Patents

Literature

79results about How to "Avoid oxidation loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

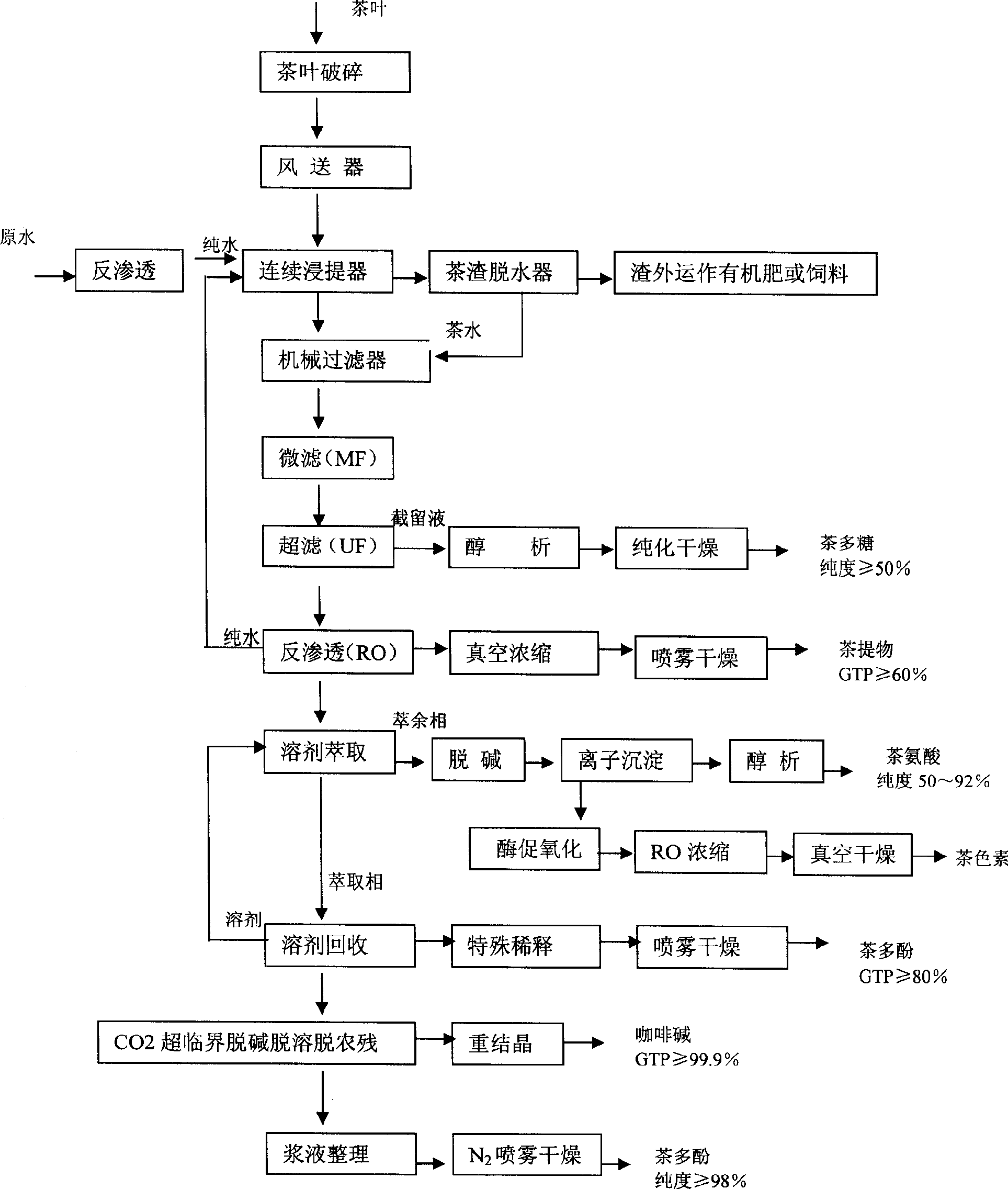

Process for extracting tea polyphenol, theanine, tea polysaccharide and tea pigment from tea

InactiveCN1837201AHigh purityReduce labor intensityCarboxylic acid amide separation/purificationBulk chemical productionForeign matterPhenolic content in tea

The invention discloses an extracting polyphenol, theanine, tea polysaccharide and tea pigment method from tea, which is characterized by the following: using deionized water for lixiviating tea at constant temperature with continuous flow upstream at multi-speed; adopting microstrainer to dislodge the foreign matter of raffinate; using hyperfiltration for putting-off pectin and protein; concentrating by hyperfiltration and dehydration; extracting tea polyphenol by acetic acid ethyl ester and recovering dissolvant; stripping caffeine of extracting extract phase, pesticide residue and dissolvant by CO2 supercritical fluid; getting tea polyphenol by low-temperature nitrogen spray-drying; using alcohol separation and low temperation vacuum drying by hyperfiltration trapped fluid to prepare tea polysaccharide; separating alcohol recrystallization by basic copper carbonate and hydrogen sulfide to get theanine; using enzymatic oxidation and alkaline air to oxygenate remain polyphenols substance of liquid phantom; getting tea pigment by hyperfiltration dehydration compression and vacuum drying; merging caffeine form carbon dioxide above-critical fluid and caffeine from carrene; recovering dissolvent; using deionized water for washing; obtaining caffeine by recrystallization vacuum drying.

Owner:张守政

Preparation method for tea extract

The invention discloses a preparation method for a tea extract, belonging to the technical field of extraction of effective components of tea leaves. The preparation method comprises the following steps: firstly, carrying out low-temperature rapid freezing treatment on high-quality commercial tea leaves; then immediately crushing; then combining a high-voltage pulsed electric field (PEF for short) technology, an ultrasonic treatment technology and a low-temperature enzymolysis technology; and carrying out low-temperature extraction in a whole process. According to the preparation method for the tea extract, the loss of effective components, caused by high-temperature processing, is avoided, and the extraction rate of the effective components of the tea leaves is also improved. The process is simple and low in cost; the introduction amount of extraneous food additives, processing auxiliary agents and chemical substances is reduced; the natural nutritional ingredient and the flavor of the tea leaves are kept to the greatest extent, the low-carbon production is realized and the environment is protected.

Owner:LVJIN DEV FUJIAN

Tea wine and preparation method thereof

InactiveCN103305371AHigh alcohol contentSweet and mellow tasteAlcoholic beverage preparationFlavorAlcohol

The invention provides a tea wine and a preparation method thereof. The tea wine is prepared by mixing a tea extraction solution and a grain saccharification solution and fermenting. The preparation method provided by the invention comprises the following steps of: firstly leaching tea to prepare the tea extraction solution; secondly mixing Chinese sorghum, rice and corn according to a certain proportion, crushing, steaming, boiling and saccharifying to obtain the saccharification solution, mixing with the tea extraction solution, adding koji, and forming a tea fermentation solution by liquid-state fermentation; and finally performing sterilization, blending, fining, filtering, aging and secondary filtration to obtain the tea wine. The tea wine is characterized in that a product provided by the invention has the characteristics of heavy tea fragrance, sweet and mellow taste, coordination of various flavors, long after-taste and the like; and furthermore, compared with the traditional tea wine, the tea extraction solution is adopted for performing fermentation together with the Chinese sorghum, the rice and the corn, the functional active ingredients in the tea can be retained to the greatest extent, the blending of a base wine is simultaneously performed after fermentation, the shortcomings of low alcohol degree of the fermented wine and complex process and pungent smell of the distilled wine can be overcome, the softness of the tea and the rigidity of the wine can be perfectly combined, and the species of tea and wine products are enriched.

Owner:四川省广汉市常乐春酒厂(普通合伙)

Copper alloy

ActiveUS20070169855A1Decreases stacking fault energyLow melting pointRespiratory disorderMetalCopper alloy

Disclosed is a copper alloy. The copper alloy consists essentially of Cu : 69 to 88 mass %, Si : 2 to 5 mass %, Zr: 0.0005 to 0.04 mass %, P : 0.01 to 0.25 mass %, and Zn : balance; has relation of, in terms of a content of an element a, [a] mass %, f0=[Cu]−3.5[Si]−3[P]=61 to 71, f1=[P] / [Zr]=0.7 to 200, f2=[Si] / [Zr]=75 to 5000, and f3=[Si] / [P]=12 to 240; has a metal structure that contains α phase and, K phase and / or γ phase, and has relation of, in terms of a content of a phase b, [b]%, in an area rate, f4=[α]+[γ]+[K]≧85 and f5=[γ]+[K]+0.3[μ]−[β]=5 to 95; and has an average grain diameter of 200 μm or less in a macrostructure when melted and solidified.

Owner:SANBO SHINDO KOGYO CO LTD

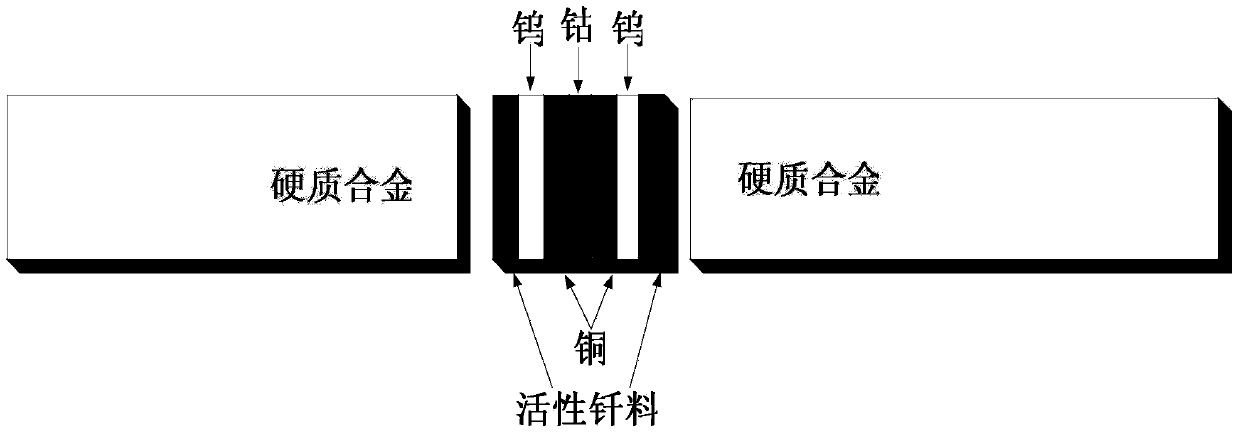

Method for preparing sandwich type composite brazing filler metal for hard alloy brazing

ActiveCN104043915ASimple preparation processIncrease productivityWelding/cutting media/materialsSoldering mediaCemented carbideFiller metal

The invention relates to a method for preparing composite brazing filler metal, in particular to a method for preparing sandwich type composite brazing filler metal for hard alloy brazing. The method for preparing the sandwich type composite brazing filler metal for hard alloy brazing mainly solves the problems that when used for brazing of one kind of hard alloy and another kind of hard alloy, existing brazing filler metal has the disadvantages that residual stress of a joint is high, cracking occurs easily, the strength of a brazing seam is low in the working process and production cost is high. The method comprises the steps of (1) surface pretreatment, (2) active brazing filler metal cleaning, (3) fixation, (4) cold rolling machining and annealing treatment and (5) activating reaction treatment. The sandwich type composite brazing filler metal is simple in preparing process, high in production efficiency, and suitable for connecting processes such as vacuum brazing, brazing in controlled atmosphere and diffusion brazing of one kind of hard alloy and another kind of hard alloy; residual stress of the joint between one kind of hard alloy and another kind of hard alloy is remarkably reduced, the strength of the brazing seam is improved, and the performance of the overall hard alloy component is improved; the sandwich type composite brazing filler metal is adaptive to brazing of a large amount of hard alloy with various specifications in a furnace, largely improves production efficiency of hard alloy brazing and reduces production cost.

