Patents

Literature

101results about How to "Increase Yield %" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

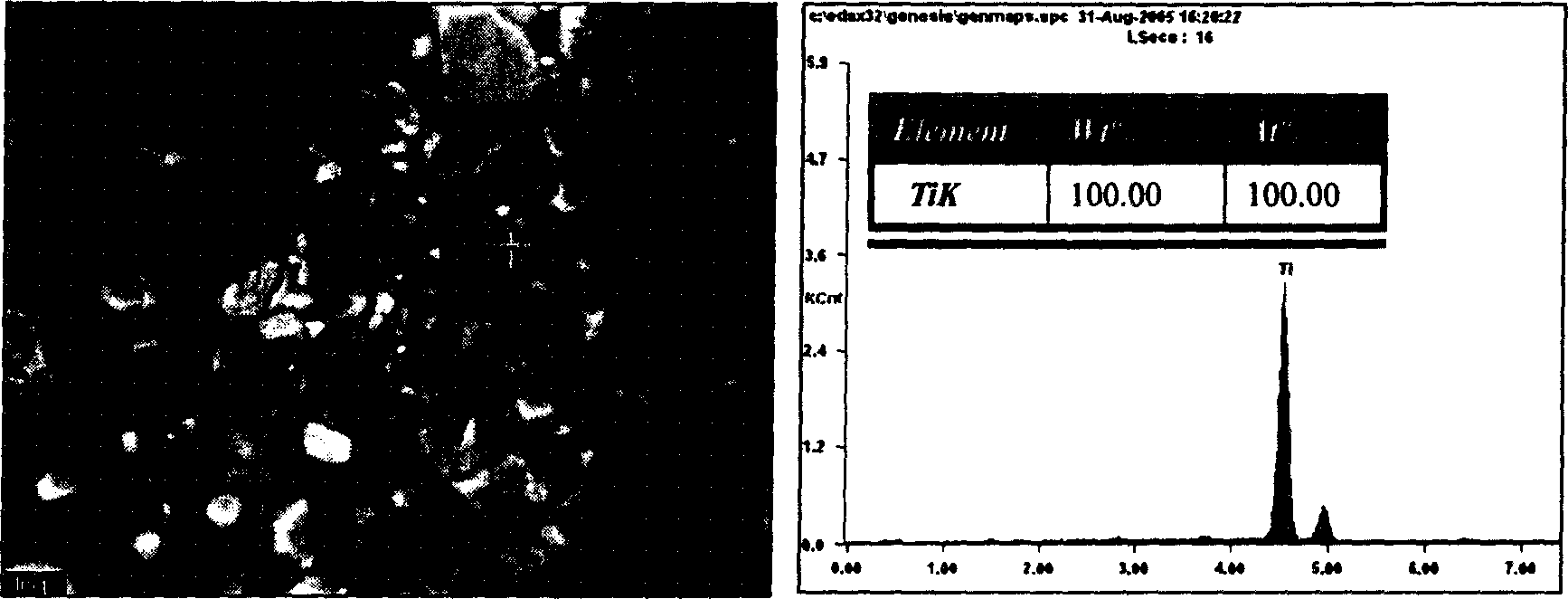

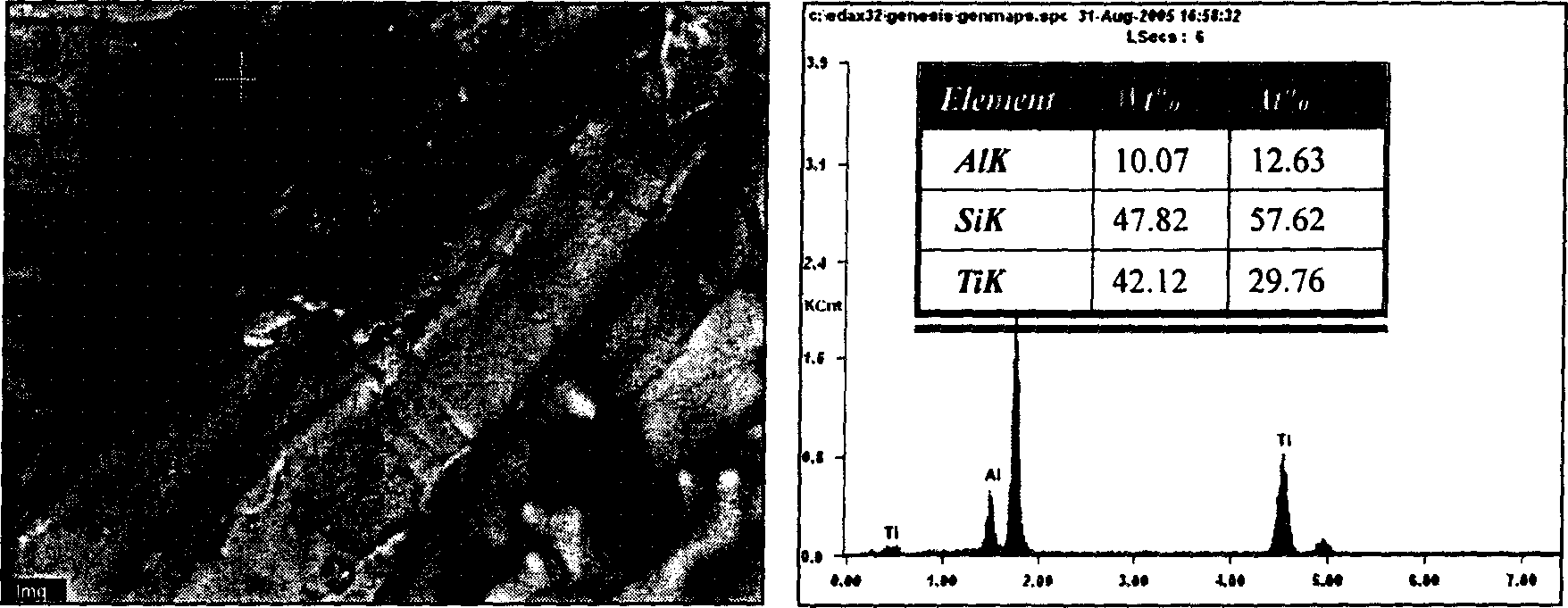

Method of preparing titanium and titanium alloy using titanium containing furnace clinker

A process for preparing Ti metal from the Ti contained slags includes such steps as proportionally mixing said slags with C, Al, Fe and Mg, stirring, and smelting for thermal reducing in plasma furnace, DC arc furnace or AC arc furnace. Its advantage is high output rate.

Owner:WUHAN UNIV OF SCI & TECH

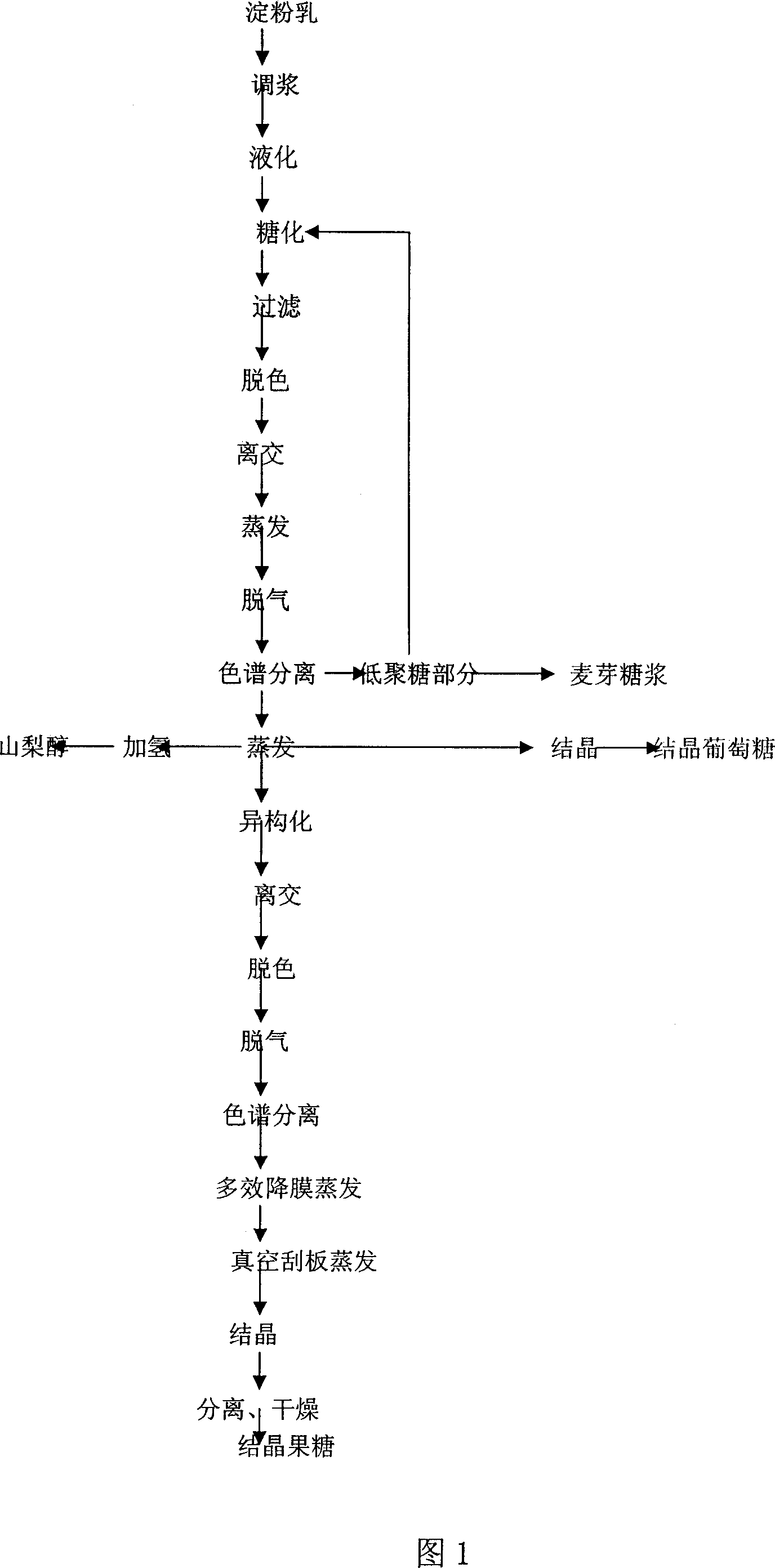

Method of extracting high-purity glucose from saccharified glucose syrup

InactiveCN1928121AHigh DX valueReduce processGlucose productionGlucose-Fructose SyrupSimulated moving bed

The present invention discloses method of extracting high purity glucose from saccharified glucose syrup, and the method has the advantages of simplicity, high purifying effect, high quality of obtained glucose liquid, etc. The method is that by means of simulating movable bed technology, saccharified glucose syrup is separated to prepare high purity glucose and functional oligose. Specifically, saccharified glucose syrup as material is separated completely into glucose and oligose in a simulating movable bed chromatographic system with water as elutant and at the temperature of 60-80 deg.c, so that the component with rich glucose and the component with rich functional oligose are obtained.

