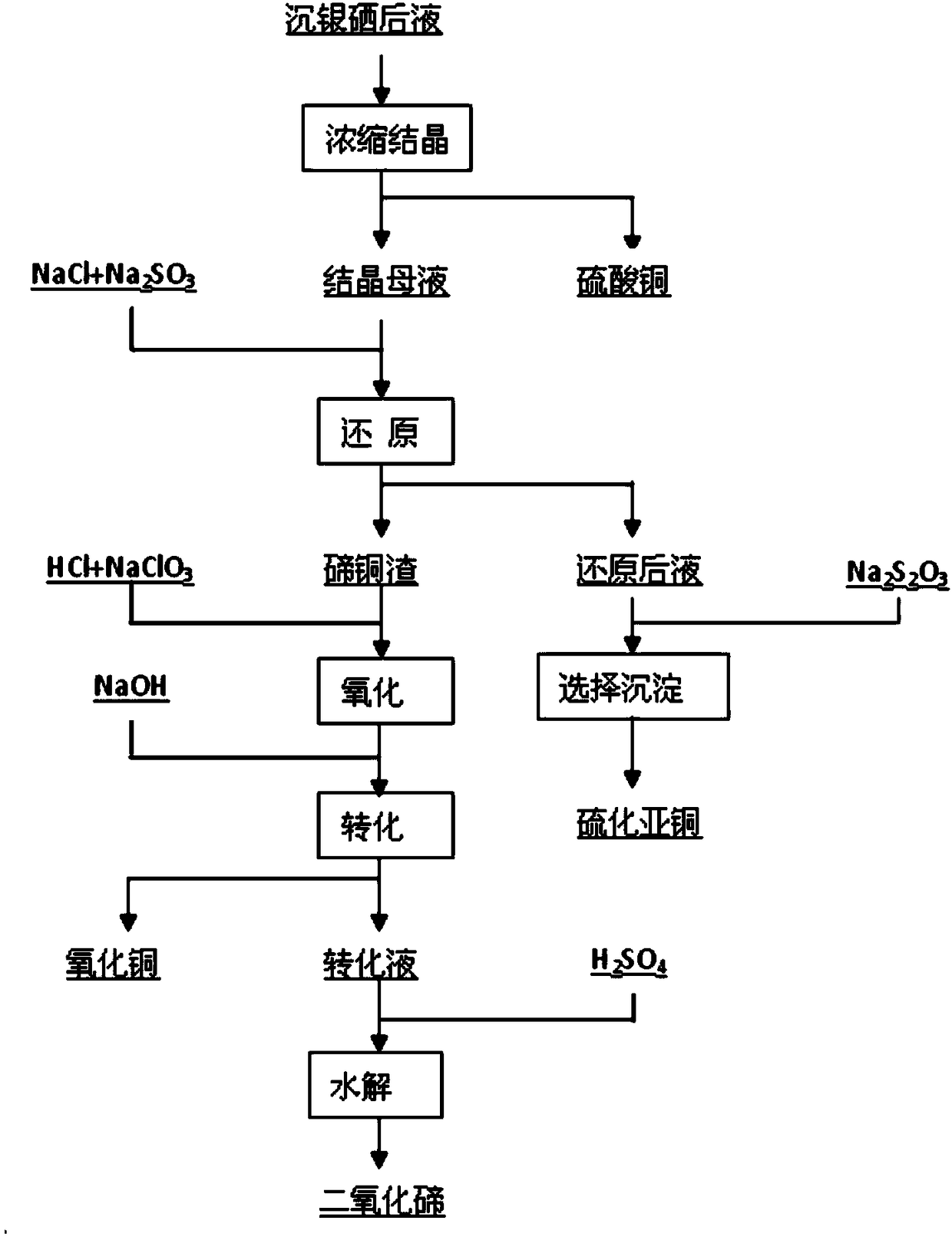

Method for treating tellurium-containing waste liquor

A treatment method and technology for waste liquid, which are applied in the improvement of process efficiency, binary selenium/tellurium compounds, selenium/tellurium oxides/hydroxides, etc., can solve the problem of high copper powder price, high cost and low export price and other problems, to achieve the effect of high comprehensive recovery rate of copper and tellurium, good separation effect of copper and tellurium, and increased economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Concentrated crystallization

[0058] Transferred 500L copper anode slime high-pressure decopper treatment produced silver selenium after the liquid, composition: Cu 32.92g / L, Te2.89g / L, Se 0.06g / L, As 6.53g / L, Bi 0.20g / L, h 2 SO 4 198.1g / L. Concentrate at high temperature, crystallize, and filter to obtain copper sulfate crystals and 240L of crystallization mother liquor. Obtain 46kg of copper sulfate crystals, which contain Cu 25.5%. Main element content in the crystallization mother liquor: Cu 18.58g / L, Te 5.81g / L, Se 0.08g / L, As 13.44g / L.

[0059] 2. Restore

[0060] Add 16.85 kg (1.2 mol / L) of table salt and 4.20 kg of reducing agent sodium sulfite (3 times the theoretical amount) to the obtained crystallization mother liquor. The reduction temperature is 80°C and the reaction time is 1.5 h to reduce tellurium into the slag to obtain the reduced slag. (tellurium and cuprous chloride) 2.67kg, wherein 99% of tellurium is reduced and enters the reduction sla...

Embodiment 2

[0071] 1. Concentrated crystallization

[0072] Transfer 500L silver selenium solution, composition: Cu 42.02g / L, Te 3.41g / L, Se 0.051g / L, As 6.13g / L, Bi 0.099g / L, H 2 SO 4140.16g / L. Concentrate, crystallize, and filter to obtain 62.2 kg of copper sulfate crystals, which contain 24.5% of Cu. Obtain 220L of crystallization mother liquor, mother liquor composition: Cu 26.16g / L, Te 7.377g / L, Se 0.083g / L, As 11.99g / L, Bi0.24g / L.

[0073] 2. Restore

[0074] In the obtained crystallization mother liquor, add salt 12.5kg (1mol / L), reducing agent sodium sulfite 6.5kg (4 times of theoretical amount), reduction temperature 80 ℃, reaction time 1.5h, tellurium is reduced in the slag, obtains reducing slag ( tellurium and cuprous chloride) 3.66kg, reduction slag composition: Cu 25.66%, Te 44.06%, Se 0.68%, As 0.039%, Bi<0.001%. 220L of the reduced liquid was obtained, and its composition included: Cu 21.6g / L, Te 0.049g / L, Se 0.0012g / L, As 15.36g / L, Bi 0.25g / L. 99% of the tellurium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com