Patents

Literature

386results about How to "Improve the level of comprehensive utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sea shell micropowder filler and its use

InactiveCN1475520AImprove the level of comprehensive utilizationImprove mechanical propertiesPre treatmentMaterials science

A shell microparticle filler used for high-molecular materials to improve their thermal and mechanical performance is prepared from shell through pulverizing, classifying, high-temp stabilizing and decoloring, and chemical surface modifying. It features its surficial hydrophilic, lipophilic and active properties.

Owner:孙建宁 +1

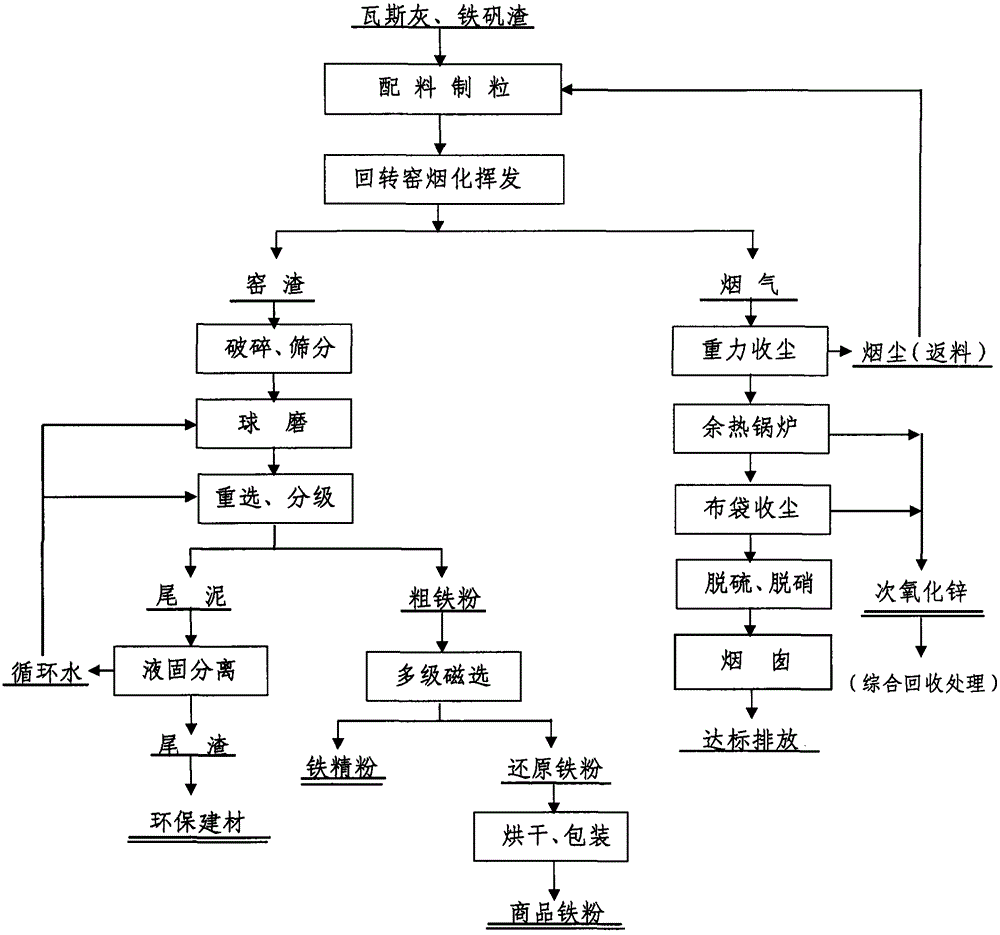

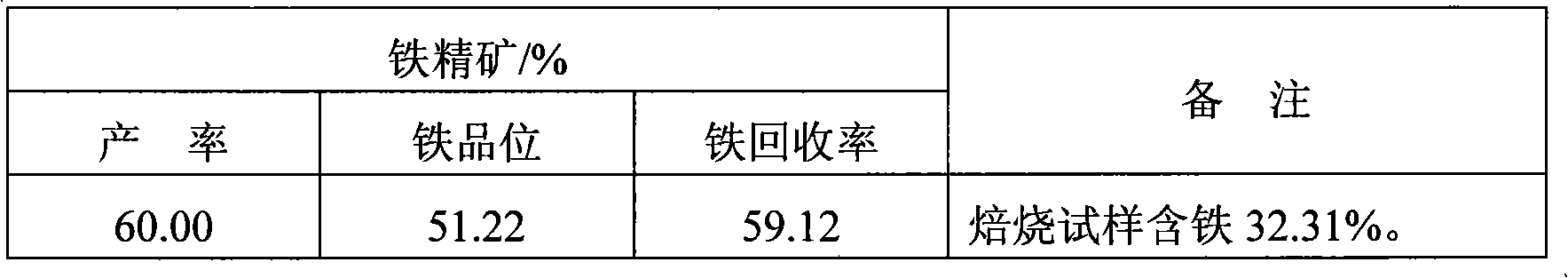

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

Method for preparing gardenia pigments from Gardenia jasminoides Ellis

ActiveCN102732050AImprove the level of comprehensive utilizationReduce manufacturing costNatural dyesFermentationFiltrationMacroporous resin

The invention discloses a method for preparing gardenia pigments from Gardenia jasminoides Ellis, and belongs to the technical field of natural pigment preparation methods. The method comprises the following steps: carrying out crushing peeling, extraction, filtration, macroporous resin purification, eluting, concentrating, drying and the like on Gardenia jasminoides Ellis which is a raw material to obtain a gardenia yellow pigment and geniposide, and processing the geniposide through a biological engineering technology and a membrane filtration and acid precipitation process to prepare a gardenia blue or red pigment. The method allows the production cost of the gardenia yellow pigment to be reduced and the comprehensive utilization level of the raw material to be simultaneously improved; and the prepared series pigments can be applied to fields of foods, health products, cosmetics, medicines and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Roof greening light host material made from industrial and agricultural wastes

ActiveCN101960980AReduce loadReduce weightSolid waste disposalCultivating equipmentsNatural resourceAdditive ingredient

The invention provides a roof greening light host material made from industrial and agricultural wastes and is characterized in that the industrial and agricultural wastes serve as the major ingredients to prepare a light roof greening planting substrate; the substrate is a compound with the following main materials: flyash, coal cinder, straw grains, garden wastes and yellow soil; the proportions of the materials are as follows: 11-20% of flyash, 10-22% of coal cinder, 20-25% of straw grain, 20-32% of garden waste and 18-20% of yellow soil. In the invention, the common industrial and agricultural wastes are applied to the light roof greening planting substrate, which facilitates reduction of the cost of roof greening materials, improves comprehensive utilization level of natural resources and promotes cyclic utilization of the industrial and agricultural wastes and protection of the natural environment. The material of the invention has the advantages of few component types, easily available materials, low cost, environmental protection and high efficiency and suitability for large-scale promotion throughout the country.

Owner:武汉市林业果树科学研究所 +1

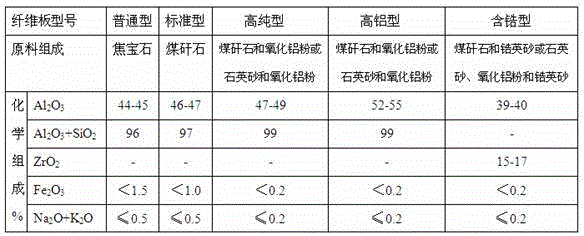

Method for manufacturing aluminium silicate ceramic fiber using coalgangue and its use

InactiveCN1422820AImprove the level of comprehensive utilizationReduce pollutionGlass making apparatusFiberAluminium silicate

The invention refers to a method of making aluminum silicate ceramic fibery by gangue and the application. It uses the gangue as raw material and is produced by calcinations, melting, spray-blow or centrifugal swinging to make thread. The gangue chemical components: Al2O3>=43.00%, SiO2+Al2O3>=85.00%, Fe2O3 <=1.00%, K2O+Na2O<=0.50 and burning loss quantity<=15.00%, firstly calcining the gangue at 1000-1600 C degree for 300-360h, then melting in at 2100-2300 C degree.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

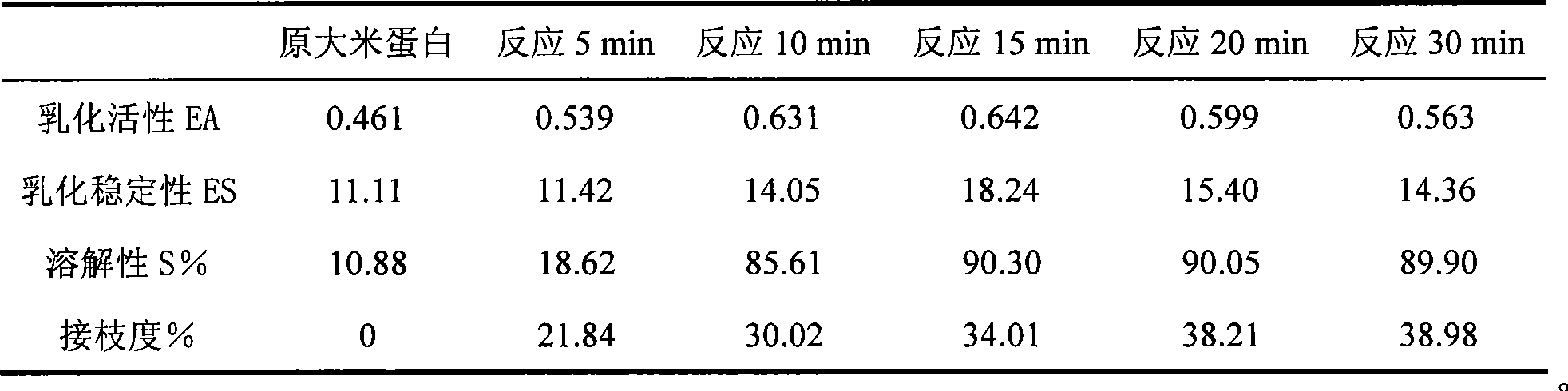

Method for improving rice protein functional property with protein-polysaccharide graft coupling technology

InactiveCN101429226AImprove functional propertiesImprove the level of comprehensive utilizationPeptide preparation methodsPhosphorylationRice protein

The invention provides a method for improving functional property of rice protein by protein-polyoses graft coupling technology, which belongs to the technical field of hydrophobicity vegetable protein modification. The method is to carry out glycosylation modification on a side product of producing rice starch and rice syrup, namely the rice protein as a raw material by different glycosyl donors through a wet method. Dissolvability, emulsibility, foamability and other functional properties of the rice protein are effectively improved and sufficiently utilized through the graft reaction of the rice protein and sugar. Compared with methods chemically modifying the vegetable protein, such as alkylation, phosphorylation, deamidization and the like, the method is safe and environment friendly, a rice protein-polyoses graft coupling product can be used as a natural macromolecular emulsifying agent or a protein nutritional reinforcing agent to sufficiently reflect and exert low sensitivity and high nutritive characteristic of the rice protein, thereby effectively expanding the application field of the rice protein. Meanwhile, the method provides theoretical reference for deep research and development of the hydrophobicity vegetable protein.