Owner:SHANDONG XIWANG SUGAR

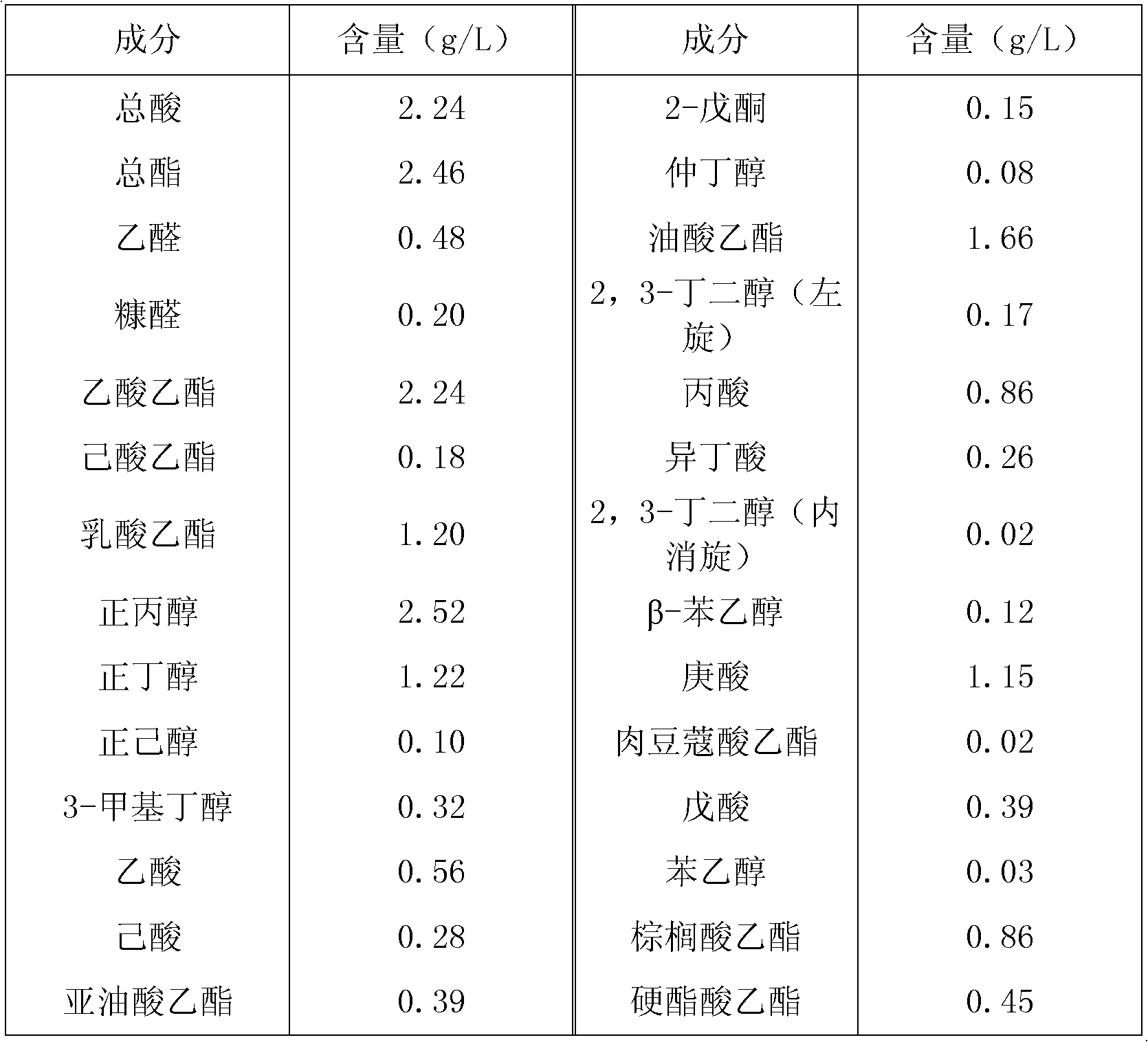

Method for producing white spirit by utilizing waste spent grains

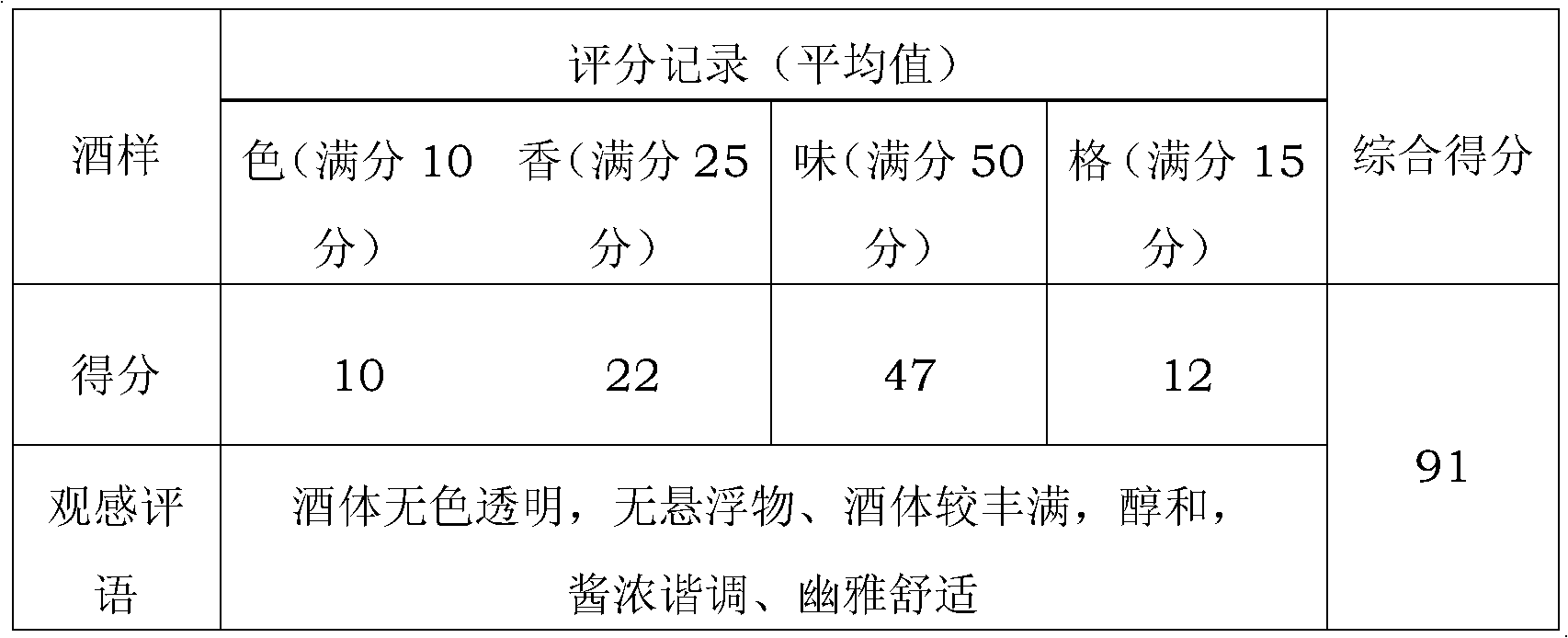

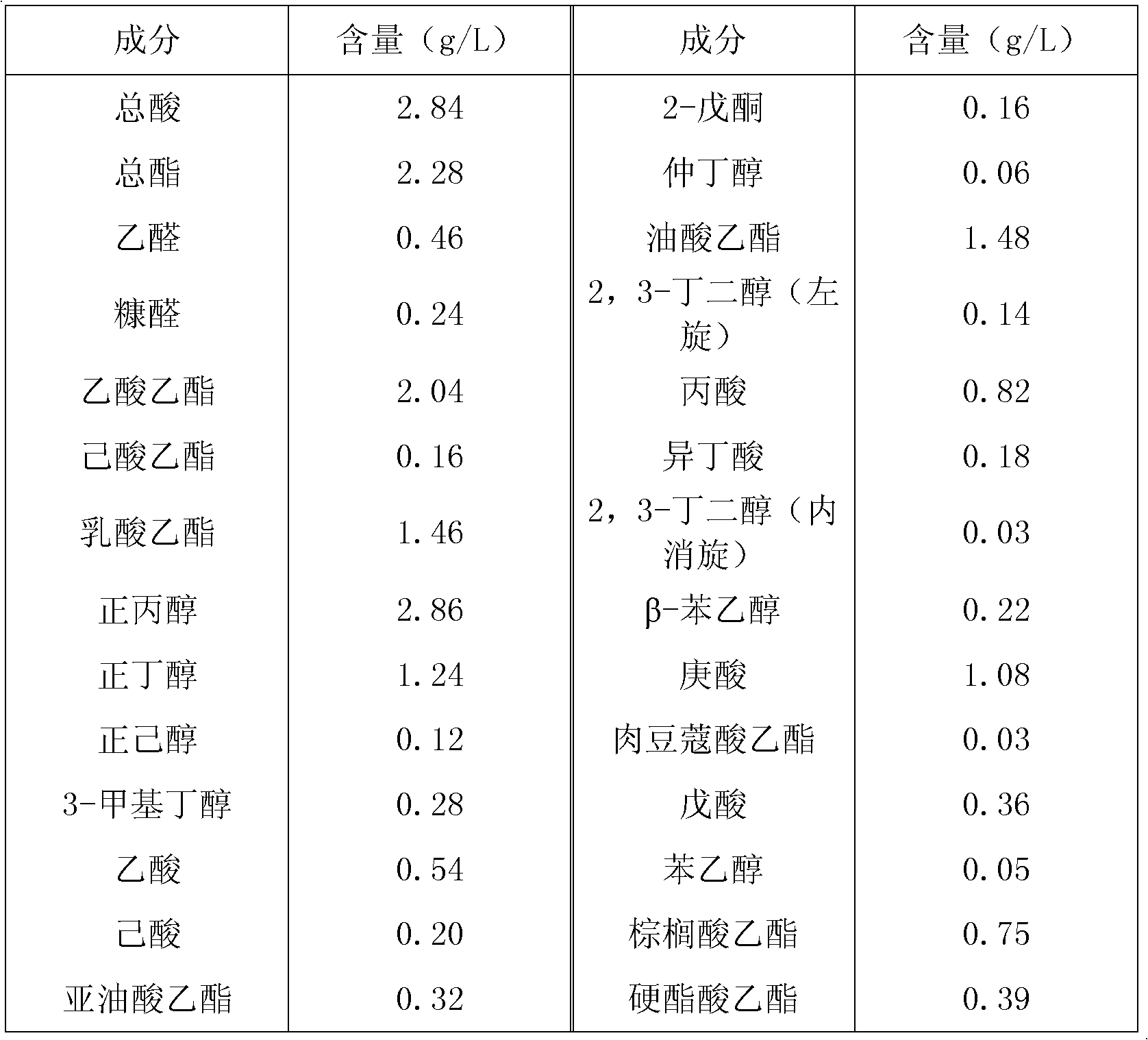

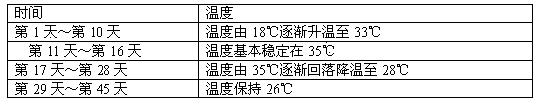

The invention relates to a method for producing white spirit by utilizing waste spent grains, belonging the wine-making field. The technical problem solved by the invention is to provide a method for producing high quality white spirit by utilizing waste spent grains. The method comprises the following steps: 1) distiller's yeast is added in waste spent grains to mix evenly and stack; 2) when the temperature of the waste spent grains 20cm below the surface of the heap is 45-65 DEG C, the heap is broken and cooled to 25-35 DEG C, the waste spent grains are placed in a cellar to ferment; and 3) after the fermentation, the product is discharged from the cellar and then distilled to obtain the white spirit. The method uses the white spirit waste spent grains with rich nutrients as fermentation source and adopts the piling production technology of the Maotai-flavor liquor; the obtained white spirit has the delicate and mellow taste of the luzhou-flavor liquor and the mellow and refreshing taste and fragrant Maotai-flavor of the Maotai-flavor liquor; and the product quality reaches the level of the high-quality wine. By adopting the method, the consumption of grains can be reduced and the yield of the high-quality wine can be increased, thus the method has wide application prospect.

Owner:LUZHOU PINCHUANG TECH

Method for culturing cyprids of balanus reticulates on large scale

The invention discloses a method for culturing cyprids of balanus reticulates on a large scale, which comprises the following steps: after ovum of the balanus reticulates is bred into naupliar larva, putting the naupliar larva into a culture medium with bait for constant temperature culture in dark environment; performing intermittent lighting on the naupliar larva in the constant temperature culture process; and performing cold storage on the appeared cyprids. The method can overcome the defects of high death rate, small and unstable yield, quick settlement and metamorphosis processes, incapacity of storage and accumulation and the like in the breeding process of the cyprids, greatly improve the yield of the cyprids, effectively prolong the time of a drifting stage of the cyprids, promote the settlement synchrony of the cyprids, and provide required experimental materials for screening marine fouling organism antifouling compositions and studying environmental toxicology, along with wide application prospect.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Brewing method of fen-flavor liquor

ActiveCN104212693ASimple processIncrease yieldMicroorganism based processesAlcoholic beverage preparationMonascusChemistry

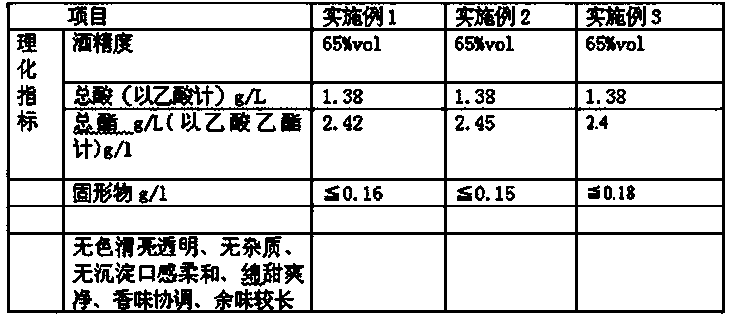

The invention discloses a brewing method of fen-flavor liquor. The brewing method comprises the steps of firstly, smashing sorghum to form sorghum powder, adding warm water, stacking, moisturizing, and then, filling the sorghum powder into a retort boiler to steam to obtain cooked sorghum powder; filling rice hulls into the opened retort boiler to steam; smashing the cooked sorghum powder, adding warm water to uniformly mix, cooling, adding the steamed rice hulls to uniformly mix, then, adding a yeast for making hard liquor and monascus, storing in a cellar, and fermenting for 45 days to obtain fermented grains; and distilling the fermented grains at a high temperature, and storing the fermented grains in a liquor storage tank for more than 1 year to obtain the fen-flavor liquor. The brewing method has the advantages that the process is simple, the quality of the liquor is stable, the yield of white spirit is increased, the style of the liquor is kept, and the produced fen-flavor liquor is softener in taste, sweet and refreshing, coordinated in fragrance and relatively long in aftertaste.

Owner:BEIPIAO HUAYI WINE

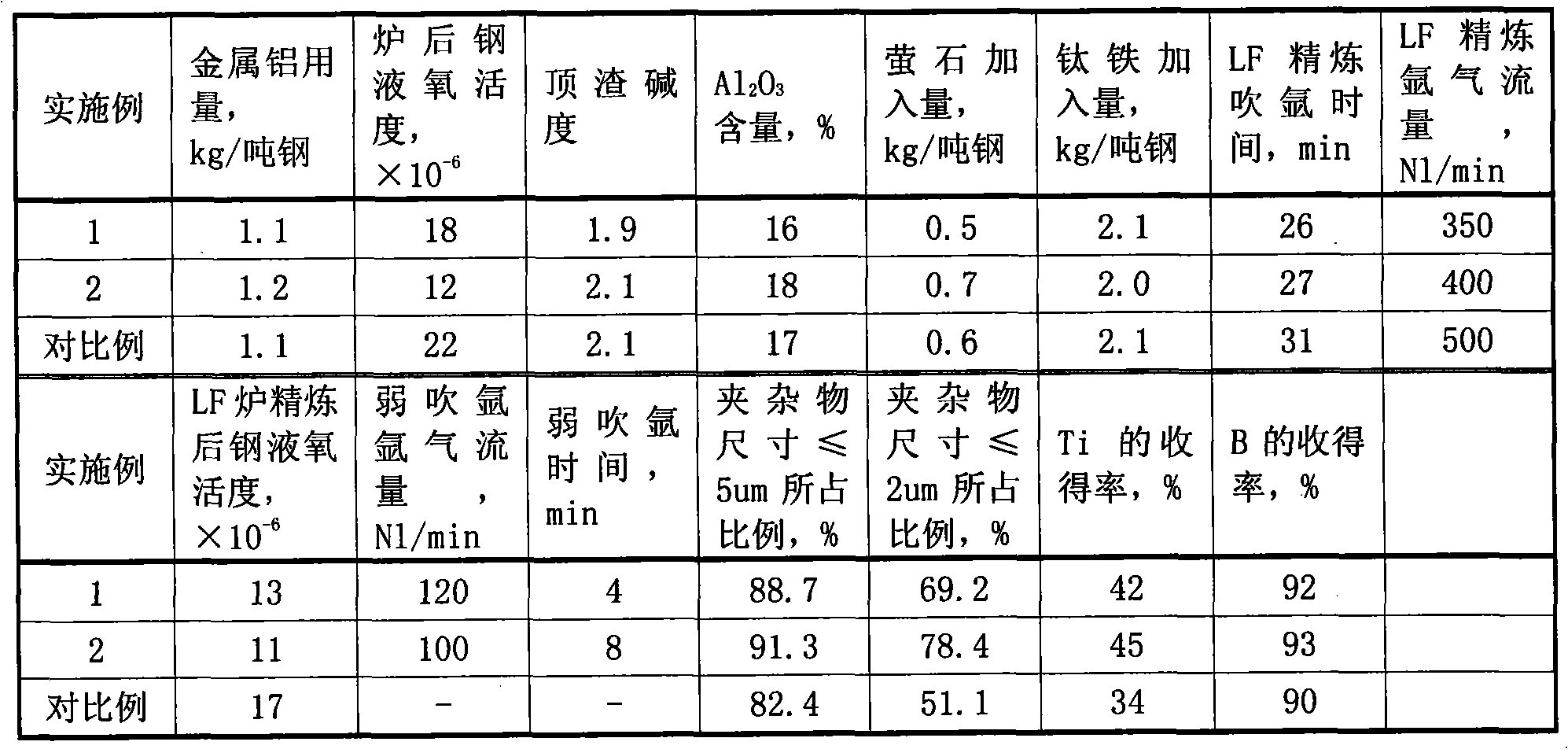

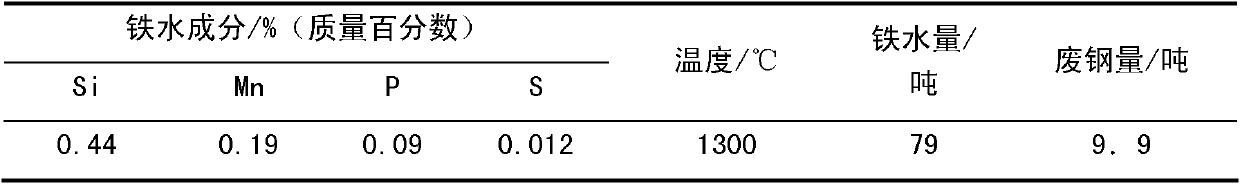

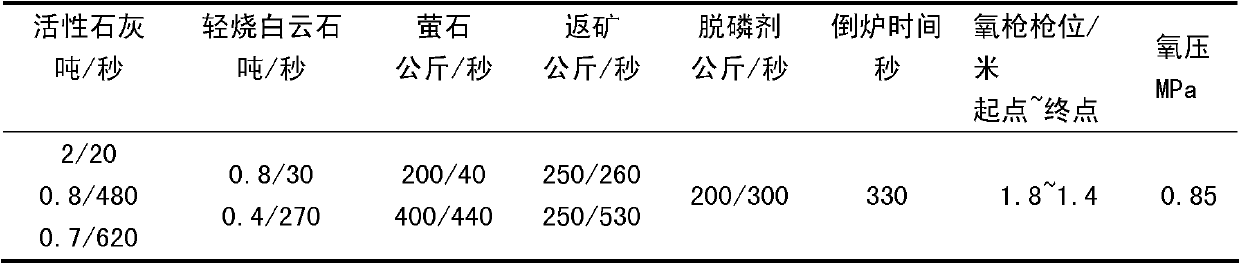

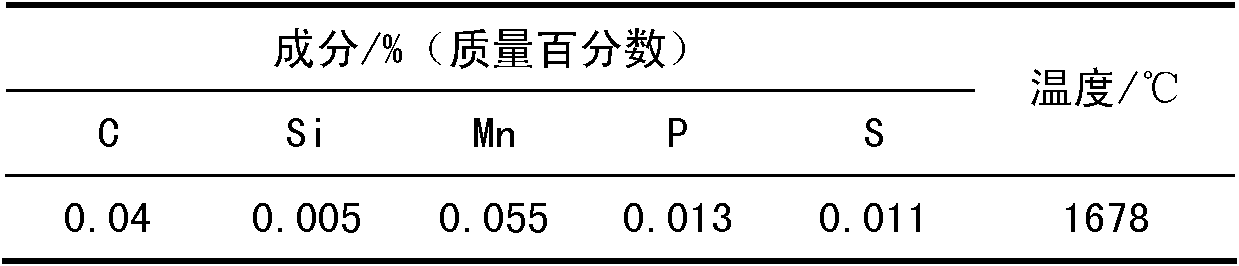

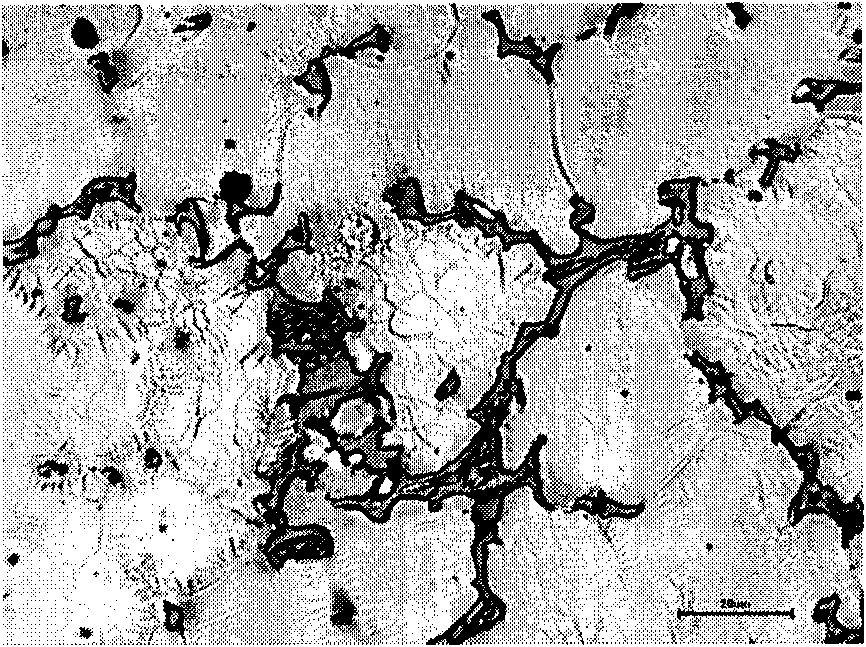

Inclusion control method for pipeline welding wire steel

ActiveCN102031334AInclusion size reductionIncrease yieldProcess efficiency improvementArgon flowDeoxidization