Owner:哈尔滨瀚霖科技开发有限公司

Preparation method of noni wine

ActiveCN102776099AHelp to separateAvoid oxidation lossAlcoholic beverage preparationVitamin CFruit juice

The invention discloses a preparation method of noni wine. The preparation method is implemented according to the following steps of: (1) cleaning and arranging noni fruits, removing bad and decayed fruits and impurities, then adding SO2 for disinfecting, crushing, conducting self digestion, clarifying and separating; (2) adjusting the components, adding active dry yeast for fermenting, changing barrels, filtering after the fermentation, and ageing; and (3) blending, ageing, bottling and disinfecting to obtain the noni wine. According to the preparation method disclosed by the invention, the endogenesis enzyme contained in the noni fruits is utilized for self digestion of pulps, so that the separation of fruit juice and pomaces is facilitated; due to the addition of sulfur dioxide, the oxidation loss of vitamin C and the like of the noni wine can be avoided, the storage rate of the nutrient contents of the noni wine is increased, and the immune of a human body is enhanced; and secondly, after the noni fruits are fermented, the flavor of the noni product is improved, the prepared wine is pure and mild in taste, is harmonious in sweetness and sourness, and unique in flavor.

Owner:海南西沙诺丽生物科技有限公司

Composite slag for smelting stainless steel with back method at same time of desulfurization dephosphorization

ActiveCN101294235AImprove desulfurization effectReduce sulfur contentProcess efficiency improvementGranularitySlag

The invention provides composite slag which is used for smelting a stainless steel by using a return method and also used for desulfuration and dephosphorization at the same time. The composite slag comprises the components and proportioning by weight as follows: when the content of CaO is 1 part, BaO and / or BaCO3 is 0.6 to 1.8 parts, CaF2 and / or BaCl2 is 0.3 to 0.6 parts, and Fe2O3 is 0.01 to 0.15 parts. When limes are used as CaO material, the content of the CaO in the limes is more than 92 percent, the sulfur content is less than 0.025 percent, and the silicon dioxide content is less than 1 percent. The purity quotient of other components are demanded to reach more than 98 percent. The granularity of the composite slag is less than 1cm<3>.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

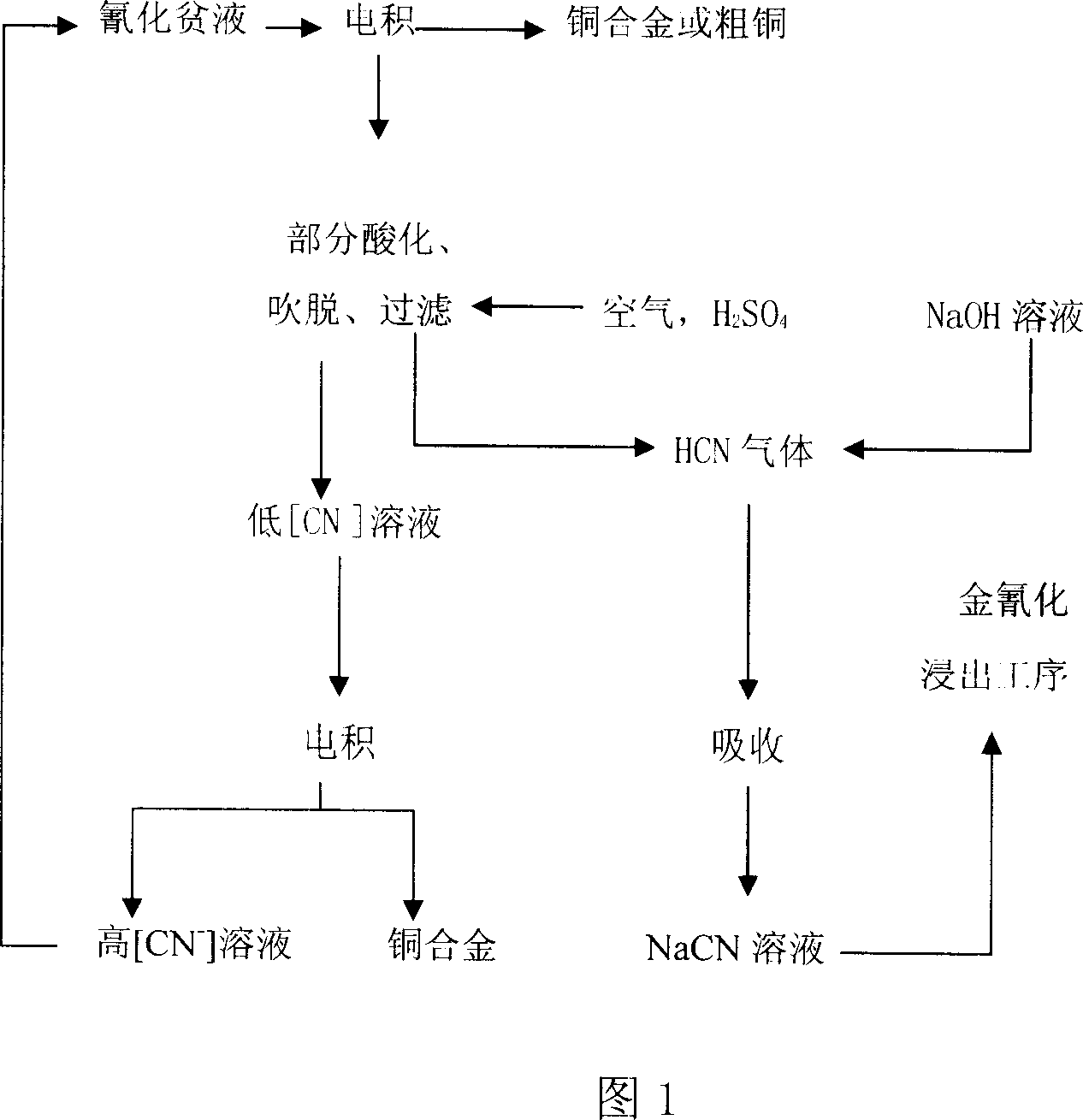

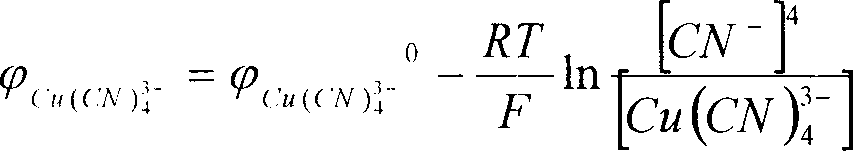

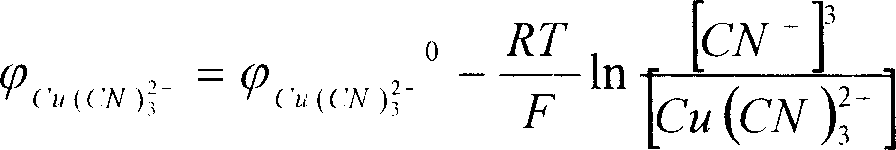

Method for recovering copper from cyanide-containing waste water and related waste water treatment method

InactiveCN101008090AHigh cathode current efficiencySolve the problem of low current efficiencyPhotography auxillary processesWater/sewage treatmentElectricityCyanide

The invention discloses a method for recovering copper from cyanic waste water and relative wastewater treatment method, belonging to non-ferrous metallurgy and environmental protection field. It is characterized in that it combines diaphragm electrodeposition with part of acidification, adds acid into electrodeposition liquid and aerates to blow off and recover free CN-, which greatly increases cathodic current efficiency; it employs diaphragm electrodeposition, that is to employ cationic exchange membrane to separate free cyanogen and metal- cyano complex from anode, to avoid cyanogen oxidation in anode; the waste electrodeposition liquid can be reused in cyanogen extraction process, or discharged after further treatment.

Owner:TSINGHUA UNIV

Freeze-dried fruit and vegetable product suitable for people suffering from dysmasesis and preparation method of freeze-dried fruit and vegetable product

InactiveCN105192612AEasy to eatAvoid oxidation lossFood preservationFood preparationSucroseSaccharum

The invention discloses a freeze-dried fruit and vegetable product suitable for people suffering from dysmasesis. The freeze-dried fruit and vegetable product is prepared by mixing raw materials in parts by weight as follows: 10-30 parts of wheat germs, 20-40 parts of milk powder, 1-10 parts of corn peptides, 1-10 parts of rice peptides, 100-300 parts of cabbages, 100-300 parts of carrots, 100-300 parts of broccoli, 100-300 parts of tomatoes, 200-350 parts of Chinese yams, 300-500 parts of apples, 300-500 parts of bananas and 30-80 parts of sucrose powder. The processed freeze-dried fruit and vegetable product has rich fruit and vegetable tissue ingredients and nutritional ingredients of the milk powder, the corn peptides, the rice peptides and the like, adopts a reasonable formula, has comprehensive nutrition and fragrance of fruits and vegetables and is easy to chew and blend, and a nutritional product supplementing fruits and vegetables is provided for the people suffering from dysmasesis.