Owner:JIANGNAN UNIV

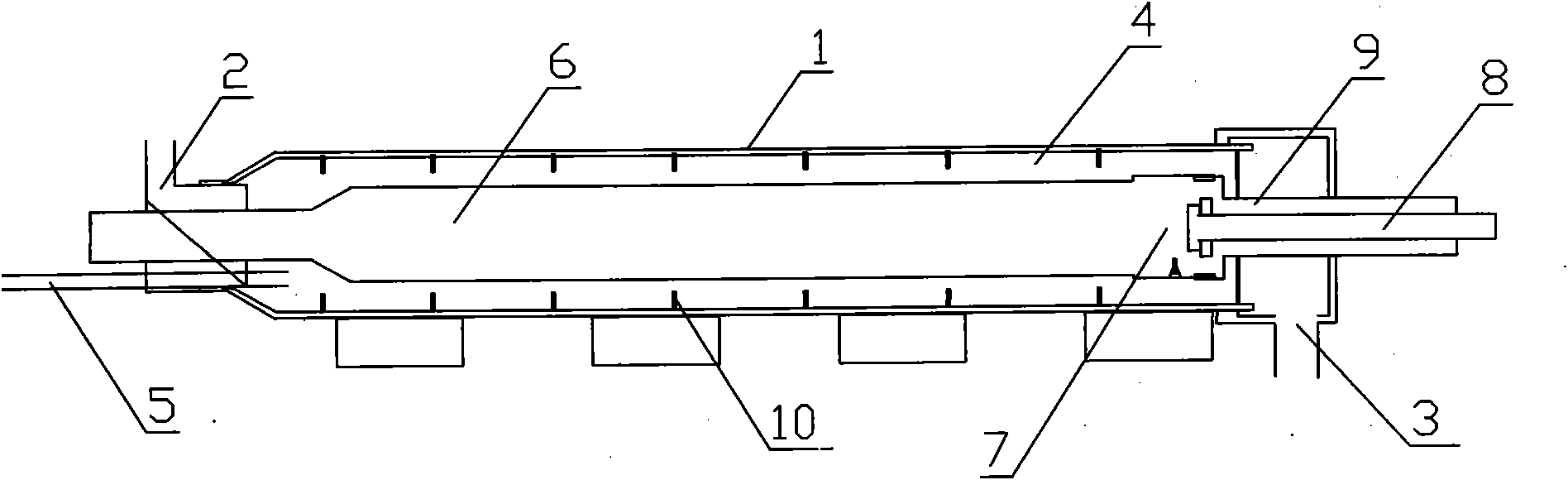

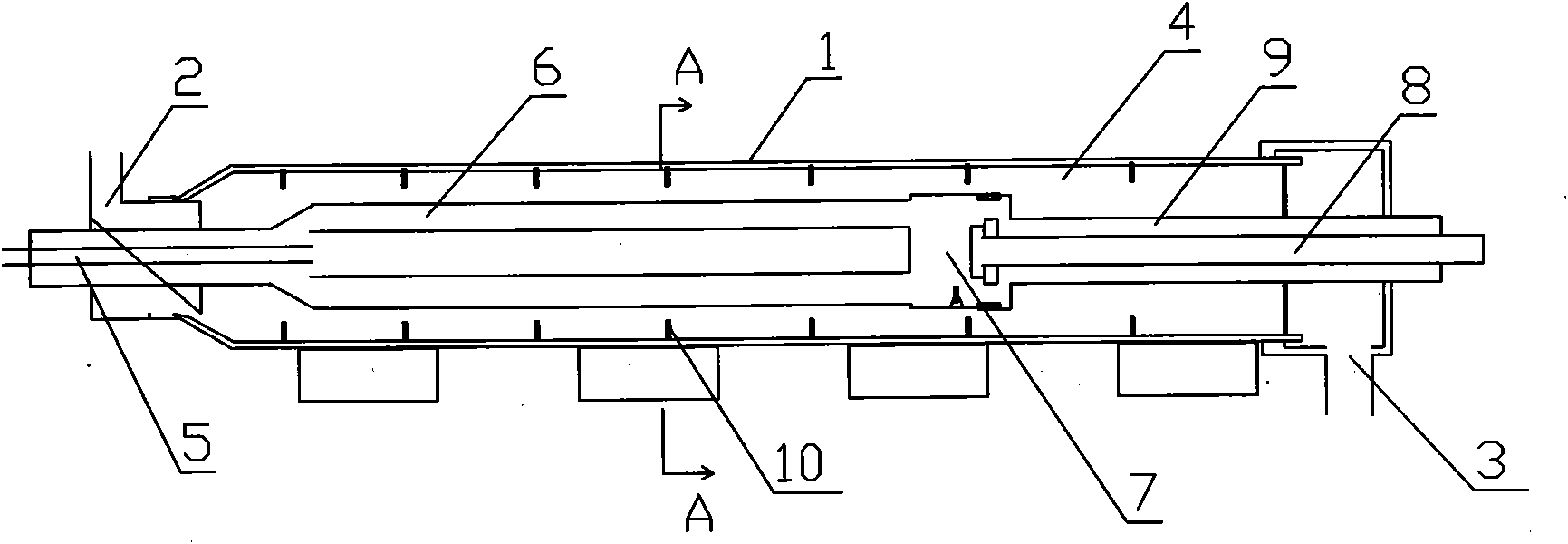

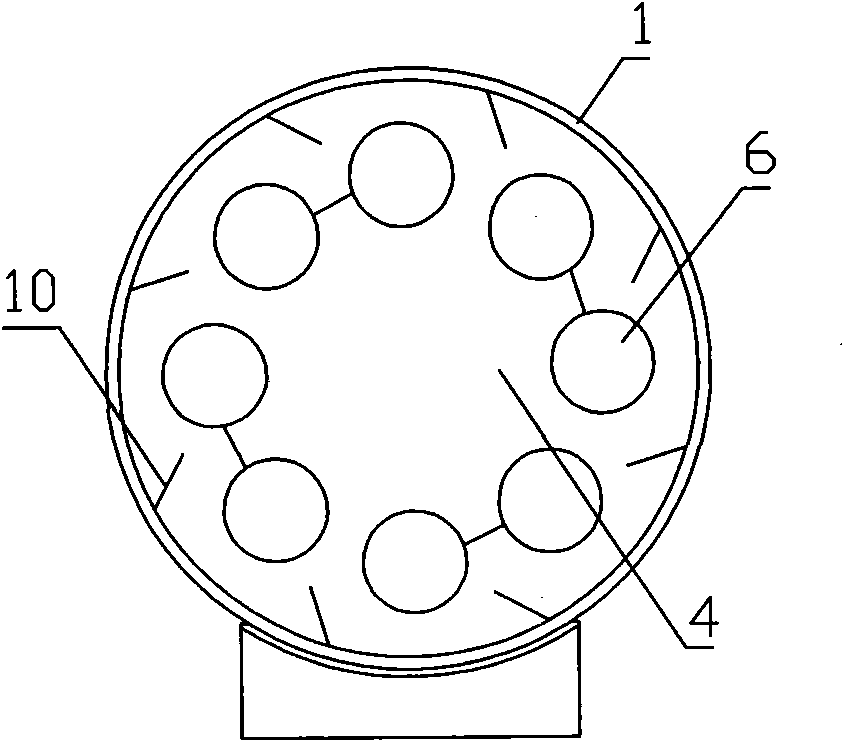

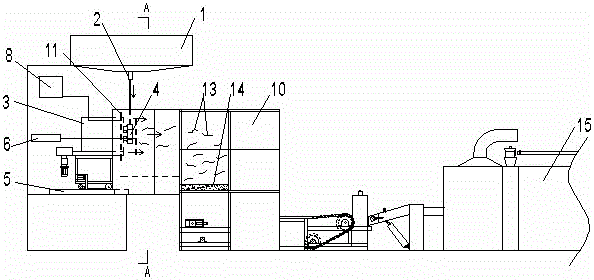

Coal decomposing equipment

InactiveCN101985558AEfficient decompositionIncrease profitMechanical conveying coke ovensCombustible gas coke oven heatingDecompositionTar

The invention discloses coal decomposing equipment, comprising a sealed kiln body with a feeding hole and a discharge hole, wherein the kiln body is provided with a flame gas pipe heating mechanism; coal propelling and decomposing channels are formed between the flame gas pipe heating mechanism and the inner wall of the kiln body; and a coal decomposed gas collecting pipe communicated with the coal propelling and decomposing channels is arranged on the kiln body. As the equipment conducts and radiates vast heat generated by the flame gas pipe heating mechanism on the coal dust in the coal propelling and decomposing channels, the coal dust fully absorbs the heat and is heated and decomposed into gases, tar gases and coal with higher heat value in the coal propelling and decomposing channels, the gases and tar gases are connected with a gas dedusting and liquefying mechanism outside the rotary kiln by the coal decomposed gas collecting pipe, and the gases and tar gases obtained through decomposition are collected, dedusted, separated and liquefied under pressure.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

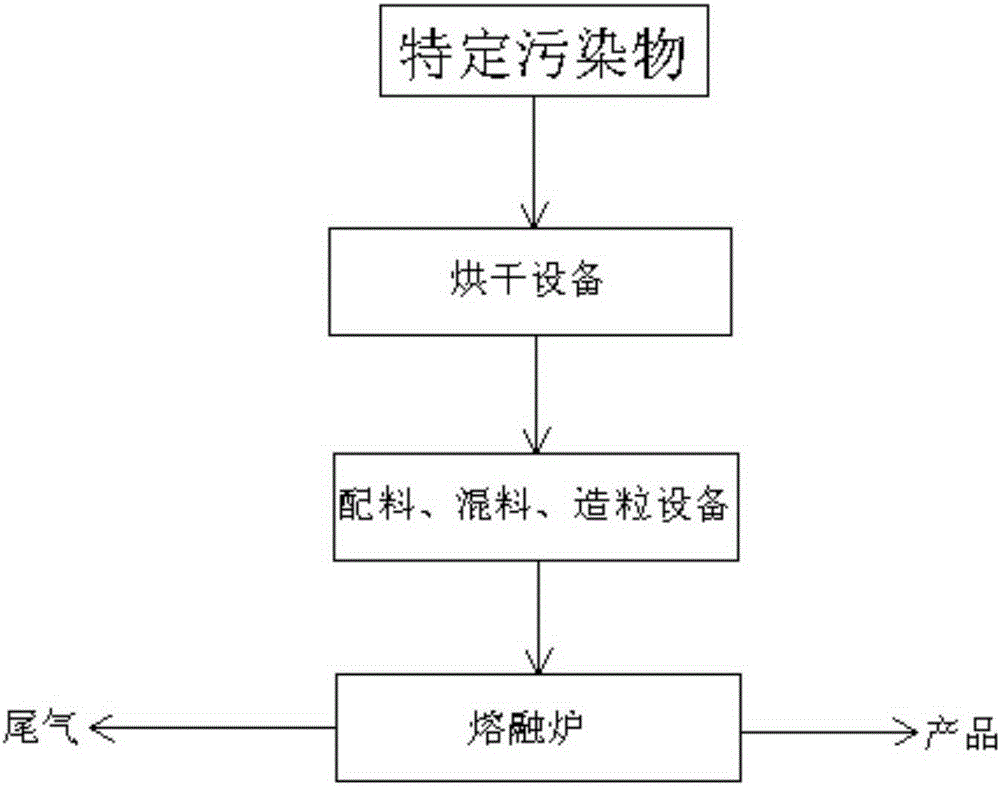

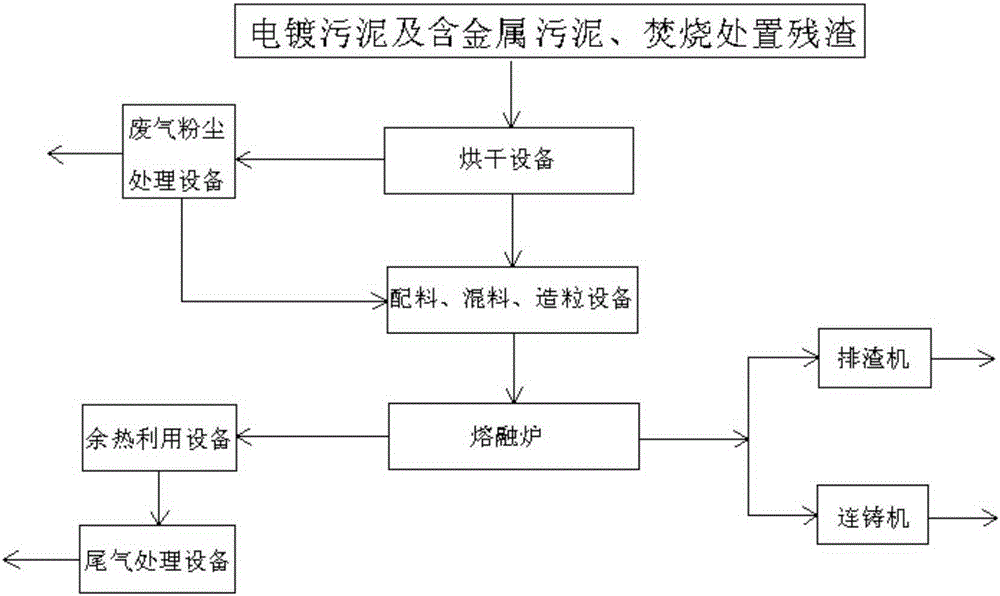

Method for treating specific pollutants through high-temperature melting technology

InactiveCN105344698AReduce operating costsResourcefulSolid waste disposalTransportation and packagingSludgeSlag

The invention provides a method for treating specific pollutants through a high-temperature melting technology. The specific pollutants comprise electroplating sludge, sludge containing metal and / or incineration disposal residues. The method comprises the steps that pretreatment is carried out, wherein the specific pollutants are pretreated, the water content of the specific pollutants is reduced to be 10 wt% or lower, and dry specific pollutant materials are obtained; burdening, blending and granulating are carried out, wherein regulating components are added as needed, mixed and granulated, and a granulated mixture is obtained; melting is carried out, wherein the granulated mixture is melted at the melting temperature ranging from 1,200 DEG C to 1,800 DEG C; and products are obtained, wherein the melted metal is settled on the lower layer and is discharged to obtain a metal alloy, and slag and a small part of metal float above the melted metal and are discharged to obtain glassy-state slag. After the specific pollutants are treated through the method, harmless and pollution-free resource materials can be obtained, and the method can be used for resource recycling, and is good in economic benefit and beneficial to commercial popularization.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

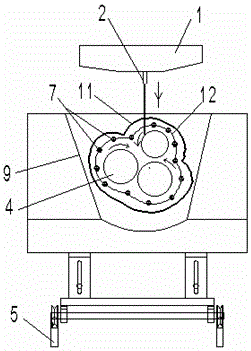

Aluminum silicate thread throwing fiber board and manufacturing method thereof

ActiveCN105734833AImprove the level of comprehensive utilizationReduce pollutionFilament/thread formingNon-woven fabricsFiberThermal insulation

Disclosed is a manufacturing method of an aluminum silicate thread throwing fiber board. The method comprises the steps that raw material coal gangue and flint clay are mixed proportionally and placed into a resistance furnace to be molten, molten liquid flows out strand by strand through a drainage pipe at the bottom of the resistance furnace and falls on a thread throwing machine to be condensed into fiber, an adhesive spraying mechanism sprays out adhesives in a fog shape and uniformly coats the surface of the aluminum silicate thread throwing fiber with the adhesives, the fiber is blown to a cotton collection machine through an annular wind belt to be subjected to negative pressure collection to form cotton, and the aluminum silicate thread throwing fiber board is manufactured through the steps of curing, cutting and the like. The production technology is simple, and the automation degree is high. The manufactured aluminum silicate thread throwing fiber board has the smooth and flat surface, high physical strength and good thermal insulation property.

