Patents

Literature

56 results about "Alcohol industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The alcohol industry, also known by neo-prohibitionists as Big Alcohol, is the commercial industry involved in the manufacturing, distribution, and sale of alcoholic beverages. The industry has been criticised in the 1990s for deflecting attention away from the problems associated with alcohol use. The alcohol industry has also been criticised for being unhelpful in reducing the harm of alcohol.

Method for producing fuel alcohol through alkaline method preprocessing plant fibre

InactiveCN101182551ASolve the shortage problemLow costBiofuelsLiquid carbonaceous fuelsSocial benefitsAlcohol

The invention relates to a method for pretreating the plant fiber with alkaline process to produce the fuel alcohol; the raw material of plant fiber is crushed and pretreated by sodium hydroxide solution to make the wood fiber residues; and then the residues are synchronously fermented by cellulase, xylanase and enzymolysis; the fermentation liquor is extracted and purified to get the alcohol. The invention can fully utilize the gramineous plant fiber and convert the waste into precious one; in this way, the invention is characterized by wide raw material sources, low price and cost; moreover, the invention is fit for industrial mass production and can substitute the method of burning alcohol industrial food raw materials. Therefore, the invention has obvious economic and social benefit.

Owner:HENAN TIANGUAN GRP

Wine lees fiber paper pulp and paper made thereof

InactiveCN1844569ASave resourcesReduce manufacturing costNatural cellulose pulp/paperPulp beating methodsFiberSlurry

The invention relates to a lees fiber pulp and the method for producing paper with said pulp. Wherein, it uses the less generated by alcohol industry as raw material, via breaking, screening, braising, and washing, to produce the lees fiber pulp that containing the fibrin and hemicellulose; it can be mixed with the slurries made from wood, bamboo, straw, or recycled waste paper, into mixed pulp, to be fed to paper maker to produce paper; or it can only use the less as raw material to produce less fiber pulp, to be diluted and mixed with water to be fed to paper maker to produce paper. The invention enlarges the raw material resource of paper industry, reduce the producing cost of paper, and solve the problem of environment pollution.

Owner:肖剑鸣

Compound enzyme for producing reducing sugar by degrading maize straws

InactiveCN101532004AHigh industrial application valueHigh glucoseHydrolasesFermentationPectinaseHigh energy

The invention provides a compound enzyme for producing reducing sugar by degrading maize straws. The compound enzyme is prepared from pectase, cellulose, hemicellulase, ligninolytic enzyme, amylase, prolease, lipase and chitosanase. Compared with the prior art, 1) the yield of the reducing sugar by degrading the maize straws has high yield, and the gross amount of the reducing sugar of straws per gram reaches over 480 mg, so the compound enzyme has wide application prospect in the fuel alcohol industry; 2) compared with sugar preparation by acid process, severe acid pollution is prevented to facilitate subsequent fermentation; and 3) compared with monomer cellulose or simple compound enzyme, the pretreatment of steam explosion with high energy consumption is not required, and the amount of the reducing sugar is increased by over 1 time; meanwhile, glucose and xylose in a degradation product have high content, side products are few so as to contribute to subsequent fermentation, the industrial application value of the maize straws is improved, and the compound enzyme can be applied to production of single cell protein and fuel alcohol.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

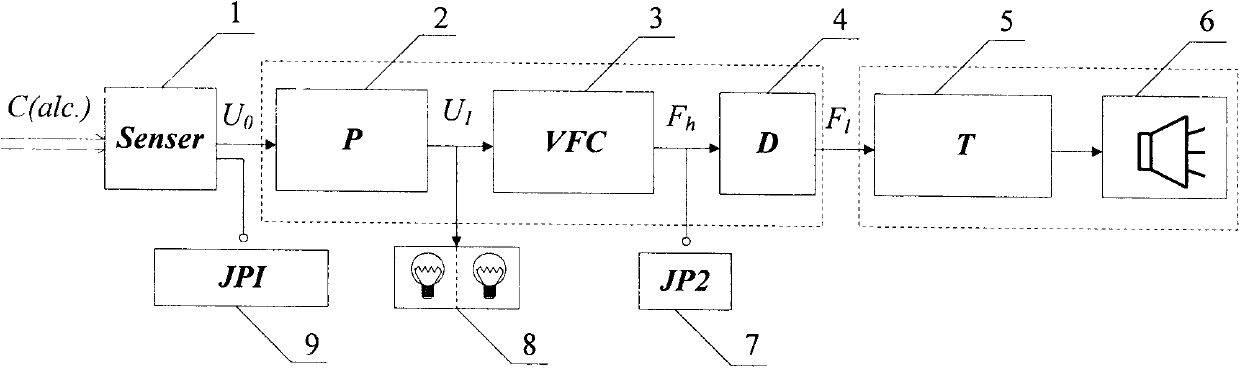

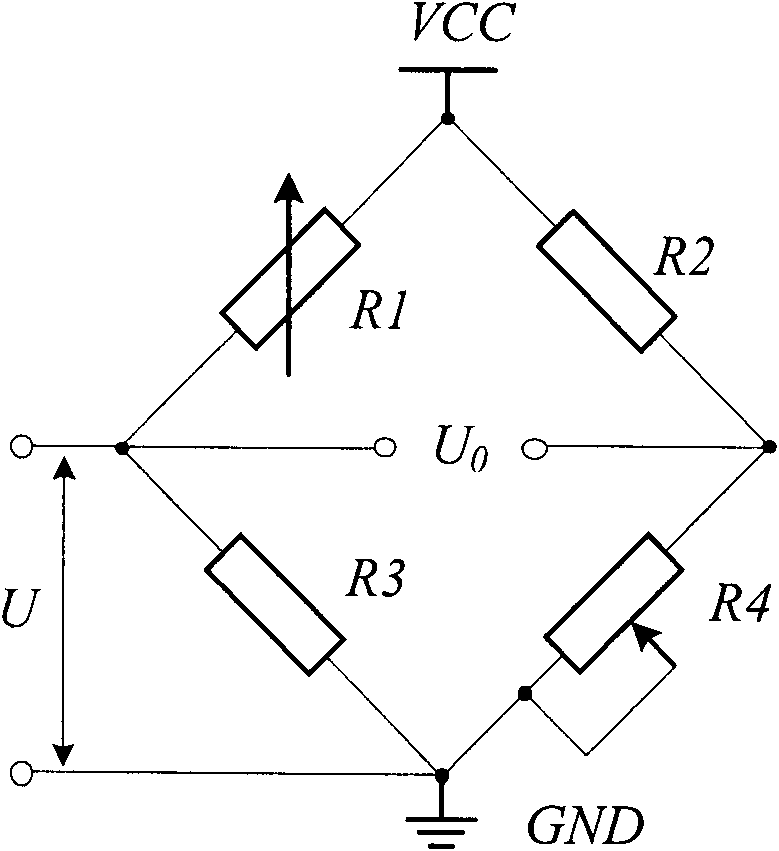

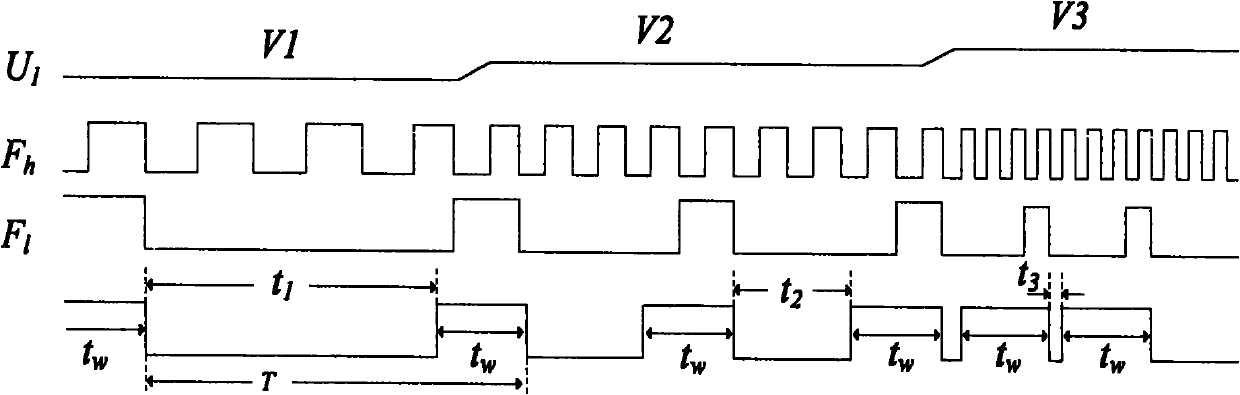

Alcohol detection alarm device

InactiveCN102004122ARealize non-human interventionMaterial analysis by electric/magnetic meansAlcohol contentEngineering

The invention discloses an alcohol detection alarm device which is used for detecting alcohol content in air or breath of a drunk driver and giving an alarm, and the alarm frequency of the alcohol detection alarm device varies with the change of the detected alcohol concentration. The alcohol detection alarm device comprises a sensor detection circuit, a signal conversion circuit and an alarm circuit, wherein the signal conversion circuit converts a voltage signal into a frequency signal so that the alarm frequency can increase with the rise of the alcohol concentration. When the detected alcohol concentration is low, an alarm sound is a prompt tone for prompting the drunk driver; and when the detected alcohol concentration is high, the alarm circuit alarms frequently, and the alarm sound becomes noise to agitate the drunk driver to force the drunk driver to give up driving. Meanwhile, the alcohol detection alarm device has the functions of directly detecting the alcohol concentration in breath and outputting an alcohol concentration signal in an external access way, is mainly applied to vehicle-mounted alcohol detection and an alcohol industry field, and can be used as portable alcohol detection equipment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

