Patents

Literature

86results about How to "Reduce investment in fixed assets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

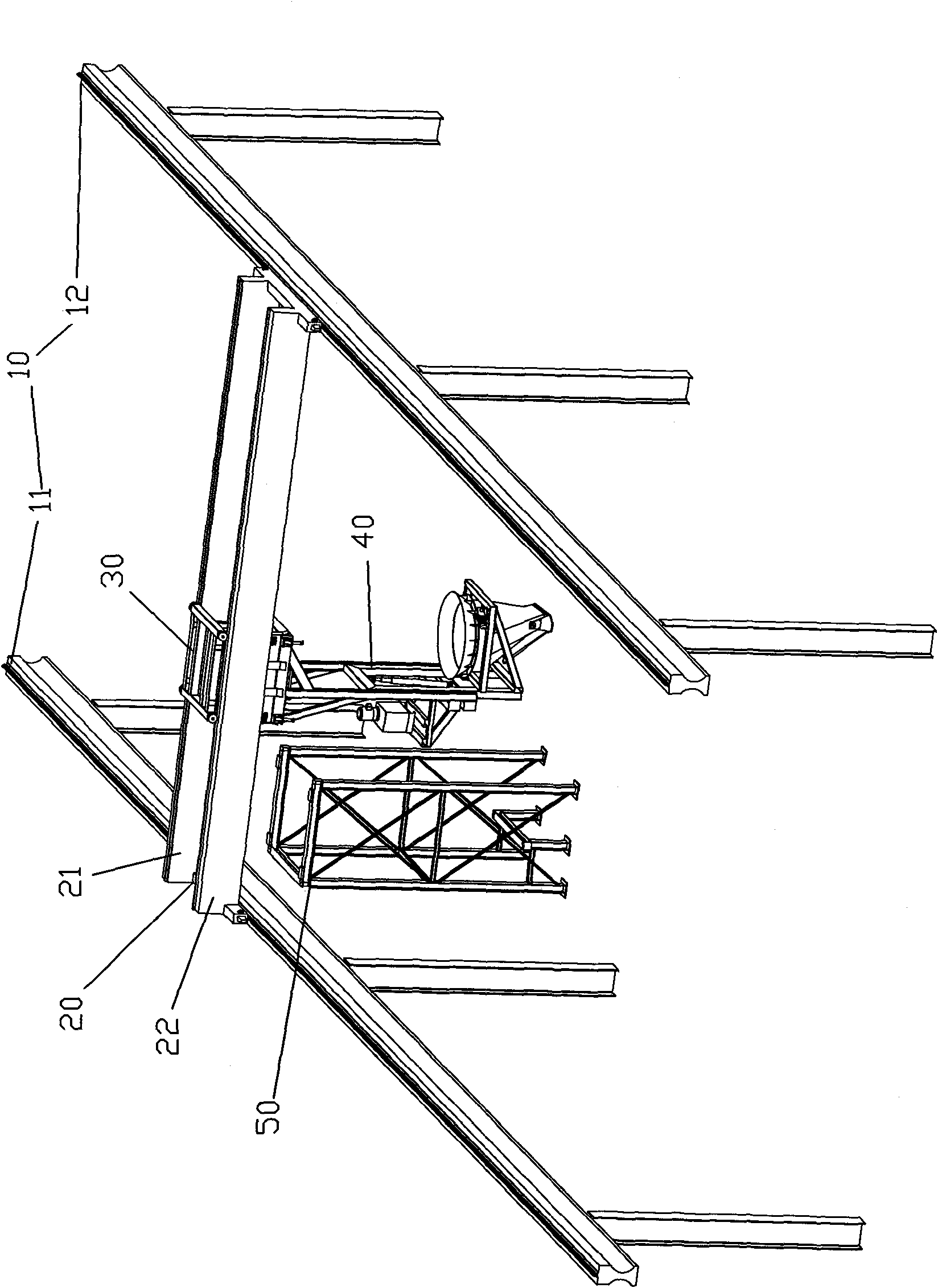

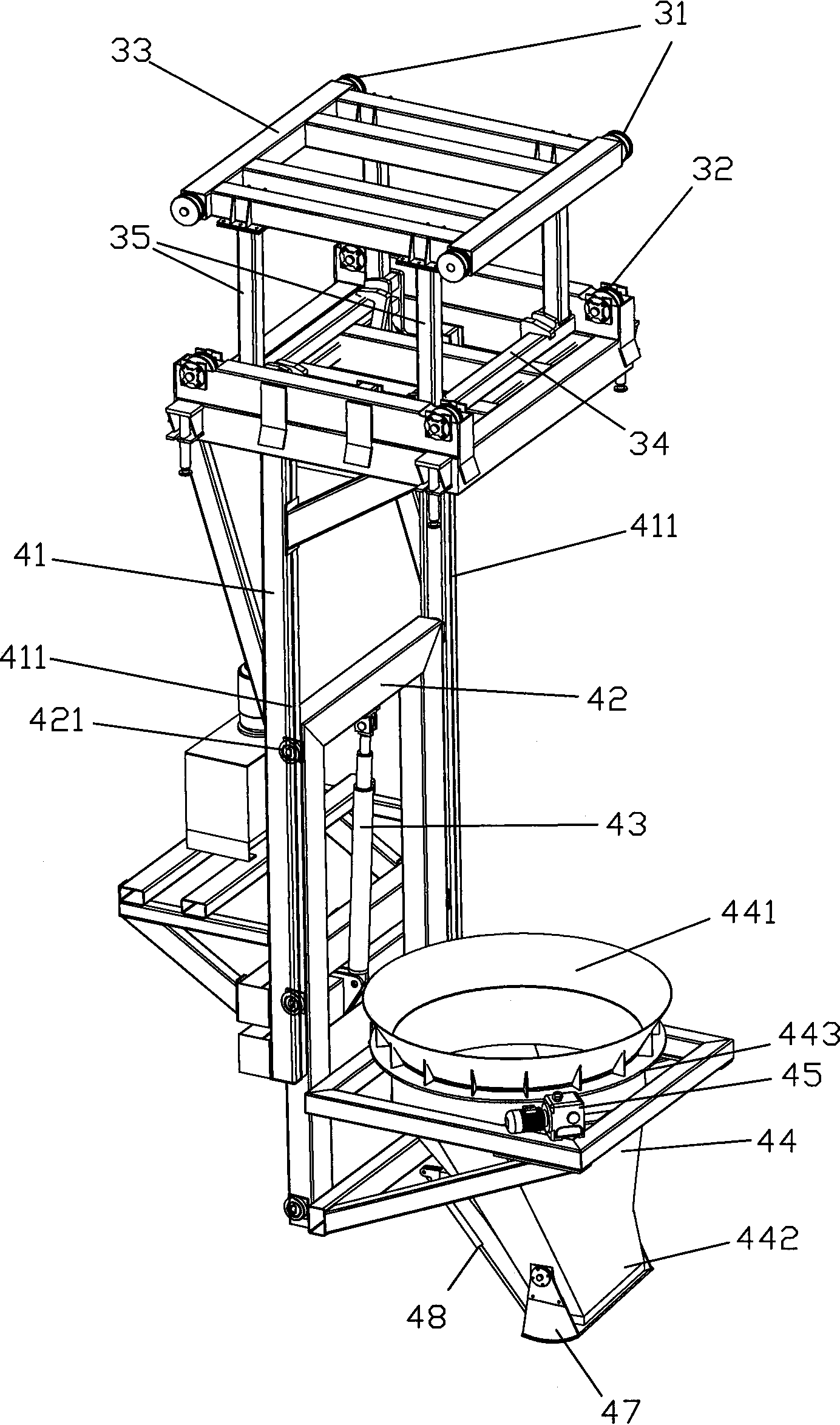

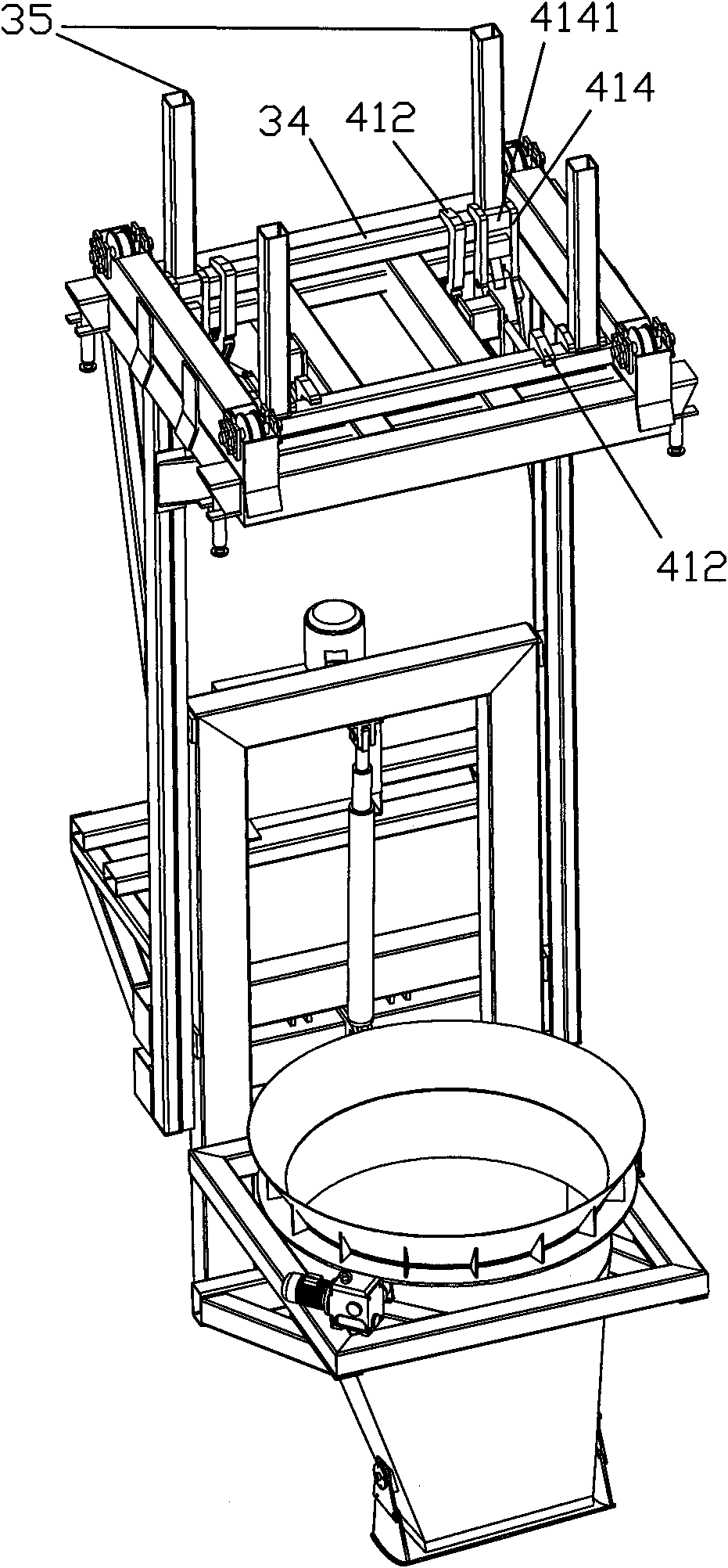

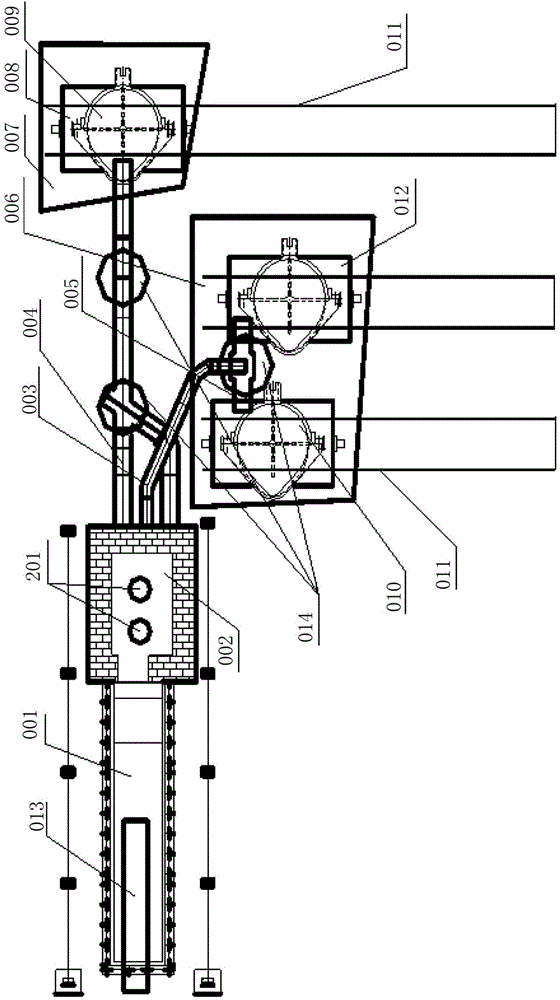

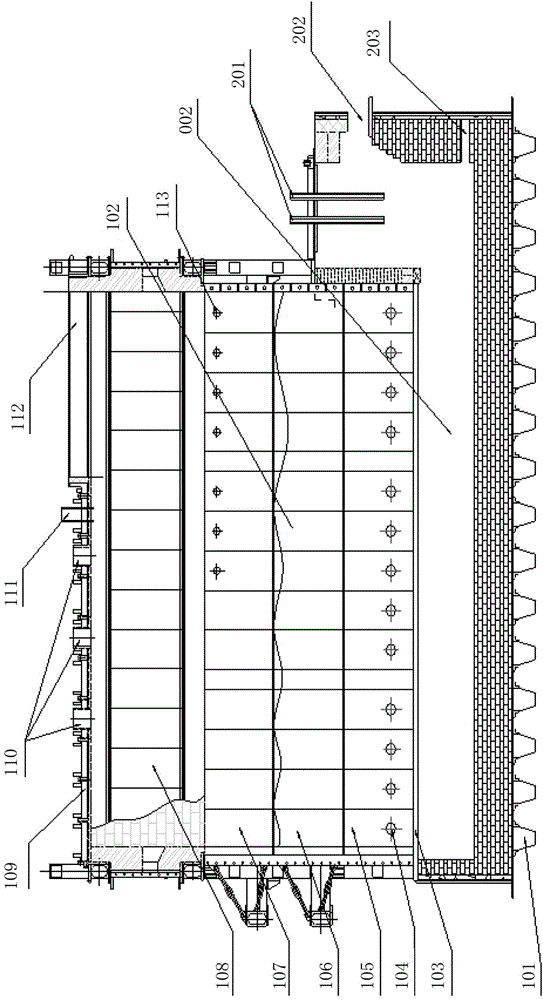

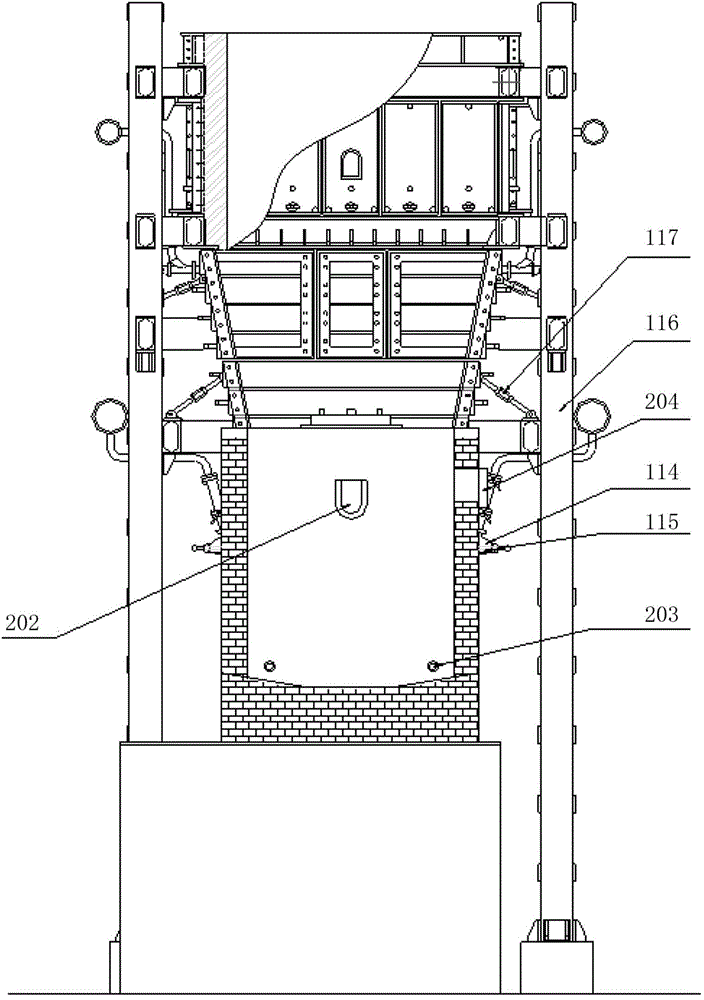

Concrete spreader and spreading method thereof

ActiveCN102140846ABig spaceRealize all-round clothBuilding material handlingReciprocating motionEngineering

