Extraction and preparation method of abamectin B2a

An abamectin extraction technology, applied in the field of antibiotic extraction and preparation, can solve the problems of high cost, unsuitability for industrial production, and limited recycling scale, and achieve the effects of low production cost, easy process control, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

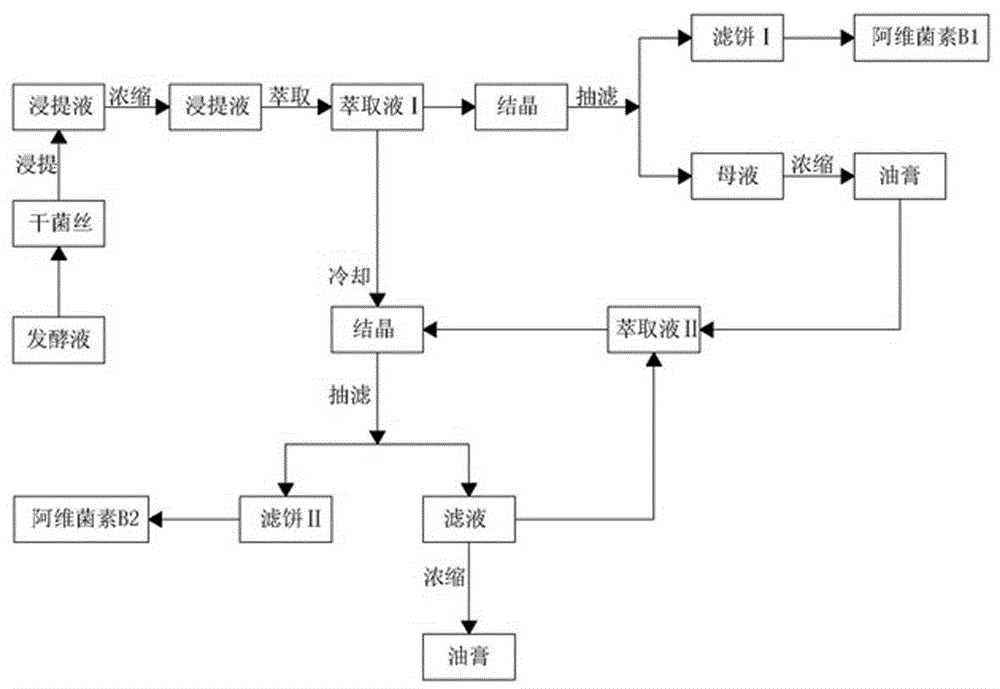

[0034] Refer to the process figure 1 , the specific steps are:

[0035] a, using the abamectin fermented liquid as the starting material, pumping it into the plate frame for filtration. In order to increase the filtration rate, an appropriate amount of filter aid can be added to the abamectin fermentation broth, and the fermentation broth can also be heated to 80°C to 90°C. Mycelium is obtained after filtering, and then dried to obtain dry mycelium. Place the dried mycelium in a reaction tank, add ethanol to soak and extract (referred to as extraction). The add-on of ethanol is advisable with being able to immerse mycelium completely, and the concentration of ethanol can be selected according to the range shown with conventional leaching method, and the present invention is preferably with 75-95%. After the dried mycelium is soaked in ethanol for 2-5 hours, the extract is collected and set aside; the filter residue can be repeatedly extracted with ethanol for 2-3 times, and...

Embodiment 2

[0049] Refer to the process figure 1 , the specific steps are:

[0050] a, using the abamectin fermented liquid as the starting material, pumping it into the plate frame for filtration. Mycelium is obtained after filtering, and then dried to obtain dry mycelium. The mycelium is placed in a reaction tank, and 85% ethanol is added for extraction. The addition of ethanol is advisable to be able to submerge mycelium completely. After the mycelium was soaked in ethanol for 3 hours, the extract was collected for subsequent use;

[0051] b. Pour the extract into the evaporating tank, heat to concentrate the extract until it does not contain ethanol, then add a certain amount of toluene and water, heat up to 80-100°C, stir for 30min-40min, let stand, and discharge to the bottom aqueous solution, and the organic solution was collected to obtain the extract I.

[0052] c. Add perlite filter aid to the extract Ⅰ, stir for 30-40 minutes, and after stirring evenly, cool down to 10-0°C...

Embodiment 3

[0055] a, using the abamectin fermented liquid as the starting material, pumping it into the plate frame for filtration. Mycelium is obtained after filtering, and then dried to obtain dry mycelium. Place the mycelium in a reaction tank, add 60% ethanol for extraction. The addition of ethanol is advisable to be able to submerge mycelium completely. After the mycelium is soaked in ethanol for 5-6 hours, the extract is collected and set aside;

[0056] b. Pour the extract solution into the evaporating tank, heat and concentrate the extract solution to contain no ethanol, then equal amount of DMF, stir for 20min~30min, let it stand still, discharge the aqueous solution at the bottom, collect the organic solution, and obtain the extract solution Ⅰ .

[0057] c. After removing DMF from the extract solution I, add 1% diatomaceous earth filter aid to the obtained material solution, stir for 20-30 minutes, after stirring evenly, cool down to 5-0°C for crystallization, after a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com