Patents

Literature

115results about How to "Expand the scope of selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

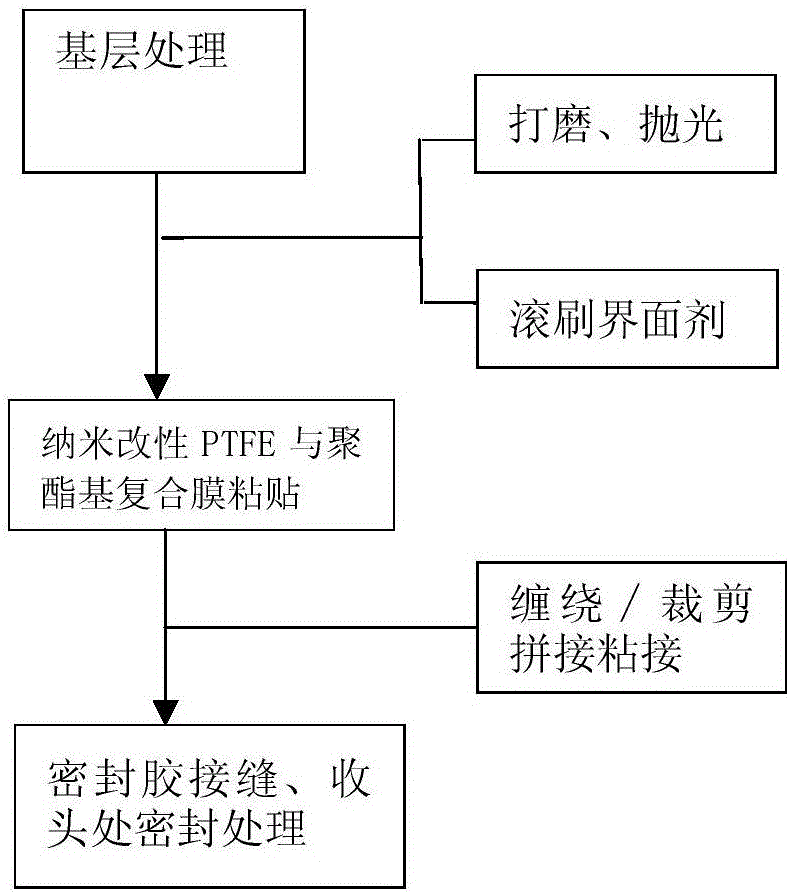

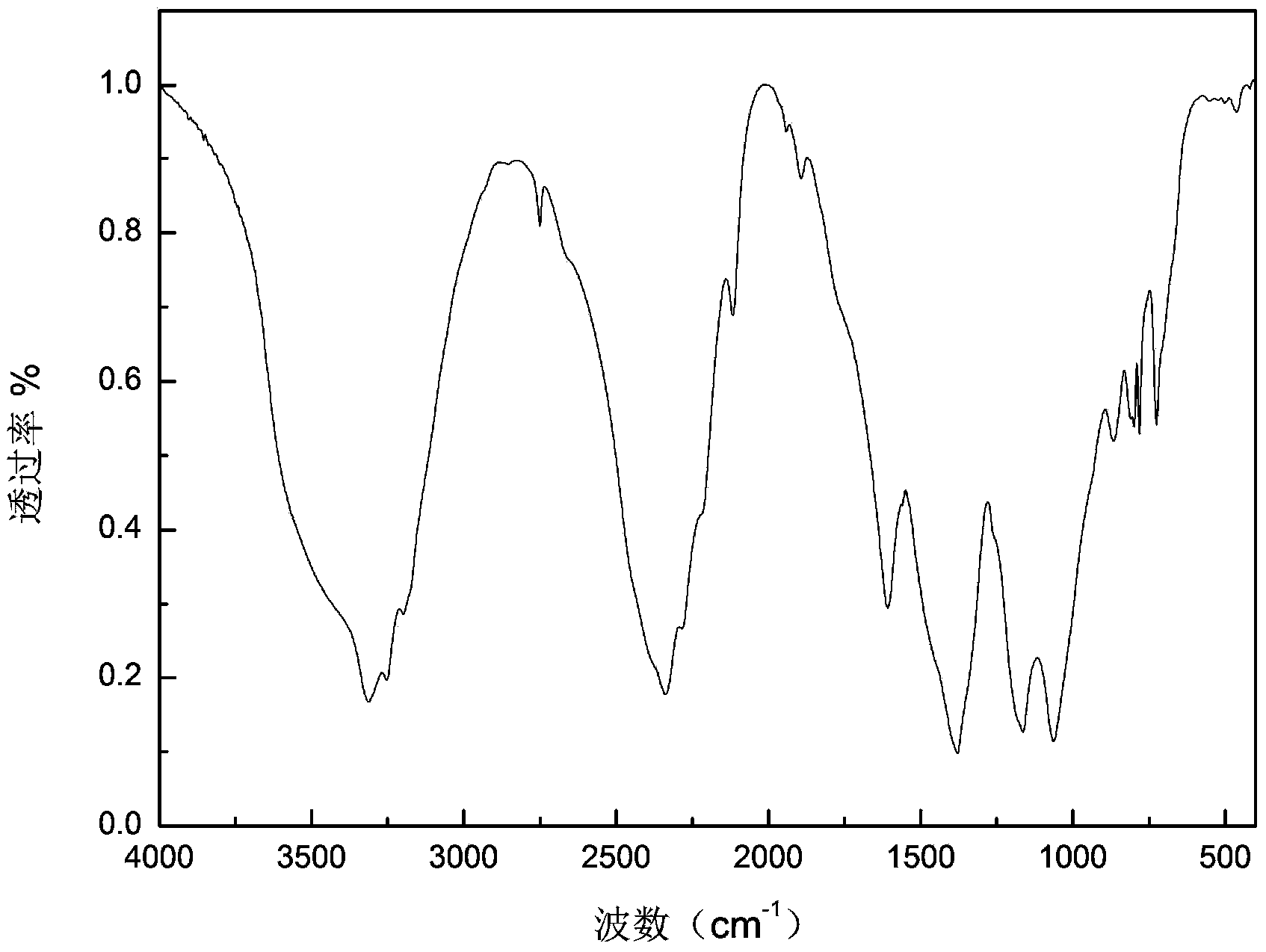

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

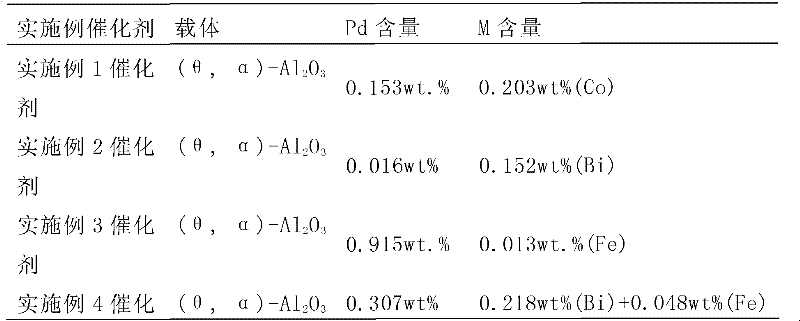

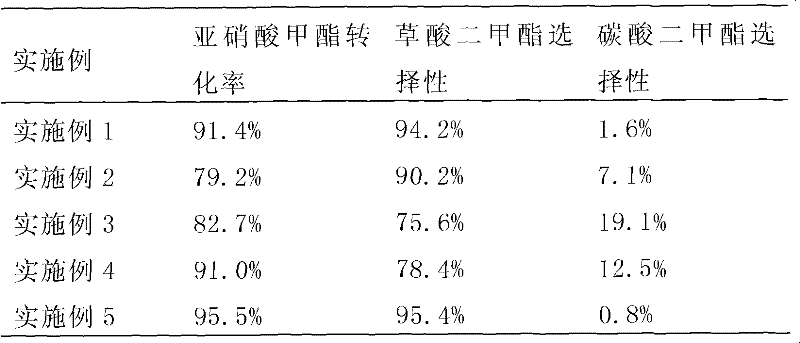

Supported catalyst used in selective synthesis, and preparation method and purpose thereof

ActiveCN102218330AExpand the scope of selectionTo achieve selective regulationOrganic compound preparationPreparation by carbon monoxide or formate reactionActive componentCatalyst support

The invention relates to a supported catalyst used in selective synthesis. The catalyst comprises a main active component, an auxiliary active component, and a catalyst carrier. The main active component is Pd and / or its oxide, wherein the weight percentage content of the main active component is 0.01% to 1.0%. The auxiliary active component is at least one of the metals of Fe, Ni, Co, and Bi, and / or at least one of the oxides of the metals of Fe, Ni, Co, and Bi, wherein the weight percentage content of the auxiliary active component is 0.01% to 0.5%. The left component is Al2O3, which is thecatalyst carrier. The invention also relates to a preparation method and a purpose of the catalyst. As an experiment result, with the adding of the catalyst, relative selectivity of mesoxalic dimethyl ester and dimethyl carbonate in reaction products can be modulated.

Owner:PUJING CHEM IND SHA +1

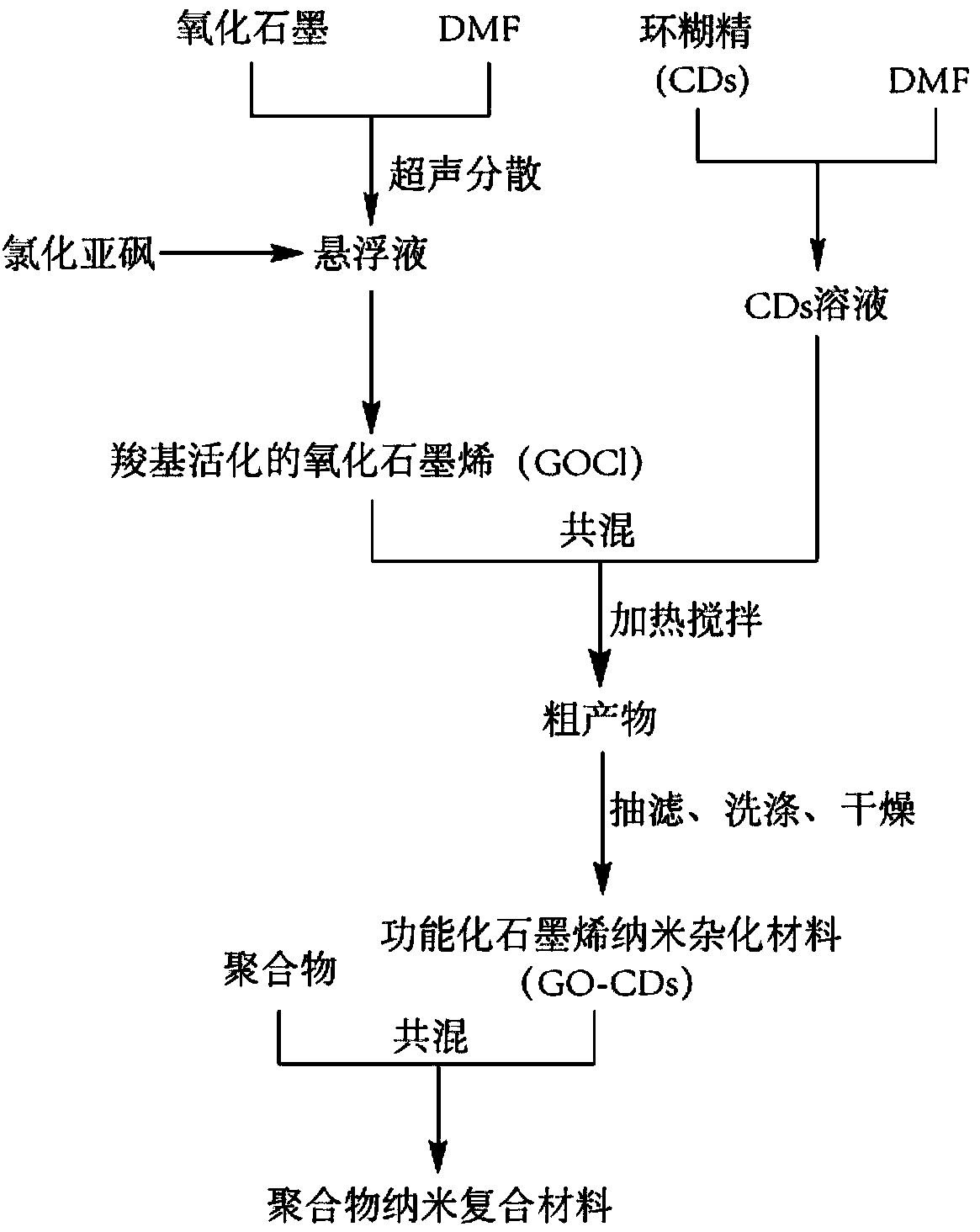

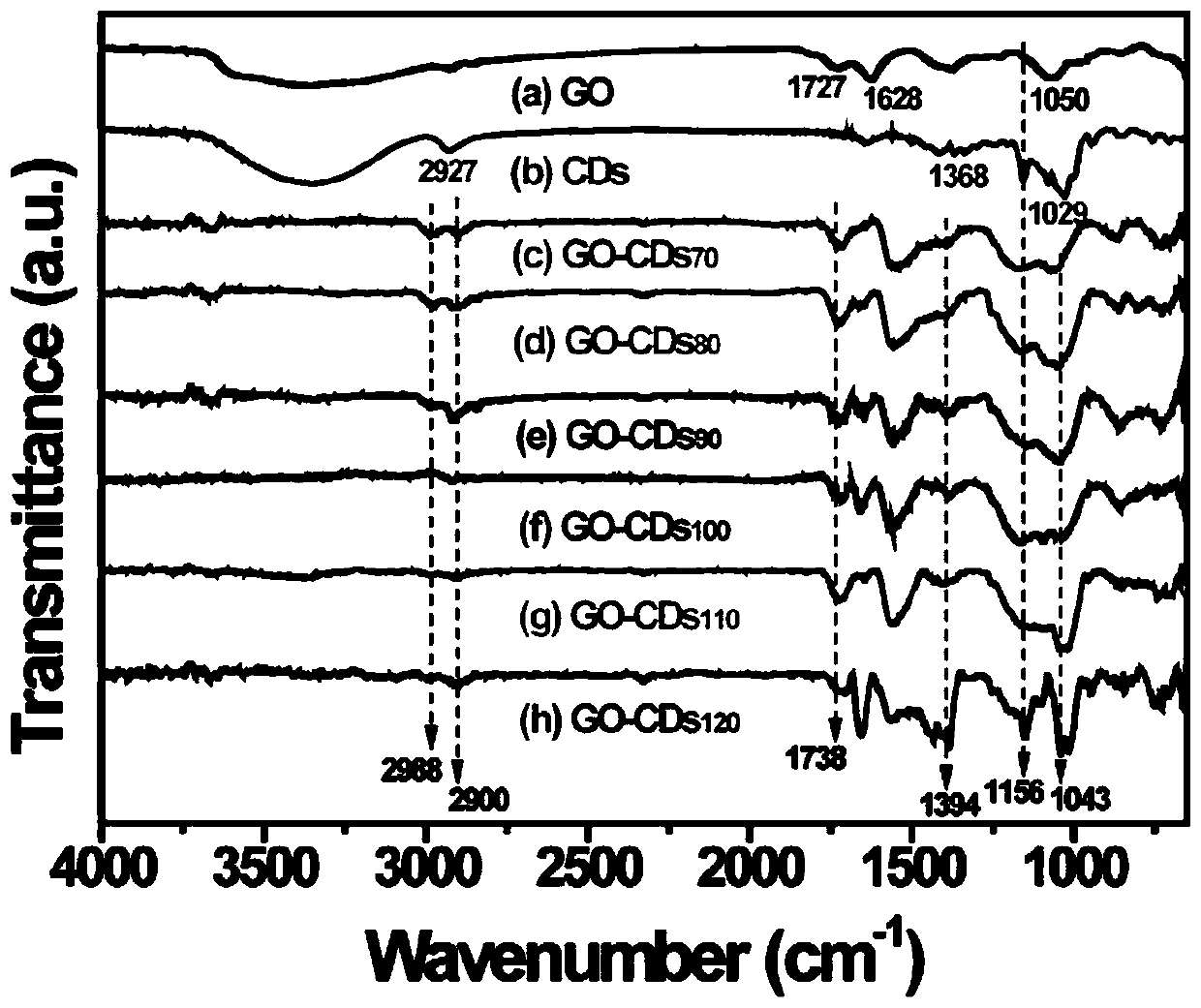

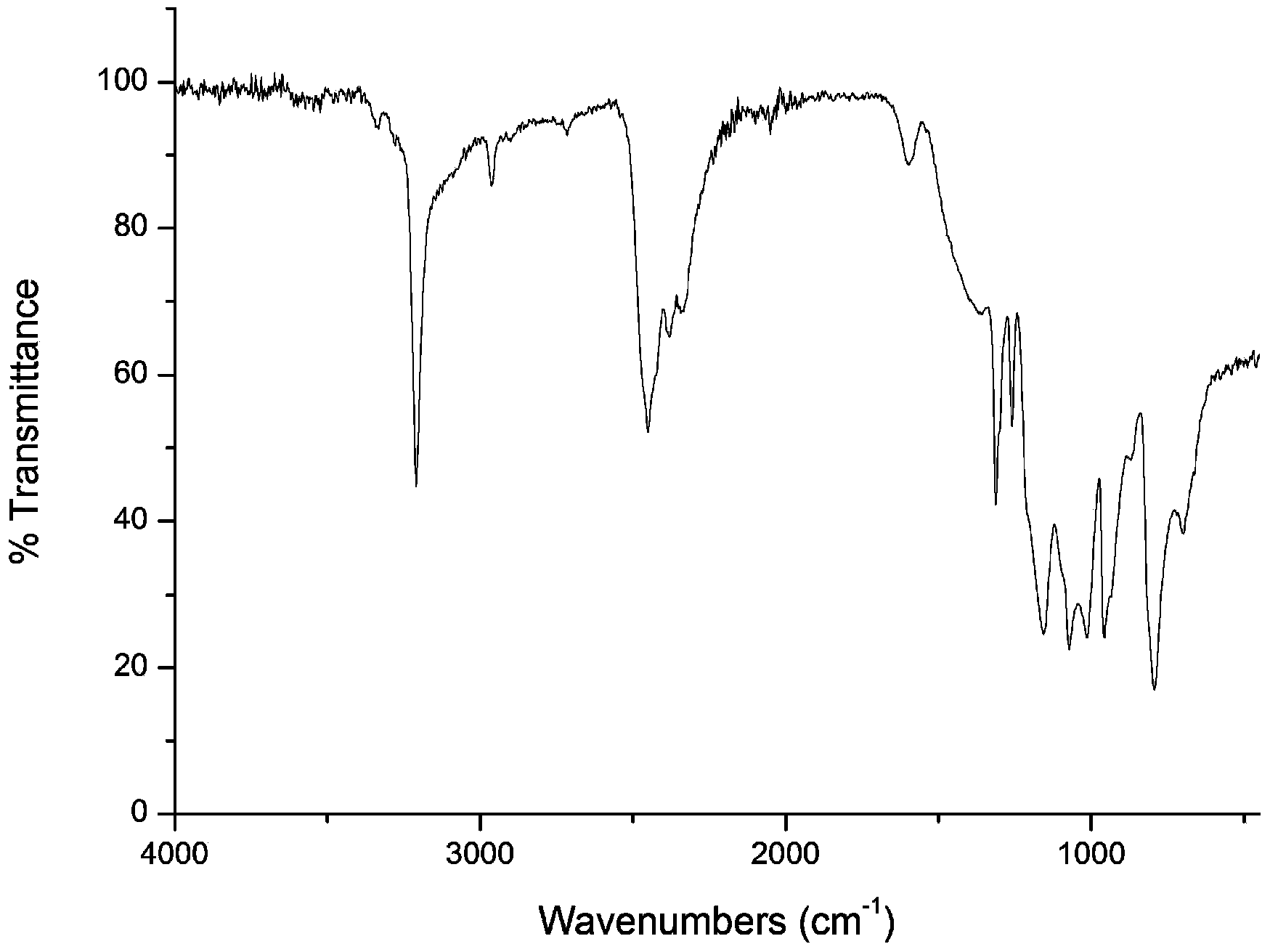

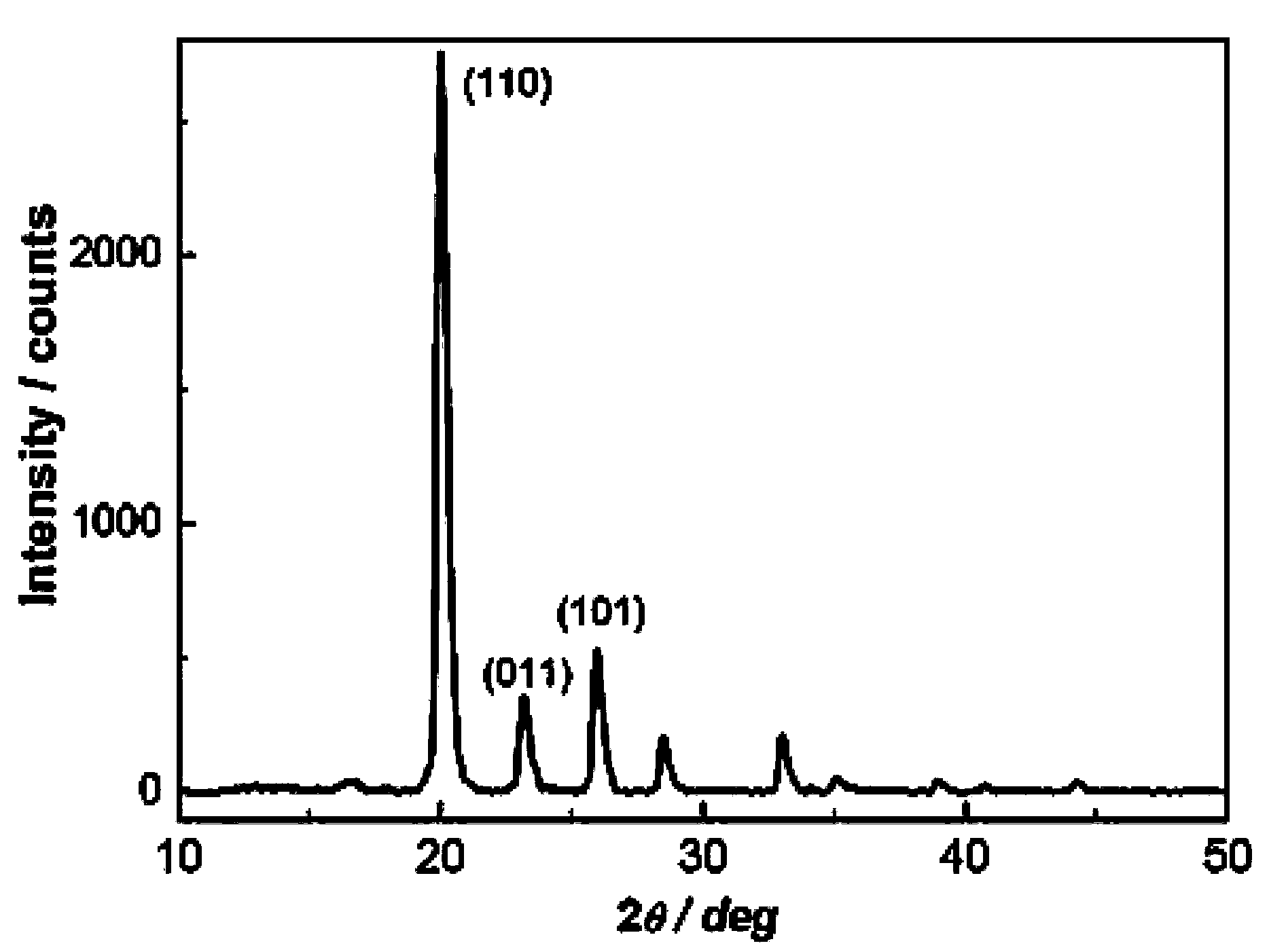

Polymer based nanocomposite and preparing method thereof

The invention discloses a polymer based nanocomposite and a preparing method thereof. According to the invention, an organic covalent modification technology is adopted, polyhydroxy cyclodextrin molecules are anchored on a graphene oxide nanosheet through a coupling agent, excellent dispersion in various solvents is realized through utilizing the hydroxyl on the cyclodextrin to simulate the characteristic that the graphene oxide is enriched with oxygen species, the capacity of cyclodextrin on the graphene oxide is controlled through adjusting the reaction temperature, further the solvent dispersing performance and thermal stability of functionalized hybrid materials can be effectively regulated and controlled; besides, the solvent blending technology is adopted, the cyclodextrin functionalized grapheme based nano hybrid materials are used as fillers to prepare different-polymer based nanocomposite; through the adoption of the method, the intermolecular and intramolecular interfacial interaction are further enhanced so as to improve the thermal stability of the functionalized nano materials and polymer based nanocomposite adopting the nano materials as fillers, besides, the synthetic steps are simple and efficient, the aftertreatment is simple and concise, and large-scale preparation is facilitated.