The invention provides an inclusion control method for pipeline welding wire steel, which comprises the following steps of: (1) converter back deoxidization: performing strong deoxidization on molten steel by adopting aluminum melt on the rear converter after the welding wire steel converter finishes smelting; (2) low-frequency (LF) converter refining: after the oxygen activity of the molten steel of the rear converter is not more than 20*10<-6>, performing LF converter refining treatment on the molten steel; forming slag in 10 to 20 minutes when the LF refining begins, and adding fluorite, wherein the alkalinity of top slag is 1.5 to 4.0, and the content of Al2O3 is 15 to 25 percent; adding titanium and iron at the medium term of refining for further deoxidization, wherein the LF argon blowing time is 25 to 35 minutes, the argon flow is 300 to 400N1 / min, and the temperature of the molten steel in the refining process is between 1,550 and 1,630 DEG C; and (3) molten steel argon blowing and stirring: after the oxygen activity of the molten steel is not more than 15*10<-6>, performing weak argon blowing and stirring on the molten steel, wherein the argon flow is 50 to 150N1 / min, andthe argon blowing time is 3 to 8 minutes. The method can reduce the size of inclusions, properly control the number of the inclusions and improve the yield of elements such as Ti, B and the like in the steel.

Owner:ANGANG STEEL CO LTD

Converter steelmaking technology for directly reducing-alloying manganese ore

InactiveCN102168160AIncrease yieldLow costManufacturing convertersProcess efficiency improvementFerromanganeseHigh energy

The invention relates to a converter steelmaking technology for directly reducing-alloying manganese ore and aims at solving the problems such as high cost of an alloying way taking manganese-series alloy as material, as well as high energy consumption and serious pollution in the production process of manganese-series alloy, and the like in the existing steel making technology. The technical scheme is based on a double-slag steelmaking process; and by the technology adjustment methods of reducing the quantity of added steel slag, adopting high lance-position soft blow operation, feeding manganese ore after turning down the converter, reducing the quantity of the secondary added slag and the like, the yield of manganese in the direct reduction process of manganese ore during the smelting with the conventional converter is greatly improved, the manganese-alloying effect is achieved, the manganese-alloying cost is reduced, and the ferromanganese making link with high energy consumption and serious pollution is curtailed.

Owner:WUHAN IRON & STEEL (GROUP) CORP

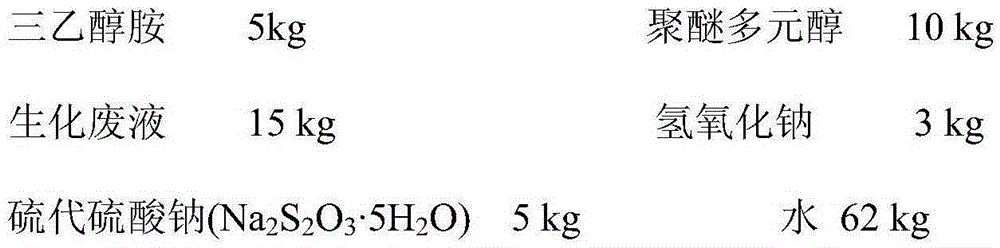

Cement grinding aid

The invention provides a cement grinding aid. The cement grinding aid comprises raw materials as follows: triethanolamine, polyether polyol, sodium hydroxide, sodium thiosulfate and a biochemical waste liquid, wherein the biochemical waste liquid is one of or a mixture of a waste liquid produced during production of industrial sodium gluconate and a waste liquid produced during production of an industrial itaconic acid product. The cement grinding aid can optimize the cement grain composition, activate the early strength of cement, improve the powder grinding efficiency of the cement and reduce energy consumption.

Owner:ZHANGQIU HUAMING CEMENT

Making method of yellow rice wine distiller's yeast

The invention relates to fermentation distiller's yeast, in particular to a making method of yellow rice wine distiller's yeast. The making method includes the following steps that (1) raw materials are prepared; (2) a mixture A obtained in the step (1) is kept at the temperature of 75-85 DEG C for 15-20 min, and added with pure rhizopus and yeast after being cooled to 30 DEG C, and a distiller's yeast blank is obtained; (3) the distiller's yeast blank obtained in the step (2) is cultured in a distiller's yeast chamber at the temperature of 26 DEG C for 30 h, the mould grows vigorously, the whole surface of the distiller's yeast blank is full of the mould, and at the time, the distiller's yeast blank is moved out of the distiller's yeast chamber to be baked or aired dry, so that the yellow rice wine distiller's yeast is obtained. The making method of the yellow rice wine distiller's yeast has the advantages that a traditional distiller's yeast making method is combined with the modern technology, the produced yellow rice wine distiller's yeast can be directly used for liquid fermentation wine making and wine making with uncooked materials, the wine yield is improved by 15 percent compared with traditional distiller's yeast, labor is saved by 30 percent, and the economic benefits of a winery are improved.

Owner:FUJIAN SHAOWU NIES BIOLOGICAL TECH

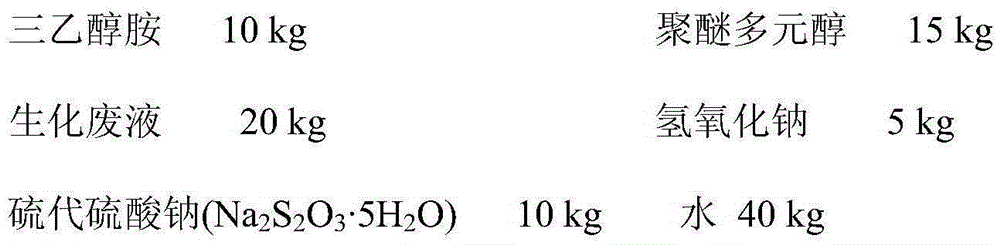

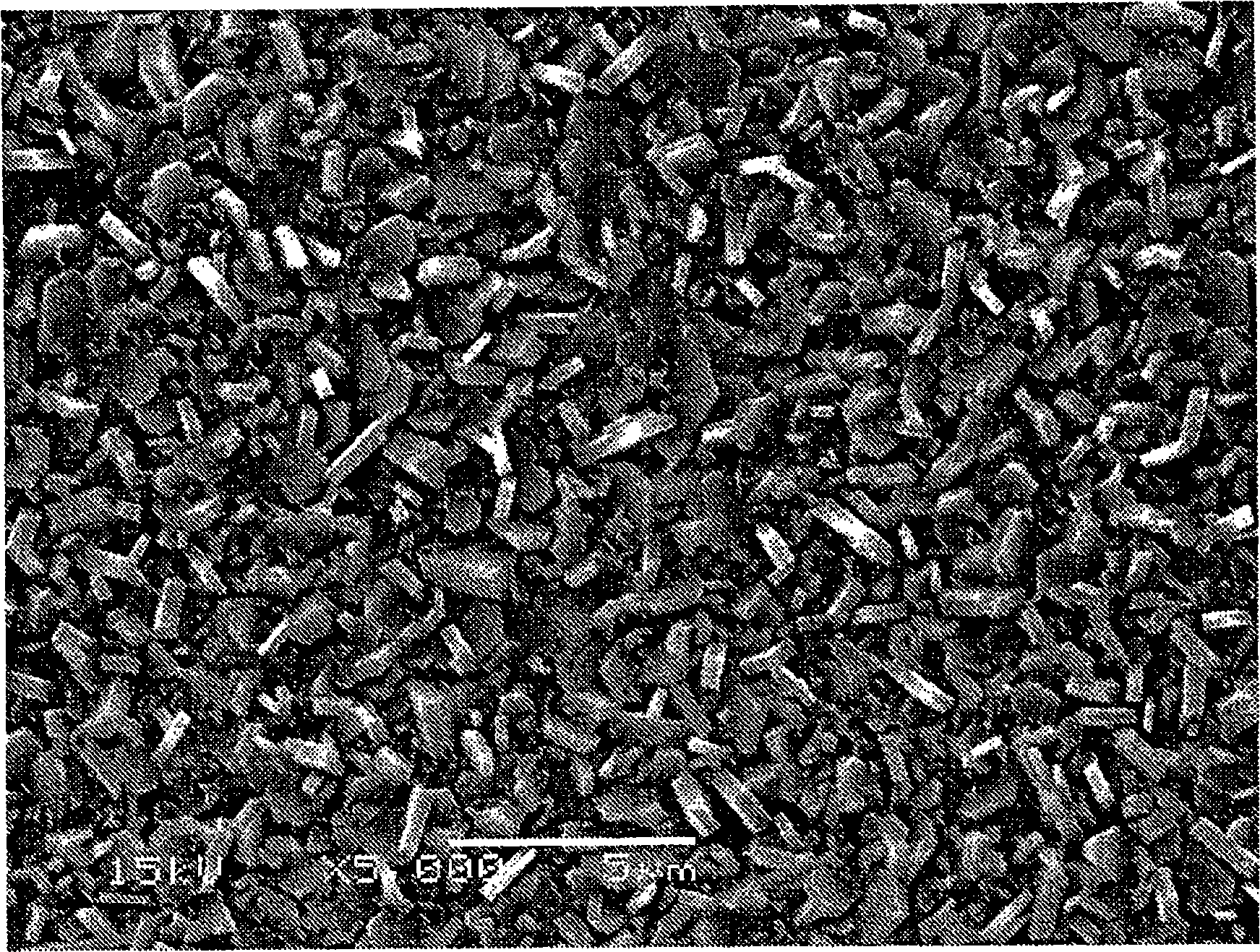

Carbon-coated aluminum material, and method for production thereof

ActiveCN101548028AIncrease yieldImprove adhesionElectrode manufacturing processesElectrolytic capacitorsAluminiumMagnesium

Disclosed is a carbon-coated aluminum material in which the adhesion between a carbon-containing layer and an aluminum material can be maintained for a long period. Also disclosed is a method for producing the carbon-coated aluminum material. The carbon-coated aluminum material comprises an aluminum foil (1), a carbon-containing layer (2) and an intermediate layer (3). The intermediate layer (3) has a first surface region (3) which contains a carbide of aluminum and is formed on at least a part of the surface of the aluminum foil (1). The carbon-containing layer (2) has a second surface region (21) which is extended toward the outside of the first surface region (3). The carbon-containing layer (2) further contains a carbon-containing particle (22). The second surface region (21) is formed between the first surface region (3) and the carbon-containing particle (22), and contains a carbide of aluminum. In the aluminum foil (1), the aluminum content is 99.6% by mass or more, the lead content is 10 ppm by mass or less, and the magnesium content is 10 ppm by mass or less.

Owner:TOYO ALUMINIUM KK

Composite purification flux containing cerium-magnesium alloy, and production method

A composite cleaning flux containing CeMg alloy is proportionally prepared from magnesium chloride, sodium chloride, potassium chloride, calcium chloride, barium chloride, and cerium carbonate and potassium tetraborate. Its functions include suppressing loww of Ce, decreasing the content of Fe as harmful element, and removing the non-metal impurities from alloy.

