Process for extracting tea polyphenol, theanine, tea polysaccharide and tea pigment from tea

A technology of theanine and tea polyphenols is applied in the field of extracting tea polyphenols, theanine, tea polysaccharides and tea pigments from tea leaves, which can solve the problem that tea resources are not fully utilized, the yield is low, and the purity of tea polyphenols is high. problem, to achieve the effect of significant biological activity, high product purity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

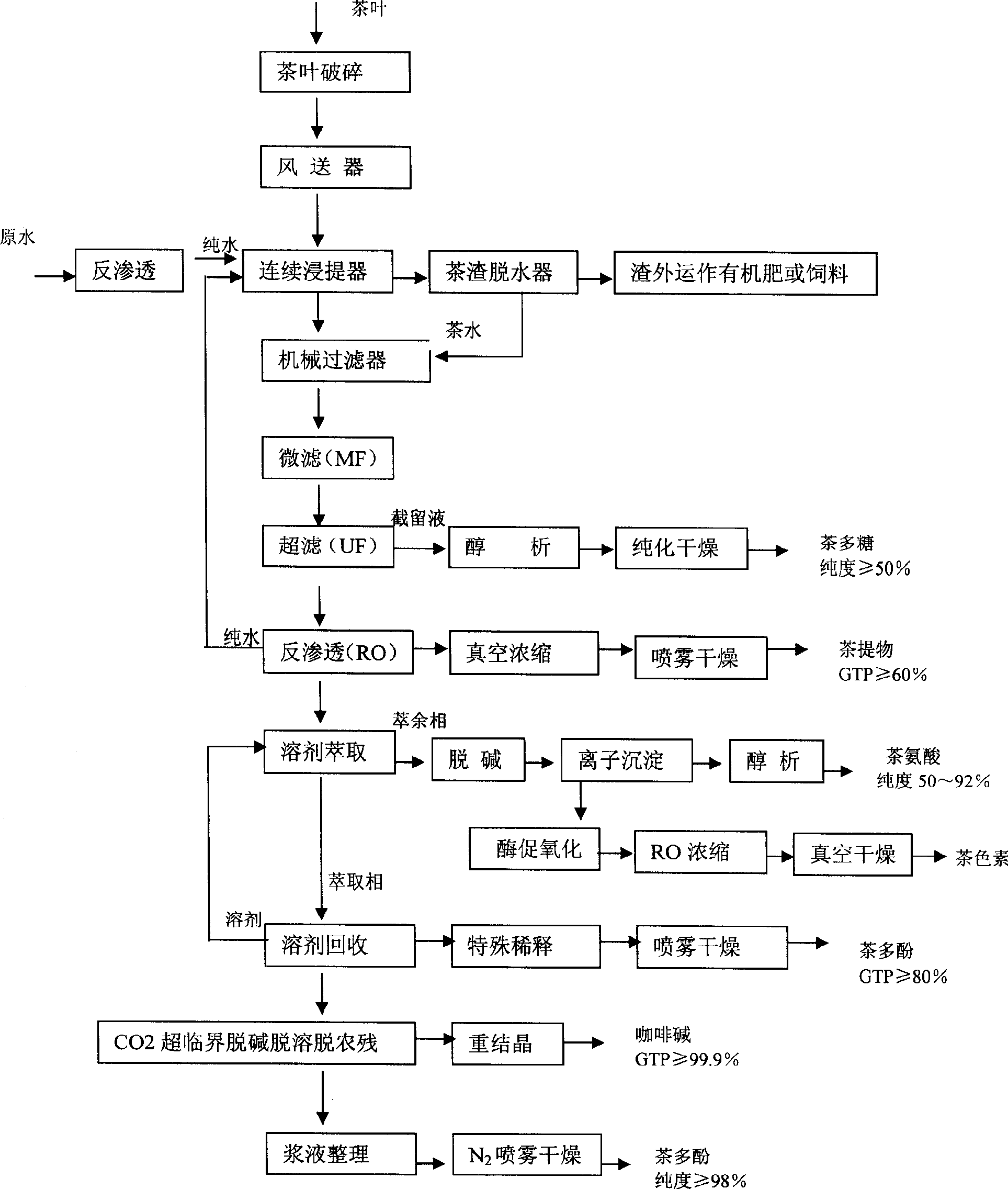

Image

Examples

Embodiment Construction

[0024] According to the process step example of the process flow chart of the extraction method of the present invention, describe in detail.

[0025] 1. Weigh 2000 grams of green tea, crush it to 20 meshes, extract with 40 liters of 85°C deionized water at constant temperature and dynamic 6-stage countercurrent leaching, and use 5% citric acid aqueous solution to adjust the pH value to 6.5-6.8. The leaching time is 90 minutes. Solid-liquid separation to obtain the extract, quick cooling to a temperature below 35°C, and filtering through a 120-200-mesh industrial filter and a microfilter with a pore size of 0.1-5um to obtain 35.6 liters of refined extract. The separated tea dregs can be used as feed or organic food after drying. Fat;

[0026] 2, the described refined extract is intercepted pectin, protein and lipopolysaccharide with the ultrafiltration membrane of cutting molecular weight 5~100,000, and the extracting solution that ultrafiltration sees through is concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com