Owner:NANJING UNIV OF SCI & TECH

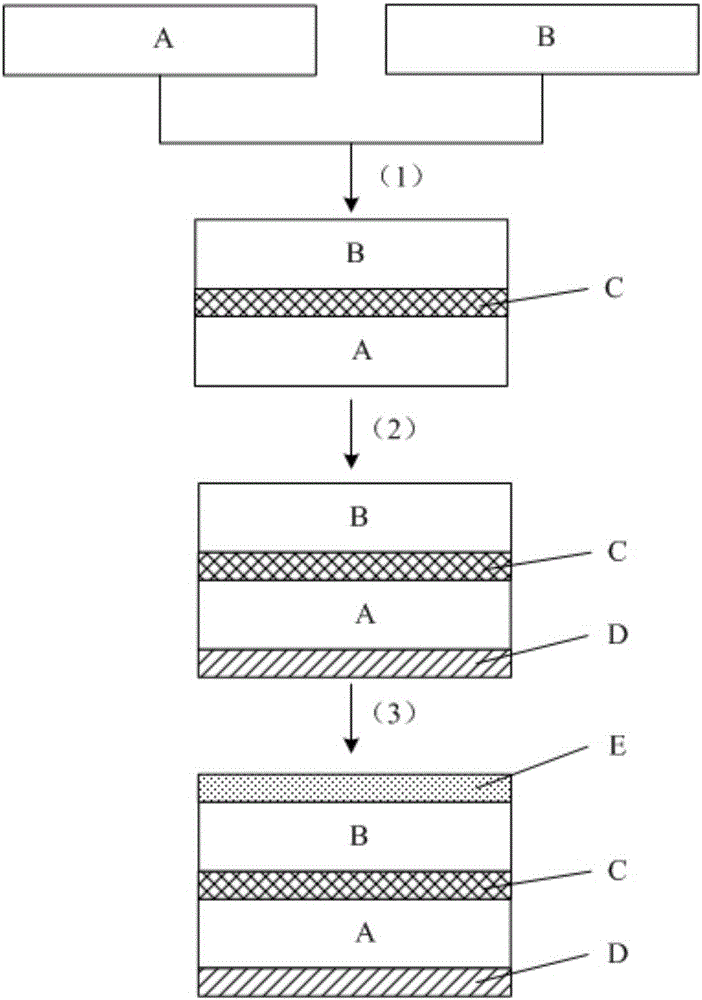

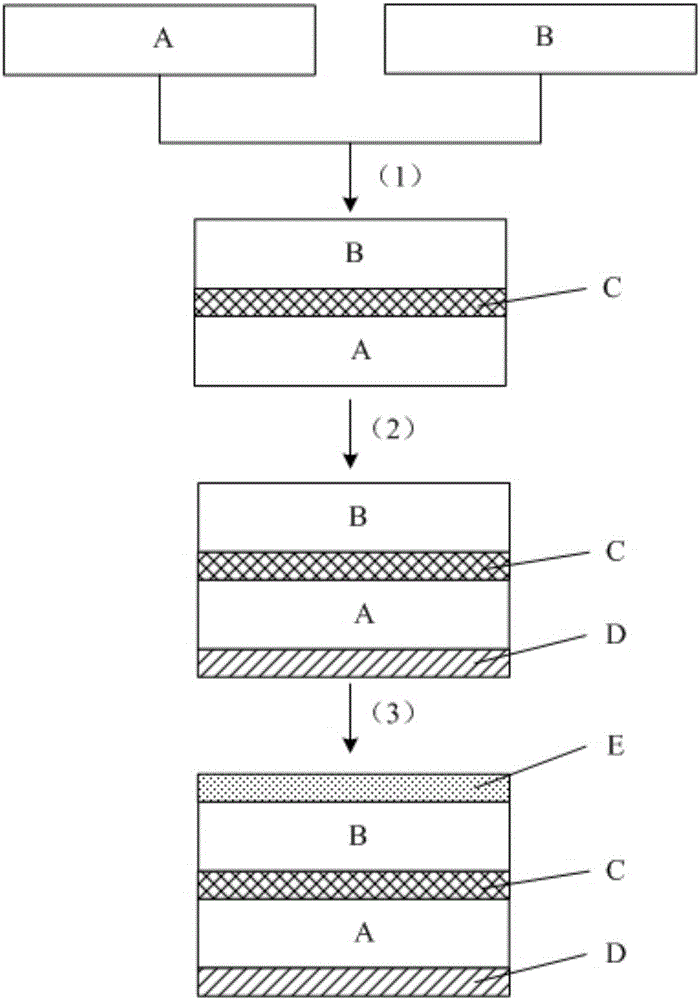

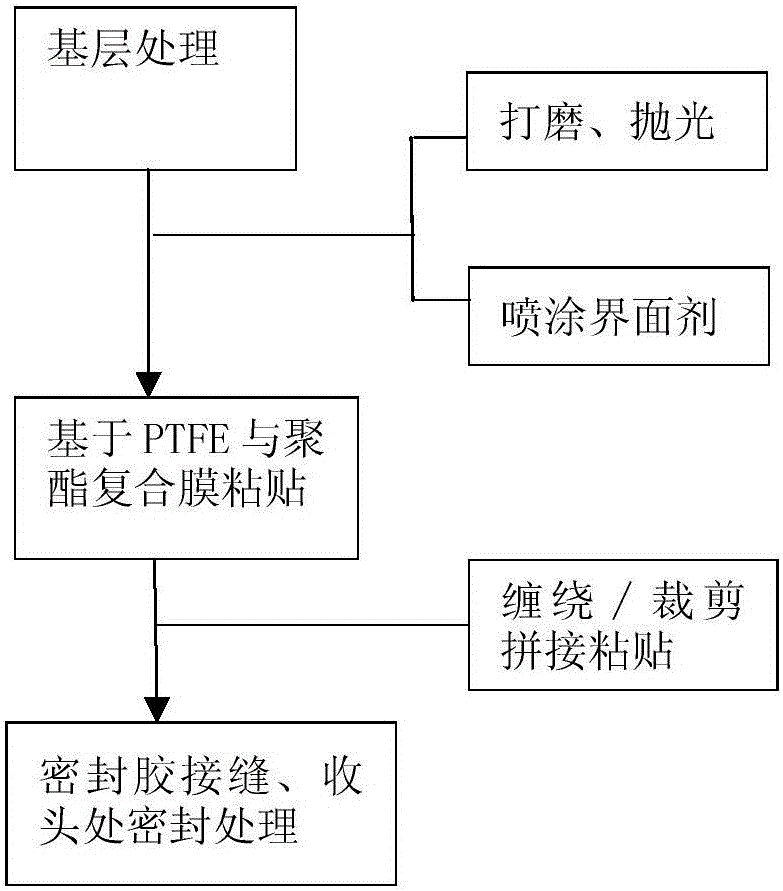

Preparation method and application of PTFE and polyester-based composite film for preventing wind turbine blades from icing

ActiveCN106313812AHigh peel strengthHigh bonding strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterBenzoyl peroxide

The invention discloses a preparation method and application of a PTFE and polyester-based composite film for preventing wind turbine blades from icing. The method includes the steps that a bonding composite agent is adopted for lamination complexing, an interface adhesive is applied, and a pressure-sensitive adhesive is adopted for photo-initiated pressure-sensitive adhesive application. The bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, benzoyl peroxide and (4)ethoxylated bisphenol A dimethacrylate; the photo-initiated pressure-sensitive adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, butyl acrylate, (4)ethoxylated bisphenol A dimethacrylate, 4,4'-bis(diethylamino)benzophenone and dimethylformamide. The method and the composite film solve the non-adhesion technical problem that a PTFE film can not be pasted on the surfaces of wind turbine blades with an adhesive directly, the bonding peel strength is improved, and the composite film is suitable for wind turbine blades of various models.

Owner:NANJING HAOHUI HI TECH CO LTD

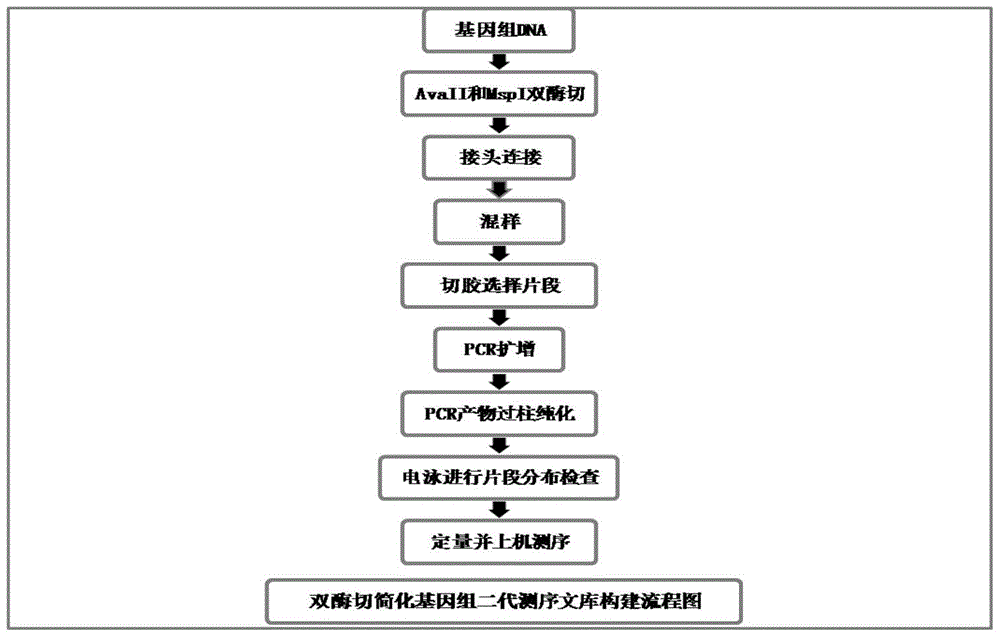

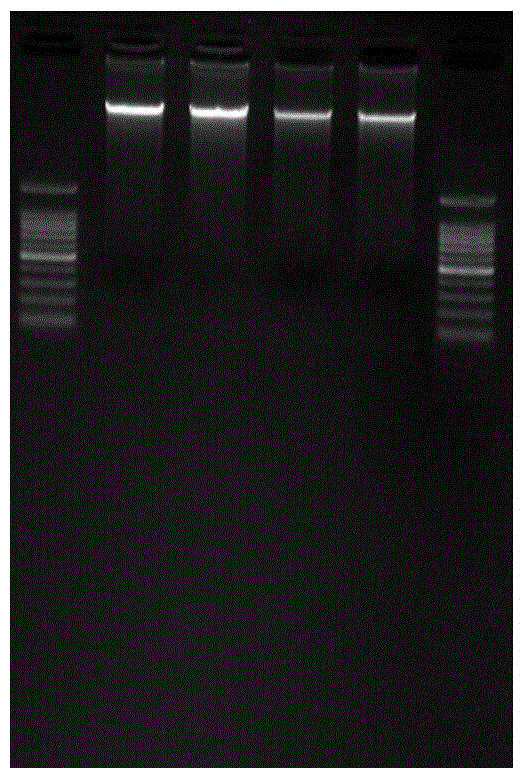

Construction method for double enzyme digestion simplified genome next generation sequencing library and matched kit

InactiveCN105696088AGet rid of dependenceSimplify the library building processMicrobiological testing/measurementLibrary creationGenomic sequencingEnzyme digestion

The invention provides a construction method for a simplified genome next generation sequencing library based on double enzyme digestion and a kit. Aiming at defects of an existing construction method for the double enzyme digestion simplified genome next generation sequencing library, the double enzyme digestion combined range is expanded, and excessive dependence on expensive instruments of constructing the simplified genome library is reduced, the library construction flow path is simplified, library construction cost is reduced, the sequencing efficiency is improved, and meanwhile the technology is easy and flexible to operate and easier for researchers to master and can be realized in a common molecule lab. The construction method is particularly suitable for miniature or medium-scale labs needing to conduct SNP molecular marker development, genetic map construction, population genetics research, phylogeny biological research and the like on a great number of species with incomplete reference genomes. The construction method has good practical application value and application prospects in the fields of molecular breeding of agriculture, conservation biology and evolutionary biology.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI

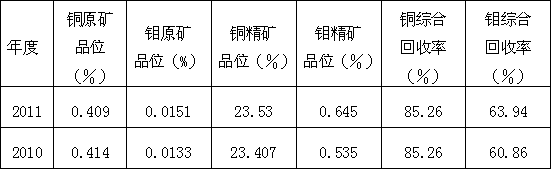

Selection method for copper sulfide copper minerals and associated elements thereof

The invention belongs to mineral processing field, relates to a beneficiation method, and particularly relates to a selection method for copper sulfide copper minerals and associated elements thereof. The method comprises rapid flotation, bulk flotation and selection period flotation. The rapid flotation step is composed of one-time rougher flotation and one-time selection. The bulk flotation step is composed of one-time copper-sulfur mixing rougher flotation and two-time scavenging. The selection period flotation step is composed of one-time rougher flotation, two-time selection, and three-time scavenging. By means of the selection method for the copper sulfide copper minerals and the associated elements thereof, rapid flotation is conducted on rough concentrate, pyrite is little in content, copper minerals are mainly monomers and rich aggregates, and selection is conducted under a weak alkali environment, so that lime is saved, and recycling of the associated elements is guaranteed at the same time. Bulk flotation is conducted on the rough concentrate, pyrite and copper-poor aggregates are high in content, regrinding high-alkali separation process is adopted, and therefore the tenor and the recovery rate of copper are enabled to be high.

Owner:JIANGXI COPPER

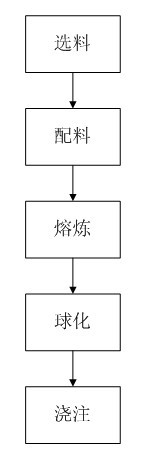

Production method of cast state high extension rate ductile iron

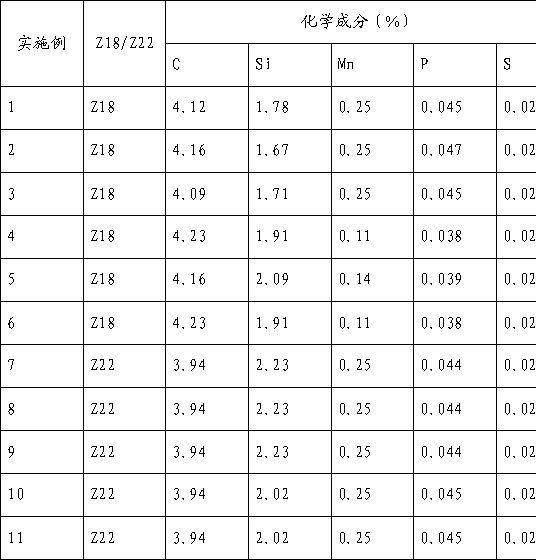

InactiveCN1948534AShorten the production cycleEnhanced self-expanding and refilling capabilitiesChemical compositionSilicon alloy

A method to produce as-cast spheroidal graphite iron with high elongation percentage is disclosed, which belongs to the field of casting technique. Steps of the method are as follows: One of foundry pigs such as Z18 or Z22 is taken as material. Based on weight proportion, there are 35-95% pig iron of Z18 or Z22, returns<55%, scrap steel <12% and 0.6-2.5% ferro-silicon. Prepared materials are melted in furnace and nodularized by shocking, in which the addition of nodularizer is 1.4-1.8% of weight of melted iron. Nodularizer is covered and compacted with 75 size ferro-silicon which is 0.3-0.5% of melted iron. The 75 size ferro-silicon is inoculated again before discharging melted iron to nodularize. Weight proportion of chemical constitution of nodularized melted iron is C3.5-4 %,Si2.6-3.2%,Mn0.15-0.5%,P<=0.06%,S<=0.03%. Nucleating agent is used for instantaneous inoculation when extending cast, which can get as-cast spheroidal graphite iron with high elongation percentage. The method can lower cost, shorten production cycle of casts and extend preferred range of materials. Casts are not tend to get shrinkage voids. None or small quantity of ferro-silicon alloy is added in furnace rear, which can save cost.

