Method for preparing magnesium-gadolinium-yttrocalcite ternary intermediate alloy

A binary master alloy and master alloy technology, applied in the field of metallurgical technology preparation, can solve the problems of sedimentation and composition segregation, difficult control of alloy composition, small diffusion coefficient, etc., reduce oxidation and burning loss, promote homogenization, The effect of accelerating diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

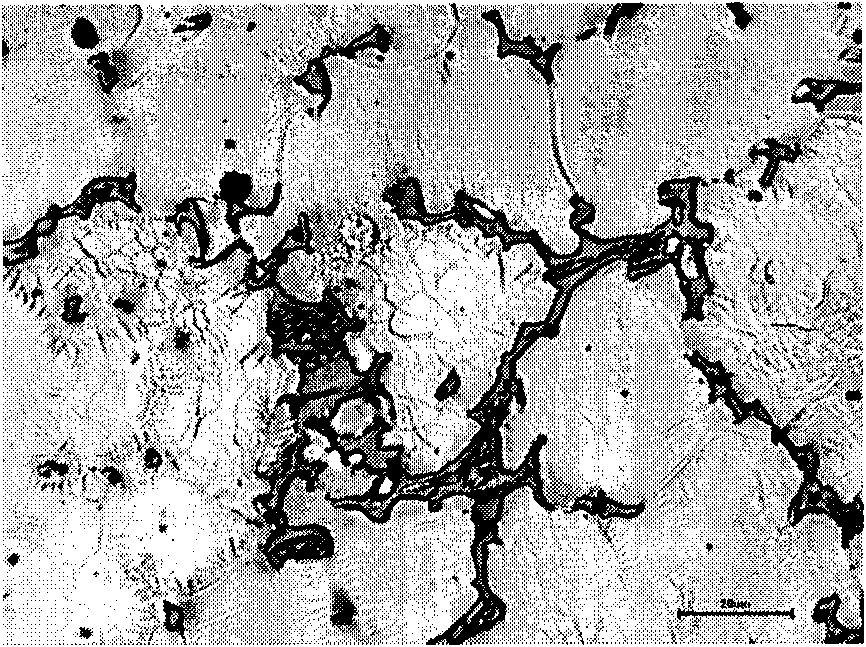

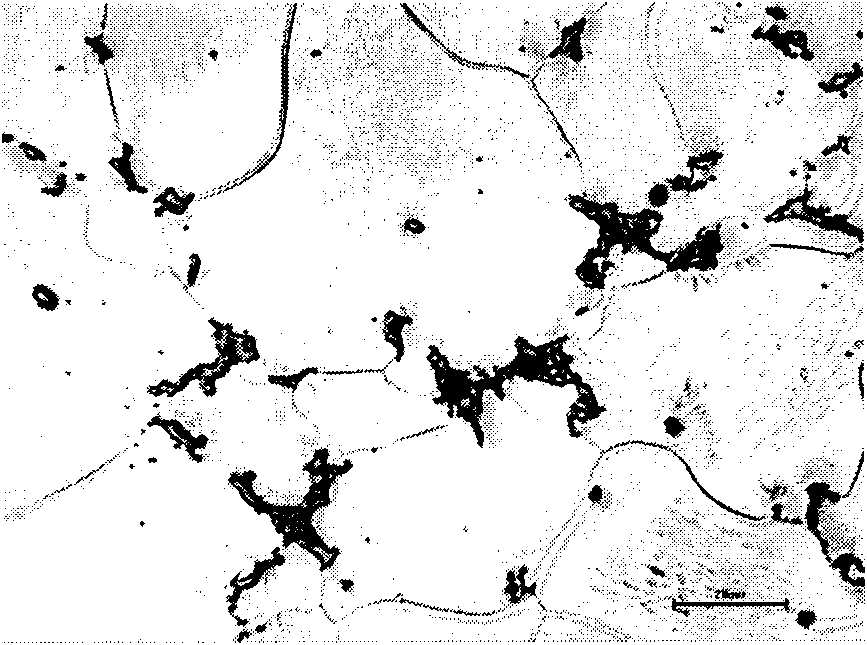

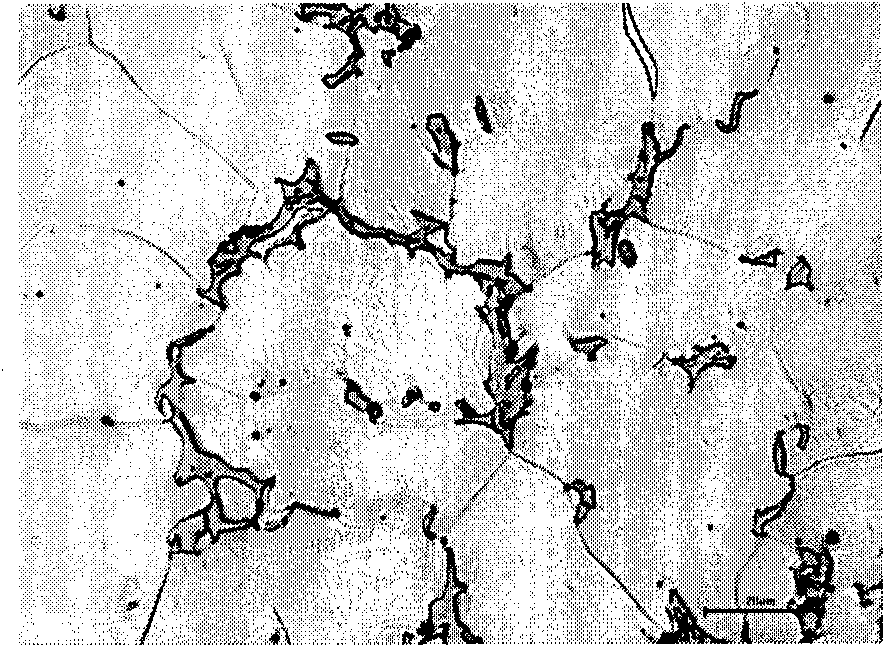

Image

Examples

Embodiment 1

[0025] A method for smelting 46 kg of Mg-Gd-Y ternary master alloy, wherein the alloy composition (percentage by weight) is 11.83% Gd, 6.48% Y, and the rest is Mg.

[0026] Step 1, get its raw material to be the Mg-10wt.%Y binary master alloy ingot of 37.52kg and the Mg-60wt.%Gd binary master alloy ingot of 10.34kg; Clean up two kinds of binary master alloy surfaces, and pre- Heat to 150°C;

[0027] Step 2: Turn on the melting furnace, which adopts resistance melting furnace equipment, and add 37.52kg of Mg-10wt.% Y binary master alloy ingots into the melting furnace, heat up and melt; when the temperature rises to 400°C, start The inert gas Ar gas is introduced to protect the melt from oxidation and combustion;

[0028] Step 3: When the Mg-Y binary master alloy is completely melted, raise the temperature to 730°C, add the Mg-Gd binary master alloy; dilute the original Mg-Y alloy melt; hold it with iron clamps The Mg-60wt.% Gd master alloy ingot is placed under the liquid su...

Embodiment 2

[0032] A method for melting 68 kg of Mg-Gd-Y ternary master alloy, wherein the alloy composition (weight percentage) is 7.88% Gd, 5.25% Y, and the rest is Mg.

