Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

An environmental protection and energy saving, roofing technology, applied in the direction of roof covering layer, roofing, roofing with flat/curved panels, etc., can solve the problems of increasing the amount of brine, short service life, large water absorption, etc., to reduce the amount of brine, not easy to The effect of moisture absorption and halogen return and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

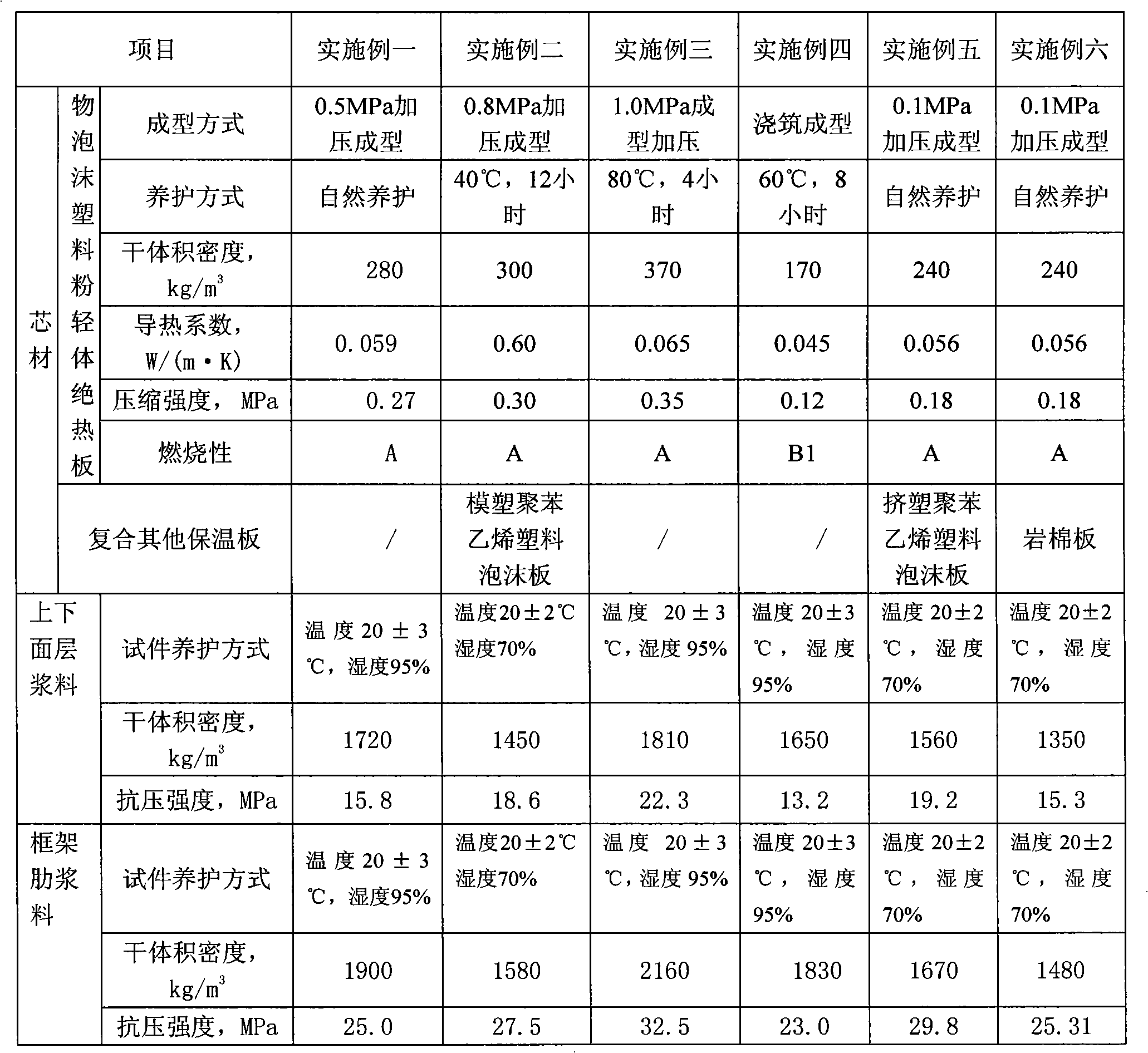

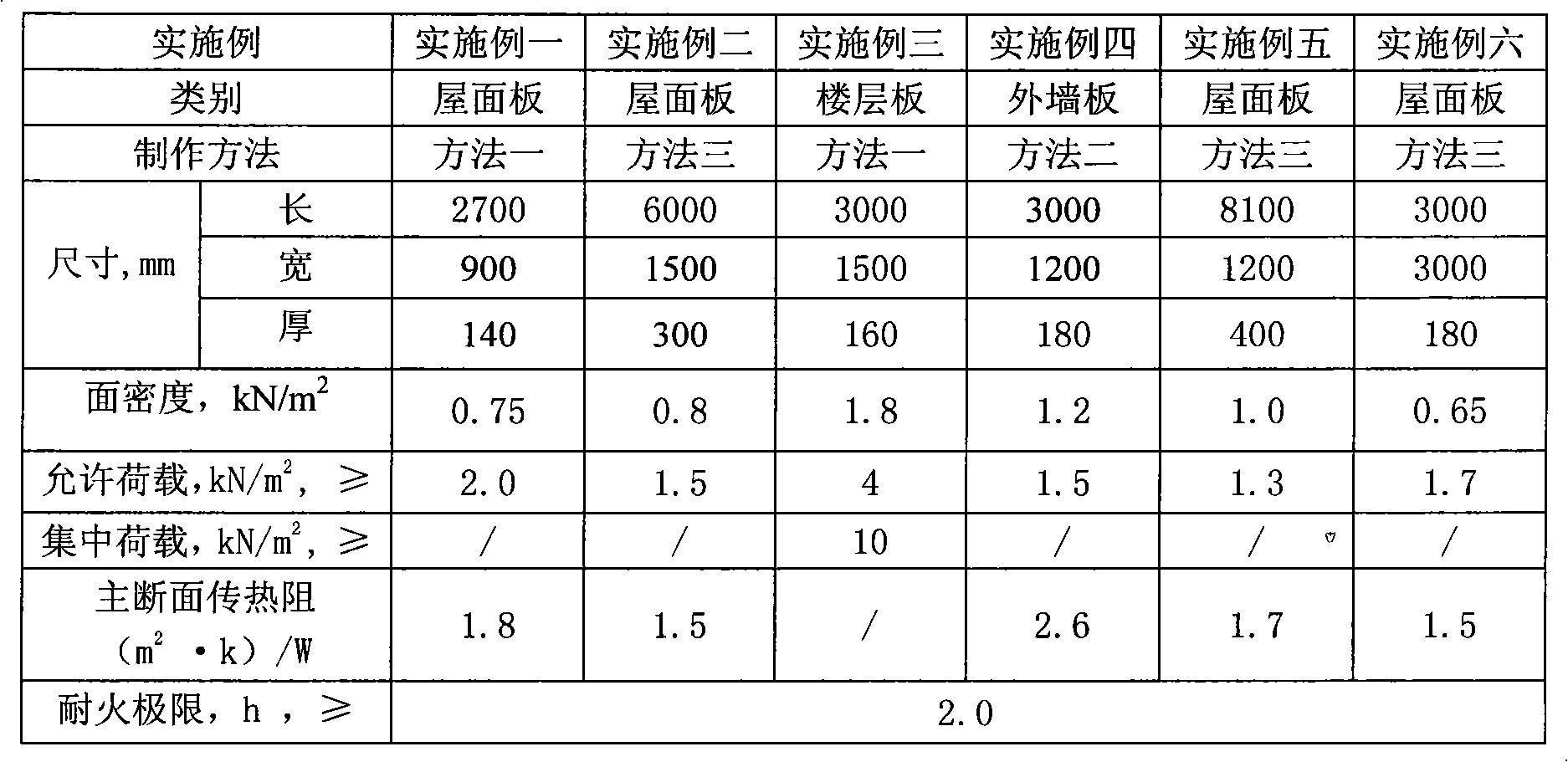

Embodiment 1

[0052] An environment-friendly, energy-saving and fireproof lightweight wallboard, comprising an upper layer, a lower layer and frame ribs, a heat insulating board is arranged between the upper layer and the lower layer, and the heat insulating board is a cement polymer foam plastic powder light body heat insulating board. The upper layer and the lower layer are provided with glass fiber mesh cloth, and the lower layer is also fixedly connected with frame ribs, and the frame ribs are provided with anti-corrosion steel skeletons.

[0053] The cement polymer foam plastic powder light-body thermal insulation board is composed of the following materials, and the ratio of parts by weight is:

[0054] 100 parts of rapid hardening sulfoaluminate cement, 60 parts of class II fly ash,

[0055] 15 parts of diatomaceous earth,

[0056] Vinyl acetate and ethylene copolymer powder (Vac / E) 2 parts,

[0057] 0.8 parts of hydroxypropyl methylcellulose ether, 0.3 parts of silane-based water ...

Embodiment 2

[0076] An environment-friendly, energy-saving, and fire-resistant lightweight roof panel, except that the materials of the upper and lower layers and the frame ribs are different, and the heat-insulating layer is made of cement polymer foam plastic powder, and the light-weight heat-insulation board is used in combination with molded polystyrene plastic foam board. The structures are all the same as in Embodiment 1.