Owner:CHAGNSHU QIANJINDING CASTING

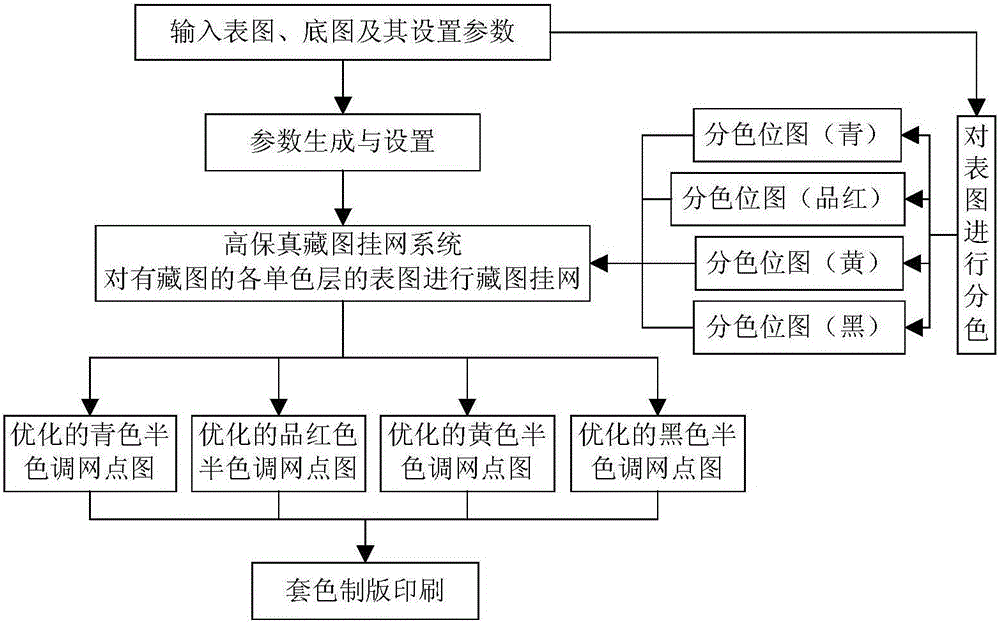

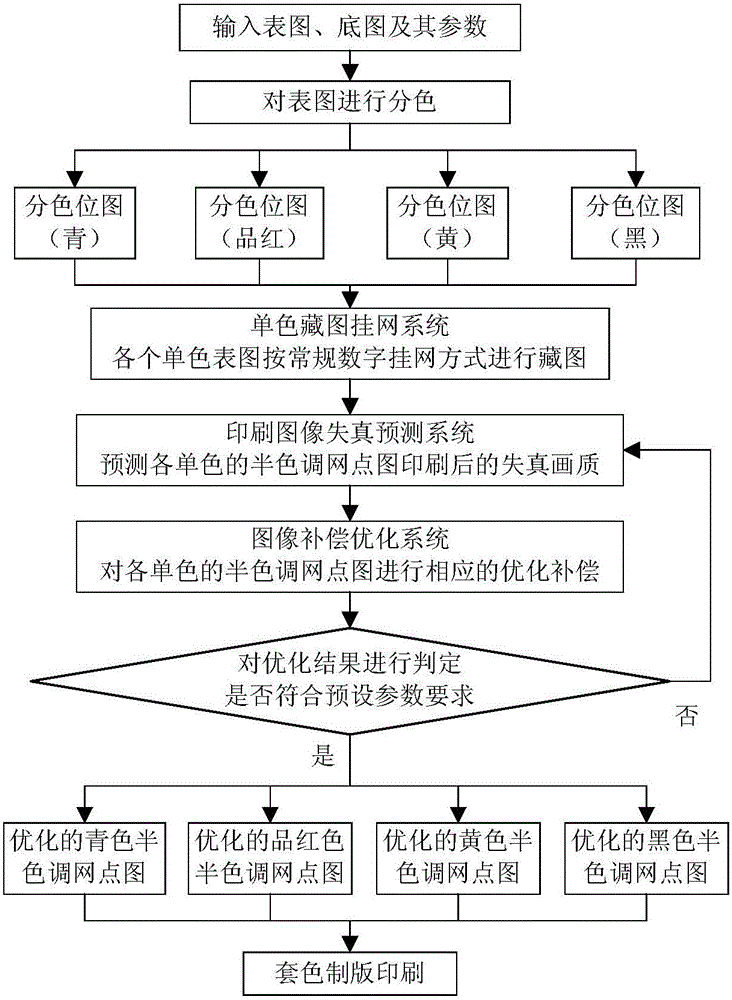

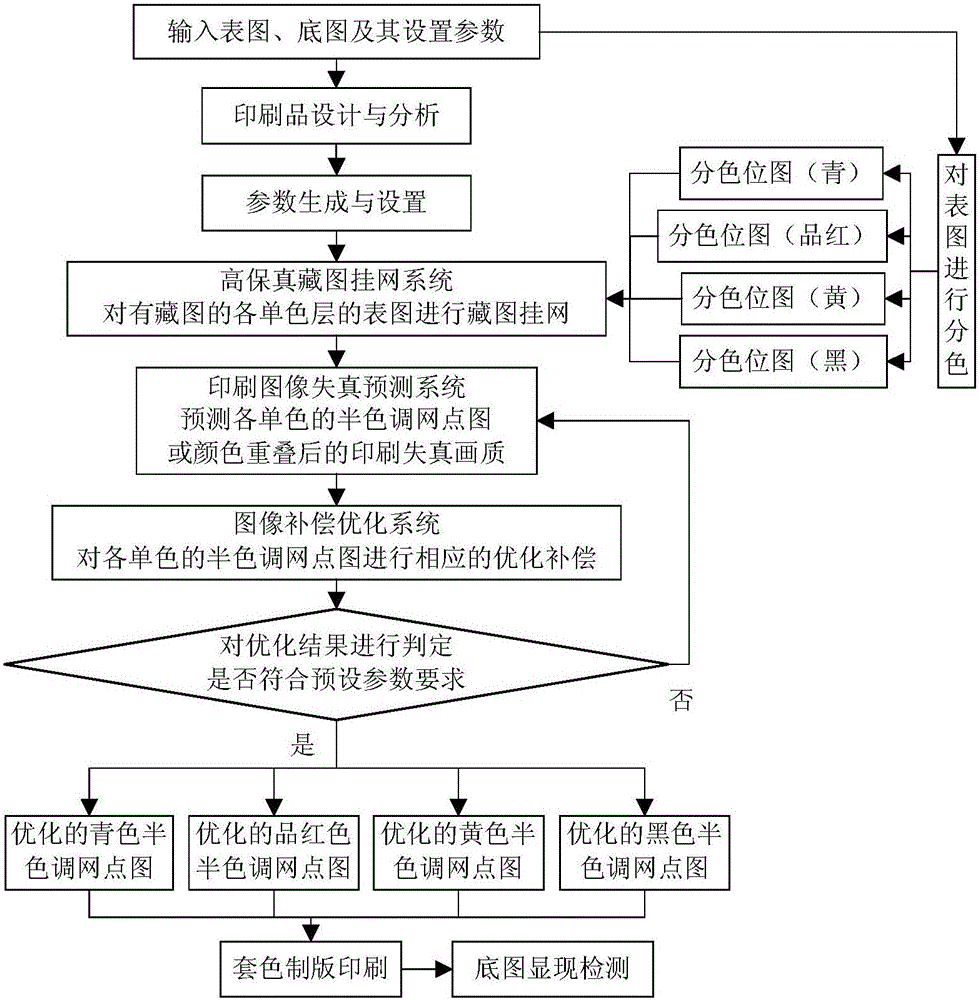

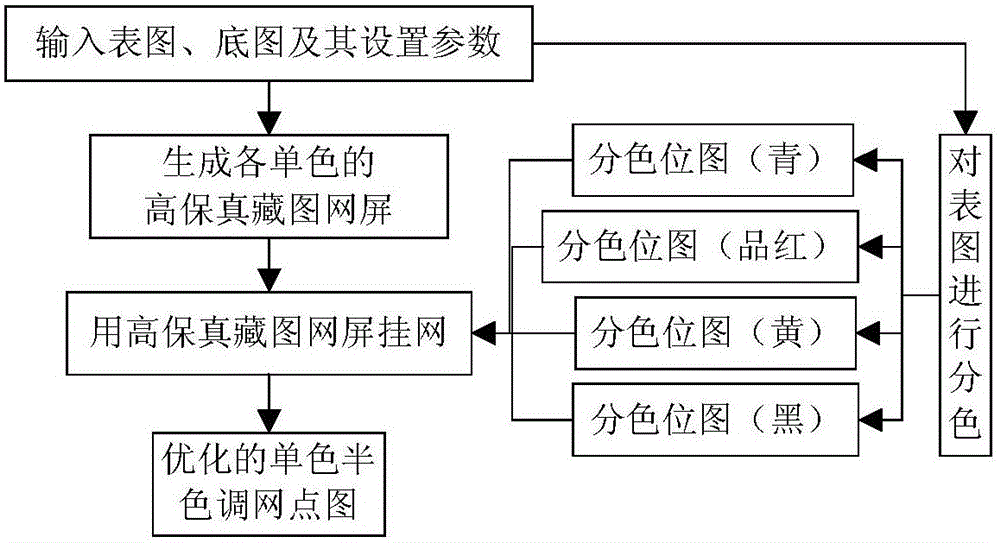

Anti-counterfeiting method based on high-fidelity hidden figure and anti-counterfeiting system thereof

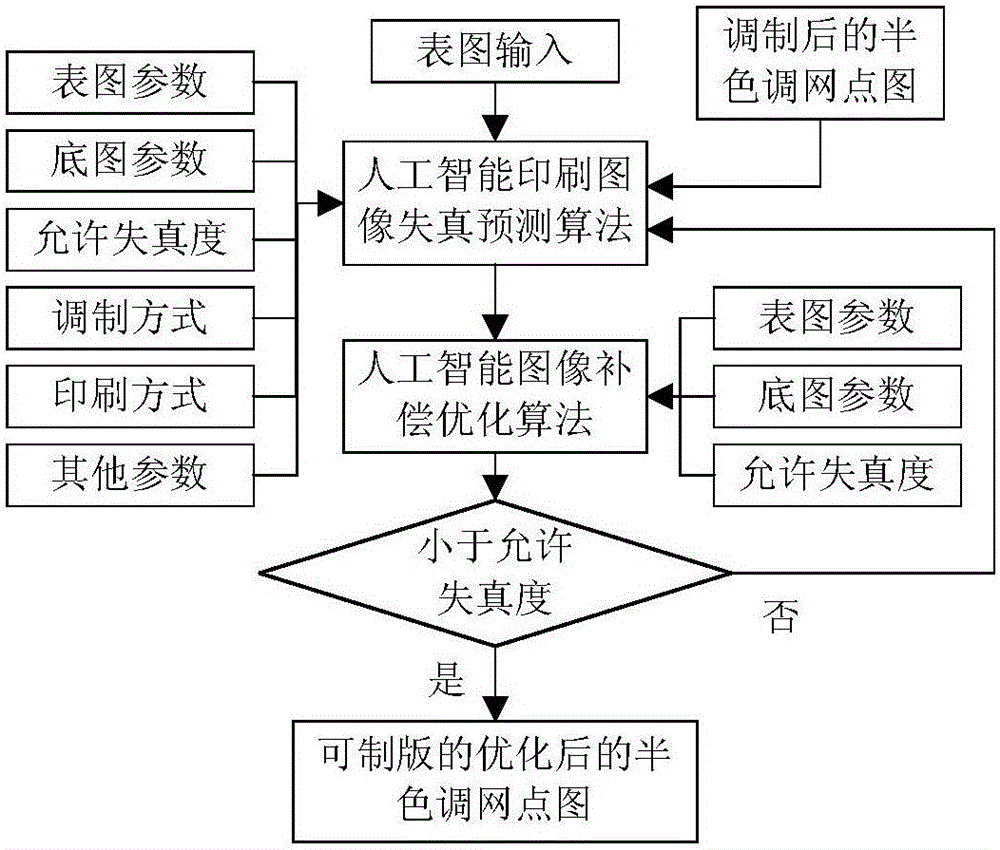

ActiveCN106203567AIntuitive chart effectImprove fidelityRecord carriers used with machinesAlgorithmImaging quality

The invention provides an anti-counterfeiting method based on a high-fidelity hidden figure and an anti-counterfeiting system thereof, and belongs to the technical field of counterfeiting prevention. A surface figure, underlying figures and the corresponding relation thereof are analyzed by using a hidden figure print pre-printing analysis module so that concrete parameter settings are generated. Then the multilayer high-definition underlying figures are hidden by using a high-fidelity hidden figure digital net hanging module under the full-color high-quality surface figure. The high-fidelity hidden figure digital net hanging module performs image quality distortion prediction and optimization compensation for the set printing mode, plate-making printing is performed on the optimized and compensated high-fidelity halftone net figure, a high-fidelity anti-counterfeiting print is outputted, and an appropriate detection means is selected to detect the high-fidelity anti-counterfeiting print so that the anti-counterfeiting objective can be realized. According to the anti-counterfeiting method based on the high-fidelity hidden figure and the anti-counterfeiting system thereof, the quality of the surface figure can be effectively enhanced, the selection range of the surface figure can be enlarged, and the underlying figures are large in modulation amplitude, high in contrast, great in visual effect, high in resolution and wide in the range of color gradation so that the hidden figure anti-counterfeiting means is enabled to be diversified and the anti-counterfeiting performance can be effectively enhanced.

Owner:臧戈平

Bobtail high-strength rivet connection pair and manufacturing method thereof

InactiveCN102345658AExpand the scope of selectionLow manufacturing costRivetsFurnace typesQuenchingHigh intensity

The invention discloses a bobtail high-strength rivet connection pair and a manufacturing method thereof. The manufacturing method comprises the following steps of: forming a rivet blank provided with a nail head and a rod body through processing a cylindrical metal material; subsequently, carrying out quenching and tempering heat treatment on the rivet blank; carrying out finish turning or grinding processing on the rod body, thus the rod body is subjected to diameter reduction to form a rod body with a middle diameter for manufacturing a locking groove and a pull trough; carrying out cold rolling depression treatment on the rod body with a middle diameter so as to manufacture the locking groove provided with discontinuous annular grooves and the pull trough; providing a rupture groove between the locking groove and the pull trough so as to obtain the rivet; processing the cylindrical metal material so as to form a riveting sleeve blank provided with a sleeve head and a sleeve body; and then carrying out heat treatment so as to obtain a riveting sleeve. The prepared rivet and the riveting sleeve have excellent comprehensive mechanical property, and meet the international standard ISO 898.18.8 level requirement; and the construction work performance (clamping force, pulling-out force and shearing force) of the rivet connection pair meets the requirement of United States Standard US, MIL, P-23469. In addition, the manufacturing method provided by the invention has the advantages of simple process and low cost, and is convenient for customers.

Owner:彭亮生

Infrared reflexive aggregate and preparation method thereof

InactiveCN102040878AImprove reflective effectGood heat insulationInorganic pigment treatmentReflecting/signal paintsMicrometerPre treatment

The invention discloses an infrared reflexive aggregate. In the infrared reflexive aggregate, pretreated mica is taken as a substrate, and a clading layer with the thickness of between 0.5 and 5 micrometers is coated on the outer surface of the substrate; the thickness of the mica is between 0.5 and 5 micrometers, and the grain diameter is between 0.5 and 120 micrometers; and the cladding layer is doped zinc oxide, and the doped zinc oxide consists of ZnO serving as a main metal oxide and doping metal in a molar ratio of 0.1 to 10 percent. The invention also provides a preparation method of the infrared reflexive aggregate simultaneously, which comprises the following steps of: 1) pretreating the mica; and 2) coating the cladding layer outside the outer surface of the pretreated mica serving as the substrate. In the aggregate, the excellent infrared reflexive performance of the doped zinc oxide serving as a film is reserved, the aggregate is used for preparing a transparent or semitransparent infrared reflexive coating film, and thus, the problem of the infrared reflection of deep color coatings is solved to a certain extent.