Owner:鄂尔多斯市天旭轻合金有限责任公司

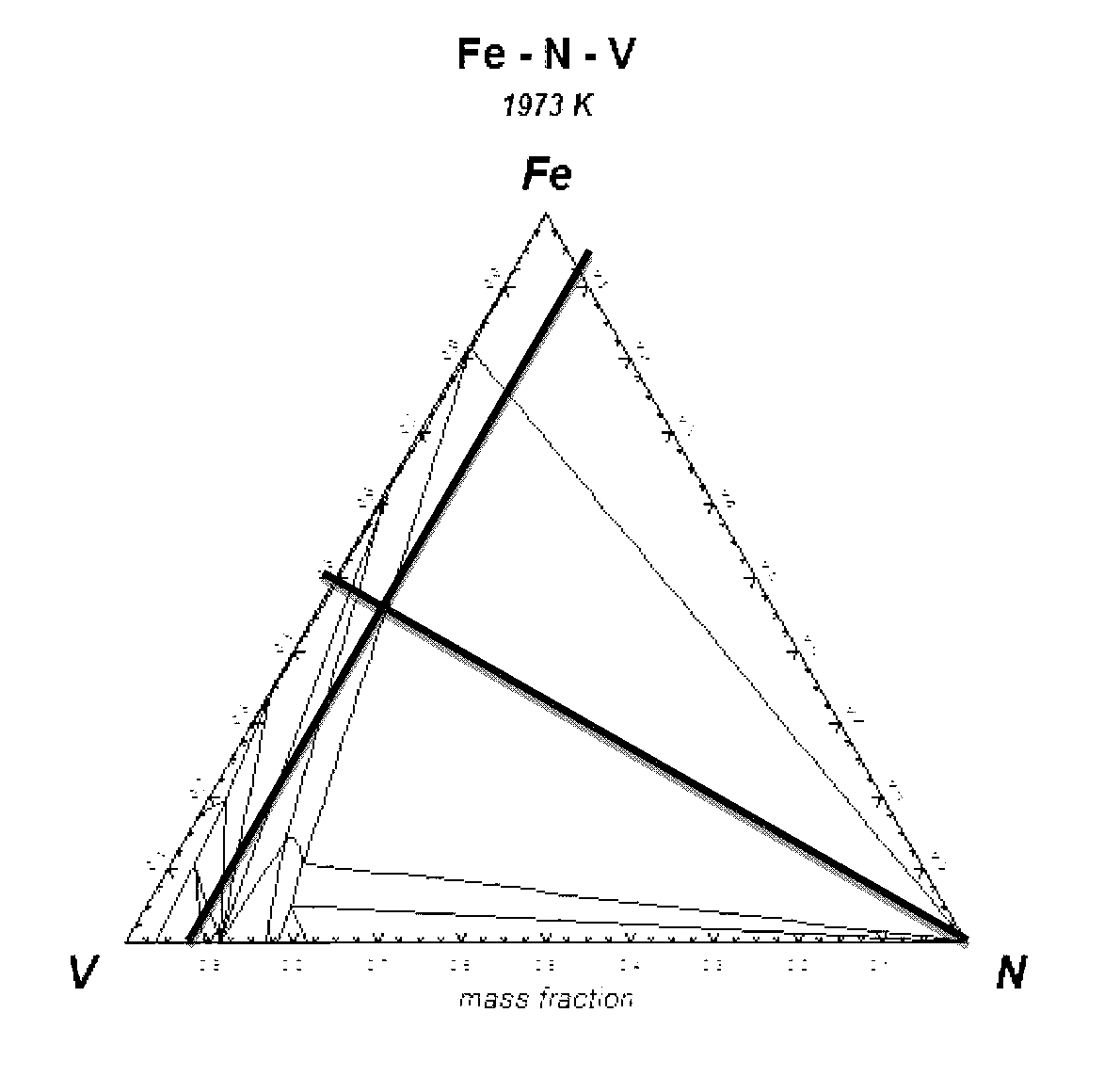

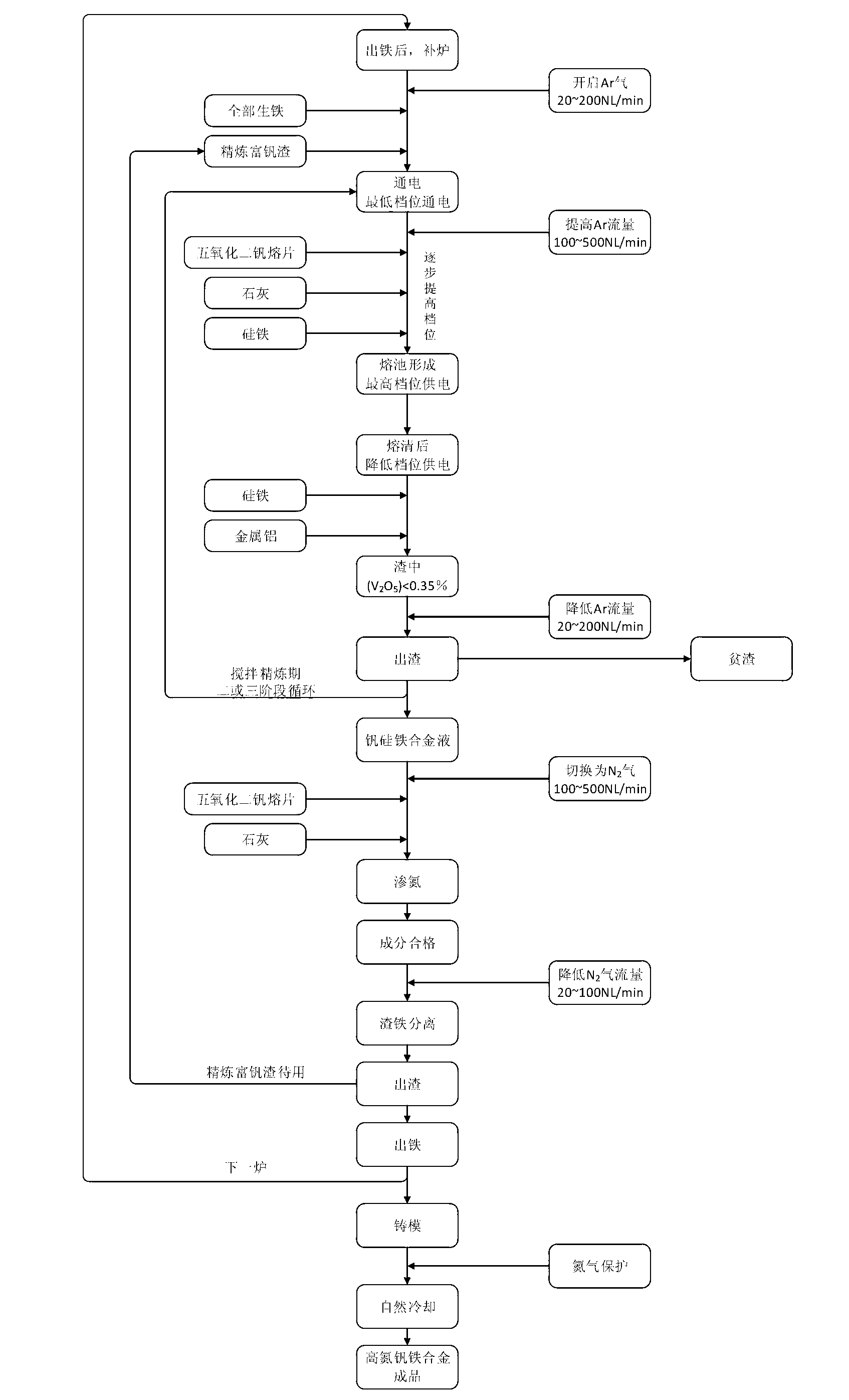

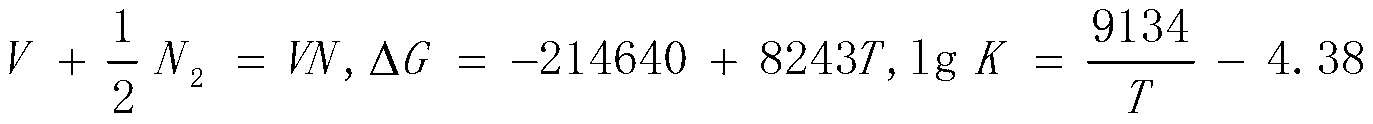

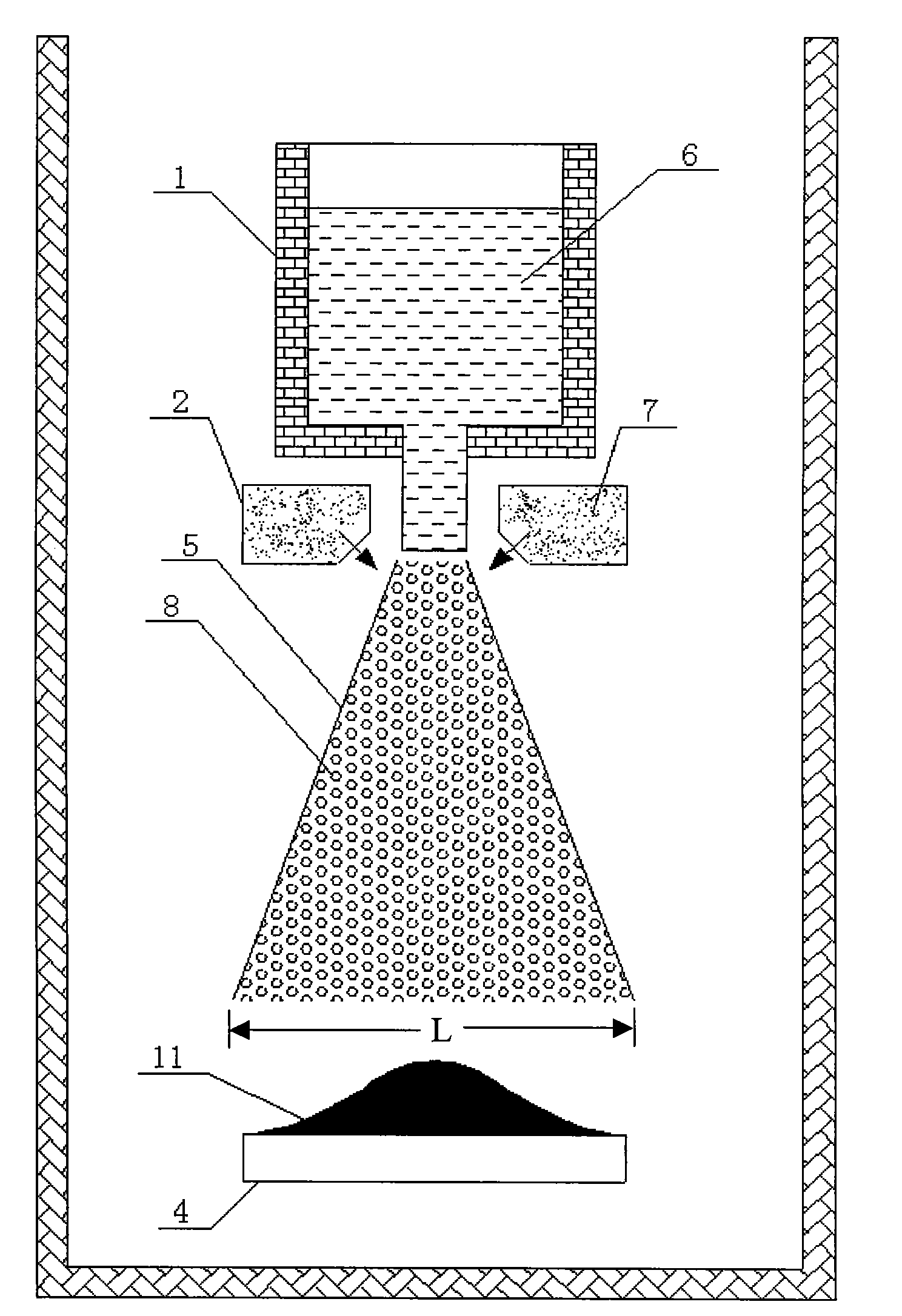

Method for generating nitrogenous ferrovanadium alloy through utilizing ferrovanadium electric-arc furnace

