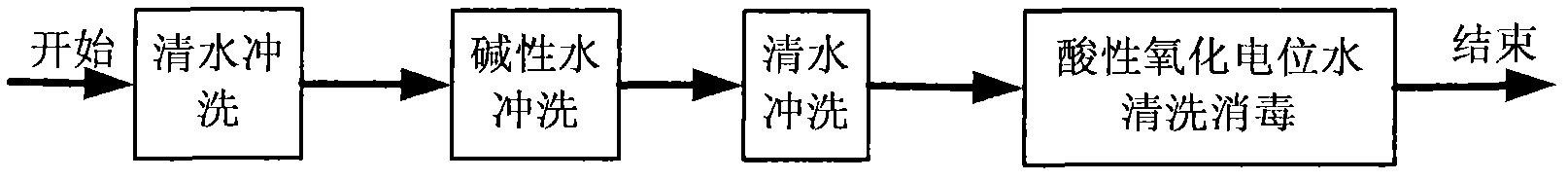

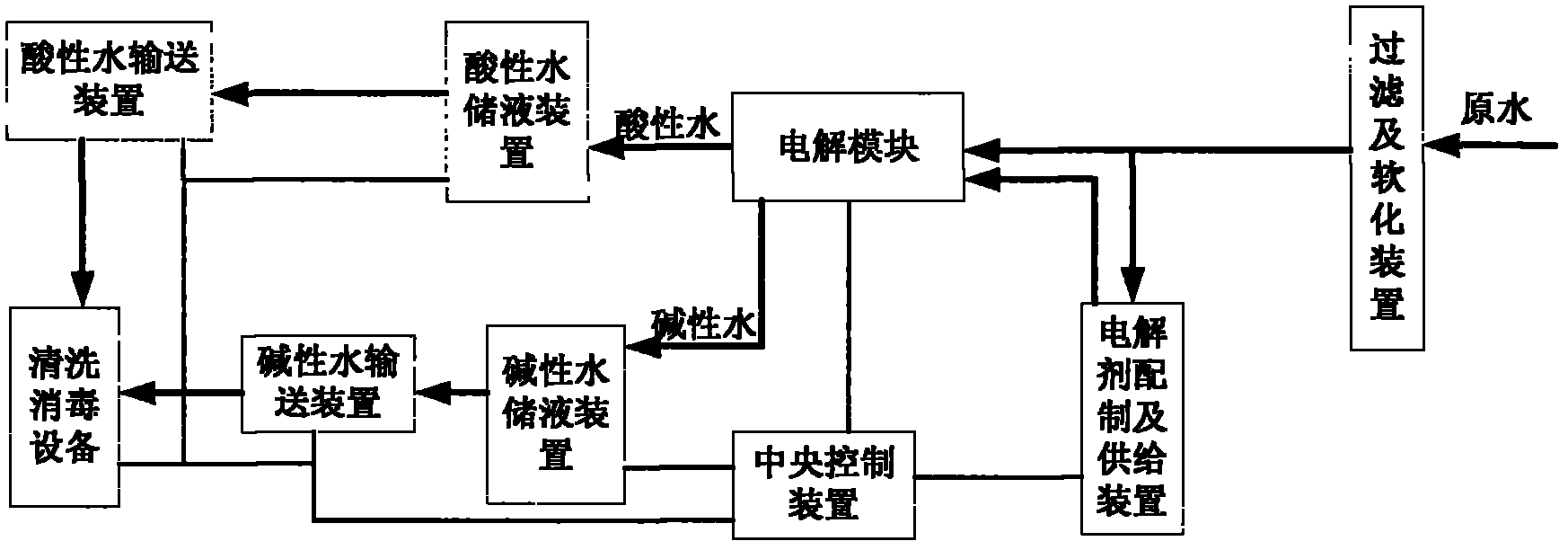

System and method for cleaning and sterilizing related equipment in beer producing process

InactiveCN102380113ASolve instabilityReduce usageBathroom accessoriesLavatory sanitoryAlkaline waterAcid water

Owner:BEIJING GRET RESOURCES ENVIRONMENTAL PROTECTION TECH

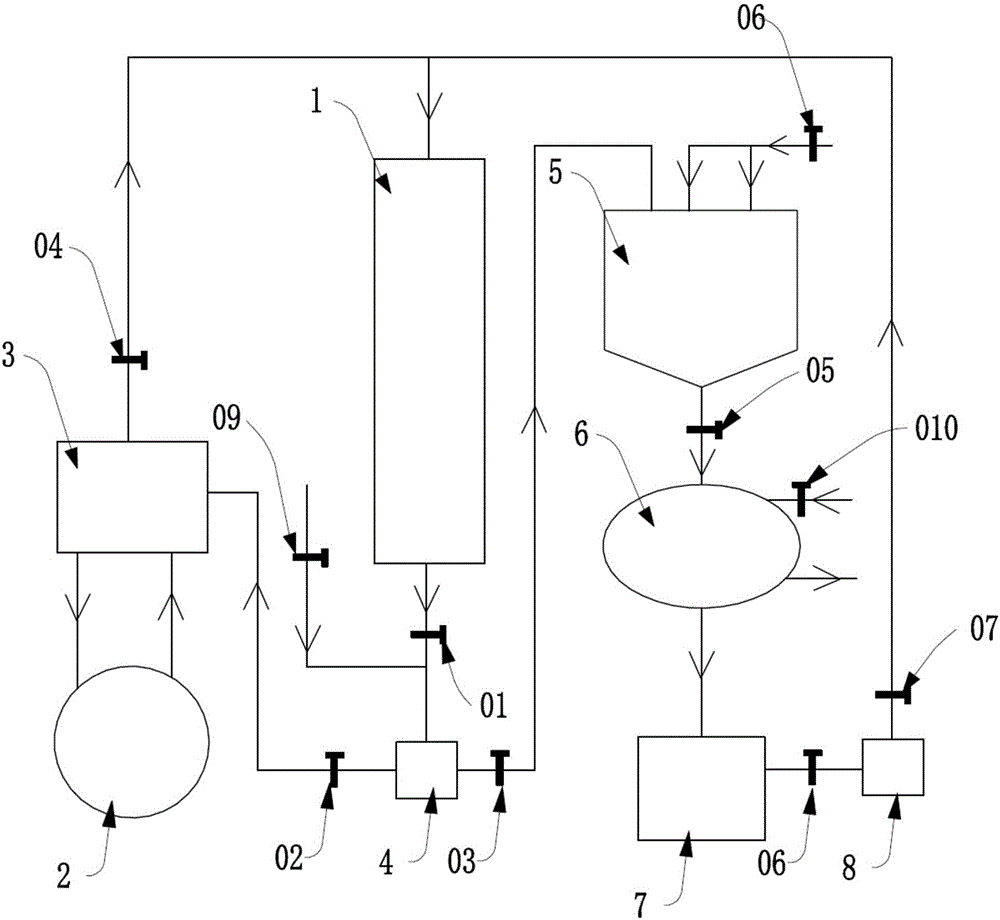

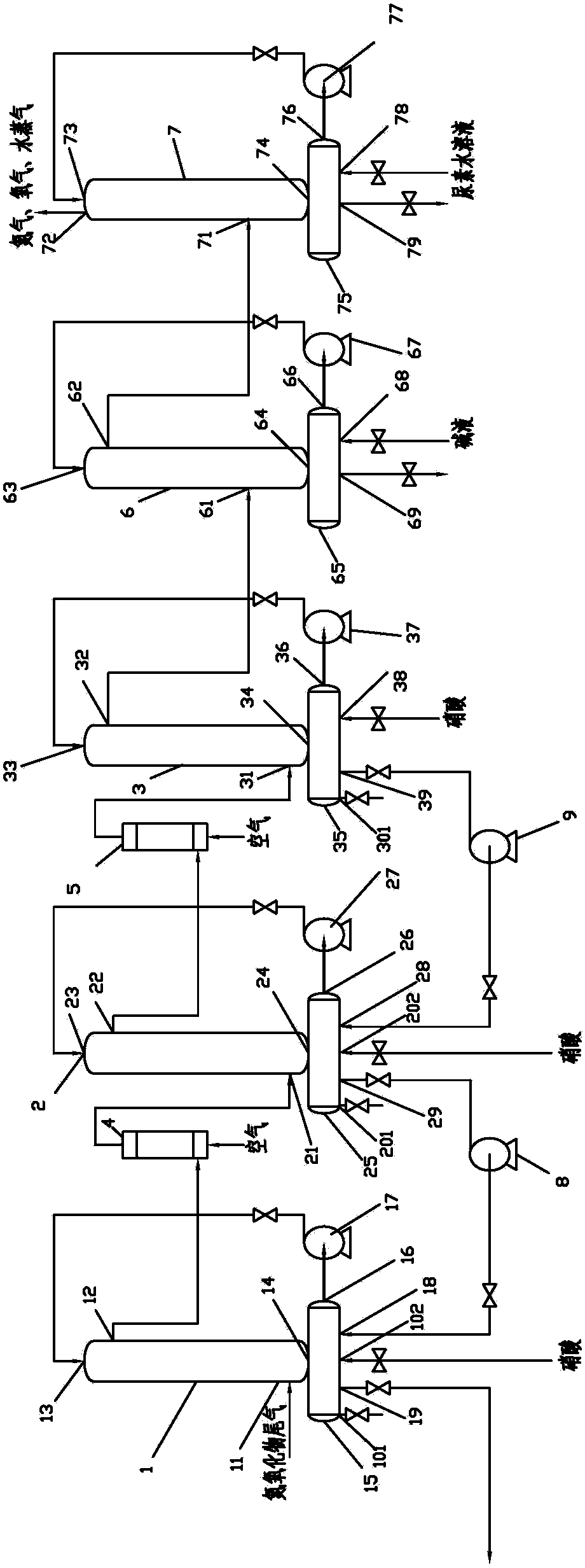

Treatment system and method of nitric oxide in nitrotoluene nitric acid oxidation tail gas

ActiveCN103537178AImprove absorption efficiencyReduce the unit consumption of nitric acidDispersed particle separationPhysical chemistryNitric oxide

The invention discloses a treatment system and method of nitric oxide in nitrotoluene nitric acid oxidation tail gas, belonging to the field of chemical engineering. The system comprises a plurality of acid absorption towers, gas mixers, alkali absorption towers and urea absorption towers, wherein mother liquid used in the reaction process is used as an acid solution for absorption, is subjected to step-by-step absorption treatment by virtue of the acid absorption towers in an adverse current mode, and is then subjected to the treatment of the alkali absorption towers and the urea absorption towers again, so that residual nitric oxide is completely broken into nitrogen to be discharged to the upper air; the acid absorption liquid required in the whole process is the auto-reacted mother liquid; after full absorption, the obtained acid liquid can completely meet the production requirement, thus greatly reducing the unit consumption of the raw material nitric acid. According to the treatment system and method, the treatment rate of the nitric oxide in the tail gas is more than 99%, the maximum recovery rate can reach more than 90% along with the increase of the numbers of the acid towers, and the absorption efficiency and comprehensive utilization level of the nitric oxide tail gas are improved.

Owner:浙江优创材料科技股份有限公司

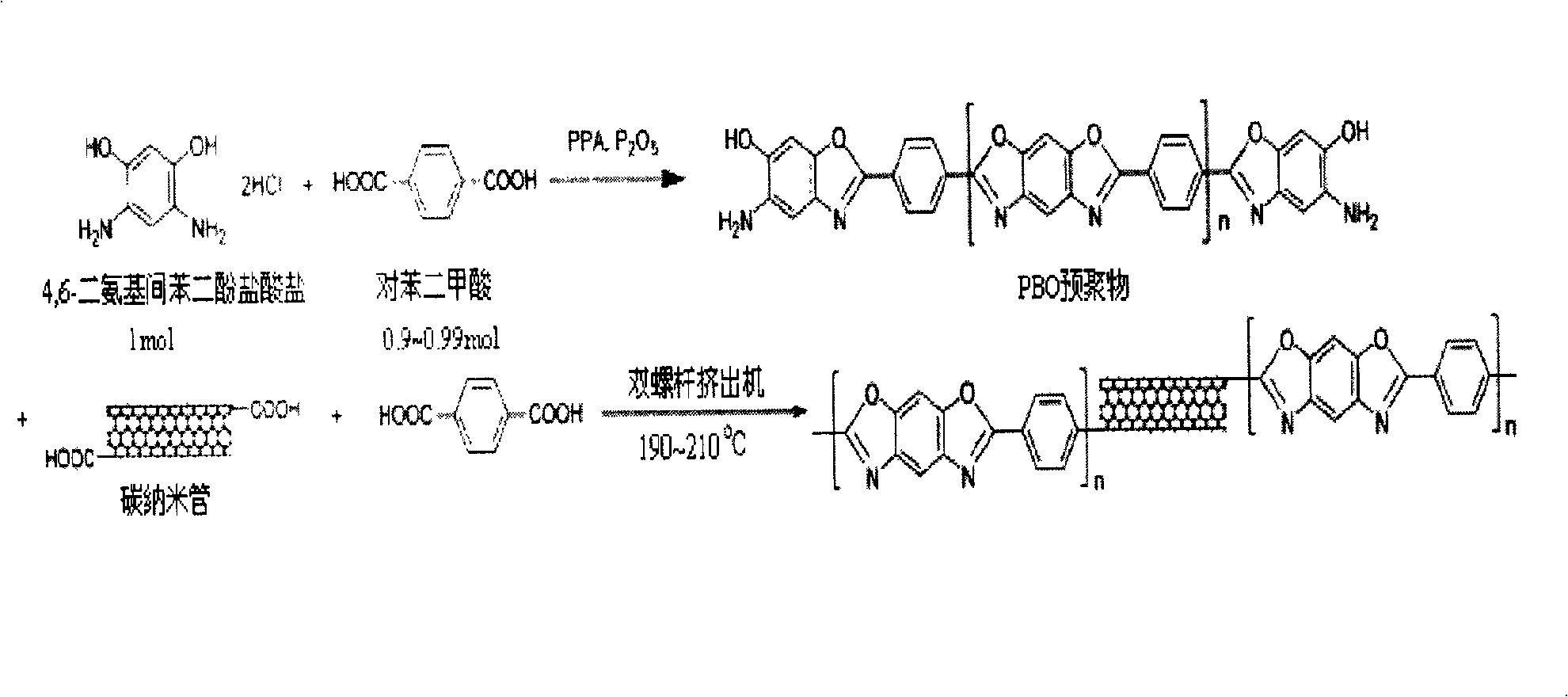

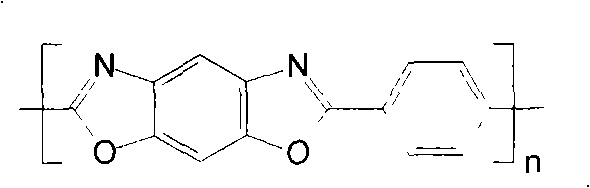

Method for preparing poly(p-phenylene) benzo dioxazole composite fiber containing carbon nano tube