Owner:ZHEJIANG UNIV

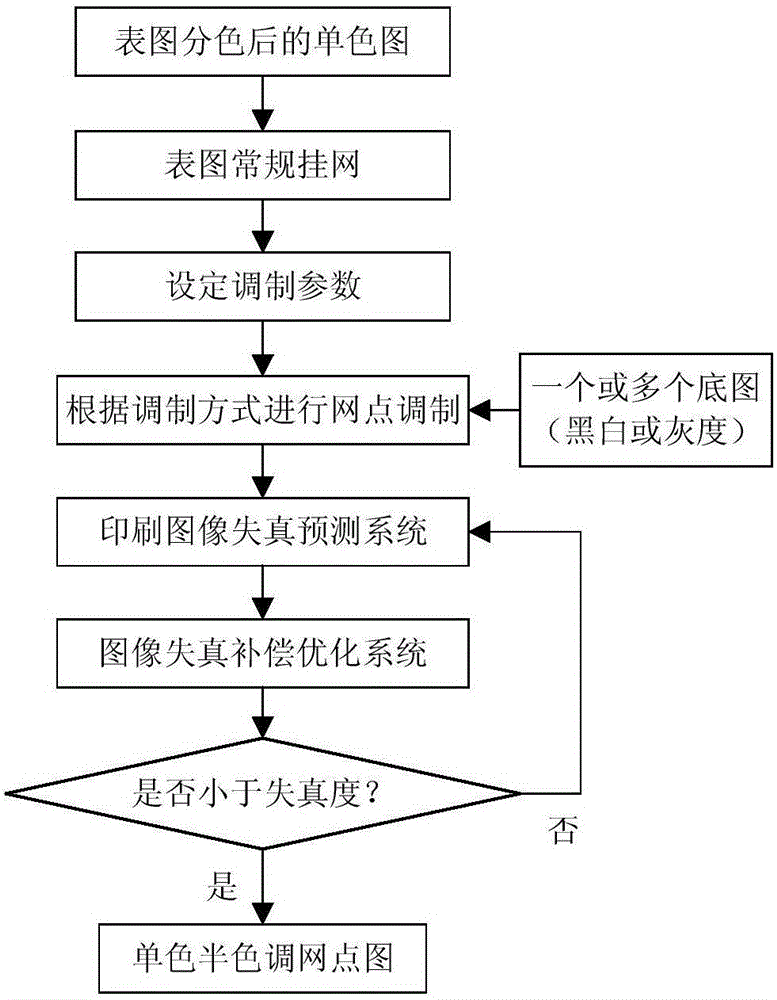

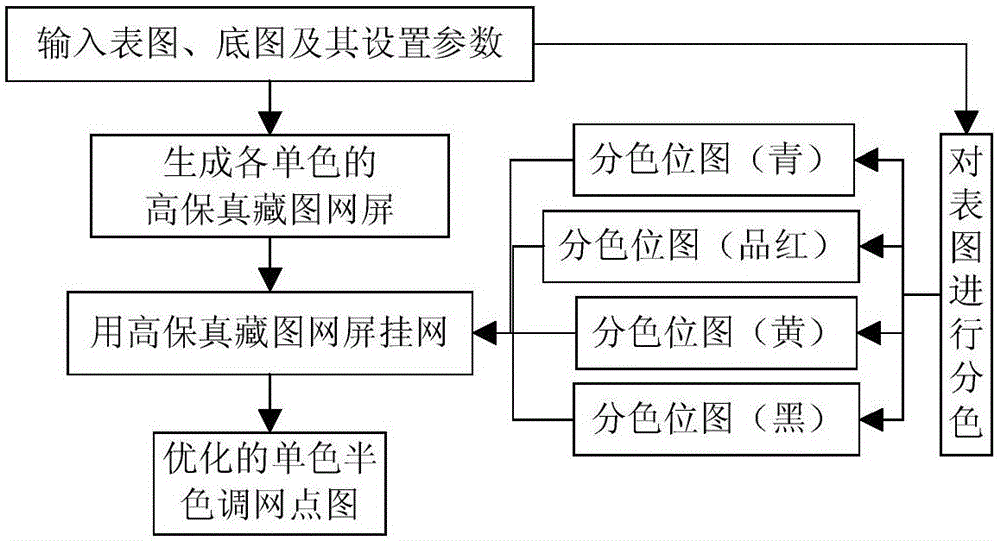

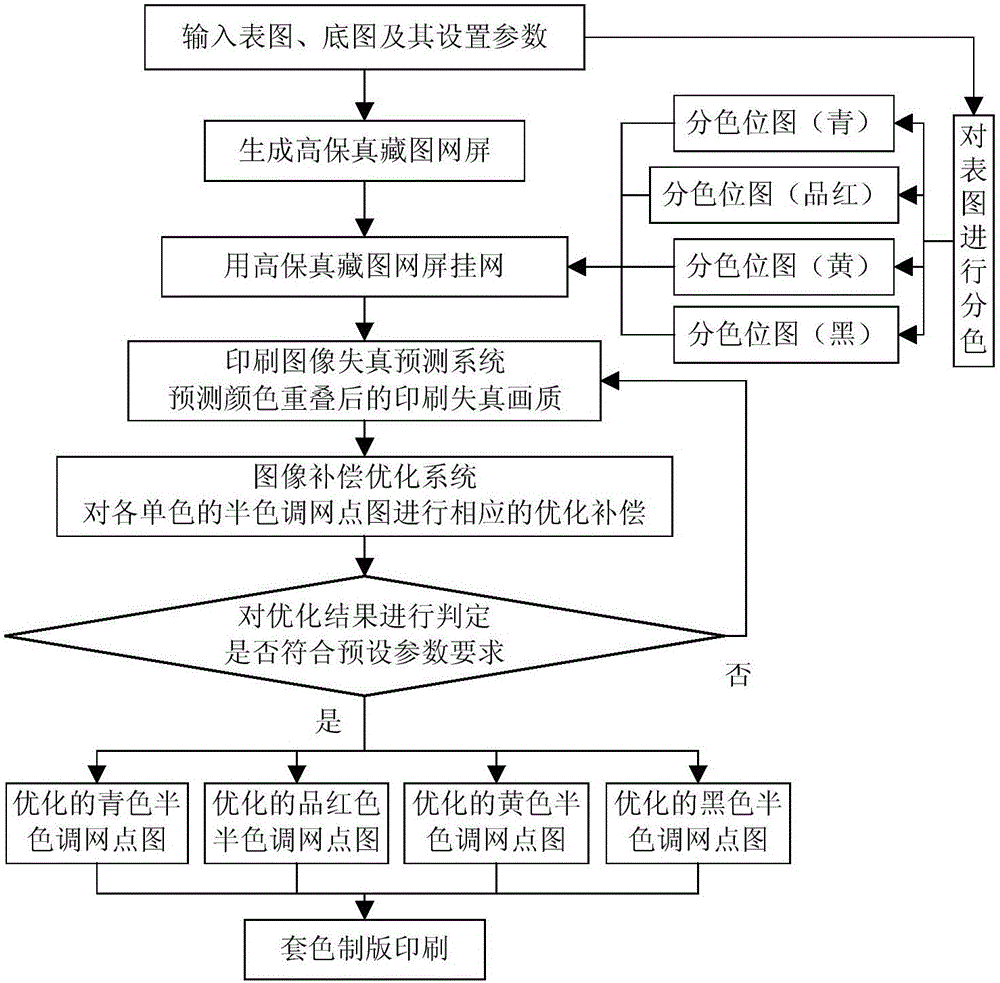

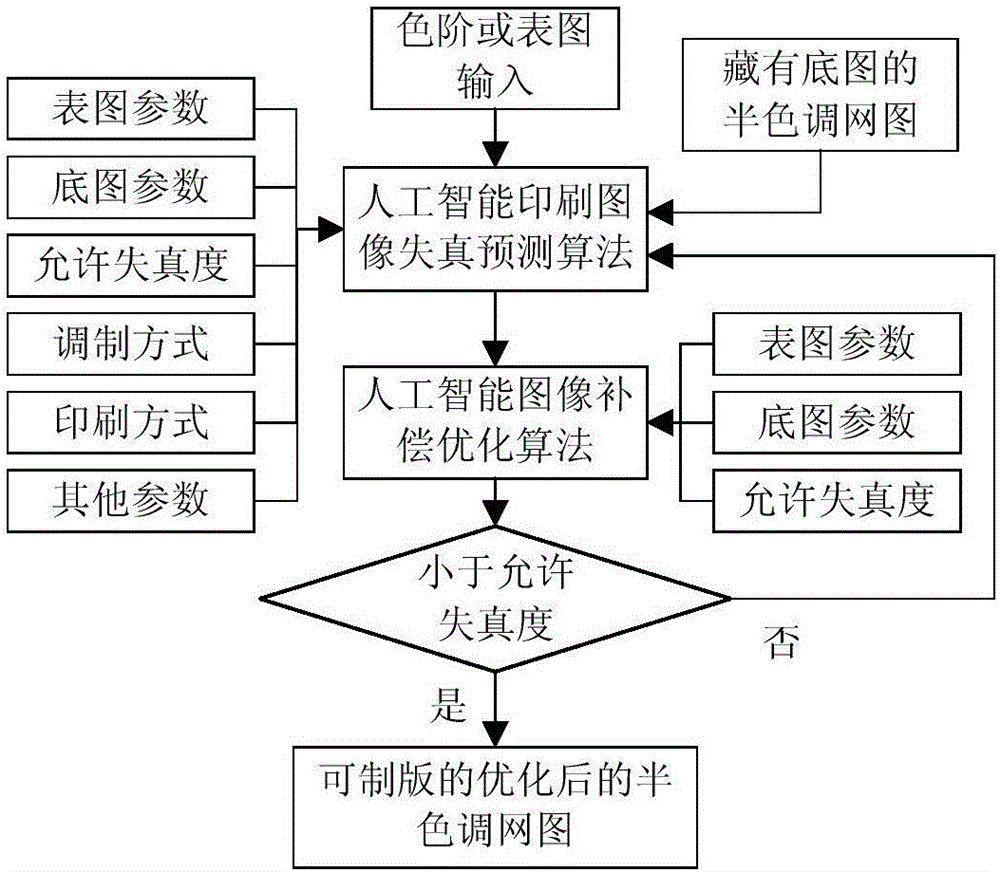

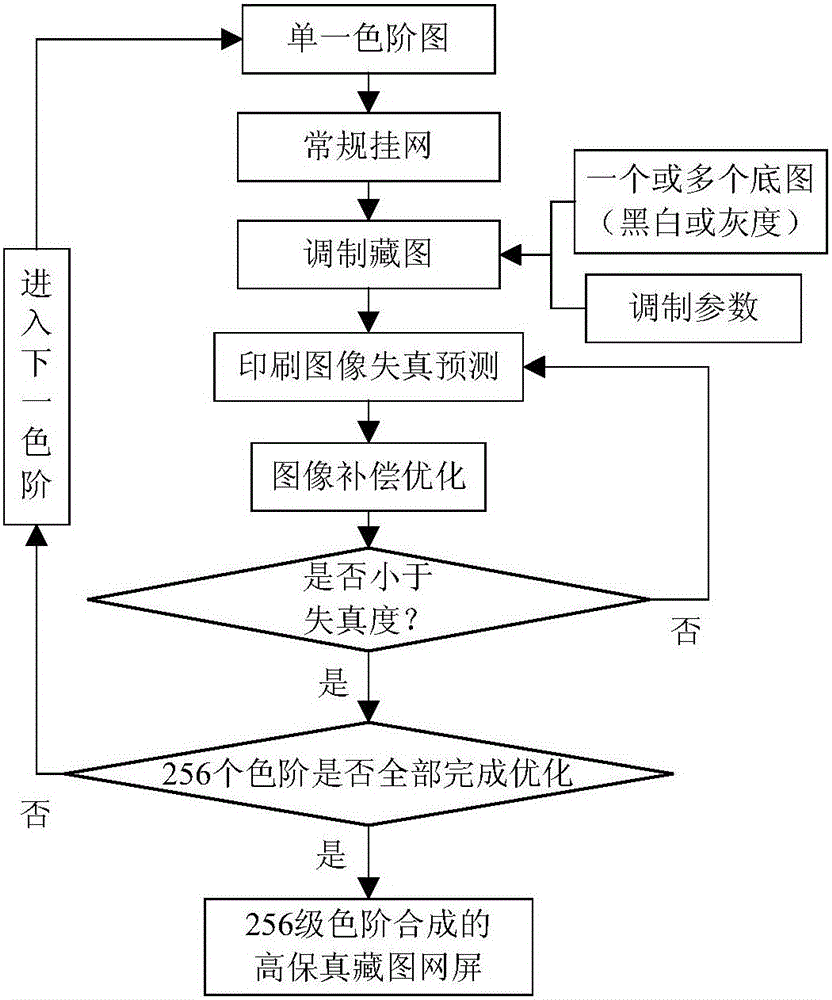

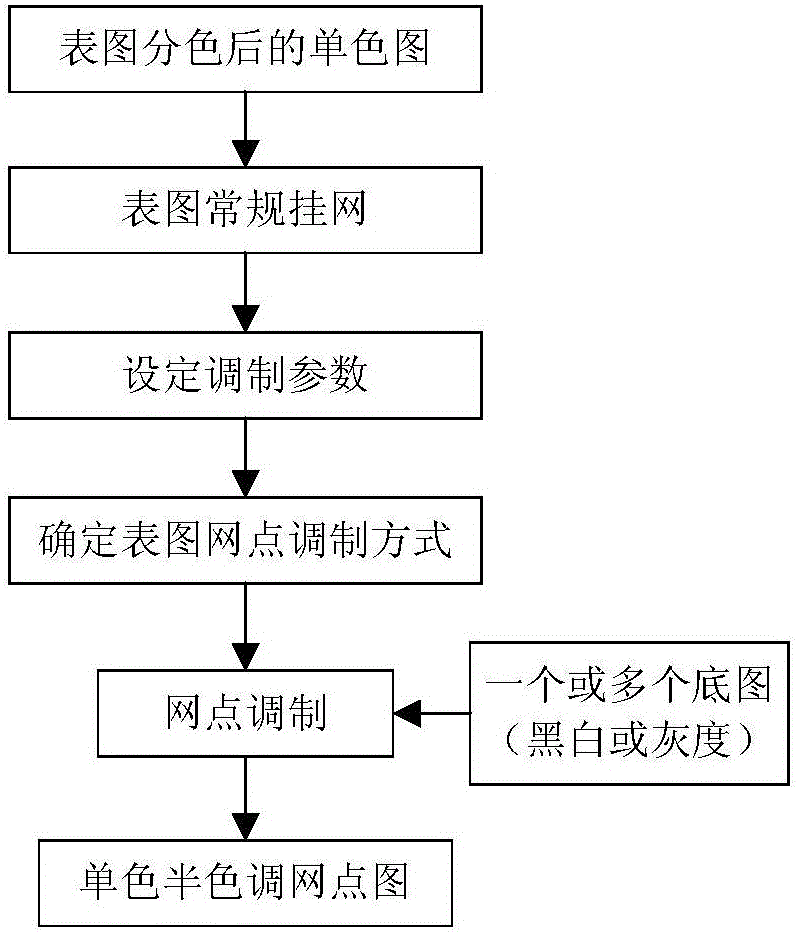

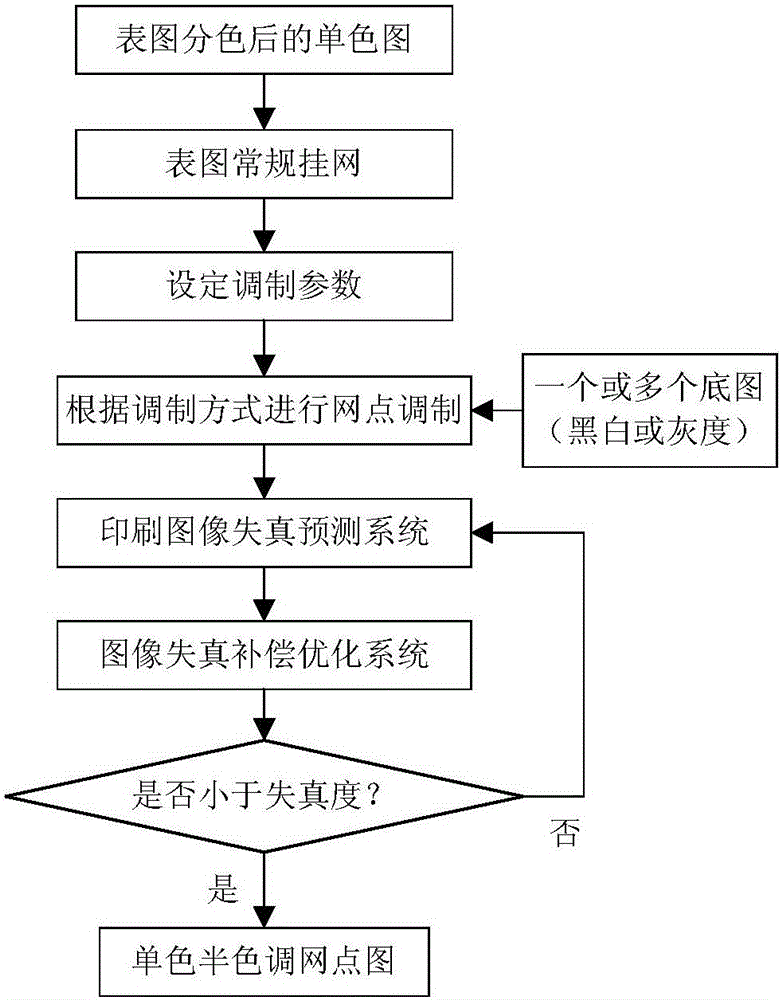

Digital screening method and system based on high-fidelity hidden picture screens

ActiveCN106157265AGray scale can vary widelyExpand the scope of selectionImage enhancementImage analysisScreening methodPrediction system

The invention provides a digital screening method and system based on high-fidelity hidden picture screens and relates to the technical field of anti-counterfeit printing. The method comprises: separating based on color, generating monochromic high-fidelity screens comprising an underlying picture, wherein picture defects are quantitatively and precisely predicted through a printed picture distortion prediction system and are precisely aligned and compensated through a picture compensation and optimizing system, and screening corresponding monochromic superficial pictures with the high-fidelity screens comprising one underlying picture to obtain high-fidelity printed material with an underlying picture; the system comprises a color separating module, a high-fidelity hidden picture screen generating module, a screening module and a platemaking printing module. The digital screening method and system based on high-fidelity hidden picture screens can hide multiple layers of high-definition multi-gray underlying pictures at the premise of ensuring high fidelity of the superficial picture, can effectively improve the quality of superficial and underlying pictures, are suitable for various mesh modulation modes and their combination, and are particularly suitable for the case with constant underlying pictures and a significantly changed or replaced superficial picture.

Owner:臧戈平

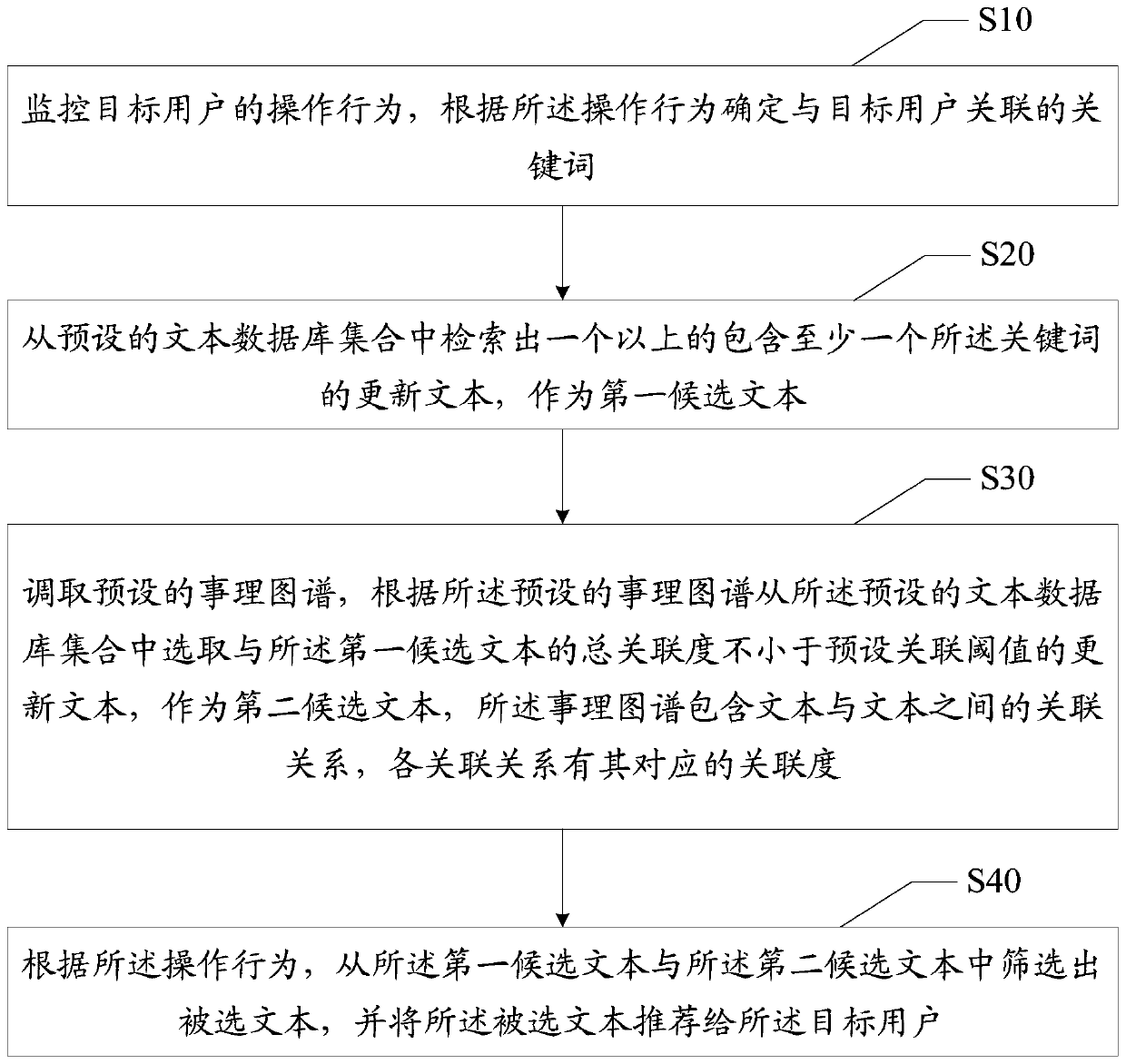

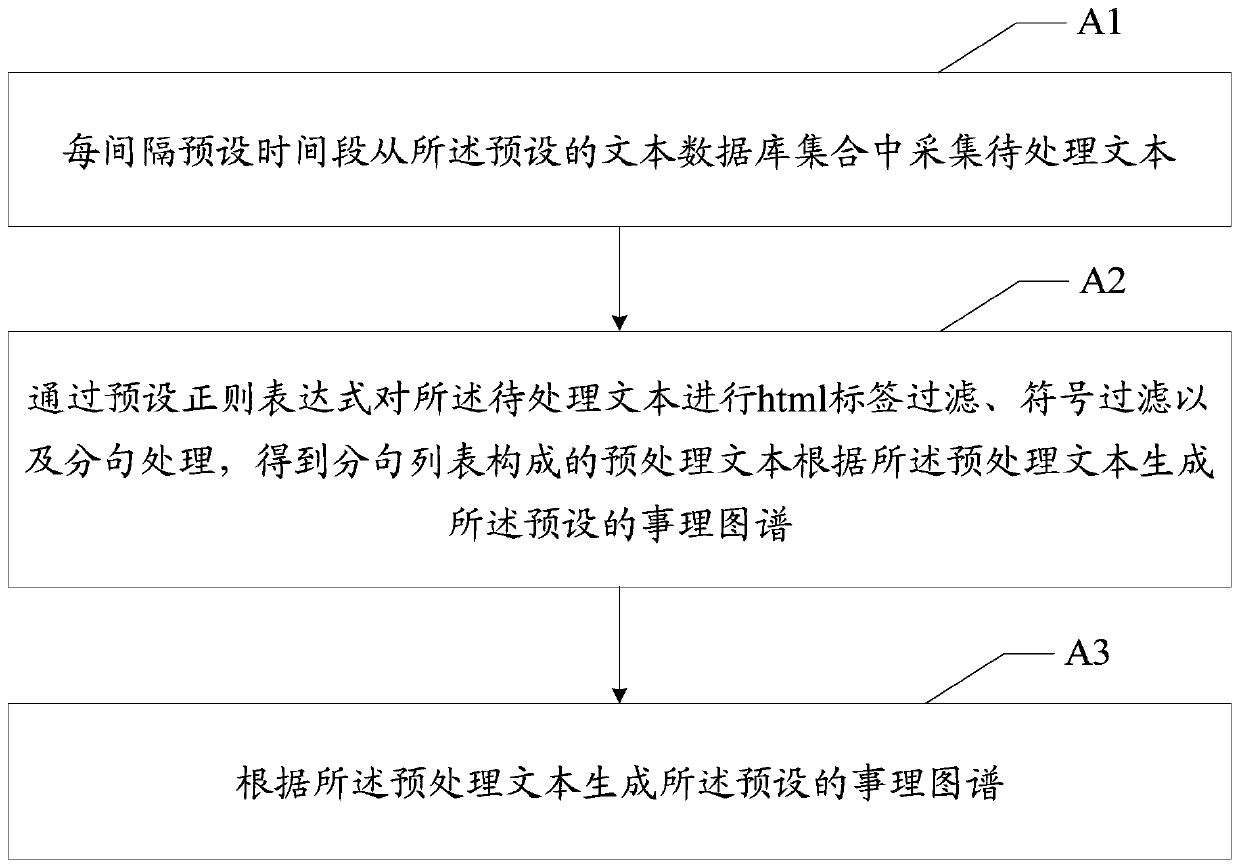

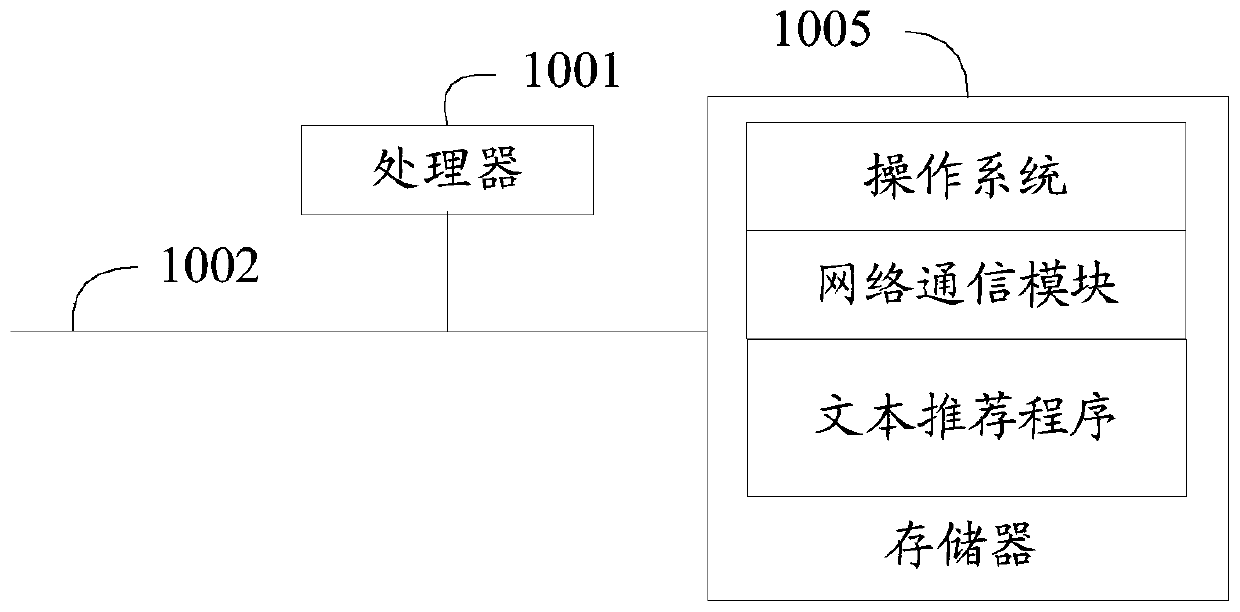

Text recommendation method and device, equipment and medium

PendingCN110888990AExpand the scope of selectionAvoid simplificationSemantic analysisSpecial data processing applicationsText databaseEngineering

The invention discloses a text recommendation method and device, equipment and a medium, and relates to the technical field of financial science and technology, and the method comprises the steps: monitoring an operation behavior of a target user, so as to determine a keyword associated with the target user; searching more than one updating text containing at least one keyword from a preset text database set to serve as a first candidate text; calling a preset cause map, selecting an updated text of which the total association degree with the first candidate text is not less than a preset association threshold value from a preset text database set according to the map to serve as a second candidate text, the cause map including association relationships between texts, and each associationrelationship having a corresponding association degree; and according to the operation behavior, screening out a selected text from the first candidate text and the second candidate text and recommending the selected text to the target user. The technical problems that in the existing recommendation process, recommendation is too simple, and the recommendation accuracy is low are solved.

Owner:WEBANK (CHINA)

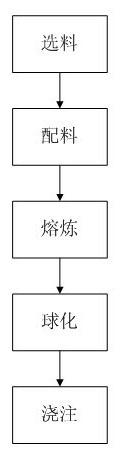

Production process of high-elongation nodular cast iron being as cast condition

The invention discloses a production process of high-elongation nodular cast iron being as cast condition. The production process comprises the following steps: sorting; burdening: taking materials by weight percentage as follows: 35-45% of cast iron Z18 or Z22, less than 35% of foundry returns and 30-55% of steel scraps; melting: putting burdened materials into a furnace for melting, melting the materials into molten iron, rising the temperature of the molten iron to be 1600-1650 DEG C, carburetting and complementing silicon; then conducting desulfuration process; complementing oxygen and reducing manganese and conducting dephosphorization process; finally carrying out on-the-spot chemical contents analysis, adjusting the chemical contents, conducting the next operation after the chemical contents are qualified; balling by utilizing pour-over method; and breeding instantly by adopting an inoculant when in casting so as to obtain the high-elongation nodular cast iron being as cast condition. According to the high-elongation nodular cast iron being as cast condition provided by the invention, the cost is lowered, the production period of a cast is shortened; the sorting range of the raw materials of the nodular cast iron is enlarged; the cast can not shrink easily; and the cost is saved, silicon iron alloy does not need to be added or is little added after the casting treatment.