Owner:UNIV OF SCI & TECH BEIJING +1

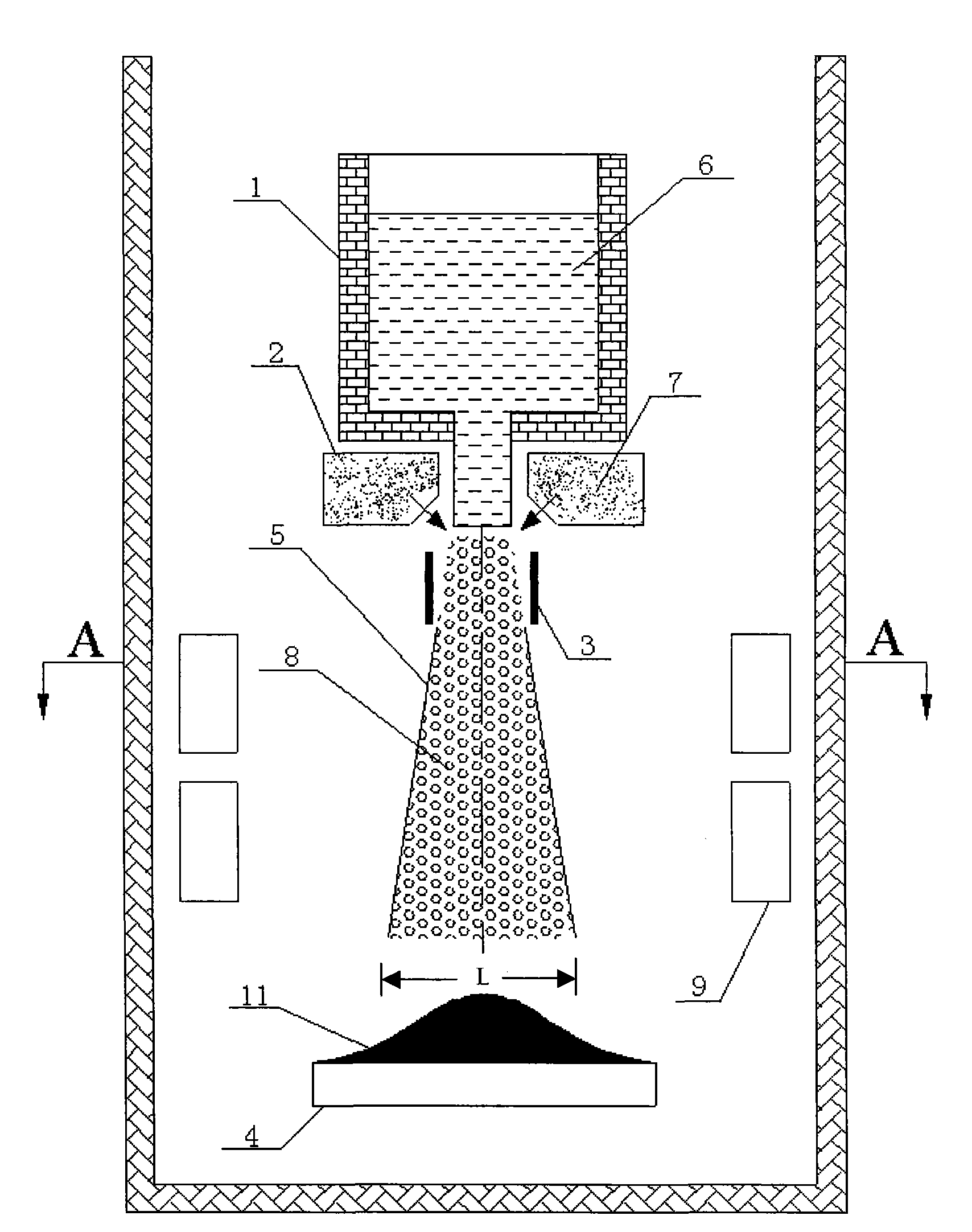

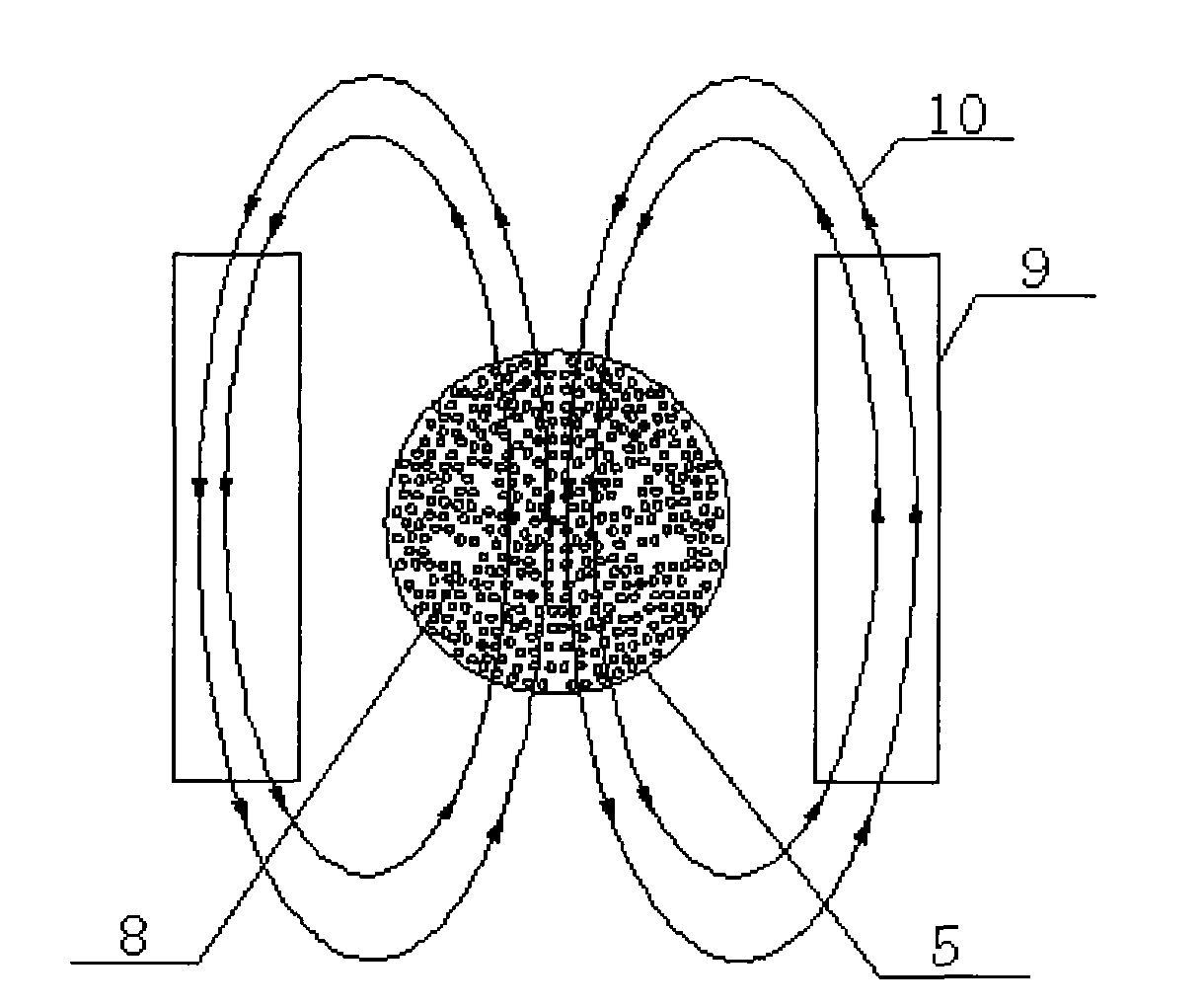

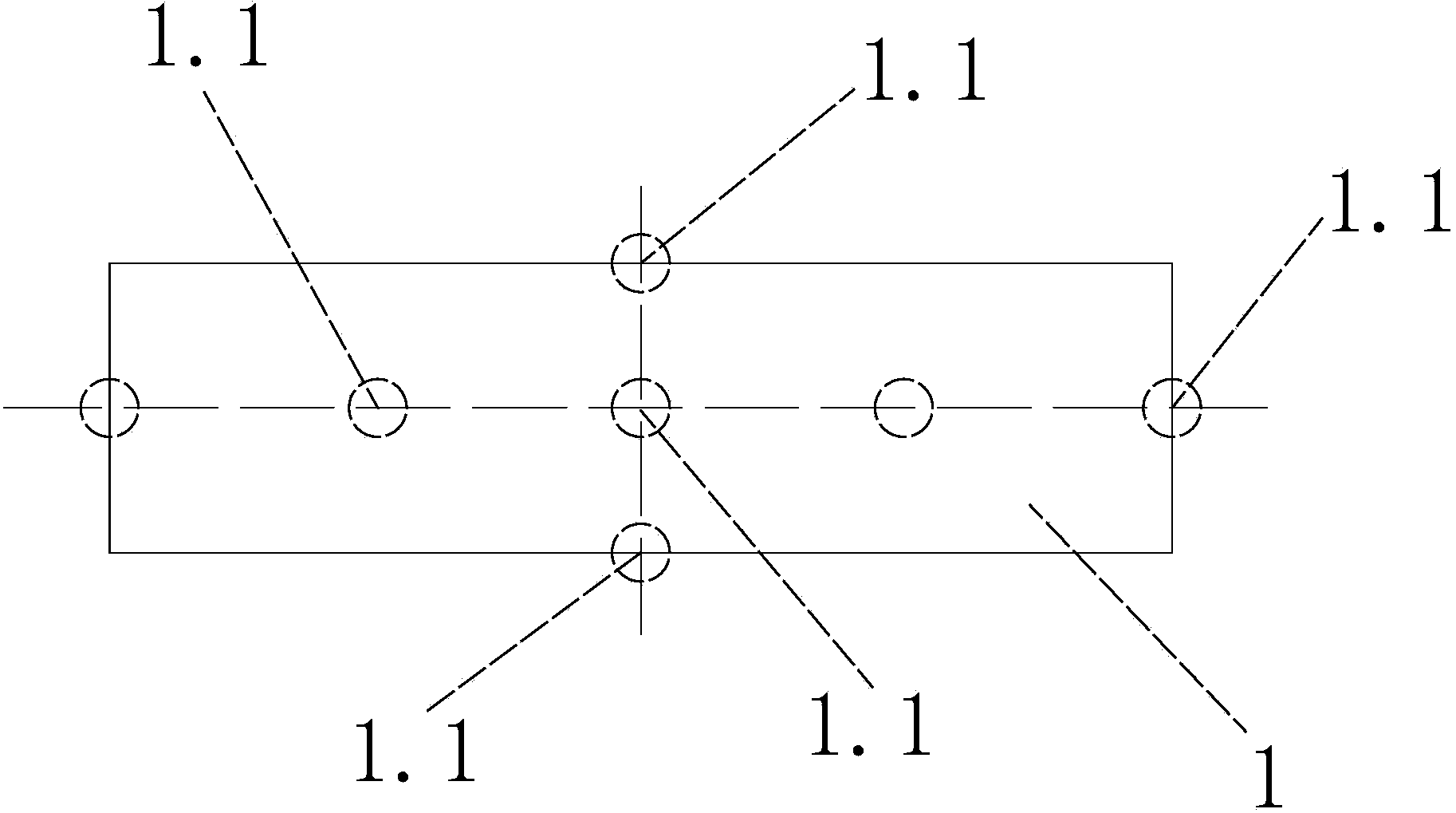

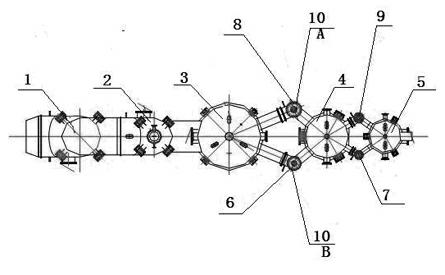

Deposit preform injection moulding device with additional magnetic filed

ActiveCN101875032AIncrease yieldImprove the quality of formingLiquid spraying apparatusSpray discharge apparatusDivergence angleInjection moulding

The invention belongs to the field of metal blank processing, and particularly relates to a deposit preform injection moulding device. The deposit preform injection moulding device with an additional magnetic filed comprises a crucible (1), an atomizer (2), a charging electrode and a depositor (4); the crucible (1) and the atomizer (2) are communicated by a guide pipe; the depositor (4) is arranged below the outlet of the nozzle of the atomizer (2); an atomized grain flying region (5) is arranged between the nozzle of the atomizer (2) and the depositor (4); the charging electrode (3) is arranged at crushing sites where molten metal (6) is separated into the atomized grains (8); and a magnetic field generation device (9) is arranged around the atomized grain flying region (5) and under thecharging electrode. In the invention, the flying paths of the atomized grains can be changed to reduce the taper divergence angle of the atomized grain flying region by using an additional magnetic filed, thereby greatly improving the yield of the molten metal; and in addition, by changing the direction and magnitude of the magnetic filed, the moulding quality of deposit preform can be improved and the production cost of the deposit preform can be reduced, therefore, the economic benefits can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

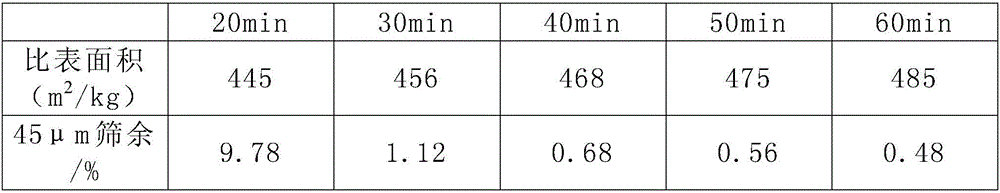

Preparation method of cement grinding aid

The invention relates to the field of cement production, in particular to a method for preparing a cement grinding aid; (1) raw material preparation: weigh the raw materials according to the parts by mass: 10-15 parts of propylene glycol, 3-5 parts of unsaturated polyester resin, 6-12 parts of sodium thiosulfate, 2-8 parts of calcium formate, 0.6-0.8 parts of Tween-80, 6-12 parts of alkyl polyglycosides, 10-30 parts of maleic anhydride, 2-6 parts of nano silicon dioxide , 2.4-5.6 parts of sodium hexametaphosphate, 2-6 parts of allyl polyoxyethylene ether, 1.8-4.8 parts of water-retaining cellulose; (2) preparation of modified triethanolamine; (3) preparation of grinding aid: step Take 5-25 parts of modified triethanolamine prepared in (2) and add it to the stirrer, then add the raw materials except calcium formate and sodium thiosulfate, mix and stir evenly, carry out a polymerization reaction at 75°C for 5h, add calcium formate, sulfur Substitute sodium sulfate, after stirring evenly, drying to obtain the grinding aid; the method of the invention is simple and the production cost is low; the prepared cement grinding aid has the advantages of good water retention, and can improve the specific surface area and appearance of cement.

Owner:汤海涛

Method used for realizing dispersion uniform distribution of bismuth element in alloy steel containing bismuth

The invention discloses a method used for realizing dispersion uniform distribution of bismuth element in alloy steel containing bismuth. The method comprises following steps: 1) molten iron is subjected to desulfuration; 2) converter smelting is performed, aluminum iron alloy and ferro-silicon alloy are added successively after steel tapping, and then a ladle slag modifier is added for ladle slag modification; 3) ladle slag is refined; 4) an alloy feed pipe made of a fire resistant material is inserted into steel liquid level so as to be 100 to 300mm below of the steel liquid level, and metal bismuth element, which possesses a low melting point, and granularity of 3 to 30nm, and is easy to gasify, is added into the molten iron using the alloy feed pipe, wherein adding amount of bismuth element is 0.5kg / t.s or less; 5) argon is taken as a bottom blowing gas of steel ladle, wherein intensity of argon is controlled at 30 to 100l / min.ts; and 6) a continuous casting platform is used for casting, protective atmosphere pouring is adopted for the whole course, and weak electromagnetic stirring is adopted in a secondary cooling section. The method is high in yielding rate; is capable of diffusing bismuth element in steel, so that uniform distribution is realized, excellent steel comprehensive properties are obtained, and properties of every parts of steel are uniform; and can be widely used in the field of molten steel smelting technology.

Owner:武汉钢铁有限公司

Brewing process of sweet yellow wine

InactiveCN102424783AIncrease yieldFull bodiedAlcoholic beverage preparationAmino acidTraditional Chinese medicine

The invention discloses a brewing process of sweet yellow wine and particularly relates to a sweet yellow wine brewing process. The process comprises the following steps: sorting, washing rice, soaking, cooking, saccharifying, alcoholizing, compressing wine and the like. In the invention, three types of starters and a segmented starter application brewing process are adopted, the problems that the traditional sweet yellow wine is not thoroughly saccharified and alcoholized so as to cause the characteristics of low wine yield, low alcohol content, pure taste and the like are thoroughly solved. The sweet yellow wine is prepared from the following raw material components in parts by weight: 5000 parts of rough sticky rice, 30 parts of traditional starter, 15 parts of self-made traditional Chinese medicine starter and 9 parts of yellow wine active dry yeast. The production process comprises raw material treatment, cooking, saccharification fermentation, alcoholization fermentation, squeezing ageing and sterilization package. The sweet yellow wine prepared by using the process disclosed by the invention has the characteristics of elegant, light-yellow and transparent color, pure flavor and sweet, tasty, soft and moist taste, and leads a person to endless after tastes. The wine contains various amino acids and various trace elements.

Owner:李忠盘

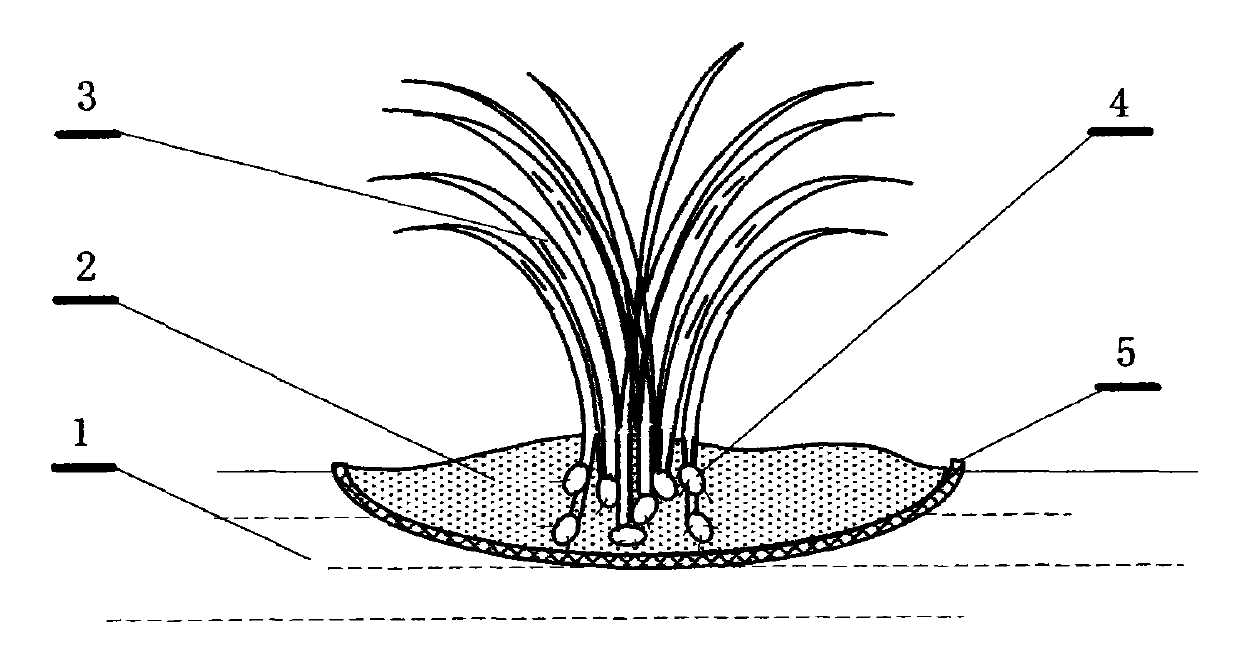

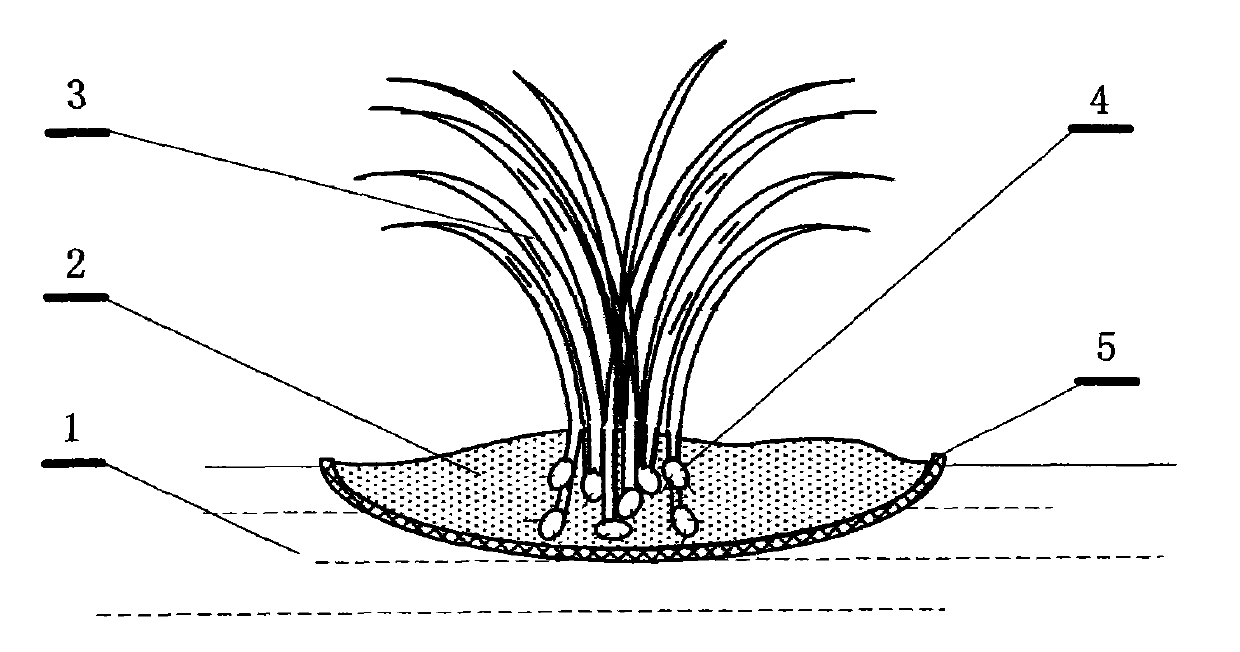

Cyperus planting and harvesting technology

The invention discloses cyperus planting and harvesting technology, which belongs to the technical range of crop cultivation. The technology is characterized by comprising the following steps of: ditching according to a certain row space in a field, wherein the bottoms of the ditches are cambered; laying nylon nets at the bottoms of the dug ditches; laying a base fertilizer and soft sand soil on the nylon nets; digging holes and performing bunch planting according to a certain plant spacing; and pulling the nylon nets up to sieve out the sand soil in the nets and picking the cyperus at the root of the cyperus esculentus during the harvesting of the cyperus.