InactiveCN101407945AImprove performanceHigh tensile strengthMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberCarbon nanotube

The invention relates to a preparation method of PBO composite fibers containing carbon nano tubes, which comprises the steps of carrying out acid oxidation treatment to the carbon nano tubes, preparing PBO prepolymer solution, adding a carbon nano tube solution after the acid oxidation treatment, a TPA suspension and the PBO prepolymer solution into a double screw extruder for carrying out high-efficient blending reaction so as to be extruded, preparing the PBO composite fibers containing the carbon nano tubes by dry-jet wet spinning and the like. Compared with the PBO composite fibers synthesized under the same conditions, the PBO composite fibers prepared by the method of the invention have the tensile strength improved by 10 to 90 percent and the modulus improved by 10 to 50 percent. The PBO composite fibers containing carbon nano tubes and prepared by the method can be taken as a reinforcing agent of thermosetting resin, rubber, plastics and the like, and can be applied in protective clothing, flame resistant materials, or friction material and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

High peroxide autodeposition bath

InactiveUS20080160199A1Meet needsAvoid disadvantagesNon-fibrous pulp additionCoatings with pigmentsPhysical chemistryCross linker

This invention provides an autodeposition bath composition and process capable of coating zinciferous metal surfaces with minimal pinhole formation, comprising (a) at least one polymer, (b) at least one emulsifier, (c) optionally at least one cross-linker, (d) at least one accelerator component such as acid, oxidizing agent and / or complexing agents, (e) an average minimum concentration of H2O2 of at least 100 parts per million, (f) optionally, at least one filler and / or colorant, (g) optionally, at least one coalescing agent, and (h) water.

Owner:HENKEL KGAA

High thermal conductive wear resistant polyphenylene sulfide composite material and preparation method thereof

The invention belongs to the technical field of electronics, and in particular relates to a high thermal conductive wear resistant polyphenylene sulfide composite material and a preparation method thereof. The material contains the following components byweight: 45-80 parts of PPS, 15-50 parts of a conductive filler, 1.5-5 parts of acompatibilizer, 1-3 parts of a silane coupling agent. The conductive filler is a mixture of carbon nanotube (CNT) and carbon fiber (CF). The invention adopts an acid oxidation method for the treatment of carbon nanotubes and carbon fiber, and solves the problems of high snarling degree, difficulty in disperse, and poor bonding performance with a matrix resin of a thermal conducting filler. A melt blending method is used to disperse a variety of additives with excellent performance into PPS, so as to solve the defects of incompatibility of thermal grinding tolerance and high mechanical property of an existing material. The prepared by high thermal conductive wear resistant polyphenylene sulfide composite material has light weight, high heat conductivity, wear resistance and excellent comprehensive mechanical properties.

Owner:深圳市高科塑化有限公司

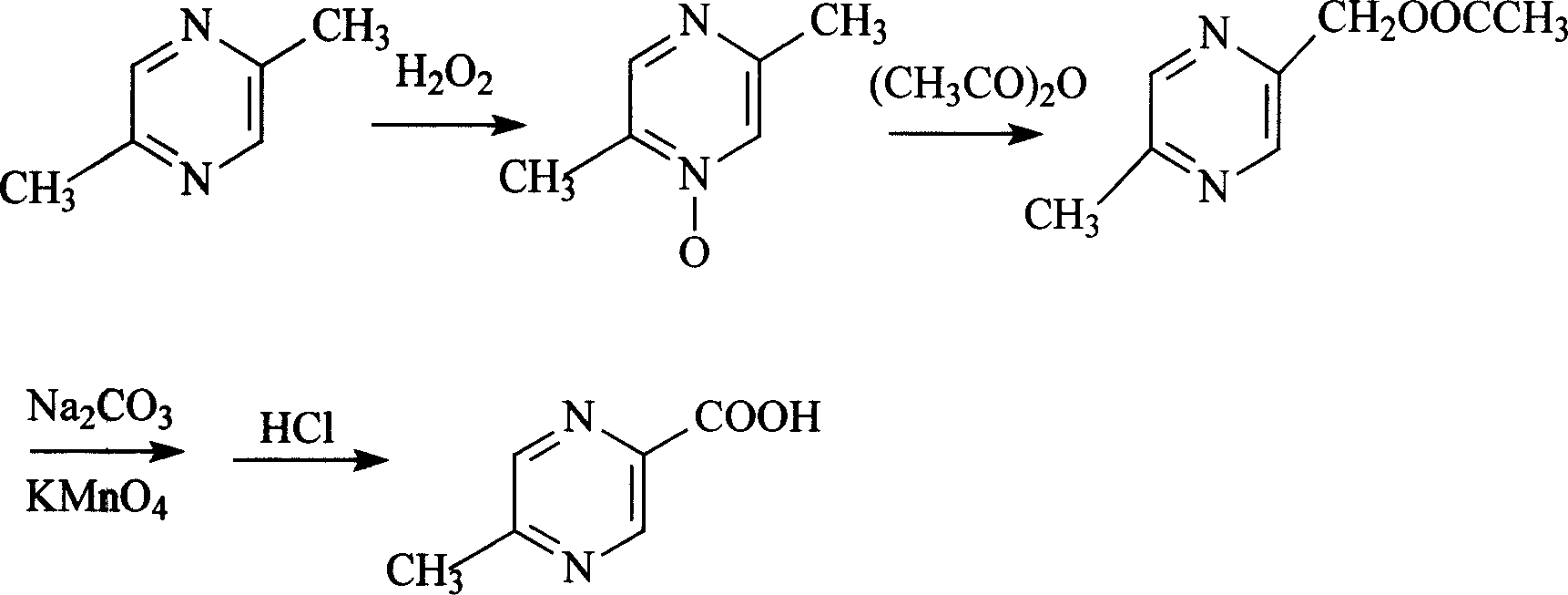

Process of selective synthesizing 5-methyl pyrazine-2-carboxylic acid using 2,5-dimethyl pyrazine

This invention use 2,5- dimethyl pyrazine as raw materials, selectively synthesize 5-methyl pyrazine-2-carboxylic acid. Its technology is use 2,5 - dimethyl pyrazine as raw material, through oxidation of nitrogen and hydrogen peroxide, acetic anhydride acid oxidation, hydrolysis and oxidation process, gain 5-methyl pyrazine-2-carboxylic acid. HPLC analysis of their content is over 99%, with 0.1 mol / L of sodium hydroxide titration, content is not less 98%, melting point is not less than of 163 deg, the quality of medicine to meet glipizide, Acipimox requirements. The process is scheme simple, high-yield, low cost and suitable for industrial production.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