Owner:CHAGNSHU QIANJINDING CASTING

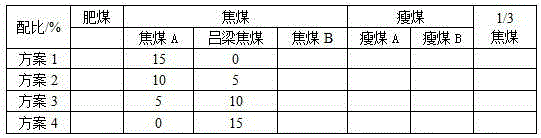

Method for carrying out coal source development by comprehensively applying coal petrography indexes

ActiveCN104449778AExpand the scope of selectionOptimize coal blending structureCoke ovensPhysicsProcess engineering

The invention relates to a method for carrying out coal source development by comprehensively applying coal petrography indexes. The method comprises the following steps of: I, carrying out coal petrography analysis on a new coal type, and judging coal as a single coal type when reflectivity standard deviation is less than 0.10; II, analyzing the coal quality indexes on the coal, and comparing ash content, volatile content, sulfur content, a caking index G value and a colloidal layer thickness Y value with those of a coal type which is in use; III, evaluating the coking property of the new coal type by using an experimental coke oven, and comparing with a substituted coal type, wherein coke strength indexes include M40, M10, CRI and CSR; IV, substituting the new coal type for the coal type which is in use according to the proportion of 4%-18%, and experimenting two coal blending schemes by using two experimental coke furnaces, wherein the coke strength indexes include M40, M10, CRI and CSR; V, trying to use the new coal type on an industrial 7.63 m coke furnace, and inspecting the coke strength indexes including M40, M10, CRI and CSR. The method disclosed by the invention can be used for partially or wholly substituting the coal resource which is in use so as to widen the selecting range of the coal resource.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

High-fidelity hidden image figure screen frequency determination method and system based on direct correction

ActiveCN106157336AQuality improvementExpand the scope of selectionImage enhancementImage analysisImage resolutionGray level

The invention provides a high-fidelity hidden image figure screen frequency determination method and system based on direct correction, and relates to the technical field of anti-counterfeiting printing. The method includes the steps that after a bottom image is hidden in a surface image at a conventional screen frequency, image defects caused in the image hiding and printing processes are quantitatively and accurately predicted through a printed image distortion prediction system, accurate alignment compensation is carried out through an image compensation optimization system, and a high-fidelity printed product including the bottom image is obtained. The system comprises a color separation module, a screen frequency determination module, a screen point modulation module, a printed image distortion prediction module, an image distortion compensation optimization module, an optimization result judgment module and a platemaking printing module. By means of the high-fidelity hidden image figure screen frequency determination method and system based on direct correction, the multilayer high-definition and multi-gray level bottom image is hidden under the condition that the high fidelity of the surface image is guaranteed, the quality of the surface image can be effectively improved, the selection range can be widened, the bottom image is large in modulation amplitude, good in visual effect and high in resolution ratio, and the high-fidelity hidden image figure screen frequency determination method and system based on direct correction are suitable for various screen point modulation modes and a combination thereof.

Owner:臧戈平

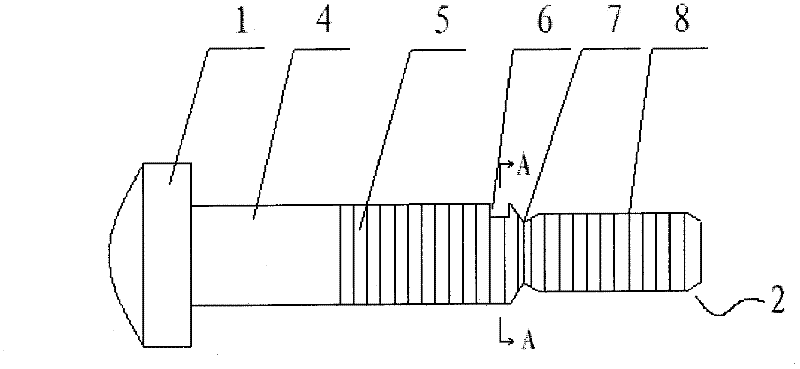

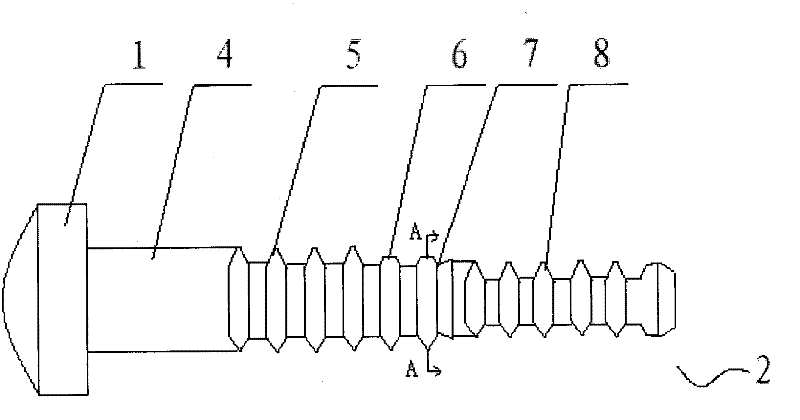

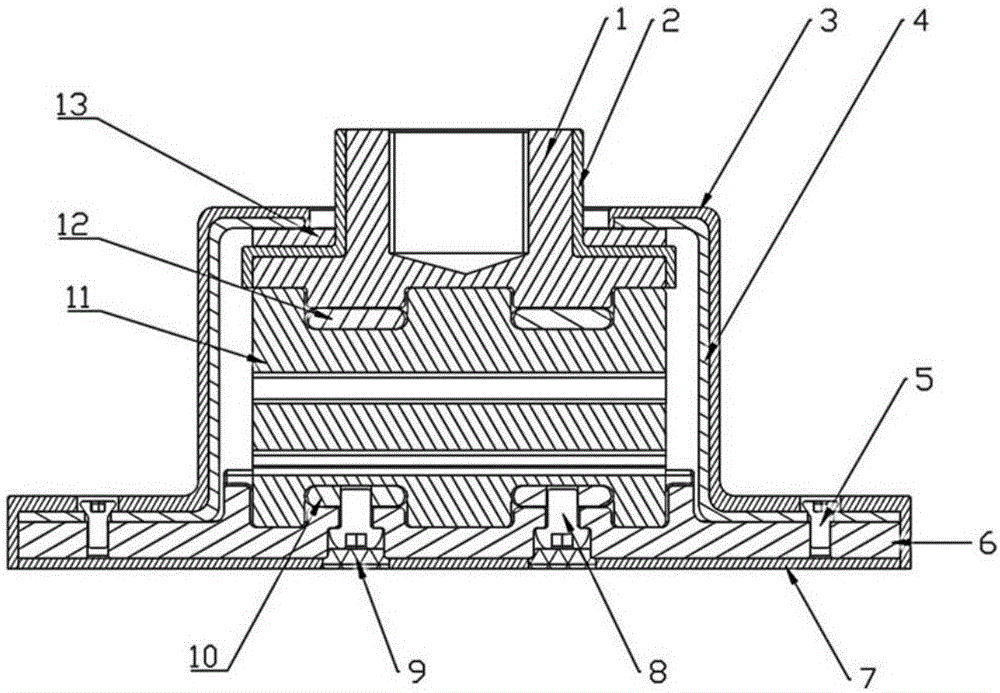

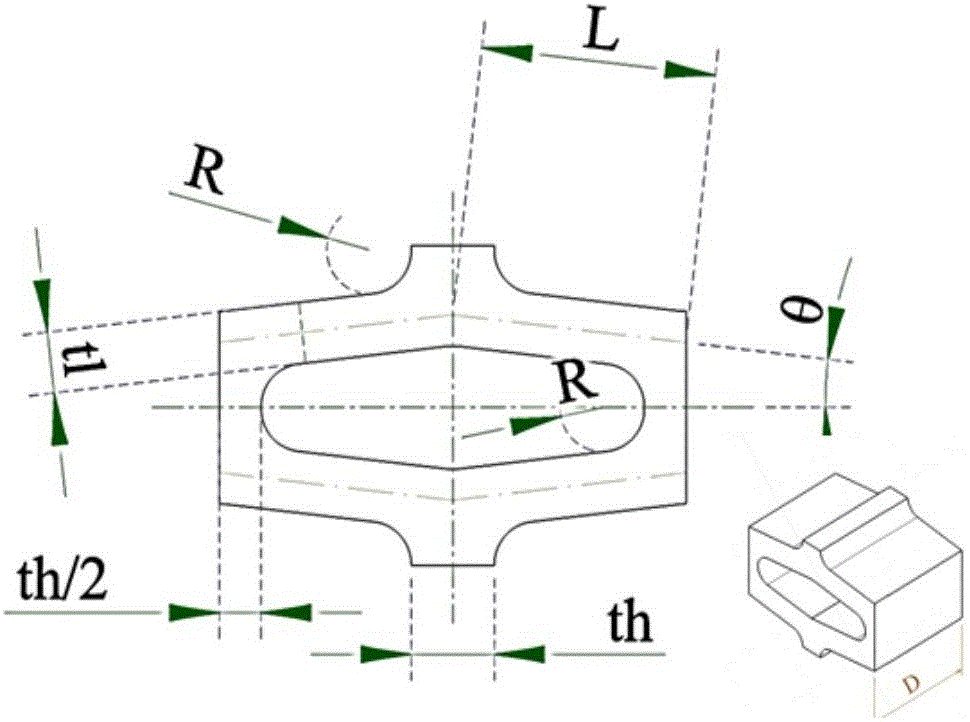

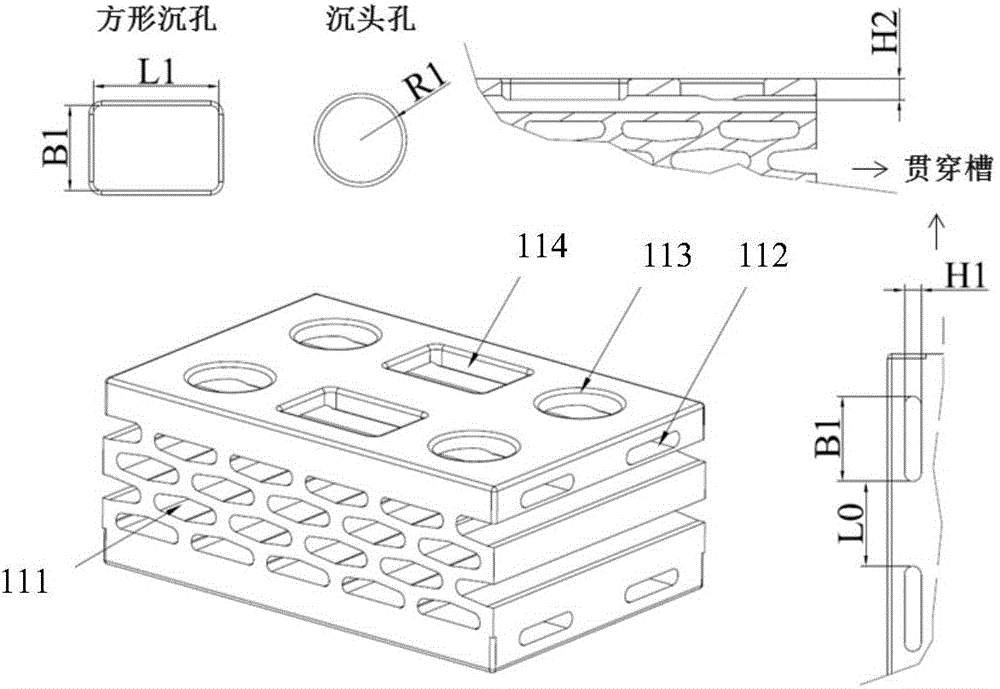

Metamaterial vibration isolator

ActiveCN106567900AExpand the scope of selectionShorten the development cycleSpringsShock absorbersEngineeringNoise reduction

The invention belongs to the technical field of vibration and noise reduction and particularly relates to a vibration isolator. The metamaterial vibration isolator comprises a metamaterial vibration isolation component and other components serving as structural components, namely an upper end cover, a limiting protective hood, a lower base plate, surface rubber coating layers, fastening bolts, a bottom implanted framework, an upper implanted framework, rubber plugs and a sealing gasket. According to the metamaterial vibration isolator, the metamaterial technology is utilized; limitation of certain apparent natural laws of traditional vibration isolation materials is broken through; the metamaterial function exceeding common intrinsic properties of original substrates is achieved, and thus the contradiction generated between low intrinsic frequency and large static deformation of a vibration isolator can be well regulated; the vibration isolation effect in the main bearing direction and anti-swinging performance in the non-bearing-direction of the vibration isolator are achieved at the same time; and a new path is provided for reducing vibration and noise of a ship or warship.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

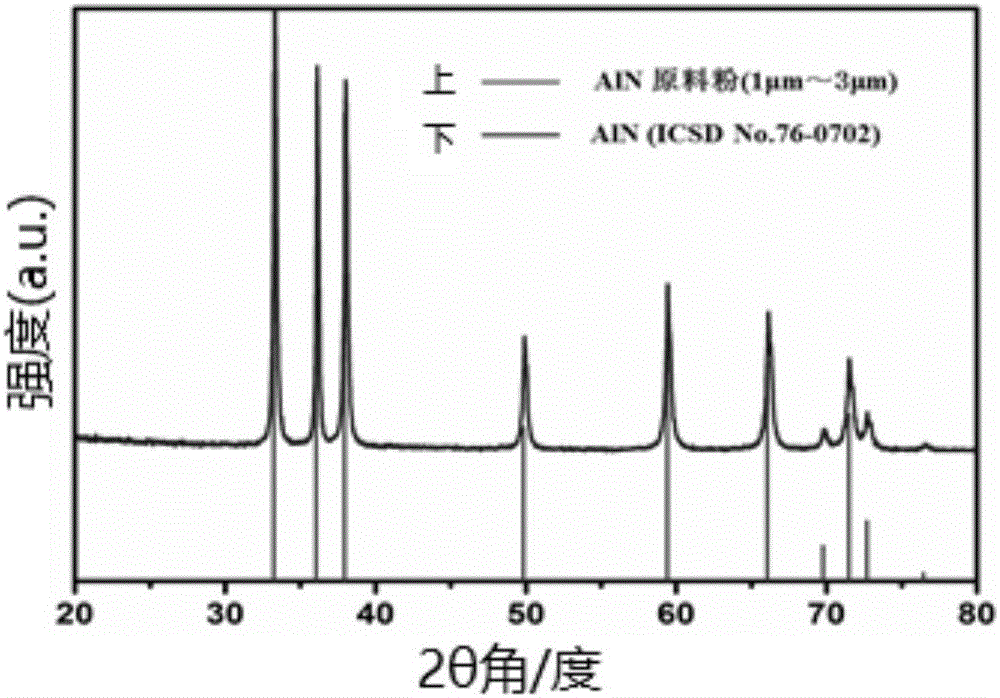

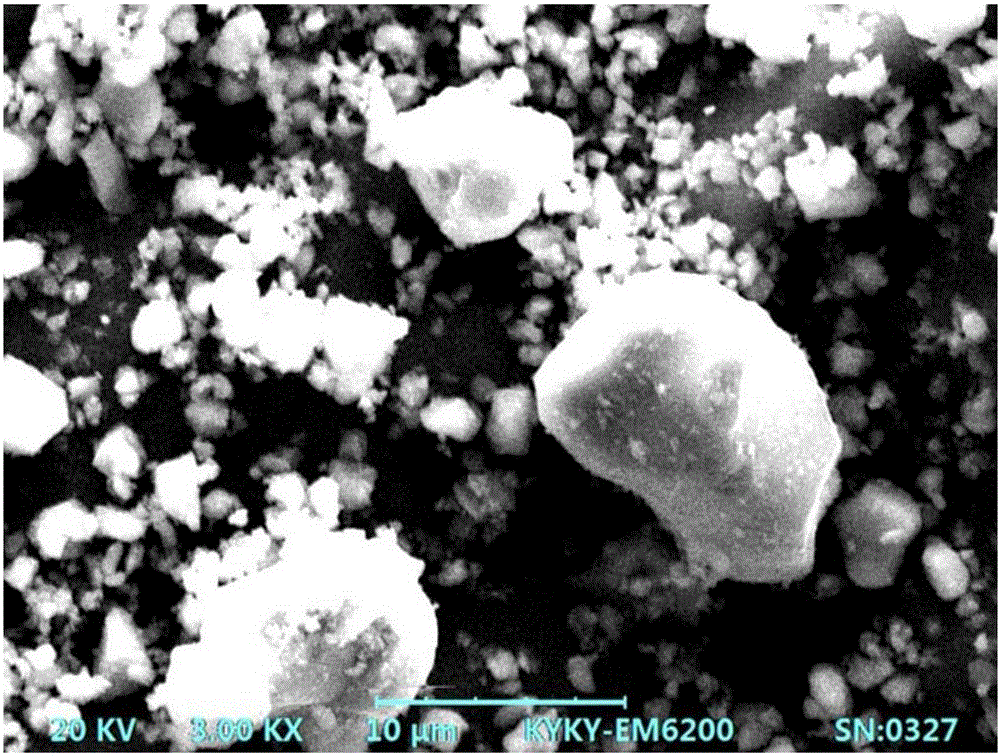

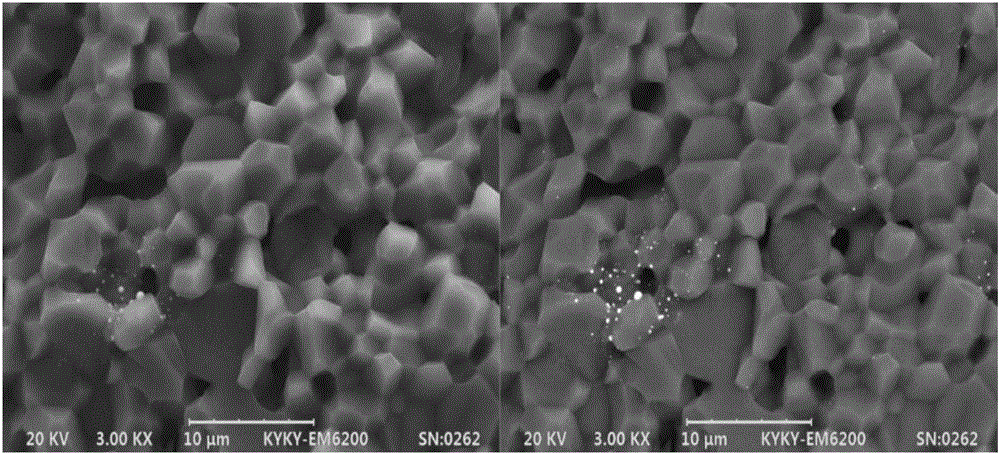

Method for preparing aluminum nitride electronic ceramic base plate by using tape casting method and solvent for tape casting method for preparing ceramic

ActiveCN107522495AImprove working conditionsSignificant environmental benefitsSlurryTriethylamine phosphate

The invention discloses a method for preparing an aluminum nitride electronic ceramic base plate by using a tape casting method. The method comprises the following steps: preparing tape casting slurry, and molding the tape casting slurry by using the tape casting method, thereby obtaining the aluminum nitride electronic ceramic base plate, wherein the tape casting slurry comprises a benzene-free mixed organic solvent, aluminum nitride ceramic powder and sintering aids; the benzene-free mixed organic solvent comprises three or more than three of absolute ethyl alcohol, isopropyl alcohol, n-butyl alcohol, triethyl phosphate and dibasic acid ester; and the solvent accounts for 28-40% of the mass of the aluminum nitride ceramic powder. The invention further provides a method for preparing high-solid content aluminum nitride tape casting by using an organic solvent which is non-toxic, relatively environmentally friendly and low in cost. The aluminum nitride electronic ceramic base plate which is high in density, uniform in microstructure and high in heat conductivity is prepared under a relatively low high temperature condition, and the tape casting production process is green and environmentally friendly and applicable to industrial popularization.