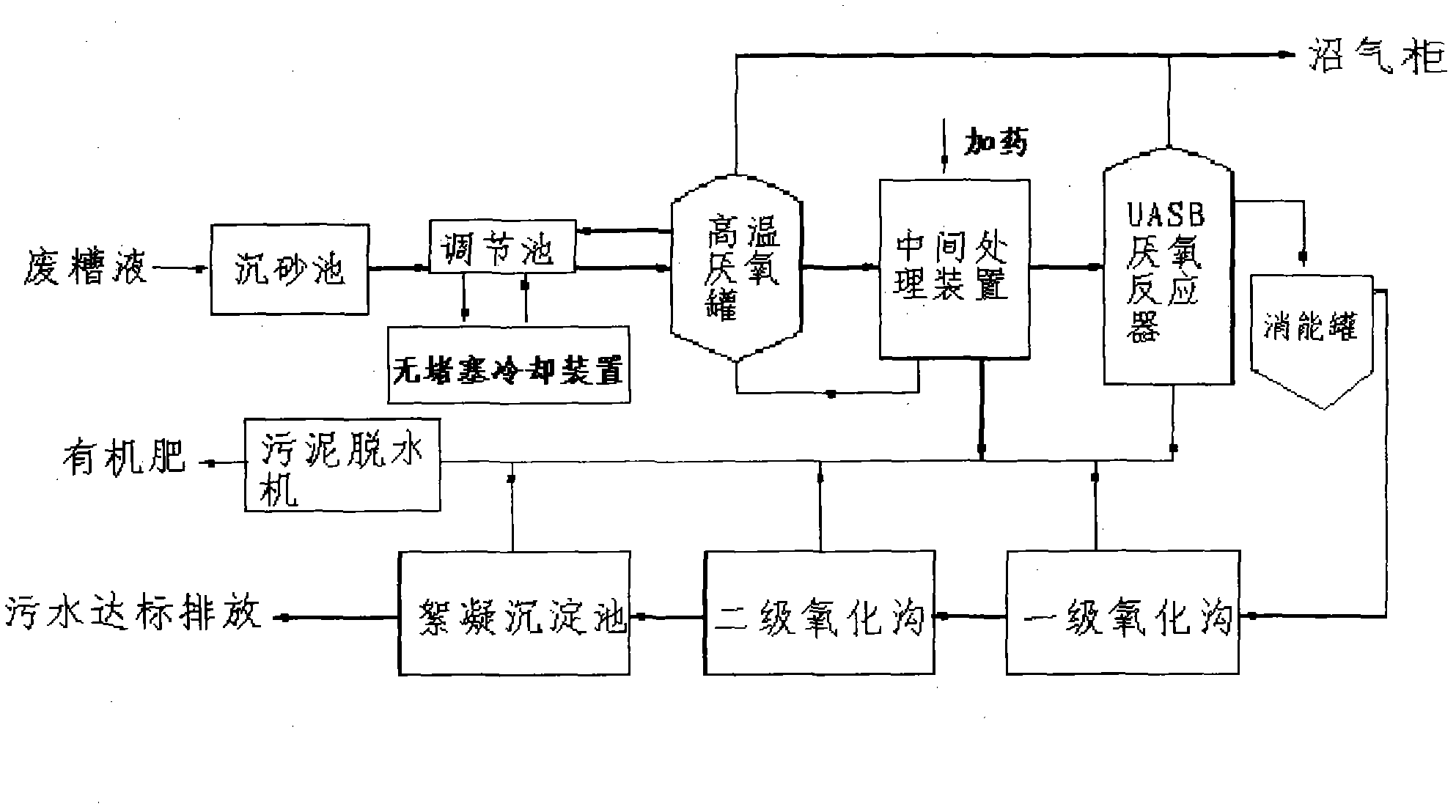

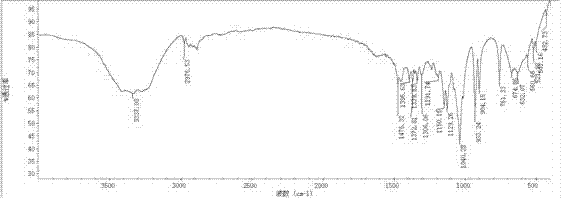

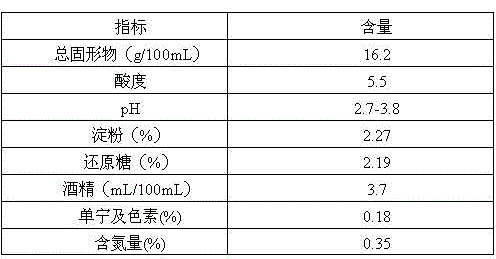

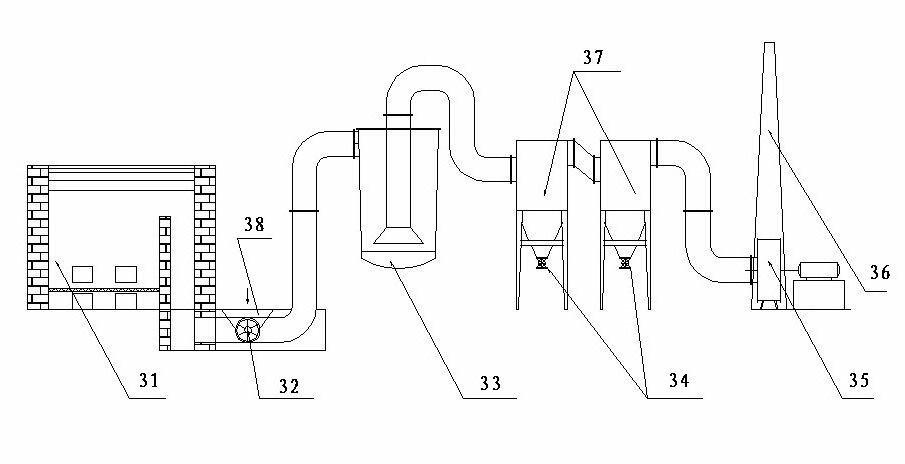

Treatment method of potato type non-grain starch fuel ethanol distiller solution

InactiveCN102107989AReduce potential energyGuaranteed concentrationSludge treatment by de-watering/drying/thickeningBio-organic fraction processingSerial sectionAnaerobic reactor