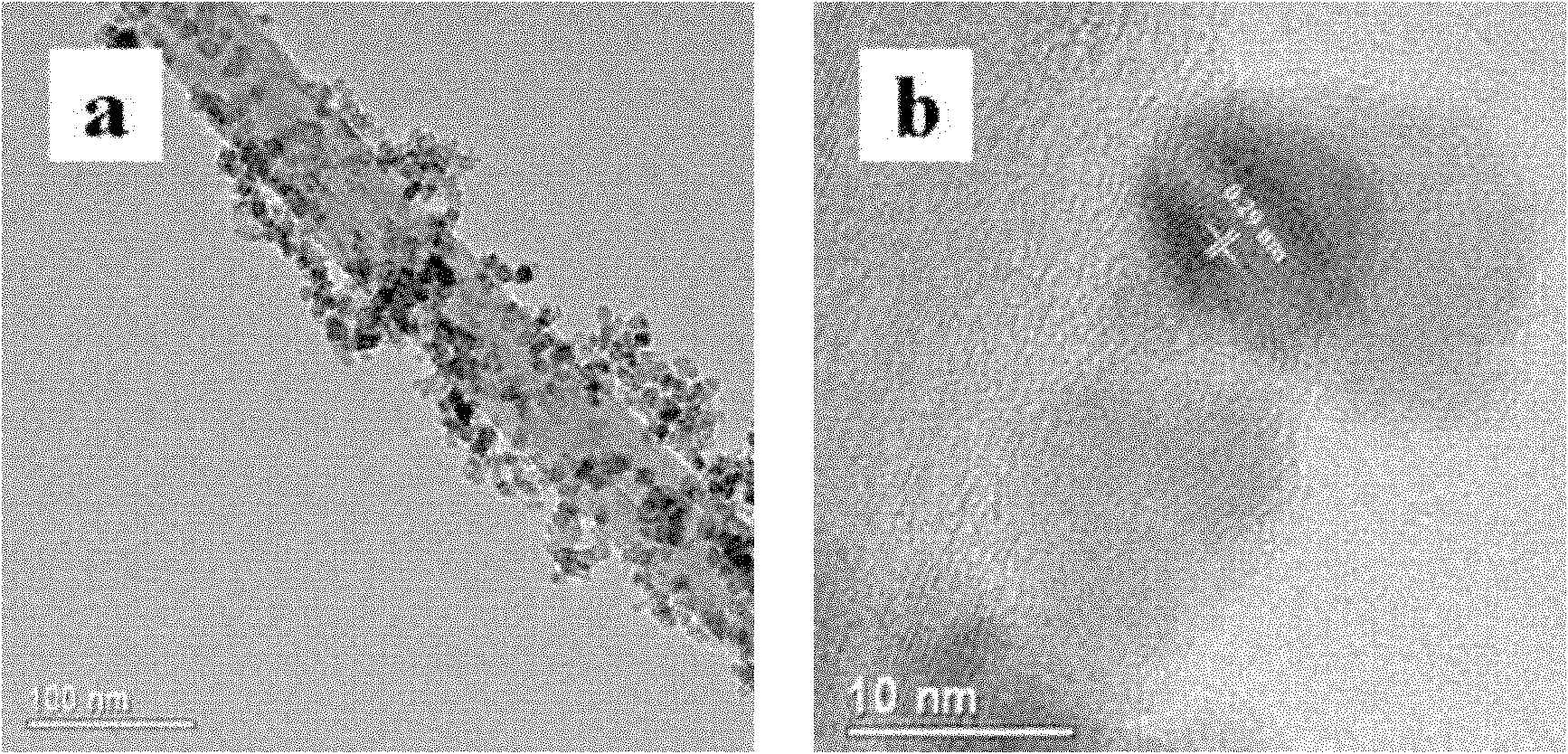

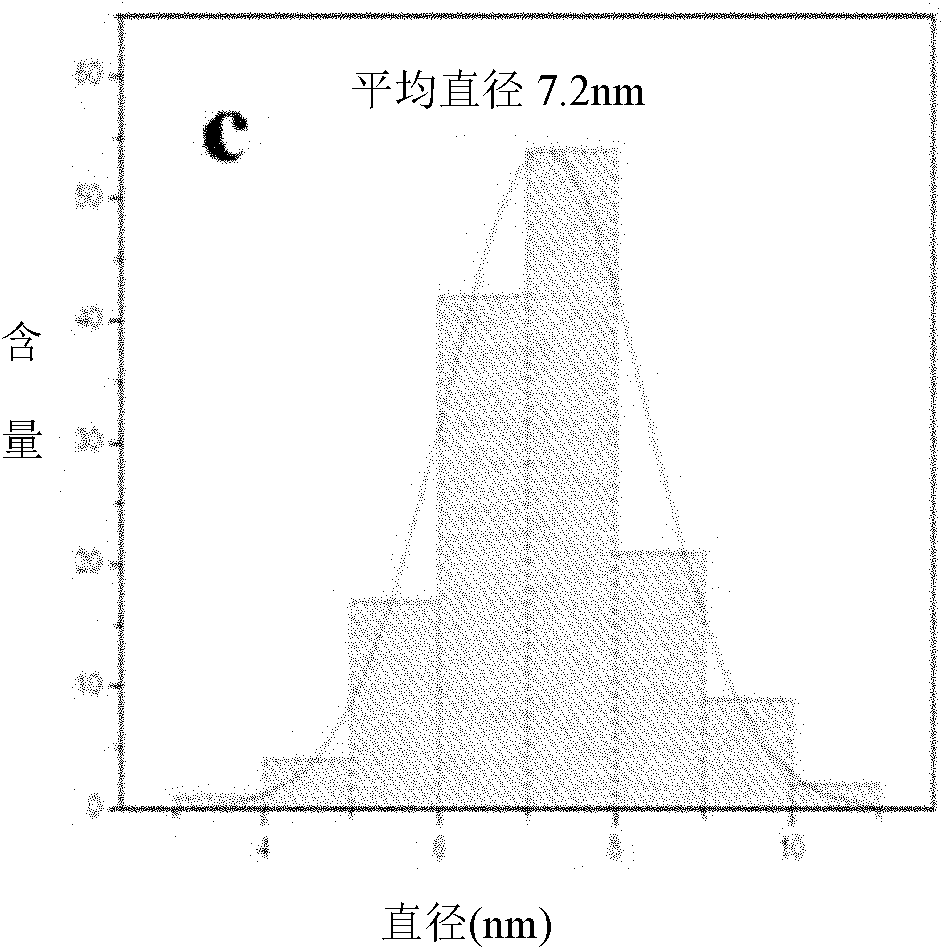

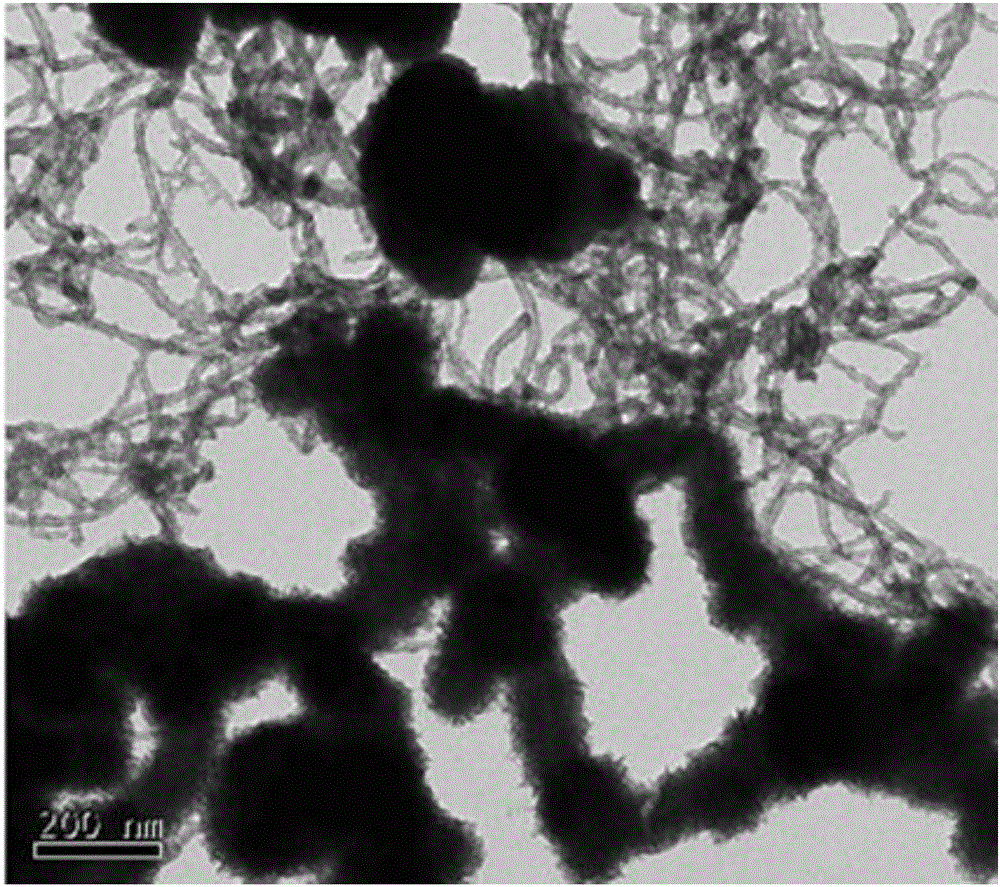

Carbon nanotube/chitosan/magnetic ferrite nanoparticle composite material, and preparation method and application thereof

InactiveCN102068705AImprove integrityGood biocompatibilityNMR/MRI constrast preparationsEmulsion deliveryFerrite nanoparticlesMagnetic resonance imaging contrast medium

The invention discloses a carbon nanotube / chitosan / magnetic ferrite nanoparticle composite material. A preparation method of the material comprises the following steps of: coating chitosan polymer and magnetic ferrite nanoparticles on multi-wall carbon nanotubes from inside to outside in turn; modifying the surfaces of the carbon nanotubes by coating the chitosan; and depositing the magnetic ferrite nanoparticles on the carbon nanotubes in situ by a hydrothermal method. The material prepared by the method has higher saturation magnetization rate and T2 relaxation coefficient, and is a good magnetic resonance imaging contrast medium. In the invention, concentrated acid oxidation treatment is not required to be performed on the carbon nanotubes in advance, so that the structural integrity of the carbon nanotubes is protected; and the preparation method has the advantages of readily available raw materials, low cost and the like, is easy to operate and is suitable for industrial production.

Owner:SHANGHAI NORMAL UNIVERSITY

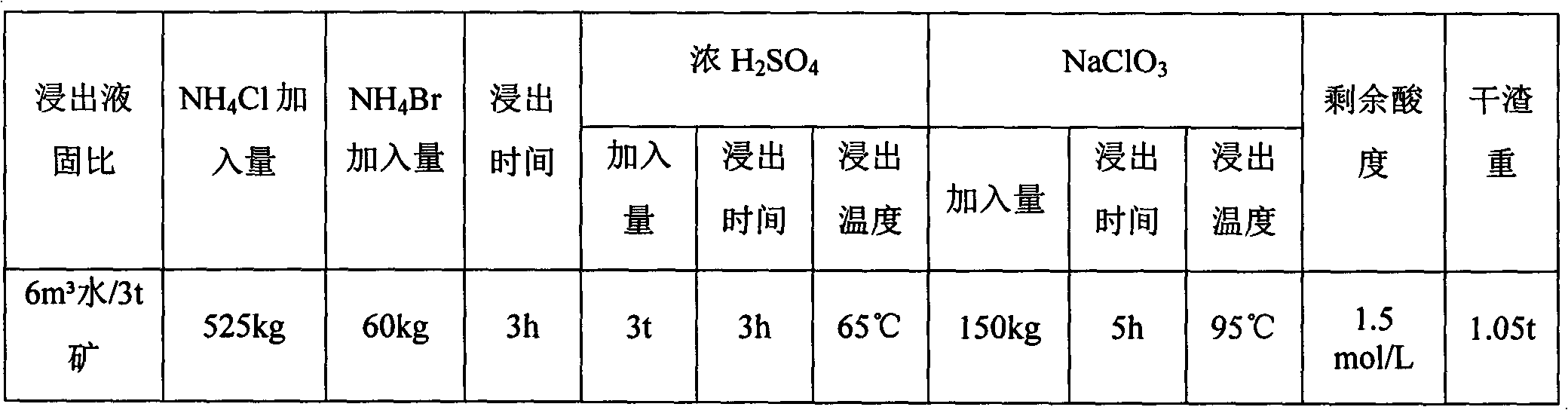

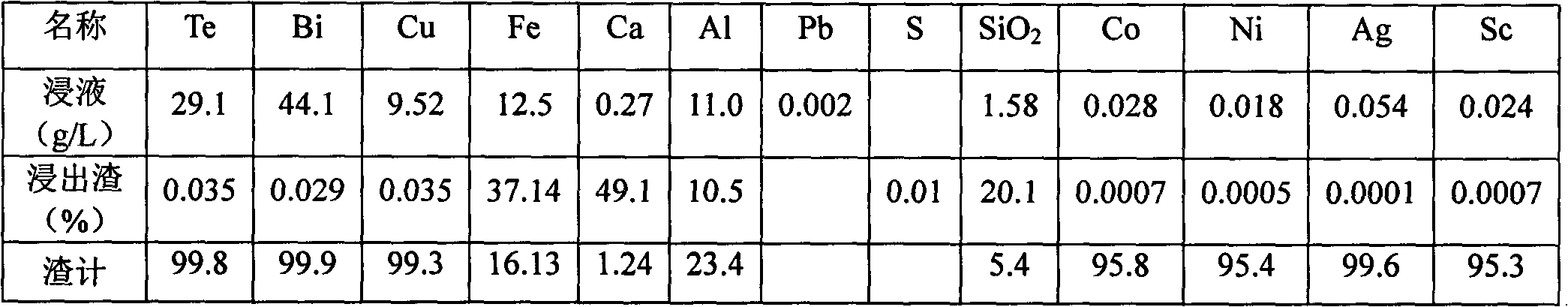

Wet metallurgical method with comprehensive reclamation, basically no three wastes and zero discharge

The invention discloses a wet metallurgical method with comprehensive reclamation, basically no three wastes and zero discharge, and belongs to the fields of wet metallurgy and environmental friendliness. Aiming at the problems that the conventional wet metallurgical process can only reclaim partial valuable elements serving as commodities and produces a large amount of waste water, waste slag and waste gas so as to cause resource waste and generate environmental hazards, the invention provides the new wet metallurgical method. The method is characterized in that: scattered components, rare components, rare earth, noble metals and other valuable components can reach optimal leaching rate and enter the solution by adopting a high-strength leaching agent such as a high acid oxidation and complexing leaching agent or a high alkali oxidation and complexing leaching agent and using high-strength physical and chemical conditions such as high-temperature and high-pressure leaching. By high-strength leaching, the filtered and washed leached slag reaches the standards of raw materials of building materials or standards for making of iron, aluminum and the like and other chemical raw materials. In order to achieve comprehensive, effective and economic separation and purification and make auxiliary materials such as the leaching agent and the like not wasted, recycle of leachate and waste water is adopted, so that the purposes of comprehensive reclamation, basically no three wastes and zero discharge are basically fulfilled. Therefore, the wet metallurgical technology is more economic, more effective, energy-saving and environment-friendly.

