Excellent and efficient carbon fiber biofilm carrier modification method

A high-efficiency carbon fiber, biofilm carrier technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as poor hydrophilicity and too smooth surface, reduce time and improve mass transfer. Efficiency, the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

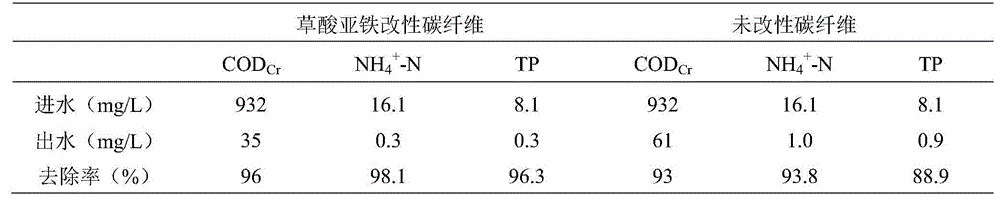

Embodiment 1

[0020] Step 1: The carbon fiber filaments are wound into bundles and placed in a solution containing 0.1mol / L HNO 3 In the large beaker of the solution, acid oxidation is carried out, and the immersion time is 12h to increase the surface functional groups and surface activity of carbon fibers and prepare for the attachment of organic iron;

[0021] Step 2: Rinse the acid-oxidized carbon fiber to neutrality with deionized water, and dry it for later use;

[0022] Step 3: configure 0.1mol / L ferrous oxalate solution carbon fiber organic iron modifier, place the carbon fiber bundles in the organic iron modifier for 24h at room temperature, and use the liquid phase impregnation method to make the carbon fibers fully contact with ferrous oxalate;

[0023] Step 4: Rinse the ferrous oxalate-modified carbon fiber bundles with deionized water until the rinsing solution is colorless, and dry, and the ferrous oxalate has been attached to the surface of the carbon fibers to obtain a ferrou...

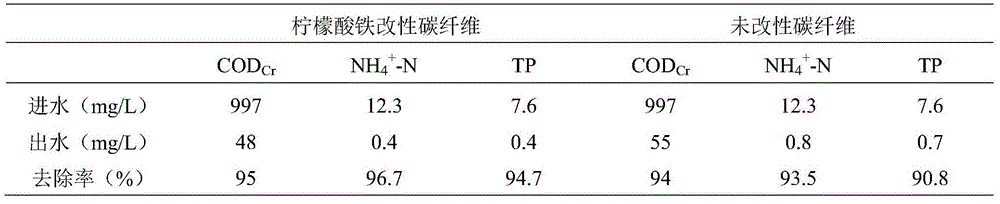

Embodiment 2

[0030] Step 1: The carbon fiber filaments are wound into bundles and placed in HNO containing 0.05mol / L 3 In the solution, acid oxidation is carried out, and the immersion time is 24h to increase the surface functional groups and surface activity of carbon fibers and prepare for the attachment of organic iron;

[0031] Step 2: Rinse the acid-oxidized carbon fiber to neutrality with deionized water, and dry it at 80° for later use;

[0032] Step 3: configure 0.1mol / L ferric citrate solution as carbon fiber organic iron modifier, put carbon fiber bundles in the organic iron modifier by liquid phase immersion method at 30 °C for 12h, intermittently supplemented by ultrasonic vibration, the frequency is 90Hz, each oscillation time is 90min, and the time interval is 1.5h, so that the carbon fiber filament and the ferric citrate are fully contacted;

[0033] Step 4: Rinse the ferric citrate modified carbon fiber bundles with deionized water until the rinsing solution has no color, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com