Owner:HEBEI GUOMEI NEW BUILDING MATERIAL CO LTD

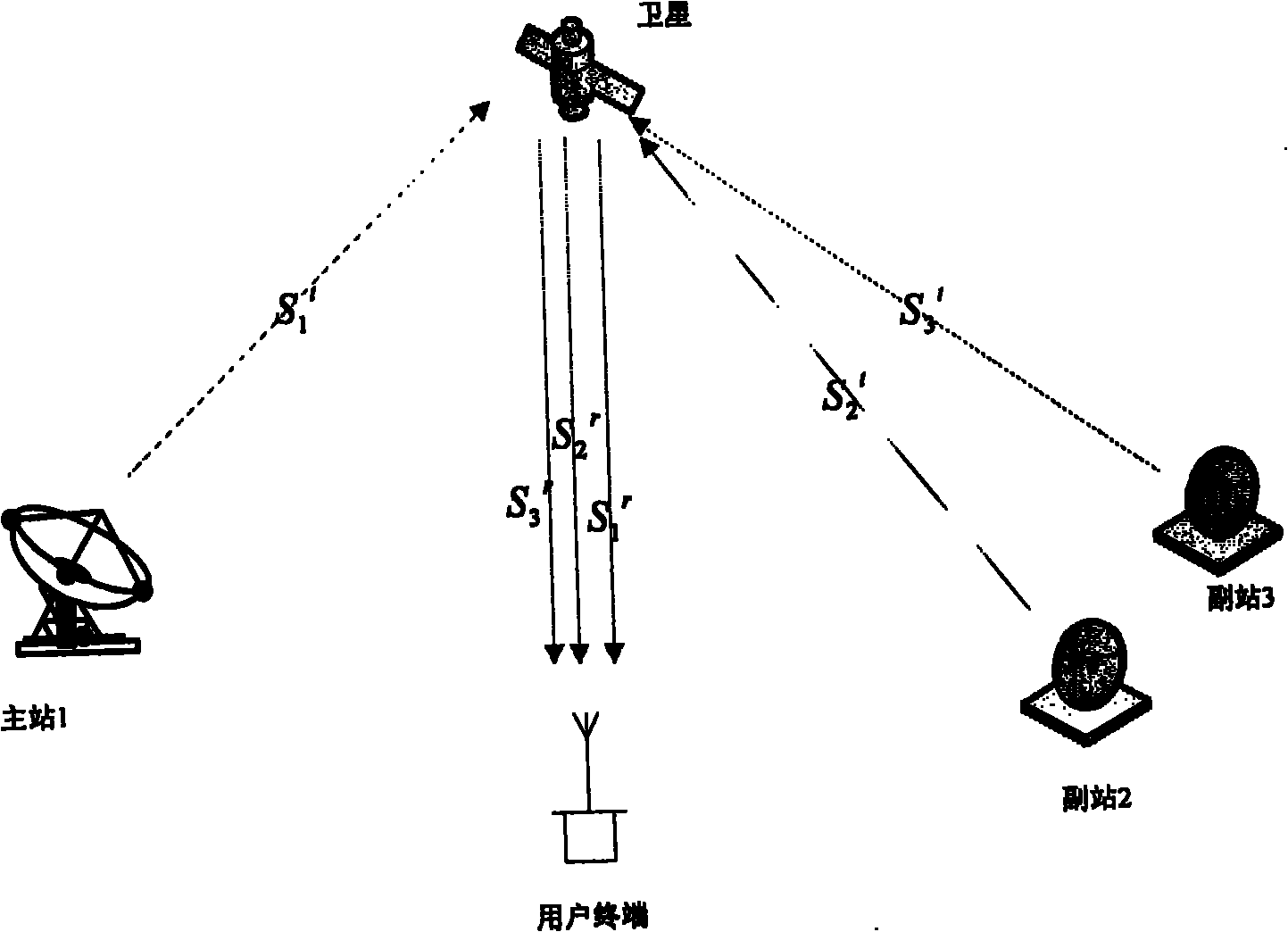

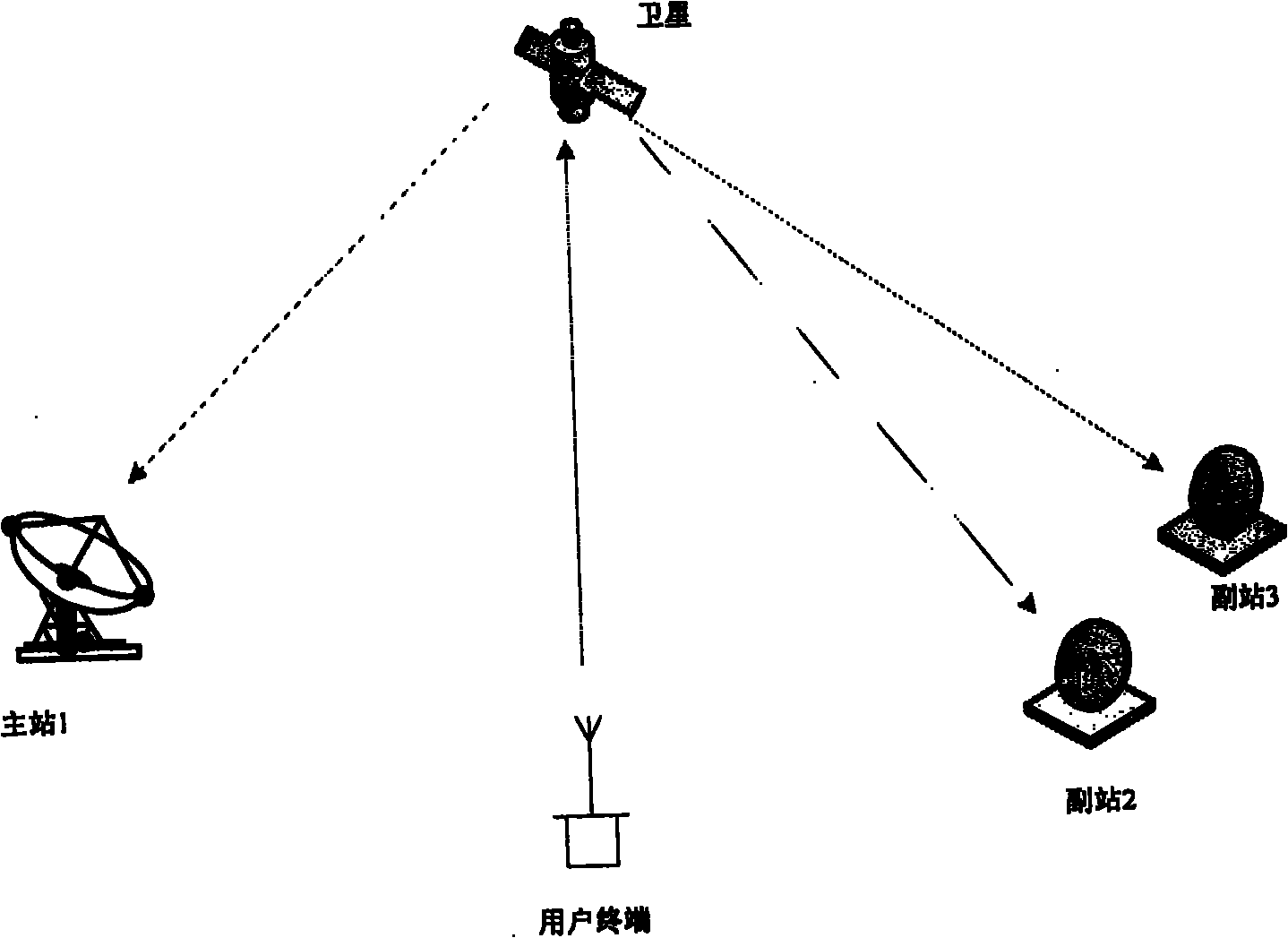

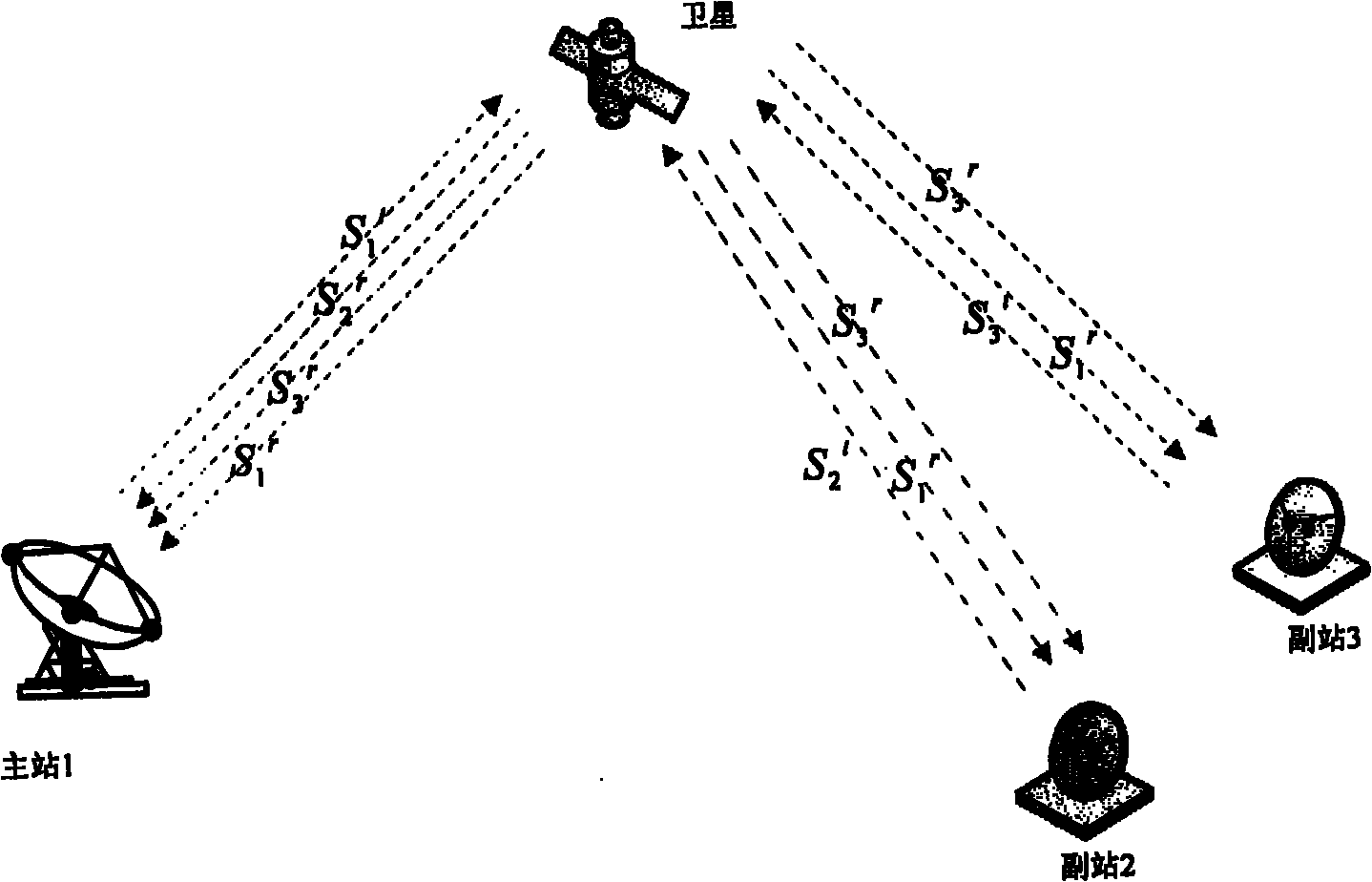

Bidirectional satellite navigation and communication positioning method and system

InactiveCN102213764AVersatileReduce system investmentSatellite radio beaconingTelecommunications linkEnvironmental geology

The invention discloses a bidirectional satellite navigation and communication positioning method and system, relating to a satellite technology. The system is provided with an outcoming and incoming positioning link and a communication link, comprises satellite ground stations (a master station and an auxiliary station), a synchronous communication satellite and various user terminals, is a highly-integrated navigation positioning and communication integrated bidirectional information system, has various functions, such as bidirectional pseudorange measurement, positioning, velocity measurement, posture measurement, direction finding, time service, help calling, monitoring, surveying, communication, search and rescue, service, and the like and has the characteristics of high precision (relative positioning precision: millimeter level (1Sigma); measuring frequency: 50Hz; velocity measurement precision: 0.01mm / s; bidirectional time service precision: superior to 0.1ns; and communication information transmission rate: 50bps-2400bps), less investment, short construction period, good completeness, high reliability, and the like.