The invention relates to special engineering mechanical equipment spreading previously stirred concrete on a designated working face, in particular to a concrete spreader and a spreading method thereof. The concrete spreader comprises a main track unit, a large travelling crane, a small travelling crane, a spreading main machine and a hopper, wherein the large travelling crane longitudinally reciprocates on the main track unit by dint of the driving of a drive device; the small travelling crane horizontally reciprocates on the large travelling crane by dint of the driving of the drive device;the spreading main machine comprises a main stand, a stock bin lifting platform and a lifting oil cylinder, wherein the main stand is connected with the small travelling crane and the stock bin lifting platform can be lifted along the main stand; the hopper is arranged on the lower part of the stock bin lifting platform, a discharge outlet and a feed inlet of the hopper are eccentric at least 300mm, and the hopper reciprocates at an angle of 180 degrees by dint of the driving of a speed reduction motor. The invention realizes the omnibearing spread by dint of the longitudinal motion of the large travelling crane on the main track unit, the horizontal motion of the small travelling crane on the large travelling crane, the up-and-down motion of the stock bin lifting platform on the main stand and the self-rotation motion of the hopper and has larger spreading space without a spreading dead angle.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Process for biologically pulping

InactiveCN1616758AReduce pollution loadQuality improvementNon-woody plant/crop pulpCellulose material pulpingFiberPre treatment

The biologically pulping process includes the following steps: pre-treating cotton fiber material with polyxylose enzyme to obtain pulp material; and normal pressure and low temperature steaming and rinsing of the pre-treated pulp material with alkali and H2O2. The said pulping process has low cost of eliminating impurity from the material, lowered bleaching chemical liquid consumption and raised paper pulp quality.

Owner:CHINA BANKNOTE PRINTING & MINTING

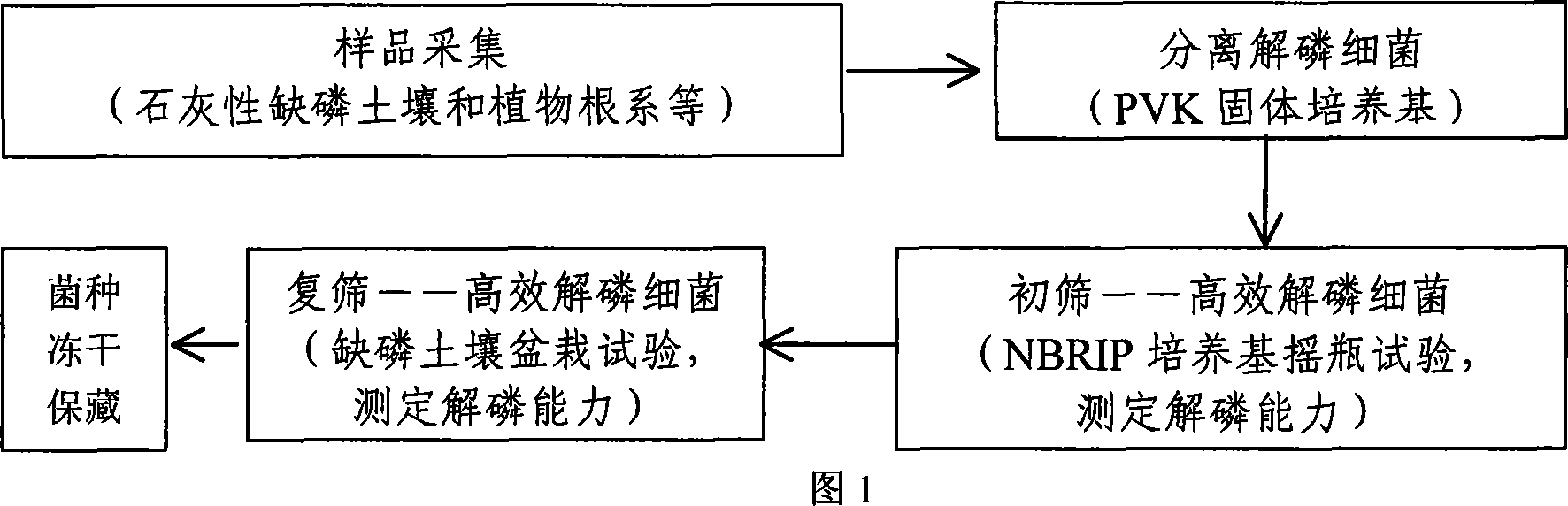

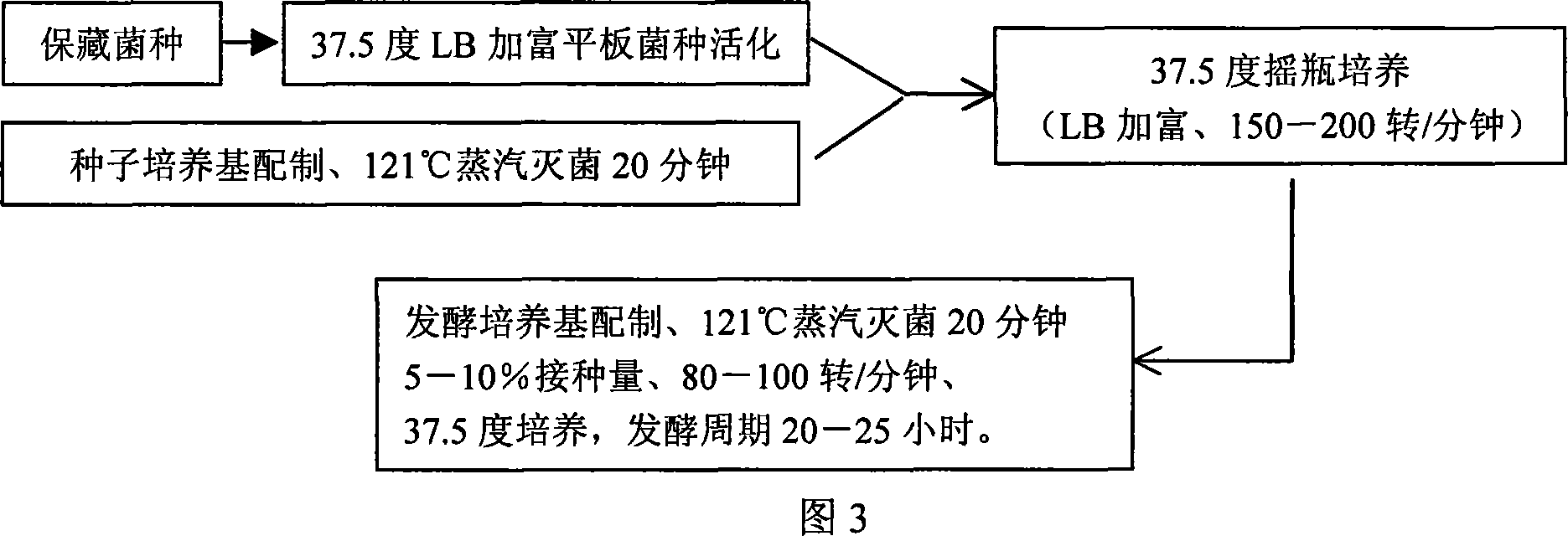

K3 bacterial strain capable of dissolving calcium phosphate in soil and organic microbial fertilizer therewith

ActiveCN101066897APhosphate dissolving effect is remarkableImprove the growing environmentMicroorganism based processesOrganic fertilisersTotal nitrogenBacterial strain

The present invention relates to agricultural production technology, and is especially one kind of K3 bacterial strain capable of dissolving calcium phosphate in soil and microbial fertilizer produced with the K3 bacterial strain. The bacterium strain with powerful calcium phosphate dissolving capacity is separated from limy soil, used in liquid fermentation, and mixed with specific organic carrier to produce phosphate decomposing microbial organic fertilizer, which contains phosphate decomposing microbes in 5x10<7> / g, total nitrogen in 4 wt%, total potassium in 1-2 wt%, total phosphorus in 1-2 wt% and organic matter in 35 wt%. Test shows that the phosphate decomposing microbial organic fertilizer can provide phosphorous nutrients in the effect similar to chemical phosphate fertilizer, and the phosphate decomposing bacterium can reach soluble phosphorus concentration in calcium phosphate solution up to 643 mg / l.

