Method for preparing aluminum nitride electronic ceramic base plate by using tape casting method and solvent for tape casting method for preparing ceramic

A technology of aluminum nitride ceramics and electronic ceramics, applied in the field of ceramic materials, can solve problems such as operator's physical harm and environmental pollution, and achieve the effects of huge environmental protection benefits, improvement of operating conditions, and reduction of industrialized energy consumption ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The aluminum nitride ceramic substrate is prepared by benzene-free casting method, and the steps are as follows:

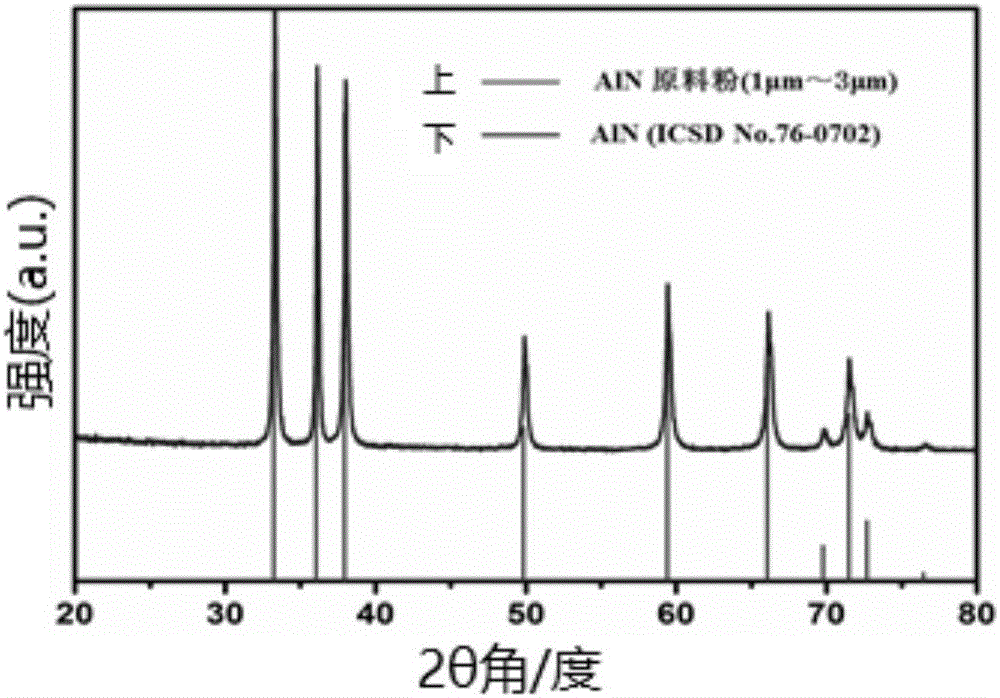

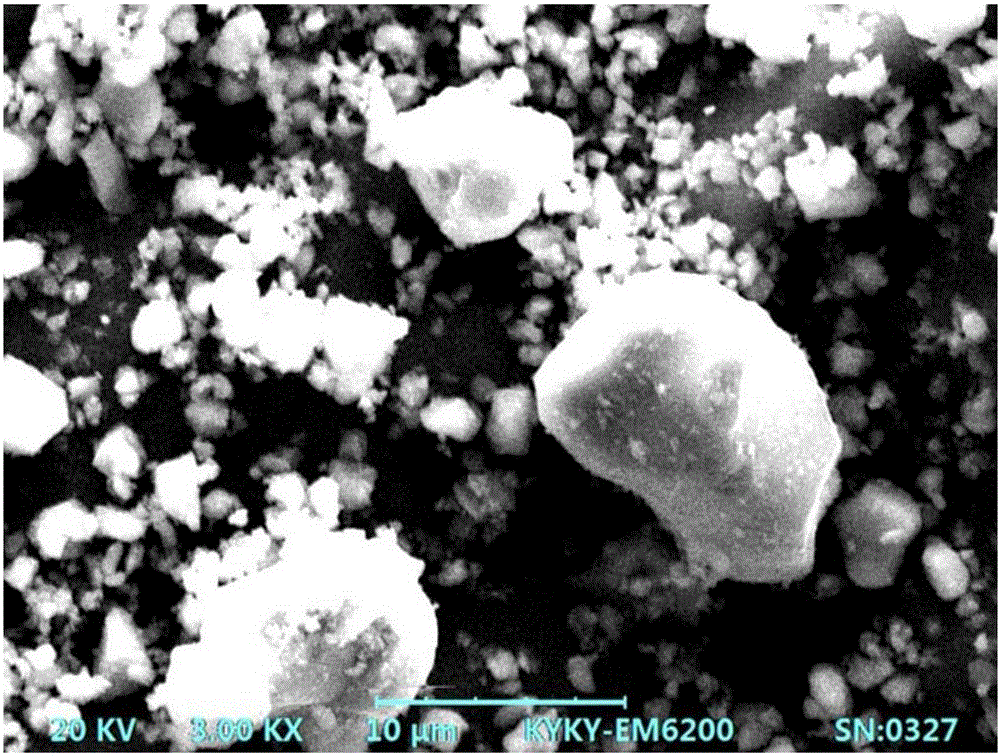

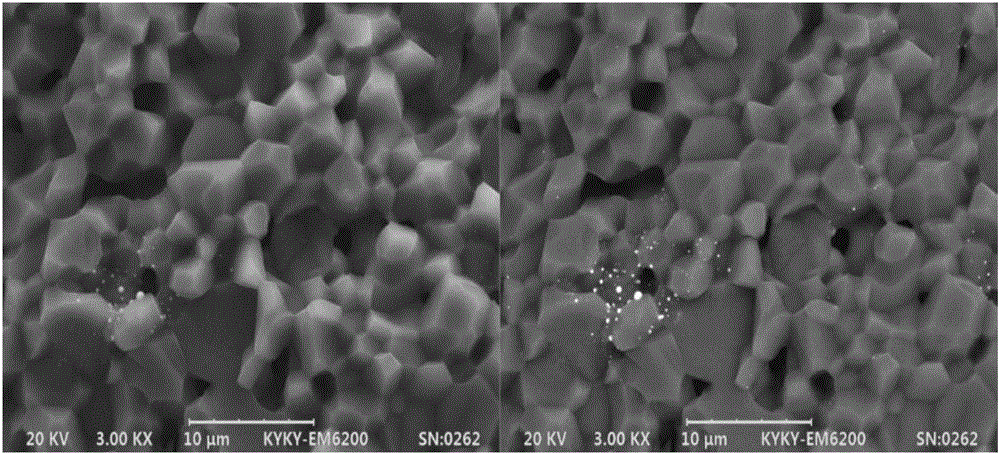

[0093] (1) Take 122.97g of AIN powder, and the measured oxygen content of the powder is 1.52at%. Because the powder contains other metal oxides and oxygen impurities, other oxygen content is deducted in this calculation. According to the addition rule of yttrium ion, it is The ratio of the molar mass to the oxygen content of the aluminum nitride powder is (0.3~0.6):(M-A-B), where M is the measured oxygen content of the aluminum nitride powder, and A is the oxygen content of the metal oxide in the aluminum nitride ceramic powder , B is the oxygen content of other sintering aids; preferably 0.5:(M-A-B), the amount of yttrium ions or lanthanide rare earth ions to be added is calculated to be 0.01844mol, wherein the molar ratio of yttrium ions to praseodymium ions is 0.8:0.2, join Y 2 o 3 Powder 3.33g, Pr 2 o 3 Powder 1.22g, in order to make this part of th...

Embodiment 2