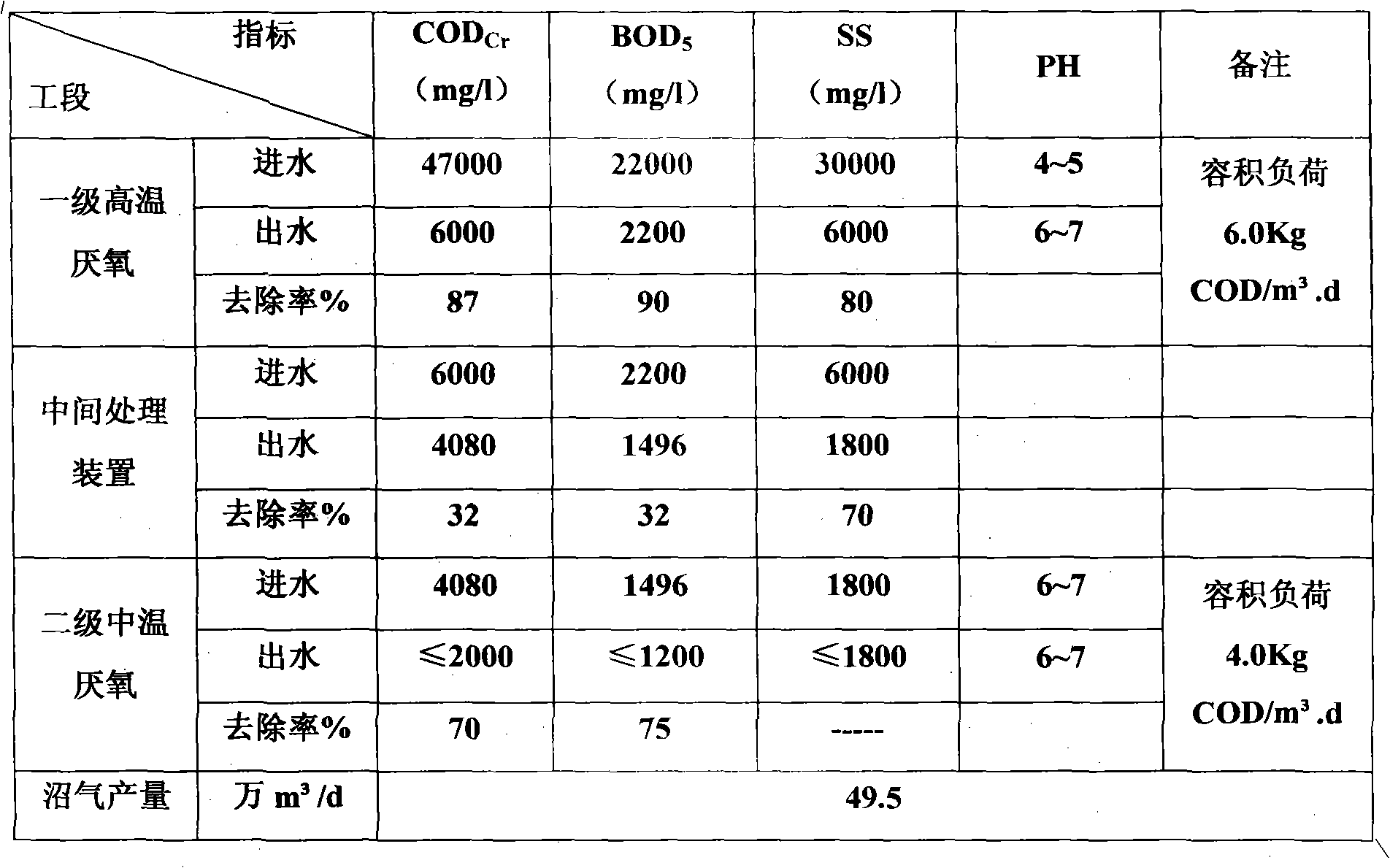

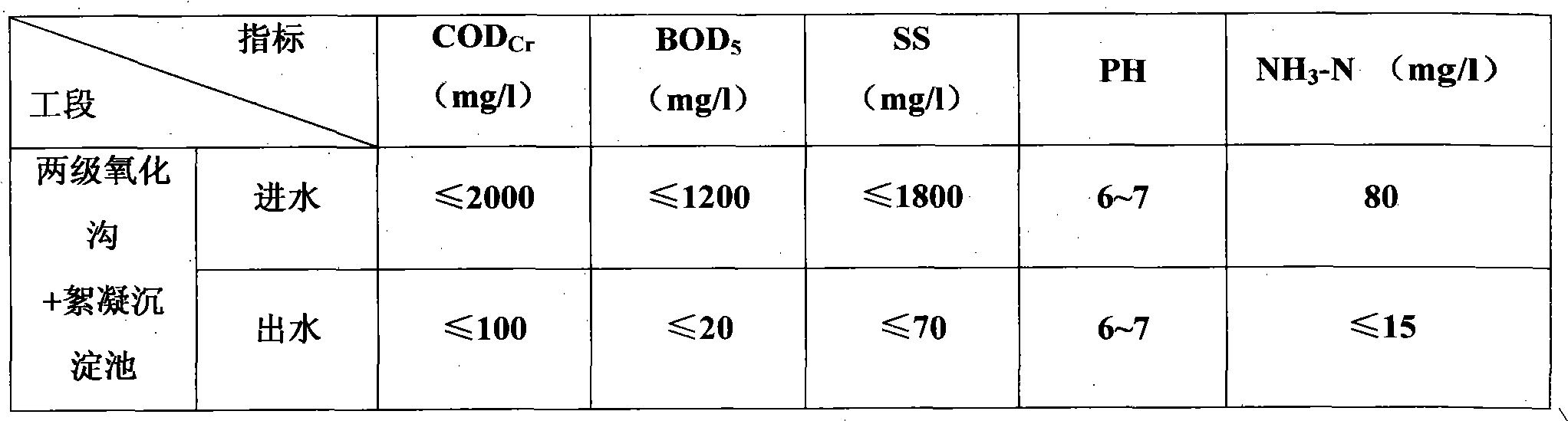

The invention relates to a treatment method of potato type non-grain starch fuel ethanol distiller solution. The method comprises the following steps: waste distiller solution is pretreated simply and adjusted by an adjusting tank and then enters an anaerobic treatment system, wherein the first-stage anaerobic treatment adopts well mixed high temperature anaerobic fermentation and the second-stage anaerobic treatment adopts a medium temperature UASB anaerobic reactor; different microorganisms are utilized to degrade the organic pollutants in the wastewater and generate biogas; a cooling device, a setting tank and an air flotation device are arranged between the two anaerobic reactors to ensure the concentration of the well mixed high temperature anaerobic sludge; the two-stage anaerobic effluent enter two serial sections of oxidation ditches to further remove the organic matter; different denitrification technologies are selected according to ammonia nitrogen indexes to obtain stable denitrification effect; and finally flocculation precipitation and physicochemical treatment are performed, and the obtained water meets the standards and is discharged. The method of the invention has low cost, stable technology and high biogas extraction efficiency of wastewater; and the obtained sludge is used as organic fertilizer and the effluent meet the grade A standard of the integrated wastewater discharge standard (GB8978-1996) for the alcohol industry.

Owner:ZHONGJU TIANGUAN BIOLOGICAL ENERGY

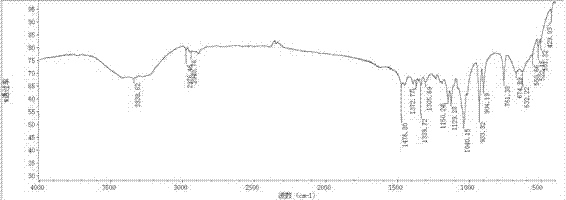

Preparation method of fermentation state zinc feed additive

ActiveCN104543400AReduce manufacturing costImprove resource utilizationBacteriaAnimal feeding stuffChemical synthesisResource utilization

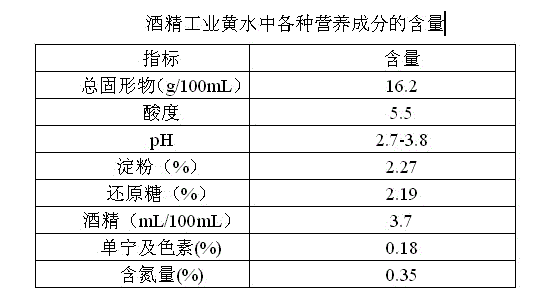

The invention provides a preparation method of a fermentation state zinc feed additive. The preparation method comprises the following steps: firstly preparing a fermentation substrate by taking alcohol industry yellow water, bran, powder dregs, corn flour and other industrial and agricultural side products as raw materials, then performing microbiological screening and acclimatization and culture to obtain zinc-rich microorganism, inoculating to the prepared fermentation substrate and fermenting, and drying, grinding and packaging the fermented materials to obtain the fermentation state zinc feed additive. Compared with the chemically synthesized zinc feed additive, the fermentation state zinc feed additive adopts the powder dregs, bran, alcohol industry yellow water and other side products as culture raw materials and substrates, so that the resource utilization is increased, the production cost of the zinc feed additive is lowered, and the prepared fermentation state zinc feed additive is more stable in bioavailability and higher in absorption rate, and the zinc absorption rate is 30%-42% which is 2.3-3.3 times that of anhydrous zinc sulfate, and 2.1-3.0 times that of zinc-amino acid chelate.

Owner:河南岐伯实业有限公司

Catalyst for synthesizing methanol and preparation thereof

ActiveCN101322940AIncrease productivityIncrease the areaOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlcoholPromotion effect

The invention relates to a catalyst used for methanol synthesis and a preparation method thereof which belong to the field of chemical catalysts and the preparation thereof. The catalyst used for methanol synthesis is a CuO / ZnO / Al2O3 catalyst that is added with Si element and used for methanol synthesis, the catalyst consists of CuO with the mass percentage of 60 to 70 percent, ZnO with the mass percentage of 21 to 30 percent, Al2O3 with the mass percentage of 4 to 10 percent and SiO2 with the mass percentage of 1 to 3 percent. Compared with congeneric catalysts, the specific surface area and pore volume of the catalyst increase by 10 to 20 percent after being added with the Si element; reaction activity is obviously improved more than 10 percent; the catalyst has great promotion effect on the technological progress of methyl alcohol industry. By using the catalyst, as for production devices with the same scale, the usage of catalyst is correspondingly reduced; due to high conversion rate, the recycle ratio is lowered and energy consumption is saved, thus being capable of greatly improving the production efficiency of methyl alcohol.

Owner:大连瑞克科技股份有限公司

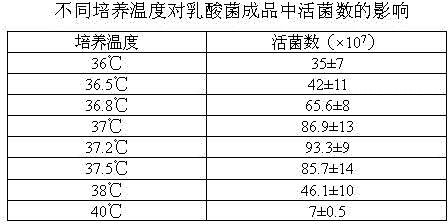

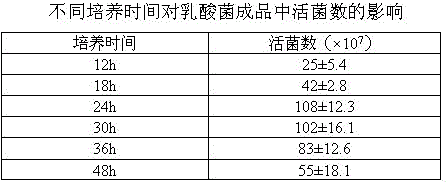

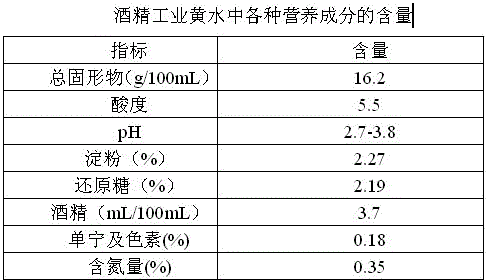

Method for production of lactic acid bacteria by utilizing ethanol industrial yellow water

InactiveCN104004675AReduce manufacturing costExpand sourceBacteriaMicroorganism based processesEcological environmentAcetic acid bacteria

A method for production of lactic acid bacteria by utilizing ethanol industrial yellow water includes collection and treatment of the ethanol industrial yellow water, cultivation of the lactic acid bacteria in the ethanol industrial yellow water, and receiving and preparation of the lactic acid bacteria. The method for production of the lactic acid bacteria by utilizing the ethanol industrial yellow water not only can make full use of the ethanol industrial yellow water, reduce the treatment cost of the yellow water, optimize comprehensive utilization of the yellow water and improve the ecological environment, but also can expand sources of a nutrition substrate in a conventional lactic acid bacteria production, lower the production costs and expand the application scope of lactic acid bacteria.