Owner:PENYAO ENVIRONMENTAL PROTECTION

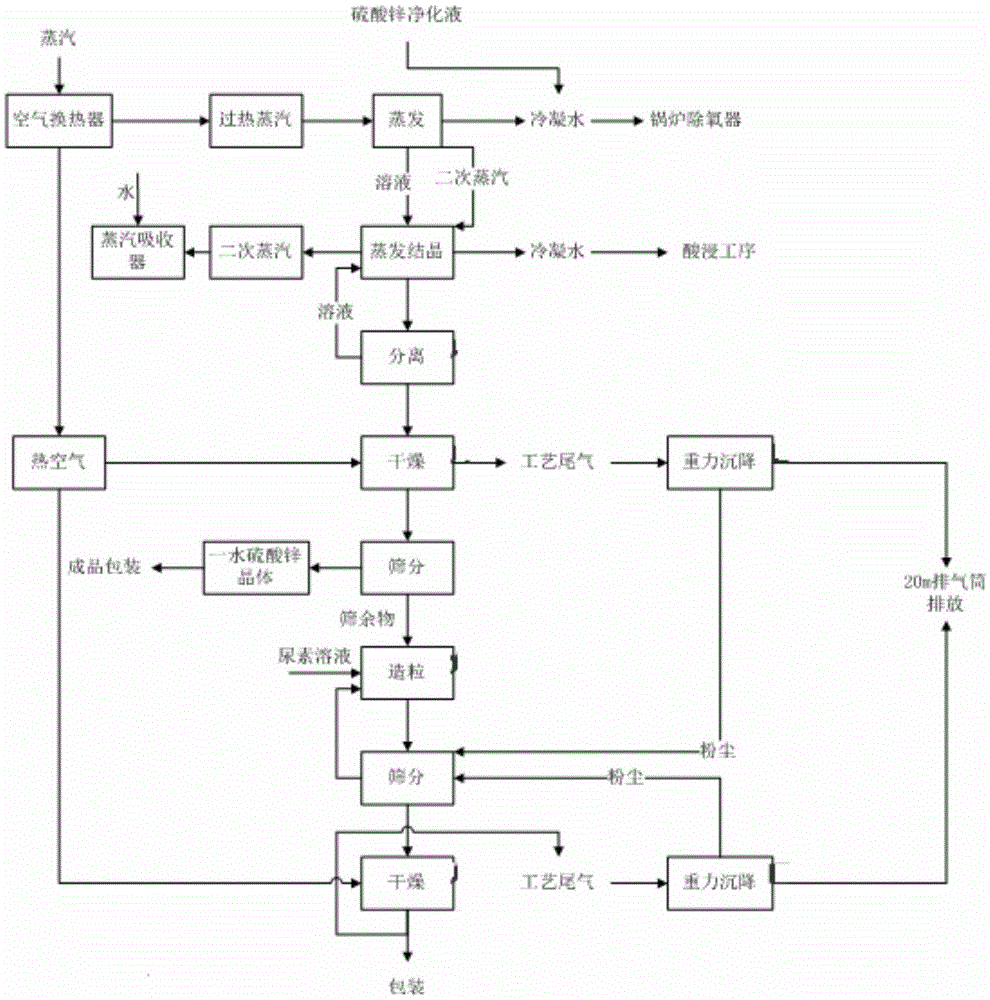

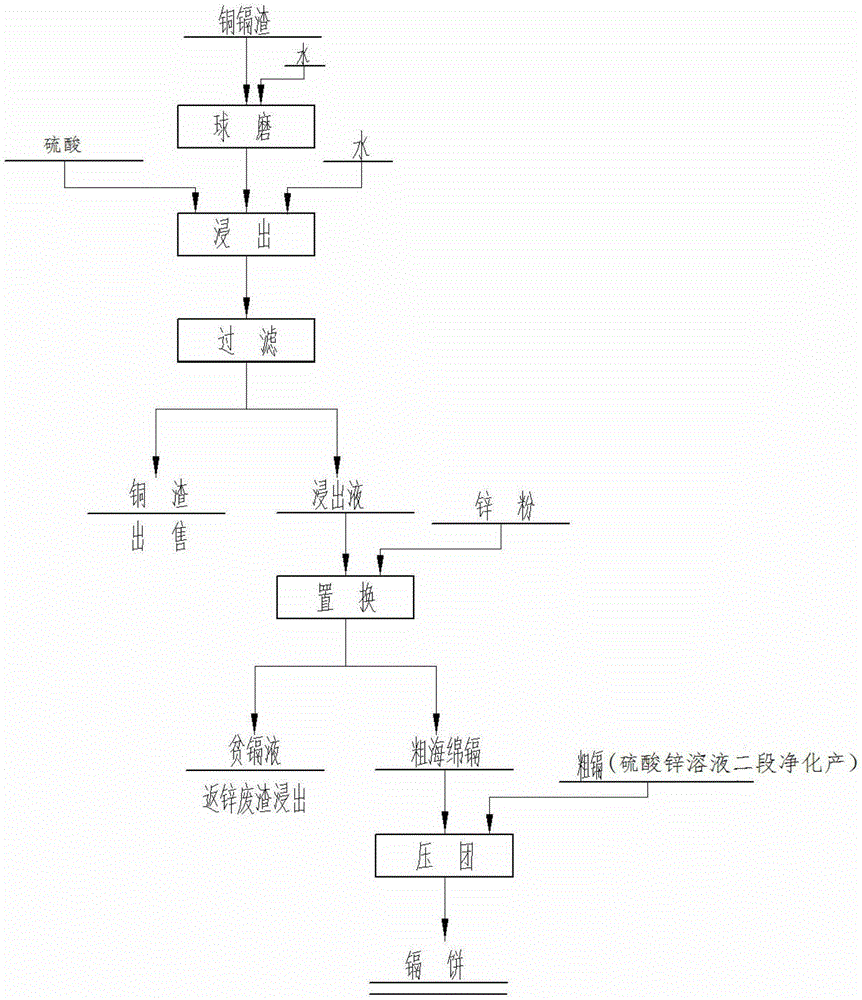

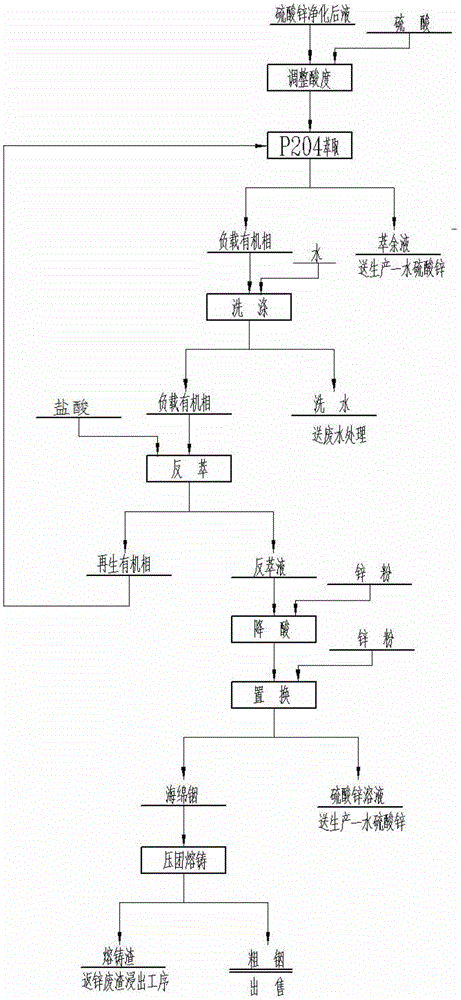

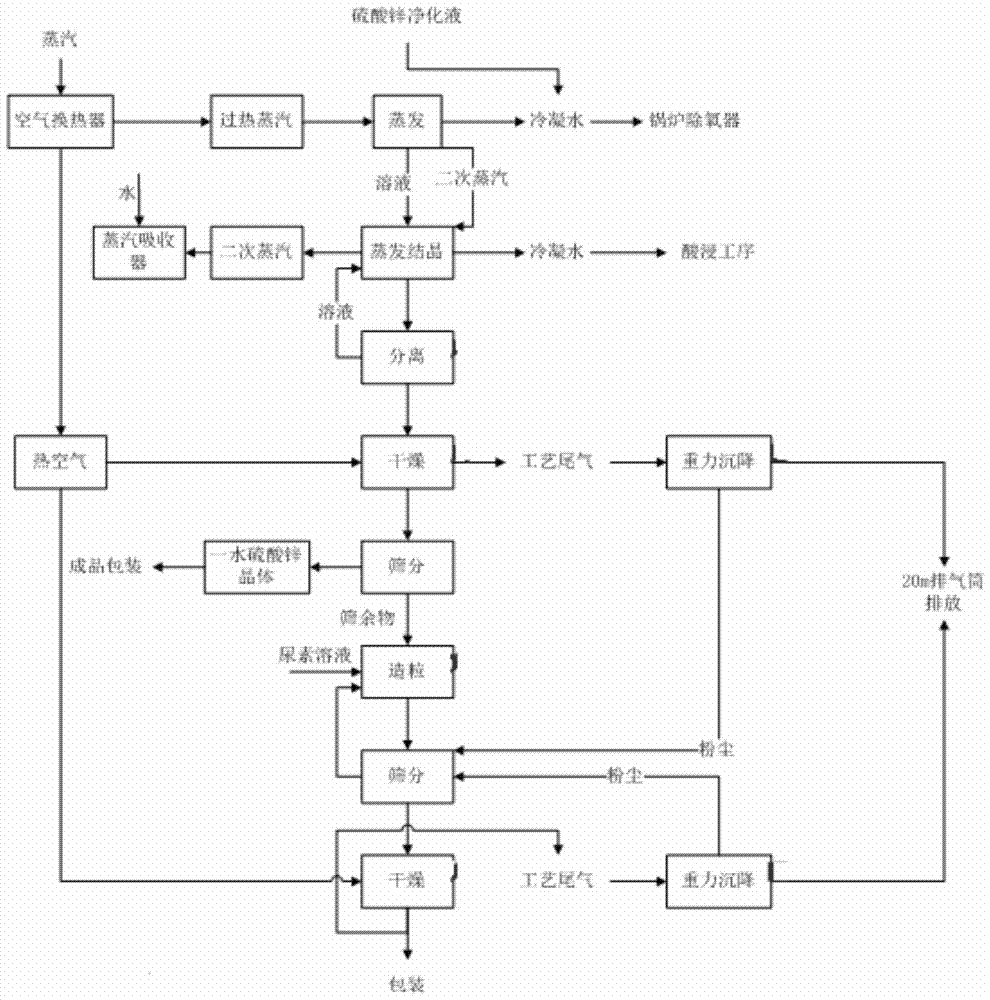

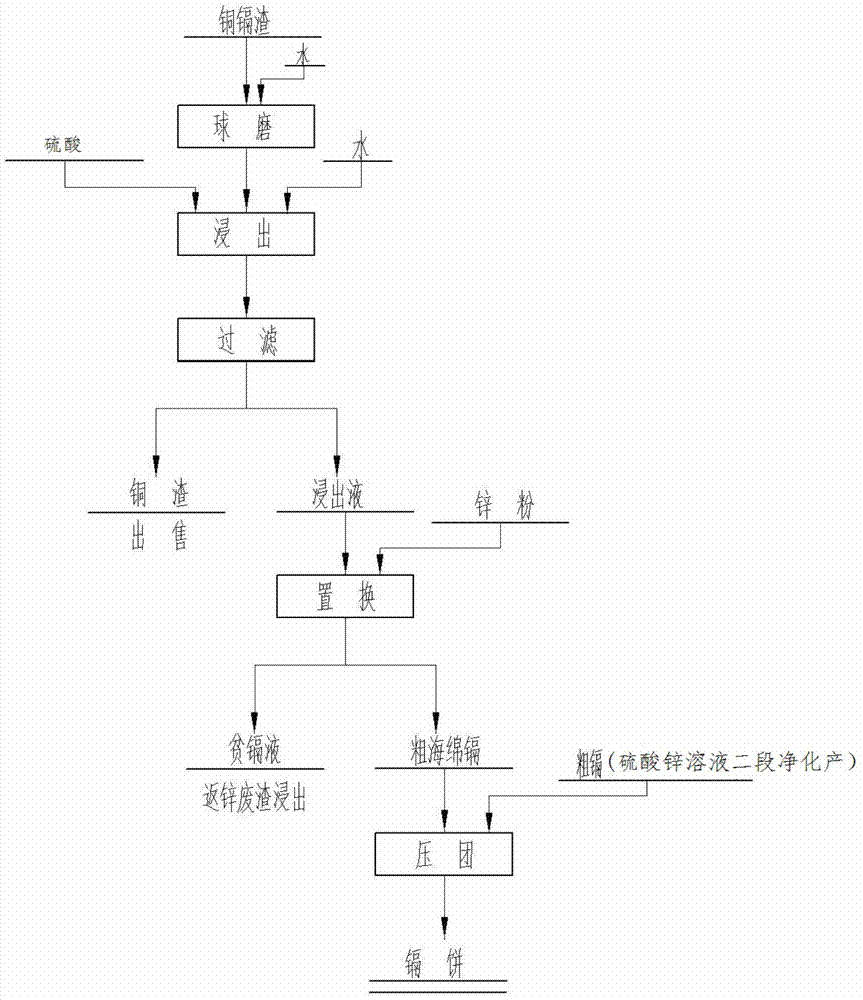

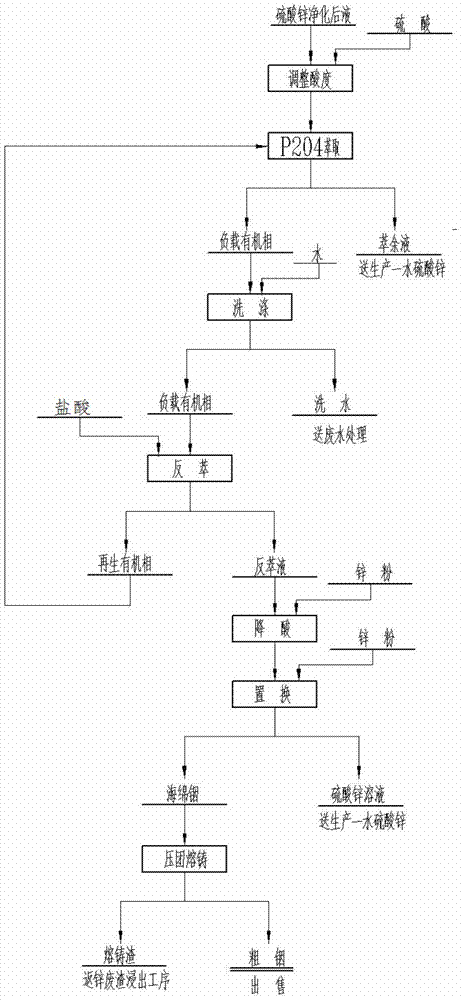

Process for producing zinc sulphate monohydrate from waste acid and waste zinc dross

ActiveCN105274342AAchieve recyclingStructural changeProcess efficiency improvementIndiumCadmium Cation

A process for producing zinc sulphate monohydrate (feed grade) from waste acid and waste zinc dross includes the steps of (a) sulfuric acid leaching, (b) deironing, (c) purification for copper and cadmium removal, (d) dechloridation, (e) defluorination, (f) indium and cadmium extraction and (g) evaporative crystallization. The feed-grade zinc sulphate monohydrate is produced from the waste acid, waste zinc dross and the like, comprehensive utilization of waste is achieved, and the production cost of raw materials is reduced, so that resources are saved. Therefore the waste of massive zinc enterprises in China is recycled to produce economic benefits, the waste is changed into the valuable, a disadvantage is turned into an advantage, secondary utilization of the waste is achieved, comprehensive recycling of waste acid and waste dross resources is achieved, solid and liquid are separated, and the concentration crystallization and drying technology, the energy saving technology and the like are improved. The work of energy conservation, water conservation, comprehensive utilization, environment protection and the like is completed, the social benefits are remarkable, and remarkable environmental protection benefits and economic benefits are achieved.

Owner:湖南鑫海环保科技有限公司

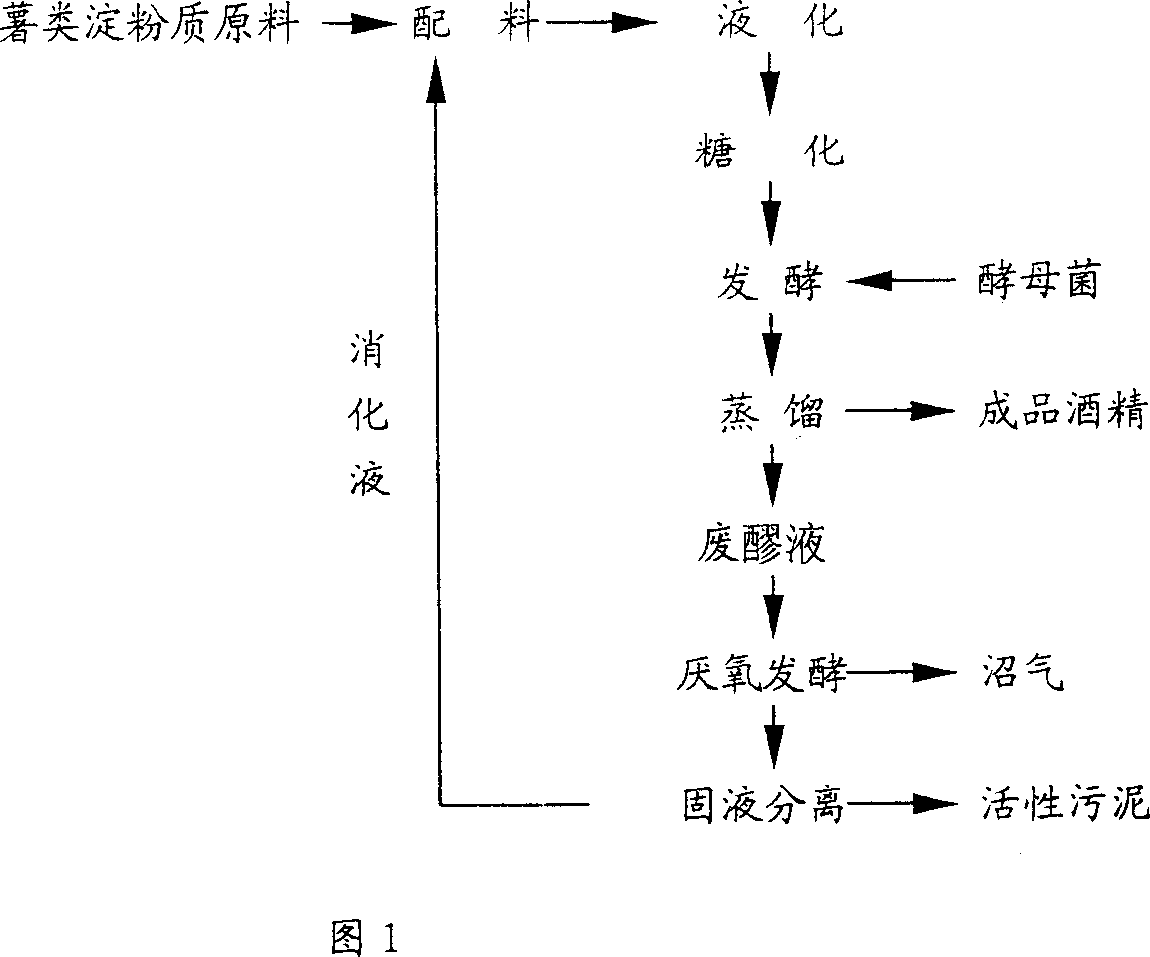

Circulation production process for alcohol with potatoes as main materials

ActiveCN1966695ASmall footprintReduce investment in fixed assetsBiofuelsMicroorganism based processesBiogasChemistry

The invention relates a annuliform production technique for producing alcohol with potato materials by utilizing anaerobic digesting solution as the technology ingredient water. The invention comprises the steps of: crushing potato starchiness materials, adding digesting solution, alpha- amylase, stirring uniformly, heating, incubating, liquefying, cooling, adding diastase, cooling after saccharification, inoculating yeast, culturing at constant temperature, distilling to obtain the product of alcohol, cooling the distilled waste mash, anaerobic-fermenting to obtain biogas, separating the broth to obtain digest and active sludge, and recycling the digest into the next fermentation to form a ring cycle. The distilled waste mash only needs anaerobic fermentation, which reduces the occupied ground area greatly and fixed asset investment. anaerobic fermentation is low cost, recycle of the digest can realize zero release of fermentation wastewater, completely eliminate the environmental pollution caused by the high concentration wastewater released by the present production of alcohol, and save large amount of water.