Owner:王钧

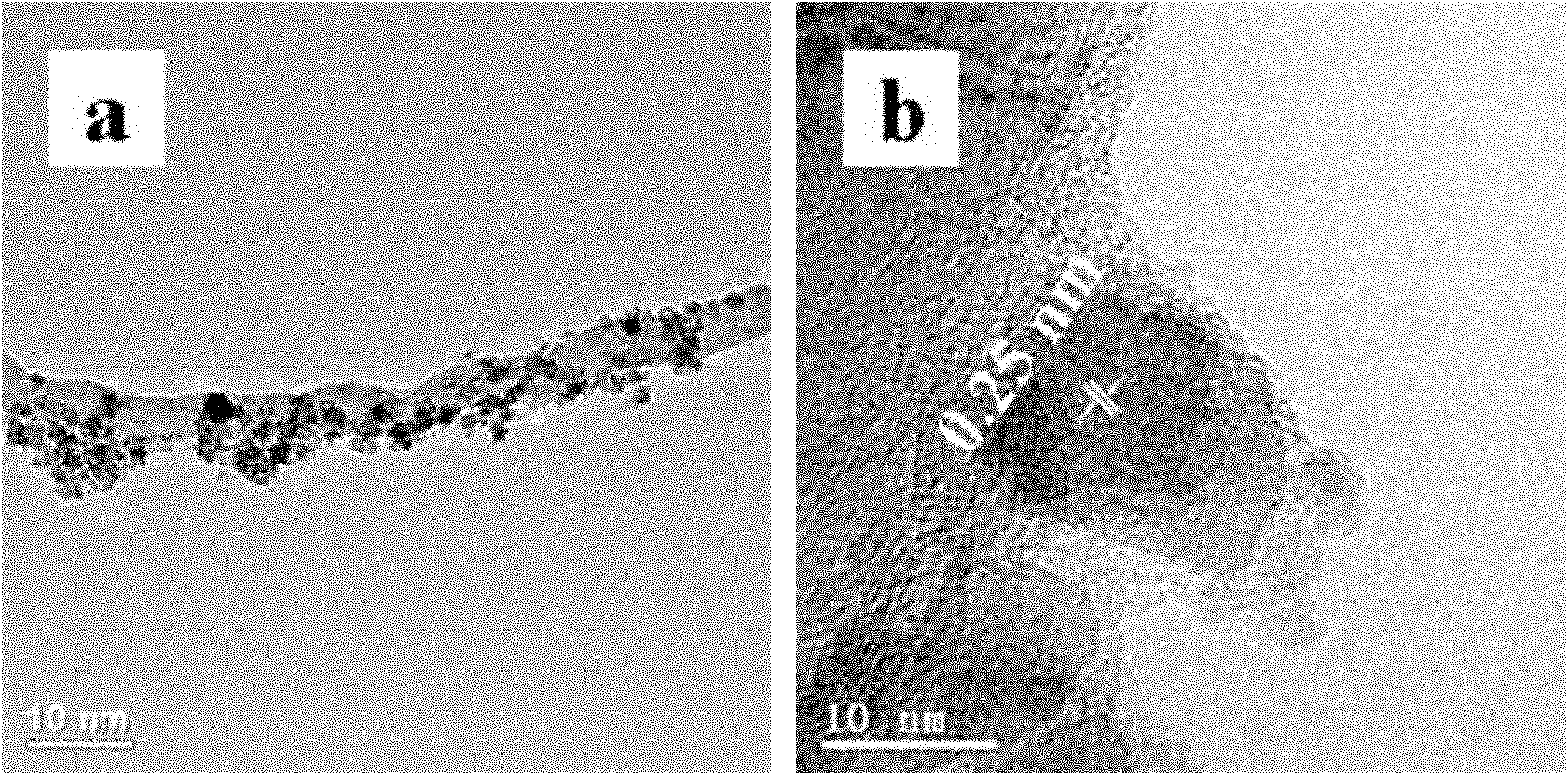

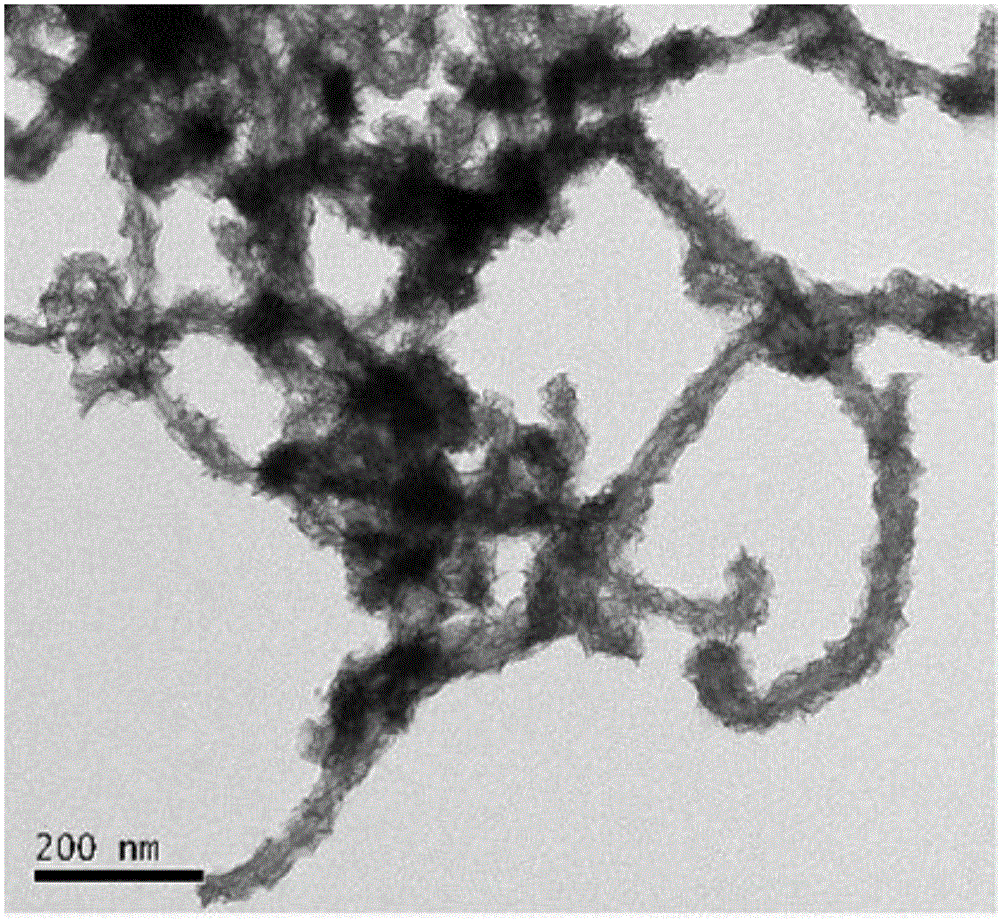

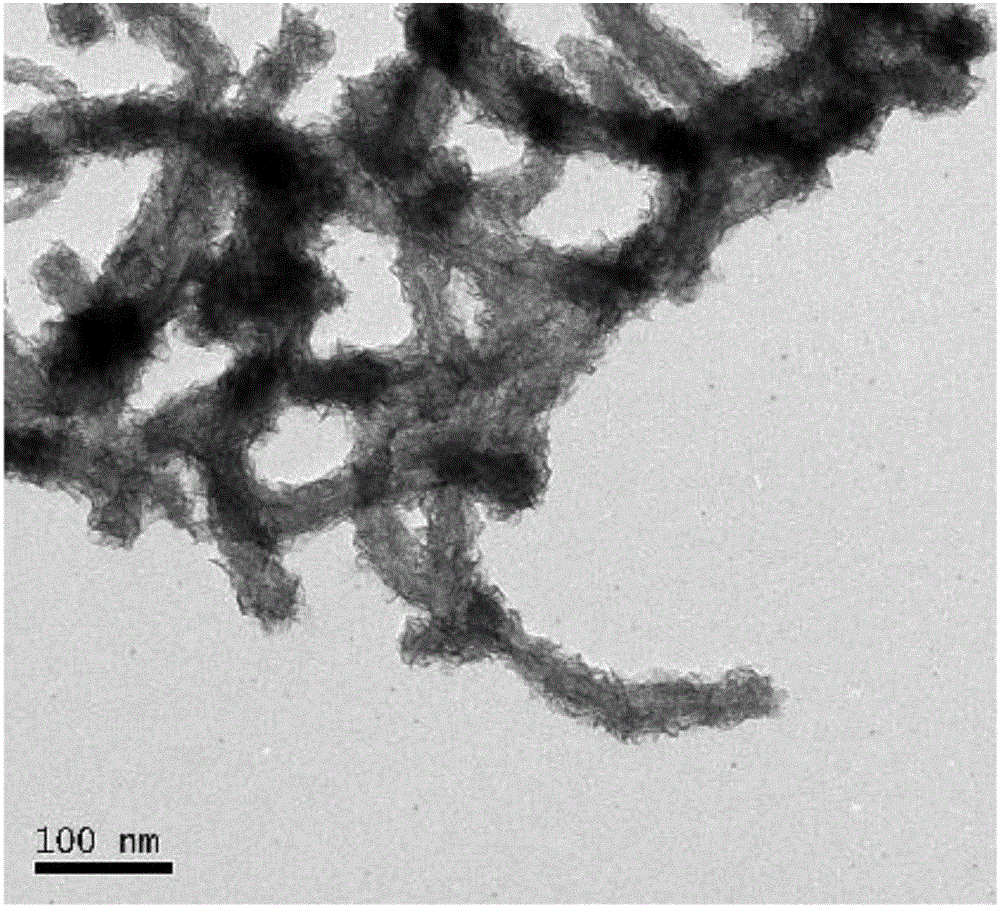

Preparing method for MoS2-CNT multi-level nano-structure electrolysis water hydrogen production material

ActiveCN106521545ARealize rationalityAchieve comprehensive optimizationPhysical/chemical process catalystsElectrodesElectrolysisNano structuring

The invention discloses a preparing method for a MoS2-CNT multi-level nano-structure electrolysis water hydrogen production material. The method comprises the following steps that firstly, a multi-walled carbon nanotube is subjected to functionalization, the carbon nanotube is subjected to acid oxidation treatment, and the functionalization carbon nanotube is obtained; secondly, MoS2-CNT preparing is conducted, after an alcohol-water mixing solvent and the functionalization carbon nanotube are mixed and dispersed, ammonium molybdate and thiourea are then added for the reaction, and a product is obtained after separating and washing. Through coordinated regulation and control of a multi-level three-dimensional structure and interphase interaction, reasonable construction and comprehensive optimization of a MoS2-CNT electrocatalyst structure are achieved, efficient electro-catalysis hydrogen evolution reaction performance with commercialization prospects is obtained, and a new thought is provided for improving catalytic activity of different kinds of electrocatalysts through the multi-level structure and interphase connection regulation and control strategy.

Owner:SOUTH CHINA AGRI UNIV

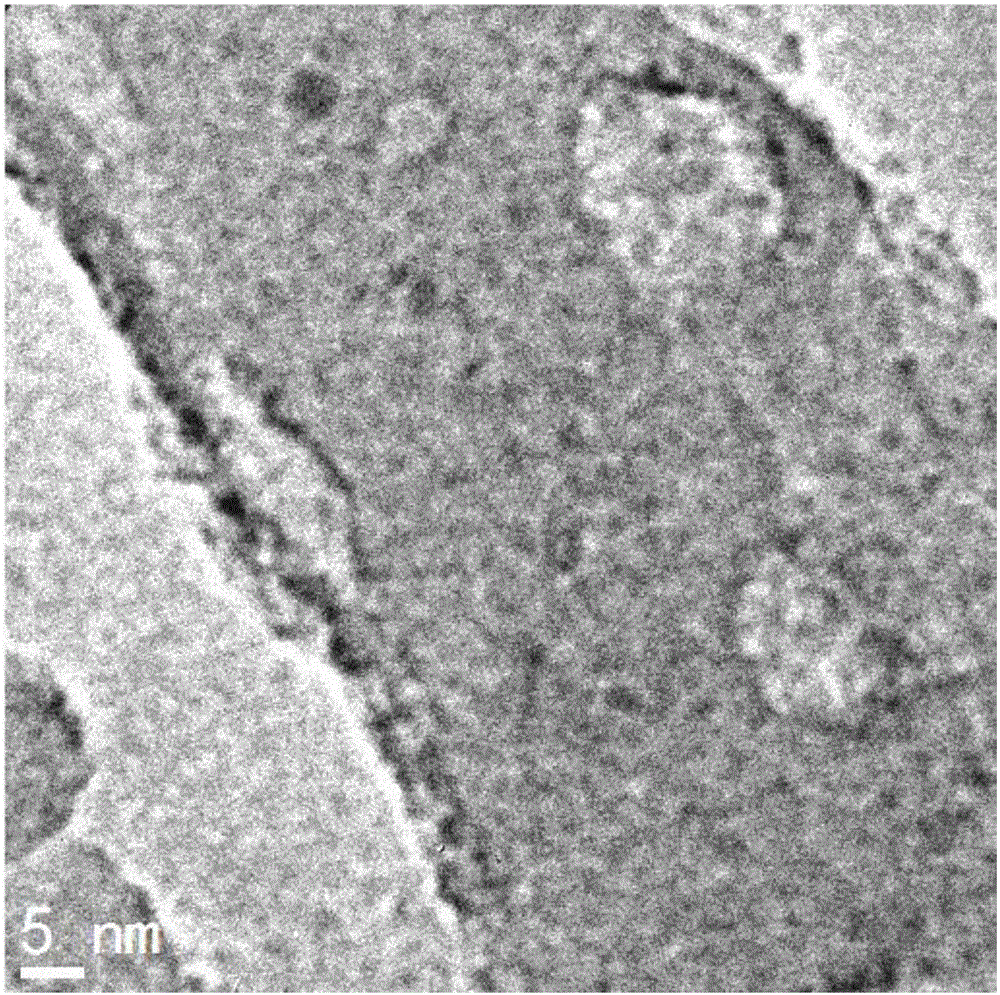

Preparation method of porous carbon nanotube

The invention relates to a preparation method of a porous carbon nanotube, and aims to solve the problems of easiness in agglomeration, poor dispersity and small specific surface area of a carbon nanotube. The porous carbon nanotube is prepared from a carbon nanotube serving as a raw material through solution preparation, ultrasonic dispersion treatment, acid oxidation, freeze drying, vacuum sintering, acid soaking, washing-suction filtration and drying in vacuum. The preparation method has the advantages of advanced and rapid process, and accurate and abundant data; a product is black powder with the particle diameter of less than or equal to 60nm; pores are uniformly distributed in the surface of the carbon nanotube, and the pore diameters are less than or equal to 10nm; the product purity is up to 99.5 percent, and the specific surface area is increased by 520 percent; the method is an advanced method for preparing the porous nanotube tube.

Owner:TAIYUAN UNIV OF TECH

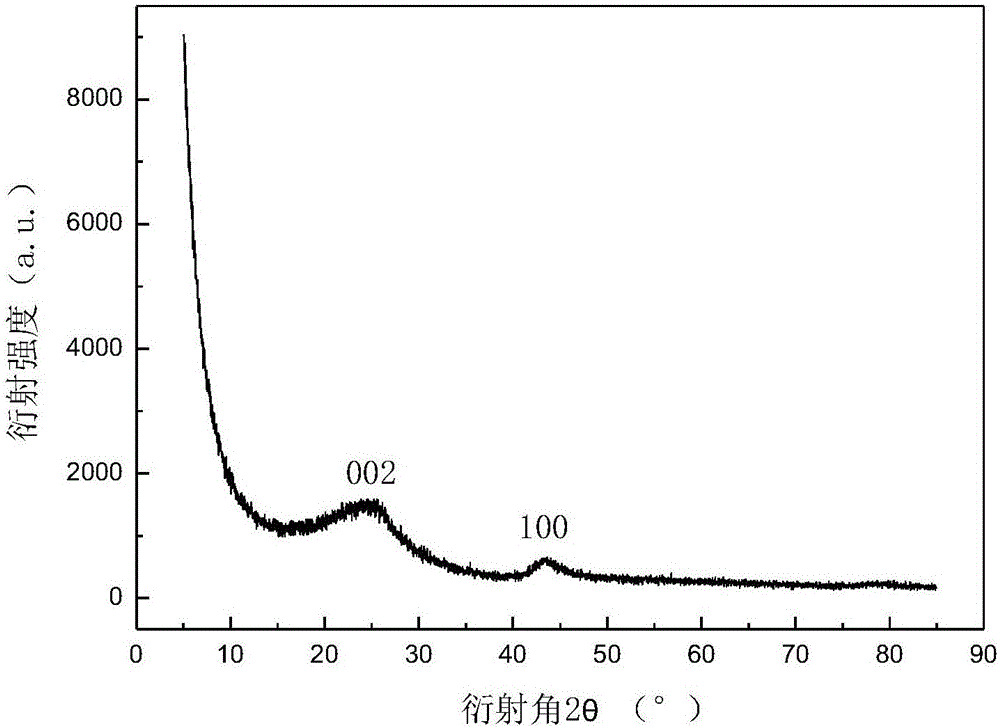

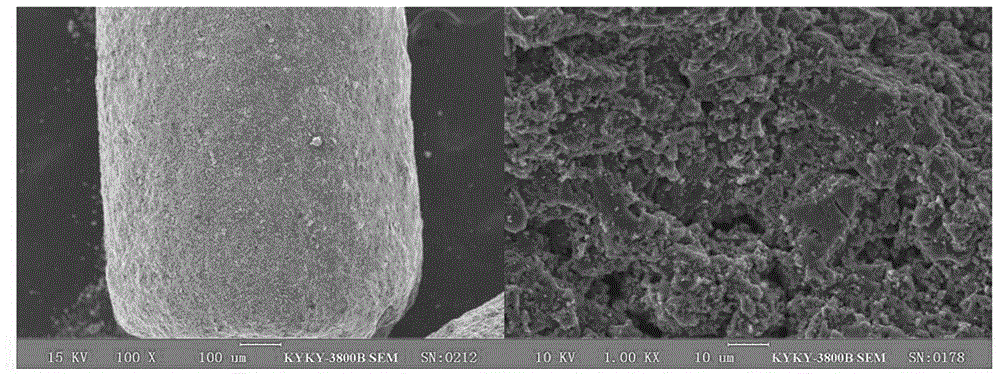

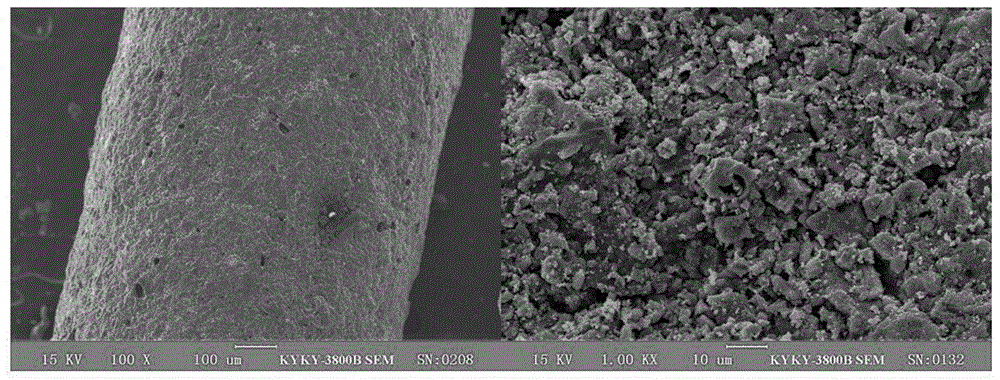

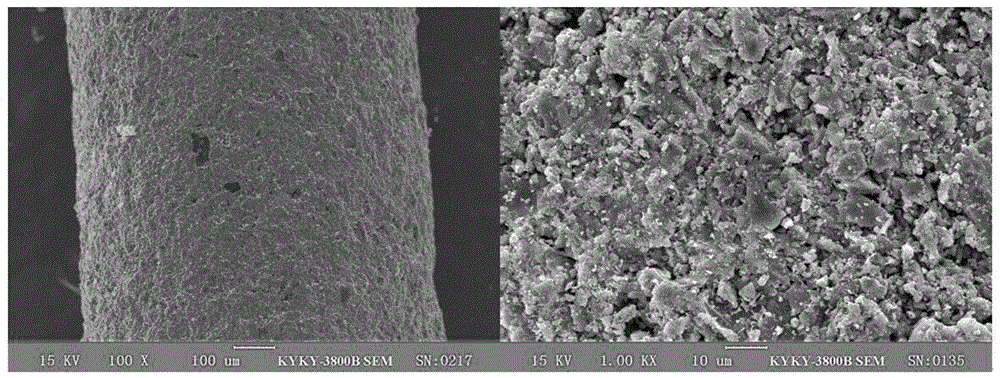

Method for preparing low-temperature denitration nitrogen-rich porous carbon material

InactiveCN106563482ARaw materials are cheap and easy to getThe process is simple and easy to controlGas treatmentPhysical/chemical process catalystsWater vaporPorous carbon

The invention discloses a method for preparing a low-temperature denitration nitrogen-rich porous carbon material. The method includes the steps that raw coal and semi-coke particles are used as the main body, a binding agent and deionized water are used as the object, and a porous carbon material can be obtained by means of mixing, forming, carbonization and water vapor activation in sequence; and finally mixed acid oxidation and ferrous acetate reduction are carried out to form the low-temperature high-denitration efficiency nitrogen-rich porous carbon material. The raw material is low in price and easy to obtain, the process is simple and controllable, the operating conditions are mild, and the denitration rate of the nitrogen-rich porous carbon material obtained can reach 65% or above at different temperatures.