Owner:HENAN UNIV OF SCI & TECH

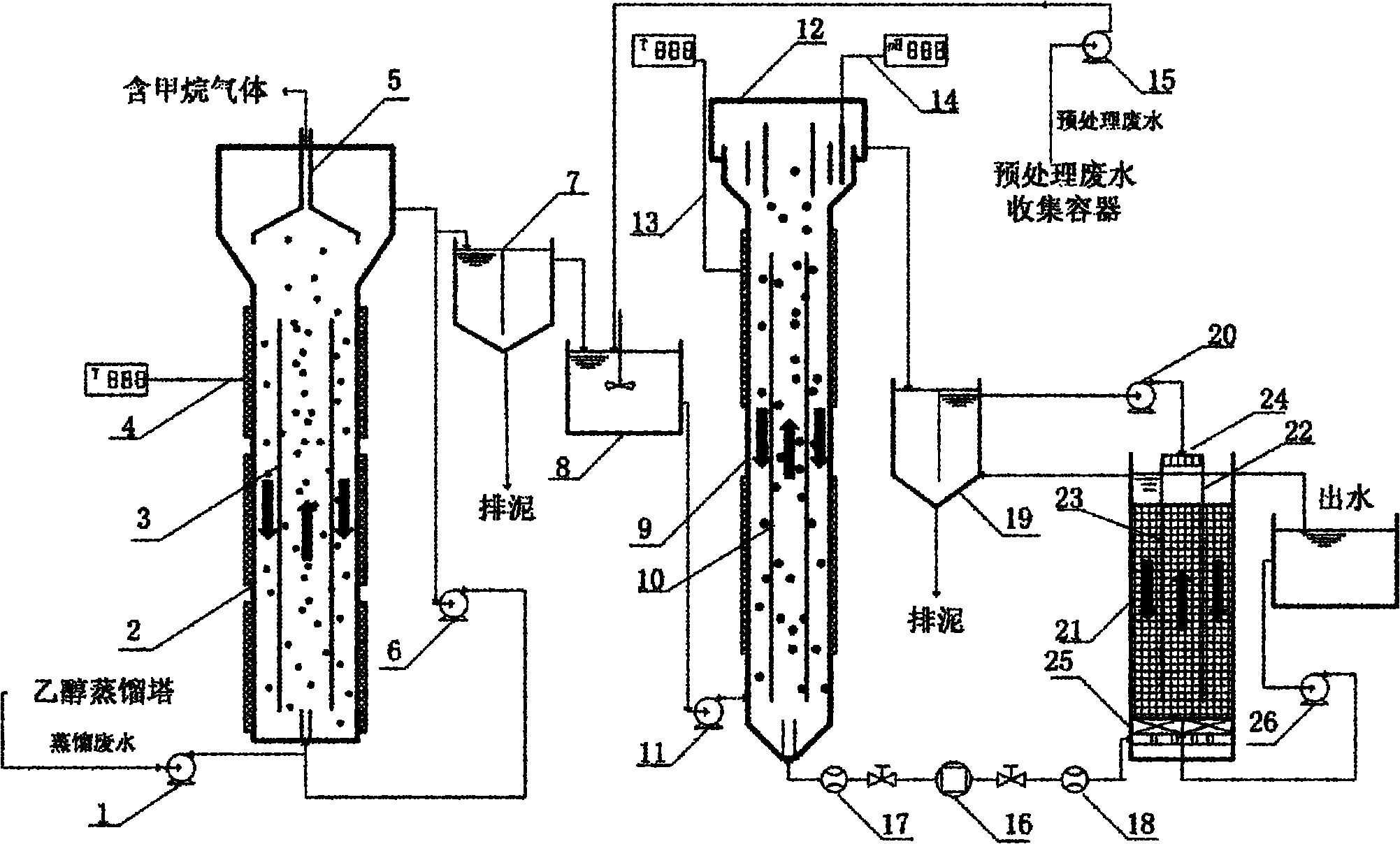

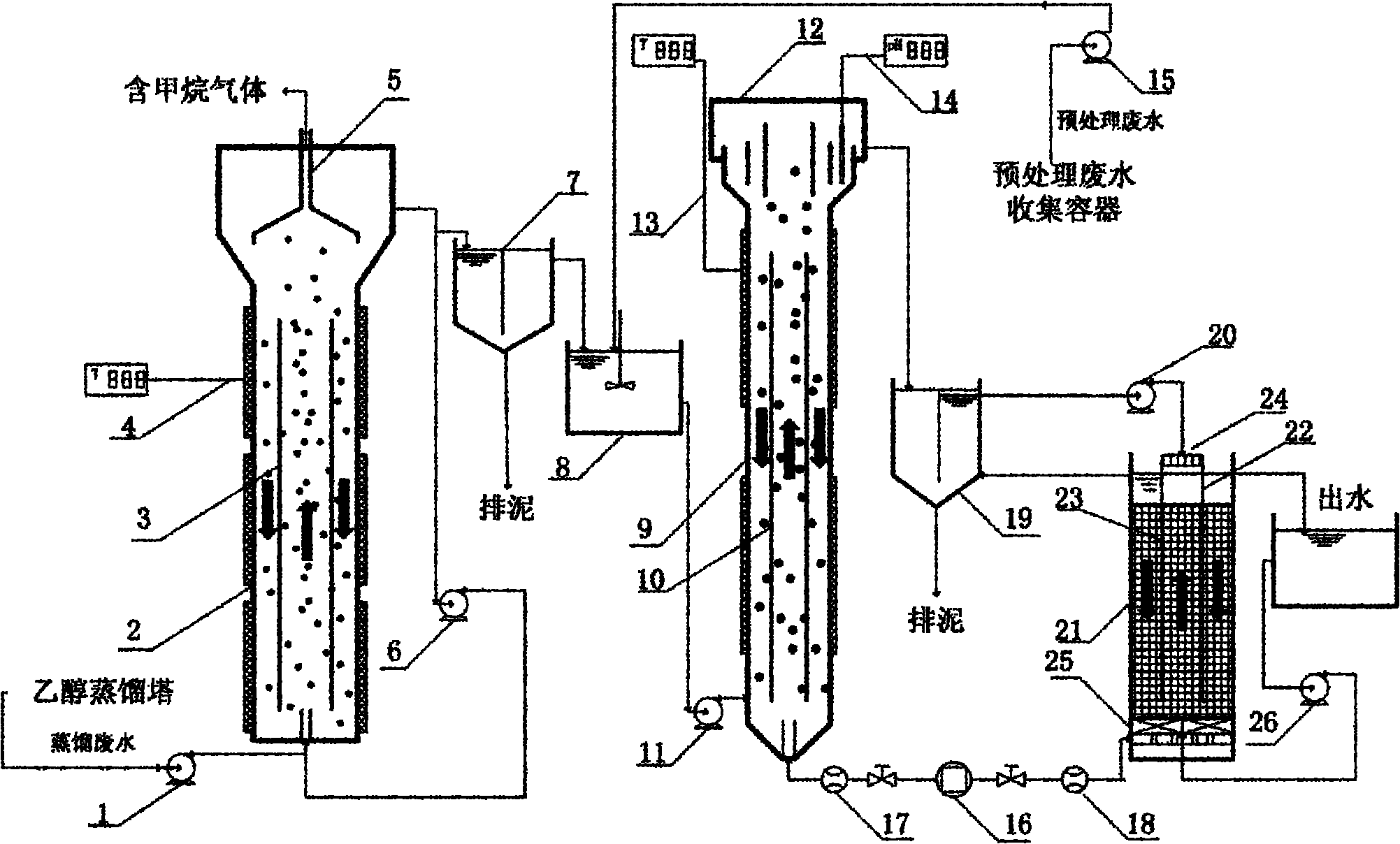

Integrated treating device and method of fuel ethanol distillation wastewater of corn straw and high ammonia nitrogen pretreatment wastewater

InactiveCN101985381AGood removal effectIncreased degradation rateTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationDistillation

Owner:TIANJIN UNIV

Method for extracting xylose by strong-flavor solid white wine vinasse

ActiveCN103088166AImprove use valueHigh puritySugar derivativesSugar derivatives preparationCelluloseLees

The invention relates to a method for extracting xylose by strong-flavor solid white wine vinasse. The method comprises the steps of pretreatment of vinasse, hydrolyzation of vinasse, trash purification of hydrolysate, concentration of acid hydrolysis solution, and xylose crystallization. The method is characterized by comprising the steps of controlling the temperature at 120 DEG C after removing part of the impurities by pretreatment of the vinasse; extracting the xylose by 2% of dilute sulphuric acid; neutralizing extracting solution by CaCO3, decoloring active carbon, removing impurities of the acid hydrolysis solution via 732# cation exchange resin and D301 anion exchange resin orderly; removing impurities by yeast fermentation, and finally concentrating and crystallizing to obtain the xylose crystal. Waste vinasse in the white alcohol industry is taken as a material to extract the xylose; the extraction rate of the xylose is high and achieves over 8% (relatively to dry basis of the vinasse); the utilization value of the vinasse is improved; and the method has a great significance on the development of comprehensive utilization of the vinasse and other cellulose wastes in our country, and has good popularization and application prospects.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Preparation method of selenium yeast feed additive

ActiveCN104543399AReduce manufacturing costImprove resource utilizationAnimal feeding stuffResource utilizationCorn flour

The invention relates to a preparation method of a selenium yeast feed additive. The preparation method comprises the following steps: firstly preparing a fermentation substrate by taking alcohol industry yellow water, bran, rice bran, corn flour and other industrial and agricultural side products as raw materials, then performing yeast screening and acclimatization and culture to obtain selenium-rich yeast, inoculating to the prepared fermentation substrate and fermenting, and drying, grinding and packaging the fermented materials to obtain the selenium yeast feed additive. Compared with the chemically synthesized selenium yeast feed additive, the selenium yeast feed additive adopts the rice bran, bran, alcohol industry yellow water and other industrial and agricultural side products as culture raw materials and substrates, so that the resource utilization is increased, the waste and environment pollution can be decreased, and the production cost of the selenium yeast feed additive is lowered.

Owner:河南岐伯实业有限公司

Preparation method of fermentation state copper feed additive

ActiveCN104543398AReduce manufacturing costImprove resource utilizationAnimal feeding stuffChemical synthesisMicroorganism

The invention provides a preparation method of a fermentation state copper feed additive. The preparation method comprises the following steps: firstly preparing a fermentation substrate by taking alcohol industry yellow water, bran, powder dregs, corn flour and other industrial and agricultural side products as raw materials, then performing microbiological screening and acclimatization and culture to obtain copper-rich microorganism, inoculating to the prepared fermentation substrate and fermenting, and drying, grinding and packaging the fermented materials to obtain the fermentation state copper feed additive. Compared with the chemically synthesized copper feed additive, the fermentation state copper feed additive adopts the powder dregs, bran, alcohol industry yellow water and other side products as culture raw materials and substrates, so that the resource utilization is increased, the production cost of the copper feed additive is lowered, and the prepared fermentation state copper feed additive is more stable in bioavailability and higher in absorption rate, and the copper absorption rate is 19.2% or higher which is three times that of anhydrous copper sulfate.