Owner:JIANGNAN UNIV

A method for direct reduction of industrial waste slag in rotary hearth furnace

InactiveCN102277461ALow mechanical strength requirementIncrease flexibilityProcess efficiency improvementHearthProcess conditions

The invention relates to a direct reduction method for treating industrial waste slag in a rotary hearth furnace, belonging to a new direct reduction ironmaking process in the metallurgical industry. The main process is: ingredients - mixing - pellets - drying - preheating - reduction - metallized pellets. Metallized pellets with a metallization rate of over 80% can be obtained after reduction in a rotary hearth furnace. The present invention comprehensively recycles and utilizes valuable elements in iron-containing industrial waste residues, economically obtains reducing agent resources, and solves the problem of low falling strength of cold solidified carbon-containing pellets prepared in the process of comprehensive recycling of industrial waste residues It has the advantages of high metallization rate, simple operation, easy control of process conditions, less equipment investment, low production cost, easy to meet raw material conditions, etc., and the overall process is more energy-saving than the furnace smelting process. It is also more environmentally friendly, and more importantly, the method can comprehensively recycle industrial waste, reduce its pollution to the environment, and save energy and protect the environment.

Owner:UNIV OF SCI & TECH BEIJING

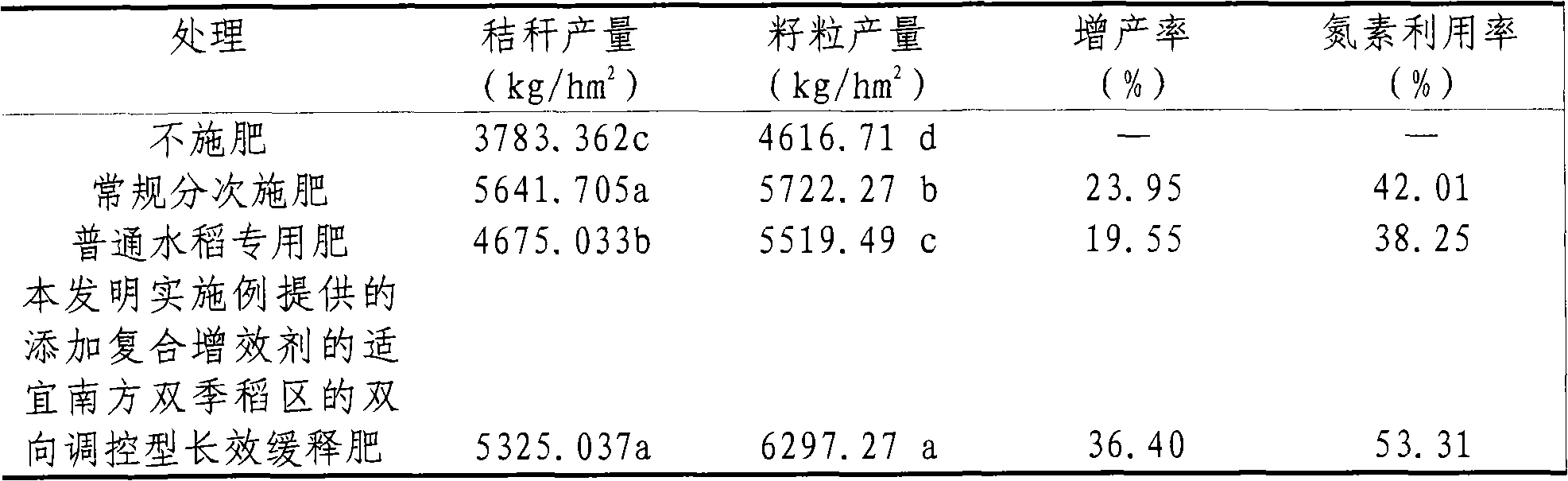

Special root-inducing slow release high-efficiency fertilizer for double cropping rice and preparation method thereof

InactiveCN102153416AInhibition of urease activitySupplementary needsFertilizer mixturesRoot growthPotassium

The invention discloses a special root-inducing slow release high-efficiency fertilizer for double cropping rice and a preparation and application method thereof. The preparation method comprises the following steps: mixing and blending nitrogen fertilizer and compound synergist in a blender for 3-5 minutes to obtain root-inducing slow release high-efficiency nitrogen fertilizer; and then, continuing to mix with phosphorus fertilizer and potassium fertilizer for about 5 minutes to obtain the finished fertilizer, wherein the compound synergist is prepared by uniformly mixing the following materials in percentage by weight: 3.4-3.8% of borax (B), 2-2.5% of hydroquinone (HQ), 0.9-1.4% of dicyandiamide (DCD), 33-36% of silicon fertilizer (SiO2), 9-14% of polyaspartic acid (PASP), 31-38% of humic acid (HA) and 9-12% of phosphorus activator. The finished fertilizer is used as basal fertilizer to be completely applied after rice soaking and in the early rice transplanting stage, and no additional fertilizer is required for the later stage; the amount of applied fertilizer for early rice is 40-45 kg / mu; and the amount of applied fertilizer for late rice is 50-55 kg / mu. The fertilizer disclosed by the invention has the dual effects of promoting root growth and delaying nutrient release, can greatly improve the nutrient utilization ratio and rice yield, is convenient to produce and use, and has the advantages of high technical compatibility, low cost, environment friendliness and the like.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

Method of preparing pnenolic aldehyde foam from modified foamable phenolic resin

The invention relates to a method for preparing phenolic foam with the modified phenolic resin. In the invention, it mixes 100 weight share of cashew oil modified phenolic resin, 1~4 weight share of surfactant, 2~8 weight share of foaming agent, and then it adds 8~15 weight share of curing agent into the mixture and stirs it for 2~15 minutes, and then it cures the mixture at 65 ~ 80deg.C environment for 30 ~ 125 minutes to achieve the phenolic foam.

Owner:安徽复材科技有限公司

Antago nistic fungus capable of preventing and treating continuous crops blight and its microbial organic fertilizer

InactiveCN1775035AHigh soluble carbonIncrease organic nitrogen contentBiocideBio-organic fraction processingContinuous croppingBiotechnology

The present invention relates to an antagonistic bacillus and microbial organic fertilizer produced by using said antagonistic bacillus for overcoming and eliminating continuous-cropping crop blight. Said invention utilizes a separation process to obtain the antagonistic bacillus which has obvious antagonistic action for blight fungus. The microbial organic fertilizer produced by mixing said antagonistic bacillus and organic farmyard manure is applied in the soil, then the antagonistic bacillus can be quickly reproduced, and the blight controlling rate can be up to above 80%.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Method for preparing mannitol utilizing dextrose

InactiveCN1524837ALower glucose levelsReduce consumptionPreparation by oxygen reductionChromatographic separationIsomerase

The invention relates to a process for preparing mannitol by using glucose as raw material, which comprises the steps of, converting glucose solution partly into mannose under acidic condition at temperature 60-160 deg. C by using molybdates as catalyst, separation by crystallization, converting part of the residual glucose in the mother liquid after separation by crystallization into fructose through glucose isomerase column, obtaining the miscible liquid of glucose, mannose and fructose, hydrogenation for obtaining the miscible liquid of sorbic alcohol and mannose, wherein the mannitol crystal can be prepared through the crystallization and purification of miscible liquids.

Owner:谭卫星

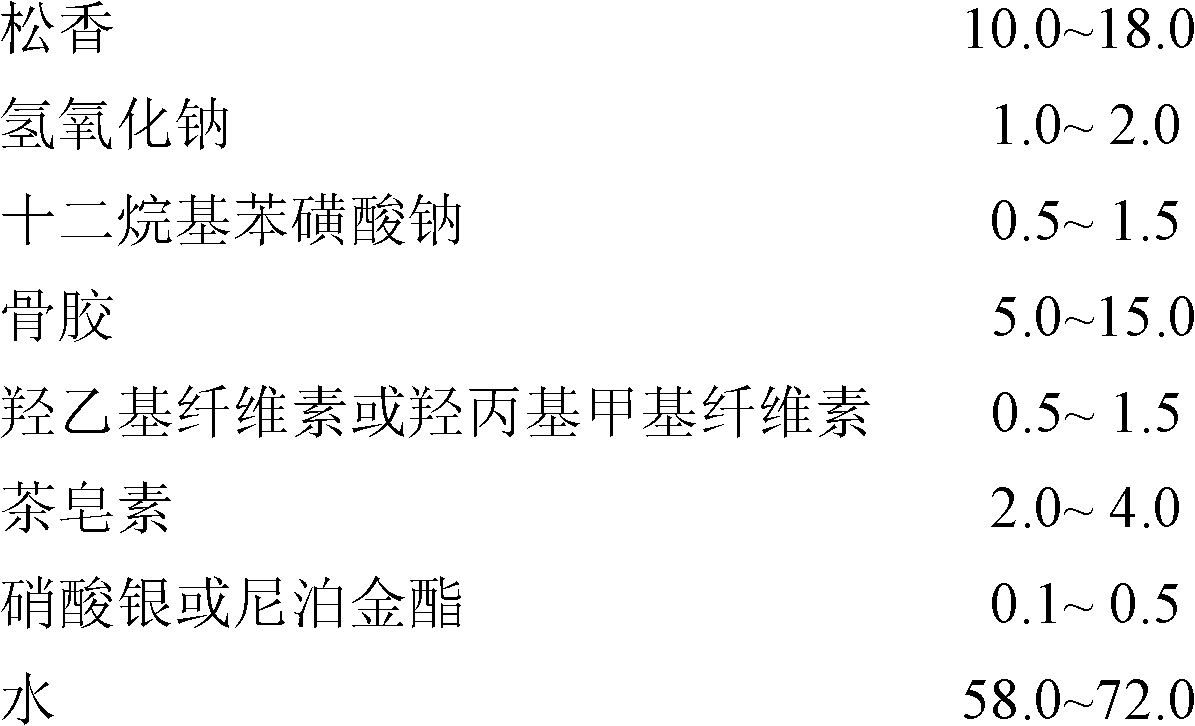

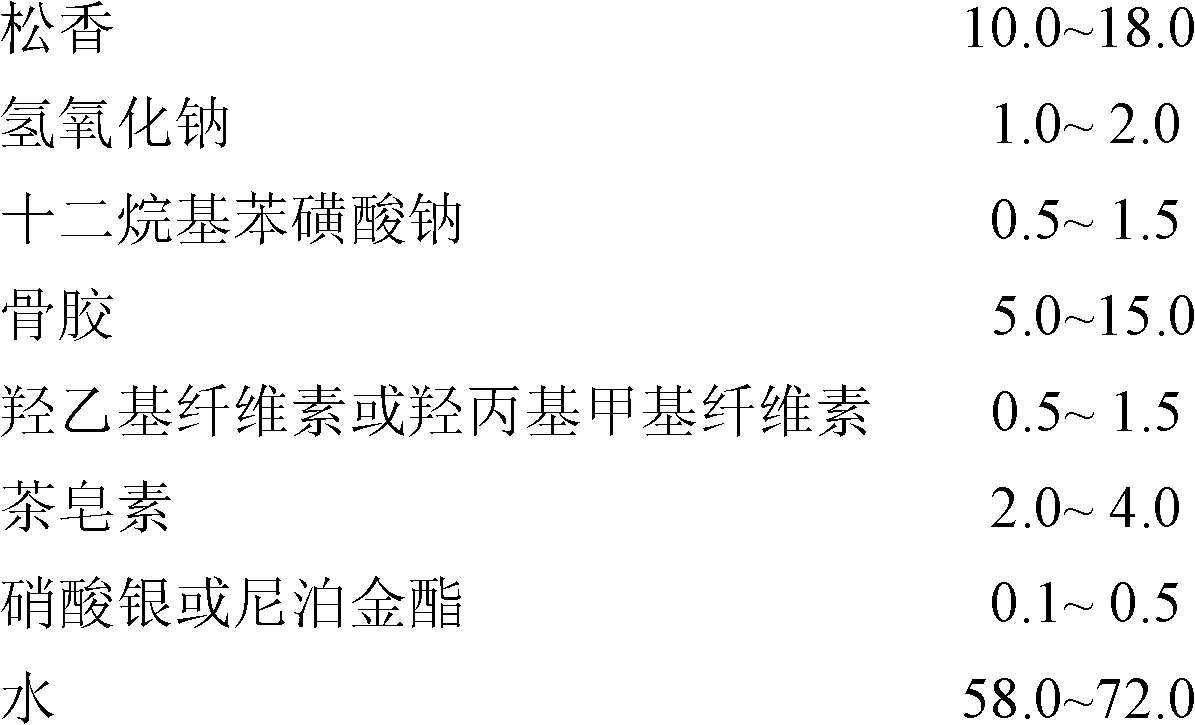

Concrete foaming agent and preparation method thereof

The invention relates to a concrete foaming agent and a preparation method thereof. The concrete foaming agent comprises raw materials in mix proportion by mass: 10.0-18.0 of colophony, 1.0-2.0 of sodium hydroxide, 0.5-1.5 of sodium dodecyl benzene sulfonate, 5.0-15.0 of bone glue, 0.5-1.5 of ethoxyl or hydroxypropyl methylcellulose, 2.0-4.0 of tea saponin, 0.1-0.5 silver nitrate or paraben and 58.0-72.0 of water. During preparation, the preparation method comprises the steps of: soaking the bone glue in water for 24-48h; adding the colophony and the sodium hydroxide while stirring; hydrolyzing for 3-5h under the temperature of 80-100 DEG C; standing for 10min; filtering, wherein the ethoxyl or hydroxypropyl methylcellulose, the tea saponin, the silver nitrate or the paraben are added in a filtrate under the temperature of 80-100 DEG C; and completing after dissolving and cooling down. The concrete foaming agent and the preparation method thereof have the advantages of simple process,low cost, good placeability with various foamed concrete-based materials, no defoaming and unlimited application range.