Owner:SHANXI XINHUA CHEM

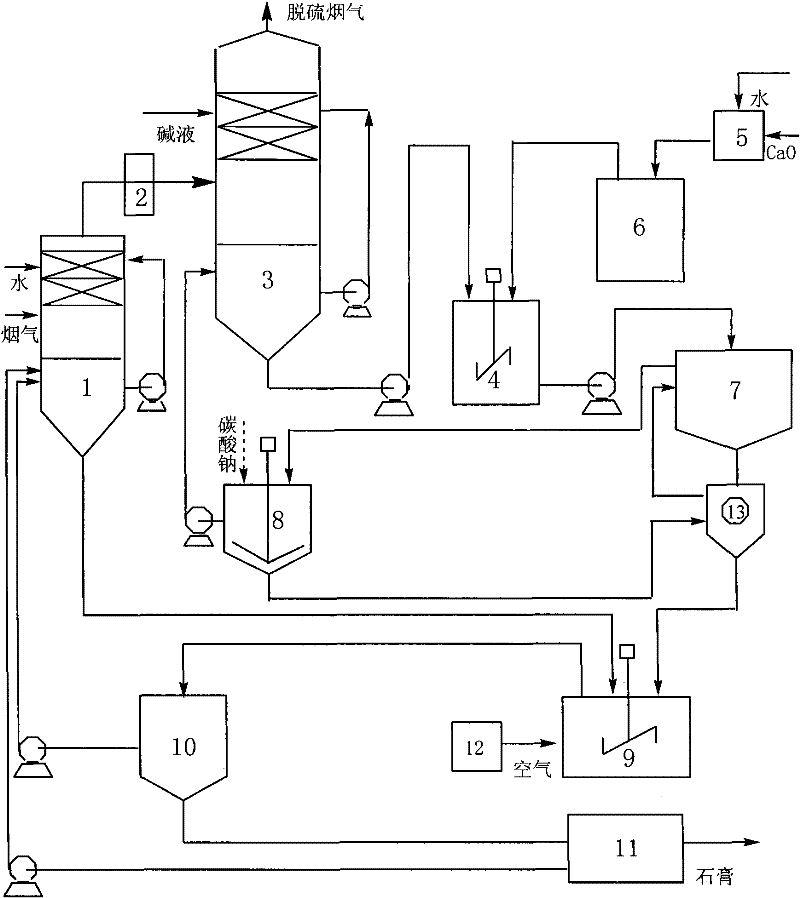

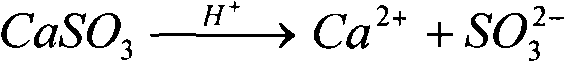

A double-alkali flue gas desulfurization process

The present invention relates to a double-alkali flue gas desulfurization process, including a flue gas absorption system, an alkali regeneration system, and a gypsum preparation system, wherein: a, the flue gas absorption system includes two parts: water absorption and alkali absorption, and sulfur-containing flue gas passes through water Absorb part of the SO2 to obtain H2SO3 solution and part of the desulfurized flue gas, and the part of the desulfurized flue gas after demisting is subjected to alkali absorption to obtain the absorption liquid and desulfurization flue gas; b. The alkali regeneration system includes regenerating the absorption liquid with lime to generate calcium sulfite and calcium sulfate precipitate, separate the precipitate to obtain a regeneration solution, and return the regeneration solution to the alkali absorption part in the absorption system; c, the gypsum preparation system includes using the H2SO3 solution obtained by absorbing water in a to acidify the precipitate obtained in b, and at the same time Oxygen-containing gas is blown in to oxidize. After oxidation, a slurry containing calcium sulfate is obtained. After conventional treatment, the slurry is obtained into gypsum and clear liquid. The invention utilizes the H2SO3 solution formed after the water absorbs the flue gas as the acidifying acid of the oxidation system, reduces the amount of added sulfuric acid, and makes reasonable use of the sulfur-containing flue gas.

Owner:CHINA PETROLEUM & CHEM CORP

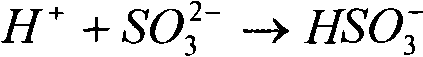

Comprehensive recovery method of bismuth matte

ActiveCN105543479AAchieving selective leachingAchieve enrichmentPhotography auxillary processesProcess efficiency improvementRecovery methodLead smelting

The invention relates to a hydrometallurgy technology for separating copper and bismuth from bismuth matte produced by a bismuth pyrometallurgy system and obtaining qualified copper products and belongs to the field of nonferrous metals hydrometallurgy. Bismuth matte is crushed, ground, sieved to be below -80 meshes and sent to a leaching tank for acid oxidation leaching, a leaching liquid is purified by a purifying agent and subjected to conventional copper electro-deposition treatment sequentially, and national standard copper products are obtained; after enrichment, leaching residues containing valuable metals such as lead, silver, sulfur and the like return to a lead smelting system for recovery, purifying residues containing the bismuth return to a bismuth smelting system for recovery of the bismuth. The recovery rate of valuable metals such as the copper, the silver, the sulfur, the bismuth, the lead and the like is high, the investment is low, energy consumption is low, no pollution is caused, no three-wastes are produced, green production is realized, and current environmental protection requirements are completely met.

Owner:ZHUZHOU SMELTER GRP

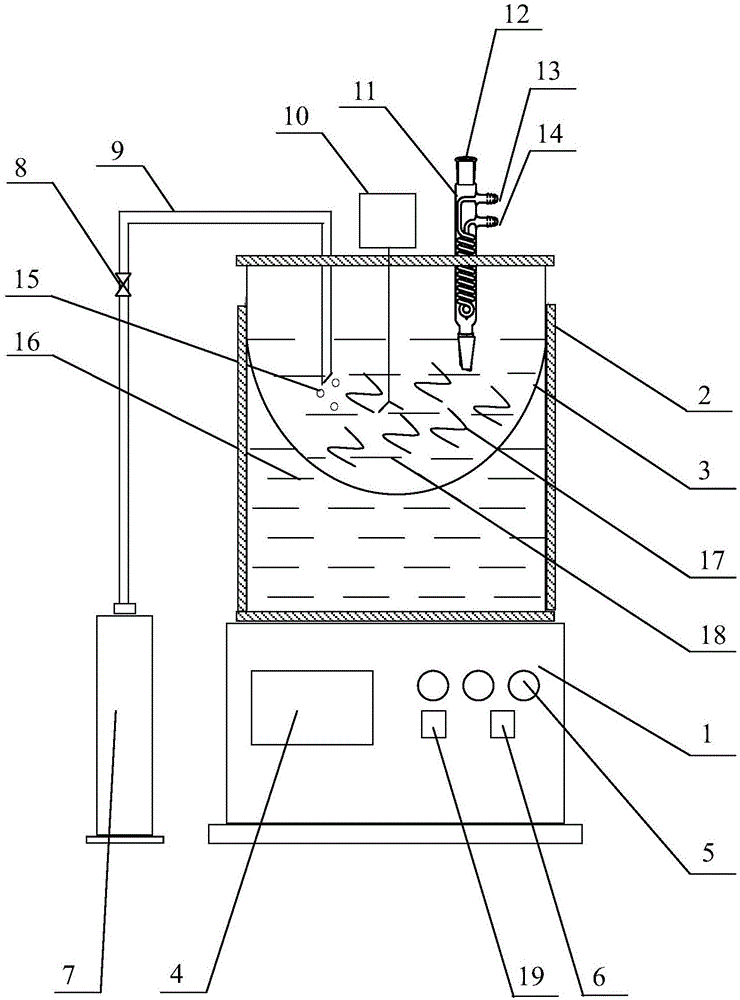

Preparation method of CNT (carbon nano-tube) membrane electrode CNT-Ti electrode used as catalyst carrier and application of CNT membrane electrode CNT-Ti electrode