Owner:NAT ASTRONOMICAL OBSERVATORIES CHINESE ACAD OF SCI

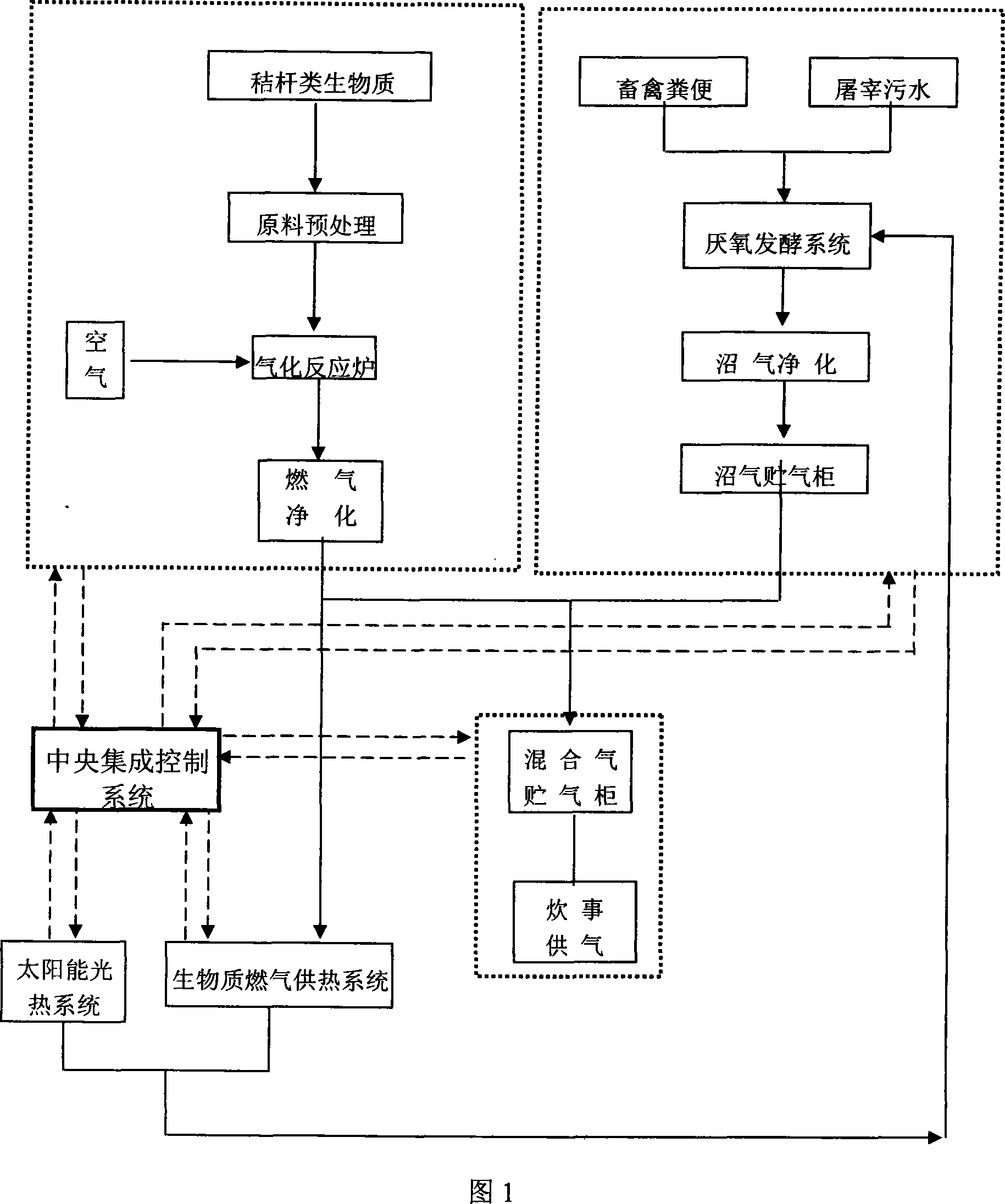

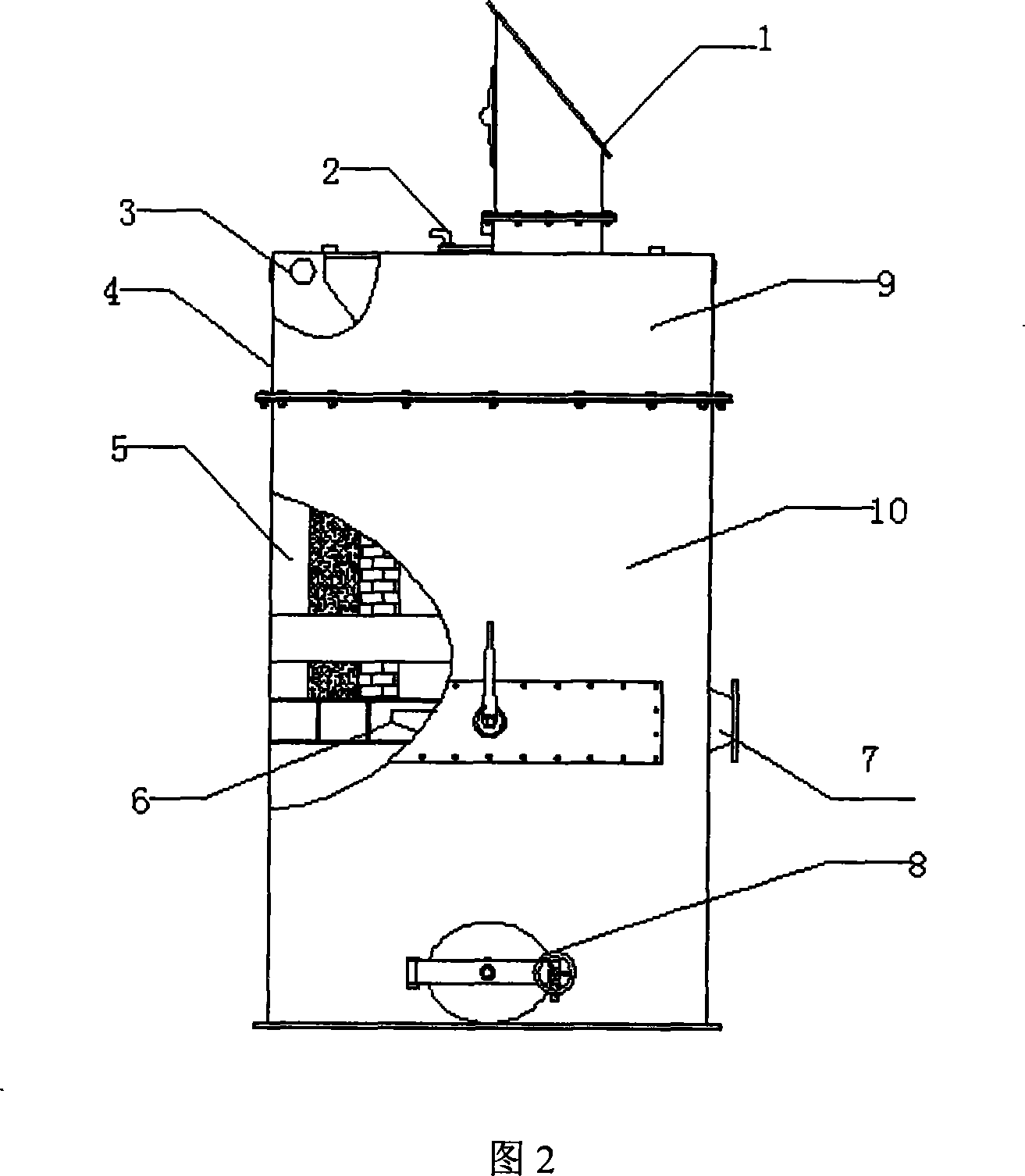

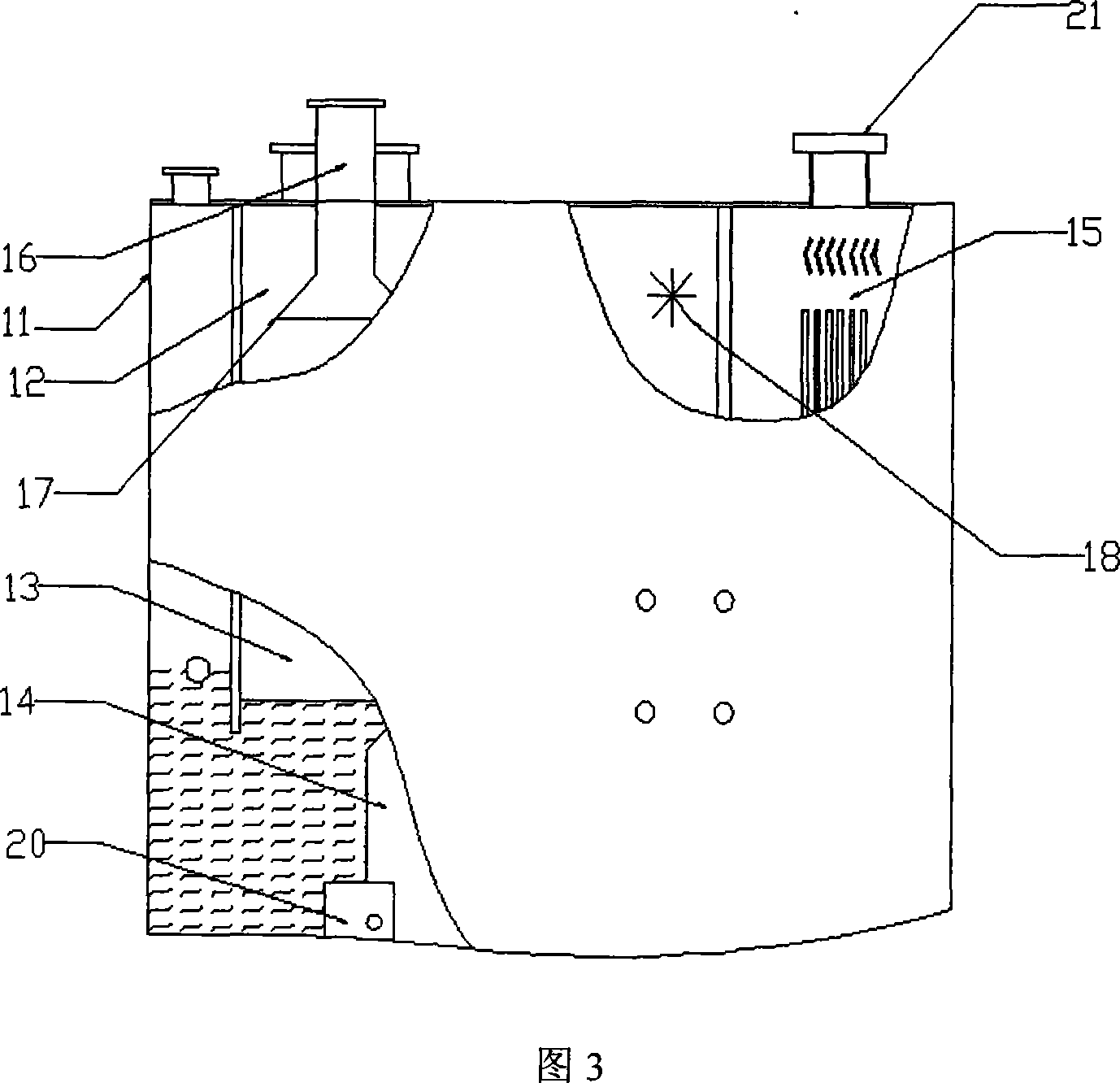

Biological energy-marsh gas fermentation-solar energy integrated utilization system

InactiveCN101063080AEfficient use ofAvoid corrosionSolar heat devicesGas production bioreactorsMarshFermentation

The invention discloses a biological mass energy-marsh gas fermentation-solar energy integrated usage system, which is characterized by the following: comprising biomass evaporated unit, marsh gas anaerobic fermentation unit, central integrated control unit, solar energy light hot unit, biomass gas heat supply unit, biomass fuel and marsh gas automatic mixed unit, fuel transmitting and distributing and user unit; connecting the central control unit and the other units separately; connecting the biomass gasifying unit with the biomass fuel heat supply unit, biomass fuel and marsh gas automatic mixed unit separately; connecting the marsh gas anaerobic fermentation unit with the biomass fuel and marsh automatic mixed unit; connecting the biomass fuel and marsh automatic mixed unit with fuel transmitting and distributing and user unit; connecting the solar energy light hot unit and biomass gas heat supply unit with the marsh gas anaerobic fermentation unit separately. This invention can transform the pollution as marsh gas source.

Owner:浙江网新百川环境科技有限公司

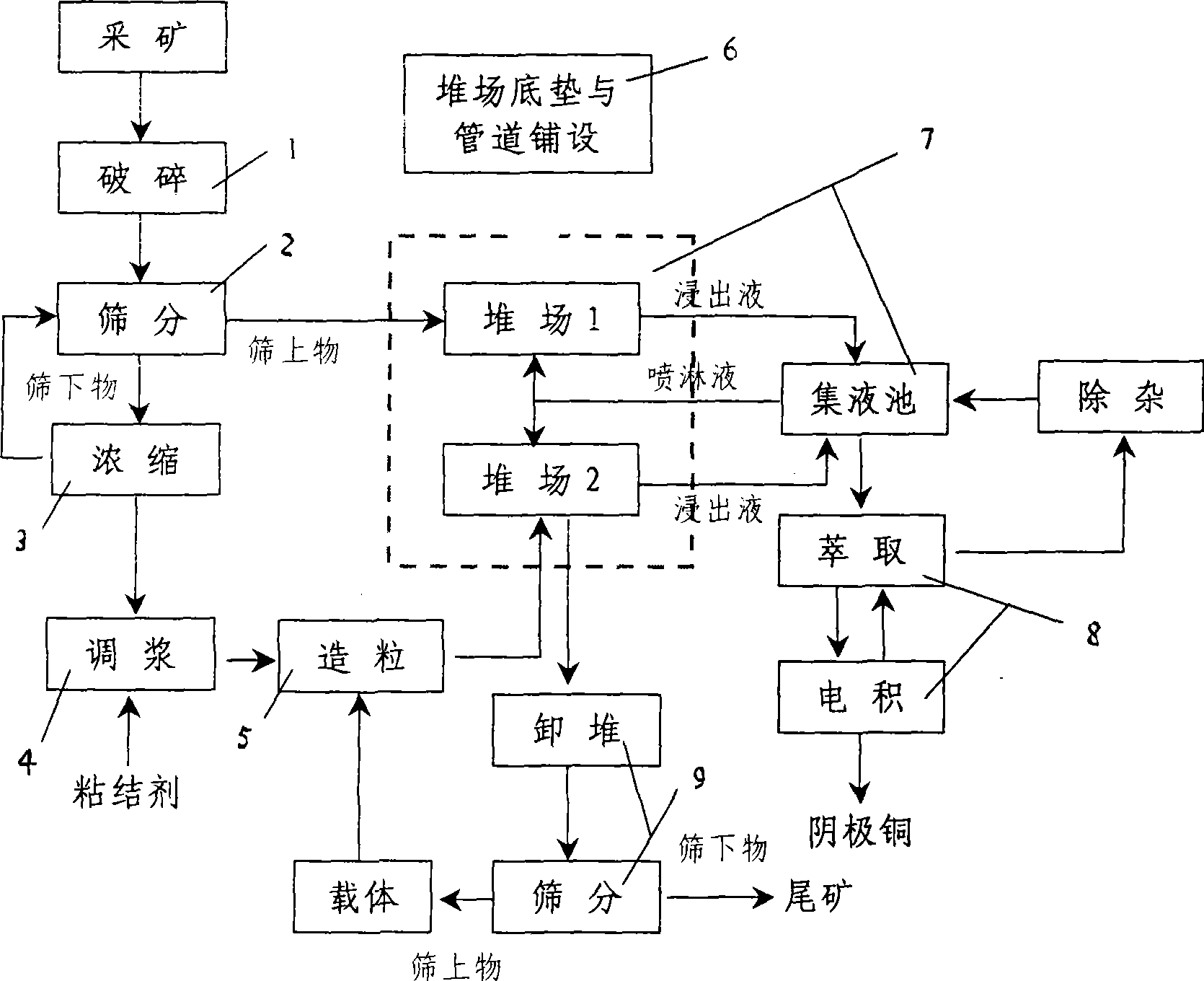

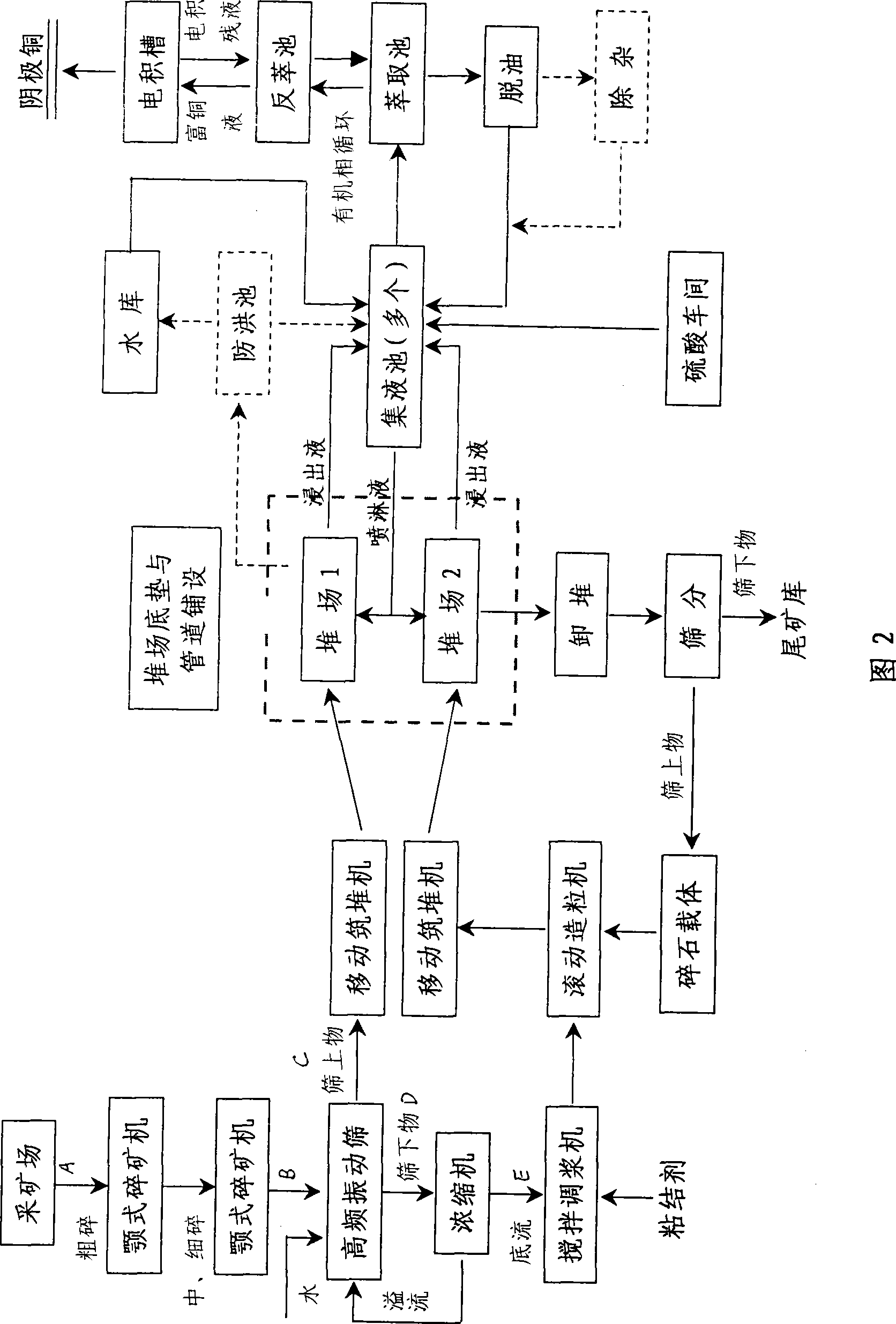

Acid heap leaching process for cupric oxide ore

InactiveCN101435021AImprove the level of comprehensive utilizationReduce pollutionPhotography auxillary processesProcess efficiency improvementPregnant leach solutionClay minerals

The invention provides a new technique of acid heap leaching of copper oxide ore. The copper oxide ore is crushed and screened, then materials on a screen are carried out conventional acid heap leaching operation and the materials under the screen carry out concentration, size mixing and granulation and then are piled and leached; and leachate rich in copper ions is treated by the procedures of extraction, electrodeposition and the like so as to obtain cathode copper sold on the market. After the materials under the screen are concentrated, a binding agent needs to be added for size mixing; after size mixing, ore pulp and prepared acid-proof gravel with the granularity of 5mm to 25mm are mixed for granulation; in the granulation and heap leaching process, the pile height is 3 to 5m, in the heap leaching process, the concentration of dilute sulphuric acid is 0.1 to 2mol / L, the spraying strength is 0.2 to 0.5L / (min.m<2>) and the leaching period is 1 to 2 months. The technique can fully utilize copper oxide ore resource which is hard to be utilized in the past time, contains a large amount of clay mineral and is easy to argillization, improves the level of comprehensive utilization of mines, saves cost and increases profit. The invention is particularly suitable for being applied to the development of copper ore resources, mainly the copper oxide ore, which are hard to treat in all regions of China, in particular to remote regions of the western highlands.

Owner:有研资源环境技术研究院(北京)有限公司

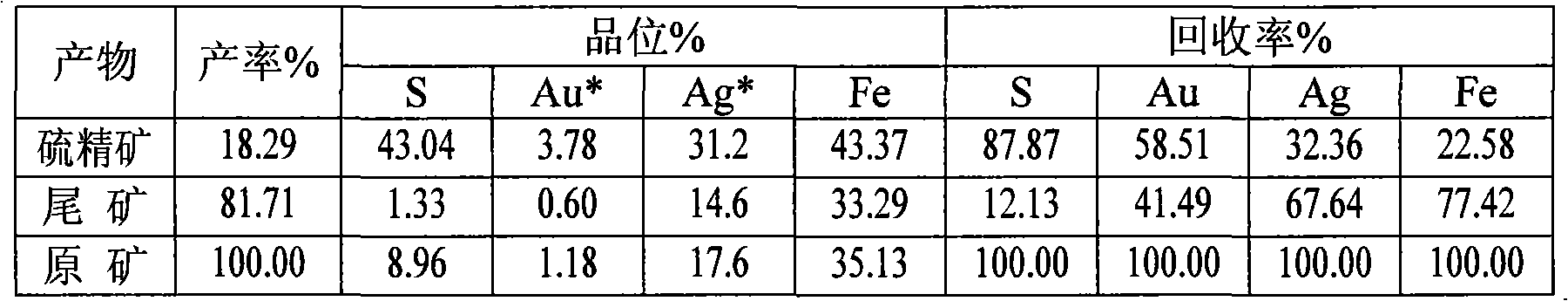

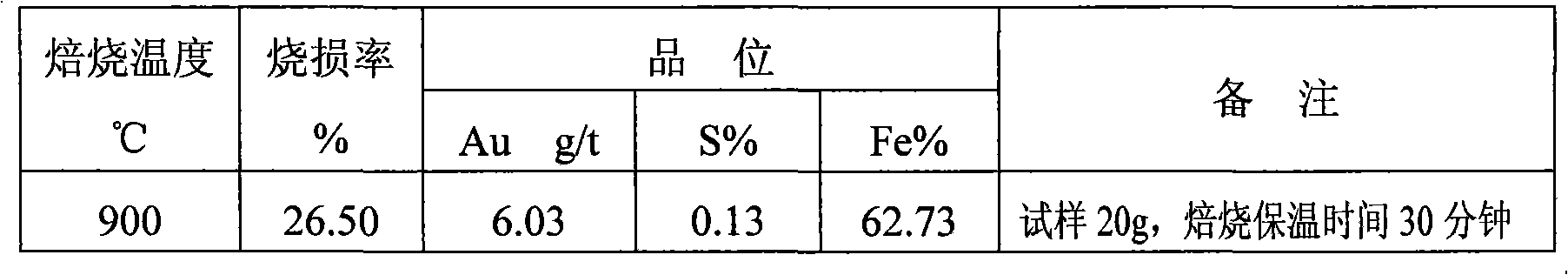

Recovery processing method for cyanogen golden mine tailing

InactiveCN101403042AImprove the level of comprehensive utilizationEmission reductionProcess efficiency improvementSulfurSludge

The invention relates to the recycle of tailings of oxidized ore containing gold with high content of sulfur and iron after cyaniding and gold extraction, in particular to a recycling and processing method of gold-cyaniding tailings. The invention uses the technology of flotation of sulfur, acid preparation with sulphur ore concentrate and gold extraction and iron obtaining by cyaniding acid sludge, magnetizing roasting and magnetic separation for obtaining iron and of selection sulfur tailings after dehydration as additive in cement to realize recycling of the gold-cyaniding tailings, realize single separation and final no-tail of gold mineral and provide the route of proper technique for recycling the gold-cyaniding tailings. The invention has the advantages of low processing cost and wide application range and is a recycling technique of the gold-cyaniding tailings, which is economic, simple and applicable and has good processing effect.