Owner:广西恩度高科技股份有限公司

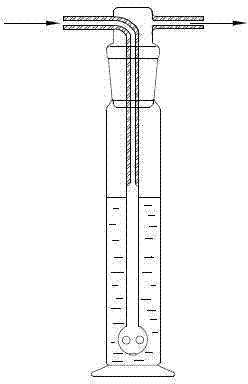

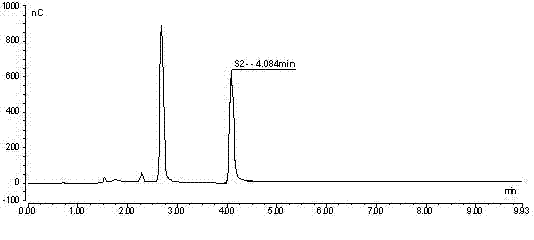

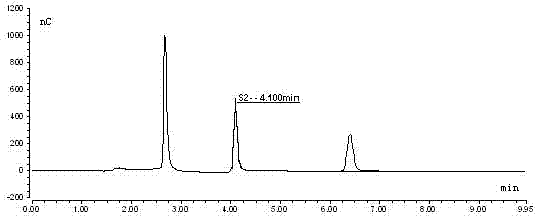

Method for measuring hydrogen sulfide in mainstream cigarette smoke

ActiveCN102539558AMethod is fastImprove ergonomicsComponent separationChromatographic separationEthylenediamine

The invention relates to a method for measuring hydrogen sulfide in mainstream cigarette smoke, in particular to an ion chromatography method for measuring hydrogen sulfide in mainstream cigarette smoke. The invention provides a method for directly measuring hydrogen sulfide in mainstream cigarette smoke, in order to solve the problem that complete capture and derivatization indirect measurement of hydrogen sulfide in mainstream cigarette smoke are susceptible to interference in prior arts. In the inventive method, an alkaline solution containing ascorbic acid, zinc acetate, ethylenediamine and sodium hydroxide is adopted to capture hydrogen sulfide in the gas phase of cigarette smoke, and anion exchange chromatographic separation and silver working electrode-equipped pulsed amperometric detector are adopted to directly measure hydrogen sulfide (sulfur ions) in the mainstream cigarette smoke. Compared with a conventional method, the inventive method has simpler operation, higher safety and higher interference resistance.

Owner:CHINA TOBACCO JIANGSU INDAL

Compound antifreeze agent and application thereof

InactiveCN104798868AHigh and low temperature protection activityIncrease added valueMeat/fish preservation using chemicalsBiotechnologySweet flavor

The invention discloses a compound antifreeze agent and application thereof and belongs to the field of food processing. The compound antifreeze agent in the formula comprises the following components in parts by weight: 2 to 8 parts of antifreeze polypeptide, 2.5 to 4.5 parts of trehalose and 0.2 to 0.5 part of polyphosphates. According to the compound antifreeze agent disclosed by the invention, the antifreeze polypeptide is taken as a main protecting agent and is combined and compounded with micromolecules to obtain a high-efficiency compound low-temperature protection formula; by using the high-efficiency compound low-temperature protection formula, the stability of minced fish products can be better kept in the low-temperature storage process of the minced fish products, the gel strength and the water holding capacity of surimi products are improved, and the protection can be provided for low-temperature storage and transportation of the surimi products; a preparation process of the antifreeze polypeptide is mature and simple and low in production cost, and is suitable for industrial production; in addition, the antifreeze polypeptide is high in low-temperature protection activity and sweetness-free, and can be used for keeping the flavor of the surimi products.

Owner:FUZHOU UNIV

Rotary blowing rotor produced with combination of plumbago and ceramic

InactiveCN101270414AGood high temperature oxidation resistanceImprove thermal shock resistanceMovable spraying apparatusCeramic compositeSlag

A rotor of rotary impeller of compositing graphite and ceramic belongs to the field of the purification treatment of aluminum melt. The invention comprises a graphite nozzle and a graphite-ceramic composite nozzle. The graphite nozzle is connected with the graphite-ceramic composite nozzle. The graphite-ceramic composite nozzle comprises two parts, and the internal part is a graphite tube which is covered with a ceramic bushing. The internal part of the graphite-ceramic composite nozzle is a through hole which is a gas channel. The graphite nozzle is equipped with a jet orifice for gas ejection. The ceramic material is silicon nitride bonded silicon carbide material, and the component and the weight percent are: 45 to 70 percent of silicon nitride and 30 to 55 percent of silicon powder. The ceramic material of the invention has the advantages of the good high temperature oxidation resistance, the good thermal shock resistance, the strong slag corrosion resistance, the high strength and the wear resistant, preventing from the erosion and oxidation of the graphite tube from aluminum liquid and air, thereby achieving the longer service life of the rotor of rotary impeller of compositing graphite and ceramic than that of the original rotor of rotary impeller with full graphite material.

Owner:SHANGHAI JIAO TONG UNIV

Superfine crushing wall-breaking method of haematococcus pluvialis cell

The invention relates to a wall-breaking method of algae, and in particular relates to a superfine crushing wall-breaking method of a haematococcus pluvialis cell. According to the method, superfine crushing equipment is adopted and is matched with liquid nitrogen equipment, so that the haematococcus pluvialis is frozen instantaneously to become brittle. Therefore, the wall-breaking rate is improved, and the protection environment of a low temperature and oxygen isolation are realized. After the wall-breaking treatment is carried out on the haematococcus pluvialis cell by using the method, the active substance of the haematococcus pluvialis cell has a high leaching rate and is not oxidated, so that the extraction ratio of the active substance is improved. The method is simple in process and convenient to operate, and can be used for performing the one-step treatment on a small quantity of samples in a short time and can also be matched with continuous equipment, sample collection equipment and the like to realize the automatic and continuous production, i.e., the mechanization degree is higher, so that the method is suitable for industrialized production. In addition, the samples are not polluted during the equipment running process, so that the safety is high.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

