Water-based energy storage luminescence floor coating and preparation method thereof

An energy storage luminescence, floor coating technology, applied in the field of floor coatings, can solve the problems that have not yet been seen, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

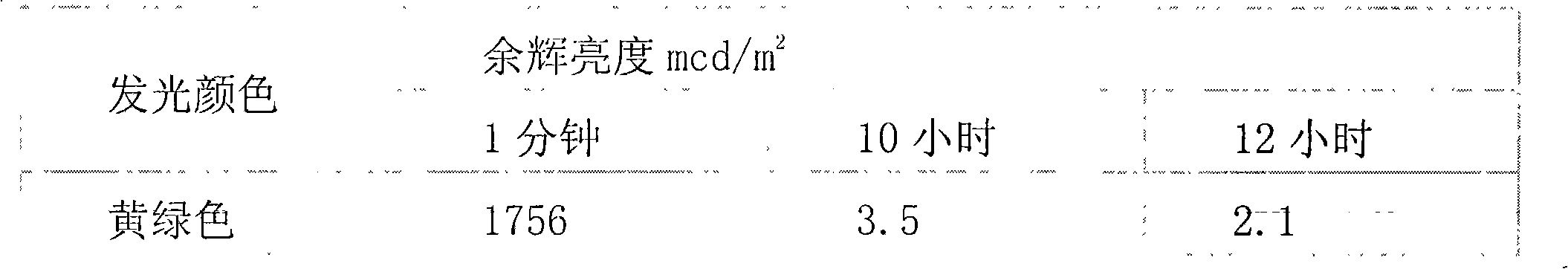

Embodiment 1

[0027] A water-based energy-storage luminous floor coating, which is composed of a main agent and an amine curing agent, and the main agent is composed of the following components in parts by weight:

[0028] 40 parts of epoxy resin, 6 parts of surface-modified luminous powder

[0029] Solid filler 10 parts Auxiliary 4 parts

[0030] 15 parts of solvent;

[0031] 8 parts of amine curing agent.

[0032] Wherein, auxiliary agent is made up of the component of following parts by weight:

[0033] Dispersant 1.0 parts Leveling agent 0.7 parts Defoamer 1.0 parts

[0034] Co-solvent 1.0 part Light stabilizer 0.3 part.

[0035] The surface-modified luminous powder is prepared by the following method: first, the surface of the luminous powder is modified with a silane coupling agent: 60 kg of long-lasting luminescent powder, 18 kg of silane coupling agent, and 180 kg of ethanol with a concentration of 99.9% are quickly Stir evenly, remove excess ethanol by evaporation (the evapora...

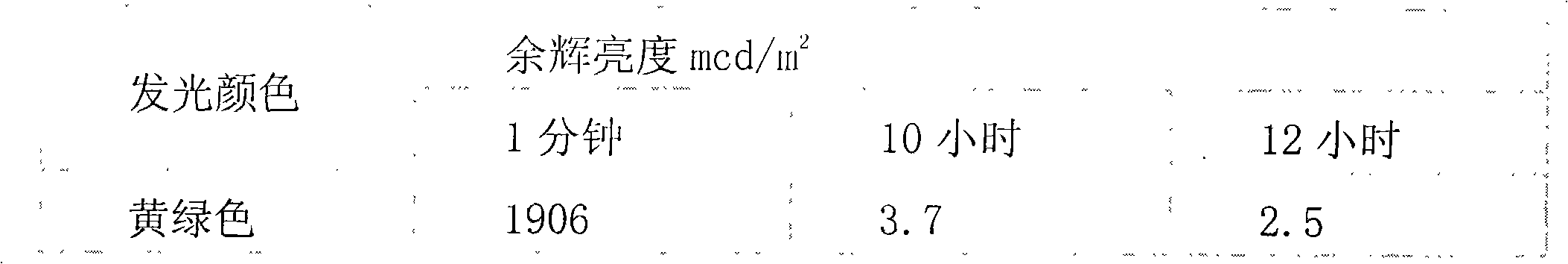

Embodiment 2

[0043] A water-based energy-storage luminous floor coating, which is composed of a main agent and an amine curing agent, and the main agent is composed of the following components in parts by weight:

[0044] 50 parts of epoxy resin, 20.5 parts of surface-modified luminous powder

[0045] 17.5 parts of solid filler, 7 parts of auxiliary agent

[0046] 22.5 parts of solvent;

[0047] 20 parts of amine curing agent.

[0048] Wherein, auxiliary agent is made up of the component of following parts by weight:

[0049] Dispersant 1.5 parts Leveling agent 1.0 parts Defoamer 1.25 parts

[0050] Co-solvent 1.75 parts Light stabilizer 1.5 parts.

[0051] The preparation method is basically the same as that of Example 1, and will not be repeated here.

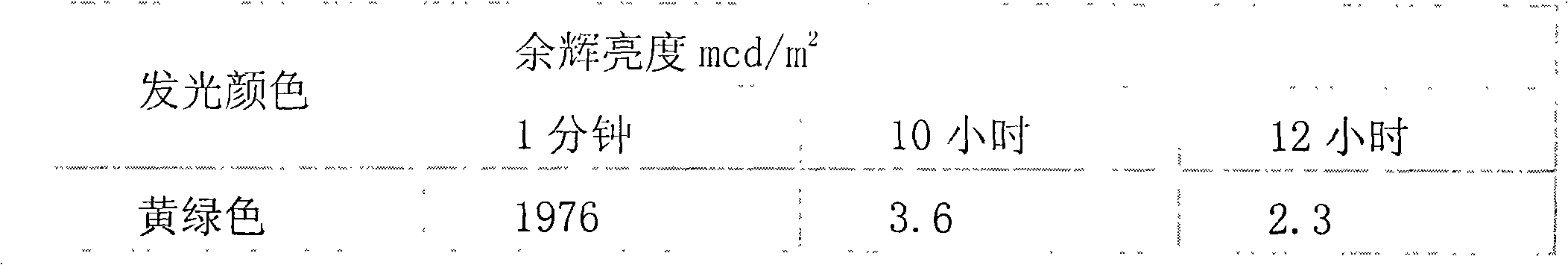

Embodiment 3

[0053] A water-based energy-storage luminous floor coating, which is composed of a main agent and an amine curing agent, and the main agent is composed of the following components in parts by weight:

[0054] 60 parts of epoxy resin, 35 parts of surface-modified luminous powder

[0055] 25 parts of solid filler, 8.5 parts of auxiliary agent

[0056] 30 parts of solvent;

[0057] 32 parts of amine curing agent.

[0058] Wherein, auxiliary agent is made up of the component of following parts by weight:

[0059]Dispersant 2.0 parts Leveling agent 1.0 parts Defoamer 1.5 parts

[0060] Co-solvent 2.5 parts Light stabilizer 1.5 parts.

[0061] The preparation method is basically the same as that of Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com