Selection method for copper sulfide copper minerals and associated elements thereof

A technology of associated elements and copper sulfide ore, applied in flotation, solid separation, etc., can solve the problems of difficulty in guaranteeing the grade of copper concentrate, low recovery rate of associated elements, and difficult separation of copper and sulfur, so as to save flotation energy consumption , improve the grade and recovery rate, and reduce the effect of lime consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

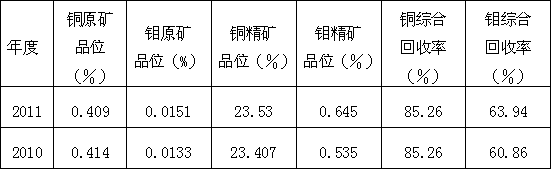

[0030] The actual production capacity of Jiangxi Copper Company's Dexing Copper Mine Dashan Concentrator is 92,000 t / d. It processes ores from the copper factory and the Fujiawu mining area. The beneficial components in the ore are mainly copper, accompanied by molybdenum, gold, silver and sulfur, etc. Beneficial components and rare metals such as rhenium, selenium, tellurium, bismuth, platinum, and palladium;

[0031] Molybdenum is the main associated element of ores in the two mining areas of Dexing Copper Mine, and its minerals are also the main carrier minerals of rare metals such as rhenium; with the increase of metal prices, how to fully recover copper while strengthening the recovery of molybdenum and other associated elements is an increasing An important subject of economic benefits, with great economic significance;

[0032] Process flow: The flotation process in the roughing section consists of one roughing, one copper-sulfur mixed roughing, and two sweepings. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com