Method for preparing low-temperature denitration nitrogen-rich porous carbon material

A low-temperature denitrification and porous carbon technology, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of small specific surface area and low low-temperature denitrification efficiency, and achieve easy-to-obtain, low-cost raw materials and mild operating conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

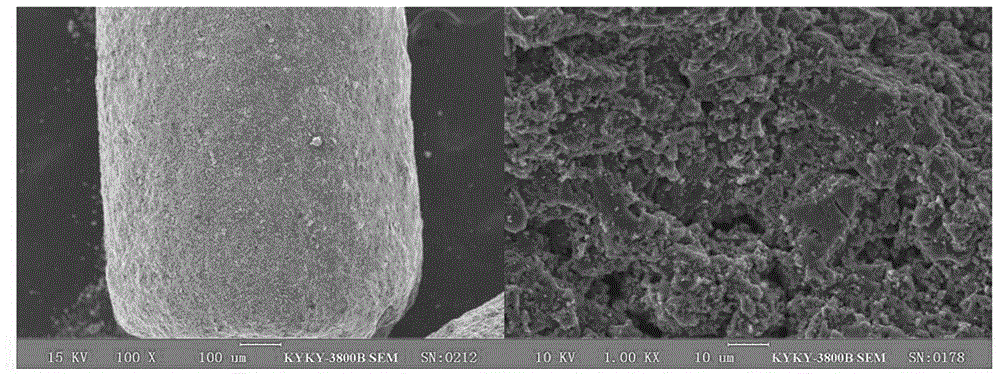

Embodiment 1

[0025] A method for preparing a nitrogen-rich porous carbon material for low-temperature denitrification, comprising the following steps:

[0026] (1) Grind 35g of anthracite and 15g of semi-coke particles into 200-mesh coal powder; mix 21g of coal powder with 3g of carboxymethyl cellulose and 4.5g of deionized water at a stirring speed of 500r / min, and then use a flat Die rolling granulator is extruded into cylindrical shape under 10MPa pressure to obtain shaped charcoal;

[0027] (2) Carbonize the above formed carbon in a high-temperature tube furnace from room temperature to 600°C for 1 hour, then raise the temperature to 850°C, pass in 12mL / min water vapor to activate for 4 hours, and naturally cool down to room temperature to obtain porous carbon Material;

[0028] (3) Slowly drop 120mL of concentrated sulfuric acid into 54mL of concentrated nitric acid, then add 114mL of deionized water into the mixed acid solution, and cool the resulting solution to room temperature fo...

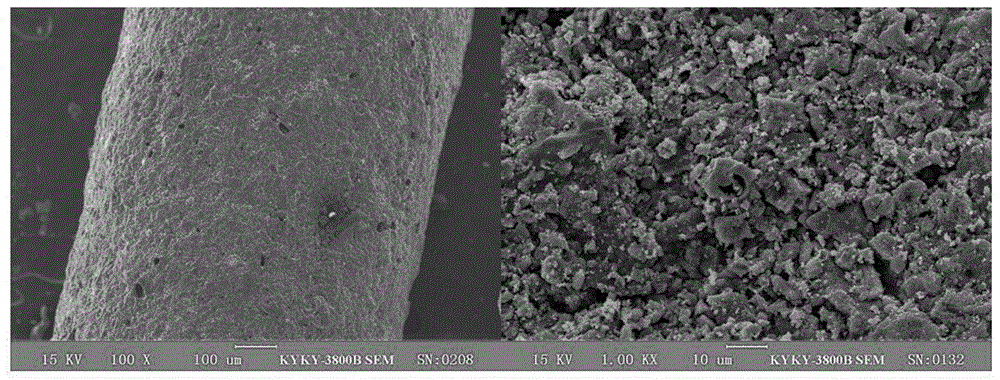

Embodiment 2

[0033] A method for preparing a nitrogen-rich porous carbon material for low-temperature denitrification, comprising the following steps:

[0034] (1) Grind 42g of bituminous coal and 18g of semi-coal particles into 225-mesh coal powder; mix 25.5g of coal powder with 6g of carboxymethyl cellulose and 8.8g of deionized water at a stirring speed of 550r / min, and then use The flat die rolling granulator is extruded into a cylindrical shape under a pressure of 25MPa to obtain shaped charcoal;

[0035] (2) Carbonize the above formed carbon in a high-temperature tube furnace from room temperature to 700°C for 2 hours, then raise the temperature to 950°C, pass in 9mL / min water vapor to activate for 3 hours, and naturally cool down to room temperature to obtain a porous carbon material ;

[0036] (3) Slowly drop 90mL of concentrated sulfuric acid into 81mL of concentrated nitric acid, then add 171mL of deionized water to the mixed acid solution, and cool the resulting solution to roo...

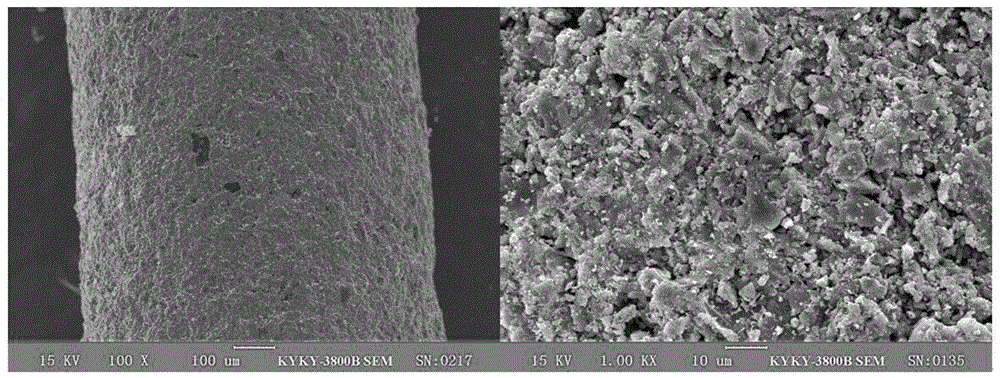

Embodiment 3

[0041] A method for preparing a nitrogen-rich porous carbon material for low-temperature denitrification, comprising the following steps:

[0042](1) Grind 49g fat coal and 21g semi-coke particles into 250-mesh coal powder; mix 51g coal powder with 12g resole phenolic resin and 18g deionized water at a stirring speed of 600r / min, and then use a flat die The rolling granulator is extruded into a cylindrical shape under a pressure of 40MPa to obtain shaped charcoal;

[0043] (2) Carbonize the above formed carbon in a high-temperature tube furnace from room temperature to 800°C for 3 hours, then raise the temperature to 1000°C, pass in 6mL / min water vapor for activation for 2 hours, and naturally cool down to room temperature to obtain a porous carbon material ;

[0044] (3) Slowly drop 60mL of concentrated sulfuric acid into 108mL of concentrated nitric acid, then add 228mL of deionized water into the mixed acid solution, and cool the resulting solution to room temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com