Circulation production process for alcohol with potatoes as main materials

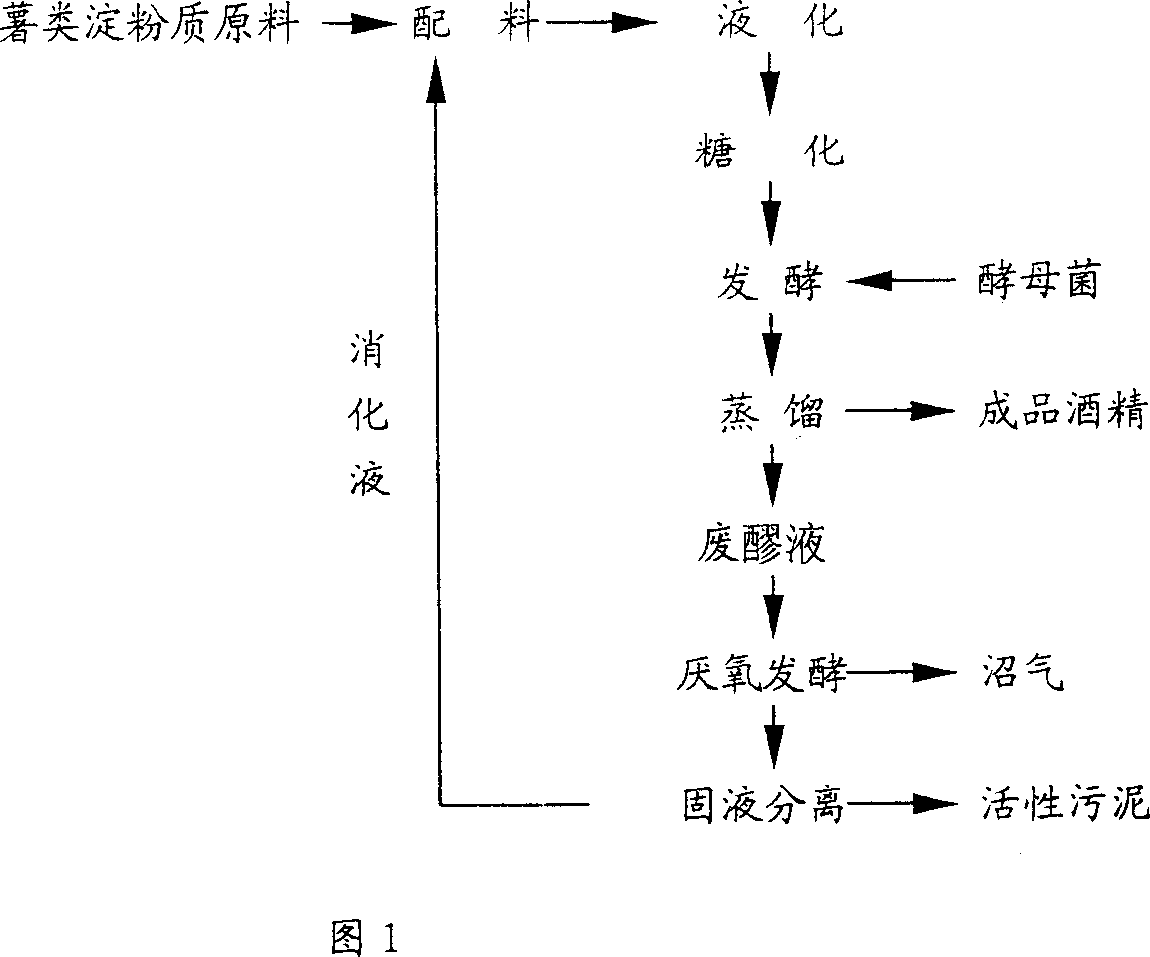

A production process and raw material technology, which is applied in the circular production process field of potato raw material alcohol production, can solve the problems of difficult and thorough wastewater treatment, non-adoption of industrial production scale, limited cycle batches, etc., and achieve the reduction of investment in fixed assets and good economic efficiency. Benefits, the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 260g of sweet potato powder, add 850ml of digestive solution of the previous batch and 150ml of tap water, add 0.13ml of high temperature resistant α-amylase with enzyme activity unit of 20000U / ml, stir evenly, heat, keep at 95℃ for 60 minutes and liquefy; then quickly cool to 62 ℃, add 0.26 ml of glucoamylase with enzyme activity unit of 100000U / ml, keep saccharification at 62°C for 1hr, after saccharification, cool to 30°C, insert 10% V / V expansion alcohol yeast (yeast inoculation amount), culture at constant temperature Fermentation is 64hr; the fermentation is over, the volume of mature fermentation broth is 1165ml, the alcohol concentration is 8.8% (v / v); 118ml of finished alcohol (95.2% v / v) is obtained by distillation, and the distillation waste liquid is 1050ml; the distillation waste liquid is cooled to 55℃ , Sent to the anaerobic fermentation tank, and then after two weeks of constant temperature anaerobic fermentation to produce biogas, COD in wastewater cr ...

Embodiment 2

[0021] 2100g of cassava flour, add 4500ml of the last batch of distillation waste liquid and 1000ml of tap water, add 1.4ml of high temperature resistant α-amylase with enzyme activity unit of 20000U / ml, stir well and heat, keep at 95°C for 50 minutes and liquefy; quickly cool down to 62°C , Add 2.6 ml of glucoamylase with an enzyme activity unit of 100000U / ml, keep the saccharification at 62°C for 1hr, cool to 30°C after the saccharification, connect to 8% V / V expansion alcohol yeast constant temperature culture fermentation, fermentation 68hr; fermentation end , The volume of mature fermentation broth is 6350ml, the alcohol concentration is 11.2%(v / v); the finished alcohol is 1030ml (95.3%v / v) and the distillation waste liquid is 5400ml, and the distillation waste liquid is cooled to 55℃ and sent to anaerobic fermentation. Anaerobic fermentation at a constant temperature in the tank for two weeks, the digestion solution is filtered to obtain 200g of activated sludge and 4500ml o...

Embodiment 3

[0023] 7800kg of cassava flour, add 29m of last batch of distillation waste liquid 3 And 5m 3 Tap water, add 5850 ml of high temperature resistant α-amylase with enzyme activity unit of 20000U / ml, stir well, heat, and liquefy at 95°C for 60 minutes; quickly cool to 62°C, add glucoamylase 11700 with enzyme activity unit of 100000U / ml Milliliters, saccharification at 62°C for 0.8hr. After saccharification, the temperature is reduced to 28°C, and 8% V / V expanded alcoholic yeast is connected for fermentation, and the fermentation is 66hr; after the fermentation, the volume of the mature fermentation broth is 35.5m 3 , The alcohol concentration is 10.3% (v / v); 3.1 tons of finished alcohol (95.2% v / v) are obtained through distillation, and the distillation waste liquid is 32.2m 3 After the sedimentation tank separates the mud and sand, it is sent to the anaerobic fermentation tank, the fermentation temperature is 55~60℃, and the biogas is collected and measured to get 1056m 3 (Pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com