Owner:河南岐伯实业有限公司

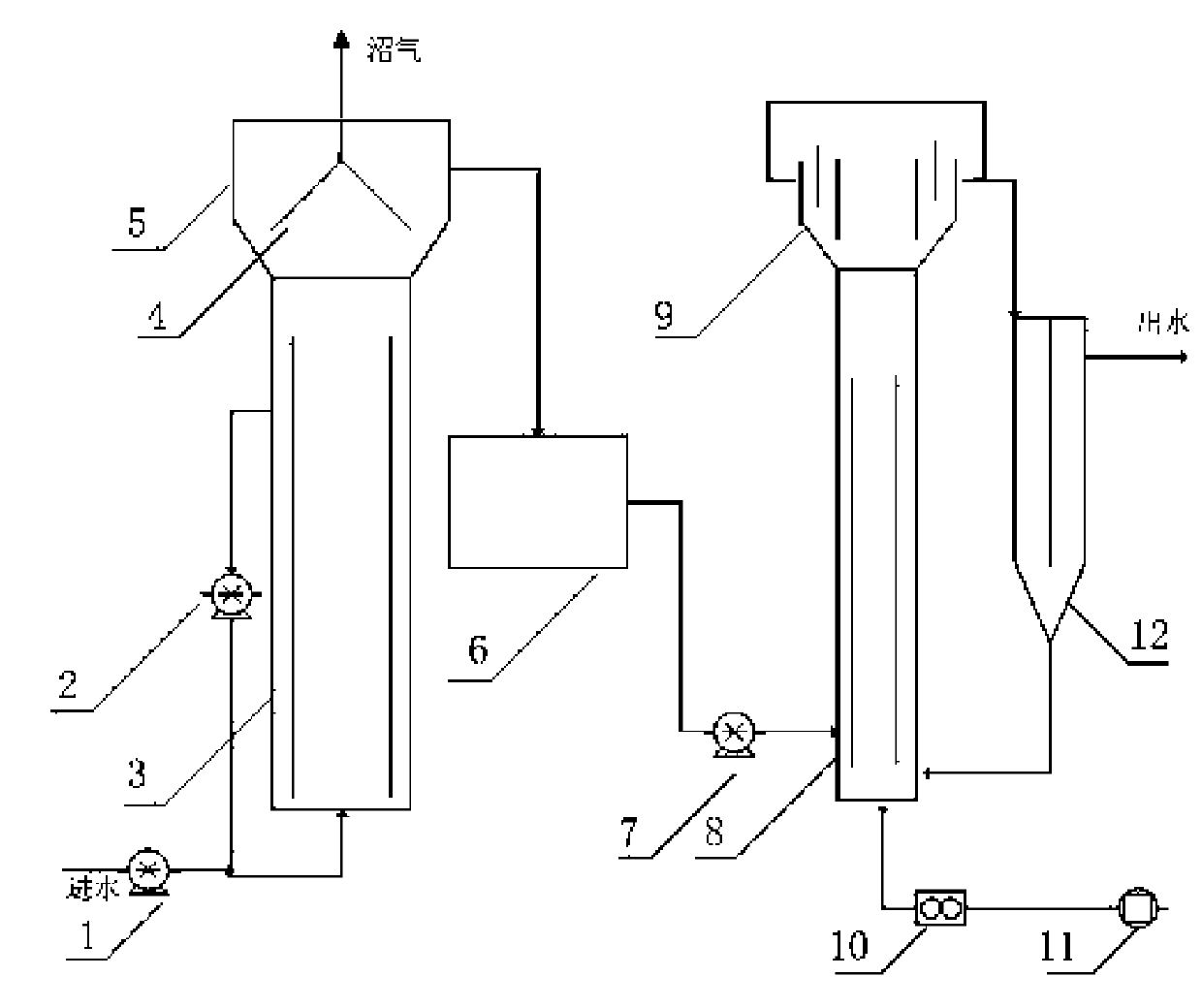

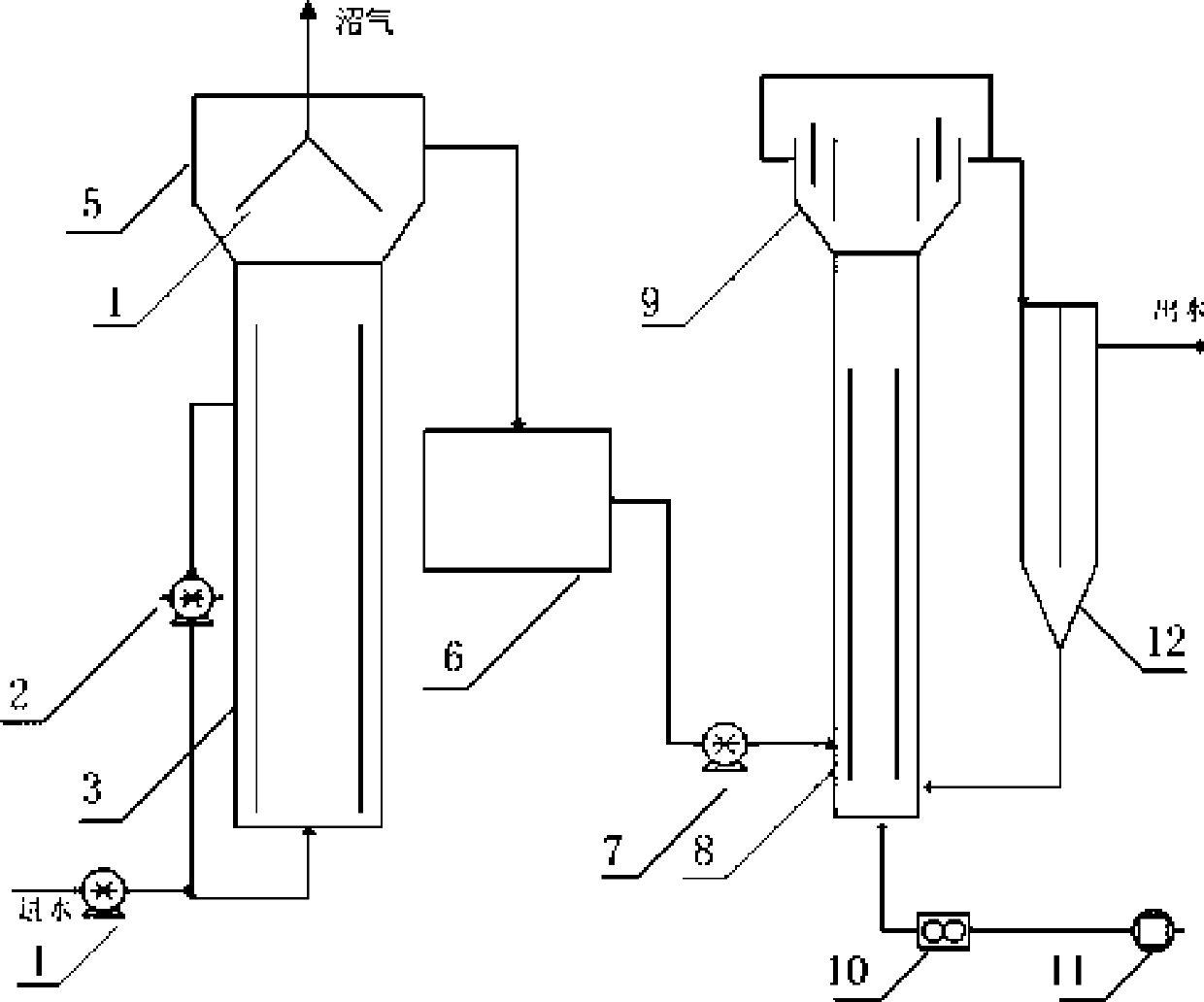

Coupling treatment device and coupling treatment method for sweet sorghum fuel ethanol wastewater circumfluence bioreactor

InactiveCN101767907AImprove mass transfer effectPrevent washout lossTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeTreatment effect

The invention relates to a coupling treatment device and a coupling treatment method for a sweet sorghum fuel ethanol wastewater circumfluence bioreactor. The device comprises a feed pump, a reflux pump, an anaerobic inner circumfluence bioreactor, a sedimentation separation zone, a three-phase separator, an intermediate regulating tank, an aerobic feed pump, an air lift type circumfluence reactor, a solid-liquid separation zone, a precipitator, an air compressor and an air flowmeter, wherein the anaerobic inner circumfluence bioreactor is provided with a cylindrical shell; a cylindrical draft tube and the three-phase separator are arranged in the cylindrical shell; the air lift type circumfluence reactor is provided with a cylindrical shell; a cylindrical draft tube is arranged in the shell; the top part of the shell is provided with the solid-liquid separation zone; and the precipitator is arranged outside the shell. An activated carbon carrier is used to fix high-temperature anaerobic activated sludge and aerobic activated sludge to form a biomembrane for biological treatment of sweet sorghum fuel ethanol wastewater; a coupling system has simple and compact structure, good treatment effect and low energy consumption, and can degrade the sweet sorghum fuel ethanol wastewater without any pretreatment; and after the wastewater is treated by the coupling system, main indexes of the wastewater reach Grade-I wastewater emission standard of national alcohol industry.

Owner:TIANJIN UNIV

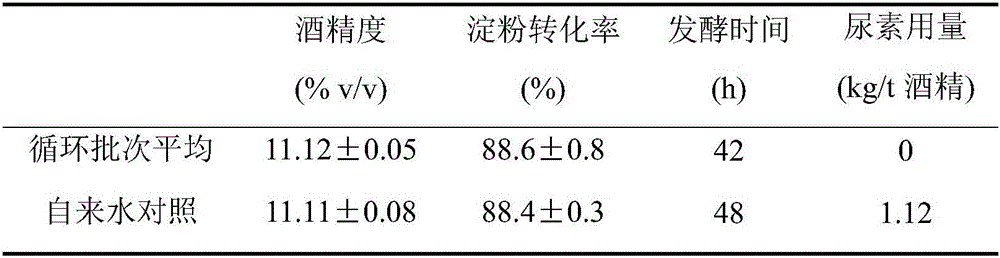

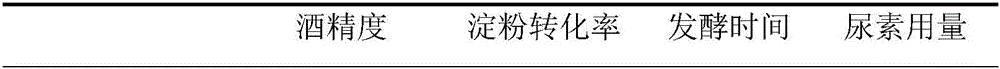

Method for partially recycling anaerobic digestion solution to serve as mixing water for alcohol production

InactiveCN106755128AReduce loadSmall footprintBiofuelsWaste based fuelReclaimed waterAlcohol production

The invention discloses a method for partially recycling anaerobic digestion solution to serve as mixing water for alcohol production, and belongs to the field of alcoholic fermentation and comprehensive utilization of alcohol production wastewater. By partially recycling anaerobic digestion solution for alcoholic fermentation, the load of the aerobic digestion stage is reduced, the accumulation degree of ammonia nitrogen in reclaimed water is also reduced greatly, and anaerobic digestion solution can be recycled without being deaminized, so that equipment investment and operation cost for deaminization of anaerobic digestion solution are saved.