Owner:梁材

Process for making bamboo leaf beautifying wine

InactiveCN102586045ASolve the problem of attached sedimentReduce investment in fixed assetsAlcoholic beverage preparationDermatological disorderYeastAlcohol content

The invention relates to a process for making bamboo leaf beautifying wine. The process comprises the following steps of: soaking and washing rice, and cooking until the rice is cooked; spreading for cooling, adding distiller's yeast in an amount which is 0.3 to 0.5 percent based on that of the rice at the temperature of between 22 and 26 DEG C, adding the rice with the distiller's yeast into a jar, performing primary fermentation at the temperature of less than 28-32 DEG C for 72 to 90 hours, performing mixed fermentation at the temperature of between 28 and 30 DEG C when secondary fermentation is performed after primary fermentation is finished, distilling when fermentation alcohol content is 12 percent, storing wine with the alcohol content of 60 percent, 48 percent and 42 percent, and ageing for more than 3 months; and adjusting the alcohol content according to product requirements. The process is characterized in that bamboo leaves are added twice in the process of making the wine. The bamboo leaf wine has mellow mouthfeel, is refreshing, and has beautifying and health protection effects.

Owner:北京奈特通达科技发展有限责任公司

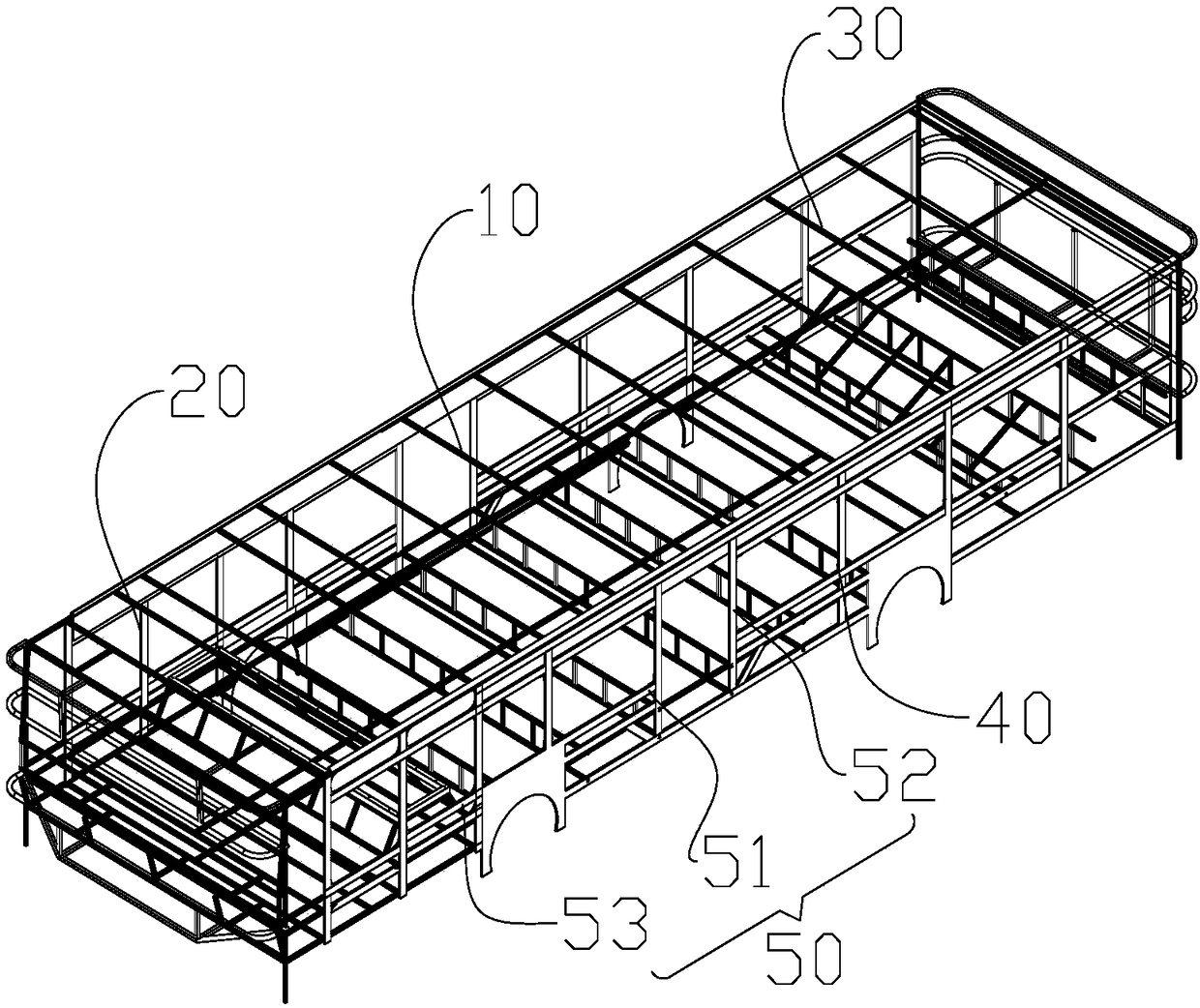

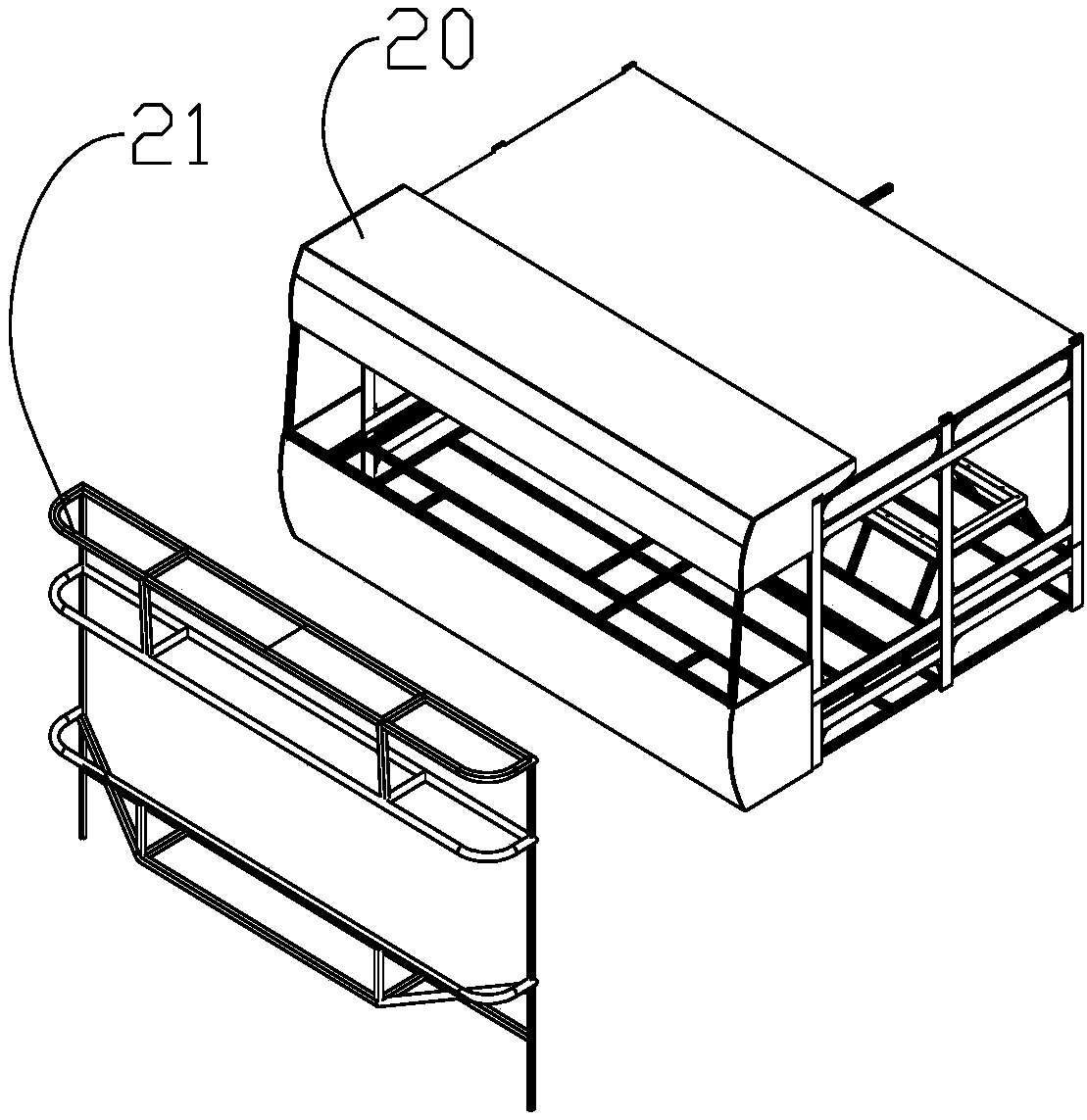

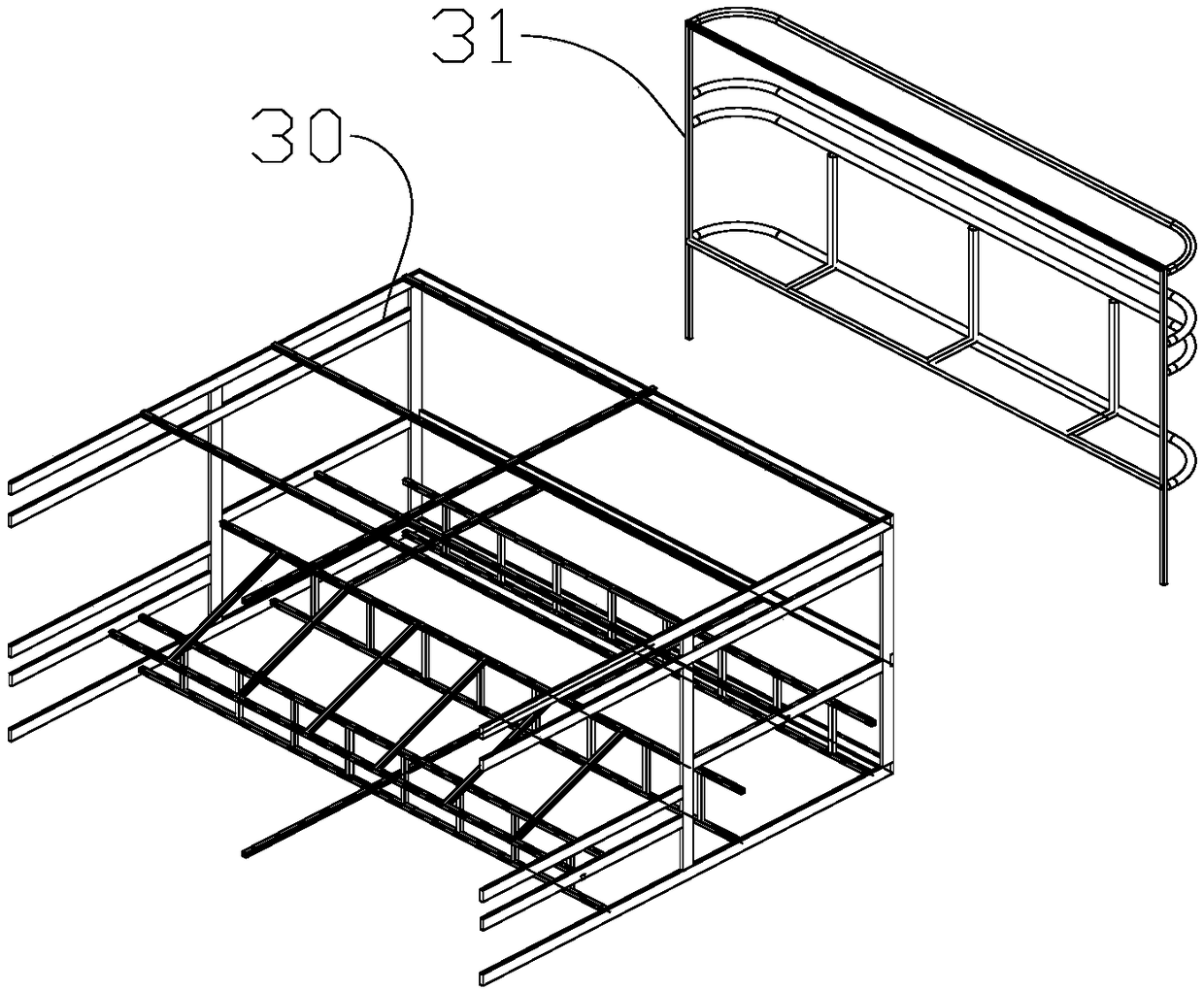

Light-weight magnesium alloy passenger vehicle body framework

PendingCN108177697ASolve the defective technical problems of poor welding performanceSolve the problem of riveting costSuperstructure connectionsPassenger vehicle superstructuresStress concentrationMetal

The invention discloses a light-weight magnesium alloy passenger vehicle body framework which comprises a vehicle body framework body, a vehicle head framework installed at the front end of the vehicle body framework body, a vehicle tail framework installed at the rear end of the vehicle body framework body and multiple connecting mechanisms. Each of the vehicle head framework, the vehicle body framework body and the vehicle tail framework is composed of multiple magnesium alloy section bars in a connected mode, and every two magnesium alloy section bars are buckled and connected into a wholethrough the corresponding connecting mechanism. The potential quality hazards of welded metal fatigue and stress concentration are effectively overcome, the technical problem that a magnesium alloy ispoor in welding performance and the problem that magnesium alloy frameworks are high in riveting cost are solved as well, and connection of the magnesium alloy frameworks of a whole vehicle is reliable.