Owner:罗仙平

Bayer process red mud and gangue porous sintered brick and production method thereof

InactiveCN103030372ARegular appearance qualityNo deformationCeramic materials productionCeramicwareTunnel kilnBrick

The invention discloses a Bayer process red mud and gangue porous sintered brick and a production method thereof. The porous sintered brick is prepared from the following raw materials: 60 to 75 parts of Bayer process red mud; 25 to 35 parts of gangue; 2 to 6 parts of tailings or wastes in chemical plants; and 0.5 to 3 parts of pore-forming agent. The preparation method of the brick comprises the following steps: after dehydrating the Bayer process red mud, mixing and uniformly stirring the Bayer process red mud and other ground raw materials, aging for 1 to 3 days, and adding water to stir aged powder in a stirring machine so as to obtain mud; carrying out extrusion forming on the mud under the extrusion pressure of 1.5 to 2.5MPa by adopting a stiff-plastic process so as to obtain a semi-finished product which accords with the specified dimension and the specified shape; and drying a mold brick and sintering the mold brick in a tunnel kiln to obtain the Bayer process red mud and gangue porous sintered brick. The product reaches the national strength standard of the sintered bricks. In the technology, the total use amount of industrial wastes is close to 100 percent; a large number of farmlands are saved; land resources are effectively protected; and the Bayer process red mud and gangue porous sintered brick and the production method thereof accord with the national policies of saving energy and reducing emission and have obvious environmental benefits, social benefits and economic benefits.

Owner:HENAN POLYTECHNIC UNIV

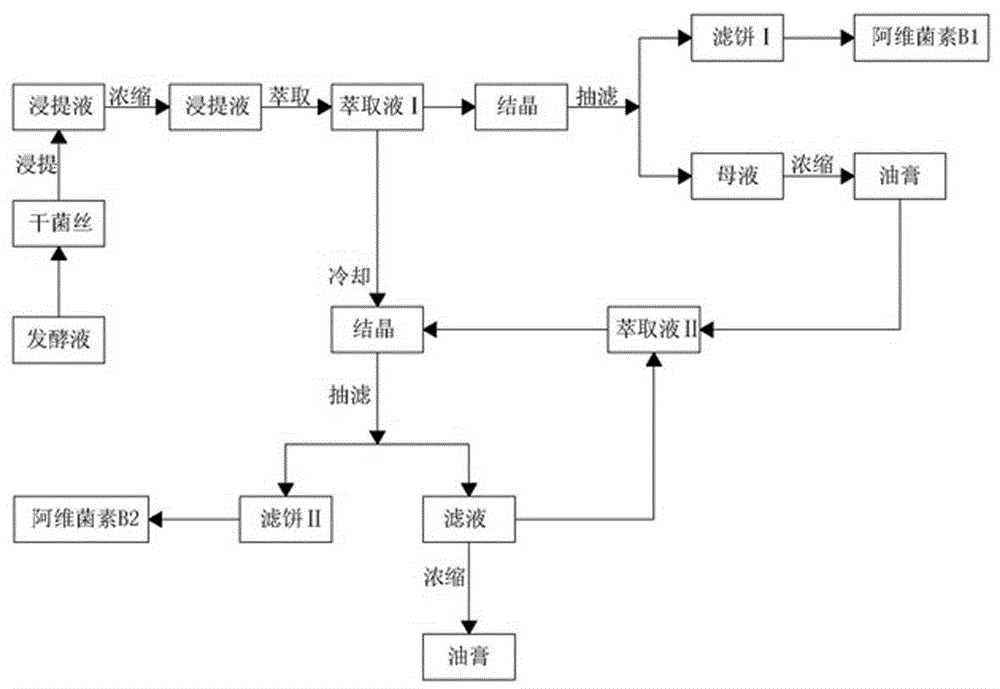

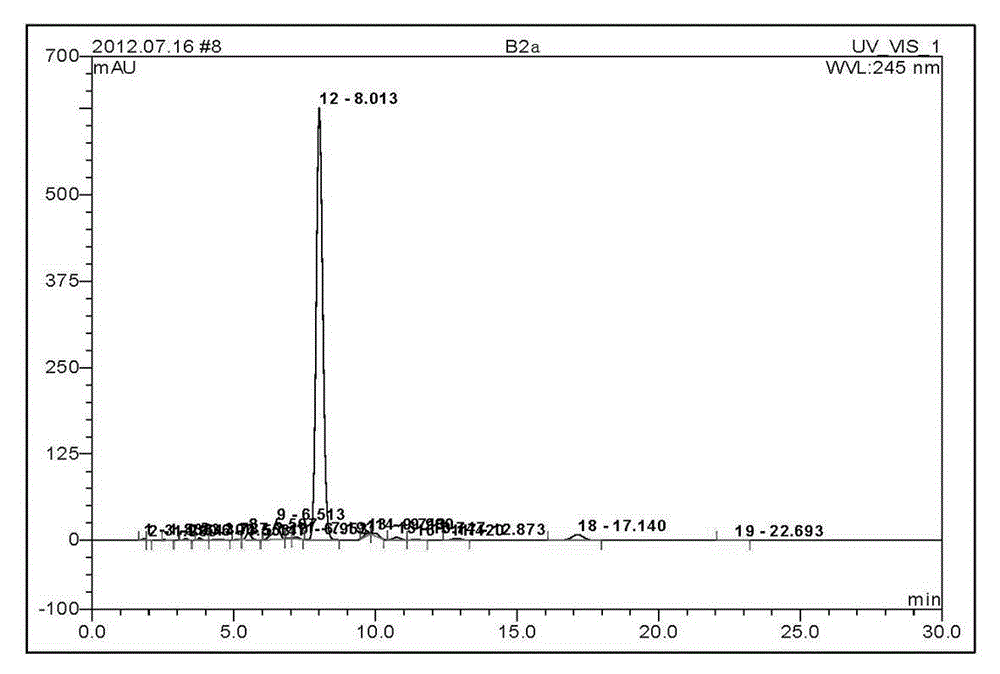

Extraction and preparation method of abamectin B2a

ActiveCN102977168AHigh extraction rateGood extractionSugar derivativesFermentationAbamectinChemistry

The invention discloses an extraction and preparation method of abamectin B2a, which comprises the following steps: preparing an abamectin fermentation liquid into dry mycelia, and leaching; concentrating the leaching liquor, and adding toluene and other extractants to carry out extraction; crystallizing the extract I; concentrating the mother solution into ointment; adding toluene into the ointment to obtain an extract II; adding a filter aid into the extract II, stirring, cooling, crystallizing, growing the grain, and carrying out vacuum filtration; adding toluene to dissolve the filter cake, heating the filtrate, cooling, crystallizing, growing the grain, and carrying out vacuum filtration to obtain an abamectin B2a crystal crude product; and recrystallizing the abamectin B2a crystal crude product to obtain the abamectin B2a crystal fine product. The method disclosed by the invention can effectively separate the abamectin B2a from the abamectin fermentation liquid, and has the advantages of high extraction rate and favorable purification effect.

Owner:HEBEI XINGBAI AGRI SCI & TECH CO LTD

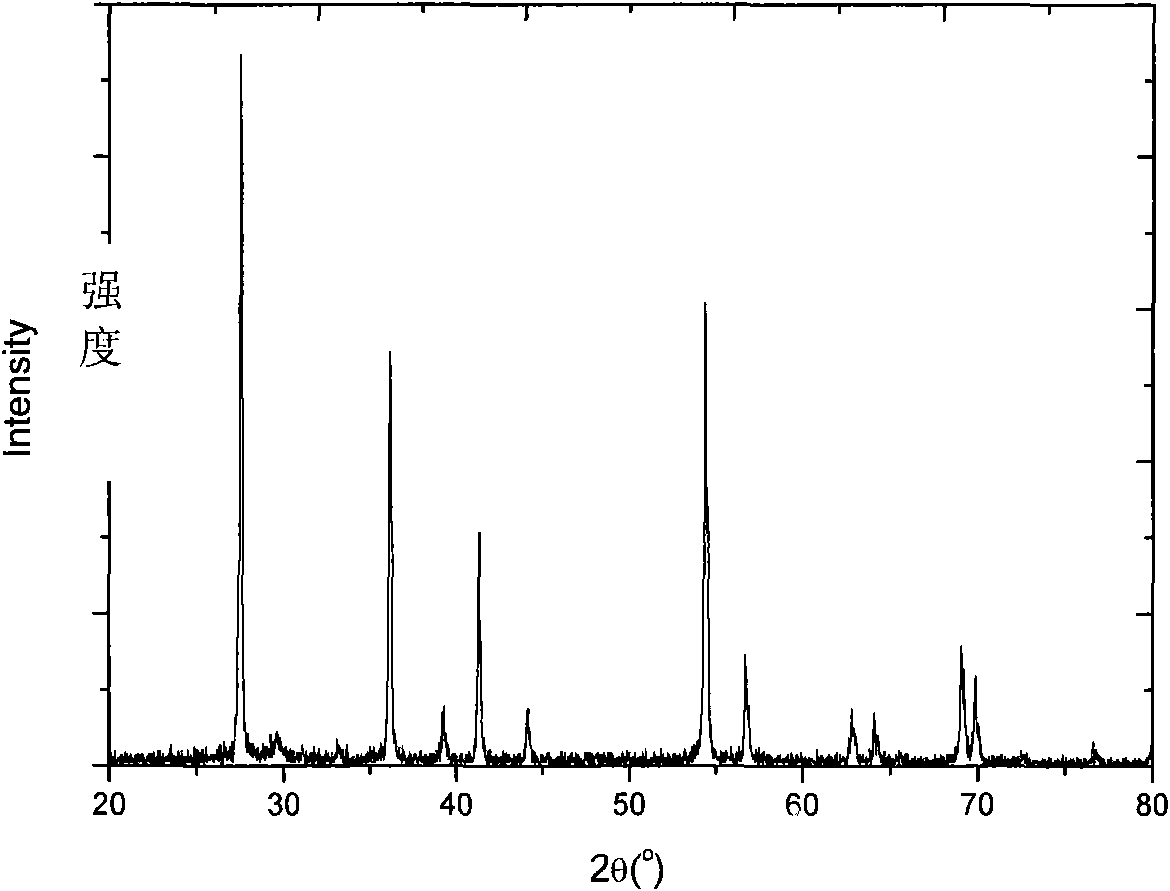

Molybdenum-containing semi-conductor photocatalysis material responding to visible light, preparation method and application thereof

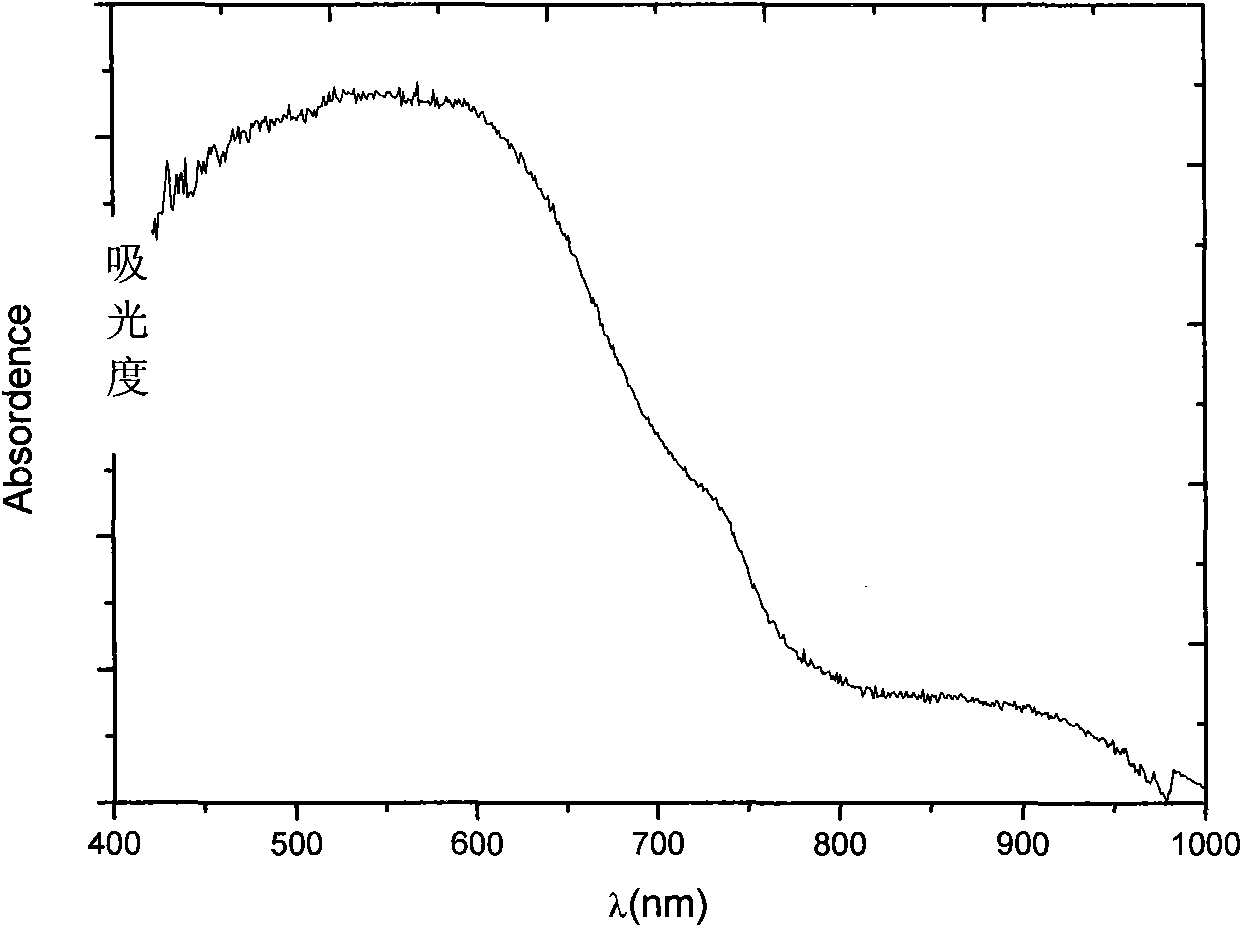

InactiveCN101559371AStrong absorption capacityEasy to prepareWater/sewage treatment by irradiationWater contaminantsSolar lightPhotochemistry

The invention relates to a molybdenum-containing semi-conductor photocatalysis material responding to visible light, wherein a molecular formula of the material is M2M1FeMoO6. In the formula, M1 is equal to Li, Na, K, Rb or Cs; and M2 is equal to Be, Mg, Ca, Sr or Ba. A preparation method for the material comprises the following steps that: an M1-containing compound, an M2-containing compound, an Fe-containing compound and an Mo-containing compound are placed into a mortar according to the mol ratio that the M1 to Fe to the M2 to Mo is 1: 1: 1: 1, and are ground and mixed evenly; and the mixture is subjected to presintering treatment the temperature is increased to be between 800 and 1,200 DEG C, and the mixture is at a constant temperature for 1 to 160 hours to obtain the molybdenum-containing semi-conductor photocatalysis material responding to the visible light. The material has low energy band gap, has good absorption under the irradiation of the visible light, and can be used for performing full spectrum absorption on solar light, or is used for removing harmful substances in the air and sterilizing under the irradiation of the visible light, or is used as a photoelectric conversion material, or is used for producing hydrogen and oxygen by performing photocatalytic analysis on water, or is used for removing organic substances which are harmful to people in sewage by the degradation. The material has the advantages of low synthesis cost, and simple and easy method.