Owner:JIANGNAN UNIV

Method for constructing yeast strain by protoplast fusion using heat-inactivated parents

InactiveCN101886069ASimple methodSimple processHybrid cell preparationBiotechnologyPigment accumulation

The invention discloses a method for constructing a yeast strain by protoplast fusion using heat-inactivated parents, belonging to the strain preparation biotechnical field. In the method, by utilizing the species difference between chromogenic yeast and liquor-making yeast, a parents-protoplast fuses and regenerates to obtain chromogenic and liquor-making fusion sub-strain from different parents by protoplast fusion using the heat-inactivated parents. The method comprises the following process steps: preparing two parent thalli and two parent protoplasts, fusing the two parent protoplasts; and detecting and selecting a fusant, and testing the fermenting property of the fusant and re-screening. The method of the invention has simple operation, easy realization of process and high breeding success rate; and the obtained yeast fusion strain has positive significance for theoretically studying metabolic control during the alcoholic fermentation and pigment accumulation processes and improving the management control efficiency of alcoholic fermentation production and provides a new way for strain breeding in alcohol industry and pigment production.

Owner:SICHUAN UNIV

Yeast food

The invention provides a yeast food, which can provide yeasts with nutrients for fermentation. The yeast food comprises the following components by weigh portion: 40 to 75 portions of nitrogen source, 15 to 25 portions of phosphor source, 8 to 15 portions of other inorganic salts and 2 to 5 portions of minor vitamins. The yeast food can prolong the stable growth period of yeasts and can be added into fermented liquor deficient in nutrients to promote the quick growth and active fermentation of the yeasts. The yeast food is an indispensible novel accessory for wine industry and alcohol industry.