Owner:李军廷

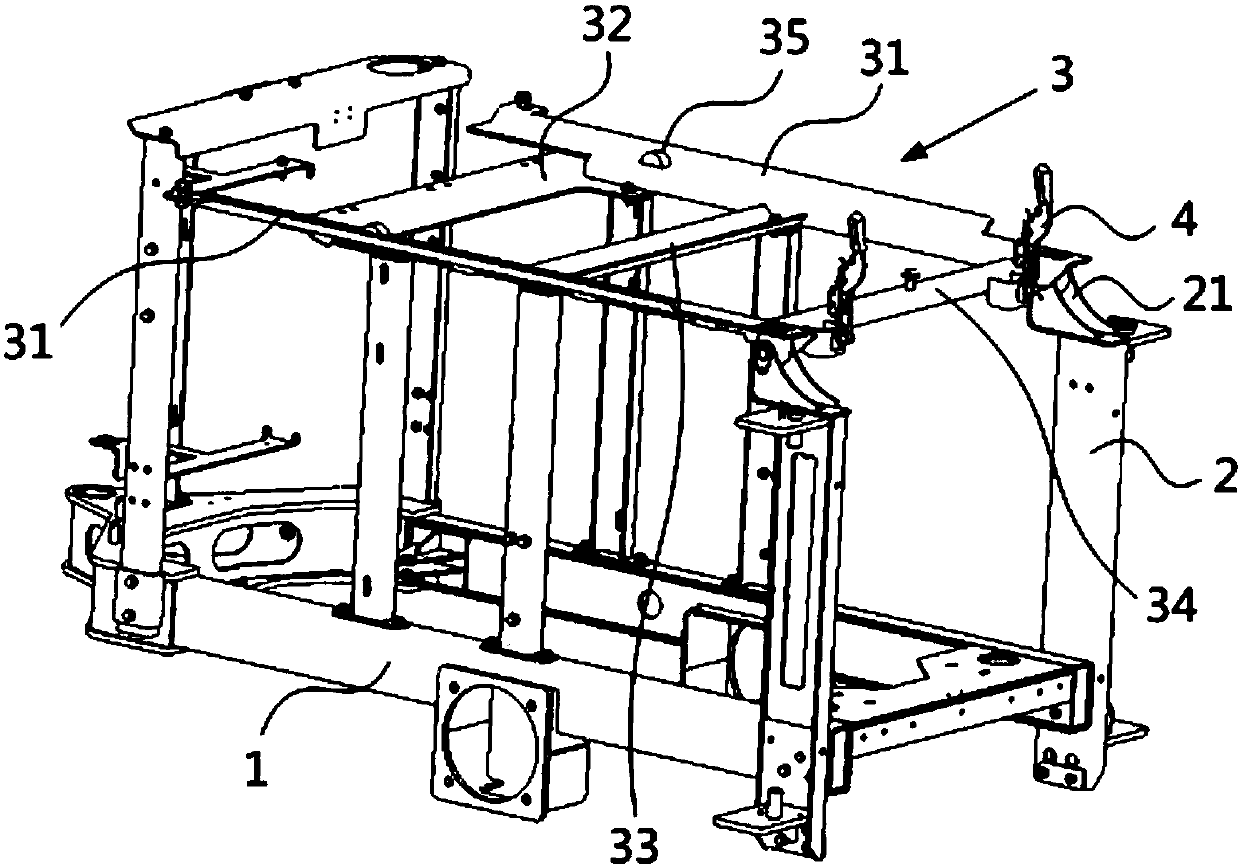

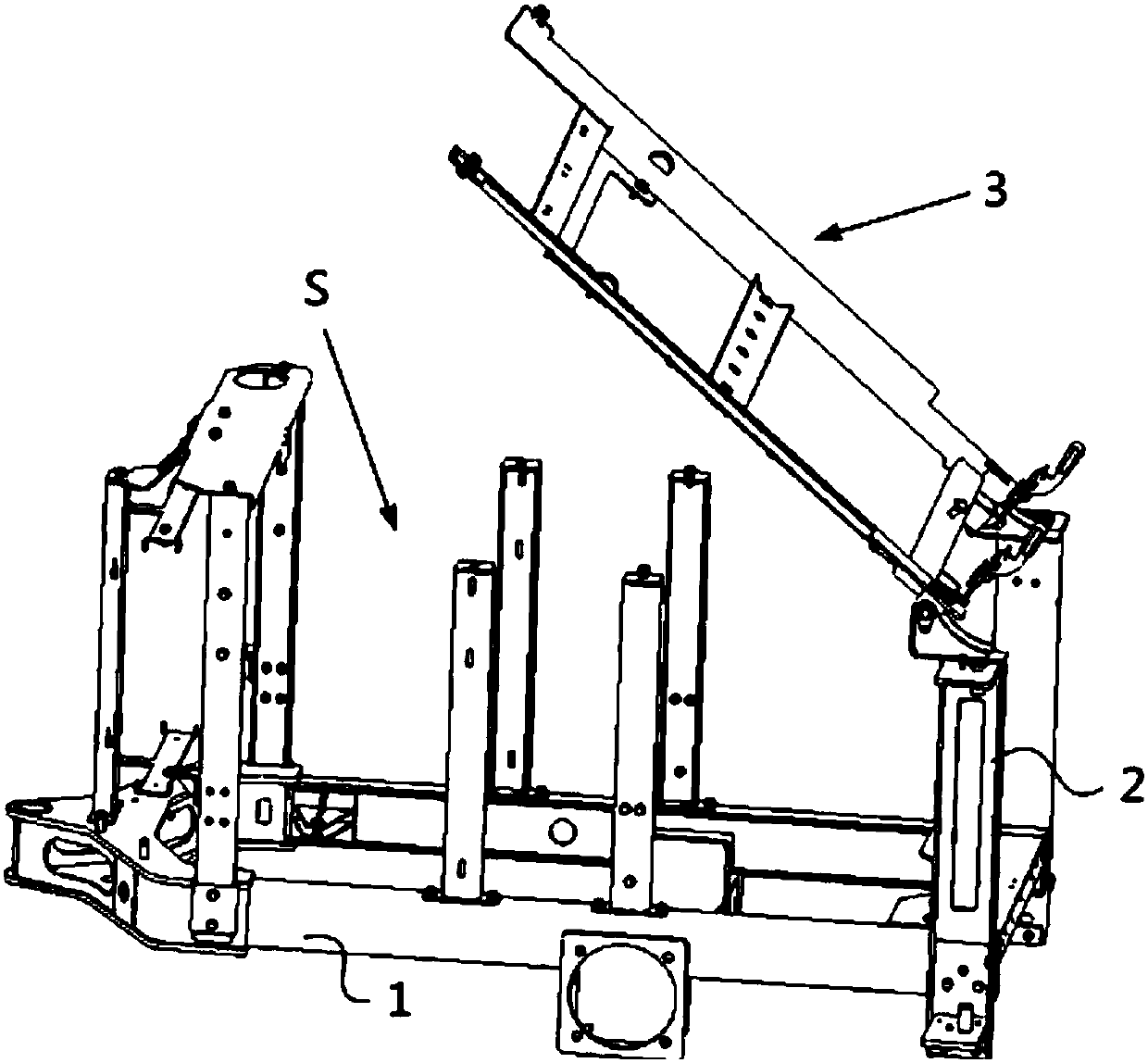

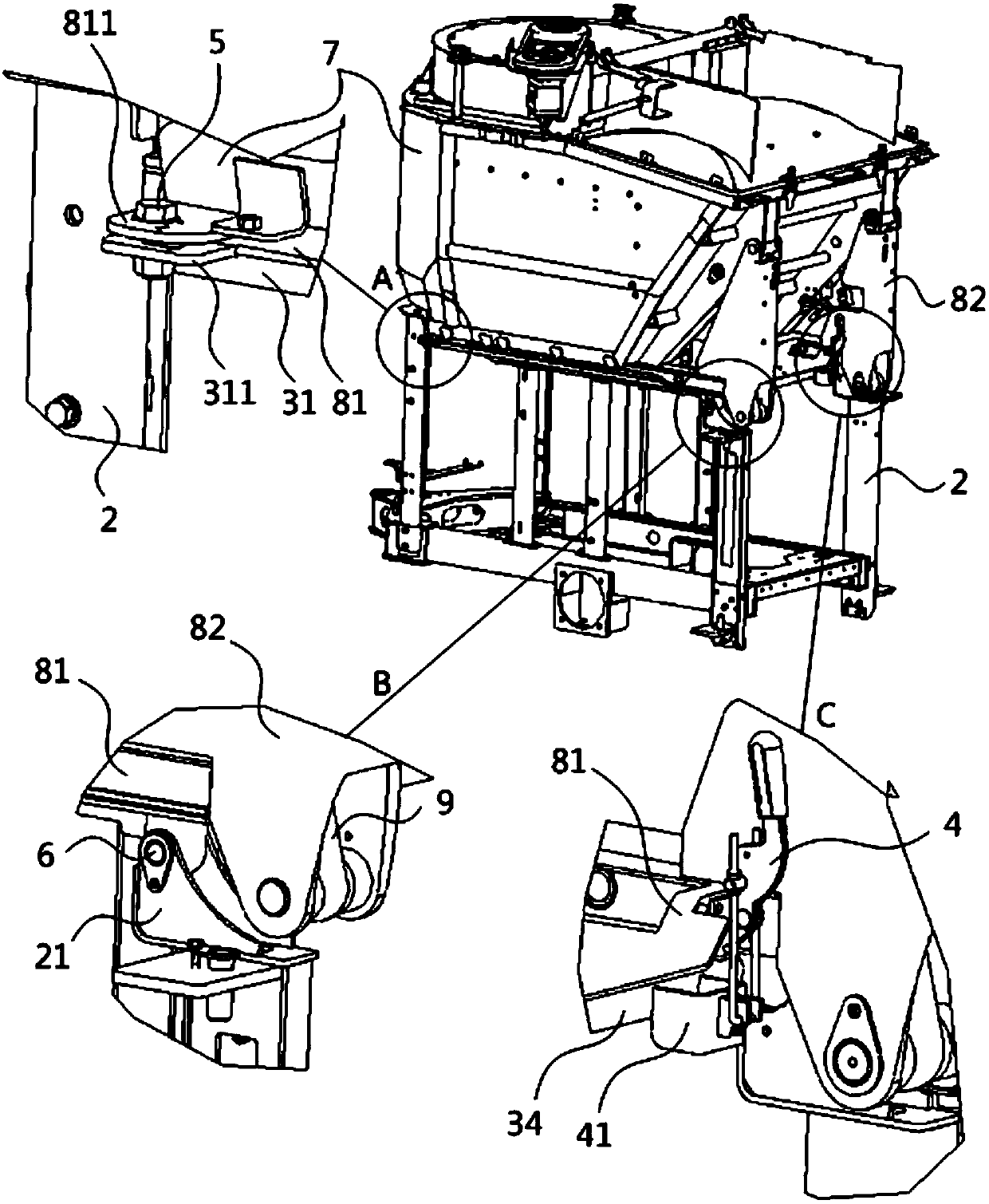

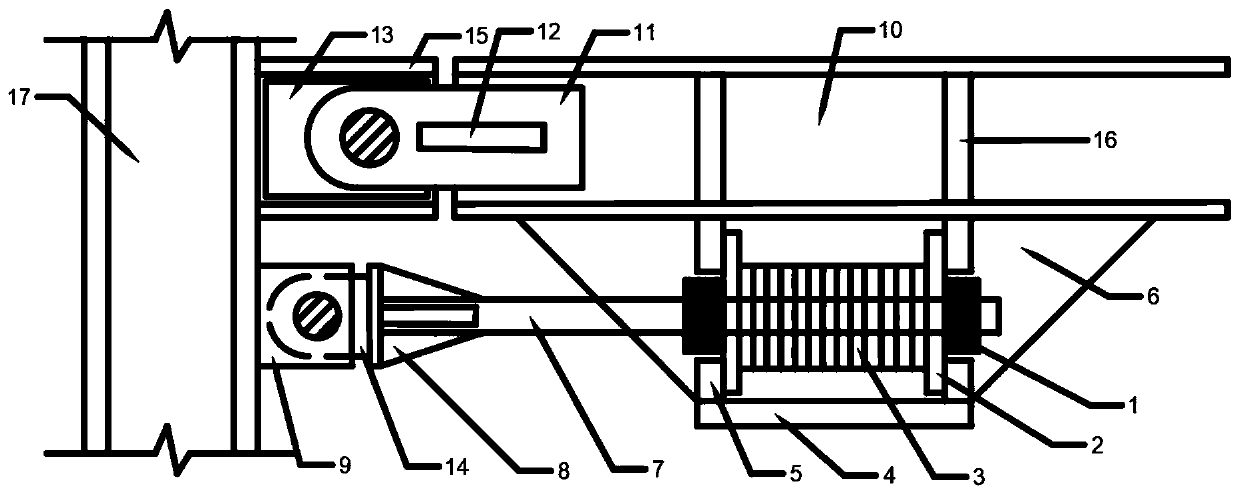

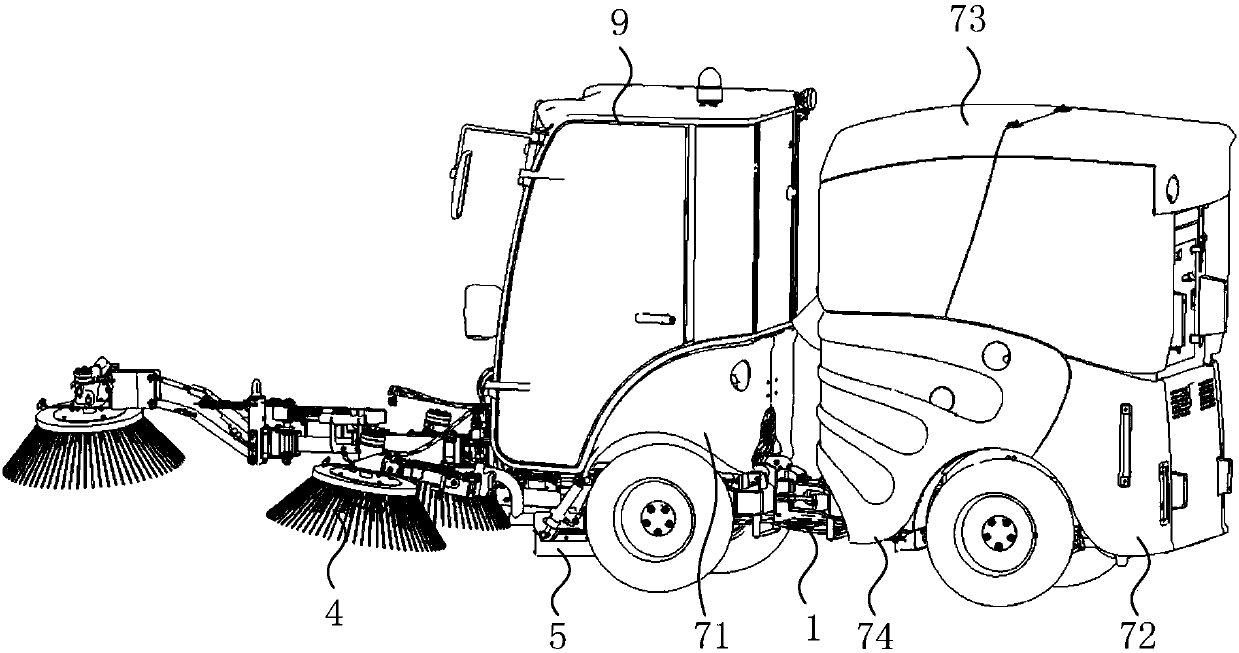

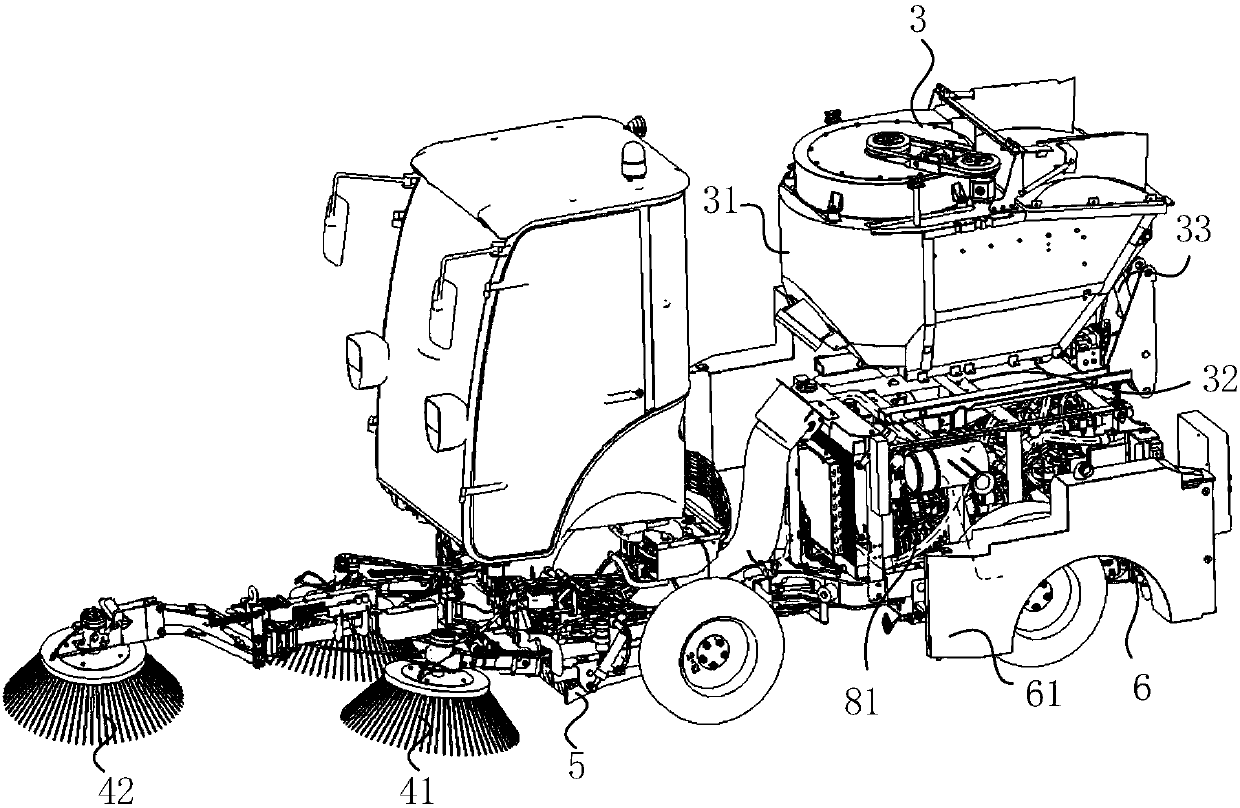

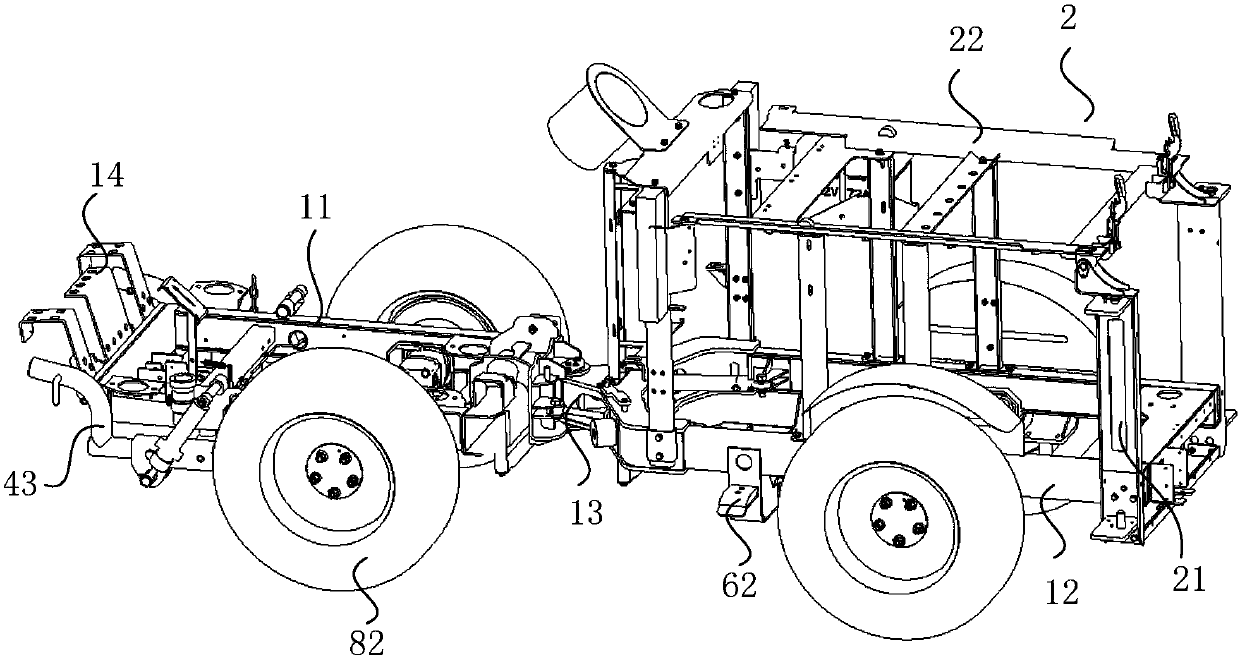

Load bearing structure, road sweeper and assembling and disassembling method of power system

The invention relates to a load bearing structure, a road sweeper and an assembling and disassembling method of a power system. The load bearing structure comprises a chassis frame (1), a chassis bracket (2) and a roll-over frame (3), wherein the chassis bracket (2) is fixed to the chassis frame (1) and an accommodation space allowing a power system to be mounted is formed by the chassis bracket (2) and the chassis frame (1); the roll-over frame (3) is located above the chassis bracket (2); one end of the roll-over frame (3) is hinged to the upper part of the chassis bracket (2) and can roll over to a predetermined angle relative to the chassis bracket (2) above the chassis bracket (2); when the power system needs to be assembled and disassembled, the operator can turn over the roll-over frame from above the chassis frame, and then the power system can be mounted; and through the of the roll-over structure, a space for convenient mounting of the power system can be provided and mounting of the power system can be simplified, so that selection restriction of the power system can be reduced and the selection range of the power system can be enlarged.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

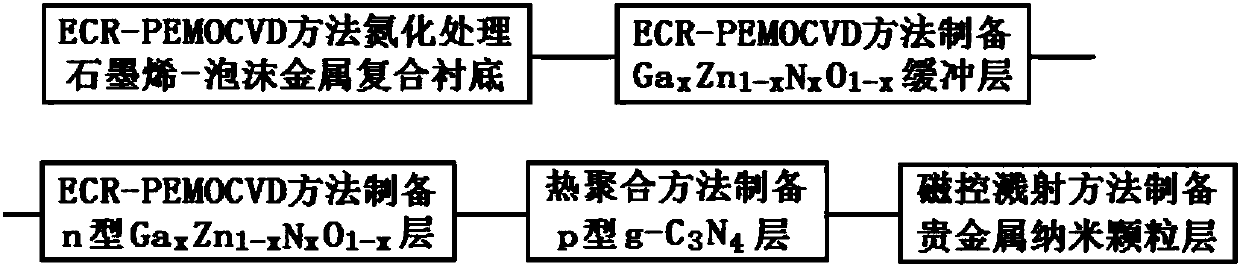

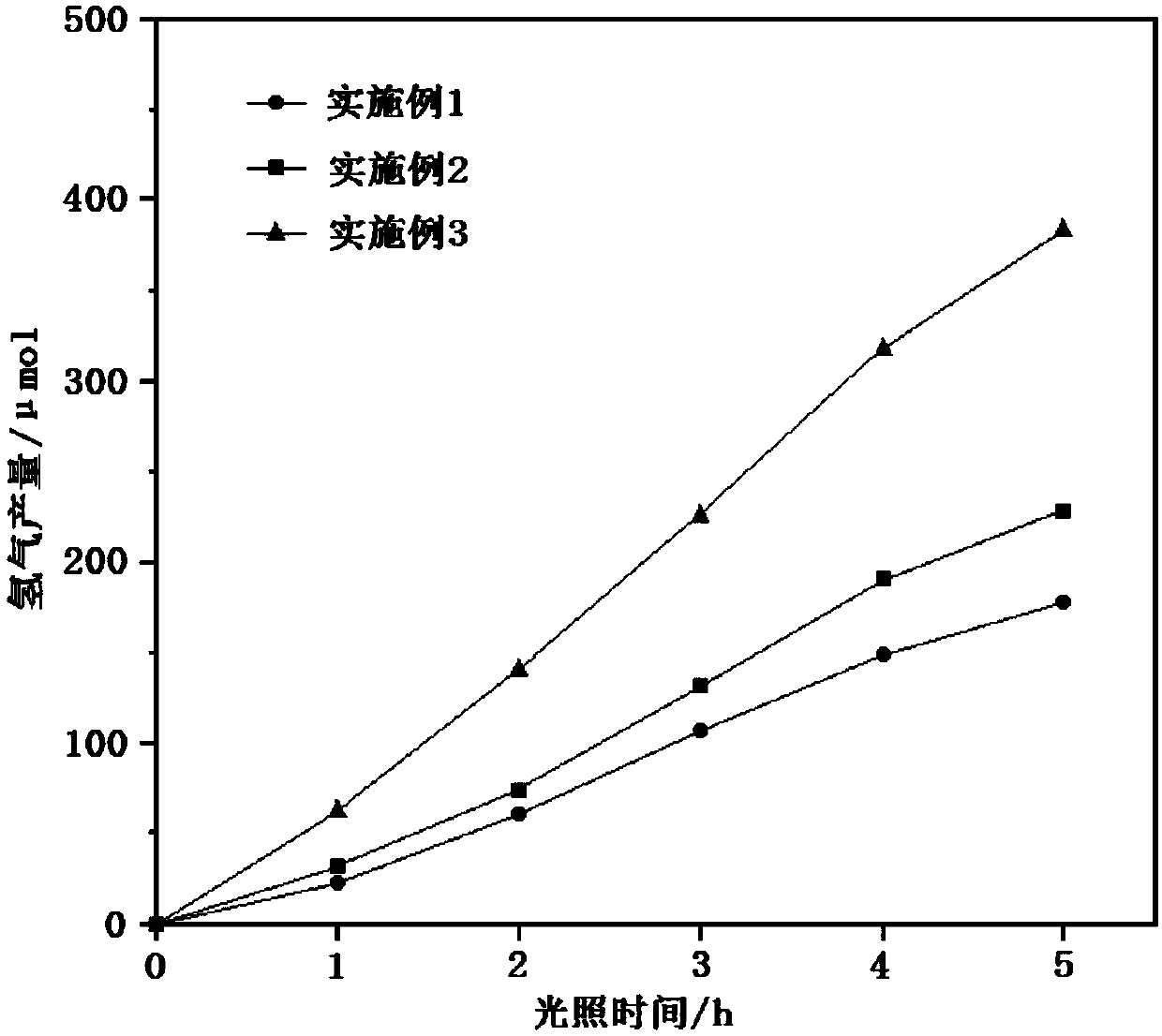

Photocatalytic thin film on foam metal-graphene composite substrate and preparation method

InactiveCN107649165AImprove mechanical propertiesUniform pore structureCatalyst activation/preparationHydrogen productionCvd grapheneNitrogen treatment

The invention belongs to the technical field of photocatalytic thin film manufacturing, and provides a photocatalytic thin film on a foam metal-graphene composite substrate and a preparation method. Concretely, the preparation method comprises the steps of taking a foam metal-graphene composite material as a substrate, firstly using an electron cyclotron resonance-plasma enhancing metal organic matter CVD (chemical vapor deposition) method to successively perform nitrogen treatment of the foam metal-graphene composite substrate, preparation of a GaxZnl-xNxO1-x buffer layer and preparation of an n-type GaxZn1-xNxO1-x layer, then using a thermal polymerization method to prepare a p-type g-C3N4 layer, and finally using a magnetron sputtering method to prepare a precious metal nanometer granular layer. The prepared photocatalytic thin film has a very good visible light photocatalysis effect, can be used for photolyzing water to produce hydrogen, degrading organic pollutant in waste water,removing harmful gas and purifying air, and has a broad application prospect.

