Coal decomposing equipment

A material and equipment technology, applied in the field of coal decomposition equipment, can solve the problems of low added value, inability to be heated uniformly, decomposition, pollution, etc., to achieve the effect of saving and utilizing energy, improving utilization rate and utilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

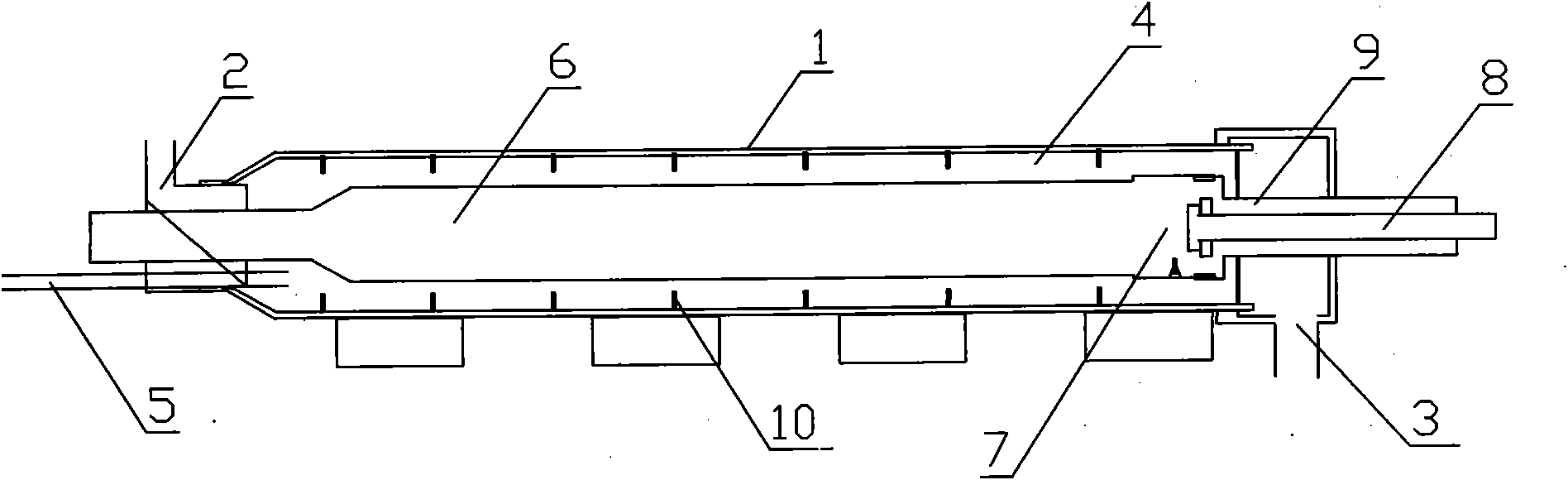

[0023] Such as figure 1 Shown: a kind of coal material decomposition equipment, including a closed kiln body 1 with a material inlet 2 and a material outlet 3, the kiln body 1 is a horizontal kiln, a rotary kiln body, and a flame gas is set inside the kiln body 1 The pipeline heating mechanism, the coal substance propelling decomposition channel 4 formed between the flame gas pipeline heating mechanism and the inner wall of the kiln body 1, the coal decomposition gas collection pipe 5 communicating with the coal substance propelling decomposition channel 4 is arranged on the kiln body 1, A push plate 10 is arranged on the inner wall of the kiln. The flame pipeline heating mechanism includes a flame heat dissipation pipe 6 and a combustion chamber 7 , and the combustion chamber 7 communicates with a fuel supply pipe 8 and an air supply pipe 9 arranged outside the kiln body 1 . The fuel in the fuel supply pipe 8 and the air in the air supply pipe 9 are mixed and burned in the c...

