Load bearing structure, road sweeper and assembling and disassembling method of power system

A load-bearing structure and power system technology, applied in the field of sanitation, can solve the problems of disassembly troubles, limit the rapid replacement and use of multi-function tools in the rear car, and achieve the effect of simplifying installation, reducing selection restrictions, and expanding the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

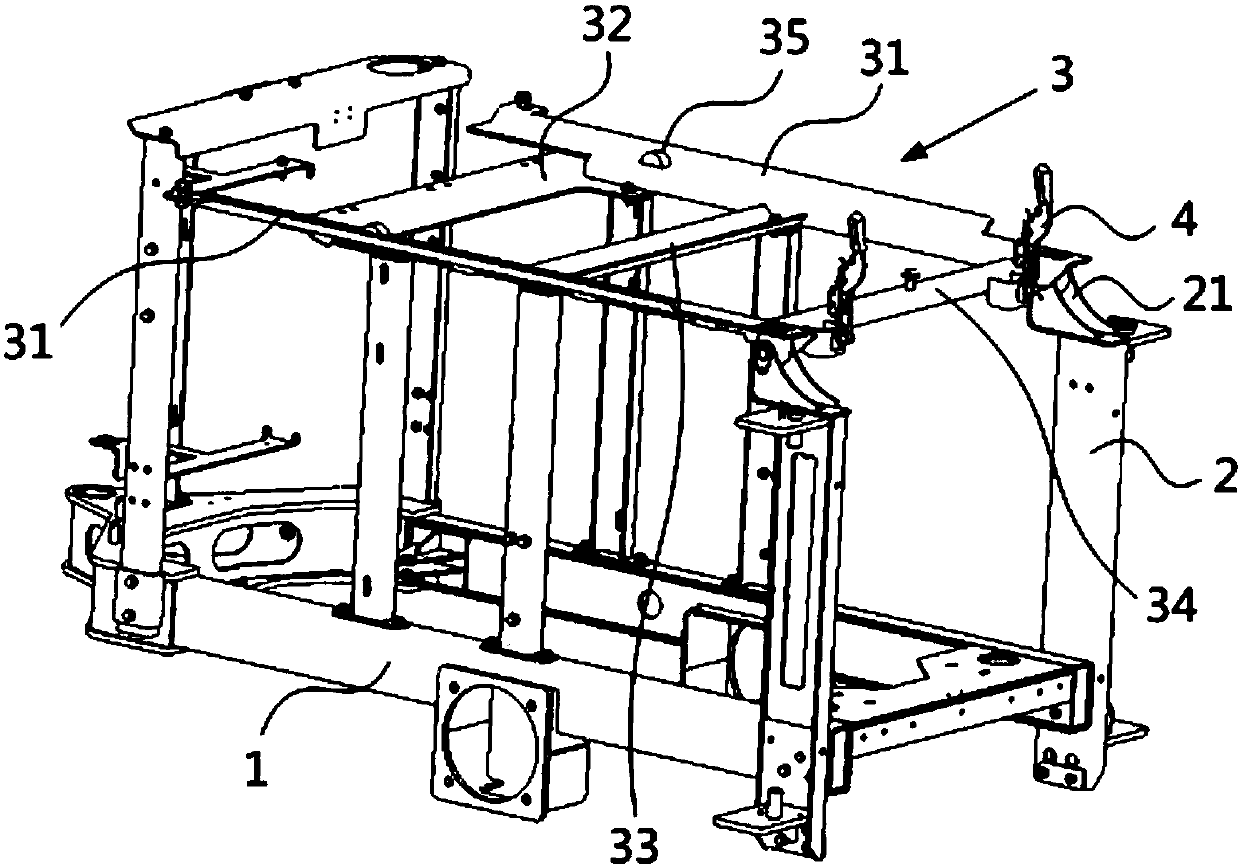