Owner:深圳市鑫镁金实业有限公司

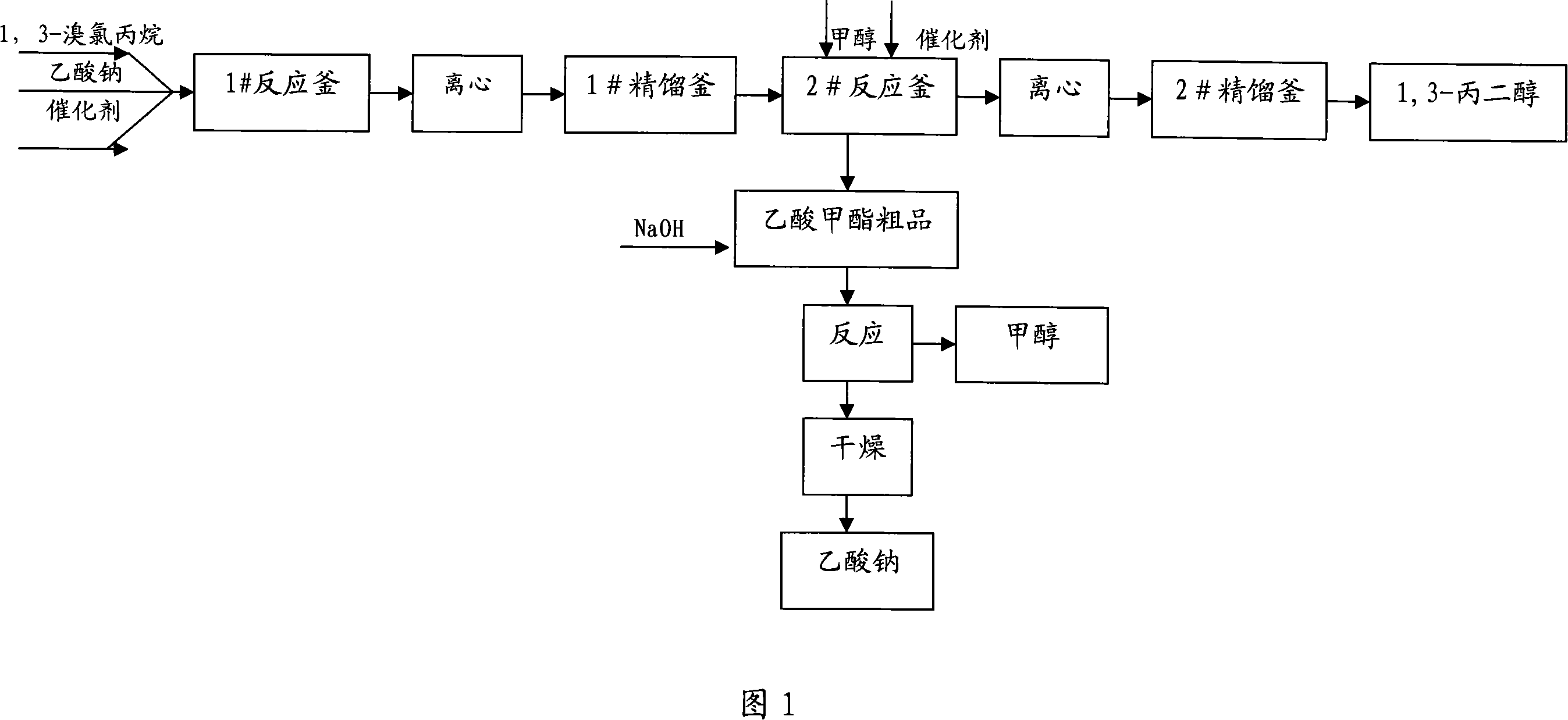

Method for producing 1,3-propylene glycol

InactiveCN101139253AHigh technical contentEasy accessPreparation by ester-hydroxy reactionBulk chemical productionSodium acetateChemical synthesis

The present invention belongs to the chemosyntheise field, which relates to a preparation method for 1,3 propylene glvcol; the method adopts two-steps reaction processes that are as follows: (1) 1,3 Fumazone is reacted with a sodium acetate in the alcohols catalyzer to create a di-esters (1,3 propyl ethyl ester); (2) the di-esters produced in Step 1 is reacted with a methanol alcohol in the resin catalyzer to create 1,3 propylene glvcol. The technical content for the technis process is much higher; the catalyzer can be used repeatedly. The conversion ratio for the material can reach up to or more than 94 percent and the purity for the product can reach up to or more than 99 percent; the investment for the fixed assets is much lower that is good for the investment product or enlarging the producing scale; the producing safety is much higher with convenient operation. The three materials in the present invention are easy to be obtained; the produced waste gas, waste liquid and waste residues are much less. The producing period is much shorter that only needs 60 hours from the material to the finished product.

Owner:邹平铭兴化工有限公司

Application of composite synergist into Southern double cropping rice

InactiveCN102653491AReduce manufacturing costEasy to acceptFertilising methodsAgriculture gas emission reductionN-Acetylmuramic acidAgricultural science

The invention relates to the field of fertilizer production, particularly application of a composite synergist into Southern double cropping rice. The composite synergist NAM (N-acetylmuramic acid) is used as a synergist applicable to slow release fertilizers for Southern double cropping rice seedlings. After the composite synergist is compounded with the slow release fertilizer, the compound fertilizer applied to the Southern double cropping rice field can greatly enhance the rice yield, is convenient for production and use, obviously reduces the greenhouse gas emission in the rice field, lowers the nitrate pollution, and has the advantages of strong technical compatibility, low cost and the like. The invention can receive favorable economic, social and ecological effects.

Owner:SHIKEFENG CHEM IND

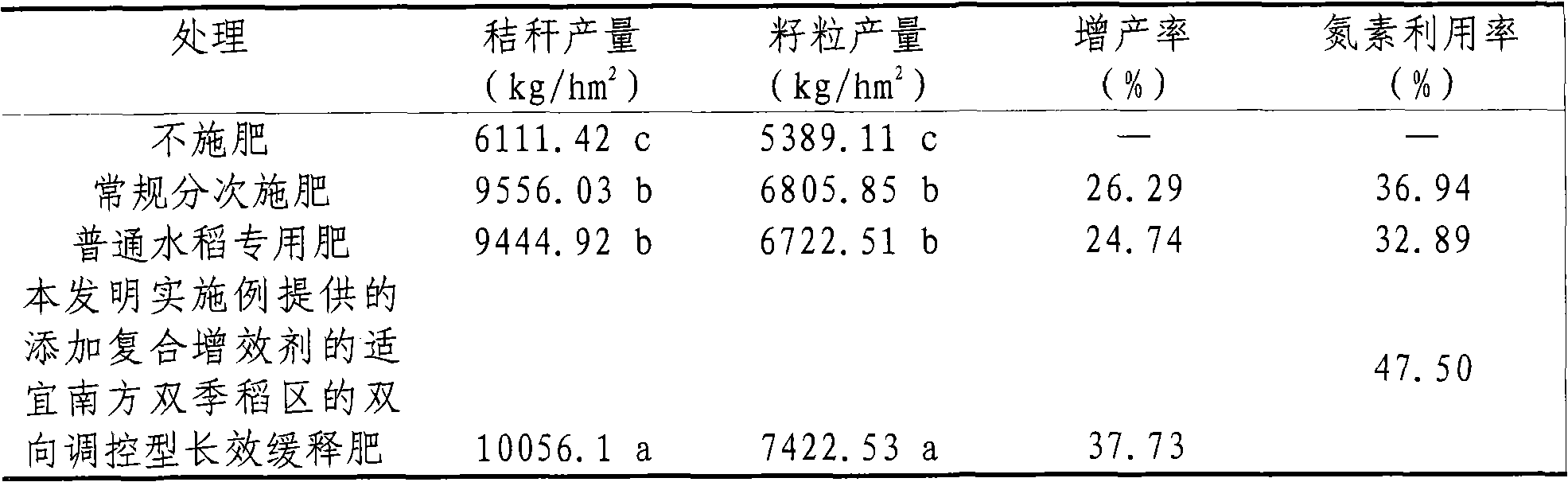

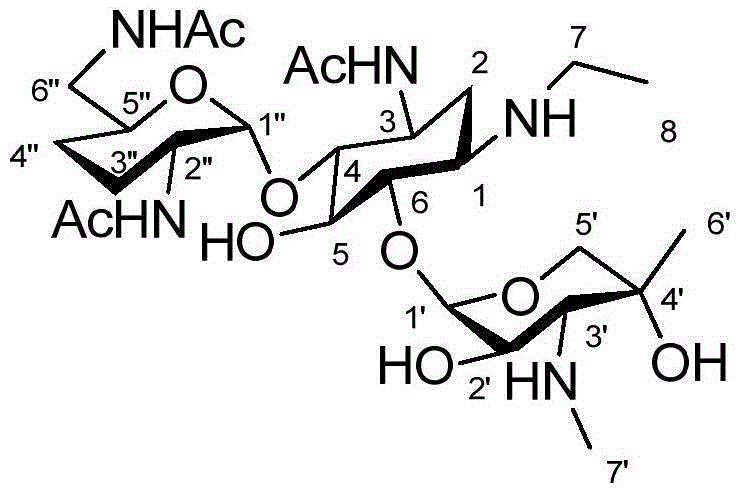

Continuous-chromatography separating and purifying method of etimicin sulfate

InactiveCN104447909AReduce layoutSmall footprintSugar derivativesChemical recyclingChromatographic separationHydrolysate

The invention relates to a continuous-chromatography separating and purifying method of etimicin sulfate. Efficient separation of the etimicin is realized by virtue of a continuous-chromatography process. The continuous-chromatography separating and purifying method of etimicin sulfate comprises the following steps: introducing hydrolysate of the synthesized etimicin into a continuous-chromatography system, performing adsorption, impurity washing and elution on the etimicin, collecting eluant, performing chromatographic column regeneration, concentrating the collected eluant, and salifying and discoloring the concentrated eluant to obtain the etimicin sulfate. The etimicin sulfate separated by the method disclosed by the invention is high in yield, high in purity, low in cost, environmentally friendly and suitable for industrial production.

Owner:WUXI JIYU SHANHE PHARM CO LTD +1

Copper smelting device with high-oxygen-enrichment double-side-blowing melting bat and operation method of copper smelting device

ActiveCN104593617AIncrease useful gas contentReduce take awayRotary drum furnacesCrucible furnacesMelting tankSlag

The invention relates to a copper smelting device with a high-oxygen-enrichment double-side-blowing melting bat and an operation method of the copper smelting device and belongs to the technical field of copper smelting devices and processes. According to the method, a large-volume hearth is used, the continuous production is performed, a single furnace is adopted so as to meet the periodic production of a PS converter, smelting slag continuously overflows from a smelting slag outlet and matte is directly discharged from a matte outlet formed in the bottom end of the hearth. During the smelting slag is discharged, the flowing direction of the smelting slag is controlled by virtue of a switching chute so that the smelting slag can be continuously discharged; the ratio of Fe to SiO2 in the smelting slag is controlled at 1.6-1.8, the ratio of a fuel to input materials is controlled at 2-2.5% and the content of copper in the smelting slag is less than or equal to 0.65%. The method has the characteristics of small construction investment, low production cost, good working environment, high degree of automation, high utilization rate of plant building and the like.

