Agricultural greenhouse construction method

A construction method and greenhouse technology, applied in the fields of botanical equipment and methods, horticulture, greenhouse cultivation, etc., can solve problems such as insufficient realization, and achieve the effects of being beneficial to agricultural management, improving heat preservation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

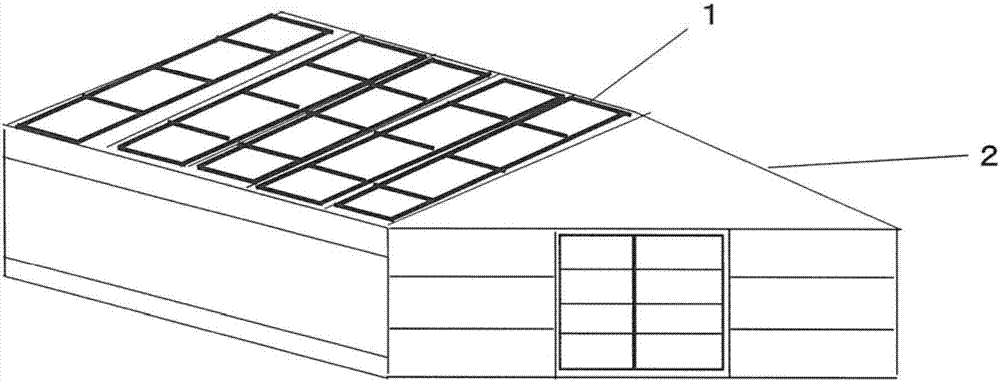

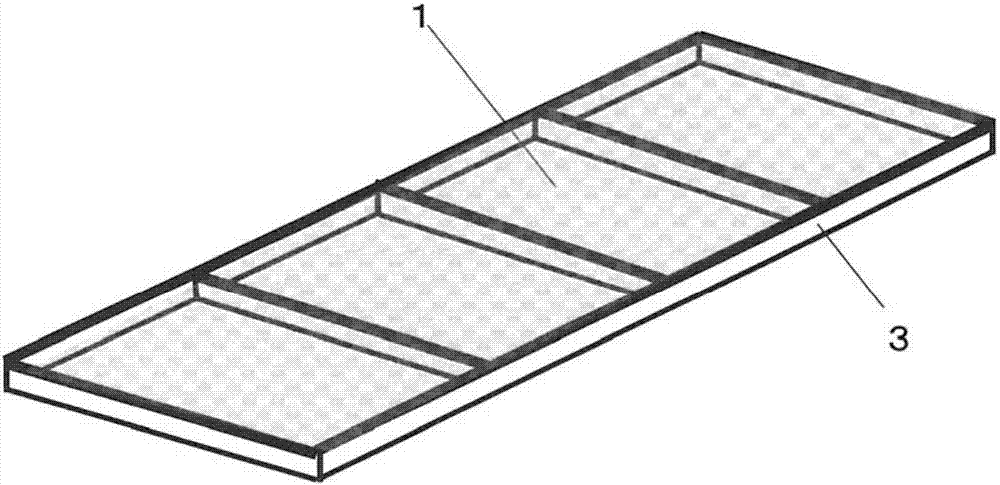

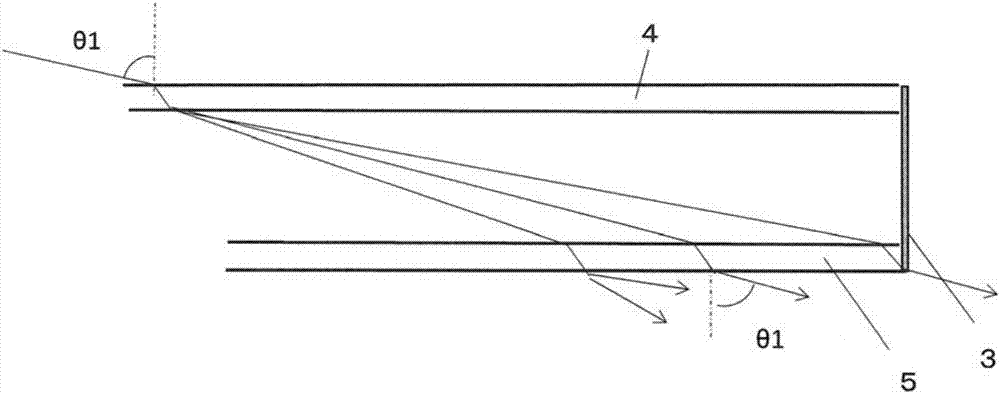

[0032] figure 1 An agricultural greenhouse of the type called a flat-sheet greenhouse is shown in which a film is spread flatly on a metal frame. figure 2 is a perspective view of panel members arranged side by side on the roof surface of the agricultural greenhouse, image 3 It is a side view of the main part of this panel part.

[0033] Such as figure 1 As shown, a plurality of roof panel members 1 are arranged side by side on the roof surface of an agricultural greenhouse (hereinafter referred to as a greenhouse). The roof panel part 1 is supported by the agricultural greenhouse structure part 2 .

[0034] Such as figure 2 As shown, the roof panel part 1 has a rectangular frame part 3 forming an outer frame. Inside the frame member 3, wooden strips are provided as reinforcement members as required. On both sides of the frame part 3, unfold like image 3 Light-diffusing light-transmitting films 4, 5 are shown.

[0035] An air heat insulating layer is formed betwe...

Embodiment approach 2

[0047] Next, an example in which a curtain for shading or heat retention is combined is shown.

[0048] exist Figure 12A , 12B Two examples of the arrangement (the position in the stored state and the unfolding direction) of the light-shielding and heat-retaining curtains are shown in . Figure 12A It is the case where the ridgeline direction of the roof of the greenhouse is at right angles to the unfolding direction of the curtain, Figure 12B This is the case where the direction of the ridge line of the roof of the greenhouse is in the same direction as the direction in which the curtain is deployed. These two are differentiated and used by the location of the greenhouse, the interval of the columns, the structure of the curtain driving device, and the like.

[0049] Here, the invention is Figure 12A In this case, the storage position of the curtain is the seam part of the roof on the north side, and the deployment direction is southward. Figure 13 A cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com