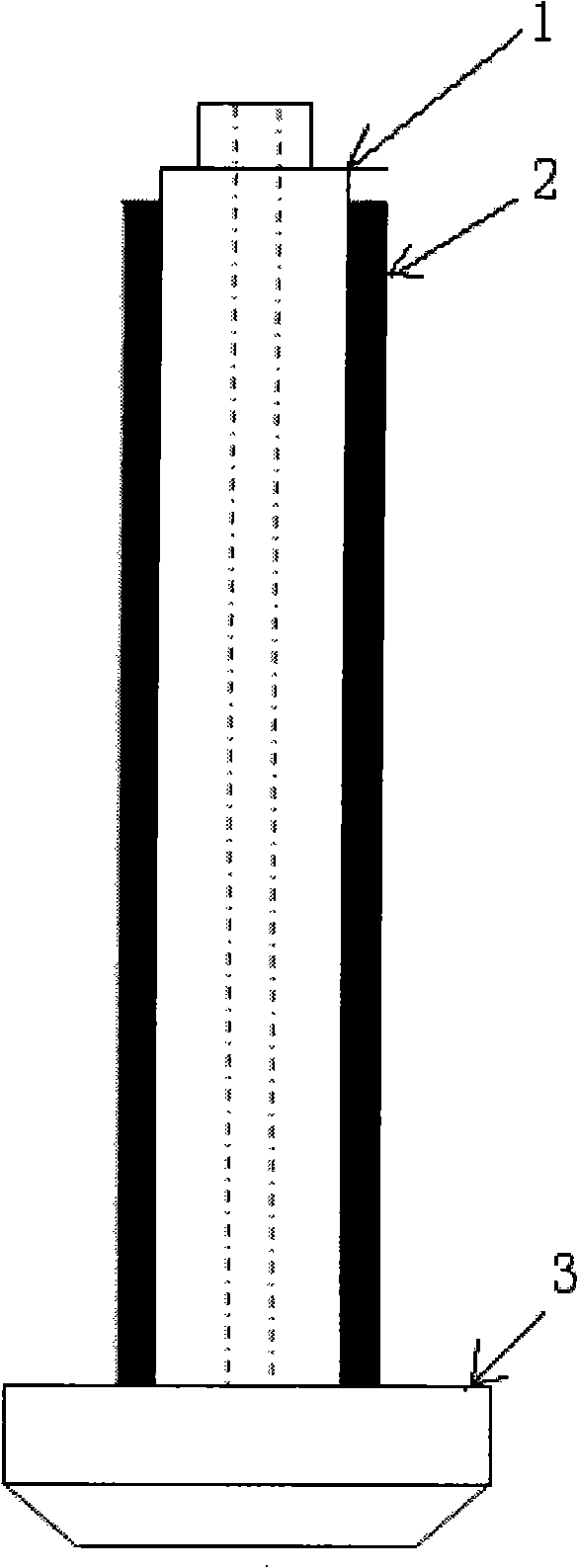

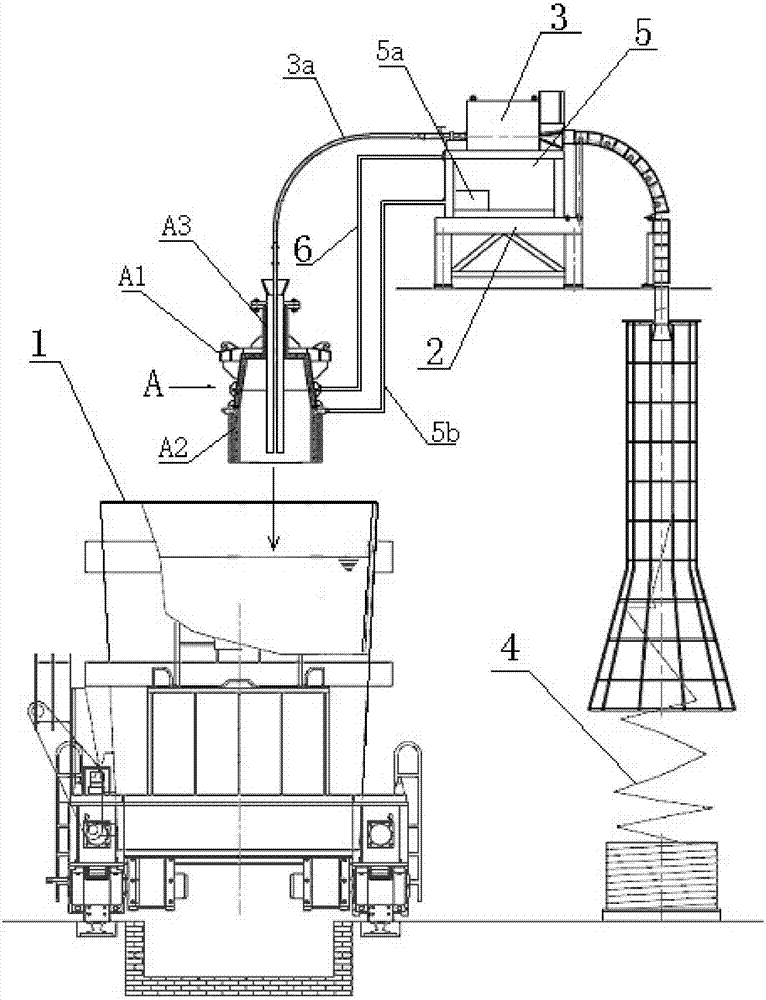

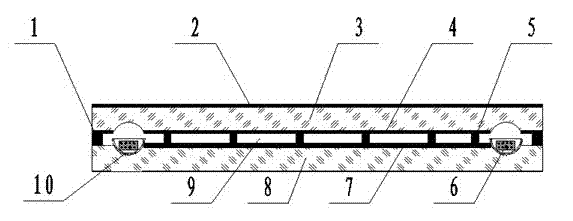

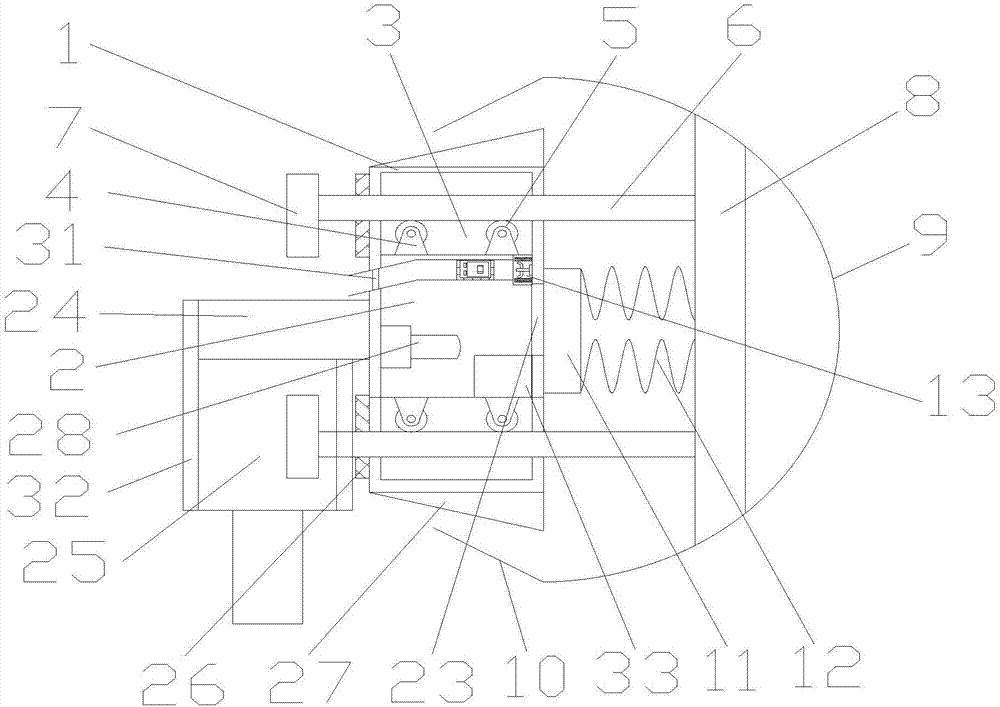

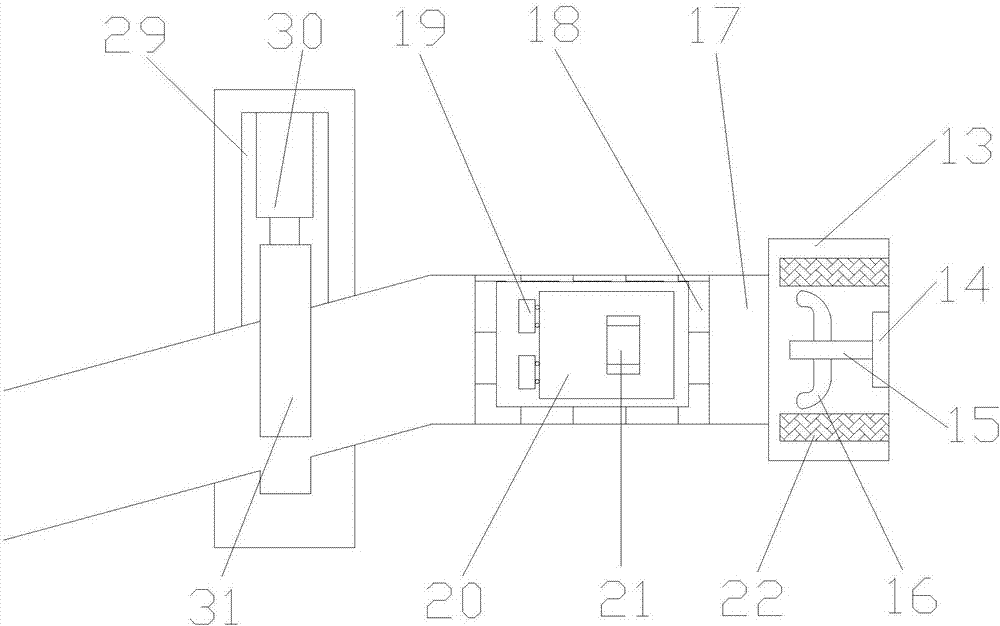

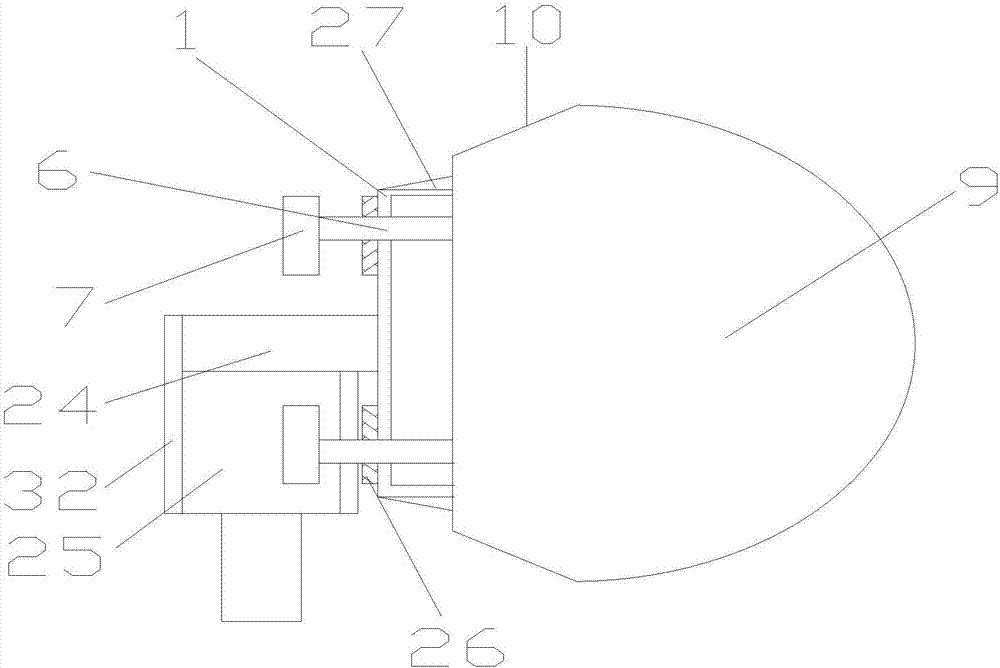

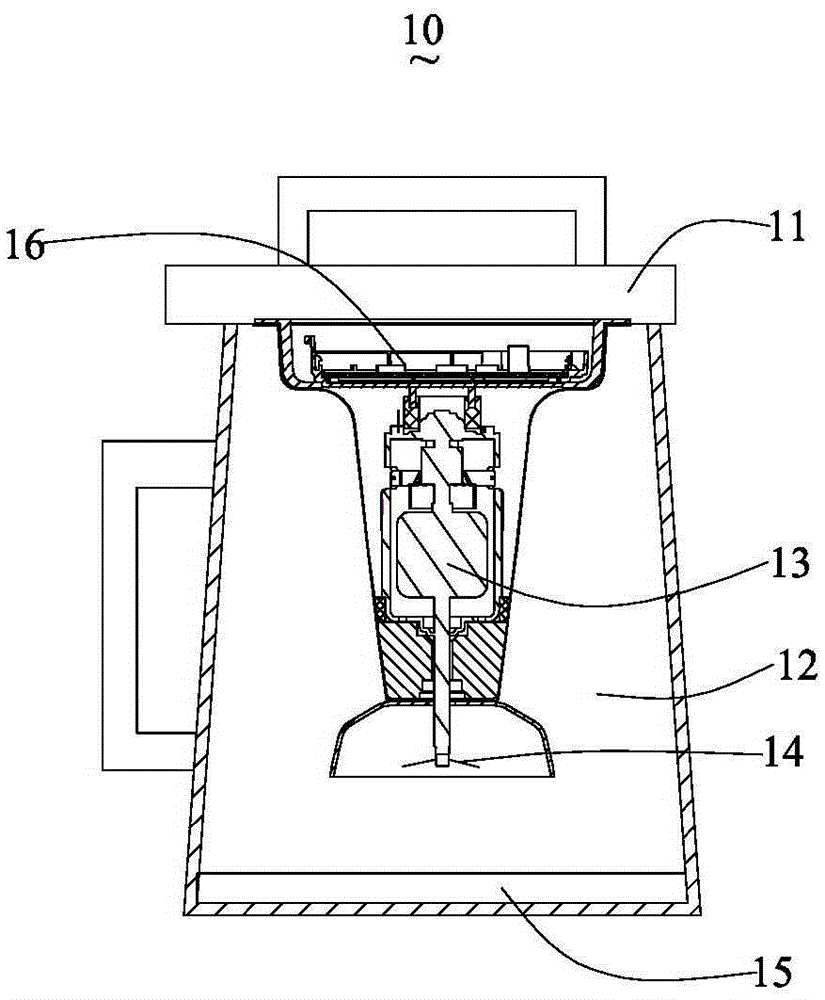

Steel ladle wire feeding auxiliary device and steel ladle wire feeding method

The invention provides a steel ladle wire feeding auxiliary device and a steel ladle wire feeding method. The steel ladle wire feeding auxiliary device comprises a steel ladle and a wire-feeder arranged on a working platform. A metal wire lead-out tube of the wire-feeder is connected with the steel ladle wire feeding auxiliary device which is arranged in an ascending and descending manner, metal wires are delivered into the steel ladle wire feeding auxiliary device by the metal wire lead-out tube, and then the metal wires are directly injected into the liquid steel in the steel ladle by the steel ladle wire feeding auxiliary device. The working platform is provided with a ventilating and dedusting device with a vacuumizing unit, and the ventilating and dedusting device is connected with the inner portion of the steel ladle wire feeding auxiliary device and is in pipeline communication with the steel ladle wire feeding auxiliary device. By means of the steel ladle wire feeding auxiliary device and the steel ladle wire feeding method, the metal wires are directly fed into the liquid steel, the phenomena that the wires are melt before entering into the liquid steel, and the wires cannot enter the liquid steel due to the fact that steel slag is too thick are avoided, and the wire yield rate is increased; gases and smoke dust are discharged into the ventilating and dedusting device, and the environmental pollution is reduced; and the metallurgical reaction conditions of the liquid steel in the steel ladle are changed by the vacuumizing unit, part of the metallurgical reaction velocity is increased, the oxidation loss of useful elements is prevented, and the alloy yield rate is increased.