Owner:秦永泽

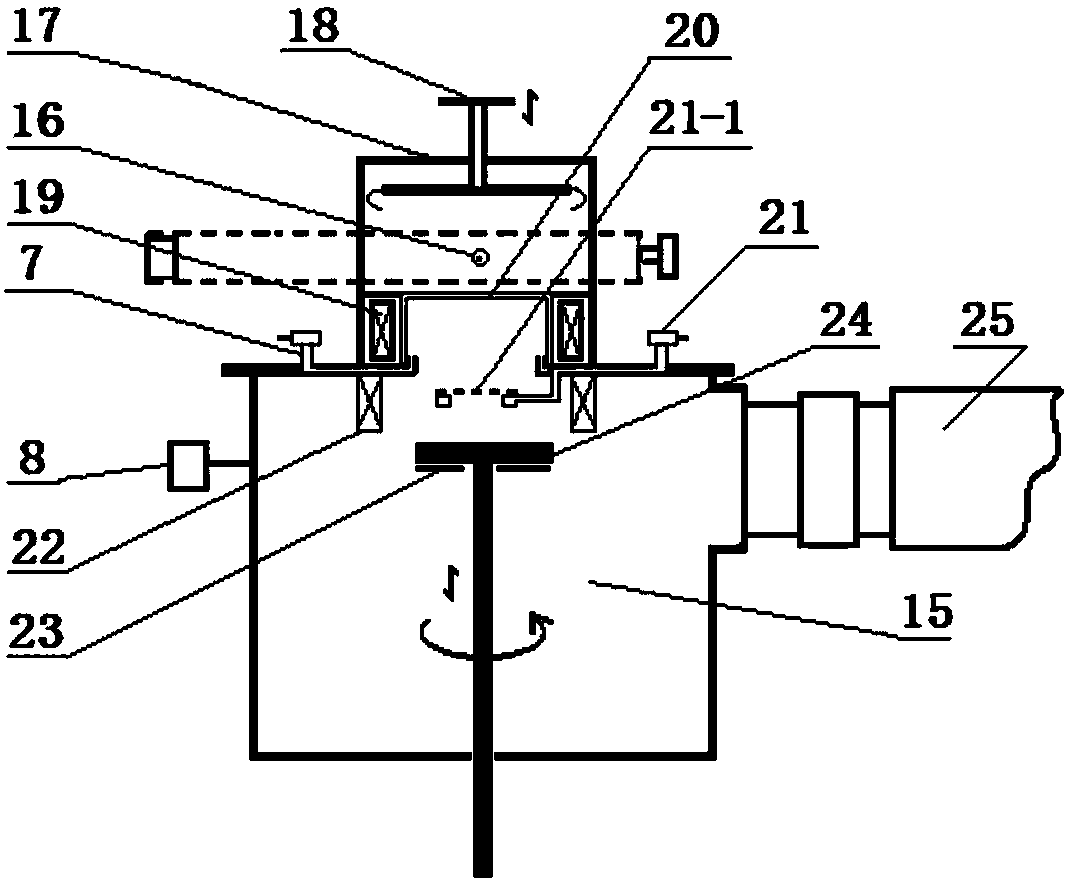

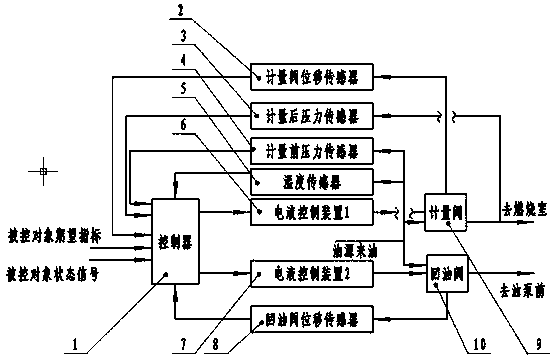

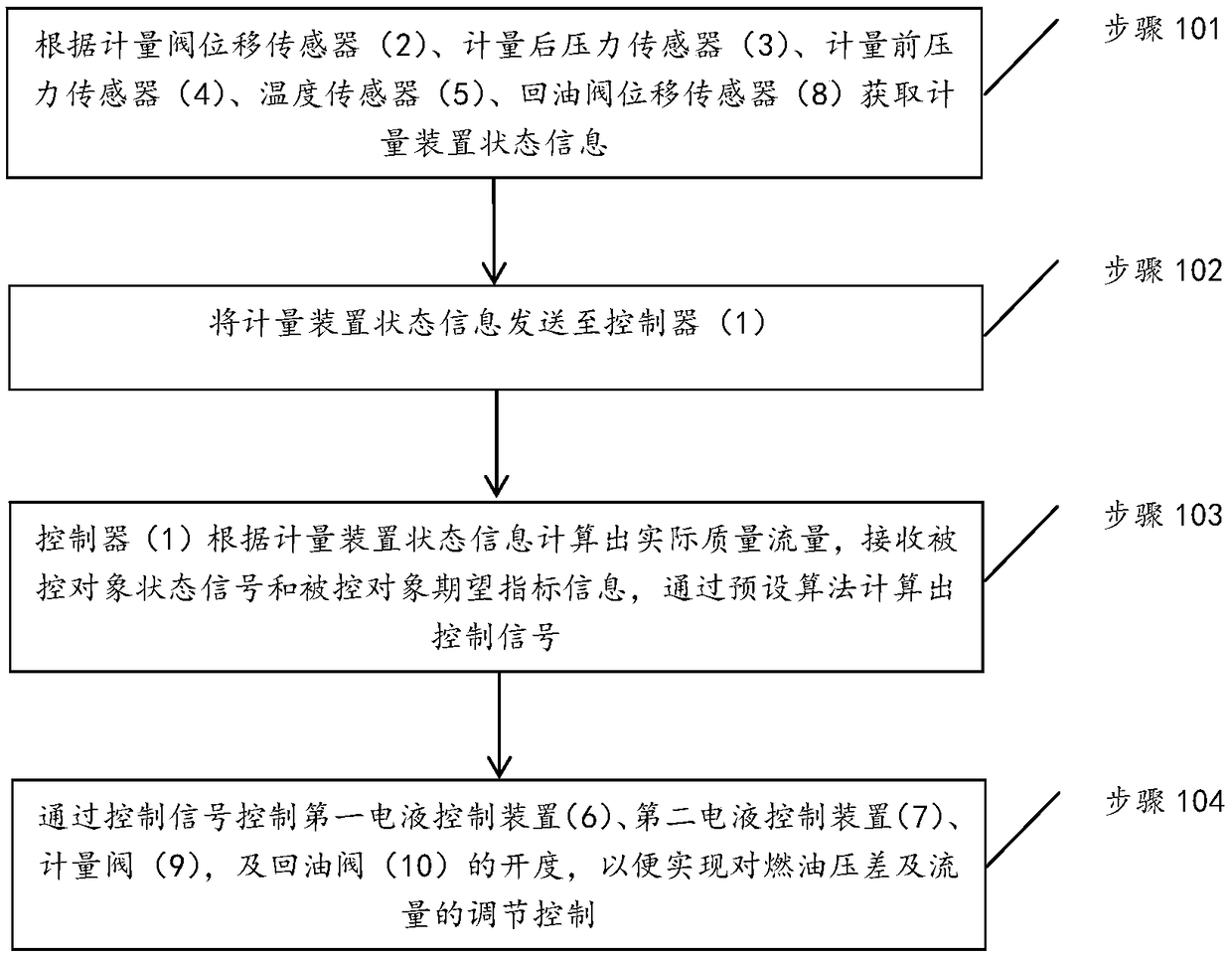

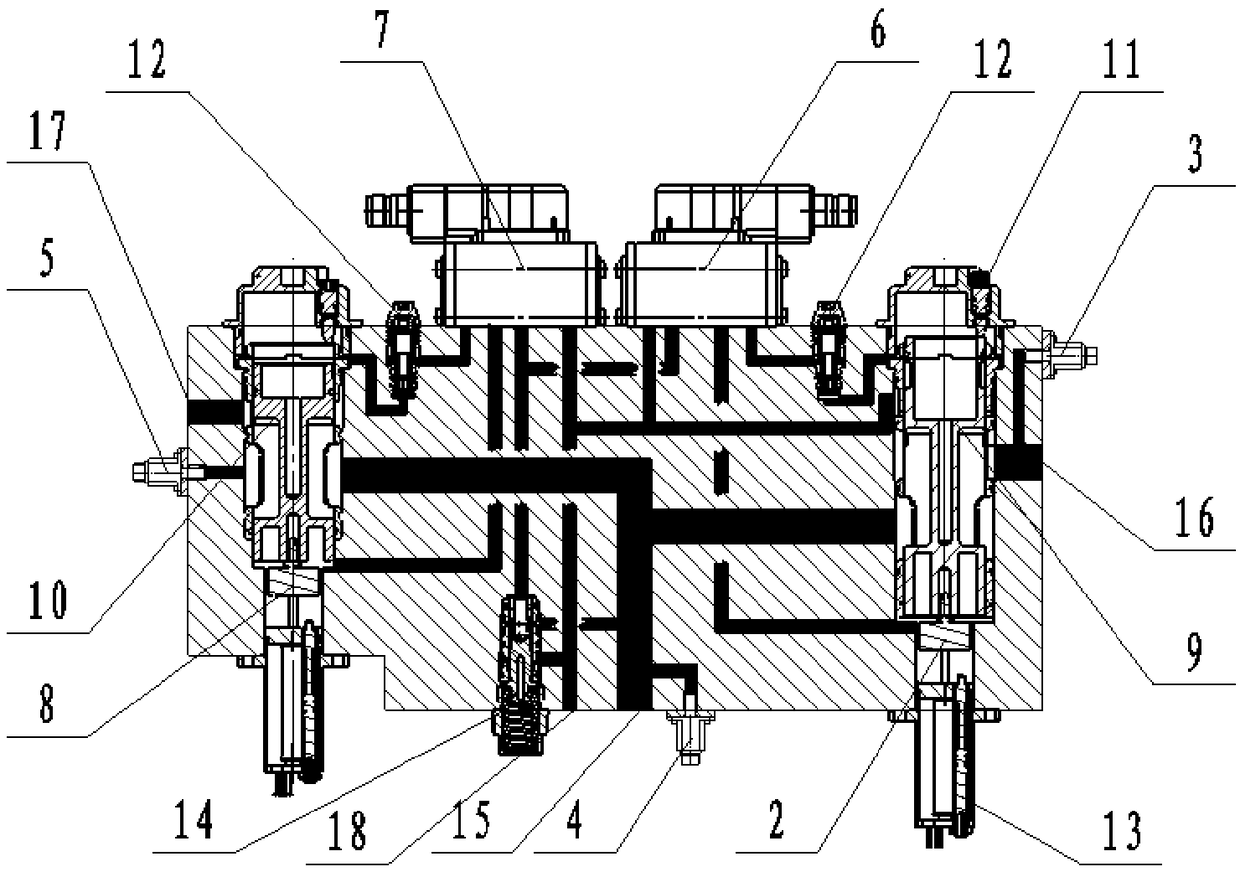

Variable pressure difference measuring method and device

ActiveCN109506723ARealize Regulatory ControlExpand the scope of selectionVolume/mass flow by differential pressureControl signalElectro hydraulic

The embodiment of the invention discloses a variable pressure difference measuring method and device. The method comprises acquiring the state information of a measuring device according to a measuring valve displacement sensor (2), a post-measurement pressure sensor (3), a pre-measurement pressure sensor (4), a temperature sensor (5) and an oil return valve displacement sensor (8); transmitting the state information of the measuring device to a controller (1); in the controller (1), calculating actual mass flow according to the state information of the variable pressure difference measuring device, receiving state signals and expected index information of a controlled object, and calculating control signals through a preset algorithm; controlling the opening degree of a first electro-hydraulic control device (6), a second electro-hydraulic control device (7), a measuring valve (9) and an oil return valve (10) through the control signals to achieve fuel pressure difference and flow adjustment control. By in real time controlling multiple variables, the variable pressure difference measuring method integrates and increases fuel measuring range and precision and response speed simultaneously, and meanwhile, expands the selecting range of varieties of fuel measuring fuel source pumps and improves reliability of the fuel measuring device.

Owner:XIAN AERO ENGINE CONTROLS

Method for preparing bio-based inorganic compound type water absorbent material

The invention provides a method for preparing a bio-based inorganic compound type water absorbent material. The method comprises the following steps of: A) adding an inorganic material in the reactor which contains 30 to 150 milliliters of aqueous solution of silane coupling agent, and stirring the mixture for 5 to 30 minutes to allow the inorganic material to adequately disperse; B) adding a bio-based material into the solution obtained by the step A in an amount of 0.7 to 3 percent based on the mass of distilled water, controlling the temperature to be between 30 and 80 DEG C, introducing nitrogen into the reactor for 15 to 30 minutes, uniformly dispersing the nitrogen, adding an initiator, continuing introducing the nitrogen into the equipment for 20 to 40 minutes, adding acrylic acid solution of a crosslinking agent and the blended solution of a sodium salt of acrylic acid and acrylamide into the solution, introducing nitrogen into the equipment for 10 to 20 minutes, performing a thermostatic reaction of the mixture for 1 to 6 hours, precipitating the product in ethanol, filtering the solution and drying the obtained product at a temperature of 65 DEG C, smashing the obtained product to obtain a target product. The prepared bio-based inorganic compound type water absorbent material has a distilled water absorptivity of more than 1,500 g / g and a saline absorptivity of 160 g / g, so the water absorbent material has good water absorptivity.

Owner:青岛生物能源与过程研究所

Presswork expression enhancement method and system based on high-fidelity image-hiding

ActiveCN106204663AOptimized for clarityContrast OptimizationImage enhancementImage analysisImage hidingComputer vision

The invention provides a presswork expression enhancement method and system based on high-fidelity image-hiding, and relates to the technical field of presswork expression. The method comprises the following steps: determining a design parameter through the early design and before-printing analysis to the presswork, hiding multilayer high-definition base images associated with a surface image under a full-color high-quality surface image through the adoption of a high-fidelity image-hiding netting system; through the prediction and optimal compensation of the color overlapping, obtaining the presswork with high expression by a printing system, wherein each layer of clear base image can be gradually observed through the corresponding detection measurement. Through the adoption of the presswork expression enhancement method and system based on the high-fidelity image-hiding provided by the invention, the complete causal relationship between the surface image and the base image can be expressed, the expression of the presswork is effectively improved, and the selection range of each of the surface image and the base image is enlarged.

Owner:臧戈平

Preparation method of boron hydrogen nitrogen energy storage material

Belonging to the preparation field of boron hydrogen nitrogen energy storage materials, the invention relates to a preparation method of a boron hydrogen nitrogen energy storage material. The preparation method provided in the invention specifically consists of the steps of: 1) adding an ammonium salt into an anhydrous solvent and conducting stirring; 2) adding a borohydride into the ammonium salt solution obtained in step 1), raising the temperature and letting them react; 3) performing filtration, and subjecting the filtrate to rotary evaporation, thus obtaining white solid powder; 4) dissolving the white solid powder in the anhydrous solvent, and conducting a recrystallization treatment so as to obtain a white crystal; and 5) subjecting the white crystal to vacuum drying, thus obtaining the boron hydrogen nitrogen energy storage material. The preparation method provided in the invention broadens the selection range of the ammonium salt, the reaction conditions are mild, the yield is high and can reach over 94%. The obtained product has high purity, which can reach a maximum of more than 99.9%. The method is of important significance for boosting practical application of the boron hydrogen nitrogen material. At the same time, the anhydrous solvent can be recycled, the cost is saved, and pollution to the environment is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

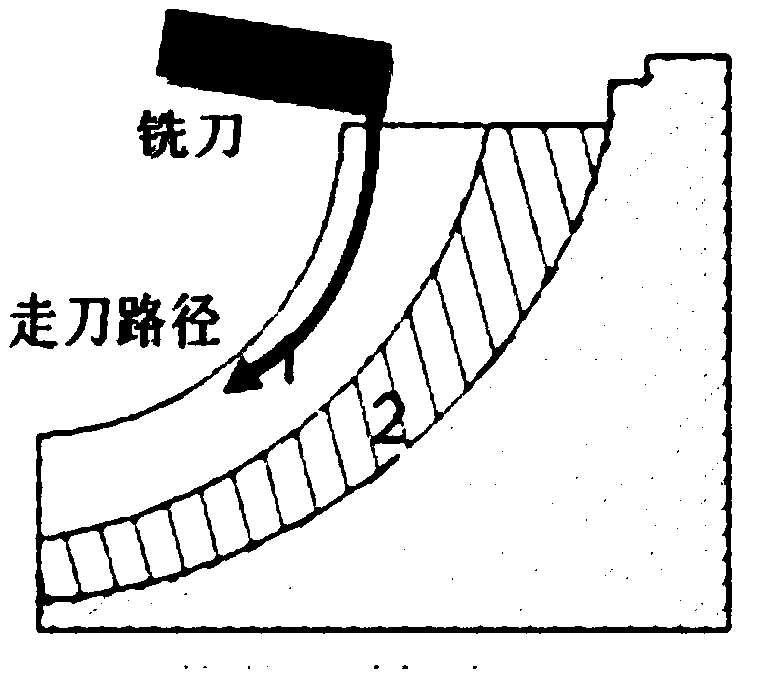

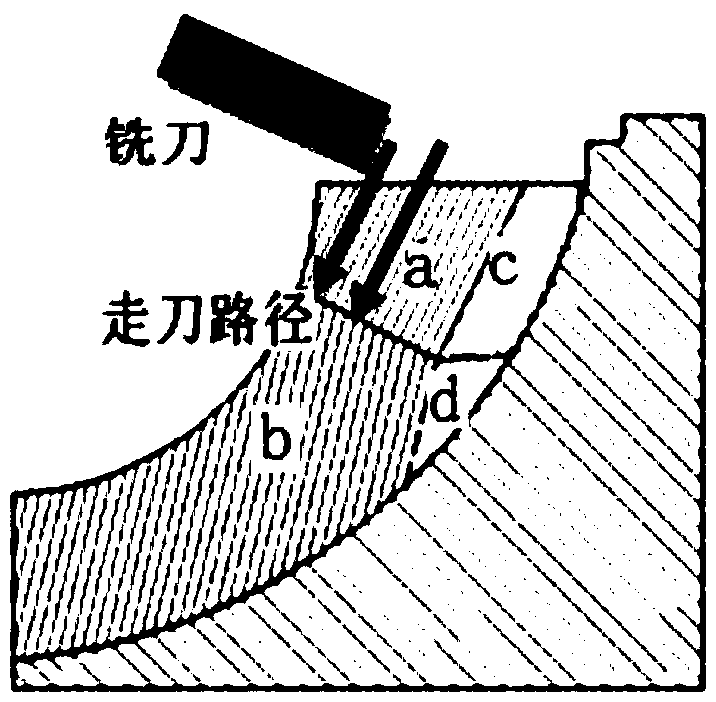

Space fixed-axis milling machining method for integral titanium alloy air compression impeller

ActiveCN109352048AExpand the scope of selectionLow costWorkpiecesMilling equipment detailsImpellerAir compression

The invention discloses a space fixed-axis milling machining method for an integral titanium alloy air compression impeller. The space fixed-axis milling machining method comprises the following stepsthat firstly, impeller roughening is conducted, wherein 1), modeling is conducted, a cavity structure between adjacent blades is determined, and modeling is conducted; 2), area division is conducted,and an impeller blank is divided into multiple areas; and 3), directional programming is conducted, one tool axis direction suitable for single-area milling is determined, then, the determined tool axis direction is fixed, the feed path suitable for the area is programmed in the direction, finally, blank milling simulating in the area is finished, a practical program suitable for machine tool machining is processed, the process is repeatedly conducted on each area, and integral impeller roughening is finished; secondly, blade finish milling is conducted; and thirdly, runner finish milling isconducted.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Self-return energy-dissipating joint for beams and column

PendingCN111042319ASolve the problem of slow deformation recoveryRealize energy consumptionProtective buildings/sheltersShock proofingStructural engineeringSteel columns

The invention discloses a self-return energy-dissipating joint for beams and a column. The self-return energy-dissipating joint comprises the steel column, the middle beam, the short beam, connectingplates, a friction plate, a limiting device, a hinged support base and a high-strength anchor rod, wherein the steel column is vertically arranged, and the middle beam is transversely arranged; one end of the short beam is fixedly connected to the steel column, and a gap is formed between the other end of the short beam and the middle beam; the two connecting plates are separately positioned at the two sides of a web of the short beam and a web of the middle beam; the friction plate is cushioned between the web of the short beam and the connecting plates; the limiting device is a barrel body or a rack body which is fixed to the bottom surface of the lower wing edge of the middle beam, and is provided with through holes in two sides; the hinged support base is fixed on the steel column; oneend of the high-strength anchor rod is hinged with the hinged support base, and the other end of the high-strength anchor rod passes through the through holes of the limiting device; and a disc-shaped spring group sleeves the high-strength anchor rod, and the two ends of the high-strength anchor rod are symmetrically provided with the limiting steel plate and the high-strength nut in a sleeved mode. Pre-pressing force is applied to the disc-shaped spring group, so that the beam and the column have self-return ability; during a strong earthquake, the short beam is hinged with the middle beam to rotate and rub to dissipate energy; and the disc-shaped spring group under the beam column joint realizes self-return.