Owner:ANGELYEAST CO LTD

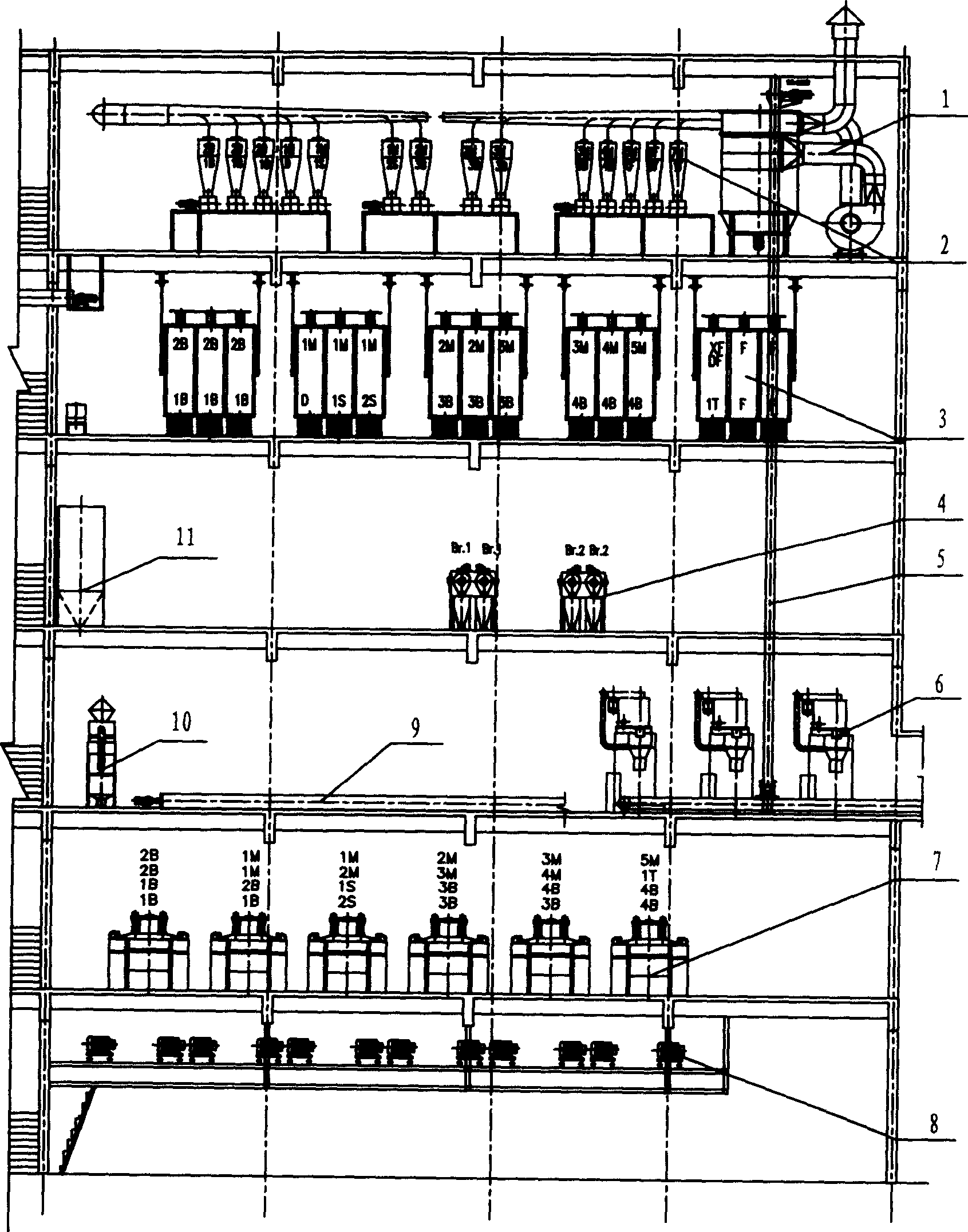

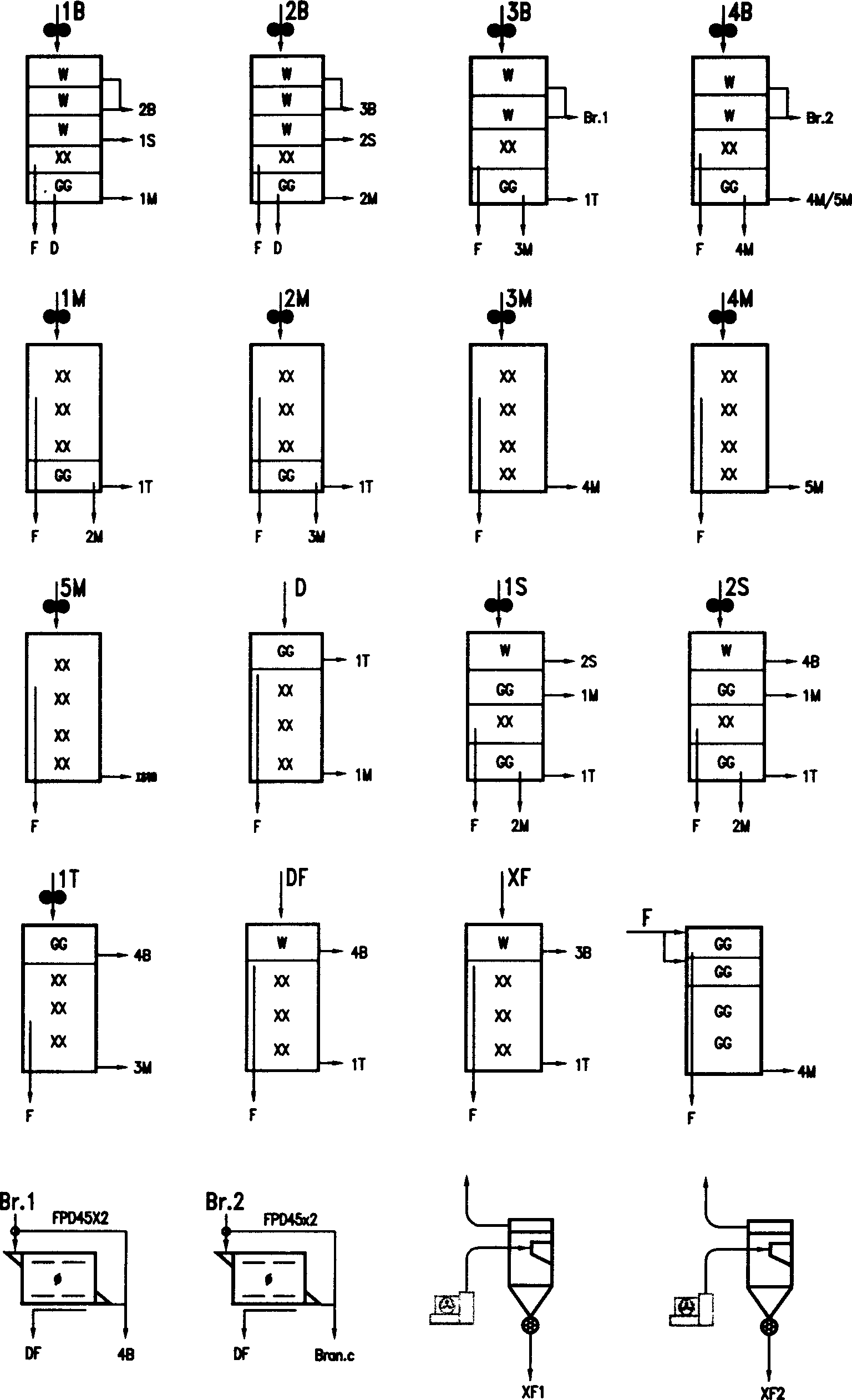

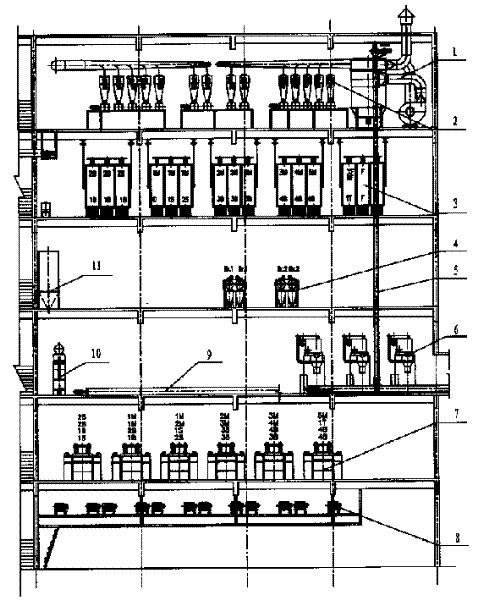

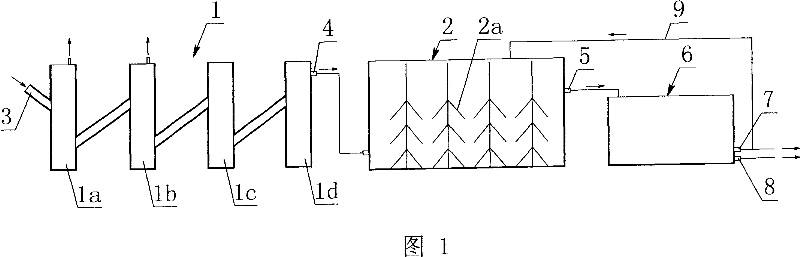

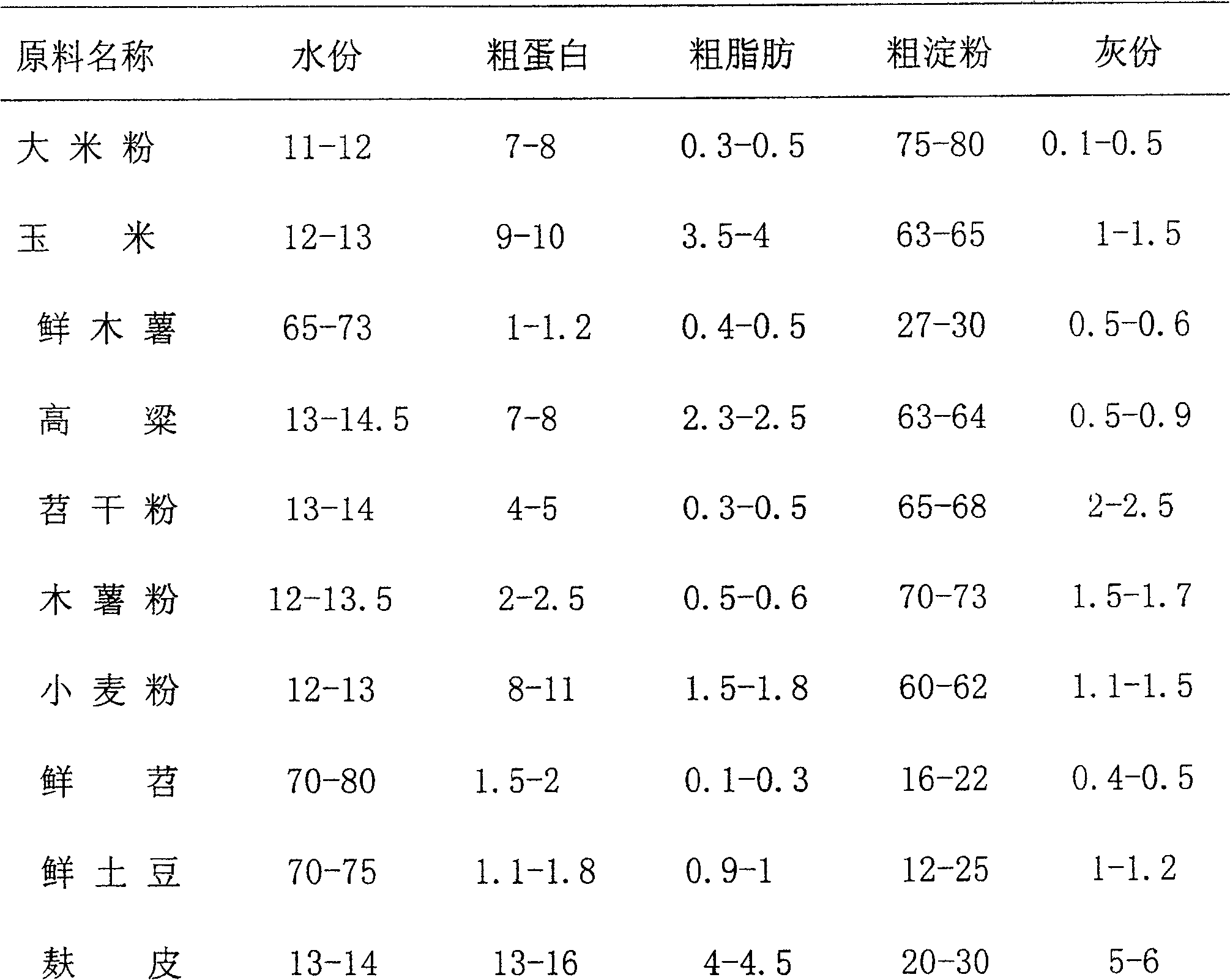

Wheat flour processing technology for starch alcohol industry and production device

InactiveCN1533839ACoarse granularityLess number of grinding passesGrain treatmentsAlcoholEngineering

A technology and apparatus for processing the wheat flour used in starch and alcohol industries are disclosed. Said apparatus is composed of a peel grinding system, a core grinding system, a dreg grinding system and a final grinding system. Said technology features that the peel is ground 4 passes, the core is gound 4-5 passes, the dreg is ground 1-2 passes, final grinding is one pass, and the bran is processed by 1-2 passes. Its advantages are simple structure and method, high output rate up to 77%, and low cost.

Owner:郑州金谷实业有限公司

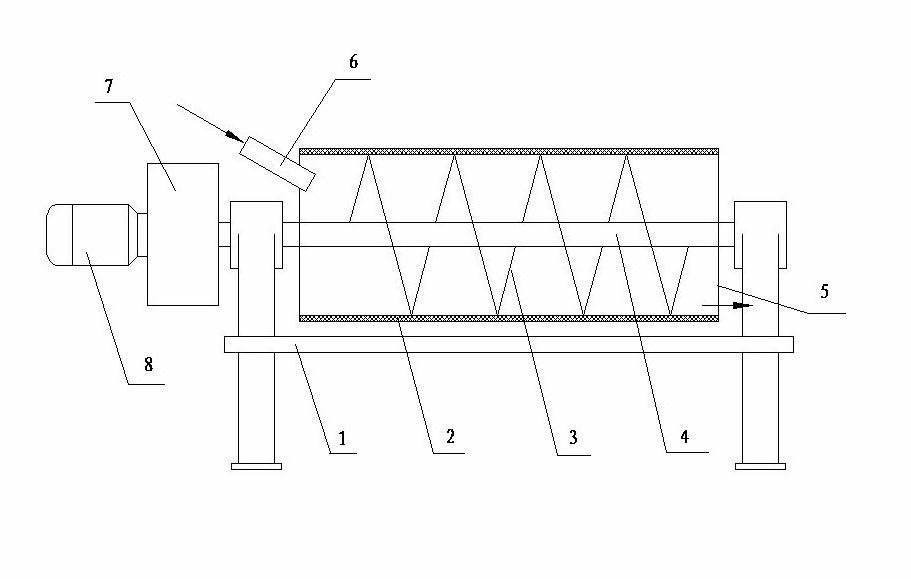

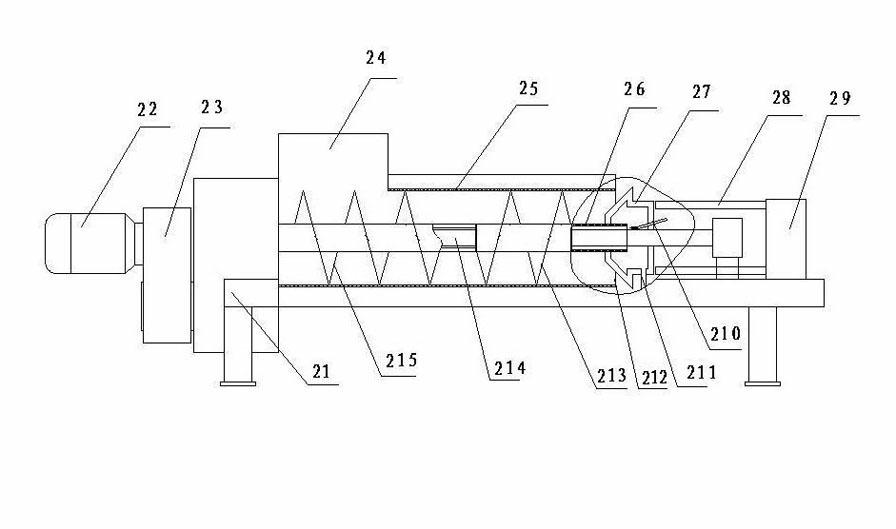

Alcohol vinasse waste slag treatment system and treatment method

ActiveCN102430563AEnable recyclingReasonable designSievingDrying solid materials with heatFiberSystems design

The invention relates to an alcohol vinasse waste slag treatment system, which is characterized by consisting of a grading separation machine, a spiral presser, a baking device and a forming machine. The invention also discloses a method for carrying out alcohol vinasse waste slag treatment by using the alcohol vinasse waste slag treatment system. The system has the advantages that the design is reasonable, the treatment effect is good, the efficiency is high, the separation, the dewatering, the drying and the granulation treatment can be realized on cassava alcohol vinasse waste slag liquid with the water content higher than 99 percent, cassava fiber particles are prepared, and the recovery and reutilization of the cassava fiber is realized. The system and the method realize the goals ofboth coal firing and waste slag and marsh gas firing in alcohol industry, the boiler number in the alcohol enterprises under the conventional arrangement conditions is reduced, and the single boiler creates the conditions for the combined heat and power generation selection boiler parameter and system efficiency improvement. The grading separation technology, the grading dewatering technology andthe forming firing technology are adopted, the enterprise system integral utilization benefits are realized, and the enterprises are effectively promoted for realizing the economic transformation by technical progress.