Owner:BAOSHAN IRON & STEEL CO LTD +1

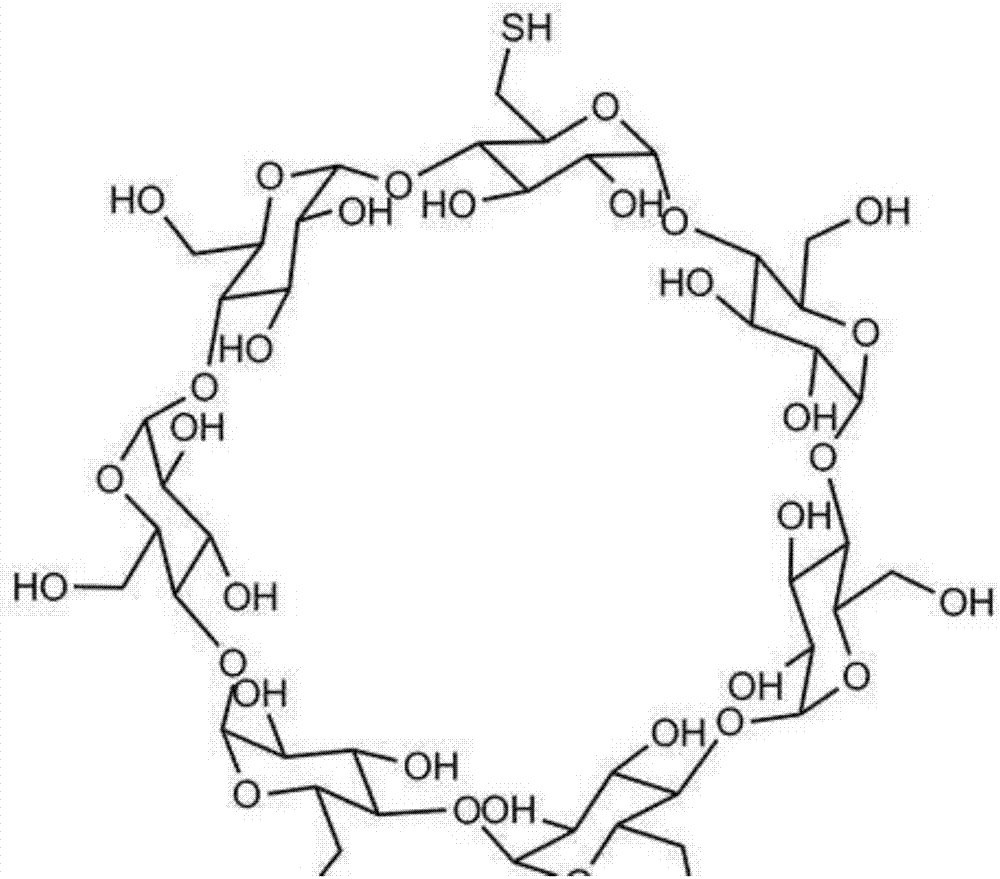

Preparation method of sandalwood essential oil microcapsules

ActiveCN107287033ALow boiling pointNot suitable for storageEssential-oils/perfumesMicroballoon preparationWater bathsLiquid state

The invention provides a preparation method of sandalwood essential oil microcapsules. The method comprises steps as follows: a sandalwood essential oil alcoholic solution and a beta-cyclodextrin solution are prepared, then the sandalwood essential oil alcoholic solution is added to the beta-cyclodextrin solution, water-bath heating at the temperature of 54-57 DEG C and stirring are maintained in the adding process, heating is stopped after dropwise adding, the mixture is continuously stirred for 3-4 h and then left to stand over a night at the temperature of 3-5 DEG C, a mixed solution is obtained, filtered and recovered, precipitates are obtained and dried in a vacuum drying box, and the sandalwood essential oil microcapsules are obtained. The sandalwood essential oil is micro-capsuled with a proper method, the sandalwood essential oil can be kept for a longer time in the transportation and storage processes, oxidation loss caused when the sandalwood essential oil makes contact with light or oxygen is avoided, liquid-state essential oil can be converted into solid-state essential oil, the sandalwood essential oil microcapsules are convenient to carry and use, and the slow-release performance of aroma components of sandalwood is improved.

Owner:BAOJI UNIV OF ARTS & SCI

Brewing technology for longan dry white wine

The invention relates to a brewing technology for longan dry white wine, and belongs to the technical field of wine brewing. The brewing technology comprises the steps that grape ears with the sugar degree being not smaller than 190 g / L and the pH value being 3.0-3.3 are selected as raw materials, stalk removal, crushing, squeezing and clarification are performed to obtain clear grape juice, the clear grape juice is fermented to obtain longan dry white wine, then, lactic acid bacteria are inoculated to perform apple lactic fermentation, apple lactic fermentation is ended when the concentration of malic acid in an apple lactic fermentation solution is not larger than 2 g / L, the concentration of tartaric acid in the apple lactic fermentation solution is 6-7 g / L, and the pH value is 3.0-3.4, then, cooling separation and filtering are performed to obtain the finished longan dry white wine. According to the technology, the method that apple lactic fermentation is ended when a part of the malic acid is reserved is adopted; due to the fact that the small amount of malic acid is reserved, the sour taste of the longan dry white wine is avoided, and the fruit flavor is sufficiently reserved while the structural sense is enhanced.