Embodiment 2

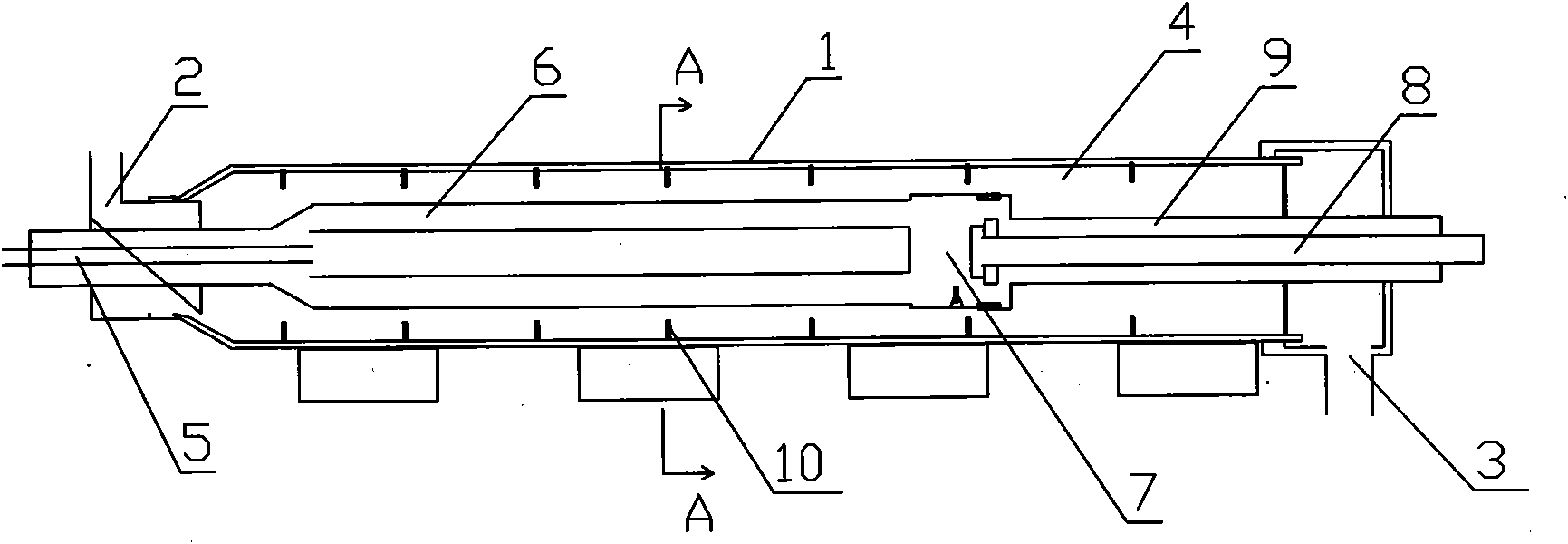

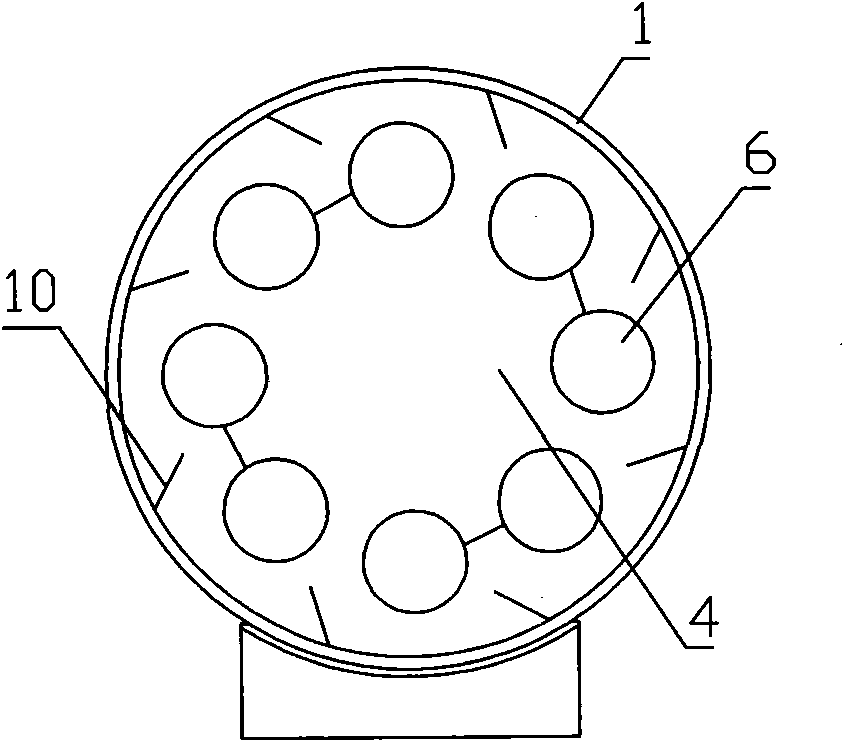

[0025] Such as figure 2 , image 3 Shown: a kind of coal material decomposition equipment, including a closed kiln body 1 with a material inlet 2 and a material outlet 3, the kiln body 1 is a horizontal kiln, a rotary kiln body, and a flame gas is set inside the kiln body 1 The pipeline heating mechanism, the coal substance propelling decomposition channel 4 formed between the flame gas pipeline heating mechanism and the inner wall of the kiln body 1, the coal decomposition gas collection pipe 5 communicating with the coal substance propelling decomposition channel 4 is arranged on the kiln body 1, A push plate 10 is arranged on the inner wall of the kiln. The flame pipeline heating mechanism includes a flame heat dissipation pipe 6, a combustion chamber 7, and a fuel supply pipe 8 and an air supply pipe 9 in communication. The flame heat dissipation pipe is a plurality of parallel close-packed pipes or tube-like close-packed pipes, which can transfer the generated heat to ...

Embodiment 3

[0027] Such as Figure 4 Shown: a kind of coal material decomposition equipment, including a closed kiln body 1 with a material inlet 2 and a material outlet 3, the kiln body 1 is a vertical kiln, the kiln body 1 is provided with a flame gas pipeline heating mechanism, The coal substance propelling decomposition channel 4 formed between the flame gas pipeline heating mechanism and the inner wall of the kiln body 1, the coal decomposition gas collection pipe 5 communicating with the coal substance propelling decomposition channel 4 is arranged on the kiln body 1, and the kiln body wall is provided Push plate 10. The flame pipeline heating mechanism includes a flame heat dissipation pipe 6 , and the flame heat dissipation pipe 6 is connected with a combustion chamber 7 , a fuel supply pipe 8 and an air supply pipe 9 arranged outside the kiln body 1 . The flame heat dissipation pipe is a plurality of parallel close-packed pipes or tube-like close-packed pipes, which can transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com