Space fixed-axis milling machining method for integral titanium alloy air compression impeller

A milling processing, titanium alloy technology, applied in the direction of metal processing equipment, workpieces, milling machine equipment, etc., can solve the problems of low feed parameters, low processing efficiency, high tool cost, etc., to expand the selection range, improve production efficiency, and reduce tool costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

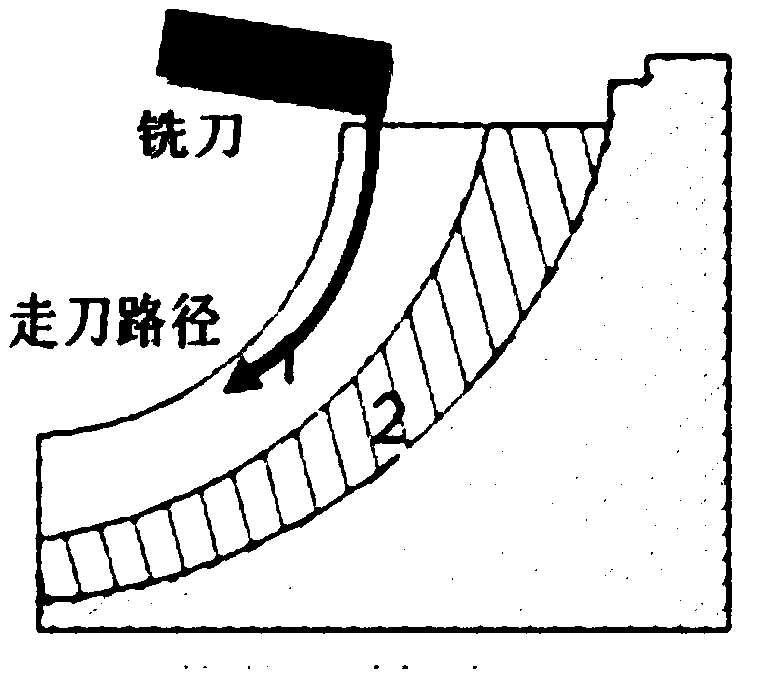

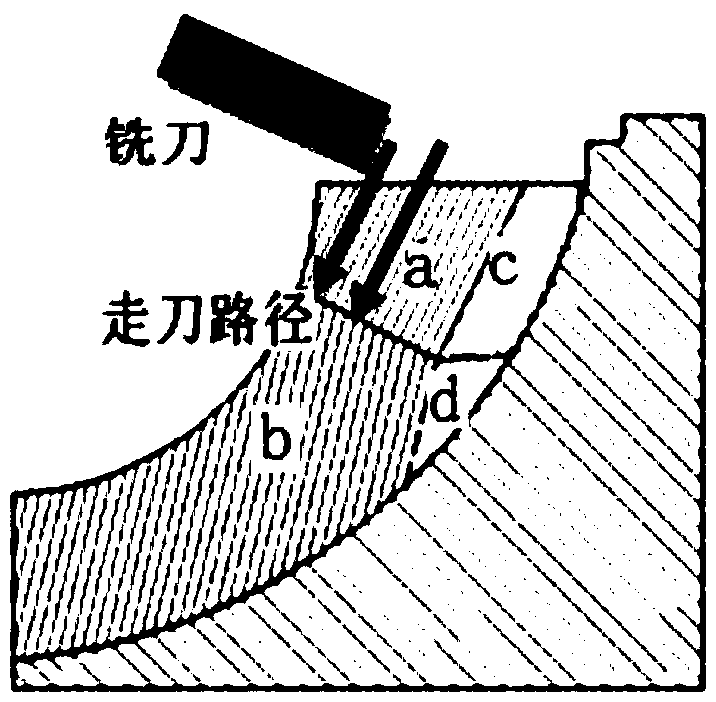

[0024] see Figure 1-Figure 5 , an embodiment of the space fixed-axis milling method of the integral titanium alloy compressor impeller, comprising the following steps:

[0025] Step 1, the impeller is opened coarsely,

[0026] 1) Modeling, determining and modeling the cavity structure between adjacent blades;

[0027] According to the consistency of the blades of the compressor impeller, it is determined that the basic unit of the blank model to be processed is an open cavity structure between adjacent blades. Before processing, it is only necessary to create such image 3 The basic model unit shown is enough. After the subsequent operation of this unit is completed, the overall machining of the complete impeller can be realized through simple indexing and rotation.

[0028] 2) Divide the area. According to the width and depth of the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com