Owner:WUHAN UNIV OF TECH

Process for producing pressed active carbon

InactiveCN101402454ALow manufacturing costImprove the level of comprehensive utilizationWater contentTar

The invention relates to a method for preparing a molded active carbon. The method comprises the following steps: a. crude coal is broken up to coal blocks of less than 10 millimeters; b. attal is removed from the crude coal; c. the crude coal is dried and dehydrated in order that the water content of the crude coal reaches between 4 and 5 percent; d. 37 to 64 percent of weak caking coal which can be used for producing developed fine micropores and secondary micropores, 25 to 41 percent of non-caking coal which can be used for manufacturing developed fine middle pores and 11 to 22 percent of rich coal which can be used for producing developed micropores and middle pores with poor mechanical strength are selected; and a powdery material with less than 200 meshes has the passing rate of more than 85 percent through pulverization; e. the powdery material is pressed and molded through a pelletizer; and the strength of the powdery material is more than 87 percent; f. molded carbon is carbonized; and g. the molded and carbonized material is activated. Before molding, the method does not select tar or other additives and only selects the weak caking coal, the non-caking coal and the rich coal which are easy to obtain locally, thereby greatly reducing production cost and improving the comprehensive utilization rate of coal of the state.

Owner:李贵义

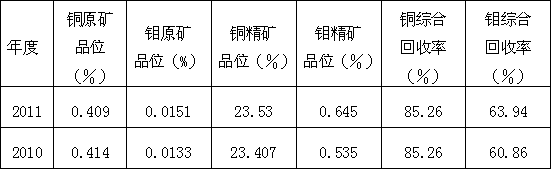

Selection method for copper sulfide copper minerals and associated elements thereof

The invention belongs to mineral processing field, relates to a beneficiation method, and particularly relates to a selection method for copper sulfide copper minerals and associated elements thereof. The method comprises rapid flotation, bulk flotation and selection period flotation. The rapid flotation step is composed of one-time rougher flotation and one-time selection. The bulk flotation step is composed of one-time copper-sulfur mixing rougher flotation and two-time scavenging. The selection period flotation step is composed of one-time rougher flotation, two-time selection, and three-time scavenging. By means of the selection method for the copper sulfide copper minerals and the associated elements thereof, rapid flotation is conducted on rough concentrate, pyrite is little in content, copper minerals are mainly monomers and rich aggregates, and selection is conducted under a weak alkali environment, so that lime is saved, and recycling of the associated elements is guaranteed at the same time. Bulk flotation is conducted on the rough concentrate, pyrite and copper-poor aggregates are high in content, regrinding high-alkali separation process is adopted, and therefore the tenor and the recovery rate of copper are enabled to be high.

Owner:JIANGXI COPPER

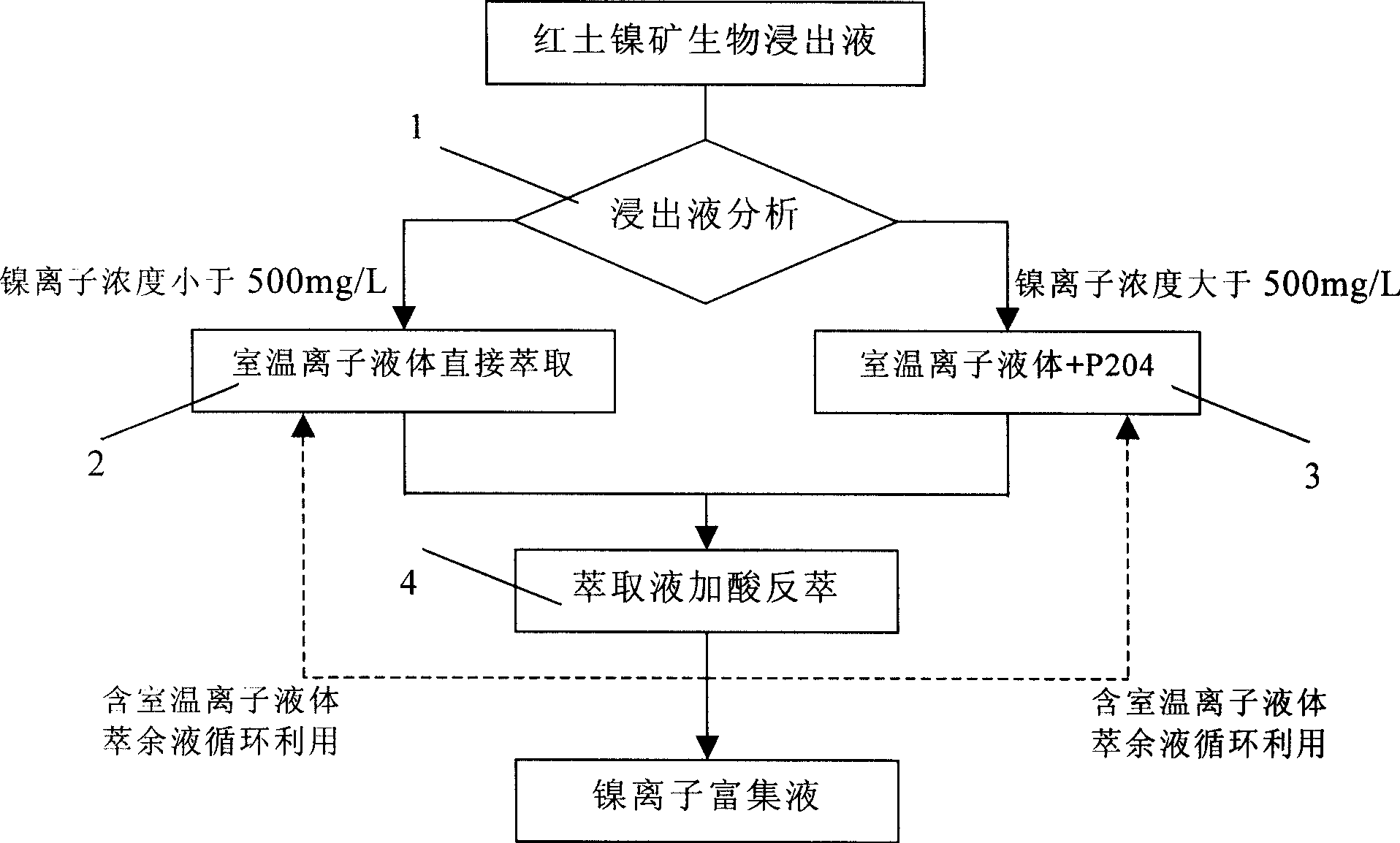

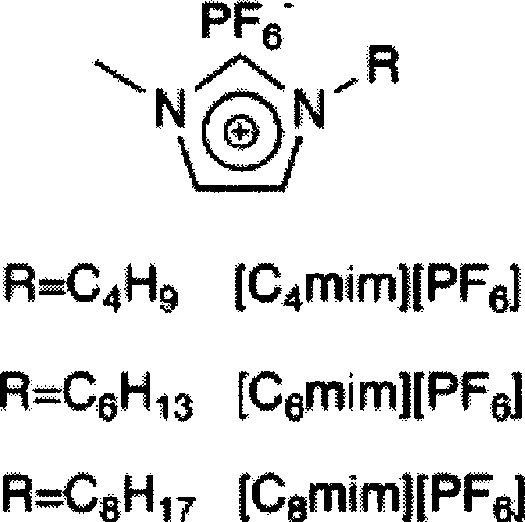

Process for recovering nickel ion from biochemical lixivium of laterite nickel mine by using room temperature ion liquid

InactiveCN101457292AReduce pollutionImprove the level of comprehensive utilizationProcess efficiency improvementLateriteCobalt

The invention discloses a process for recovering nickel ions from a bio-leaching solution of a laterite nickel ore by a room temperature ionic liquid. The process comprises the following steps: (1) mixing the room temperature ionic liquid and the bio-leaching solution of the laterite nickel ore at volume ratio of 1:50-100, fully stirring followed by standing for stratification during which an organic solvent of chelated metallic ion in the leaching solution can be partially enriched in a room temperature ionic liquid phase, and the metallic ions such as nickel, iron, cobalt and the like are transferred into the room temperature ionic liquid phase; (2) separating the room temperature ionic liquid phase, then serially adding dilute hydrochloric acid the concentration of which is 2-3mol / L and the volume of which is 1-1.5 times of the volume of the room temperature ionic liquid phase to perform a progressive re-extraction to realize the aim of recovering various metallic ions. The process has the advantages of simple operation, no emulsification, high extraction efficiency, short operation time, being easy in realizing multistage combination, high efficiency and being economic and environment-friendly. The invention establishes a new high-efficiency extraction process of the bio-leaching solution of the laterite nickel ore, fully utilizes low grade original nickel oxide ore resources, improves the comprehensive utilization level of mineral resources, reduces environmental pollution and improves economic benefit, thereby the process is applicable to exploitation and utilization of the laterite nickel ore mines in China.

Owner:有研资源环境技术研究院(北京)有限公司

Micro-grid energy optimization and evaluation method based on full energy flow model

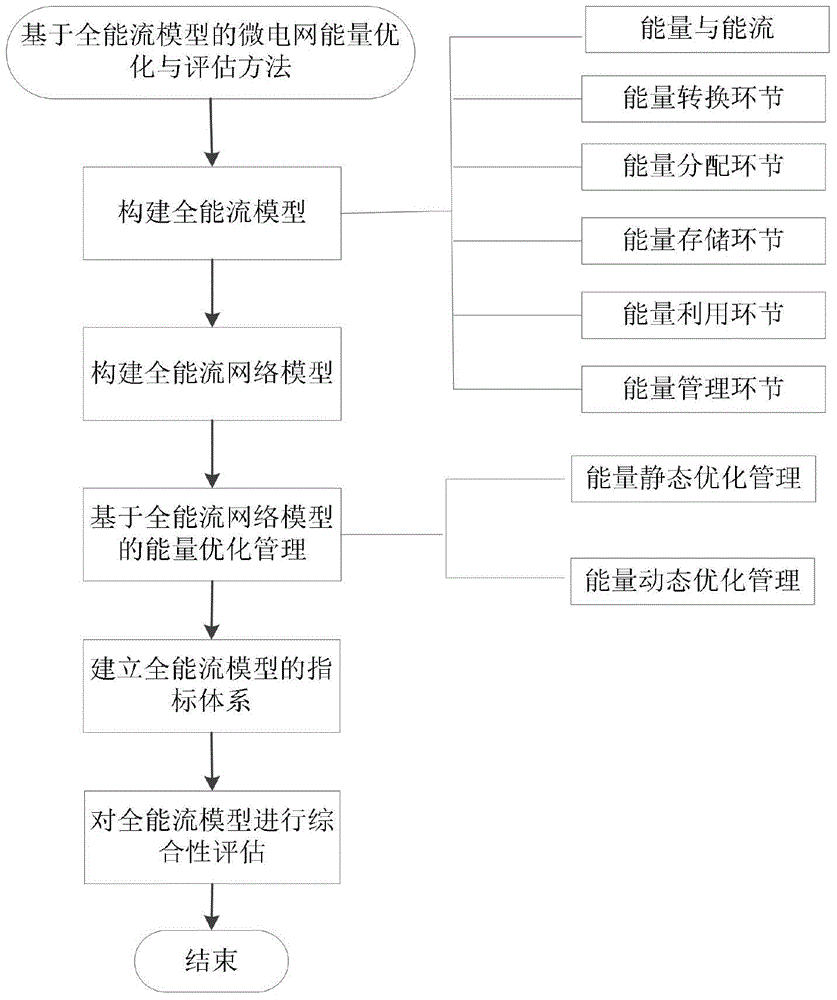

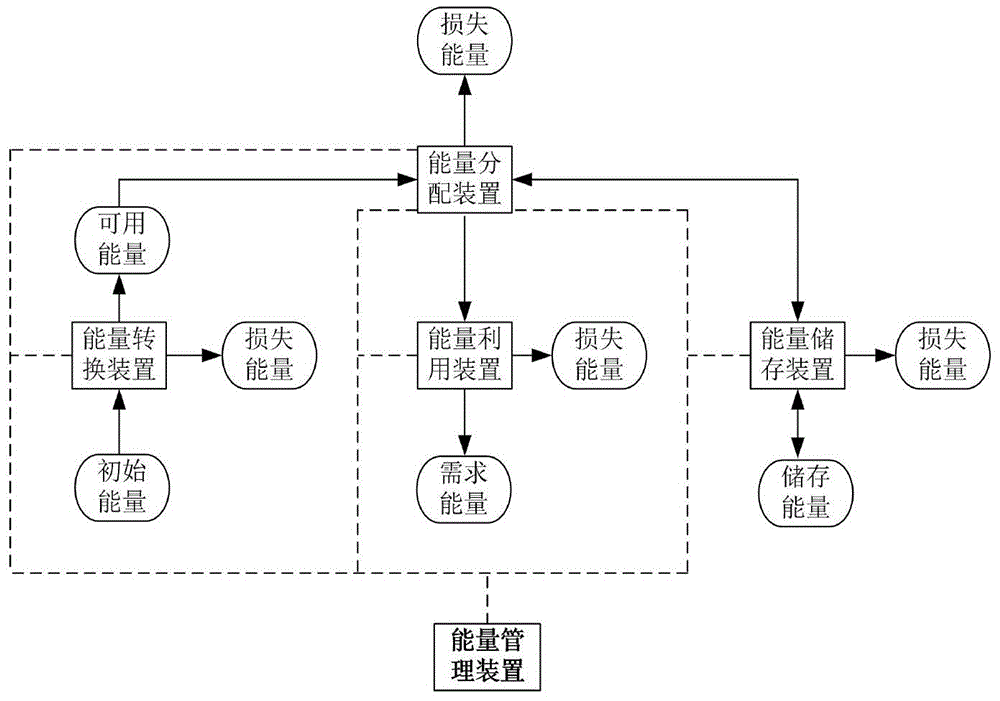

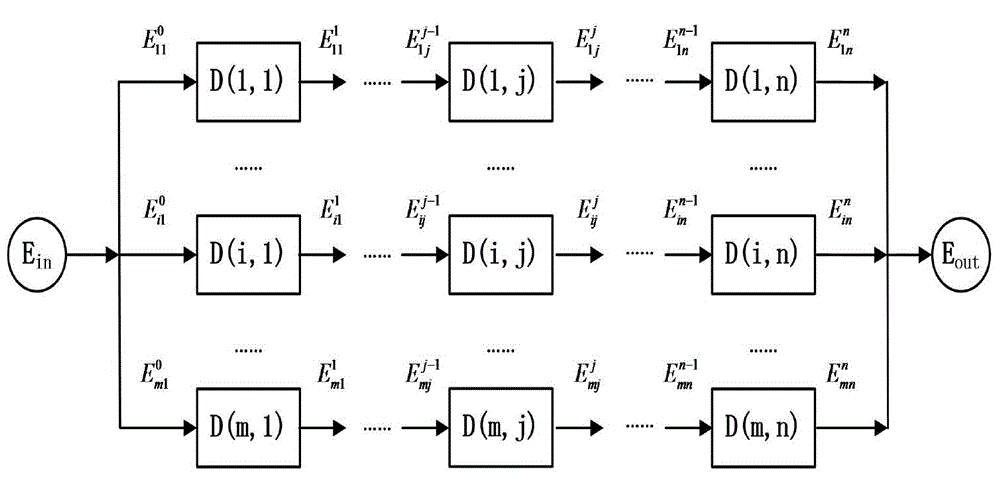

InactiveCN105373842ARealize multi-level refined energy managementEnergy optimization management in full swingForecastingSystems intergating technologiesNetwork modelIndex system

The invention relates to a micro-grid energy optimization and evaluation method based on a full energy flow model. The method includes following steps: (1) building the full energy flow model: including energy and energy flow analysis; energy conversion link analysis, energy distribution link analysis, energy storage link analysis, and energy utilization link and energy management link analysis; (2) building a full energy flow network model; (3) performing energy optimization management based on the full energy flow network model including energy static optimization management and energy dynamic optimization management; (4) establishing an index system of the full energy flow model; and (5) performing comprehensive evaluation of the full energy flow model. According to the method, processes of generation, conversion, transmission, storage, and utilization of different types of energies in a micro-grid are described via the manner of digital abstract representation, the index system is established, the micro-grid energy optimization method is proposed, unified quantification of different types of energies is realized via digital representation of energy flow, and comprehensive analysis and evaluation of energy efficiency utilization of overall and partial links are performed.