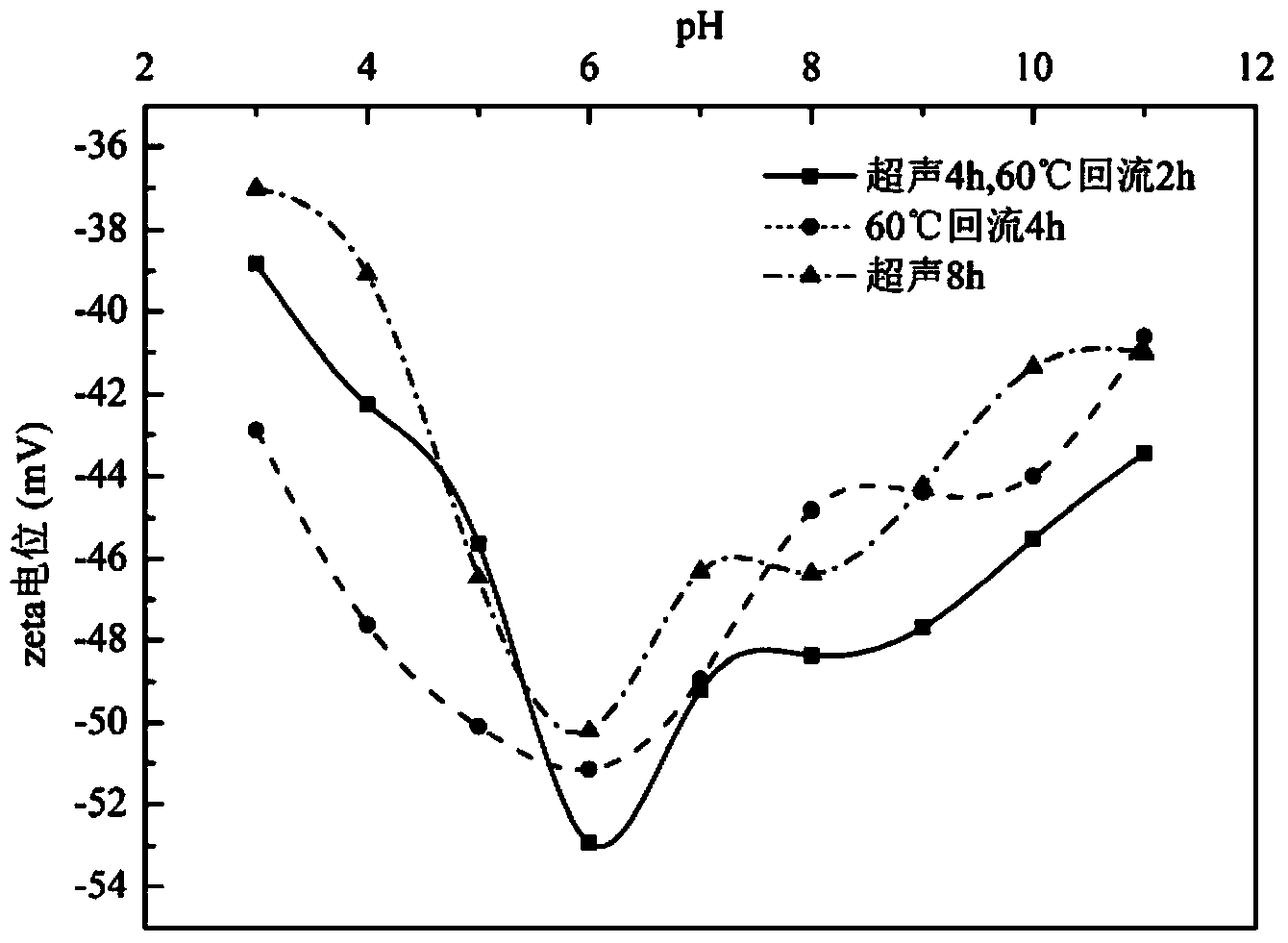

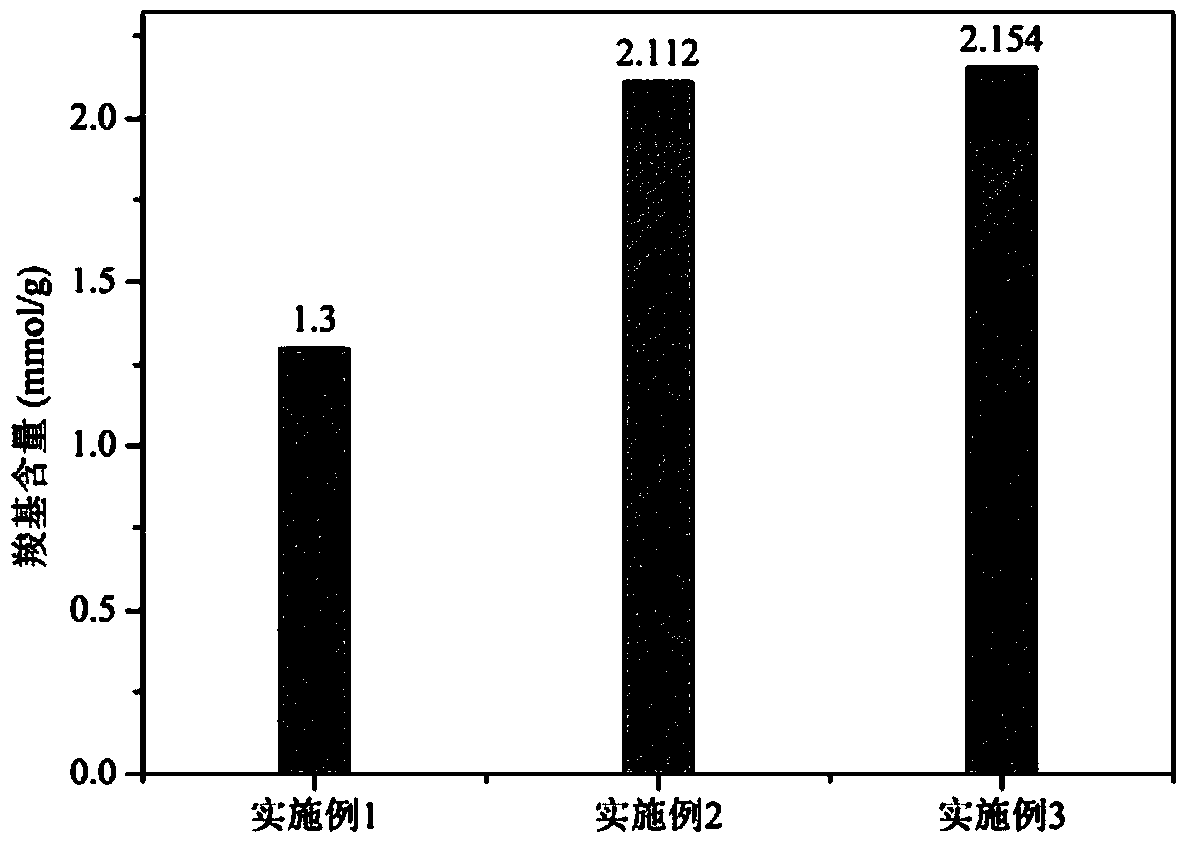

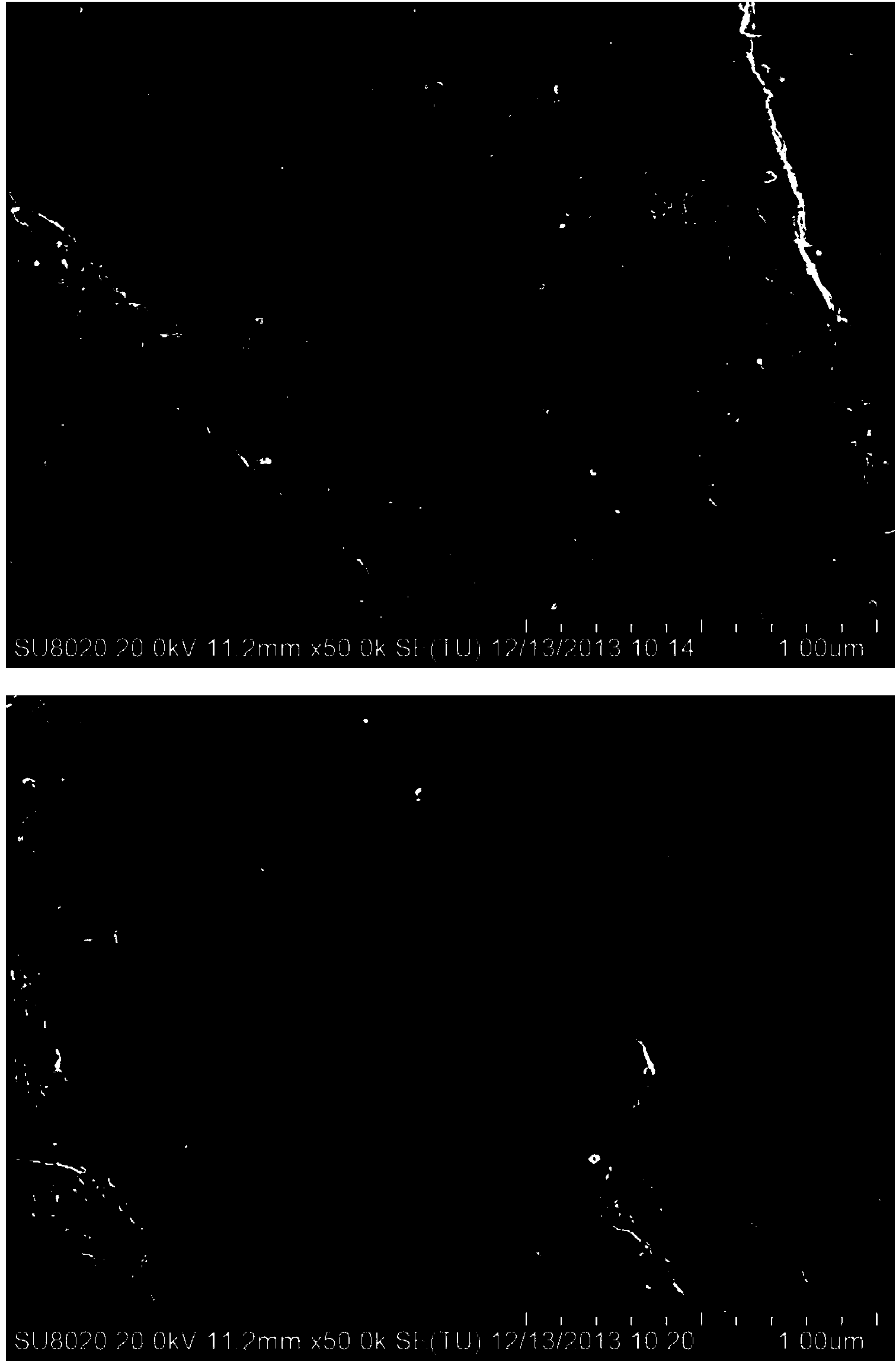

ActiveCN103882499AImprove electrocatalytic performanceAcid-resistant and corrosion-resistantElectrolytic coatingsWater/sewage treatment by electrochemical methodsZeta potentialMetal catalyst

The invention discloses a preparation method of a CNT (carbon nano-tube) membrane electrode CNT-Ti electrode used as a catalyst carrier and an application of the CNT membrane electrode CNT-Ti electrode, belonging to the technical field of electrochemical water treatment. The preparation method comprises the steps of combining two physical modes, namely ultrasound and reflux, introducing carboxyl functional groups to the wall of the CNT by adopting a concentrated acid oxidation method, determining the optional treatment method of the CNT and the optional pH value of dispersion liquid through a boehm titration method and the measurement of the zeta potential, and regulating the pH value of the dispersion liquid of the CNT to be 6, wherein the zeta potential is -53mV at the moment, so that a CNT membrane is successfully prepared on the surface of a titanium mesh by adopting electrophoretic deposition in a water phase. The preparation method is good in membrane-forming effect; the CNT membrane is uniform in dispersion, strong in capacity of loading metal catalysts and simple and convenient in operation, is an ideal catalyst carrier material, and provides material conditions for preparing electro-catalytic electrodes in the water phase.

Owner:BEIJING UNIV OF TECH

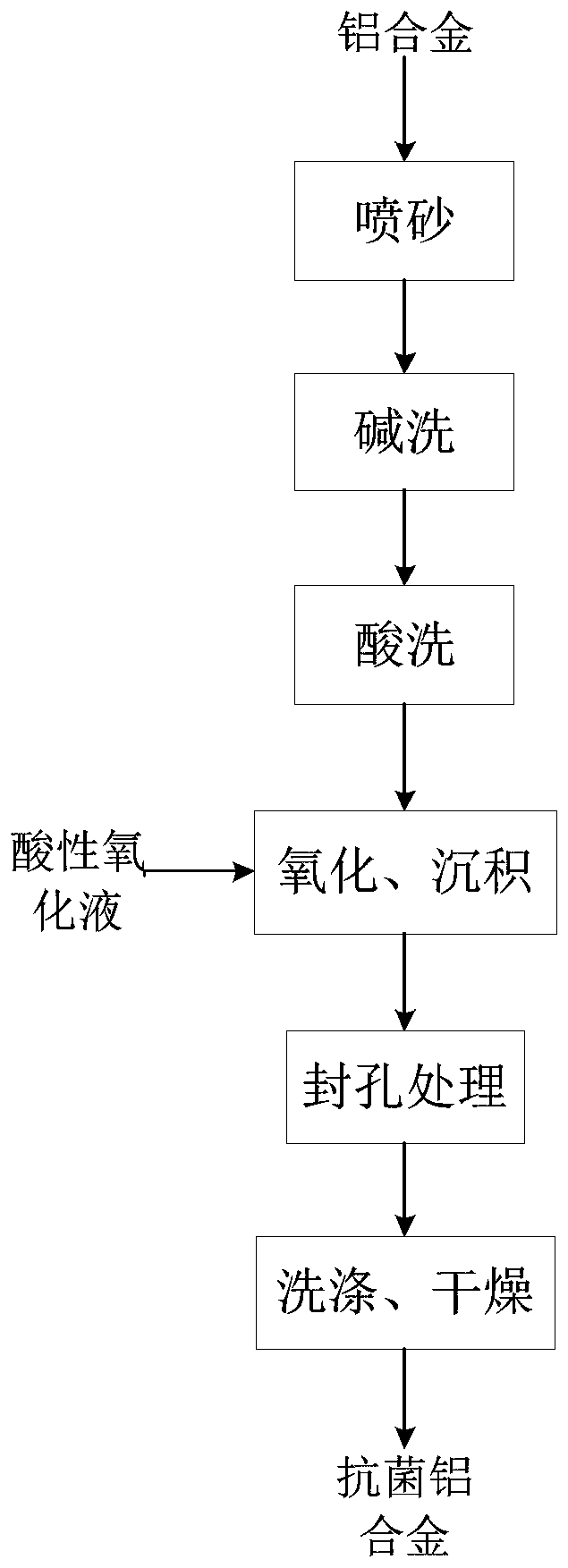

Aluminum alloy surface treatment method

ActiveCN110055572AIncrease productivityThe method flow is shortAnodisationAnodic oxidationCorrosion resistant

The invention provides an aluminum alloy surface treatment method. The aluminum alloy surface treatment method comprises the steps of conducting pretreatment on an aluminum alloy, putting the aluminumalloy into acid oxidation liquid to be subjected to oxidation and deposition under the AC condition, reducing the voltage, and conducting hole sealing treatment in the same solution to obtain the anti-microbial aluminum alloy. According to the aluminum alloy surface treatment method, the aluminum alloy is subjected to anodic oxidation, anti-microbial elements are deposited, hole sealing treatmentis conducted; hole sealing treatment can be conducted in the same solution, and then the anti-microbial and corrosion-resistant aluminum alloy is obtained. The aluminum alloy surface treatment methodis implemented through the one-step method. The process is simplified. The production efficiency of the anti-microbial aluminum alloy is improved. The production cost is reduced.

Owner:同曦集团有限公司

Process for selective oxidation of olefins to epoxides

A process for the selective oxidation of olefins to epoxides comprising the step of contacting the olefin (propylene) with an oxidant (hydrogen peroxide) in the presence of a Lewis acid oxidation catalyst (MTO), organic base (pyridine or its N-oxide), in a solvent system comprising an organic water-miscible solvent (methanol); and adding a pressurizing gas (nitrogen) to increase the pressure, whereby olefin is further dissolved in organic solvent system to increase the selectivity and yield of the desired epoxide (propylene oxide).

Owner:UNIVERSITY OF KANSAS

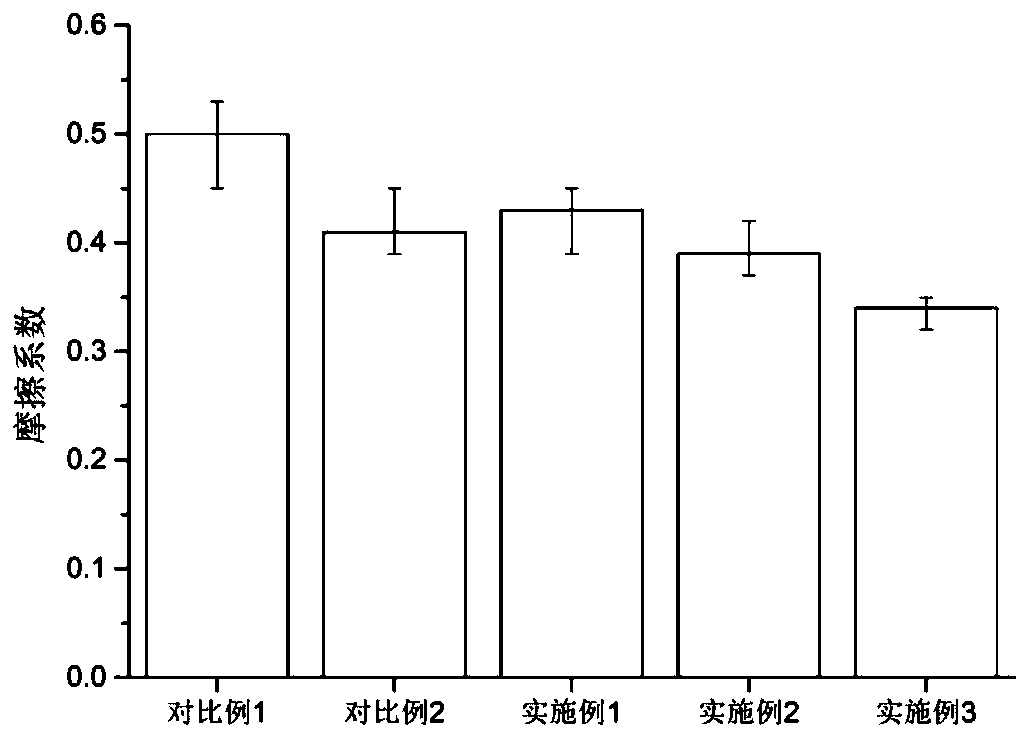

Hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating and preparation method thereof

The invention discloses a hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating and a preparation method thereof, and belongs to the technical field of cermet coatings. The preparation method includes preparing micron zinc oxide sol according to a sol-gel method, reacting the micron zinc oxide sol with a hybrid carbon nanotube, treated by a mixed-acid oxidation method, togenerate a zinc oxide / carbon nanotube composite, adding the zinc oxide / carbon nanotube composite as a nano additive to an adhesive ceramic coating, and solidifying the adhesive ceramic coating to obtain the wear-resistant anti-friction ceramic coating. Compared with non-hybridized carbon nanotube reinforced ceramic coatings, the hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating has the advantages that the bonding strength to a coating ceramic phase is high, and the friction coefficient and wear rate can be remarkably reduced in a room-temperature or high-temperature environment, so that the ceramic coating can be applied to surfaces of parts bearing collision and abrasion and has a broad application prospect.

