A kind of treatment method of tellurium-containing waste liquid

A treatment method and waste liquid technology, applied in the direction of improvement of process efficiency, binary selenium/tellurium compound, selenium/tellurium oxide/hydroxide, etc., can solve the problem of high copper powder price, high cost, and low external sales price and other problems, to achieve high copper-tellurium comprehensive recovery rate, good copper-tellurium separation effect, and increase economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

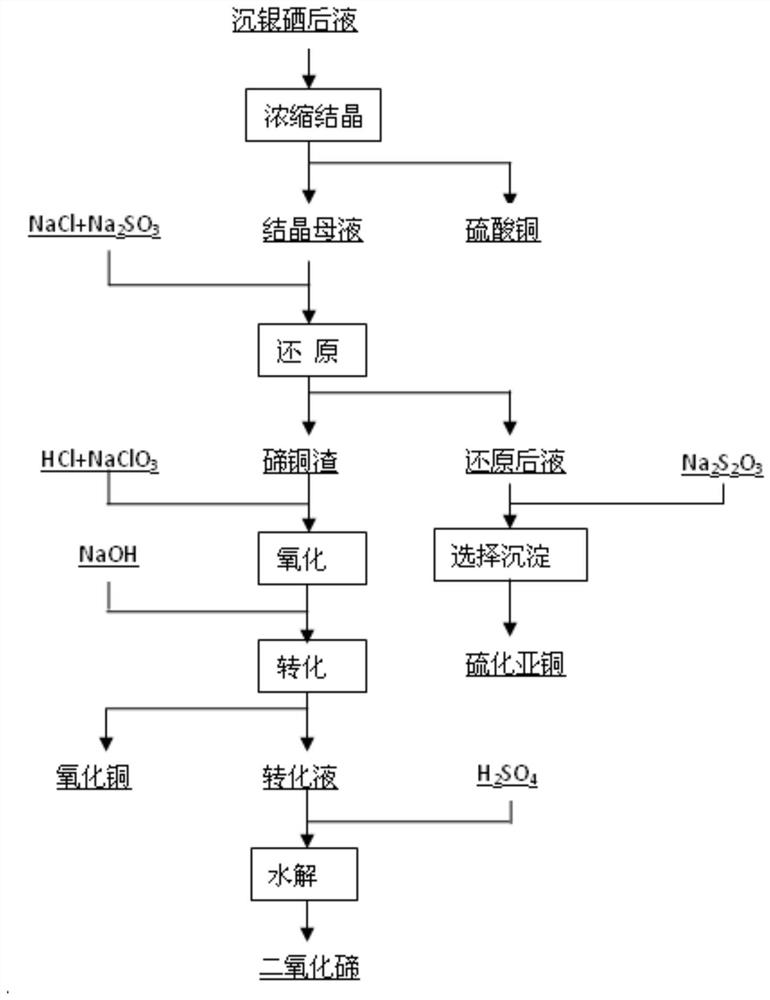

Method used

Image

Examples

Embodiment 1

[0057] 1. Concentrated crystallization

[0058] Transferred 500L copper anode slime high-pressure decopper treatment produced silver selenium after the liquid, composition: Cu 32.92g / L, Te2.89g / L, Se 0.06g / L, As 6.53g / L, Bi 0.20g / L, h 2 SO 4 198.1g / L. Concentrate at high temperature, crystallize, and filter to obtain copper sulfate crystals and 240L of crystallization mother liquor. Obtain 46kg of copper sulfate crystals, which contain 25.5% Cu. Main element content in the crystallization mother liquor: Cu 18.58g / L, Te 5.81g / L, Se 0.08g / L, As 13.44g / L.

[0059] 2. Restore

[0060] Add 16.85 kg (1.2 mol / L) of table salt and 4.20 kg of reducing agent sodium sulfite (3 times the theoretical amount) to the obtained crystallization mother liquor. The reduction temperature is 80°C and the reaction time is 1.5 h to reduce tellurium into the slag to obtain the reduced slag. (tellurium and cuprous chloride) 2.67kg, wherein 99% of tellurium is reduced and enters the reduction sla...

Embodiment 2

[0071] 1. Concentrated crystallization

[0072] Transfer 500L silver selenium solution, composition: Cu 42.02g / L, Te 3.41g / L, Se 0.051g / L, As 6.13g / L, Bi 0.099g / L, H 2 SO 4140.16g / L. Concentrate, crystallize, and filter to obtain 62.2 kg of copper sulfate crystals, which contain 24.5% of Cu. Obtain 220L of crystallization mother liquor, mother liquor composition: Cu 26.16g / L, Te 7.377g / L, Se 0.083g / L, As 11.99g / L, Bi0.24g / L.

[0073] 2. Restore

[0074] In the obtained crystallization mother liquor, add salt 12.5kg (1mol / L), reducing agent sodium sulfite 6.5kg (4 times of theoretical amount), reduction temperature 80 ℃, reaction time 1.5h, tellurium is reduced in the slag, obtains the reduction slag ( tellurium and cuprous chloride) 3.66kg, reduction slag composition: Cu 25.66%, Te 44.06%, Se 0.68%, As 0.039%, Bi<0.001%. 220L of the reduced liquid was obtained, and its composition included: Cu 21.6g / L, Te 0.049g / L, Se 0.0012g / L, As 15.36g / L, Bi 0.25g / L. 99% of the tellur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com