Owner:天佰立(北京)新技术发展有限公司

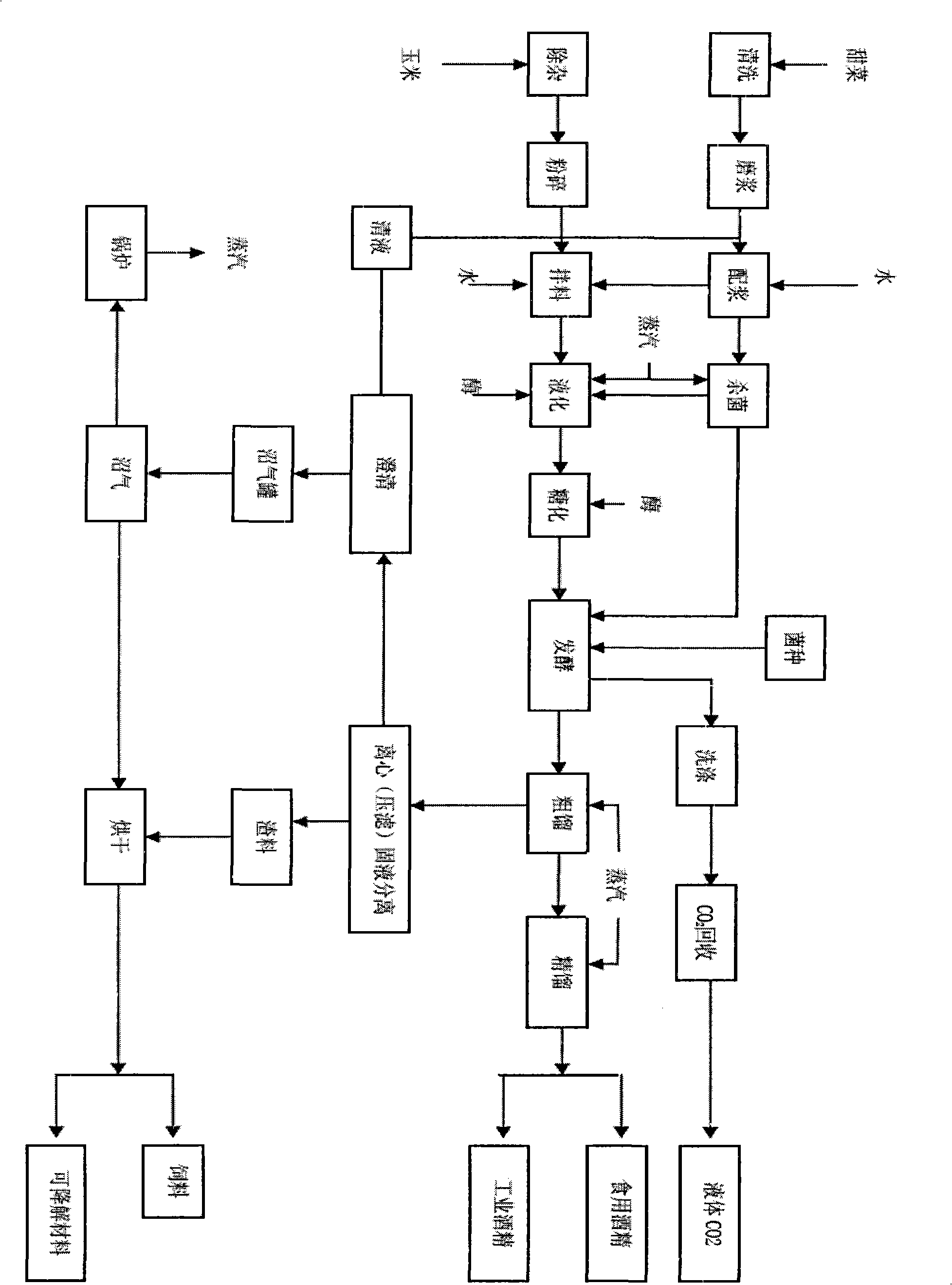

Preparation technology of grape seed polyphenols

InactiveCN1923831AReasonable designIncrease yieldOrganic chemistryChemical inhibitorsSolventGrape seed

The invention discloses a manufacturing technology of grape seed polyphenols from grape seed in the brewing industrial leftover bits and pieces, which comprises the following steps: extracting through water instead of alcohol; centrifuging; columning; condensing; extracting; spraying; drying; detecting; packing; adopting large-hole resin column to adsorb polyphenols selectily; extracting the condensed liquid through acetic ester.

Owner:浙江瑞康生物技术有限公司

Potato spirit and manufacturing technology thereof

InactiveCN104694367AThe production process steps are simpleIncrease yieldAlcoholic beverage preparationBudFlavor

Provided is a potato spirit and a manufacturing technology thereof. After a fermentation substrate prepared by fermenting of potato powder, maize buds and wheat malt is evenly mixed according to a weight ratio of 0.65 - 0.85 : 0.35 - 0.15, the fermentation is carried out, the potato spirit is prepared by steam-in distillation, the fermentation substrate prepared by fermenting of the potato powder, the maize buds and the wheat malt is used for improving the liquor yield. The manufacturing technology is simple in step and high in liquor yield, brewed white spirit is not prone to oxidation and browning, the sedimentation is few, the aroma is unique, the taste is smooth, the flavor is excellent, the functions of improving the mental state, matching with the spleen and invigorating the stomach, and maintaining beauty and keeping young are provided.

Owner:YUNLONG QIMIN AGRI TECH

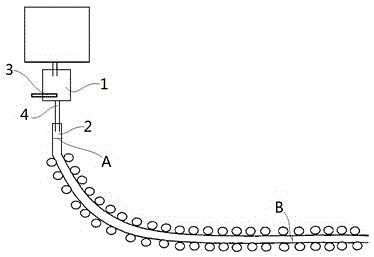

Method for determining head and tail positions and length of mixed cast blank based on continuous molten steel temperature measurement

The invention relates to a method for determining the head and tail positions and the length of a mixed cast blank based on continuous molten steel temperature measurement. The method includes the following steps that when the residual amount of molten steel in a tundish reaches the allowed lowest slag entrapment liquid level, a nozzle is closed, and a continuous casting machine is shut down; a molten steel dividing agent is added into a crystallizer, another kind of steel is added into the tundish, and the adding position of the molten steel dividing agent is the tail end of the mixed cast blank, namely the position B; the continuous casting machine is started and then is shut down when the liquid level in the crystallizer falls below the normal liquid level by 450-500 mm; when the liquid level in the tundish falls to a cast-on position, the nozzle of the tundish is opened, the continuous casting machine operates at the pull speed of v, and timekeeping is started; the temperature of the molten steel in the tundish is detected through a continuous temperature measurement device, after timekeeping is completed, the record time is t, the position is the head end of the mixed cast blank, namely the position A, the distance between the tail end and the head end of the mixed cast blank is the length (L=v*t) of the mixed cast blank, and the head end A of the mixed cast blank meets the formula A=B+L.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for preparing magnesium-gadolinium-yttrocalcite ternary intermediate alloy

The invention discloses a method for preparing a magnesium-gadolinium-yttrocalcite ternary intermediate alloy in the technical field of metallurgy, which comprises the following steps: preheating a Mg-Y binary intermediate alloy and a Mg-Gd binary intermediate alloy to 150 to 350 DEG C; putting the Mg-Y binary intermediate alloy in a smelting furnace for smelting and starting to introduce a protective gas when the temperature rises to 400 to 500 DEG C; after the Mg-Y binary intermediate alloy is smelted completely, rising the temperature to 730 to 750 DEG C, and adding the Mg-Gd binary intermediate alloy; after the Mg-Gd binary intermediate alloy is smelted completely, keeping the temperature of the melt between 730 to 750 DEG C, adding a refining agent, and refining the melt; and after the refining, keeping the temperature at 730 to 750 DEC C, and standing the melt to obtain the Mg-Gd-Y ternary intermediate alloy. The preparation method of the invention avoids the use of pure magnesium, saves time for smelting pure magnesium, reduces the oxidization and burning loss of magnesium elements in a pure magnesium smelting process, and achieves high rare earth element yield.