[0077] The cement polymer foam plastic powder light-body thermal insulation board is composed of the following materials, and the ratio of parts by weight is:

[0078] 100 parts of rapid hardening sulfoaluminate cement, 60 parts of class II fly ash,

[0079] 15 parts of diatomaceous earth,

[0080] Vinyl acetate and ethylene copolymer powder (Vac / E) 2 parts

[0081] 0.8 parts of hydroxypropyl methylcellulose ether,

[0082] 1.5 parts of calcium formate accelerator, 0.2 parts of polypropylene fiber,

[0083] 0.3 parts of silane-based water-repellent agent, 55 p...

Embodiment 3

[0101] An environment-friendly, energy-saving, and fire-resistant lightweight floor board, except that the materials of the cement polymer foam plastic powder light-body insulation board, the upper and lower layers, and the frame ribs are different, and the rest of the structure is the same as that of the first embodiment.

[0102] The cement polymer foam plastic powder light-body thermal insulation board is composed of the following materials, and the ratio of parts by weight is:

[0103] Ordinary Portland cement 100 parts, Class I fly ash 40 parts,

[0104] 10 parts of diatomaceous earth, 1 part of polyvinyl alcohol powder,

[0105] 0.5 part of methyl cellulose ether, 0.1 part of calcium stearate water repellent,

[0106] 40 parts of urea-formaldehyde foam plastic powder, 2 parts of sodium nitrite early strength agent,

[0107] 100 parts of water.

[0108] Mix and stir the above-mentioned materials into the mold evenly and pressurize 1.0MPa to form it. After curing at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com