Owner:HAINAN UNIVERSITY

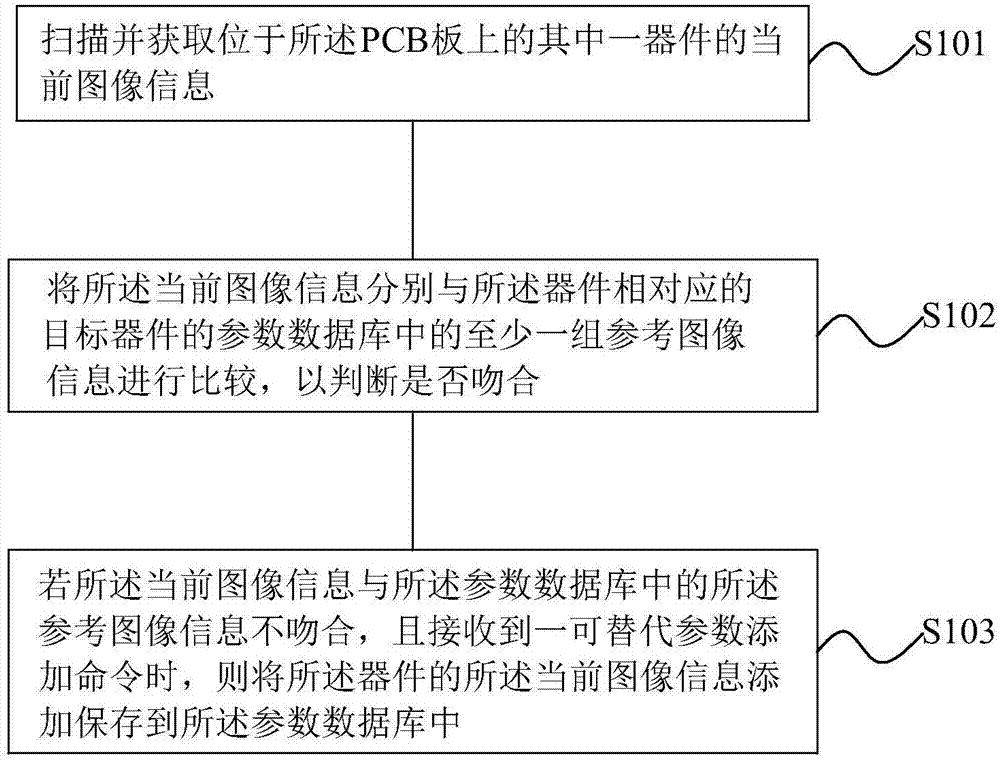

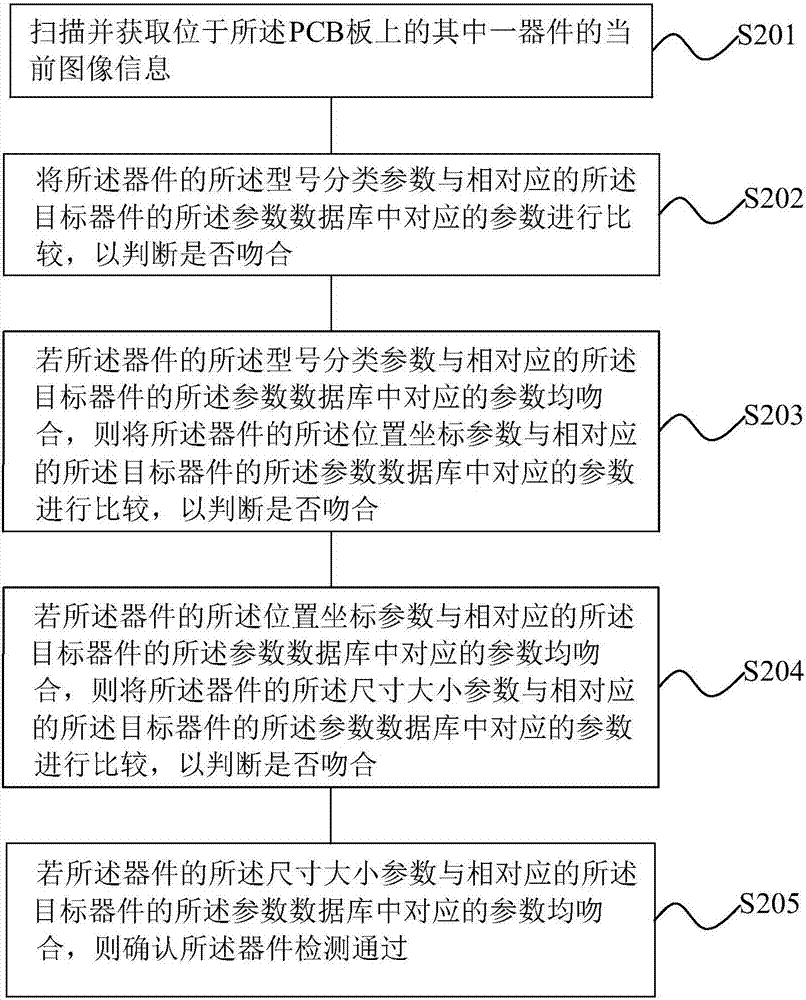

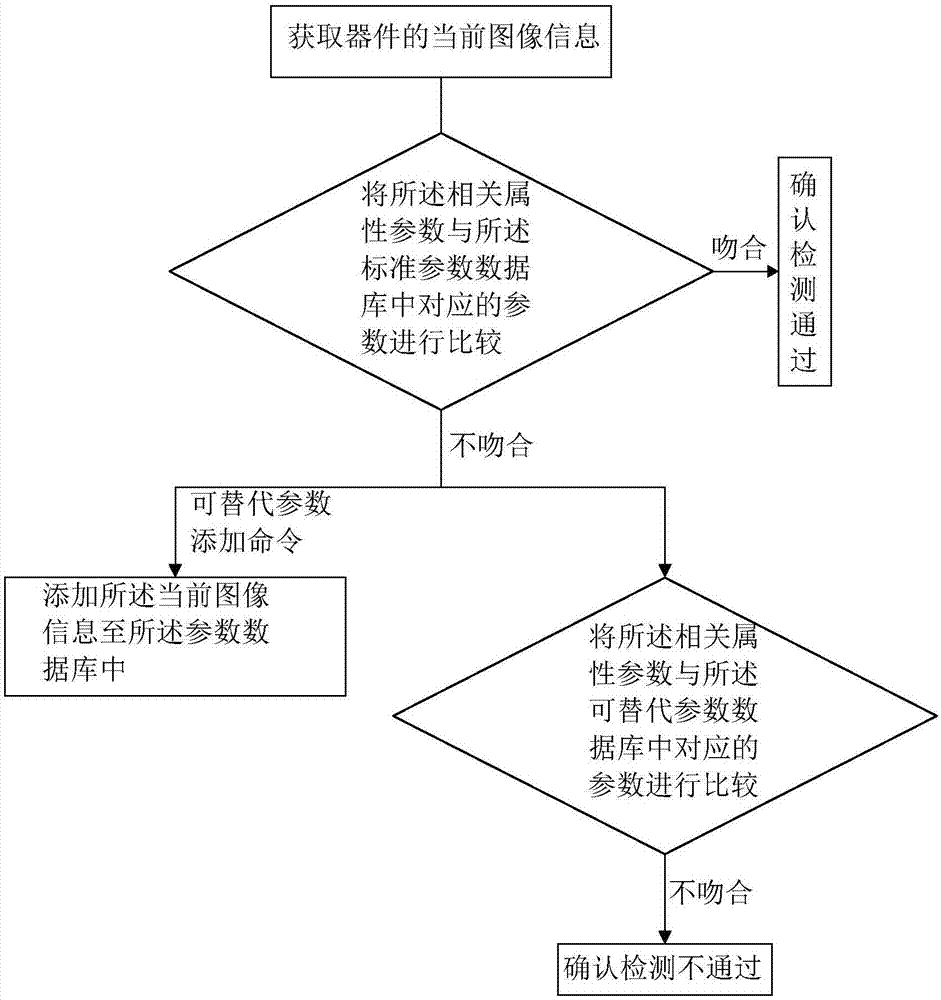

AOI device database addition method and system thereof

ActiveCN107084989AExpand the scope of selectionOptically investigating flaws/contaminationData miningData science

The invention relates to an AOI device database addition method and a system thereof. The method comprises the following steps: current image information of one device on a PCB is scanned and acquired; the current image information is respectively compared with at least a set of reference image information in a parameter database of a target device corresponding to the device so as to judge whether the information match each other; if the current image information doesn't match the reference image information in the parameter database and one replaceable parameter add command is received, the current image information of the device is added and stored in the parameter database. According to the invention, an attribute parameter of the detected device can be compared with a related attribute parameter of an original standard device and also can be compared with a related attribute parameter of a substituted device which still meets requirements, and it can be judged that the detected device meets requirements if the attribute parameter accords with any one of the related attribute parameters. Selection range of related device in the PCB card manufacturing process is widened.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

Foamed silicone rubber and preparation method thereof

InactiveCN109486203AExpand the scope of selectionImprove heat aging resistancePolymer scienceVulcanization

The invention discloses foamed silicone rubber and a preparation method thereof, and belongs to the technical field of silicone rubber materials. Vinyl silicone rubber containing different amounts ofethylene is taken as a base rubber, the introduction of a small amount of ethylene is beneficial to improving vulcanization activity, increasing the selection range of organic peroxide vulcanizing agents, improving the heat aging resistance, mechanical strength and compression permanent deformation performance of vulcanized rubber; and meanwhile, the foamed silicone rubber is prepared by adoptinga method combining freezing and two-stage vulcanization reaction, and the two-stage vulcanization reaction is beneficial to avoiding the occurrence of over-sulfur, thus improving the mechanical properties and compression permanent deformation properties of a foamed silicone rubber product. Combined with the freezing process, the foaming uniformity and mechanical properties of the prepared productare improved, and the tensile strength of the prepared foamed silicone rubber reaches 0.87 Mpa.

Owner:安徽旭川新材料科技有限公司

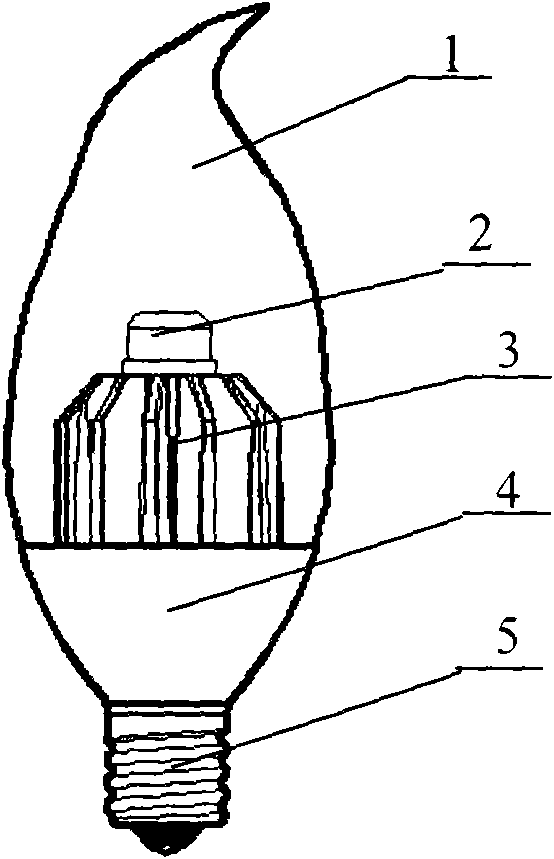

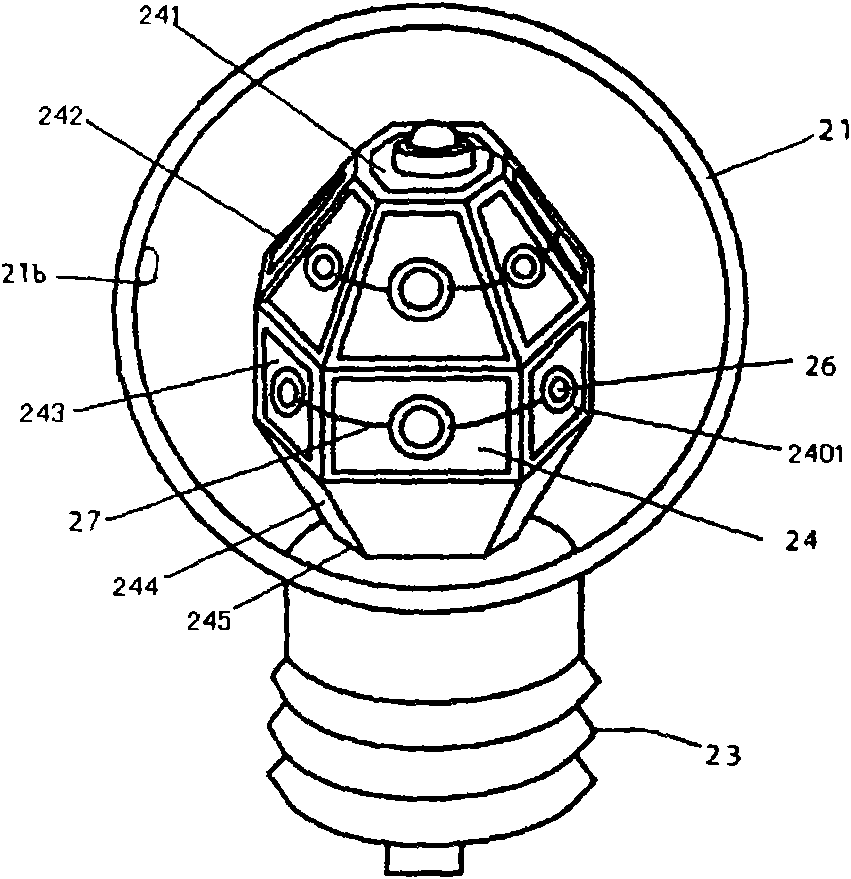

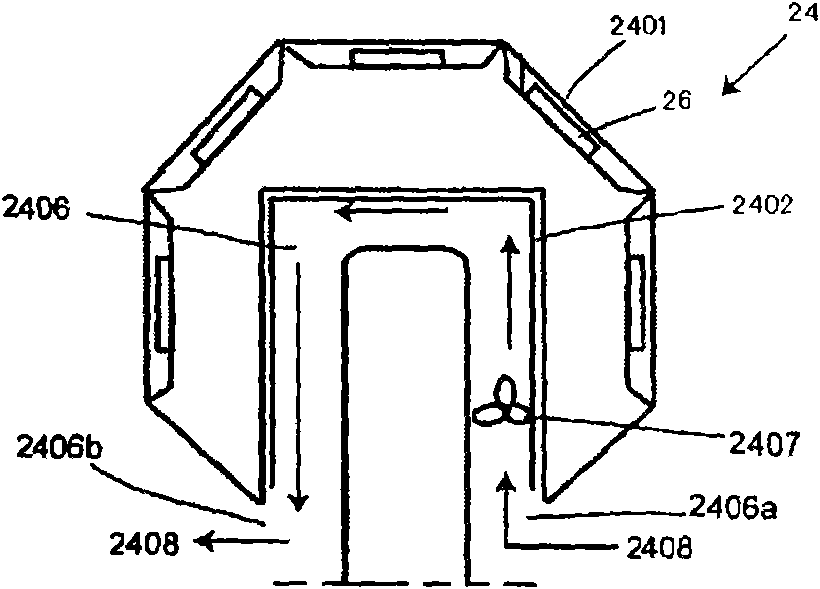

Novel large-power LED candle-type lamp

InactiveCN101655185ALow failure rateSolution to short lifePoint-like light sourceElectric circuit arrangementsEngineeringCandle

The invention discloses a novel large-power LED candle-type lamp, which consists of a large-power LED lamp, a driving circuit, a heat sink, a lamp holder, a base and a lamp shade, wherein the LED lampconsists of a large-power LED; the upper end of the heat sink is provided with a unit connected with the LED lamp; the upper part of the base supports the heat sink component and the lower part of the base is connected with the standard lamp holder; the LED lamp is screwed on the heat sink and the two poles of the LED lamp are electrically communicated with corresponding control ends of a drivingcircuit board; and the lamp shade covers the combination of the LED lamp and the heat sink in the base. The aim of the invention is to provide an environmentally-friendly, energy-saving and long-lifenovel large-power LED lamp, which adopts novel structural design that can effectively improve light brightness, LED radiation capacity and shock strength and which emits more even and brighter light.

Owner:GOLDEN VALLEY OPTOELECTRONICS

Road sweeper

PendingCN107916643ALower selection limitExpand the scope of selectionRoad cleaningVehicle frameRoad sweeper

The invention relates to a road sweeper. The road sweeper comprises a car frame, a bearing assembly and a dustbin assembly. The bearing assembly is disposed at the rear part of the car frame and comprises a supporting frame and a flipping frame, the supporting frame is arranged on the top of the car frame, and an accommodating space for installing a power system is formed in the supporting frame;the flipping frame is located above the supporting frame and is rotatably connected to the supporting frame; the dustbin assembly is arranged on the flipping frame and is supported by the flipping frame. The flipping frame can be flipped over a predetermined angle above the supporting frame, and the accommodating space for installing the power system is formed in the supporting frame. When the power system needs to be installed or disassembled, an operator can flip the flipping frame from the upper part of a chassis bracket to install the power system. The above flipping structure provides a convenient installation space for the installation of the power system, reduces the selection limit of the power system, and expands the selection range of the power system.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

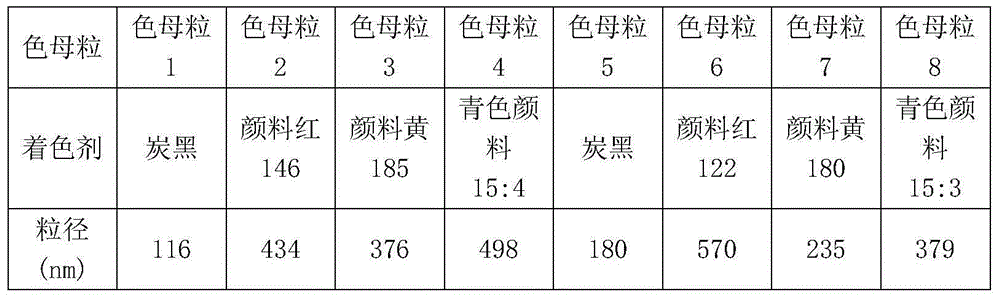

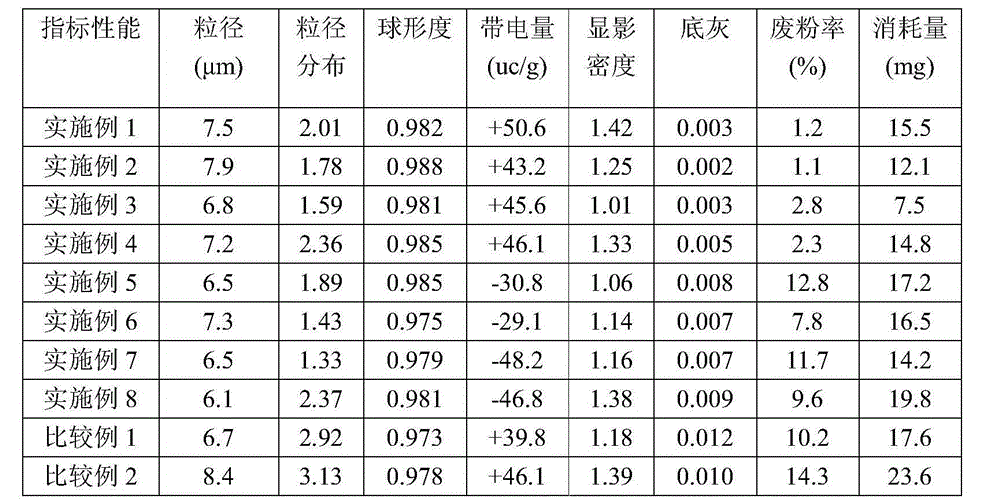

Method for preparing color carbon powder by adopting suspension polymerization method

The invention relates to a method for preparing color carbon powder by adopting a suspension polymerization method, and solves the problems that carbon powder is instable in quality and the selection of raw materials is limited in a traditional suspension polymerization method. According to the technical scheme, the method comprises the following steps: melting a coloring agent and resin, mixing the melt coloring agent and resin so as to obtain a mixture I, extruding the mixture I and crushing to obtain color master batch; adding the color master batch, wax and an initiator into monomers to obtain a mixture II, heating and stirring to dissolve the mixture II to obtain an organic phase containing the coloring agent, resin, initiator, wax and monomers; adding the organic phase into an aqueous solution containing a surface active agent, carrying out shearing dispersing on the organic phase in the aqueous solution to obtain turbid liquid, polymerizing the turbid liquid in a heating manner to obtain a color carbon powder matrix, finally filtering the color carbon powder matrix, washing the filtered color carbon powder matrix, drying, and mixing the color carbon powder matrix with additives to obtain the color carbon powder. The method is simple in procedure, low in process difficulty, easy to control, wide in raw material selection range and relatively few in adverse impact factors, and the obtained color carbon powder is relatively narrow in granularity distribution, relatively few in small particles and stable and reliable in quality.

Owner:HUBEI DINGLONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com