Owner:CHIFENG FUBANG COPPER

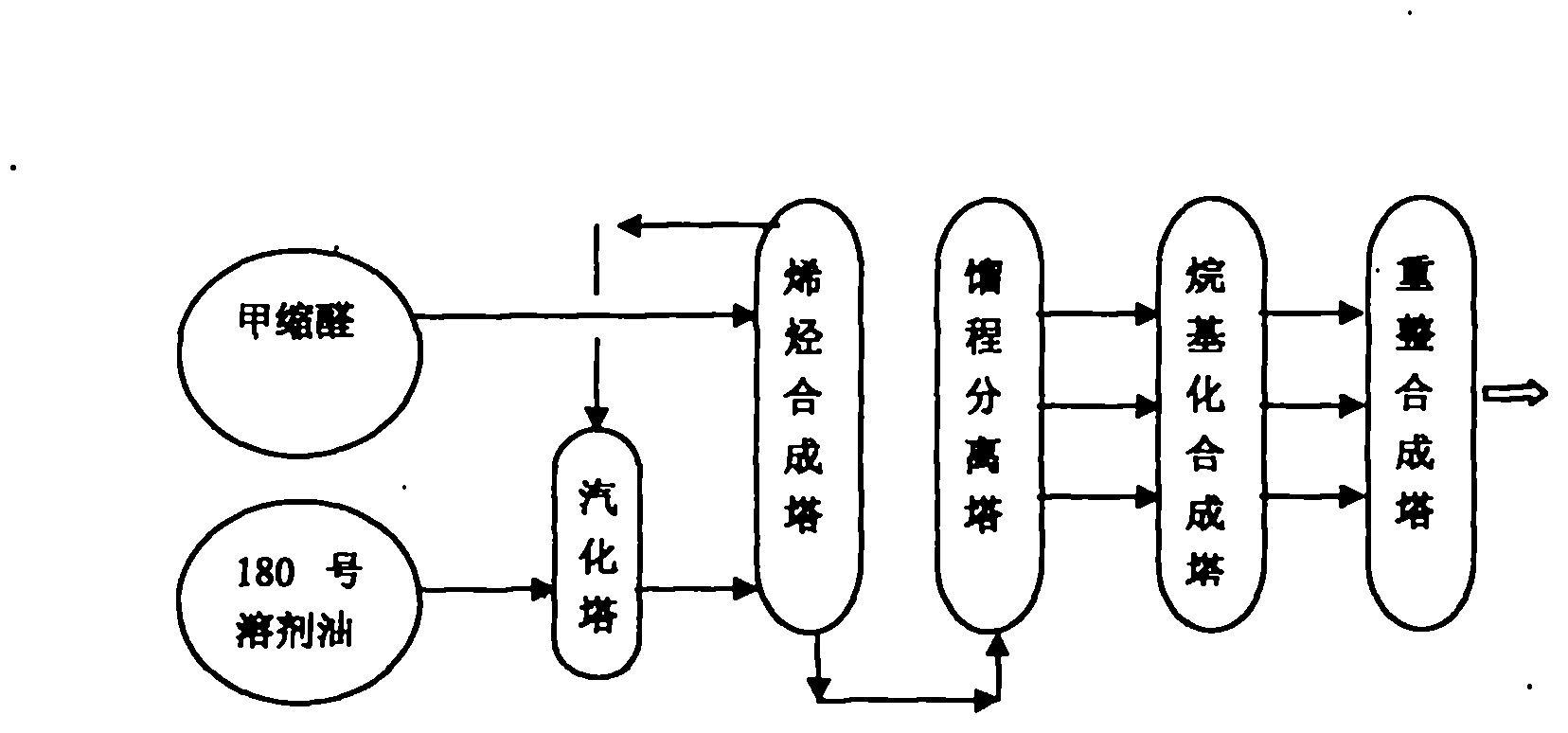

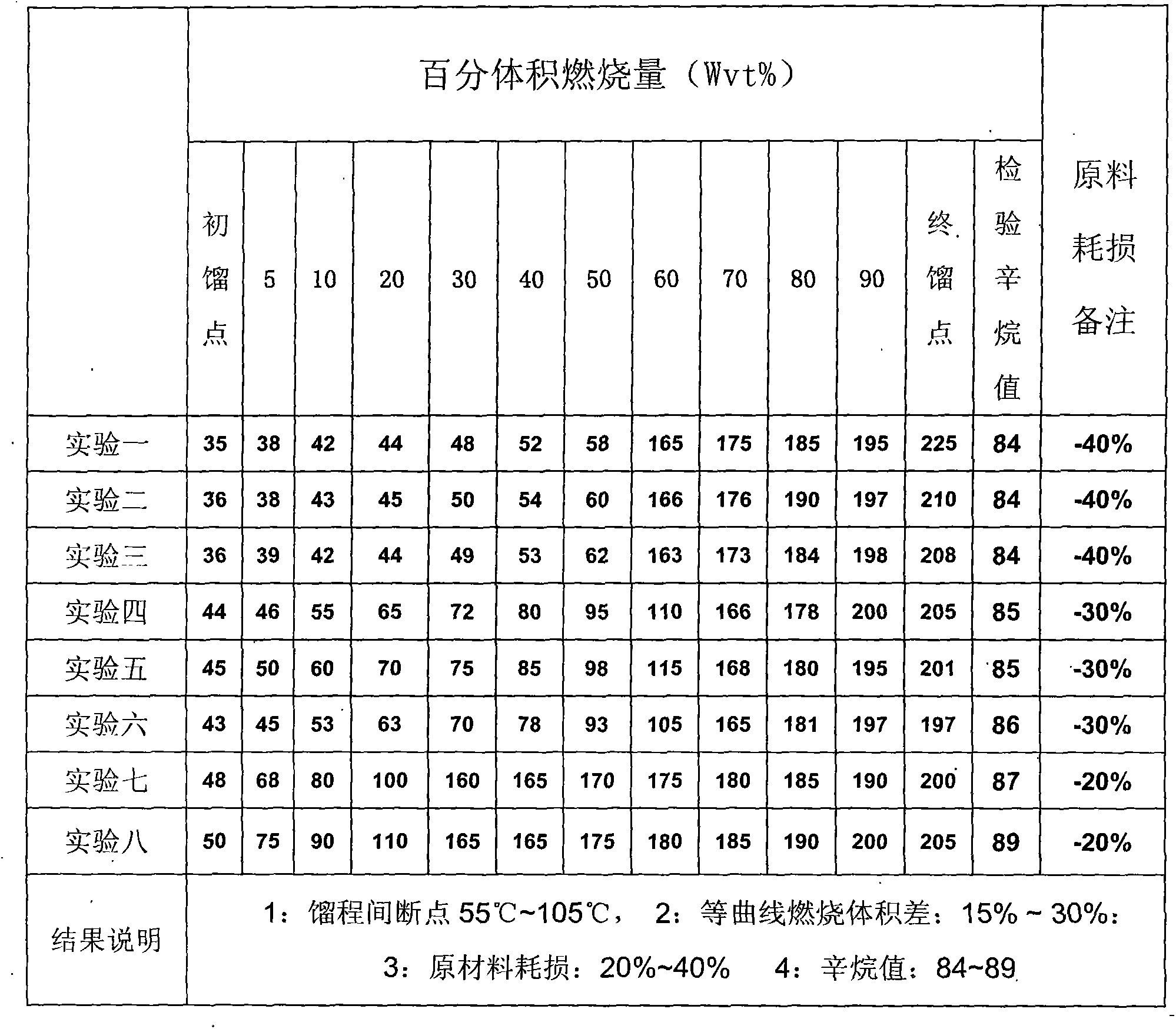

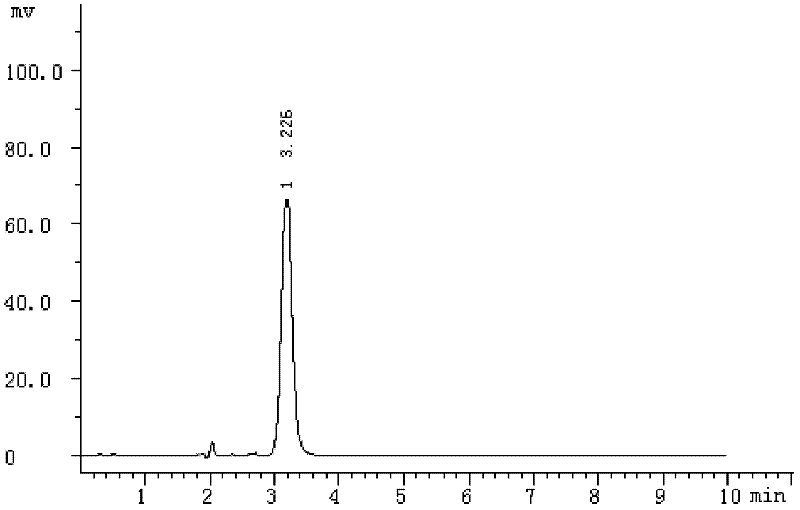

Method for preparing alkylation gasoline through polycondensation of methanol

InactiveCN103289724ALow costReduce production energy consumptionLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionDistillationSolvent

The invention discloses a method for preparing alkylation gasoline through polycondensation of methanol. The method comprises the following steps: 1) condensing formaldehyde so as to obtain methylal, deoxidize the methylal to form olefin and absorbing the methylal by using solvent oil at the same time so as to obtain mixed hydrocarbon; 2) carrying out methanol dehydroxylation addition to methylate olefin so as to obtain butane, absorbing alkane simultaneously by the mixed hydrocarbon so as to obtain multi-distillation-range alkylation mixed hydrocarbon; and 3) reforming the mixed hydrocarbon so as to obtain mixed alkane multi-distillation-range gasoline. The method for preparing alkylation gasoline through polycondensation of methanol disclosed by the invention has the advantages that the prepared gasoline meets the national standards, and the cost of raw materials can be effectively reduced for gasoline production; the fixed-asset investment of products is reduced; the energy consumption for gasoline and diesel production based on methanol conversion is reduced; and the safety and application cycle of production equipment are improved, and the method lays a foundation for the subsequent production process of CO2-methanol recycling energy.

Owner:李新勇

Process for producing aloe wine for beautification

InactiveCN102533494ASolve the problem of attached sedimentReduce investment in fixed assetsAlcoholic beverage preparationFermentation starterCooling down

The invention discloses a process for producing aloe wine for beautification. The process comprises the following steps of: soaking and washing rice, cooking until cooked, spreading and cooling down to 22-26 DEG C, adding fermentation starters at an amount of 0.3-0.5% the weight of rice, mixing, putting the resulting mixture in a fermenter, performing primary fermentation at a fermentation temperature less than 28-32 DEG C for 72-90 hours, performing after-fermentation after primary fermentation, performing mixed fermentation at 28-30 DEG C, distilling when the alcoholicity of the fermentation product is 120, preserving and aging the fermentation products with alcoholicity of 600, 480 and 420 respectively (aging time exceeds 3 months), and adjusting alcoholicity according to the product requirements. The invention is characterized in that aloe is added during the wine brewing process and the addition of aloe is performed twice. The aloe wine has mellow and fresh taste and is beneficial for beautification and health care.

Owner:北京奈特通达科技发展有限责任公司

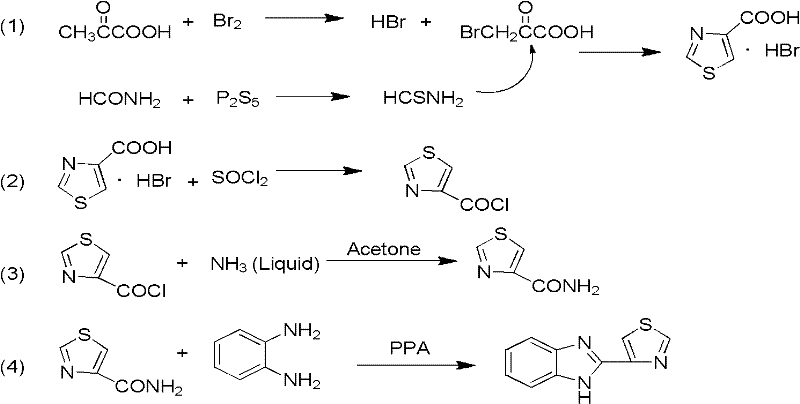

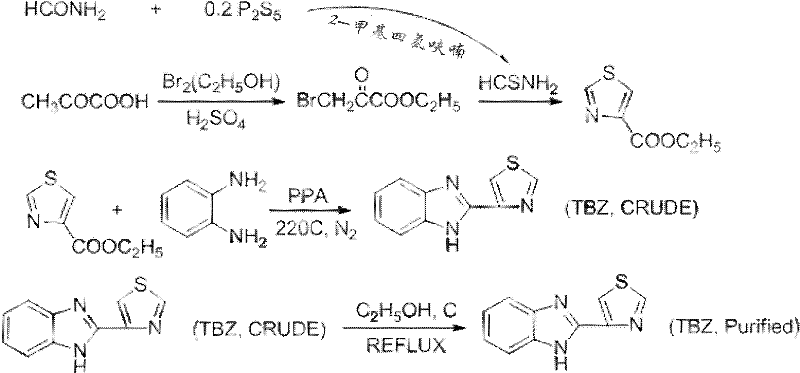

Probenazole low-toxicity bactericide and preparation method thereof

The invention relates to a probenazole low-toxicity bactericide and a preparation method thereof, and belongs to the technical field of pesticide. The preparation method comprises the following steps: dissolving bromine in ethanol to obtain solution A; adding pyruvic acid into concentrated sulfuric acid, adding the solution A and obtaining a mixture I; adding P2S5 and formamide into 2-methyltetrahydrofuran to obtain solution II; adding the mixture I into the solution II, filtering, collecting precipitate, drying the precipitate, and obtaining thiazole-4-carboxylate; adding o-phenylenediamine and thiazole-4-carboxylate into polyphosphoric acid, reacting, mixing with water, filtering, drying and obtaining coarse probenazole; and adding coarse probenazole in absolute ethanol, adding active carbon, filtering, cooling filtrate to room temperature, filtering, drying, precipitating and obtaining probenazole. In the invention, bromine is dissolved in absolute ethanol and reacted, the operability of bromine is improved, the volatilization of a hydrogen bromide gas is slowed, the subsequent absorption process is continuous and controllable, and the unsafe factors in the production are reduced.

Owner:SHANDONG MEI LUO FU AGRI POLYTRON TECH

Method for preparing packaged fermentative pickling wild pepper

The invention discloses a method for preparing a packaged fermentative pickling wild pepper, which is mainly technically characterized by comprising the following steps of: packaging a sorted and cleaned wild pepper into a food-grade packaging plastic bag by utilizing the food-grade packaging plastic bag as a fermenting container and a packaging material, and adding premixed nutritional fermenting liquid; then vaccinating streptococcus lactis for expanding the fermenting liquid; sealing in vacuum and then carrying out temperature control fermentation; and when the fermenting liquid reaches a certain acidity, terminating fermentation by adopting pasteurization. The invention solves the problems of large investment cost, long period, complicated operation, time waste and trouble caused by the condition that a great number of argil pickling fermentative jars needed by the current manufacturer during production and the wild peppers are respectively packaged into a glass bottle or a plastic bag after fermentative ripping and the problem of rot of the wild pepper in the process of fermentative pickling for a long time. The pickling wild pepper product produced with the method has propersalinity and acidity and strong fermentative pickling flavor, not only can be used as a dinning pickle product, but also can be used as the seasoning of cooking and dishes and the sour and hot seasoning of a spicy nonstaple food.

Owner:湖北渝川食品股份有限公司

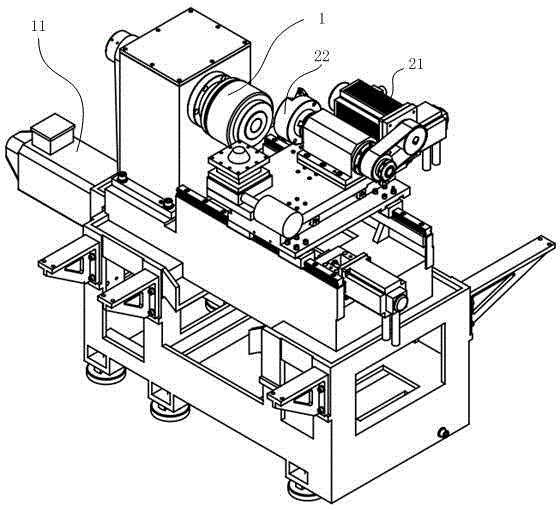

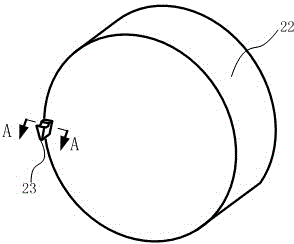

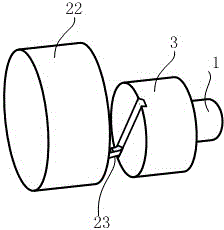

End surface grooving device

ActiveCN104551016AReduce investment in fixed assetsImprove machining accuracy and machining efficiencyTurning machinesProcessing accuracyMachining process

The invention relates to the technical field of machining equipment, in particular to a grooving device for machining the end surface of a rotary body component by utilizing a lathe. An end surface grooving device comprises a grooving machine frame, a grooving motor which is mounted on the grooving machine frame, and a cutter disk which is driven by the grooving motor; the grooving machine frame can move forward, backward, leftward, rightward, upward and downward relative to a chuck of a main shaft of a common numerical control lathe; a grooving cutter is mounted on the cutter disk; a spindle motor and the grooving motor are controlled through a synchronizing device, so that the ratio of the angular velocity of the chuck of the main shaft to the angular velocity of the cutter disk is 1:2N, wherein N is a positive integer. Theoretically, N grooves can be formed in a workpiece to be machined; the angle between every two grooves is decided by the rotating precision of the main shaft of the lathe, and is greatly superior to that decided by a rotary dial plate. Compared with the prior art, the end surface grooving device has the advantages that the investment is reduced, the machining efficiency and the machining precision are improved by replacing a subsequent milling and turning machining process and replacing a turning and milling integrated composite machining center with a lathe in the past.