Owner:HUAILAI ARISTOCRATIC MANOR WINE IND

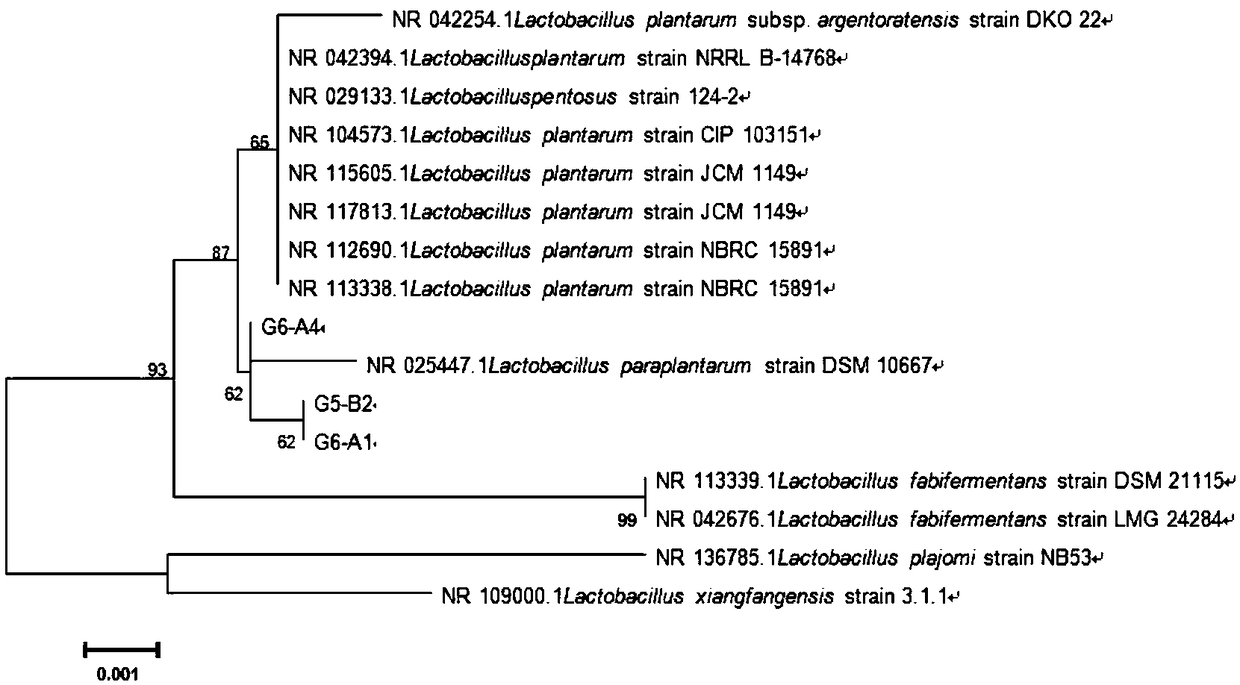

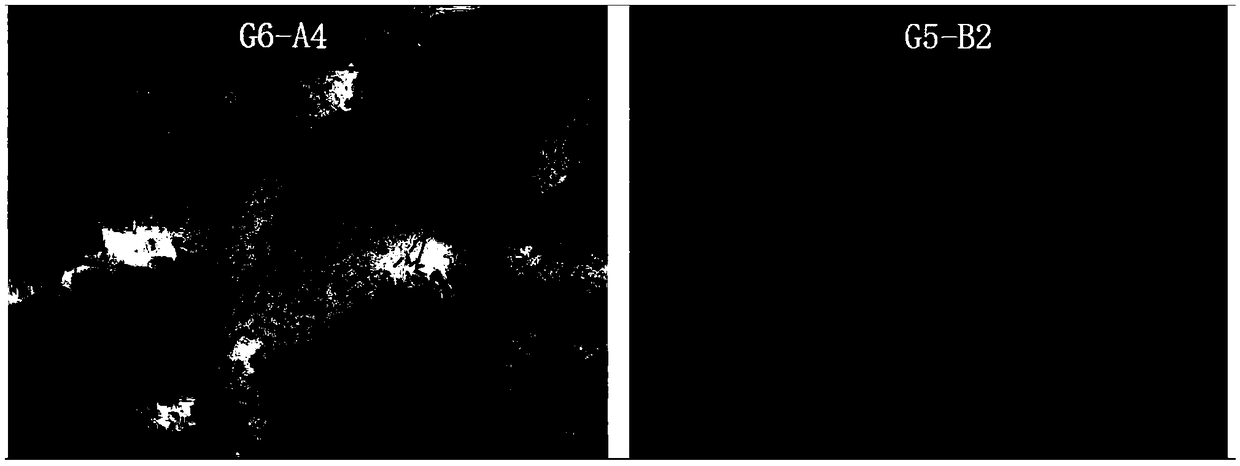

Preparation method of mango lactic acid beverage improving oxidation resistance

The invention discloses a preparation method of a mango lactic acid beverage improving oxidation resistance. The preparation method comprises the following steps of (1) preparing mango primary pulp: thoroughly washing mangos, macerating the washed mangos in a sterilized solution, taking the macerated mangos out, performing peeling, performing kernel removing and performing pulping, removing crudefibers of the mangos with a filtering cloth, and performing synergistic treatment of superhigh pressure and ultrasonic waves, so as to obtain the mango primary pulp; (2) adjusting ingredients: addingsyrup, ox bone powder, phenylalanine and tyrosine; and (3) performing fermentation: adding a fermenting agent, performing fermentation, and performing filtration, so as to obtain finished products, wherein the fermenting agent is lactobacillus plantarum. Through the adoption of the preparation method disclosed by the invention, the obtained mango lactic acid beverage is rich in fragrance and freshin mouth feel, and the clearance rate of DPPH free radicals, the clearance rate of hydroxyl radicals and the clearance rate of superoxide anion free radicals are high; and compared with mango flesh,the mango lactic acid beverage prepared by the preparation method disclosed by the invention is high in the content of flavonoid compounds, the content of polyphenol compounds and the content of mangiferin.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

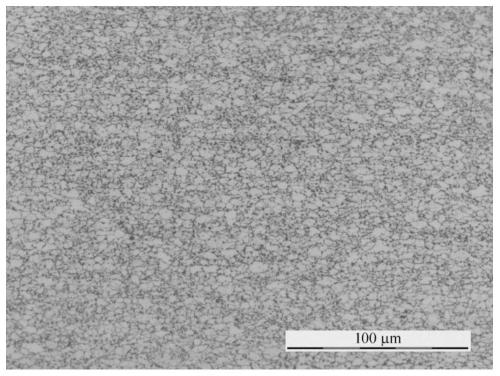

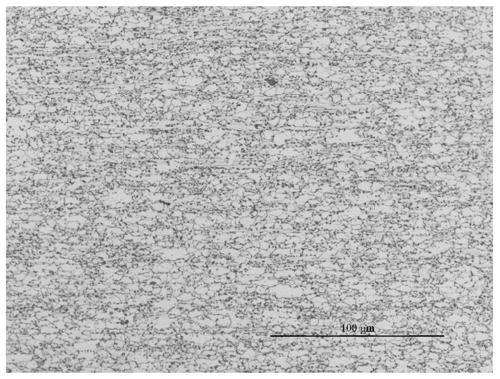

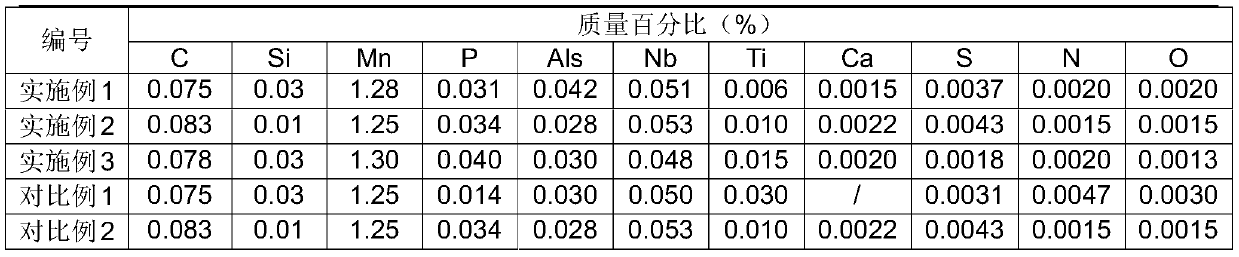

Low-alloy high-strength steel with yield strength of 460 MPa and production method thereof

The invention discloses low-alloy high-strength steel with the yield strength of 460 MPa and a production method thereof, and belongs to the technical field of steel rolling. The invention provides the low-alloy high-strength steel with the yield strength of 460 MPa in order to solve the problems that the existing low-alloy high-strength steel with the medium-high-grade strength is large in strength fluctuation and unstable in performance. The low-alloy high-strength steel comprises the following chemical components of, in percentage by weight, 0.07%-0.09% of C, less than or equal to 0.05% ofSi, 1.20%-1.50% of Mn, 0.03%-0.05% of P, 0.025%-0.060% of Als, 0.045%-0.055% of Nb, 0.005%-0.015% of Ti, 0.001%-0.003% of Ca, less than or equal to 0.006% of S, less than or equal to 0.0025% of N, less than or equal to 0.0025% of O, and the balance Fe and inevitable impurities. According to the low-alloy high-strength steel with the yield strength of 460 MPa and the production method thereof, through low-O, low-N and low-Ti control, the quantity density of the carbonitride with micron size does not exceed 3 / mm <2>; thickness distinguishing of large reduction rate, low-temperature coiling, slowcooling of a hot rolling heat preservation cover and the annealing process is adopted for a starting machine frame and an ending machine frame through finish rolling, and stable control over the product strength is achieved. The strength range between the produced low-alloy high-strength steel coils with the yield strength of 460 MPa is smaller than or equal to 70 MPa, the strength difference ofthe middle portions of the coil inner heads is smaller than or equal to 30 MPa, the yield ratio is smaller than or equal to 0.85%, and the low-alloy high-strength steel has the advantages of being lowin cost, excellent in forming performance and small in strength fluctuation.

Owner:MAANSHAN IRON & STEEL CO LTD

Vacuum glass with photoelectric conversion layer

InactiveCN102544150ASolve the problem of photoelectric conversion functionAvoid oxidation lossPhotovoltaic energy generationSemiconductor devicesSolar lightEngineering

The invention relates to vacuum glass with a photoelectric conversion layer. The vacuum glass comprises an upper glass plate, a supporting column, a vacuum sealing flux, a lower glass plate and a getter and is characterized in that the photoelectric conversion layer is arranged on one side of a vacuum cavity, and electrodes are arranged on two side surfaces of the photoelectric conversion layer and are fixed at connection parts of a conductor and the vacuum sealing flux. The photoelectric conversion layer in the vacuum cavity is used for converting solar lights into electric power so as to finish comprehensive utilization of photoelectric conversion. The vacuum glass with the photoelectric conversion layer, disclosed by the invention, has the advantages of reasonable structure, high optical energy utilization rate, effectively reduced oxidation of the photoelectric conversion layer, prolonged service life and improved photoelectric conversion efficiency, reasonable manufacturing process, low relative cost, energy saving, environment friendliness and easy popularization and application in large batch.

Owner:YANGZHOU UNIV

Preparation method of rapid dispersion type high-activity brewing kudzuvine powder

InactiveCN112617153AOptimize the dispersion effect of brewingHighlight the flavorFood freezingFood shapingBrewingRamie

The invention discloses a preparation method of rapid dispersion type high-activity brewing kudzuvine powder and belongs to the field of food processing. According to the preparation method, crude protein of fresh and tender ramie leaves can be efficiently extracted with a special solvent and is prevented from denaturing by normal-temperature concentration of a filter film, and kudzuvine powder starch can be effectively dispersed by the crude protein extract and is prevented from aggregating and caking, so that an optimized effect of the crude protein extract in brewing, dispersion and dissolving assistance of kudzuvine powder can be achieved, and the problems that kudzuvine powder is easily caked and coagulated in brewing and is difficult to disperse can be solved.