Owner:JIANGNAN UNIV

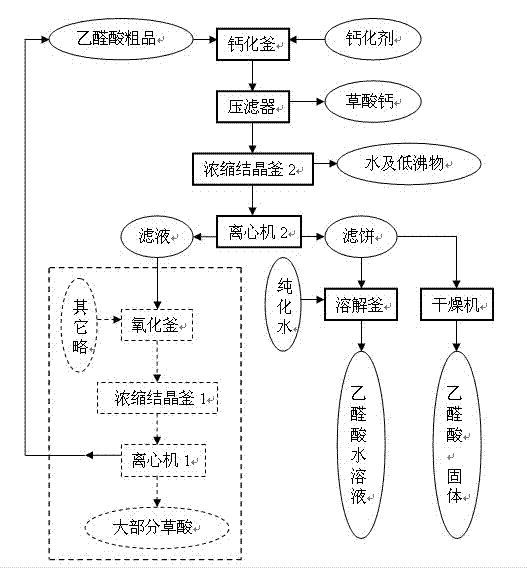

Refining method for glyoxalic acid

InactiveCN102786409AImprove product qualityEfficient separationOrganic compound preparationCarboxylic compound separation/purificationOXALIC ACID DIHYDRATEGlyoxylic acid

The invention relates to a refining method for glyoxalic acid. The method comprises the following steps: reacting a crude product obtained in a conventional process with a calcification agent so as to produce calcium oxalate deposit insoluble in a reaction system, wherein in the crude product, most oxalic acid is removed through condensation and crystallization and content of glyoxalic acid is 40 to 50%; carrying out filtering so as to remove calcium oxalate; and subjecting an obtained filtrate to reduced pressure concentration, crystallization at a low temperature, centrifugal separation and vacuum drying so to obtain a high-purity solid glyoxylic acid refined product. The method provided by the invention adds a refining process for glyoxylic acid on the base of a conventional production process for glyoxalic acid through nitric acid oxidation of glyoxal to remove oxalic acid and glyoxal in the crude product of an aqueous glyoxalic acid solution and to remove impurities like by-products produced in the process of an oxidation reaction, which enables purity and quality of the glyoxalic acid product to be improved; and the method has the advantages of a simple process, little equipment investment, convenient operation and control and low production cost and is suitable for industrial production.

Owner:HUBEI HONGYUAN PHARMA

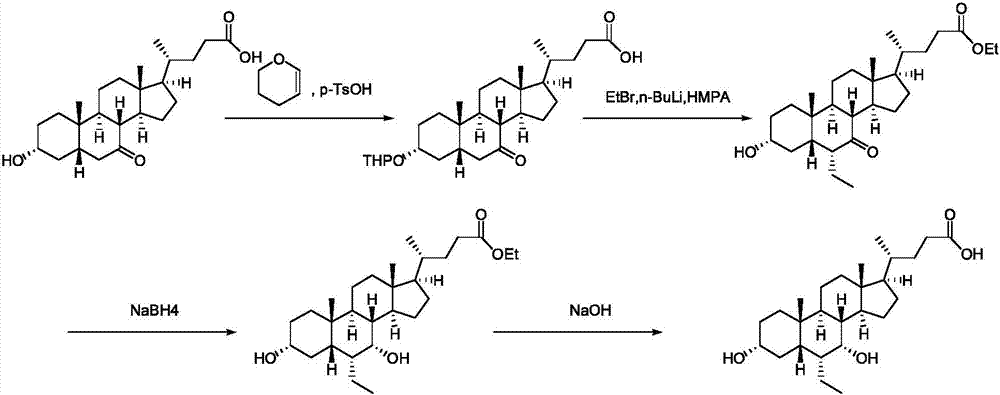

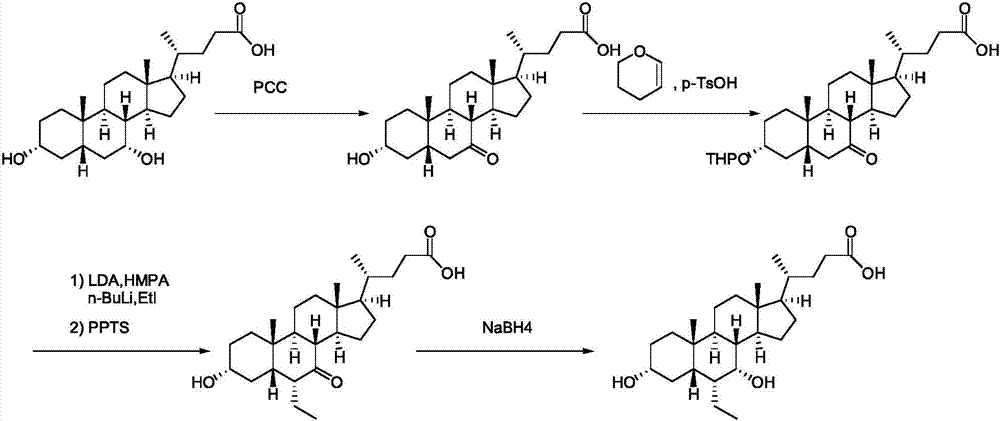

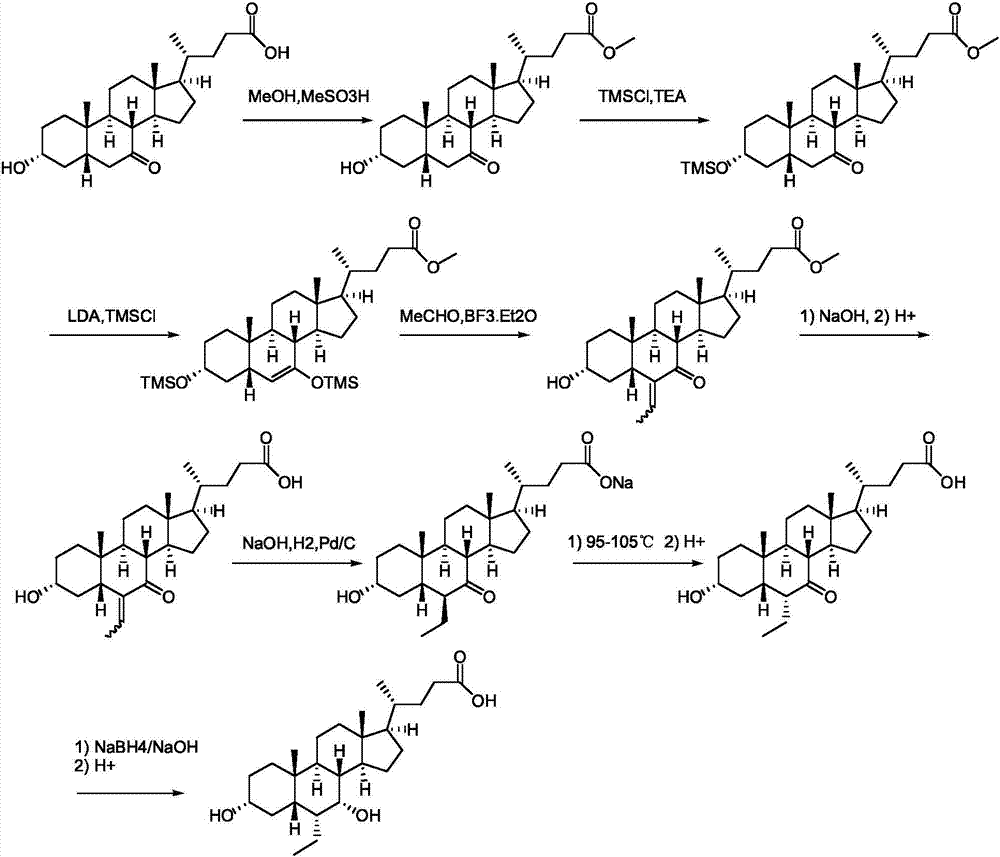

Obeticholic acid preparation method

The invention discloses an obeticholic acid preparation method, which comprises that (1) hyodeoxycholic acid II reacts with an alcohol compound III under the action of a catalyst to generate an ester compound IV; (2) the ester compound IV is subjected to PDC oxidation in dichloromethane to generate a compound V; (3) the compound V and trimethyl chlorosilane are subjected to a reaction at a temperature of -70 to -20 DEG C in tetrahydrofuran by using lithium diisopropylamide as an alkali to generate a silyl enol ether compound VI; (4) the silyl enol ether compound VI is subjected to m-chloroperoxybenzoic acid oxidation and deprotection in dichloromethane to generate a compound VII: (5) the compound VII and Yield generated from ethyltriphenylphosphonium bromide under the action of a strong alkali are subjected to a Wittig alkenylation reaction at a temperature of 0-70 DEG C to convert the ketone into the vinyl so as to generate a compound VIII; (6) the double bond of the compound VIII is subjected to catalytic hydrogenation reduction in a mixing solvent to generate a compound IX; and (7) the compound IX is hydrolyzed under an alkaline condition to generate the obeticholic acid.

Owner:XIAMEN HALOSYNTECH CO LTD

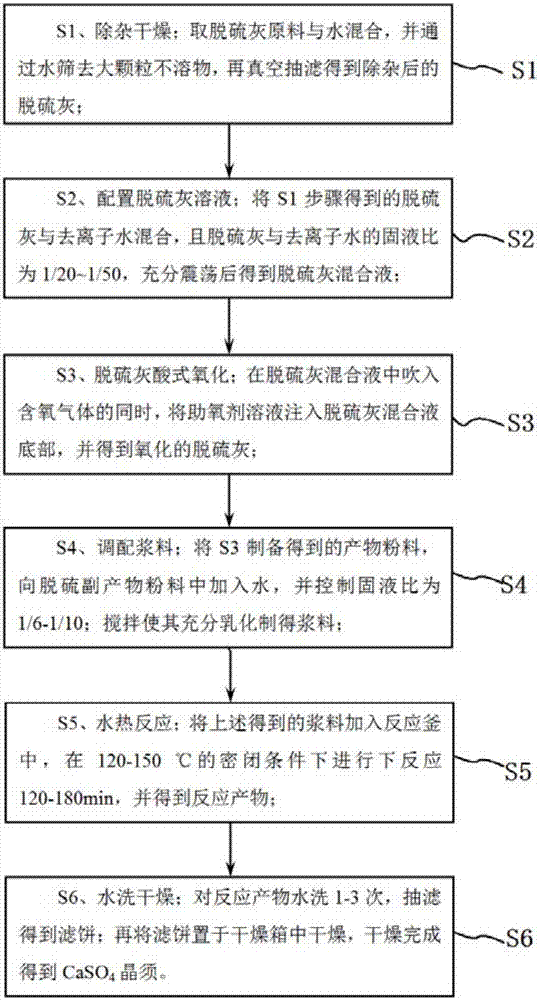

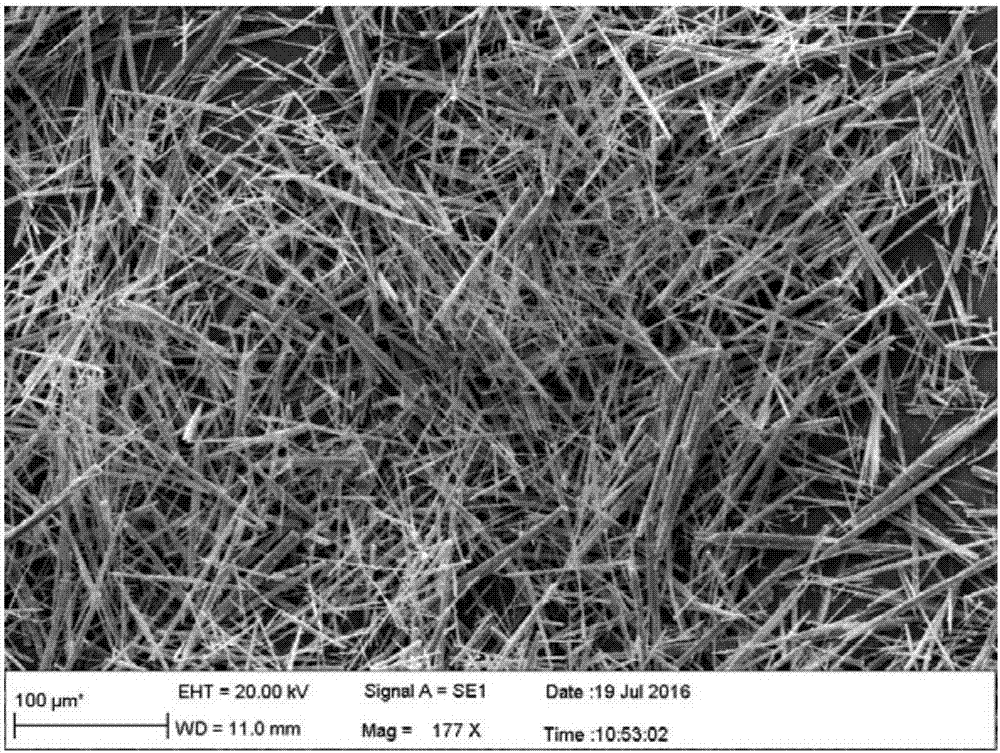

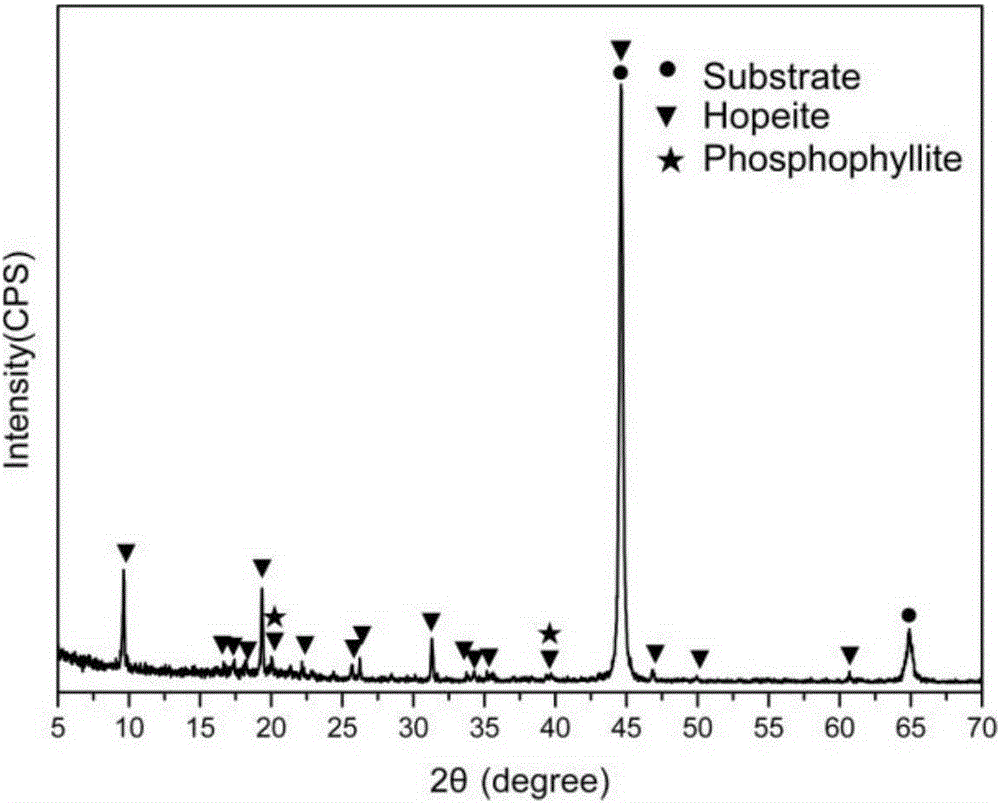

Method for preparing calcium sulfate whiskers from sintering flue gas semidry method desulfurization ash based on acid oxidation

