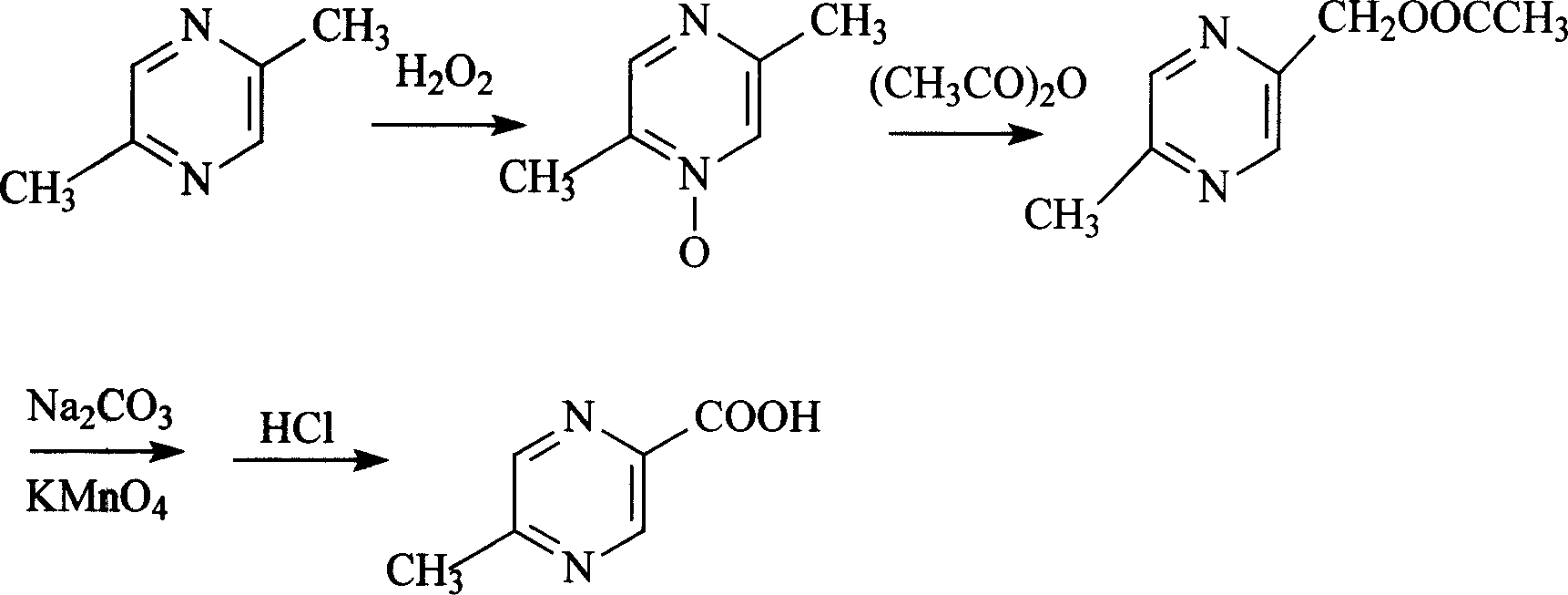

Process of selective synthesizing 5-methyl pyrazine-2-carboxylic acid using 2,5-dimethyl pyrazine

A technology of dimethylpyrazine and methylpyrazine, applied in directions such as organic chemistry, can solve the problems of high product cost, increased consumption of potassium permanganate, and the process is limited by seasonality, and achieves low cost and simple product process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 1. Single Nitrogen Oxidation

[0018] In a 1000ml reaction bottle, add 108g of 2,5-dimethylpyrazine, 450ml of water, 2.0g of sodium tungstate, and 2ml of sulfuric acid, add 114g of 30% hydrogen peroxide dropwise at 70°C for 2 hours, and continue to react at 70°C for 6 hours , to obtain 115.3 g of 2,5-dimethylpyrazine-1-oxide, with a yield of 93%.

[0019] 2, Preparation of 2-acetoxymethyl-5-methylpyrazine

[0020] In a 500ml flask, add 24.8g of 2,5-dimethylpyrazine-1-oxide, add 250ml of acetic anhydride, heat to reflux for 10h, recover the acetic anhydride and the generated acetic acid under reduced pressure, and obtain the residual oil 2-acetoxy Methyl-5-methylpyrazine 28.5g, yield 86%.

[0021] 3. Hydrolytic oxidation

[0022] In a 500ml flask, add 16.6g of 2-acetoxymethyl-5-methylpyrazine, add 50ml and 0.5g of sodium hydroxide, control the temperature at 20-25°C, add dropwise 300ml of aqueous solution containing 15.8g of potassium permanganate, After dripping, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com