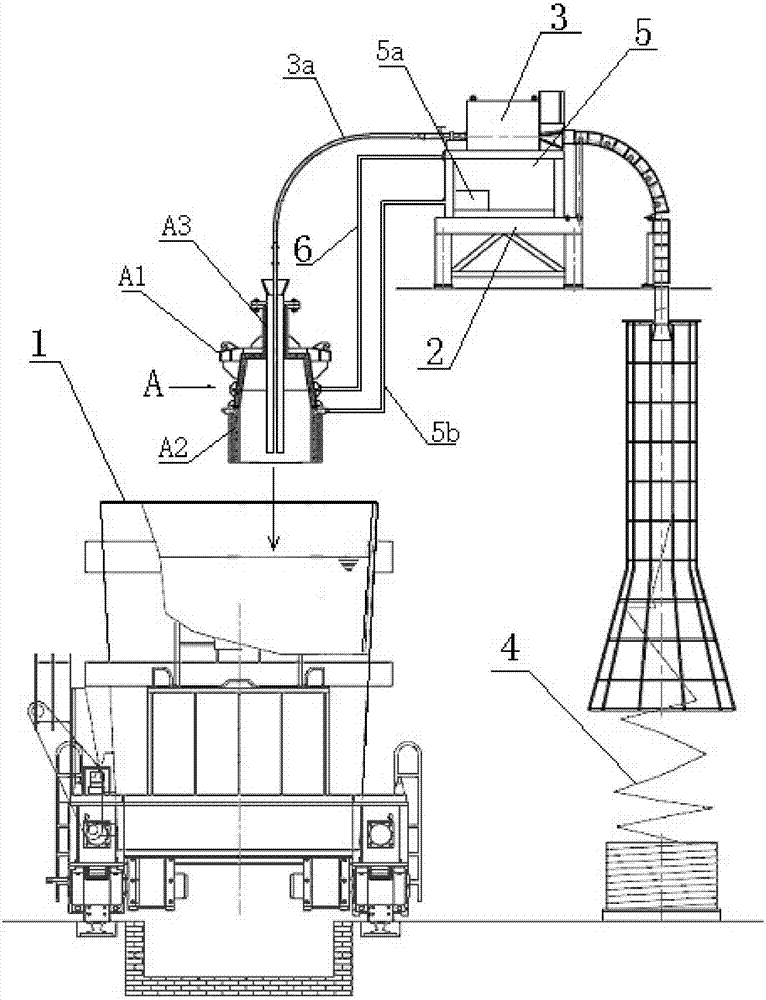

Steel ladle wire feeding auxiliary device and steel ladle wire feeding method

An auxiliary device and ladle technology, which is applied in the field of refining equipment and technology outside the steelmaking furnace, can solve the problems of affecting the processing time of molten steel, low wire yield, and poor wire feeding conditions, so as to improve the metallurgical reaction speed and increase the yield. Yield, the effect of preventing damage to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: In a 300-ton converter steel plant, feed silicon-calcium line to smelt pipeline steel.

[0044] A factory modified the original simple wire feeder at the RH station of a 300-ton converter steel plant according to a ladle wire feeding auxiliary device and a ladle wire feeding method of the present invention to smelt X70 pipeline steel, which requires calcium treatment , the original wire feeding device feeds 500 meters of Ф16mm cored wire, which contains Si-28% Ca alloy powder, and the amount of alloy per meter is 350g. The total amount of alloy powder fed in the original operation is about 175kg, including 49 kg of calcium. After the operation is completed The calcium content in molten steel fluctuates between 15-45ppm, with an average of about 21ppm, and the yield of calcium is 13%.

[0045] After the transformation, the ladle wire feeding auxiliary device A of the present invention is added, and the covered area of the immersion cover A2 of the ladle wire...

Embodiment 2

[0047] Example 2: A low-carbon aluminum-killed steel-feeding magnesium wire was smelted in a 300-ton converter steel plant.

[0048] On the same RH, low-carbon aluminum-killed steel is fed with magnesium cored wire. The outside of the magnesium cored wire is a steel strip shell, and the inside is wrapped with a Ф12.8Al-18% Mg alloy wire. The alloy is 322 grams per meter, which is equivalent to metal Magnesium 58g. The actual wire feeding amount of the original process is 500 meters, the amount of residual magnesium in the steel is 18ppm, and the equivalent yield is 19%.

[0049] After adopting a ladle wire feeding auxiliary device and a ladle wire feeding method of the present invention, the flow rate of argon blowing at the bottom of the ladle is 160 liters / minute, and after feeding wire for 500 meters, the residual magnesium content in the steel is measured to be 23 ppm, and the equivalent yield is 24%.

[0050] Through the above description and embodiments, a ladle wire fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com