Fast color changing spraying device

A kind of spraying equipment, rapid color changing technology, applied in the direction of coating, device for coating liquid on the surface, separation of dispersed particles, etc., can solve the problems of complicated color changing operation process and easy color mixing, etc., to achieve high spray quality and powder residue. Few, easy to disengage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

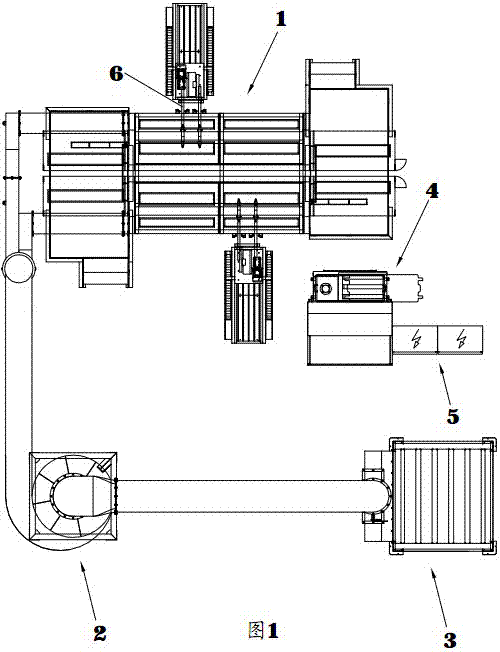

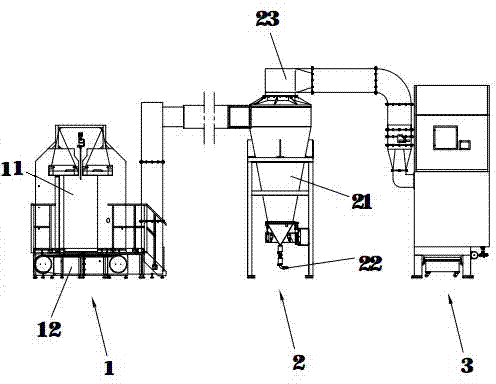

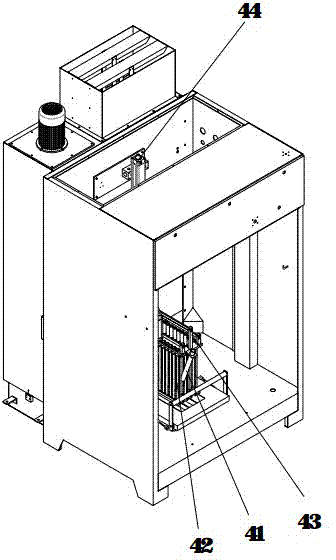

[0028] Such as Figures 1 to 6 As shown, a rapid color-changing spraying equipment includes a spraying room 1, a cyclone separator 2, a filter recoverer 3, a powder supply center 4, and an electrical box 5. The spraying room 1 is provided with a spraying chamber 11 and a spray gun 6. The bottom of the spraying chamber 11 is provided with a powder recovery device 12, and the powder recovery device 12 communicates with the inlet of the cyclone separator 2 through a pipeline, and the inlet of the cyclone separator 2 leads to a rotary separation chamber 21. The separation chamber 21 is provided with a powder outlet 22 and an air outlet 23. The powder outlet 22 communicates with the powder recovery port arranged on the powder supply center 4 through a pipeline, and the air outlet 23 communicates with the filter element recoverer 3 through a pipeline. The inlet is connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com