Owner:SHANGHAI JIAO TONG UNIV

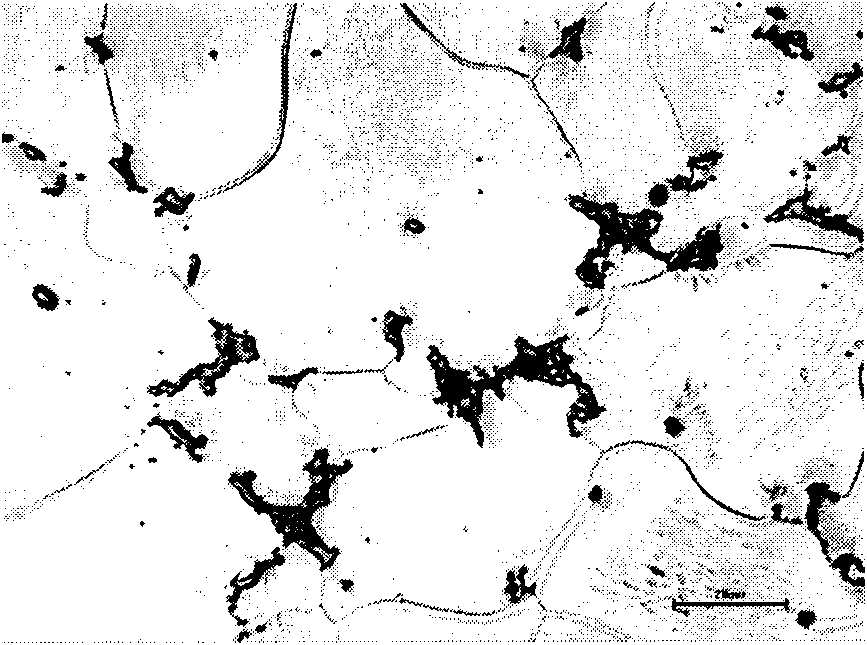

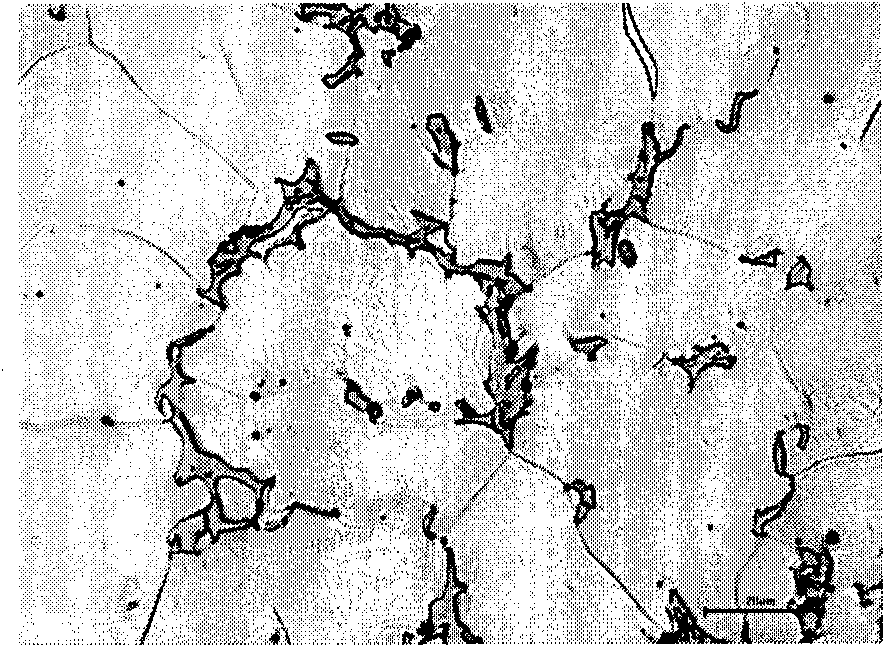

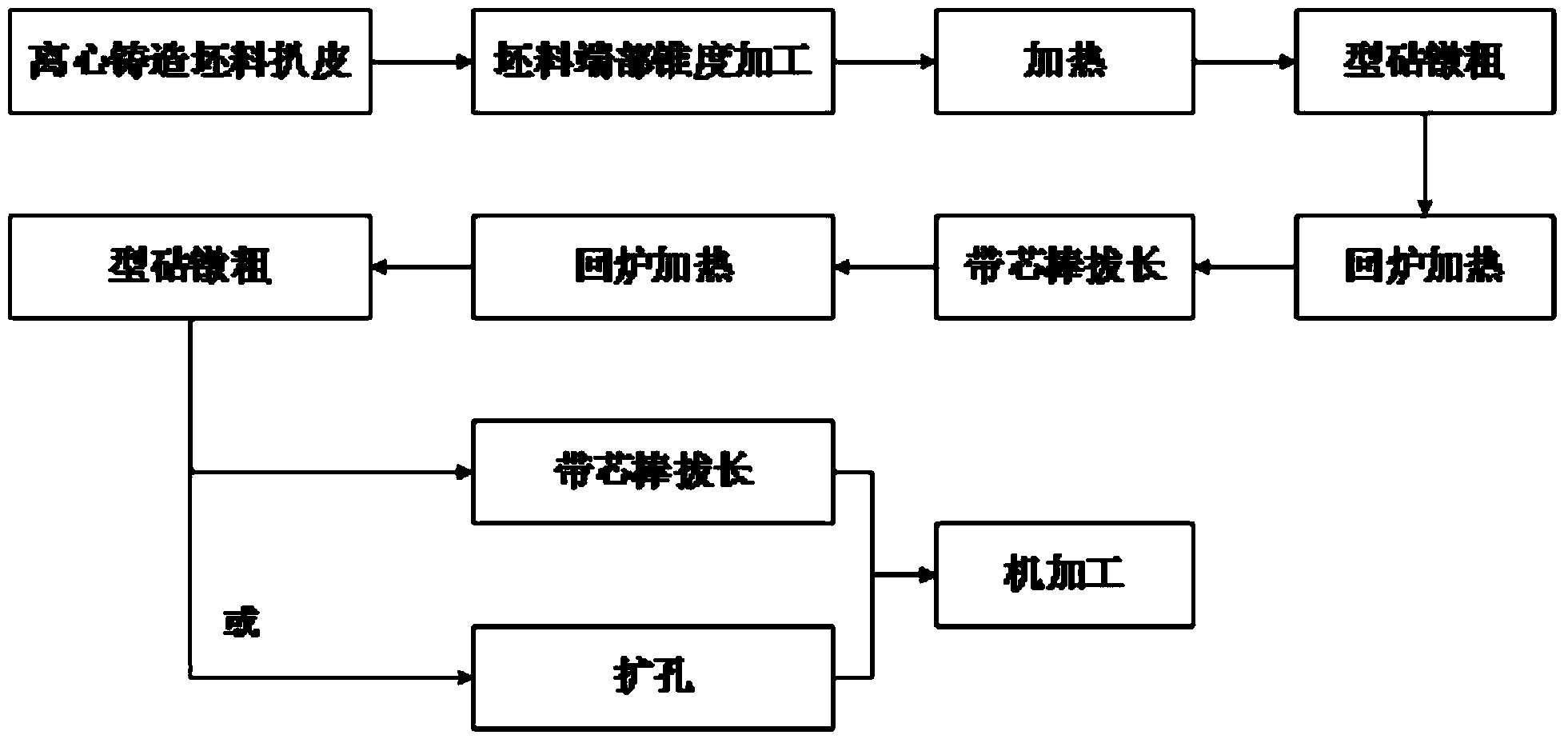

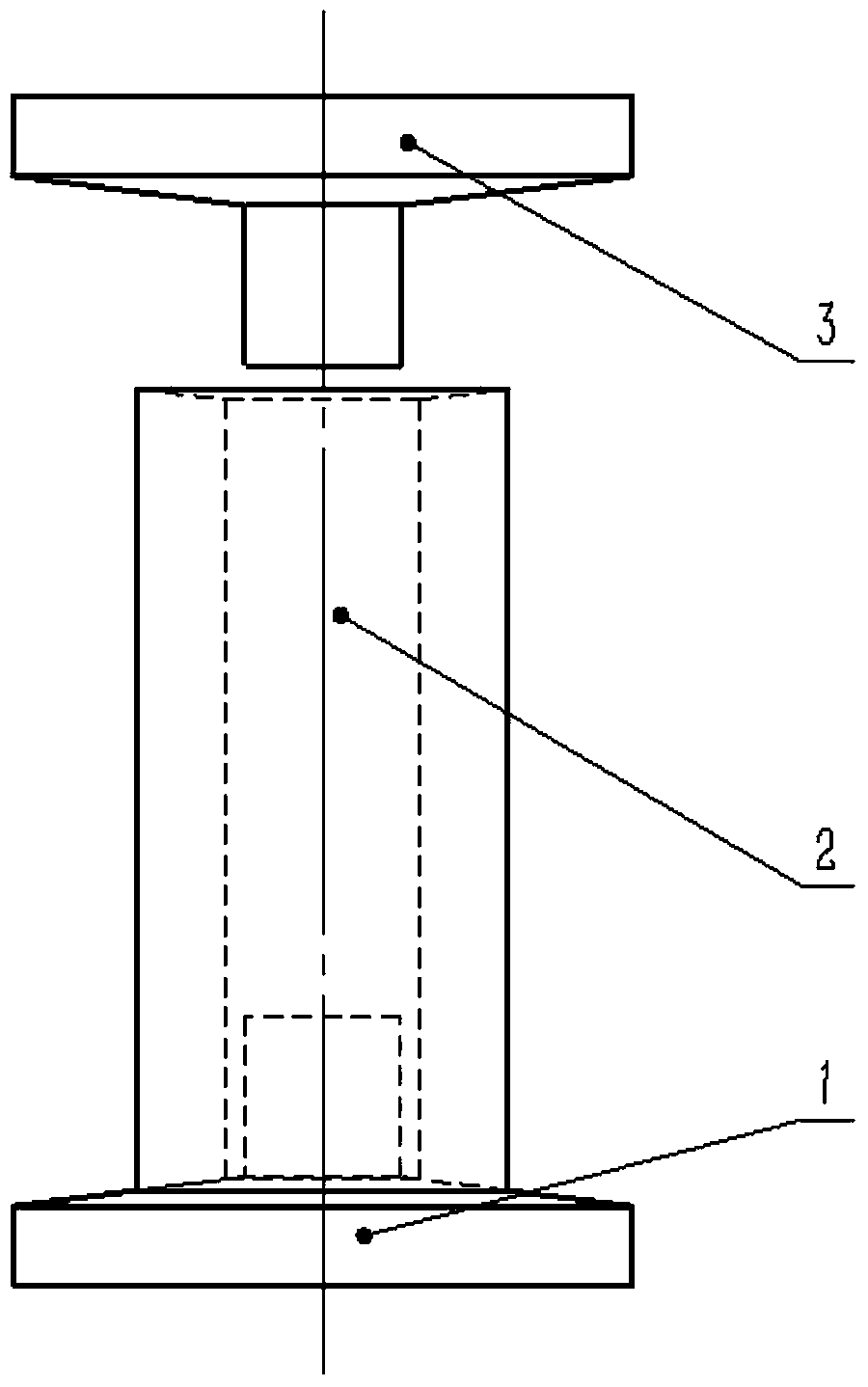

Forging process for adopting centrifugal casting hollow ingots to produce ring-shaped parts and cylindrical parts

InactiveCN104001844AIncrease yieldSave materialMetal-working apparatusSpecial designMaterials science

The invention relates to a forging process for adopting centrifugal casting hollow ingots to produce ring-shaped parts and cylindrical parts and belongs to the technical field of forging. The process comprises the steps of peeling and flaw detection of inner and outer surfaces of the casting hollow ingots, heating, hollow body upsetting on swage blocks in special design, heating, core rod drawing out, heating, hollow body upsetting on swage blocks in special design, heating, core rod drawing out to a needed dimension or pore broadening to a required dimension. Compared with a forging forming process for which solid ingots are widely adopted, the forging forming process has the comparative advantages of obviously improving the material yield, saving energy and reducing consumption.

Owner:CHINA IRON & STEEL RES INST GRP +1

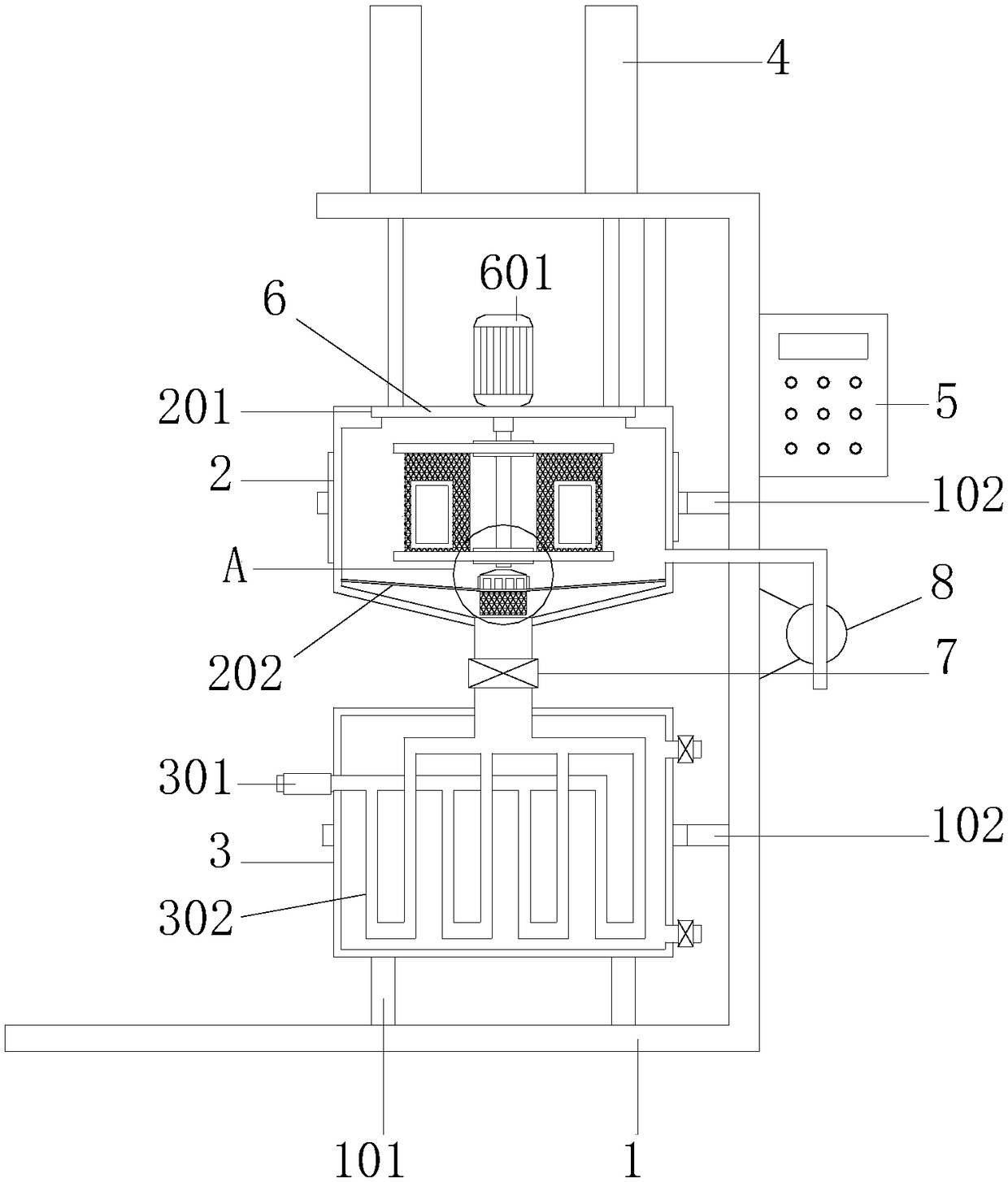

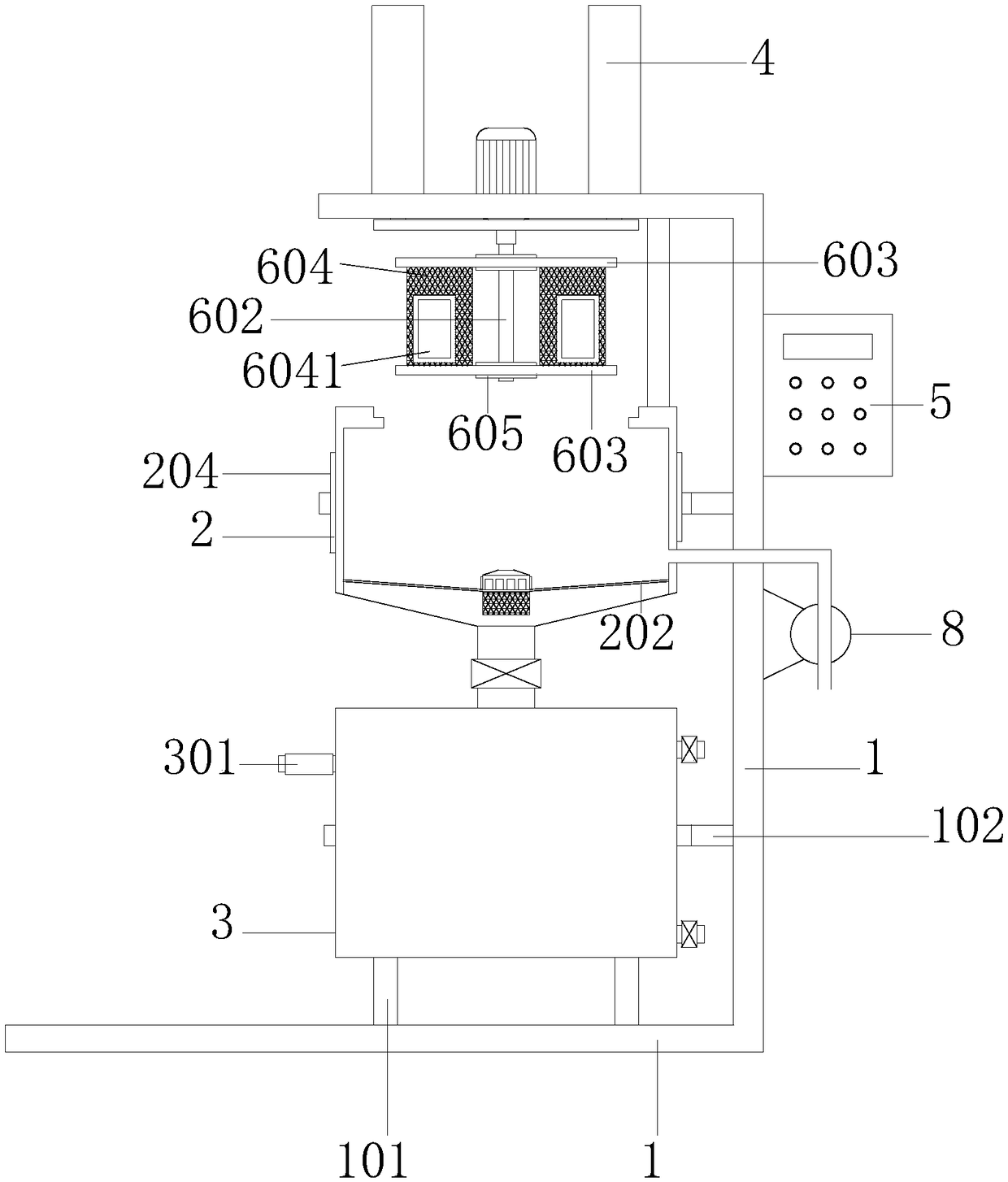

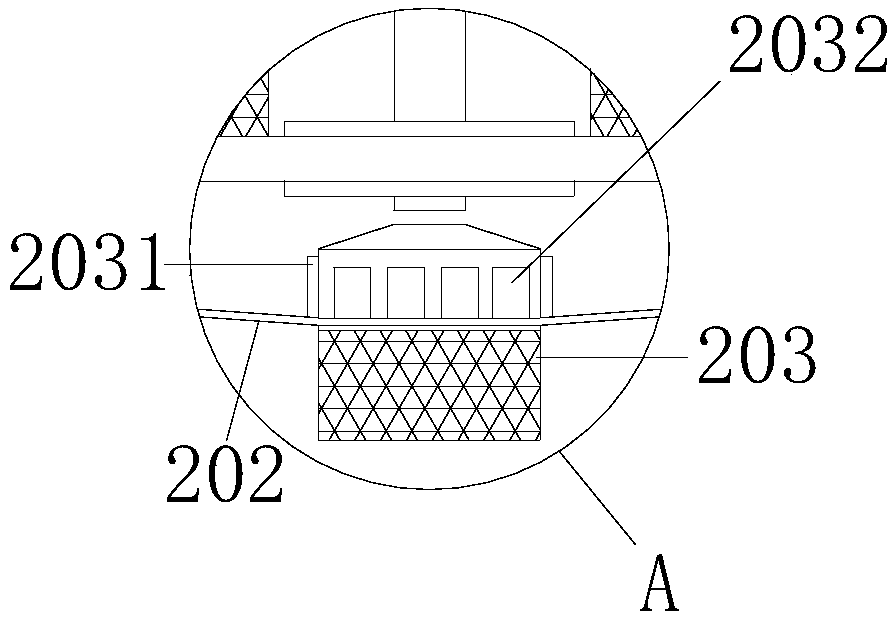

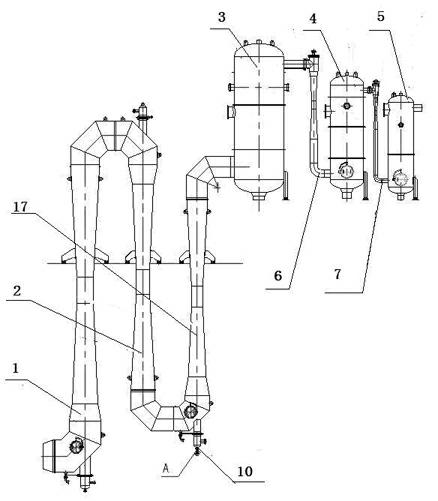

Traditional Chinese medicine decocting, filtering and cooling integrated equipment

ActiveCN108815876AImprove the extraction rate of traditional Chinese medicineIncrease yieldSolid solvent extractionFiltration circuitsEngineeringLiquid level sensor

The invention discloses traditional Chinese medicine decocting, filtering and cooling integrated equipment and belongs to the technical field of pharmaceutical equipment. The traditional Chinese medicine decocting, filtering and cooling integrated equipment comprises a frame plate. An upper tank body and a water pump are fixed to the frame plate, an annular heating plate is arranged on the side wall of the upper tank body, a sealing plate covers the upper tank body, a filter screen is embedded on the bottom side in the upper tank body, a motor is mounted in the middle of the top of the sealingplate, the output shaft of the motor penetrates the sealing plate and is connected to a rotary shaft, a plurality of traditional Chinese medicine storage tanks are fixed to the rotary shaft, two electric cylinders are also mounted on the top of the frame plate, telescopic rods at the front ends of the electric cylinders penetrate the frame plate and are connected to the sealing plate, a controller is fixed to the side wall of the frame plate, a liquid level sensor is mounted in the upper tank body, and the liquid level sensor, the annular heating plate, the water pump, the electric cylindersand the motor are electrically connected to the controller, separately. Various different traditional Chinese medicines can be separately put in the traditional Chinese medicine storage tanks to be extracted, so that the traditional Chinese medicine and dregs are prevented from being mixed together.

