Preparation method and application of rare earth doped NaYF4/carbon quantum dot dual-mode fluorescent nanocomposite

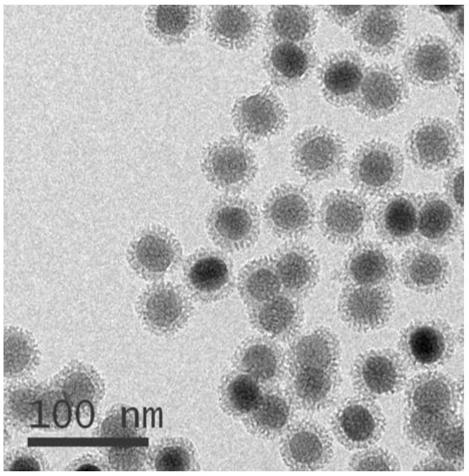

A carbon quantum dot and rare earth doping technology is applied in the field of preparation of rare earth doped NaYF4/carbon quantum dot dual-mode fluorescent nanocomposite materials, which can solve the problem of uncontrollable carbon quantum dot spacing, large composite material size, and easy aggregation and quenching. to avoid aggregation quenching, narrow size distribution, and good water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

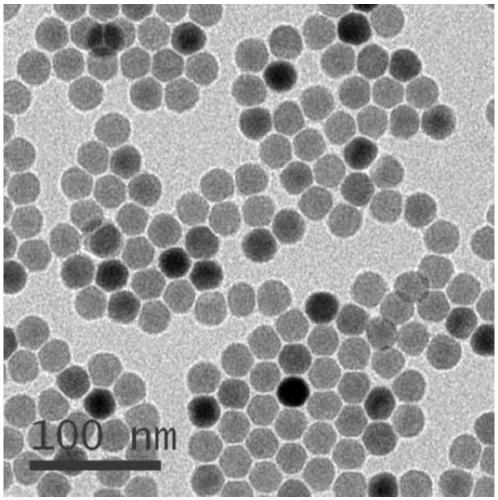

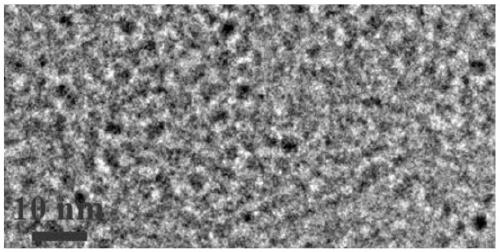

[0043] This embodiment provides a rare earth doped NaYF 4 A method for preparing a carbon quantum dot dual-mode fluorescent nanocomposite material, specifically comprising the following steps:

[0044] S1. Preparation of rare earth metal oleate precursor: weigh 2 mmol of rare earth metal salt (specifically: 0.4732 g (1.56 mmol) YCl 3 ·6H 2 O, 0.1549 g (0.4 mmol) YbCl 3 ·6H 2 O, 0.0158 g (0.04 mmol) ErCl 3 ·6H 2 O), 1.8570 g (6.1 mmol) of sodium oleate was placed in a 100 mL round-bottomed flask, 6 mL of water, 7 mL of ethanol and 14 mL of n-hexane were added, stirred magnetically, refluxed at 70 °C for 4 h, stopped heating and cooled to room temperature Finally, pour the obtained mixed solution into a separatory funnel, wash with water three times, and set aside;

[0045] S2. Preparation of Rare Earth Doped NaYF 4 Upconversion nanoparticles: put the rare earth metal oleate precursor prepared in the previous step into a 100 mL three-neck flask, add 30 mL octadecene and 1...

Embodiment 2

[0058] This embodiment provides a rare earth doped NaYF 4 A method for preparing a carbon quantum dot dual-mode fluorescent nanocomposite material, specifically comprising the following steps:

[0059] S1. Preparation of rare earth metal oleate precursor: weigh 2 mmol of rare earth metal salt (specifically: 0.4532 g (1.494 mmol) YCl 3 ·6H 2 O, 0.1937 g (0.50 mmol) YbCl 3 ·6H 2 O, 0.0023 g (0.006 mmol) TmCl 3 ·6H 2 O), 1.8570 g (6.1 mmol) of sodium oleate was placed in a 100 mL round-bottomed flask, 6 mL of water, 7 mL of ethanol and 14 mL of n-hexane were added, stirred magnetically, refluxed at 70 °C for 4 h, stopped heating and cooled to room temperature Finally, pour the obtained mixed solution into a separatory funnel, wash with water three times, and set aside;

[0060] S2. Preparation of Rare Earth Doped NaYF 4 Upconversion nanoparticles: put the rare earth metal oleate precursor prepared in the previous step into a 100 mL three-neck flask, add 30 mL octadecene an...

Embodiment 3

[0066] This embodiment refers to the preparation method of Example 1, the difference is that in step S1, the 2 mmol rare earth metal salt weighed is specifically 0.5339 g (1.76 mmol) YCl 3 ·6H 2 O, 0.0763 g (0.20 mmol) ErCl 3 ·6H 2 O, 0.0154 g (0.04 mmol) TmCl 3 ·6H 2 O; the carbon quantum dot solution added in step S4 is 8 mL of carbon quantum dot aqueous solution with a concentration of 0.6 g / mL.

[0067] For the rare earth doped NaYF prepared in this embodiment 4 / Carbon quantum dot dual-mode fluorescent nanocomposite material carries out fluorescence spectrum observation and finds that the rare earth doped NaYF provided by this embodiment 4 / Carbon quantum dot dual-mode fluorescent nanocomposite emits red light under 980 nm laser irradiation and blue light under 360 nm ultraviolet light irradiation.

[0068] The rare earth doped NaYF prepared in this embodiment 4 / carbon quantum dot dual-mode fluorescent nanocomposite material is applied to inkjet printing, the spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com