Owner:STATE GRID CORP OF CHINA +1

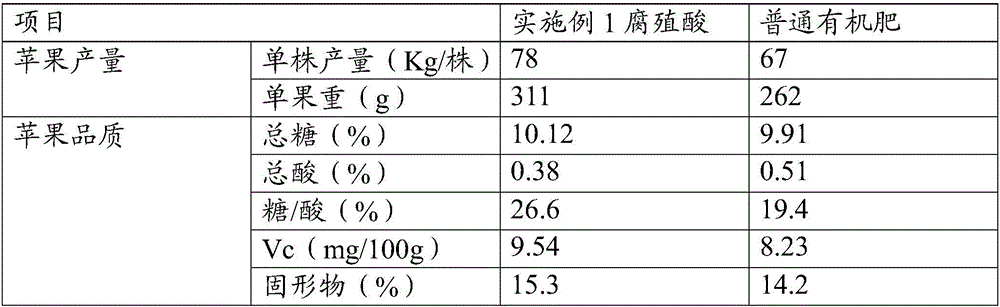

Biological humic acid fertilizer and preparing method thereof

ActiveCN106316693AImprove disease resistanceImprove stress resistanceBio-organic fraction processingBioloigcal waste fertilisersPlant growthFermentation

The invention discloses a biological humic acid fertilizer. Edible mushroom residues, apple pomace, soybean molasses, a texturizing agent, compound enzymes and complex microbial inoculants are main raw materials, all the raw materials are subjected to enzymolysis, the product and microorganisms are fermented, and the ciologiacal humic acid fertilizer is prepared. The method includes the special steps that after the mushroom residues are subjected to steam explosion, enzymolysis and fermentation are carried out through the compound enzymes and the complex microbial inoculants, and the conversion rate of biological humic acid is increased. By means of the biological humic acid fertilizer, the comprehensive utilization level of mushroom residues is increased, and the biological humic acid fertilizer has the effects of improving soil, promoting plant growth and improving disease resistance and stress resistance and improving the product quality, and has the remarkable economic benefits and social benefits.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Health care sand for egg-laying breeding pigeons

InactiveCN104431383ALow costIncrease the content of trace elementsAnimal feeding stuffMaterials scienceRaw material

Belonging to the field of agricultural culture, the invention discloses a health care sand for egg-laying breeding pigeons. The health care sand contains the following raw materials by weight part: 25 of stone seed or coarse sand, 30 of shell powder, 8 of fly ash, 8 of calcium hydrogen phosphate, 5 of salt, 4 of charcoal, 5 of a core material, 4 of scourge-clearing toxin-vanquishing powder, 2 of iron oxide red powder, 2 of gypsum powder, 3 of yeast powder, 2 of sugar, 0.5 of Dan duoduo, and 0.5 of super fiber peptide or egg flourishing. The health care sand provided by the invention is in favor of reducing cost, improving the performance and utility of health care sand, and increasing the comprehensive benefit of meat pigeon culture.

Owner:ANYANG XIANGBANG AGRI DEV

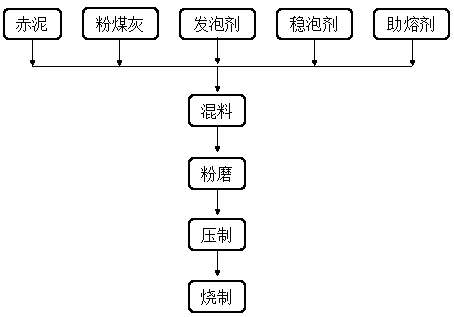

Method for preparing foam microcrystalline glass through red mud

The invention relates to a preparing method for foam microcrystalline glass, in particular to a method for preparing the foam microcrystalline glass through red mud. The preparing method aims at preparing the foam microcrystalline glass with the industrial solid waste red mud, the low energy consumption and the excellent performance. The preparing method includes the following steps that (1) industrial waste residues, fluxing agent, foaming agent and foam stabilizer are mixed to be even according to the weight ratio to form a batch mixture; (2) the mixed batch mixture is put into a ball mill and powdered; (3) the powdered batch mixture is put into a grinding tool and pressed and formed; (4) a pressed sample is put into a reacting furnace and fired. The method has the advantages that the problems that in aluminum industry of China, the discharging quantity of waste residues is large, waste residues are difficult to treat are solved, the comprehensive utilization level of the industrialwaste is improved, sustainable development of building materials in China can be achieved, and social economical benefits can be remarkably improved.

Owner:UNIV OF JINAN

Method for producing spices oil resin microcapsule

InactiveCN1449681AEfficient use ofQuality improvementCapsule deliveryFood preparationProduction rateReflux

The present invention belongs to a production method of spice oil resin microcapsule, said method includes the following steps: pretreating raw material, extracting essential oil, drying first dregs, pulverizing, extracting oil resin and drying second dregs, pulverizing, emulsifying, homogenizing, spray-drying to prepare microcapsule and mixing partial essential oil with powder material obtained after secondary drying and pulverization so as to obtain the correspondent spice powder. Firstly, said method extracts the volatile substances of essential oil from raw material, then adopts the dynamic thermal reflux process to extract oil resin at higher temperature, so that it not only can raise production efficiency by 8-12 times, but also can save equipment investment by 15-20%.

Owner:向云峰

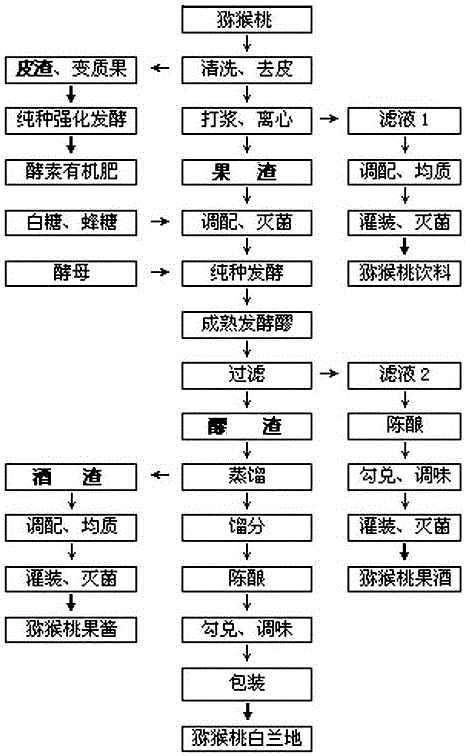

Deep processing method for pomace, wort sludge, lees and peel pomace in complete utilization of kiwi fruits

ActiveCN106497720AAchieve full utilizationImprove the level of comprehensive utilizationFood ingredient as thickening agentBioloigcal waste fertilisersSludgeActinidia

The invention discloses a deep processing method for pomace, wort sludge, lees and peel pomace in complete utilization of kiwi fruits. The deep processing method includes the steps: cleaning fresh kiwi fruits, peeling the cleaned kiwi fruits and then feeding the kiwi fruits into a beating machine for beating; performing centrifugal separation for obtained pulp to obtain filter liquid 1 for preparing kiwi fruit beverages; inoculating yeast with the pomace of the kiwi fruits, performing pure fermentation, and filtering and separating obtained fermented liquid to obtain filter liquid 2 for preparing kiwi fruit wine; distilling the wort sludge of the kiwi fruits to obtain fraction for preparing kiwi fruit brandy; blending and homogenizing the lees of the kiwi fruits to obtain mixture for preparing kiwi fruit jam; preparing enzyme organic fertilizers by the peel pomace of the kiwi fruits, fermentation deterioration fruits and washing water. According to the method, the kiwi fruits are completely utilized, the kiwi fruit beverages, the kiwi fruit wine, the kiwi fruit brandy, the kiwi fruit jam and the enzyme organic fertilizers are developed, nutrition and health care components in the pomace, the wort sludge, the lees and the peel pomace of the kiwi fruits are sufficiently utilized, the comprehensive utilization level of the kiwi fruits and additional values of kiwi fruit products are effectively improved, environmental pollution caused by rough processing is avoided, and cleaning production of production places is achieved.

Owner:SHAOYANG UNIV

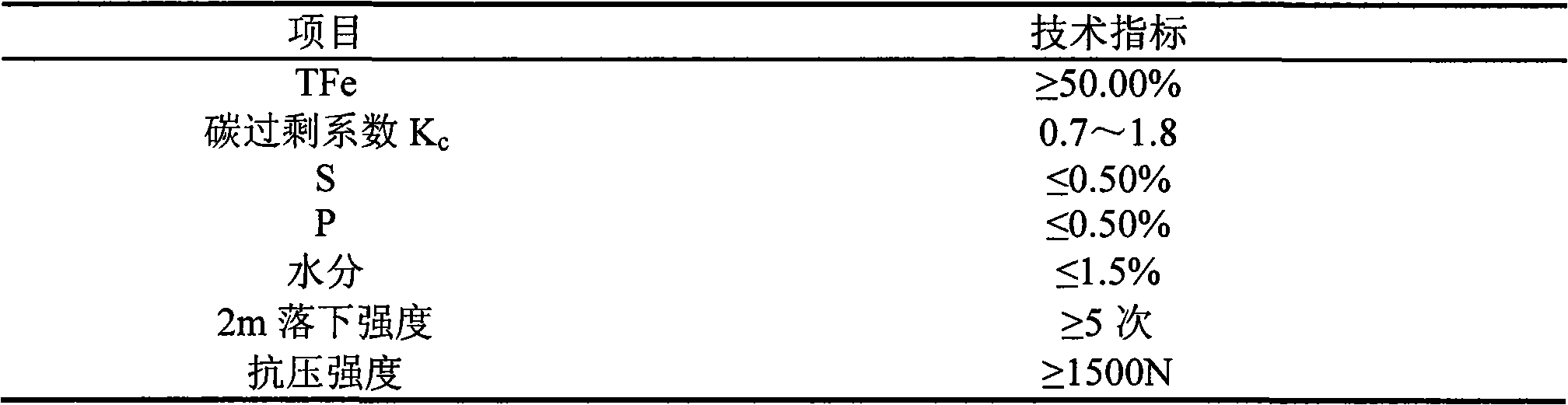

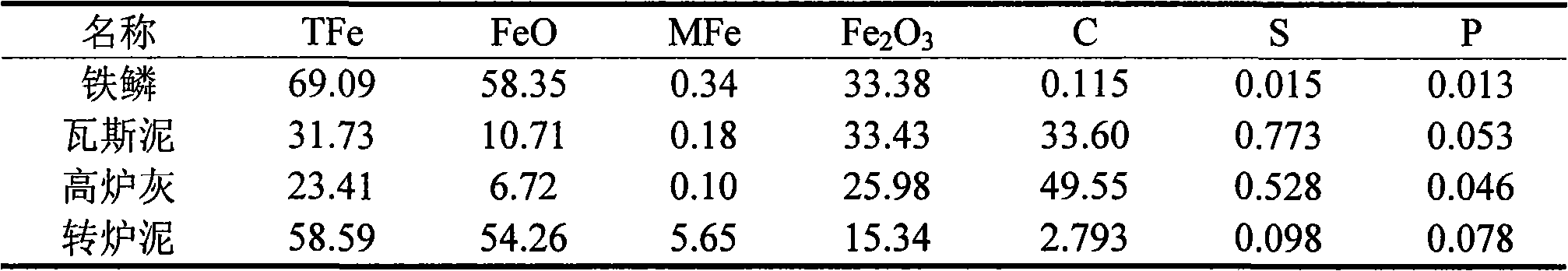

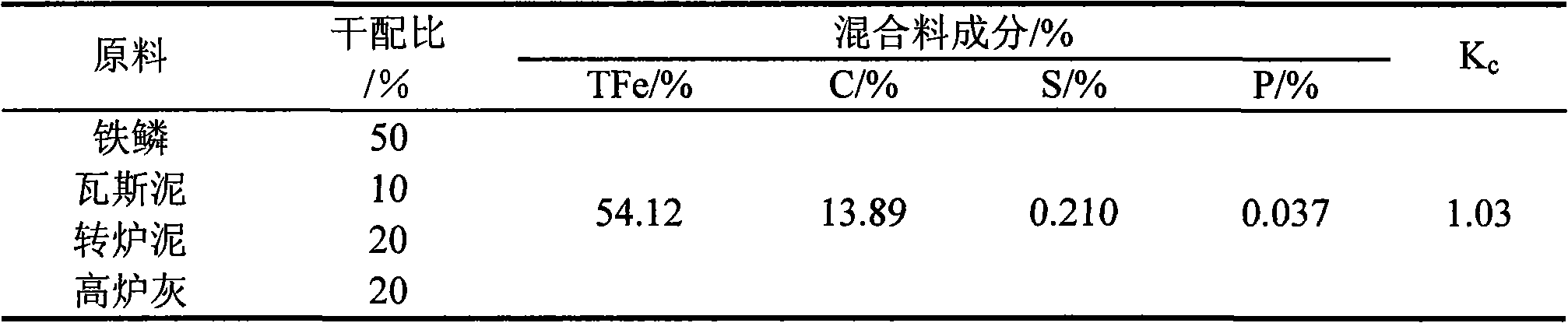

Rotary furnace cooling agent made of metallurgical waste material product and using method thereof