Owner:THE SUIZHOU ER YUE FENG FOOD

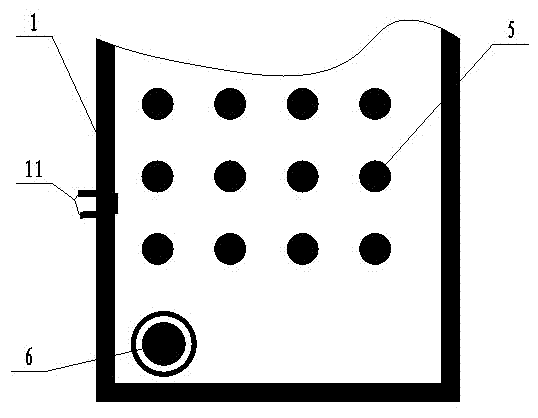

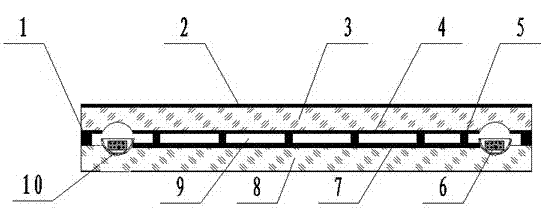

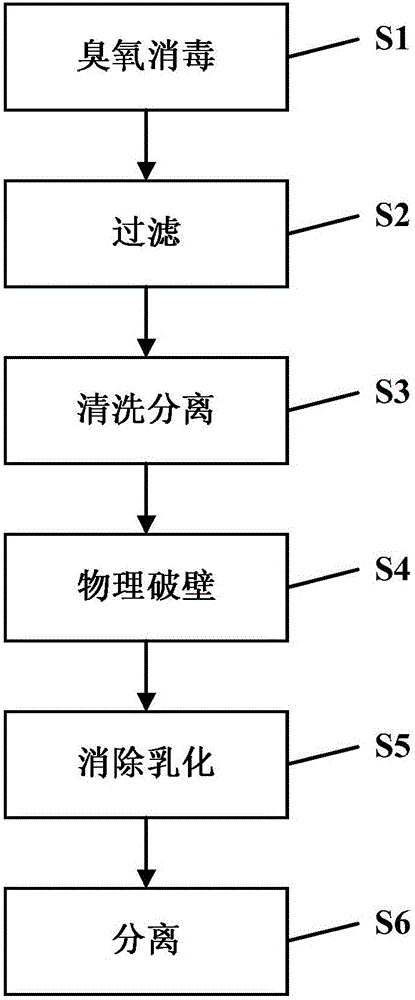

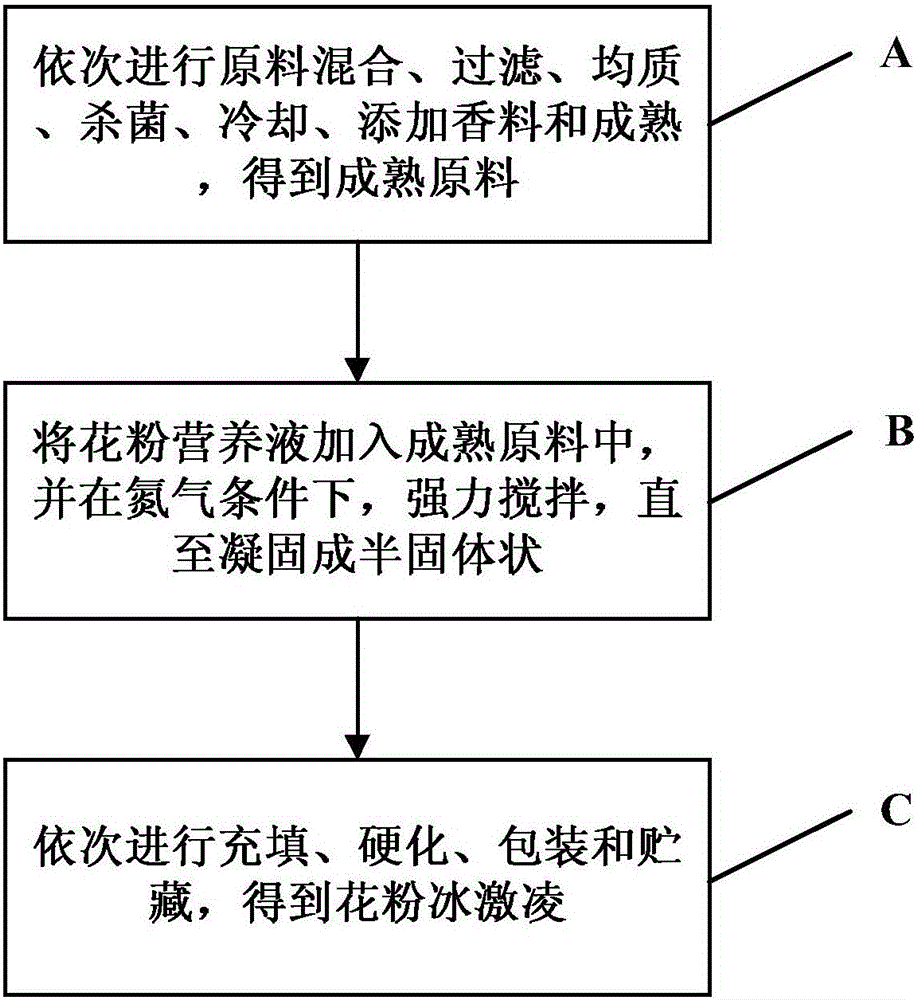

Pollen nutrient solution as well as extraction method thereof, pollen ice cream and preparation method thereof

ActiveCN104957632AGuaranteed therapeutic valuePrevent oxidation lossFrozen sweetsFood preparationNitrogen gasSemi solid

The invention discloses a pollen nutrient solution as well as an extraction method thereof, pollen ice cream and a preparation method thereof, and relates to the technical field of food, natural healthcare products and pharmacy. The extraction method of the pollen nutrient solution comprises the following steps at normal temperature and normal pressure: sterilizing raw materials in sequence by ozone, filtering, washing, separating, physically breaking the walls, eliminating emulsification and separating to obtain the pollen nutrient solution. The preparation method of the pollen ice cream comprises the following steps: at a freezing step of the ice cream, placing the pollen nutrient solution into a mature raw material, sufficiently stirring under the nitrogen condition until the mature raw material is solidified to be in a semi-solid state, and finally sequentially filling, hardening, packaging and storing the semi-solid mature raw material to obtain the pollen ice cream. By adopting the pollen nutrient solution, the taste of the pollen is improved, and the food therapy value of active ingredients can be guaranteed.

Owner:HUBEI SAY CHUN BIOLOGICAL TECH CO LTD

Lutein ester water-soluble particles and preparation method thereof

PendingCN111387499AIncrease contentAvoid oxidation lossFood ingredient as antioxidantFood ingredient as solubility improving agentFood additiveHot melt

The invention discloses lutein ester water-soluble granules and a preparation method thereof, and belongs to the field of food additives. The granules comprise the following raw materials in parts byweight: 1 part of lutein ester, 2-10 parts of an emulsifier, 0.01-1 part of an antioxidant and 1-20 parts of a carrier. The preparation method comprises the following steps: 1) respectively crushing,sieving or filtering the lutein ester, the emulsifier, the antioxidant and the carrier; 2) mixing the lutein ester, the emulsifier, the antioxidant and the carrier in parts by weight, and heating theraw materials to 55-80 DEG C to obtain a mixture; and 3) adding the mixture into a hot melt extruder, performing extruding at 100-150 DEG C for 2-5 minutes, performing cooling, crushing particles, andperforming screening to obtain the lutein ester water-soluble granules. According to the lutein ester water-soluble granules and the preparation method thereof, the obtained lutein ester water-soluble granules are good in water solubility, high in lutein ester content and high in transparency after being dissolved.

Owner:山东天音生物科技有限公司

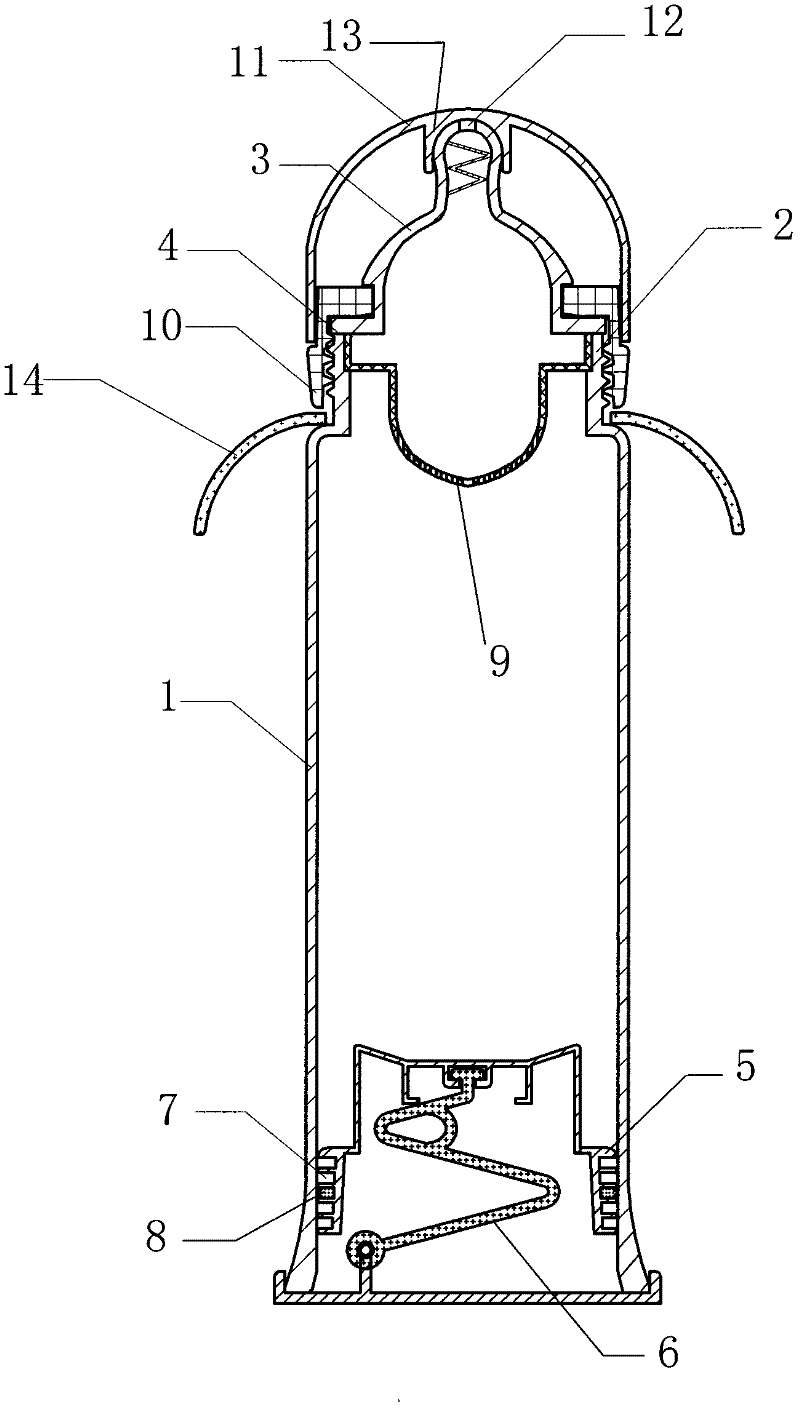

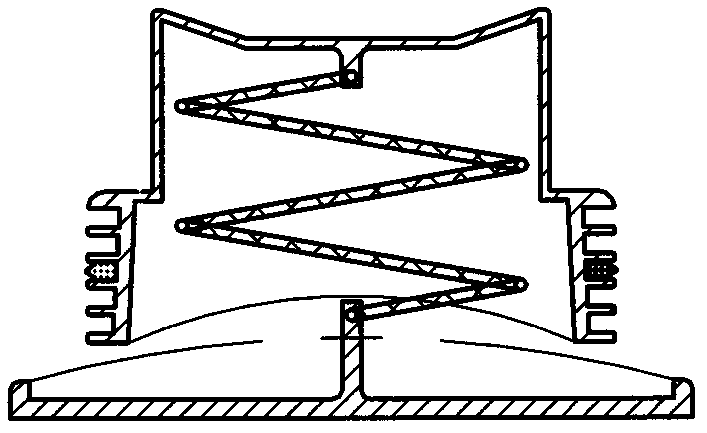

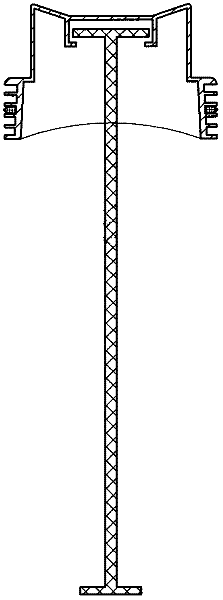

Piston-type swell prevention container

InactiveCN102381519ALong shelf lifeEasy dischargePackaging under vacuum/special atmosphereContainers preventing decayEngineeringBottle neck

The invention relates to a piston-type swell prevention container, which comprises a bottle body, a bottle neck and a suction nozzle. The bottle neck is located above the bottle body; the upper end of the bottle neck is provided with an upper bottle mouth; the suction nozzle is installed on the upper bottle mouth; the bottle body is hollow; the lower end of the bottle body is provided with a lower bottle mouth; a framework is hermetically installed on the inner wall of the bottle body close to the lower bottle mouth and is movably installed on the inner wall of the bottle body; the upper end of the framework is provided with the bottom surface of a container inner cavity; and an action mechanism used for driving the framework to move up and down is installed on the bottom surface of the framework. The provided piston-type swell prevention container can improve the preserving effect, is convenient to wash and has good swell prevention effect.

