Supported catalyst used in selective synthesis, and preparation method and purpose thereof

A supported catalyst and catalyst technology, which can be used in the preparation of organic compounds, the preparation of carbon monoxide or formate reaction, chemical instruments and methods, etc., and can solve problems such as small surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

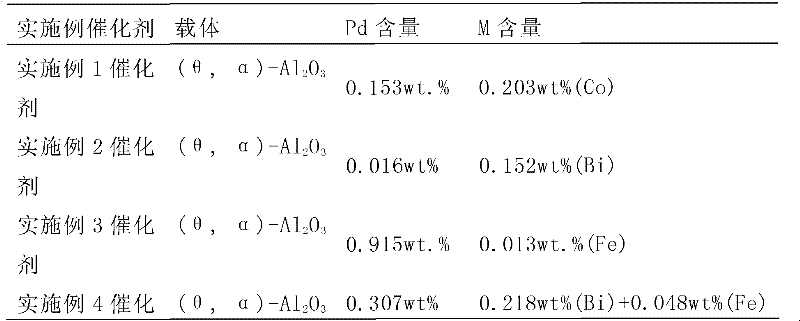

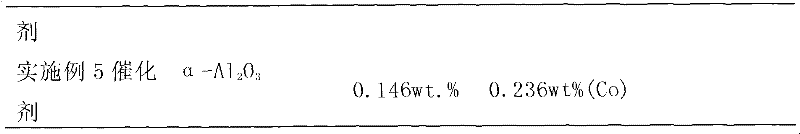

Embodiment 1

[0032] Selected (θ,α)-Al 2 o 3 The specific surface area of the carrier is 65m 2 / g, of which theta phase accounted for 7.4%.

[0033] Take by weighing 20g carrier, prepare catalyst according to the content of Pd metal weight fraction 0.15wt% and Co metal weight fraction 0.2%, its steps are as follows: the aqueous solution that pH is 9 is prepared by ammonium bicarbonate and ammoniacal liquor and deionized water, by equal volume Immersion method Weigh a certain amount of the aqueous solution, then weigh a certain amount of palladium nitrate and cobalt nitrate and dissolve it in the aqueous solution. After completely dissolving without precipitation, spray and impregnate it on the carrier at room temperature, take out the carrier after 10 minutes, After drying at ℃ for 8 hours and then firing at 300℃ for 5 hours, Pd-Co / Al can be prepared 2 o 3 catalyst. The active ingredient content is measured by ICP, see Table 1.

[0034] Before the evaluation of the catalyst, the cat...

Embodiment 2

[0036] Weigh 25g (θ,α)-Al 2 o 3 Carrier, prepare catalyst according to the content of Pd metal weight fraction 0.05% and Bi metal weight fraction 0.15wt%, its steps are as follows: prepare the aqueous solution that pH is 9 by mixing ammoniacal liquor and ammonium bicarbonate and deionized water, weigh a certain amount by equal volume Then weigh a certain amount of palladium nitrate and bismuth nitrate and dissolve in the aqueous solution. After completely dissolving without precipitation, spray and impregnate it on the carrier at room temperature. After 10 minutes, take out the carrier and dry it at 125°C for 12 Hours, and then baked at 350°C for 6 hours, Pd-Bi / Al can be prepared 2 o 3 catalyst. The contents of the active ingredients are shown in Table 1.

[0037] With the evaluation conditions of Example 1, the catalyst activity evaluation results are shown in Table 2.

Embodiment 3

[0039] Weigh 20g (θ,α)-Al 2 o 3 Carrier, prepare catalyst according to the content of Pd metal weight fraction 0.8% and iron metal weight fraction 0.05wt%, its steps are as follows: prepare the aqueous solution that pH is 8.3 by mixing ammonium bicarbonate and ammoniacal liquor and deionized water, weigh by equal volume A certain amount of this aqueous solution, then weigh a certain amount of palladium nitrate and ferric nitrate and dissolve it in the aqueous solution. After completely dissolving without precipitation, spray and impregnate it on the carrier at room temperature. After 15 minutes, take out the carrier and dry it at 135°C. 8 hours, and then baked at 350°C for 5 hours, the Pd-Fe / (θ,α)-Al can be prepared 2 o 3 catalyst. The contents of the active ingredients are shown in Table 1.

[0040] With the evaluation conditions of Example 1, the catalyst activity evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com