Owner:安徽英泰科技有限公司

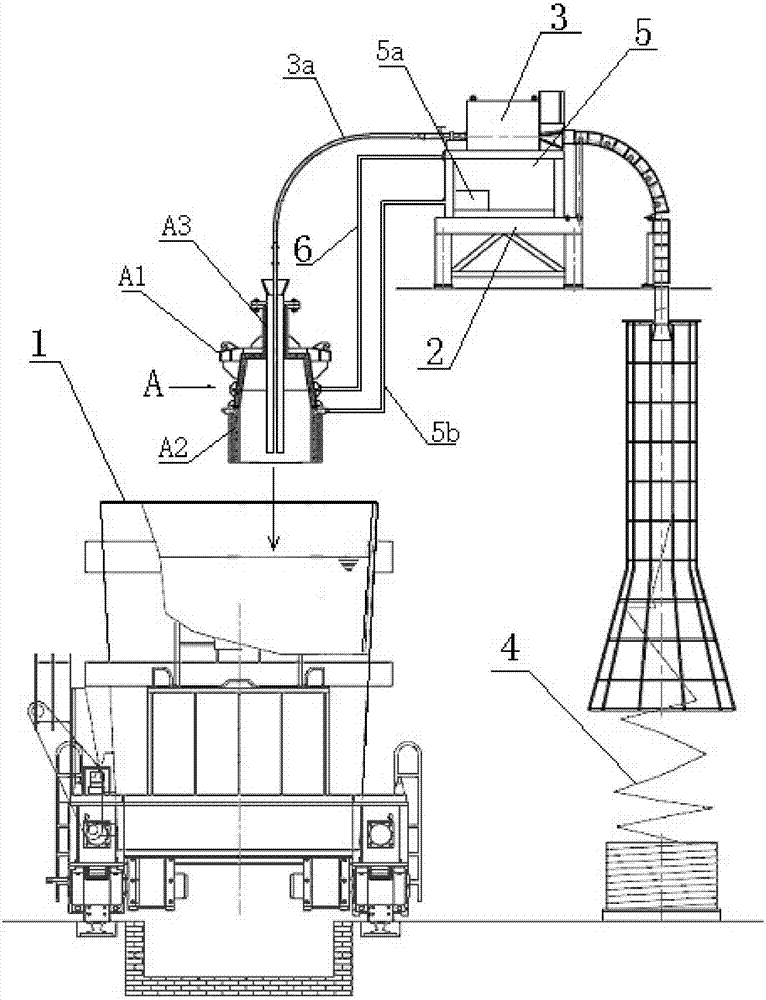

Steel ladle wire feeding auxiliary device and steel ladle wire feeding method

The invention provides a steel ladle wire feeding auxiliary device and a steel ladle wire feeding method. The steel ladle wire feeding auxiliary device comprises a steel ladle and a wire-feeder arranged on a working platform. A metal wire lead-out tube of the wire-feeder is connected with the steel ladle wire feeding auxiliary device which is arranged in an ascending and descending manner, metal wires are delivered into the steel ladle wire feeding auxiliary device by the metal wire lead-out tube, and then the metal wires are directly injected into the liquid steel in the steel ladle by the steel ladle wire feeding auxiliary device. The working platform is provided with a ventilating and dedusting device with a vacuumizing unit, and the ventilating and dedusting device is connected with the inner portion of the steel ladle wire feeding auxiliary device and is in pipeline communication with the steel ladle wire feeding auxiliary device. By means of the steel ladle wire feeding auxiliary device and the steel ladle wire feeding method, the metal wires are directly fed into the liquid steel, the phenomena that the wires are melt before entering into the liquid steel, and the wires cannot enter the liquid steel due to the fact that steel slag is too thick are avoided, and the wire yield rate is increased; gases and smoke dust are discharged into the ventilating and dedusting device, and the environmental pollution is reduced; and the metallurgical reaction conditions of the liquid steel in the steel ladle are changed by the vacuumizing unit, part of the metallurgical reaction velocity is increased, the oxidation loss of useful elements is prevented, and the alloy yield rate is increased.

Owner:BAOSHAN IRON & STEEL CO LTD +1

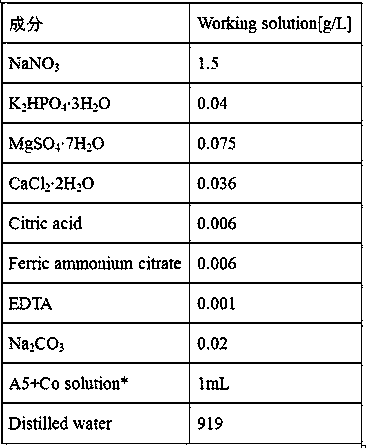

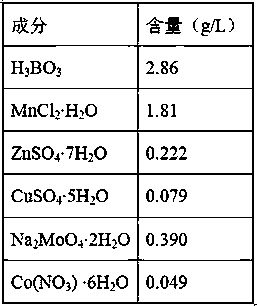

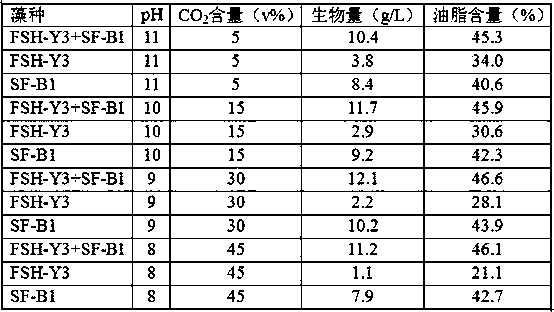

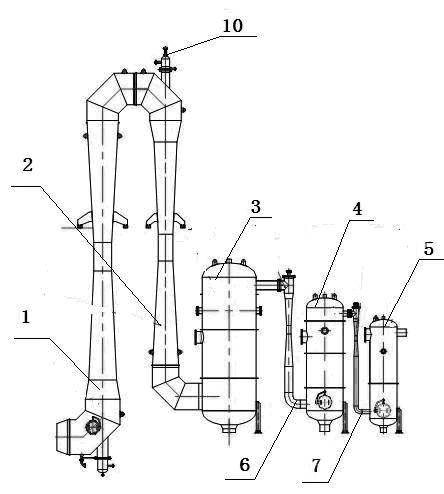

Method for preparing microalgae grease through mixed cultivation

ActiveCN109576314AIncreased tolerance and carbon sequestration efficiencyIncrease yieldBiofuelsMicroorganism based processesEcologyChlorella sp.

The invention relates to a method for preparing microalgae grease through mixed cultivation. The method comprises the steps that a microalgae culture medium and a mixed microalgae seed solution are added in a photobioreactor, the pH of a cultivation system is maintained to be 8-12, preferably, 9-11, and CO2 with the volume content being 5v%-45v%, preferably, 10v%-30v%, is introduced; mixed microalgae comprises chlorella sp. SF-B1, and meanwhile comprises parachlorella kessleri FSH-Y3 or / and scenedesmus obliqnus FSH-Y2. According to the method, the tolerance and solubleness of the microalgae culture cultivation system to high-concentration CO2 are improved, carbon fixation efficiency is improved, the harvest yield of the microalgae grease is obviously improved, and production of biodiesel is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum degree gas saving regulation system

The invention relates to the technical field of the external refining of a steel liquid furnace, and in particular relates to a vacuum degree gas saving regulation system aiming at a water vapour ejector pump. The vacuum degree gas saving regulation system comprises multi-level booster pumps, two-level ejector pumps, two-level assistant ejector pumps and three condensers and is characterized in that the multi-level booster pumps are successively communicated; the last-level booster pump is directly communicated with the first condenser; the first condenser is communicated with one port of the second condenser by the first ejector pump; the first condenser is communicated with the other port of the second condenser by the first assistant ejector pump; the second condenser is communicated with one port of the third condenser by the second ejector pump; the second condenser is communicated with the other port of the third condenser by the second assistant ejector pump; and the nozzles of the last-level booster pump, the first ejector pump and the first assistant ejector pump are respectively provided with a vacuum degree gas saving regulation device. According to the technical requirements, the vacuum degree is regulated by the system, the raw materials are saved, and the refining technology is satisfied.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

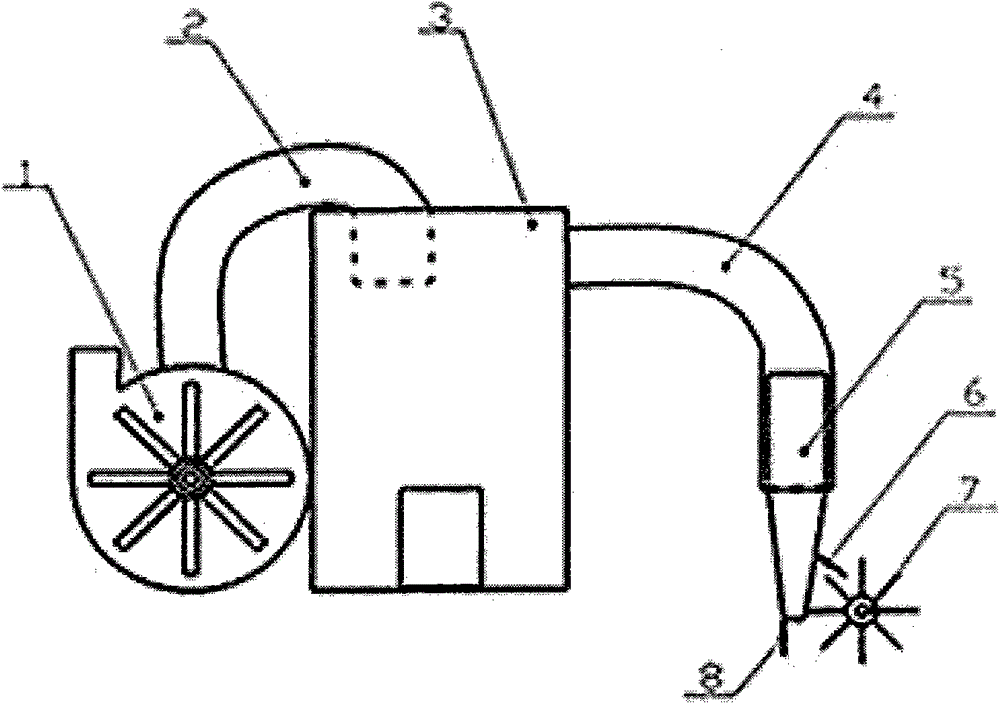

Crop ground falling seed harvesting device

The invention relates to a crop ground falling seed harvesting device, which mainly consists of a fan, an air pipe, a seed box, a seed sucking pipe, a seed sucking head, a sweeping roller and the like, wherein one end of the air pipe is communicated and connected with the fan, the other end of the air pipe is communicated and connected with the seed collecting box, one end of the seed sucking pipe is communicated and connected with the seed collecting box, the other end of the seed sucking pipe is communicated and connected with the seed sucking head, and the lower part of the seed sucking head is provided with the sweeping roller. Air sucking flow generated by the fan acts on the seed sucking head after passing through the air pipe, the seed collecting box and the seed sucking pipe, ground falling seeds swept by the sweeping roller can be subjected to air sucking type harvesting, and the crop ground falling seed harvesting device has the characteristics that the design is compact, the seed damage is avoided, and the harvesting rate is high.

Owner:张林德 +1

Technique for brewing alcohol

InactiveCN101260412AIncrease yieldSolve the shortage of raw materialsBiofuelsFermentationSweet sorghumChemistry

The invention relates to a technology for brewing alcohol which is prepared via fermenting and distilling with the existence of maltogenic amylase by adopting sugar crops (beet, sweet sorghum, sugar cane, etc.) and starch crops as raw materials, wherein, the weight proportional relation between the sugar crops and the starch crops in the raw materials is between 1 to 1 and 5 to 1. The technology for brewing alcohol not only can ferment sugar in mash into alcohol, but also can ferment slag of the sugar crops and other ingredients in the raw materials into alcohol, can effectively recover and can improve the distillation yield by 20 to 25 percent; meanwhile, because the sugar crops and the starch crops are adopted as the raw materials, the technology for brewing alcohol solves problems of raw material shortage and grain crops oriented existed in the prior industry for producing alcohol by using grain as raw material.

Owner:NINGXIA GUANGCAI NEW ENERGY HIGH TECH

Silicon-aluminium-calcium composite deoxidant and its preparing method

This invention discloses a new compound deoxidization agent for steel-smelting use, and this agent comprises the following components: silicon 30-42%, aluminum 10-28%, Ca 6-12%, and Te the rest. This invention can fast deoxidize the steel, can effectively remove the impurities in the steel melt to improve the flow ability of steel melt, and advance the quality of the product and the use method is very convenient.

Owner:张敏修 +2

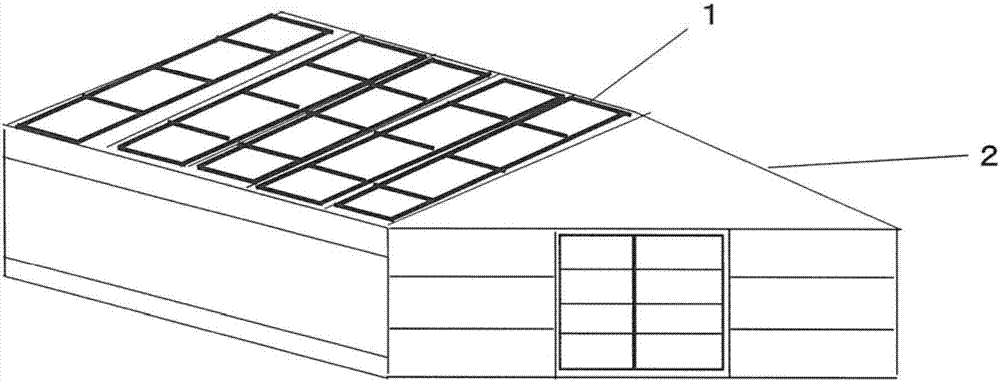

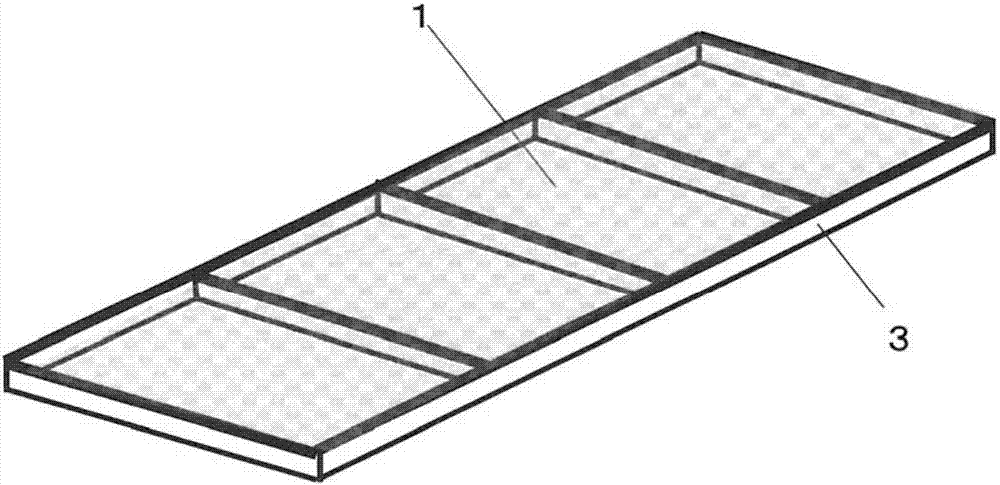

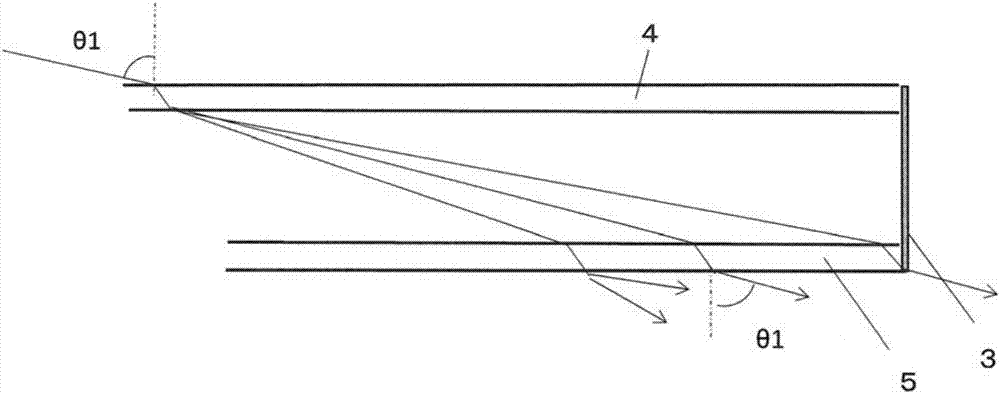

Agricultural greenhouse construction method

InactiveCN107278699AImprove thermal insulationIncrease yieldClimate change adaptationGreenhouse cultivationReflectivityTransmittance

A building direction of a greenhouse with double-layer light-transmissive films is an east and west beam, and light incidence angle is smaller than that of a north and south beam, so Fresnel reflection ratio is reduced and light transmittance of the double-layer light-transmissive film as a whole can be improved. The greenhouse has double-layer light-transmissive film or double-layer light-transmissive plates which form an air heat insulated layer. In the light-transmissive film or the light-transmissive plate, the light-transmissive film or the light-transmissive plate of at least any one of the inner side surface of the greenhouse and the outer side surface of the greenhouse is a photo diffusion light-transmissive film (4,5) or a photo diffusion light-transmissive plate which make light diffused, construction is performed in an east and west beam manner that a ridge direction of a roof is roughly in east and west direction.

Owner:ORGANIC NICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com