Owner:龙口市蓝牙数控装备有限公司

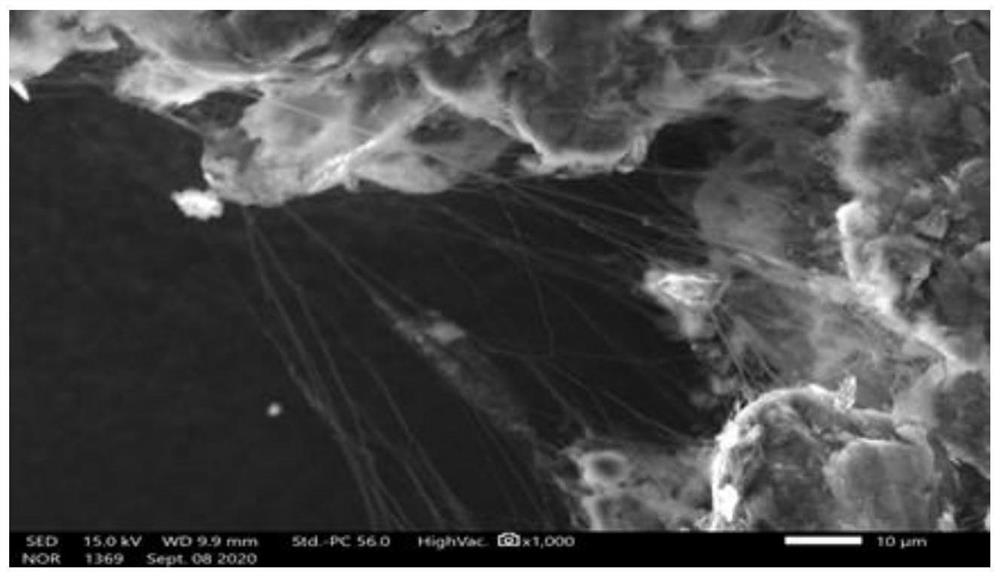

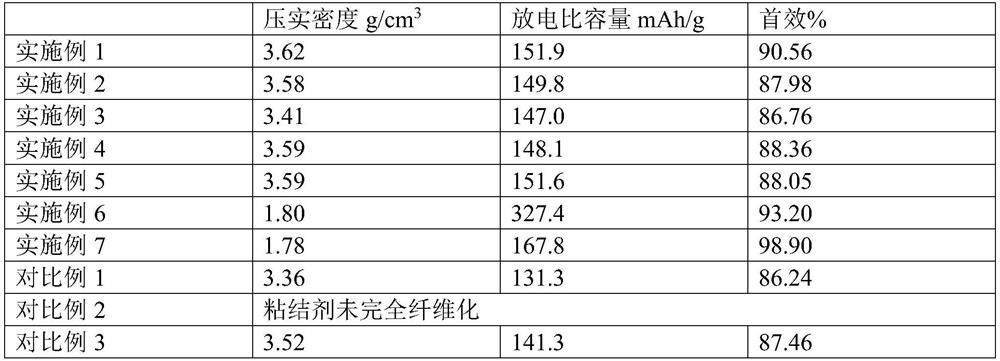

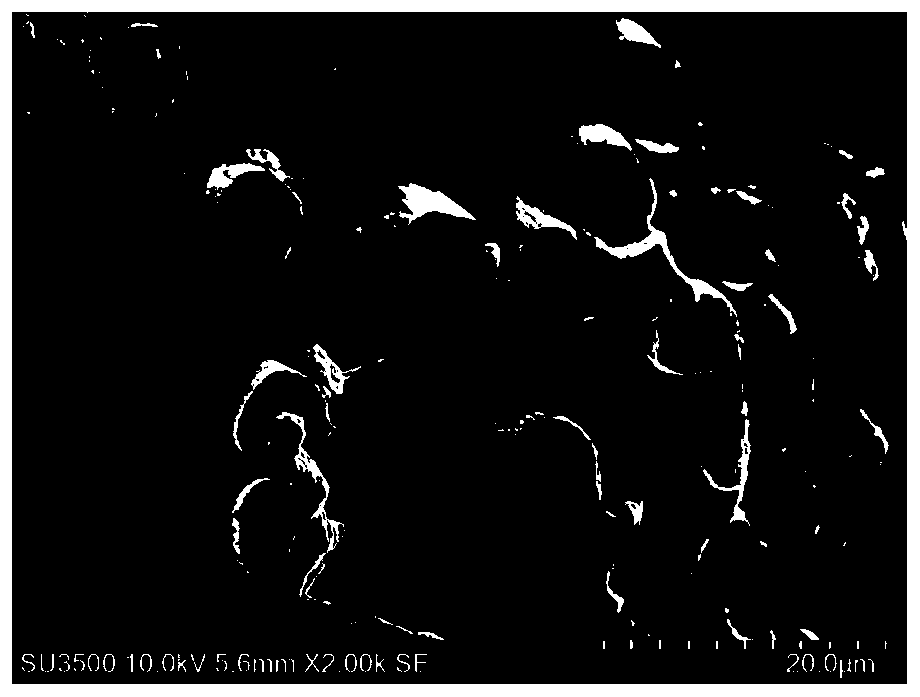

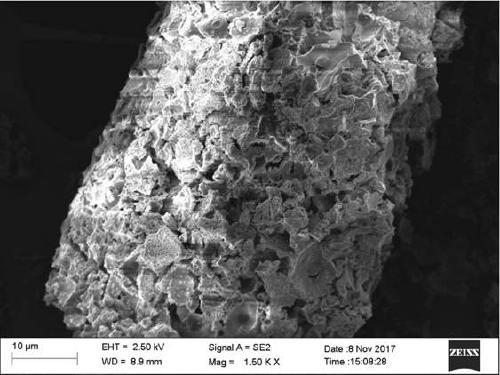

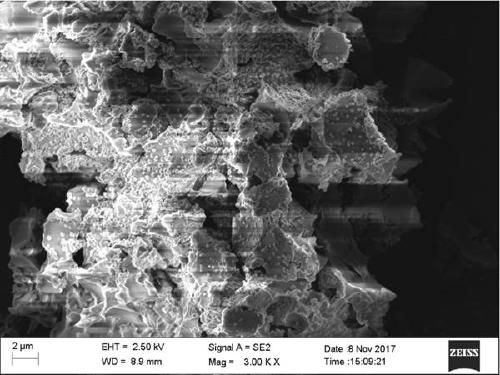

Preparation process of lithium battery electrode plate

ActiveCN113611825AIncrease productivityReduce consumptionLi-accumulatorsElectrode moldingCyclohexanoneAlcohol

The invention discloses a preparation process of a lithium battery electrode plate. The preparation process comprises the following steps: firstly, uniformly mixing an electrode active material, a conductive agent and a binder to obtain a mixture; adding an auxiliary agent into the mixture, and mixing to obtain a flocculent mixture, wherein the auxiliary agent is absolute ethyl alcohol, petroleum ether, cyclohexanone or solvent oil, or a mixture of the absolute ethyl alcohol, the petroleum ether, the cyclohexanone and the solvent oil and the flocculent mixture is prepared into a self-supporting pole piece membrane through hot rolling; and drying the pole piece film to remove the auxiliary agent, and performing hot-pressing compounding on the pole piece film and a current collector to obtain the electrode pole piece. According to the invention, the powder is directly mixed, a proper auxiliary agent is added to form a flocculent mixture, then the flocculent mixture is rolled, the electrode material is uniformly mixed, and the binder is fiberized sufficiently, so that a uniform, flexible and compact self-supporting membrane is obtained, and the self-supporting membrane is compounded with the current collector to obtain the electrode plate.

Owner:CHINA AUTOMOTIVE INNOVATION CORP

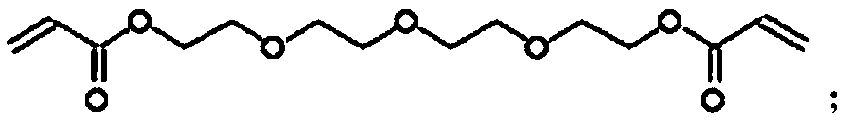

Carbon fiber sizing agent and preparation methods thereof

The invention discloses a carbon fiber sizing agent. The carbon fiber sizing agent is prepared from the following raw materials, a water-based bisphenol A epoxy resin, polyether alcohol, unsaturated acid and water, wherein the weight ratio of the water-based bisphenol A epoxy resin to the polyether alcohol to the unsaturated acid is 1: 0.5 to 5: 0.4 to 5. The polyether alcohol is selected from dimethyl trimer dimethanol; and the unsaturated acid is selected from acrylic acid. The invention also discloses three preparation methods of the carbon fiber sizing agent. The invention also discloses application of the carbon fiber sizing agent in preparation of carbon fibers and carbon fiber composite materials, and the prepared carbon fibers and carbon fiber composite materials. The carbon fibertreated by the sizing agent can be soaked by the polyester resin, so that the carbon fiber can obtain manufacturability similar to glass fiber, and the forming time of the carbon fiber composite material can be greatly reduced, the fixed asset investment of carbon fiber composite material forming equipment is reduced, and the low-cost and quick forming of the carbon fiber composite material are realized.

Owner:北京鸿羽腾风材料科技有限公司 +1

N-isopropyl hydroxylamine production method

InactiveCN1709862AReduce investment in fixed assetsLess investmentOrganic chemistryAlkaneHydroxylamine

This invention involves a method for producing N-isopropyl hydroxylamine, it uses diisopropylamine as raw materials, operates according to the following technological process: oxidation, acid treatment, condensing, neutralization, etc. to get N-isopropyl hydroxylamine. Above-mentioned catalyst should be carbon dioxide or the amine salt of the carbon dioxide; Above-mentioned acid of acid treatment can be organic acid or inorganic acid too; The solvents of above-mentioned neutralization are the ether, and can be alcohol, alkane or water. N-isopropyl hydroxylamine manufacturing method of this invention has smaller capital asserts, lower cost and simple operation, suited to producing in industrialization.

Owner:陈军民

Preparation method of distilled peppermint liquor

InactiveCN1412293ASolve the problem of adhering a large amount of sedimentReduce investment in fixed assetsAlcoholic beverage preparationFlavorYeast

The preparation method of distitted peppermint liquor incldues the following steps: soaking rice, washing and cooking, spreading and drying, mixing with distillers' yeast at 22-26 deg.C, fermenting in fermentation cylinder, front fermentation time is 72-92 hr. and fermentation temp. is below 28-22 deg.C, them making rear fermentation, adding cleaned fresh peppermint leaf into fermentation cylinder, fermenting together with rice, in which the mixing ratio of rice: peppermint leaf is 7:2.8-4, fermentation temp. is 28-30 deg.C, making distillation to obtain distilled liquors which respectively can contains 60, 48 and 42 per cent alcohol, ageing for above 3 months, regulating liquor flavour, quality checking and bottling so as to obtain the invented product.

Owner:李洁

Preparation method of graphene-PVC composite material

The invention relates to a method for preparing a graphene-PVC composite material through a one-pot process. The method includes: adopting a 500-ml three-necked round-bottom flask, adding PVC slurry at room temperature, and mechanically stirring to enable PVC particles to be uniformly suspended in an aqueous phase; adding GO slurry, and stirring and mixing well; rising temperature, adding L-ascorbic acid according to a certain mass ratio with GO, and stirring for reaction; after reaction is finished, cooling to below 50 DEG C, and centrifuging or standing; drying and screening to obtain functionalized graphene / PVC resin. Graphene oxide slurry and PVC slurry are used, so that aggregation of graphene and PVC is inhibited, dispersion is more uniform, and the graphene-PVC composite material has excellent antistatic and anti-tensile performance. The preparation method starts from raw materials, and high molecular polymer with complex structure is obtained directly without separating an intermediate. The whole preparation process is simple in operation, economical and environment-friendly. The method is suitable for industrial production.

Owner:山东鲁泰控股集团有限公司石墨烯高分子复合材料研发中心 +2

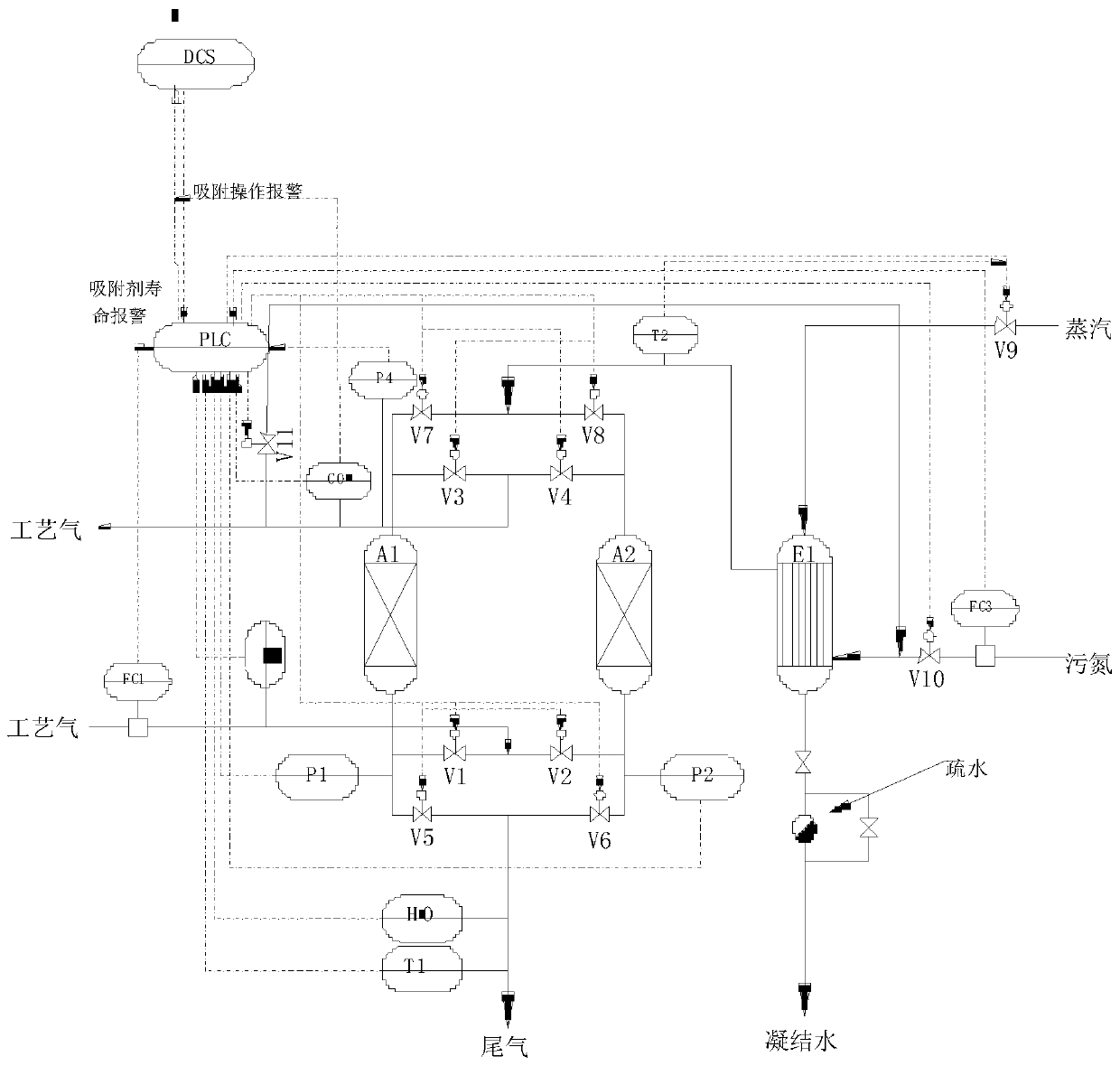

Air adsorption purification system in air separation device

ActiveCN109876594AReduce the number of control pointsReduce exchangeDispersed particle separationCO2 contentControl system

The invention provides an air adsorption purification system in an air separation device, and relates to the field of chemical engineering. The air adsorption purification system comprises a first adsorption tower, a second adsorption tower, a heat exchanger and a PLC control system, wherein the first adsorption tower and the second adsorption tower are connected in parallel; a CO2 detector is arranged at the outlet end of each of the first adsorption tower and the second adsorption tower; the inlet end of the heat exchanger is connected with waste nitrogen; the outlet end of the heat exchanger is connected in series with the first adsorption tower and the second adsorption tower; and the PLC control system controls the switching of the first adsorption tower and the second adsorption tower based on CO2 content data detected by the CO2 detector. Through the application of the PLC control system, the control points of access and output of the DCS system are reduced; the workload of DCSoperators is reduced; the mistake making probability of personnel is avoided; and the system reliability is improved.

Owner:GNSG ANHUI HONG SIFANG

A process for producing zinc sulfate monohydrate by utilizing waste acid and waste zinc slag

ActiveCN105274342BRealize comprehensive utilizationReduce manufacturing costProcess efficiency improvementIndiumEthyl Chloride

Owner:湖南鑫海环保科技有限公司

Process of extracting mannitol using glucose mother liquid

InactiveCN100540672CIncrease added valueReduce manufacturing costFermentationBlood disorderIsomerizationIsomerase

Owner:SHANDONG XIWANG SUGAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com