Owner:郑建松

Tree nutrient solution

The invention relates to a plant nutrient solution, in particular to a tree nutrient solution. The nutrient solution is formed by mixing a plant macroelement, a plant microelement, a physiologically active substance, an external source hormone and water. After the tree nutrient solution is applied to a tree, a survival rate of the large tree after transplantation can be increased as soon as possible, and the tree nutrient solution particularly has an important and positive effect on improving a metabolic function of the old tree and recovering the tree vigor.

Owner:四川韵然景观园林工程有限公司

Fructus rosae roxburghii, blueberry and black tea wine and preparation method thereof

InactiveCN106398951ATake advantage ofFully integratedAlcoholic beverage preparationPrunus salicinaNutritive values

The invention relates to the technical field of wine brewing, and in particular relates to fructus rosae roxburghii, blueberry and black tea wine and a preparation method of the fructus rosae roxburghii, blueberry and black tea wine. According to the fructus rosae roxburghii, blueberry and black tea wine and the preparation method, blueberries, fructus rosae roxburghii, black tea, prunus salicina fruits (with pulp and stones separated after ripening), pears, rice wine and active saccharomyces bayanus are reasonably mixed, so that the nutritional ingredients in the raw materials are sufficiently utilized, further, the quality of the fructus rosae roxburghii, blueberry and black tea wine is improved, and the nutritive value of the fructus rosae roxburghii, blueberry and black tea wine is enriched; meanwhile, in the preparation technology, due to the limitation of the processing steps including juicing, dreg primary steaming, braising, re-steaming and mixed fermentation, the active ingredients of blueberries, fructus rosae roxburghii, black tea, prunus salicina fruits and pears are sufficiently mixed, so that the mouthfeel and flavor of the wine are enriched, in addition, under the promoting effect of the added rice wine, the efficacies of the active ingredients in the raw materials are obviously exerted, and moreover, the fermentation treatment is carried out in the sealed environment, so that the oxidation loss of the nutritional ingredients is avoided, and the oxidation browning is avoided.

Owner:贵州恒达生物科技有限公司

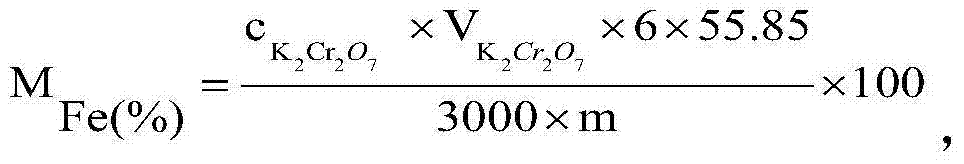

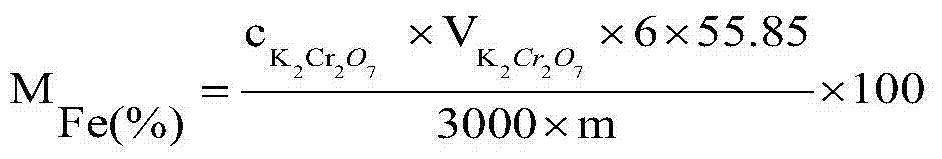

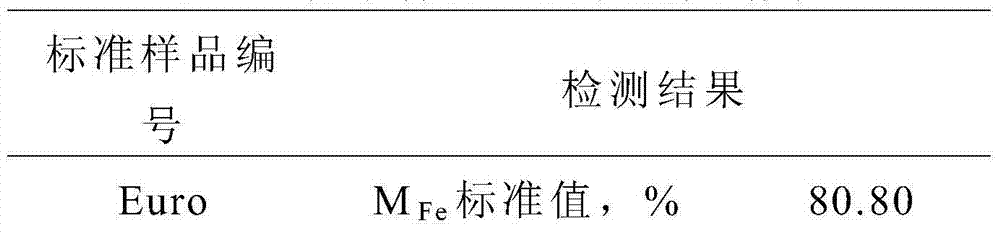

Method for measuring iron content in direct reduction iron of steelmaking auxiliary material

ActiveCN103616473AAvoid oxidation lossImprove accuracy and precisionChemical analysis using titrationMagnetic stirrerTest sample

The invention discloses a method for measuring the iron content in direct reduction iron of a steelmaking auxiliary material. The method comprises the following steps: 1, decomposing a test sample, namely, weighing a reduced iron test sample, adding an FeCl3 solution, placing on a magnetic stirrer, and stirring for 20-30min; 2, filtering the test sample, namely, filtering and sealing the stirred test sample; and 3, titrating the test sample, namely, adding sulfuric-phosphoric mixed acid in the test sample, sealing a suction filtration bottle opening by using a rubber plug, placing on the magnetic stirrer, stirring for 20-30min, opening the rubber plug of the suction filtration bottle opening, adding 50-60 drops of a 0.2% sodium diphenylaminesulfonate indicator in each 1 g of reduced iron test sample, titrating by using a sodium diphenylaminesulfonate standard solution until the solution is of a stable bluish violet, recording a volume of the consumed potassium dichromate standard solution, and calculating the content of metal iron according to a formula. The method prevents the metal iron from being oxidized, and is good in repeatability and accurate in measurement; the measurement accuracy of test sample testing is within 1.0 percent.

Owner:武汉钢铁有限公司

Pure Tieguanyin tea beverage and preparation method thereof

InactiveCN103704416BPrevent spoilageImprove leaching ratePre-extraction tea treatmentFlavorUltrafiltration

The invention discloses a pure Tieguanyin tea beverage and a preparation method thereof, belonging to the field of tea beverage processing. The preparation method comprises the following steps: at first, carrying out low-temperature rapid freezing treatment on high-quality Tieguanyin tea used as a raw material; then immediately crushing; combining a high-voltage pulsed electric field technology, an ultrasonic treatment technology and a low-temperature enzymolysis technology; carrying out an ultrafiltration technology and the like to extract tea soup at a low temperature in a whole process; and finally, blending, finely filtering, sterilizing and filling to obtain the pure tea beverage which has natural quality and flavor, pure and rich tea flavor and obvious health-care effects. The tea beverage is scientific and reasonable in formula and simple in processing process; extraneous food raw materials, essences, pigments and chemical substances are not added; only a sour agent and a sweetening agent which are the most regular in a beverage industry are used; in the whole process, a low-temperature processing technology is adopted, so that the quality and the flavor of natural Tieguanyin tea are kept to the greatest extent; the Tieguanyin pure tea beverage is the true Tieguanyin pure tea beverage.

Owner:LVJIN DEV FUJIAN

Antifreeze polypeptide-sorbitol composite antifreeze agent and application

InactiveCN104855490AIncrease added valueAvoid oxidation lossMeat/fish preservation using chemicalsPolydextroseGel strength

The present invention discloses an antifreeze polypeptide-sorbitol composite antifreeze agent and application, belonging to the food processing field. The antifreeze agent comprises the following components in parts by weight: 0.5-6 parts of antifreeze polypeptide, 0.2-4 parts of sorbitol,1-3.5 parts of glycerin, 2.5-4.5 parts of polydextrose and 0.1-0.5 parts of sodium citrate. According to the present invention, an antifreeze polypeptide acts as a main protective agent, and is combined with small molecules to obtain a composite low temperature protection formula. The product stability of surimi products can be favorably maintained during low-temperature storage of the surimi products, and the gel strength and water retention capability of the surimi products are improved, providing protection during low-temperature refrigeration and transportation of the surimi products. The antifreeze polypeptide manufacturing process is mature and simple, low in production cost, and suitable for industrial production. In addition, the antifreeze polypeptide is high in low-temperature protective activity, is not sweet, and can maintain the flavor of surimi products.

Owner:FUZHOU UNIVERSITY

Coastal wave energy strength detection front-end working device

PendingCN107515099AAvoid collisionExtended service lifeHydrodynamic testingEngineeringPressure sensor

The invention discloses a coastal wave energy strength detection front-end working device, and relates to the technical field of wave energy equipment. The coastal wave energy strength detection front-end working device comprises a shell. The shell is provided with an operating box internally. First grooves are formed in four corners of one side of the shell. A wheel is connected to one side, close to the operating box, of each first groove through a first support rotationally. A cross bar is connected with one side, away from the corresponding first support, of each wheel in a rolling mode. A stop plate is connected to one end of each cross bar fixedly. A wave bearing plate is fixedly connected with one ends, away from the stop plates, of the cross bars through a vertical plate. The upper end and the lower end of one side, close to the vertical plate, of a pressure sensor are fixedly connected with the vertical plate through a spring. The coastal wave energy strength detection front-end working device has the advantages that the device is prevented from directly contacting with sea water to cause oxidation loss, direct wave impact on a detection component is avoided, service life of the device is prolonged, and loss caused by internal damping of the device is avoided.

Owner:何珠贞

Freeze wall breaking soybean milk making method of household soymilk machine and household soymilk machine

InactiveCN105249853AReduce crushing efficiencyReduced flexibilityKitchen equipmentMilk substitutesMotor driveIntercellular space

The invention relates to a freeze wall breaking soybean milk making method of a household soymilk machine. The method includes the following stages: (1) a preprocessing stage: soaking dry soybeans and allowing the dry soybeans to fully absorb water to be saturated, and freezing the soybeans into ice soybeans; (b) an unfreezing stage: putting the ice soybeans into a cup and unfreezing and softening the ice soybeans; (c) a crushing stage: a motor drives a crushing cutter to rotate to crush the soybeans into soymilk liquid. The soybeans absorb water to expand, so that cell interiors and intercellular spaces of the soybeans are filled with water. According to the temperature transfer law, ice crystals are formed from outside to inside during a freezing process, and free water in outer layers of cell walls firstly forms into the ice crystals; at this time, the internal parts of the cell walls are liquid, the cell walls are made to deform for the first time by squeezing of the internal and external pressure, and then the ice crystals are formed in the internal parts of the cells, and the volume is expanded to squeeze the cell walls to cause a second deformation of the cell walls, so that the cell walls of the soybeans are broken.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com