Treatment system and method of nitric oxide in nitrotoluene nitric acid oxidation tail gas

A technology of nitrotoluene and nitrogen oxides, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems that nitric oxide cannot be absorbed by water, cannot be reached, and has high storage risks, and achieves improved absorption. Efficiency and comprehensive utilization level, the effect of reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

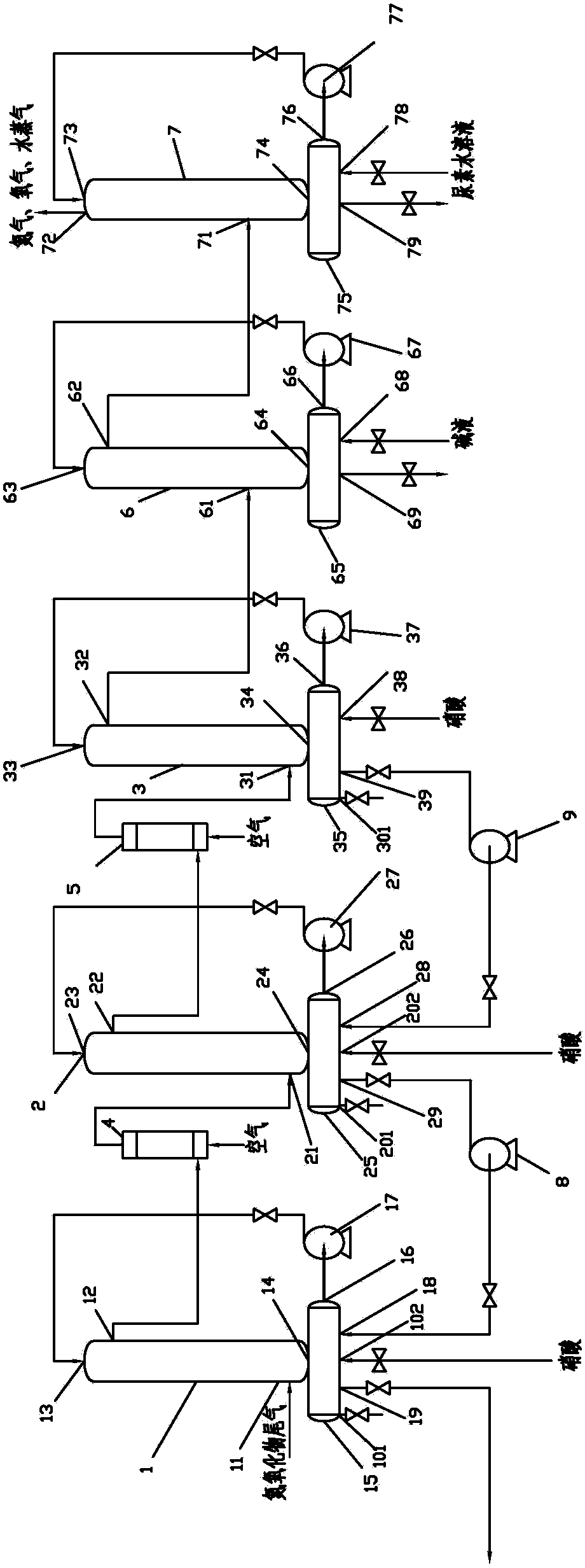

[0042] Such as figure 1 Shown, a kind of treatment system of nitrogen oxides in the nitric acid oxidation tail gas of nitrotoluene, comprises three acid absorption towers of the first stage acid absorption tower 1, the second stage acid absorption tower 2 and the third stage acid absorption tower 3, and 1 alkali absorption tower 6, and 1 urea absorption tower 7; Described acid absorption tower 1-3, alkali absorption tower 6 and urea absorption tower 7 are respectively provided with air inlet 11,21,31,61,71 and The gas outlets 12, 22, 32, 62, 72, and the above-mentioned absorption towers are connected in series through the gas pipes connected between the gas outlet of the current stage and the air inlet of the lower stage, wherein, the first-stage acid absorption tower 1 and the second-stage acid absorption tower A gas mixer 4 and 5 are respectively connected between the towers 2, and between the second-stage acid absorption tower 2 and the third-stage acid absorption tower 3. ...

Embodiment 2

[0061] In this embodiment, the system for treating nitrogen oxides in the nitric acid oxidation tail gas of nitrotoluene adopts a 4-stage acid absorption tower, and the rest of the basic structure is the same as that of Embodiment 1.

[0062] The processing method of nitrogen oxides in the described nitrotoluene nitric acid oxidation tail gas, concrete steps are as described in embodiment 1, and its difference is:

[0063] 1) First, measure and pump nitric acid solution with an initial concentration of 8% into the liquid inlet of the last-stage acid storage tank (that is, the fourth-stage acid storage tank), and at the initial liquid inlet of the third-stage liquid storage tank The nitric acid solution with an initial concentration of 13% is metered and pumped, and the nitric acid solution with an initial concentration of 18% is metered and pumped into the initial liquid inlet of the second-stage liquid storage tank. The nitric acid solution with an initial concentration of 23...

Embodiment 3

[0074] In this embodiment, the system for treating nitrogen oxides in the nitric acid oxidation tail gas of nitrotoluene adopts a 5-stage acid absorption tower, and the rest of the basic structure is the same as that of Embodiment 1.

[0075] The processing method of nitrogen oxides in the described nitrotoluene nitric acid oxidation tail gas, concrete steps are as described in embodiment 1, and its difference is:

[0076] 1) First, measure and pump nitric acid solution with an initial concentration of 9% into the liquid inlet of the last-stage acid storage tank (that is, the fifth-stage acid storage tank); The nitric acid solution with an initial concentration of 14% is metered and pumped, and the nitric acid solution with an initial concentration of 19% is metered and pumped into the initial liquid inlet of the third-stage liquid storage tank. Into the nitric acid solution with an initial concentration of 24%, metering and pumping the nitric acid solution with an initial con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com