[0033] Step 1, the raw materials are 60.4kg Mg-7.5wt.%Y binary master alloy and 10.2kg Mg-60wt.%Gd binary master alloy ingot; clean the surfaces of the two binary master alloys and preheat them to 250°C;

[0034] Step 2: Turn on the melting furnace, which adopts resistance melting furnace equipment, and add Mg-7.5wt.%Y binary master alloy ingots into the melting furnace, heat up and melt; when the temperature rises to 450°C, start to pass into Ar gas and SF 6 The mixed gas protects the melt from oxidation and combustion;

[0035] Step 3: After all the alloys in the melting furnace are melted, raise the temperature to 740°C, add Mg-60wt.%Gd binary master alloy ingot; dilute the original Mg-Y alloy melt; use iron clamps to clamp Hold the Mg-60wt.%Gd intermediate alloy ingot under the liquid surface of the melt, and sl...

Embodiment 3

[0039] A method for smelting a 69kg Mg-Gd-Y ternary master alloy, wherein the alloy composition (percentage by weight) is 10.5% Gd, 3.5% Y, and the rest is Mg.

[0040]Step 1, get the Mg-5wt.%Y binary master alloy of 60.5kg and the Mg-80wt.%Gd binary master alloy ingot of 10.4kg; Clean up the two kinds of binary master alloy surfaces, and preheat to 350°C;

[0041] Step 2: Open the melting furnace, add Mg-5wt.% Y binary master alloy into the melting furnace, heat up and melt; when the temperature rises to 500°C, start to introduce CO 2 with SF 6 The mixed gas protects the melt from oxidation and combustion;

[0042] Step 3: After all the alloys in the melting furnace are melted, raise the temperature to 750°C, add Mg-80wt.%Gd binary master alloy ingots, and dilute the original Mg-Y alloy melt. Use iron clips to fix the Mg-80wt.%Gd intermediate alloy ingot and place it under the liquid level of the melt, and slightly stir the alloy ingot, which is beneficial to the uniformit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com