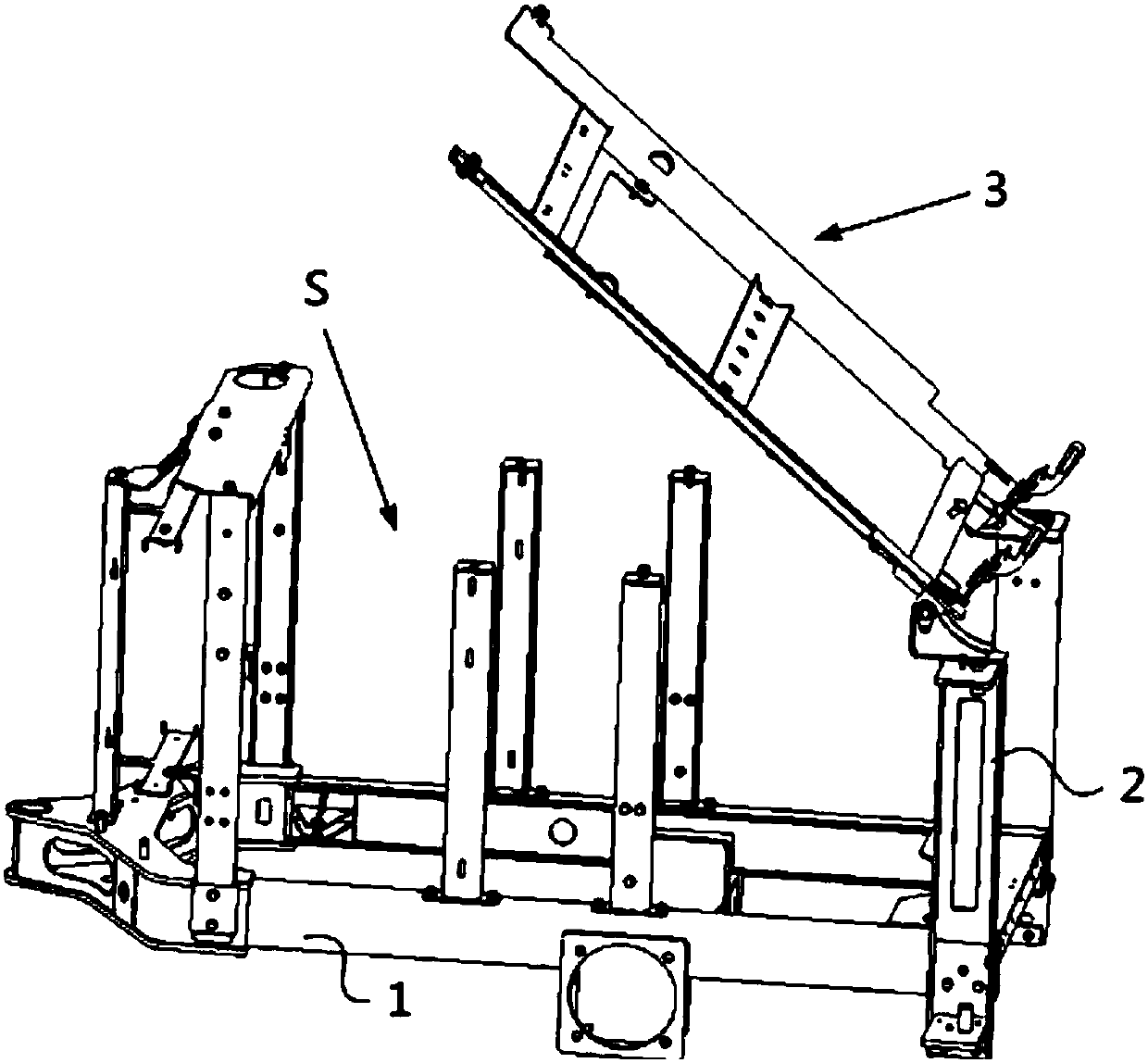

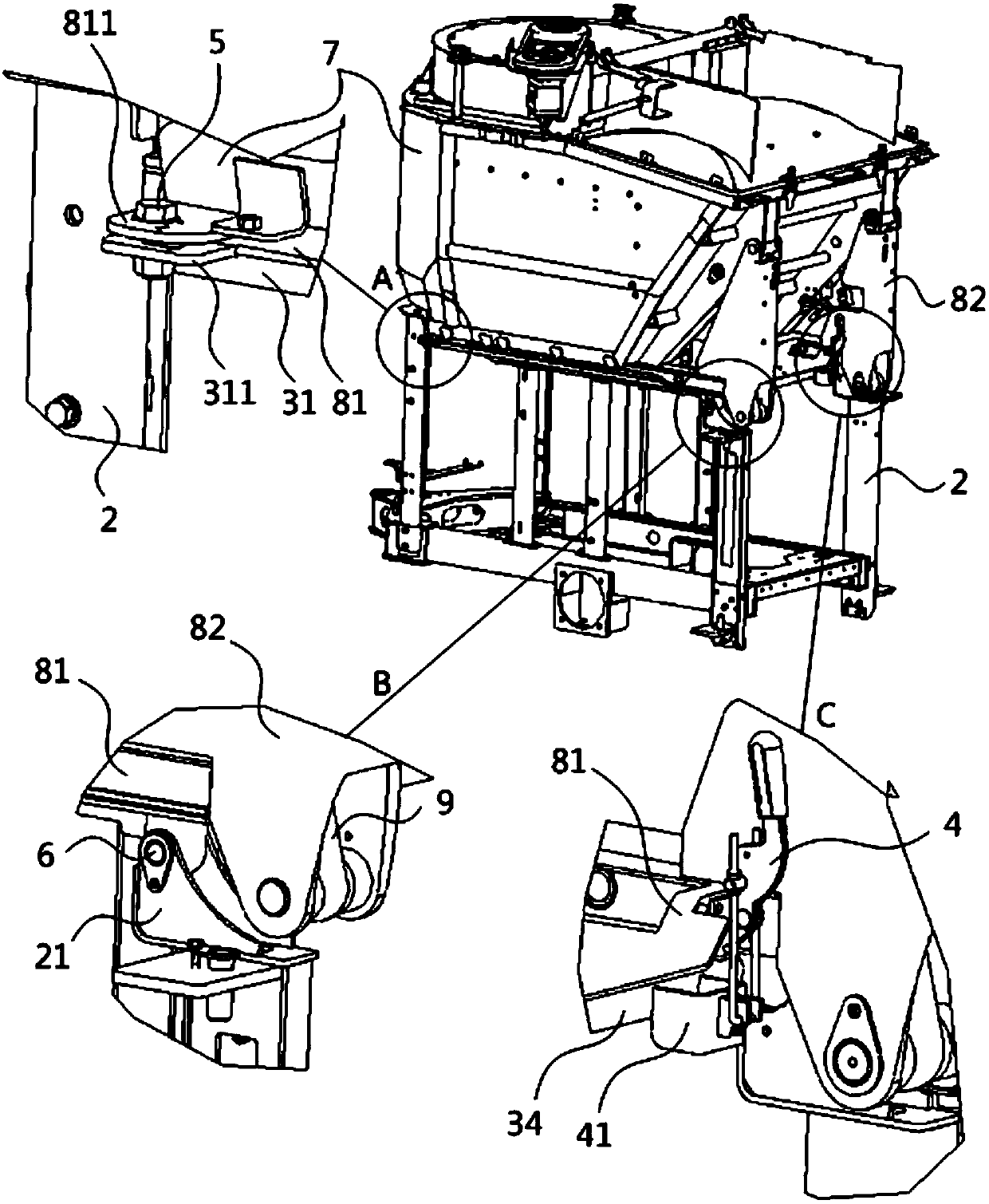

[0034] like figure 1 As shown, it is a schematic diagram of the installation structure of an embodiment of the load-carrying structure of the present invention. combine figure 2 As shown in the turned over state of the turning frame, the load-bearing structure in this embodiment includes: a chassis frame 1 , a chassis support 2 and a turning frame 3 . The chassis bracket 2 is fixed on the chassis frame 1 and together with the chassis frame 1 forms an accommodating space S for installing a power system. The overturning frame 3 is located above the chassis support 2, and one end of the overturning frame 3 is hinged on the upper part of the chassis support 2, and can be overturned at a preset angle relative to the chassis support 2 above the chassis support 2.

[0035] In this embodiment, an overturning frame capable of turning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com