ActiveCN101560583AImprove slag removal effectEmission reductionManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent and a manufacturing method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic waste material and ferreous waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%. The manufacturing method comprises: the wet materials in the carbonic waste material and the ferreous waste material are firstly dried and crushed by a crusher, and then enters a blending machine to be mixed together with the dry materials such as the iron scale and the like; the mixture is added with the caking agent to be evenly mixed, and the mixed material is sent into a mixing mill and then into a twin-roller ball press machine to be pressed into conglomeration; the pressed conglomeration is screened by a sieving machine, and the qualified screened conglomeration can be sent into a dry furnace to be dried, so that the finished product conglomeration can be obtained. The rotary furnace cooling agent completely uses the waste materials generated in the steel production, and can be used for replacing the common waste steel to be applied in smelting of a rotary furnace, so that no special reduction plant is needed for use, the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

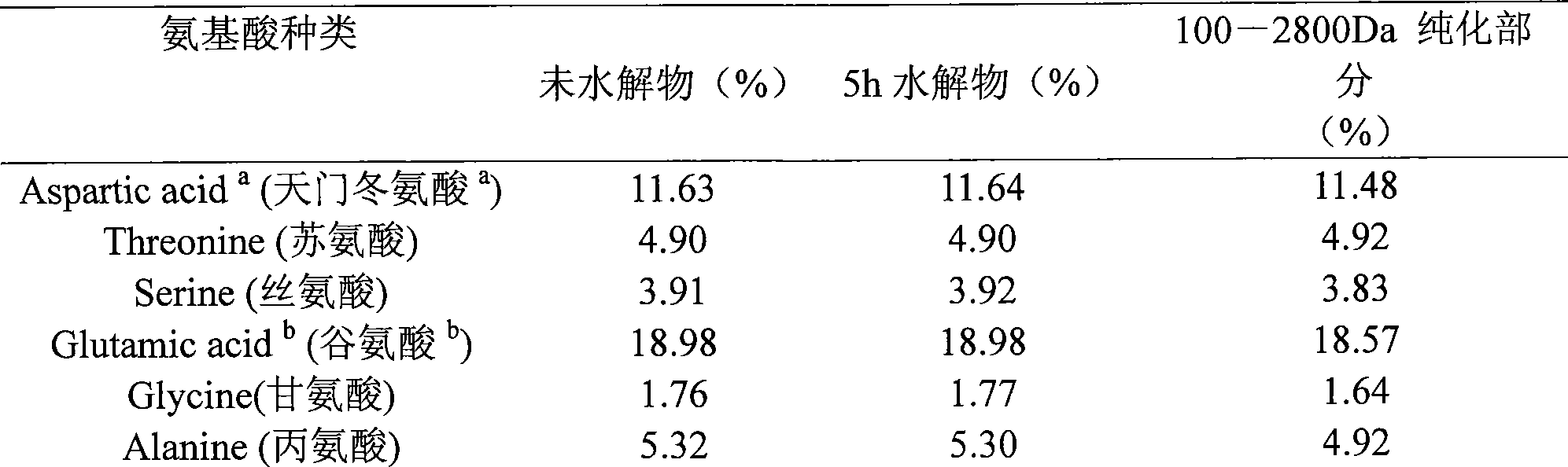

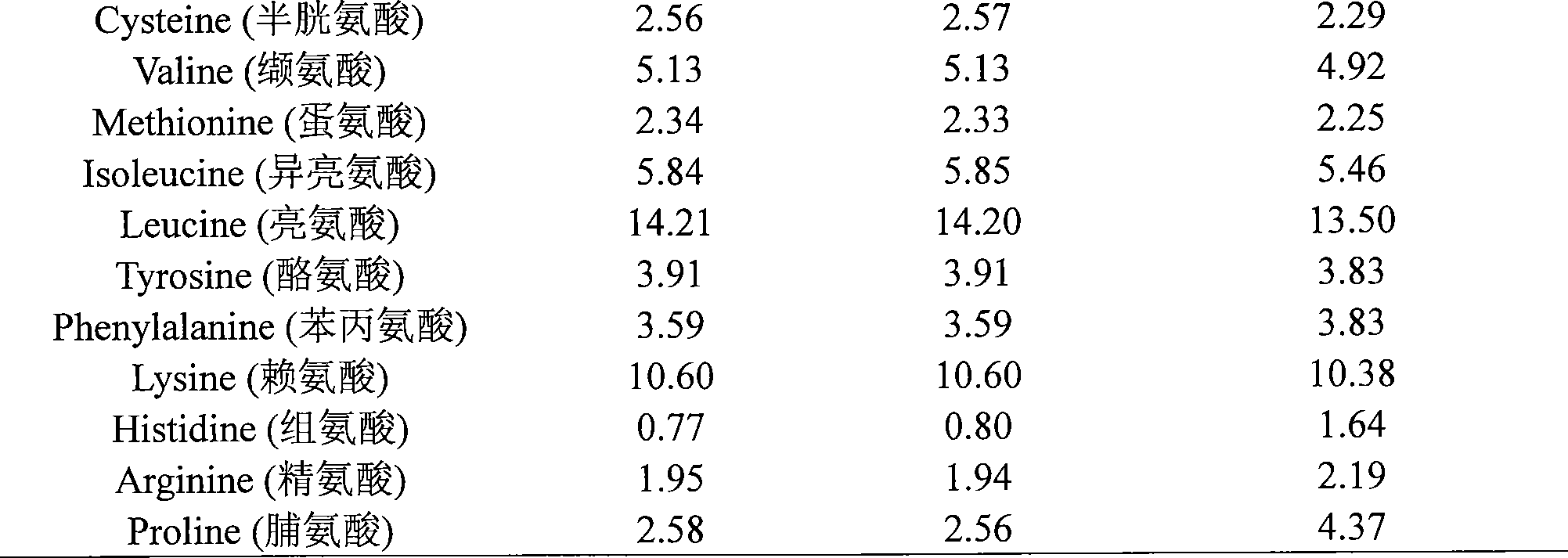

Lactalbumin polypeptide with antioxidation activity and preparation method thereof

InactiveCN101519426AIncrease profitImprove the level of comprehensive utilizationHydrolysed protein ingredientsAntinoxious agentsAlkaline proteaseProteinase activity

The invention discloses a preparation method of lactalbumin polypeptide with antioxidation activity and a product therefrom. The preparation method comprises the following steps: (1) heating lactalbumin; (2) cooling the heated lactalbumin, and adding the cooled lactalbumin in alkali protease for hydrolysis; and (3) obtaining mixed polypeptide which has strongest antioxidation activity with peptide ranging from 100-2800 Da after enzyme inactivation, temperature reduction, concentration and purification by SephadexG-10 gel chromatography column are carried out for the product of the hydrolysis. The prepared lactalbumin polypeptide has higher antioxidation activity and the capability of removing free radical as well as favorable antioxidation both in vitro and in vivo. The preparation method has simple operation, is safe and reliable compared with synthetic antioxidant, is suitable for the commercial process, and can increase the utilization rate of lactalbumin resources substantially and enhance the multipurpose use level of whey.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Preparation method of nylon 6 and natural fiber composite material

The invention discloses a preparation method of a nylon 6 and natural fiber composite material. The method comprises the steps that: 1, natural fiber is pretreated; 2, the pretreated natural fiber is dried for 24h in a lyophilization machine; and the fiber is preheated; 3, nylon 6 monomer caprolactam is heated to 80-130 DEG C and is fused; vacuuming dewatering is carried out; an initiator is added, and vacuuming dewatering is carried out; an activating agent is added, the mixture is well mixed, and vacuuming dewatering is carried out, such that an active material is prepared; and 4, the active material is added into natural fiber; rapid vacuuming is carried out; polymerization is carried out for 0.5-1.5h under a polymerization temperature; and cooling is carried out, such that nylon 6 and natural fiber composite material is obtained. According to the material, a reaction processing method is adopted, such that the natural fiber can be more uniformly dispersed in resin, and composite material interface performance can be improved. The mechanical performance of the material is higher than common nylon 6, and the material has an environment-friendly characteristic. The material has a wide application range.

Owner:SICHUAN UNIV

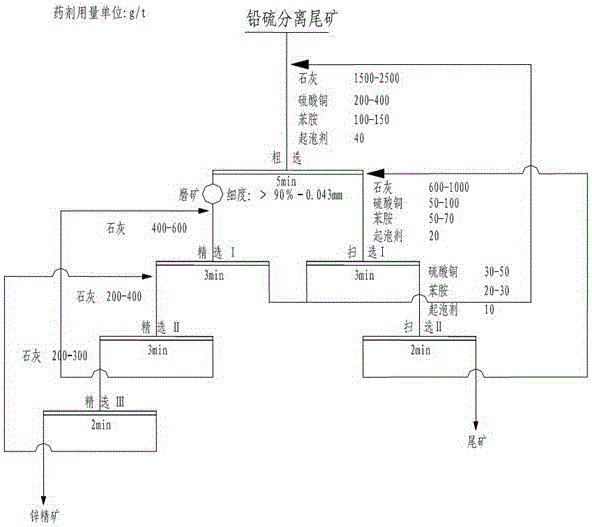

Method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate

InactiveCN106552715AImprove the level of comprehensive utilizationRelieve stressFlotationSulfur productFoaming agent

The invention discloses a method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate. The method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate comprises the steps that firstly, water is added to the separated tailings of the lead-sulfur bulk concentrate, and the mass percent concentration of a pulp is adjusted to be 25%-32%; secondly, an appropriate amount of lime is added so that the pH value of the pulp can be adjusted, and pyrite is inhibited at the same time; thirdly, copper sulfate is added as an activating agent to activate the sphalerite; and finally, a collecting agent, aniline, and a foaming agent are added for flotation of the sphalerite, the flotation procedure comprises one-time rough flotation, two-time scavenging and three-time concentration (after the concentrate obtained through rough flotation is ground to the extent that the ores reaching the grain level of >-0.043 mm account for 90%, concentration is conducted ), and effective concentration of the sphalerite is achieved. According to the sphalerite obtained through the method, the zinc grade is higher than 40%, and the recovery rate of zinc is higher than 80%. By the adoption of the method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate, the zinc lost in the lead-sulfur separated tailings, namely sulfur products, can be well recycled, the comprehensive recovery rate of zinc is improved, and the economic benefits of a concentrating plant are increased.

Owner:KUNMING UNIV OF SCI & TECH

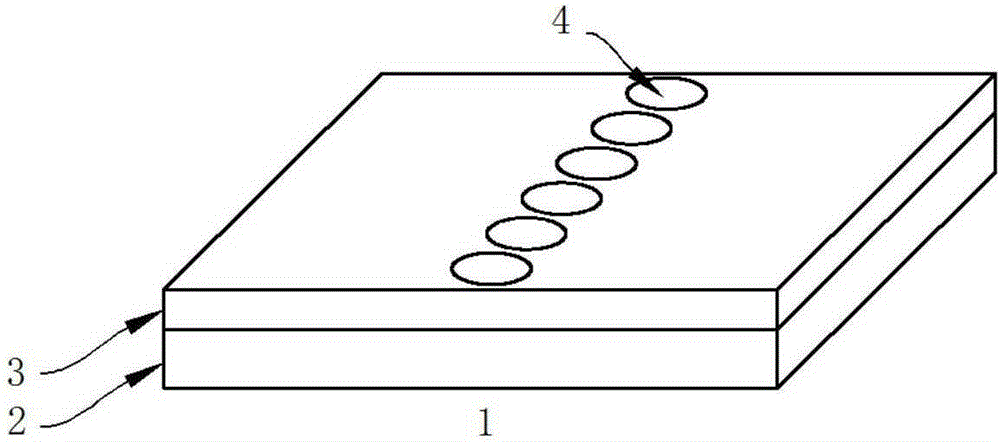

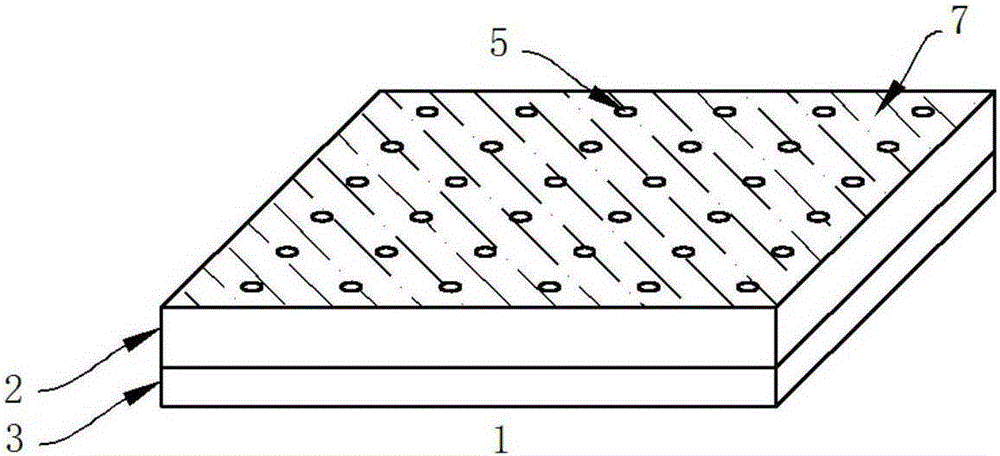

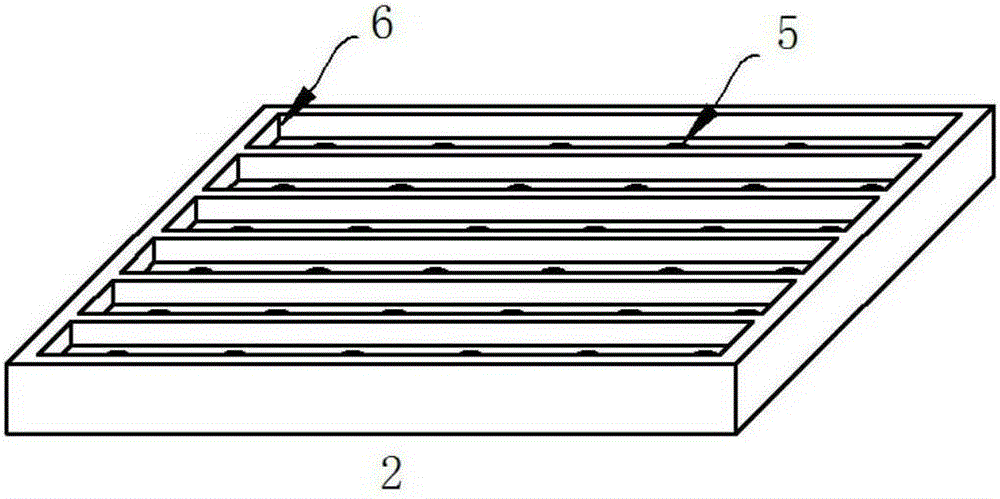

Composite cooling structure for wall of combustion chamber flame tube of aero-engine

InactiveCN105276620AImprove heat transfer effectSmall structure sizeContinuous combustion chamberCombustion chamberScale structure

The invention discloses a composite cooling structure for the wall of a combustion chamber flame tube of an aero-engine. The composite cooling structure is composed of a bottom plate wall (2) and a cover plate wall (3). The interior of the bottom plate wall (2) is cut into six parallel-connection micro-scale channel grooves (6) in the flowing direction of the flame tube, and six small air outlet through holes (5) are formed in the center line of each cut micro-scale channel groove (6). Large air inlet through holes (4) are formed in the position, corresponding to each cut micro-scale channel groove (6), of the cover plate wall (3). The bottom plate wall (2) and the cover plate wall (3) are welded into a whole, after welding is finished, bending treatment is carried out in the circumferential direction of the flame tube, and the side wall of the bottom plate wall (2) is coated with a heat barrier coating (7). According to the cooling structure, micro-scale channel cooling and diffusion hole air film cooling are combined, the micro-scale structure is fully utilized for enhancing heat transfer, and the cooling capacity of cooling air flow is achieved. The structural design and machining are simple, and the cooling structure can be achieved easily in actual machine types.

Owner:中航空天发动机研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com