ActiveCN107400929AChange React InterfaceImprove oxidation efficiencyPolycrystalline material growthFrom normal temperature solutionsResource utilizationSlurry

The invention discloses a method for preparing calcium sulfate whiskers from sintering flue gas semidry method desulfurization ash based on acid oxidation and belongs to the field of desulfurization ash resource utilization. An oxidizing aid and water are mixed to form an oxidizing aid solution, oxygen-containing gas is blown into a mixed solution of desulfurization ash and water, the oxidizing aid solution is uniformly injected to the bottom of the desulfurization ash mixed solution, the oxidizing aid comprises an acid aid with the pKa1 acidity coefficient between pKal acidity coefficients of sulphurous acid and sulfuric acid, oxidized desulfurization ash is mixed and emulsified to form slurry, and the calcium sulfate whiskers are prepared through a hydrothermal reaction of the slurry. The purity of calcium sulfate is increased by changing sufficient oxidation modification of desulfurization ash with the reaction interface in the desulfurization ash oxidation process, the theoretical strength of the prepared calcium sulfate whiskers is 0.02 E-0.05 E, the surface finish is higher, and the performance of the calcium sulfate whiskers is greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Hydrophobic modified antimicrobial cashmere fiber and manufacturing method of hydrophobic modified antimicrobial cashmere fiber

InactiveCN105088768ANot easy to fall offLow costFibre treatmentConjugated cellulose/protein artificial filamentsPolyesterCarbon nanotube

The invention discloses hydrophobic modified antimicrobial cashmere fiber. Chitosan fiber and cashmere are creatively blended, so that chitosan is uniformly distributed, cannot easily fall off and can be combined with saliva of bacterial microbe phospholipids; the chitosan is permeated and enters cell bodies to be adsorbed; the normal physiological activities of cells are disturbed, so that bacteria are killed; the bactericidal effect is durable; in addition, bamboo charcoal polyester fiber is adopted for replacing the partial cashmere fiber; the cost is reduced; various technical indexes of cashmere are also improved; added carbon nanotubes generate carboxyl and hydroxyl groups after being subjected to mixed acid oxidation modification; after the carboxyl and hydroxyl groups are added into raw materials, good dispersibility and good stability are realized. The prepared cashmere fiber adopts methacrylamide as a grafting monomer for surface grafting decoration modification; the prepared cashmere fiber has a hydrophobic antibiosis function, a far infrared function and a negative ion functions; the hand feeling of fabrics is soft; the heat insulation and comfort functions are good; the cashmere fiber is suitable for being made into casual clothes and underwears.

Owner:ANHUI TIANWEI CASHMERE PROD

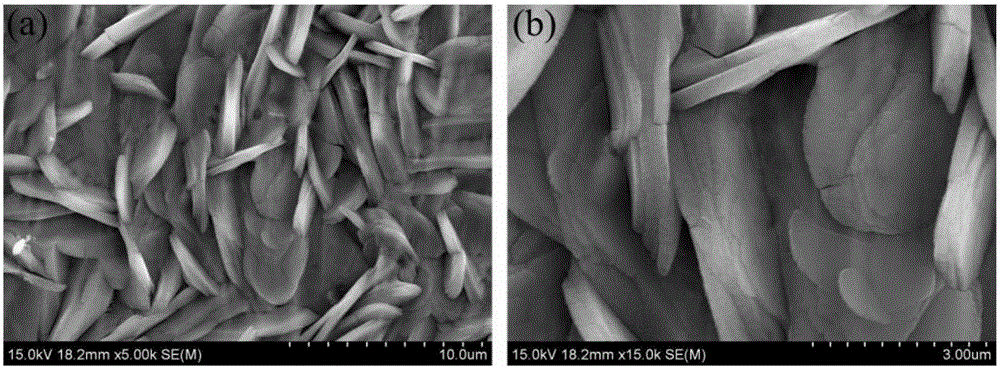

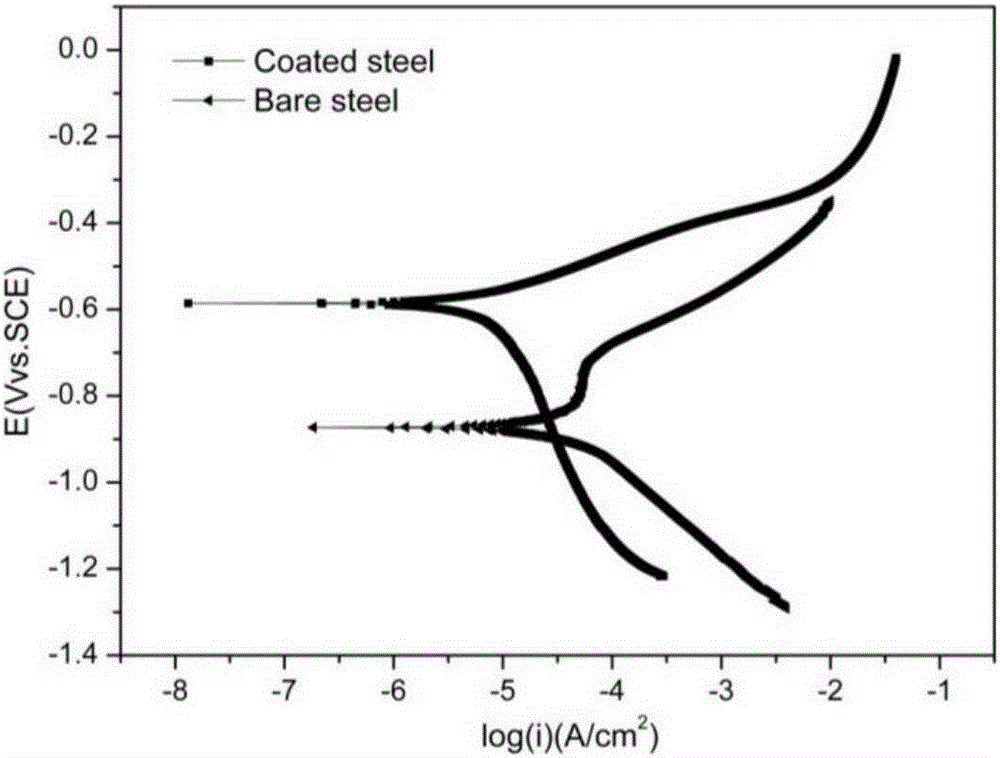

Normal/low-temperature chemical conversion solution for 35CrMnSi steel and preparing method thereof

ActiveCN105256296AReduce energy costsReduce manufacturing costMetallic material coating processesO-Phosphoric AcidChlorate salt

The invention discloses a normal / low-temperature chemical conversion solution for 35CrMnSi steel and a preparing method thereof. The conversion solution consists of the following components in percents by weight: 10-30% of nitric acid, 5-15% of phosphoric acid, 15-25% of zinc oxide, 1-5% of iron powder, 5-10% of a compound accelerant and the balance of water, wherein the compound accelerant is prepared from citric acid and chlorate. The preparing method comprises the following steps: (1), dissolving the zinc oxide in the nitric acid and the phosphoric acid; (2), then, adding the compound accelerant, and after fully dissolving, adding the water; and (3), adding the iron powder into a solution obtained in step (2), taking out the iron powder after curing, and regulating the pH value to 2.0 to 3.0. The normal / low-temperature chemical conversion solution for 35CrMnSi steel does not contain toxic components, the use method is simple and is easy to operate, energy consumption and production cost are low, one layer of even and dense conversion film consisting of 2-5mum flaky zinc phosphate crystals can be formed on the surface of a base body, and the corrosion resistance is great.

Owner:SHANDONG UNIV

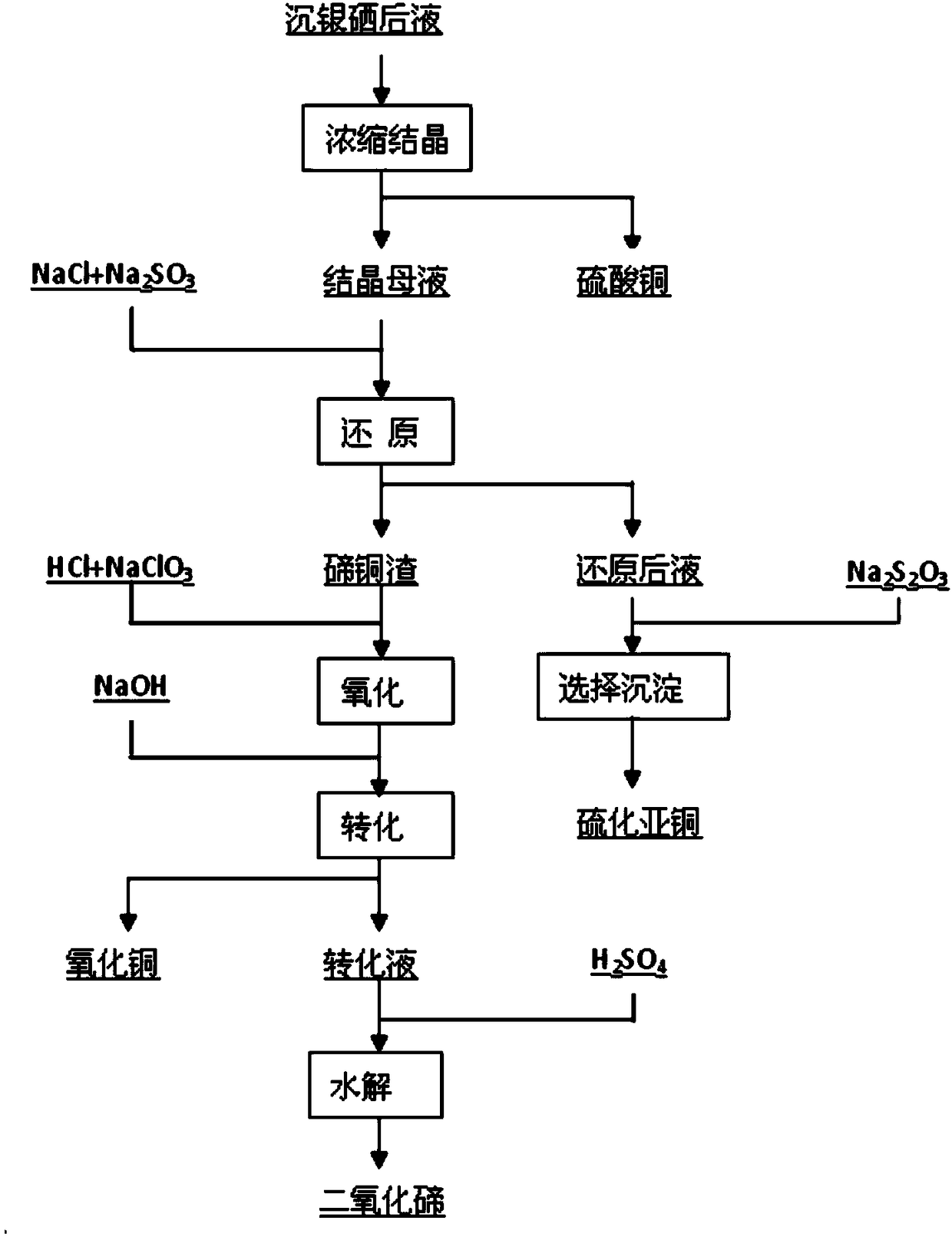

Method for treating tellurium-containing waste liquor

ActiveCN108545706ARealize step-by-step recyclingEasy to separateCopper oxides/halidesCopper sulfidesLiquid wasteHydrolysis

The invention provides a method for treating tellurium-containing waste liquor. The method comprises the following steps: S1, the tellurium-containing waste liquor is concentrated and crystallized forobtaining copper sulfate and crystallization mother liquor respectively, and the tellurium-containing waste liquor contains elements of tellurium and copper and sulfuric acid; S2, the crystallizationmother liquor is reduced with a reducing agent, and tellurium-copper slag and reduced liquor are obtained respectively; S3, an acid solution and an oxidant are adopted for acid oxidation leaching onthe tellurium-copper slag, an acid leaching solution is obtained, and the acid solution is a hydrochloric acid solution or a sulfuric acid solution; S4, the acid leaching solution is subjected to solid-liquid separation, a liquid phase is taken, pH is adjusted with sodium hydroxide to 12-14, heating is performed to a boiling state for reaction, and an alkaline conversion solution is obtained; S5,the alkaline conversion solution is subjected to acidic hydrolysis, and a tellurium dioxide product is obtained. Copper and tellurium are recovered step by step by the technical scheme, the separationeffect of copper and tellurium is good, the comprehensive recovery rate of copper and tellurium is high, the cost is low, and the economic benefit is increased.

Owner:YANGGU XIANGGUANG COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com