[0109] (1) Take 122.97g of AIN powder, and the measured oxygen content of the powder is 1.52at%. Because the powder contains other metal oxides and oxygen impurities, other oxygen content is deducted in this calculation. According to the addition rule of yttrium ion, it is The ratio of the molar mass to the oxygen content of the aluminum nitride powder is (0.3~0.6):(M-A-B), where M is the measured oxygen content of the aluminum nitride powder, and A is the oxygen content of the metal oxide in the aluminum nitride ceramic powder , B is the oxygen content of other sintering aids; preferably 0.6:(M-A-B), the total amount of yttrium ions or lanthanide rare earth ions to be added is calculated to be 0.03074mol, and the molar ratio of yttrium ions to dysprosium ions is 0.5:0.5 , join Y 2 o 3 Powder 3.47g, Dy 2 o 3 Powder 5.733g, in order to make this part of oxygen ions can form Y with enough yttrium ions or lanthanide rare earth ions 3 Al 5 o 12 Spinel or lanthanide spinel ph...

Embodiment 3

[0123] (1) Take 131.17g of AIN powder, and the measured oxygen content of the powder is 1.52at%. After calculation, the total amount of yttrium ions or lanthanide rare earth ions to be added is 0.0276mol, and the molar ratio of yttrium ions to ytterbium ions is 0.3 :0.7, join YF 3 Powder 1.208g, Yb 2 o 3 Powder 7.614g, in order to make this part of oxygen ions can form Y with enough yttrium ions or lanthanide rare earth ions 3 Al 5 o 12 Spinel or lanthanide spinel phase, and then add 1.2wt% of aluminum nitride powder and 1.57g of CaO powder.

[0124] (2) Then according to the designed 38.5Vol% volume ratio solid content, add absolute ethanol 12g, isopropanol 5.4g, n-butanol 3.95g, triethyl phosphate 8.33g, dibasic acid ester mixture 4.5g.

[0125] (3) After adding 2.08 g of polyoxyethylene sorbitol ester as a dispersant and 1.5 g of fish oil, put the above-mentioned powder and solvent into a ball milling tank, and set the ball milling speed to 240 rpm for a ball milling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com