Owner:张华民 +1

Preparation method of fermentation-state iron feed additive

ActiveCN104543402AReduce manufacturing costImprove resource utilizationBacteriaMicroorganism based processesChemical synthesisResource utilization

The invention discloses a preparation method of a fermentation-state iron feed additive. The method comprises the following steps: firstly, by adopting industrial and agricultural by-products such as alcohol industry yellow water, bran and powder dregs as raw materials, preparing a fermentation medium; carrying out microbiological screening and domesticated incubation to obtain iron-rich microorganisms, and inoculating the microorganisms into the obtained fermentation medium and fermenting; and drying, crushing and packaging the fermented material to prepare the product. Compared with chemical synthesized iron feed additives, the fermentation-state iron feed additive has the advantages that the by-products such as powder dregs, bran and alcohol industry yellow water are adopted as culture raw materials and mediums, so that resource utilization is expanded; the production cost of the iron feed additive is reduced; the prepared fermentation state iron feed additive is relatively stable in bio-availability, and relatively high in absorptivity; and the iron absorptivity is greater than 24.7%, is 5.7 times that of ferrous sulfate monohydrate, and is 1.8 times that of iron amino acid chelate.

Owner:河南岐伯实业有限公司

Production method of fiber-containing rumination fermented feed

InactiveCN111345395AImprove digestibilityHelps destroy the crystal structureFood processingAnimal feeding stuffCelluloseFiber

Owner:COFCO NUTRITION & HEALTH RES INST +1

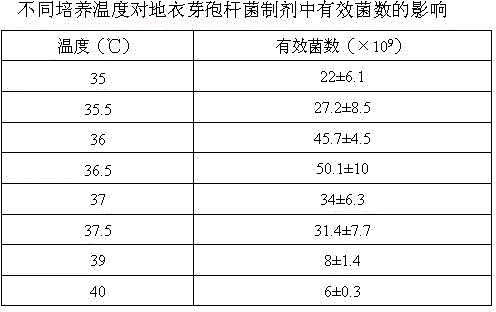

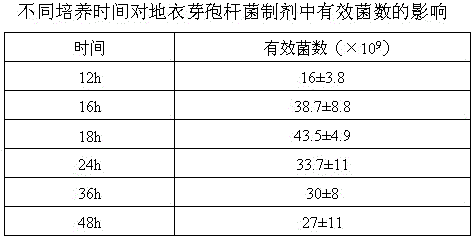

Method for fermenting and producing microbial agent by utilizing cassava alcohol residues

InactiveCN102942393AReduce energy consumptionLow costBio-organic fraction processingOrganic fertilisersMicrobial agentResource utilization

The invention discloses a method for fermenting and producing a microbial agent by utilizing cassava alcohol residues, belonging to the technical field of microbial agent production, so that the high-quality microbial agent is produced, and meanwhile, the pollution caused by the cassava alcohol residues also can be treated, and the cyclic economy benefit for the cassava alcohol industry is realized. The method for fermenting and producing the microbial agent by utilizing the cassava alcohol residues comprises the following steps of: mixing the cassava alcohol residues, humic acid decomposed coal or grass carbon and dry straw ash, wherein the water content of the mixture is controlled to be 33%-70%; adding the microbial agent being 2% of the mass of the mixture into the mixture, stirring uniformly and quickly, packing the mixture into a seal bag, carrying out anaerobic fermentation for 10 days at the normal temperature in the southern of China, thereby producing the microbial agent with the number of effective viable bacteria greater than or equal to 0.3billion / gram (higher than the national standard by 0.2 billion / gram). According to the method, the cost is low; the operation is simple; the product quality is high; the cassava alcohol residues are changed into wealth from waste, and effective resource utilization is realized; not only is the environment pollution problem solved, but also high environment-friendly expanse is saved for cassava alcohol enterprises, and meanwhile good economic benefit is brought; an enclosed biological circle of the cassava alcohol production is formed; and the cyclic economy benefit is created.

Owner:王天喜 +1

Acid-free fermentation method for producing ethyl alcohol with fresh cassava full pulp as raw materials

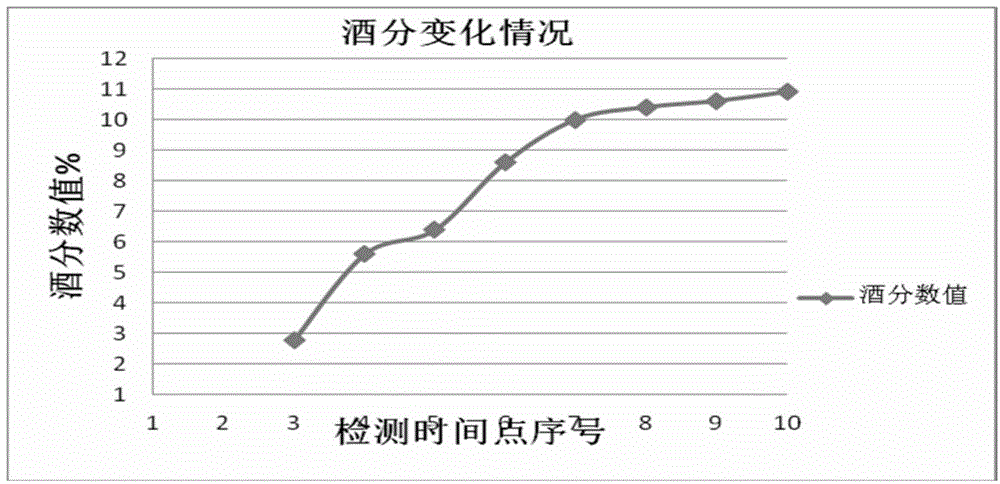

InactiveCN104531777AImprove mature mash contentReduce potential harmBiofuelsFermentationAlcoholDistillation

The invention discloses an acid-free fermentation method for producing ethyl alcohol with fresh cassava full pulp as raw materials. The acid-free fermentation method includes the technological processes of fresh cassava edulcoration, fresh cassava full pulp preparation, raw material boiling, saccharification, fermentation and distillation and purification. The acid-free fermentation method is characterized in that sundry bacteria are reduced by controlling the purity degree of the raw materials from a source; in other words, the fresh cassava raw materials are processed with a clean production process, and impurities such as mud, sand and surface skin on the surface of fresh cassava are removed, so that the sundry bacterium source is reduced to the maximum degree, and bacterium infection potential hazards in the fermentation process are reduced. Vitriol, antibiotic and a chemical sterilizing agent are replaced with a cassava fermentation compound enzyme for saccharification and fermentation, and therefore acid-free fermentation is achieved. In brief, the acid-free fermentation method is stable and reliable in process; the cost is saved; the yield is improved; and a good path is provided for revolution of the development of the ethyl alcohol industry.

Owner:广西南宁市武鸣安宁淀粉有限责任公司 +1

Treatment method and device of rice lees wastewater

InactiveCN101037280AHigh organic contentSmall footprintTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentEmission standardSmall footprint

The invention discloses a disposal method and a disposal apparatus of a rice wine lees waste water in order to provide a disposal technique of rice wine lees waste water with a small floor space, less sludge mass, low fixture costs, low energy consumption, low operation fees. The key points of the technical proposal is that: improving the conventional technics of disposing the lees waste water by anaerobic and aerobic method aiming at the characteristic that the waste water generated by the rice wine lees is relatively less, and the organic matter content is high; firstly four-stage anaerobic treatment and then SBR disposal technics and a disposal method of combining with biomembrane to reduce the waste water disposal floor space to about 50%, and the sludge mass to about 70%. The average value of CODcr of disposed waste water is 180.9mg / L; average value of BOD is 63mg / L; average value of SS is 130mg / L; pH valve is 7-8. Thus, the waste water meets the secondary discharge requirement of national GB 8978-1996 alcohol industry.

Owner:MEIZHOU WUZHISHI TECH

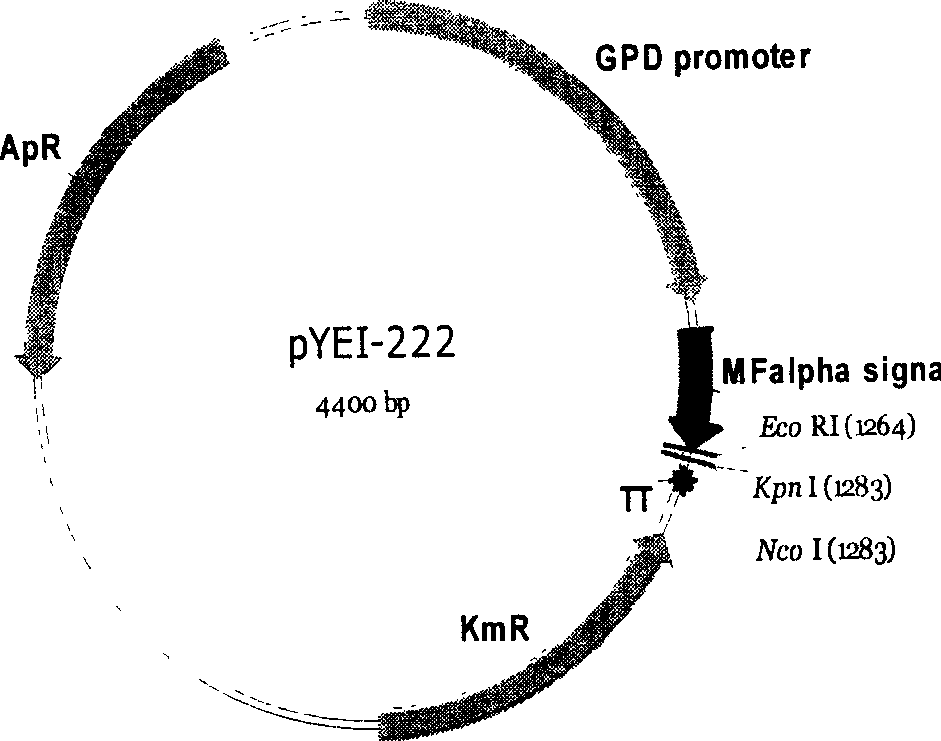

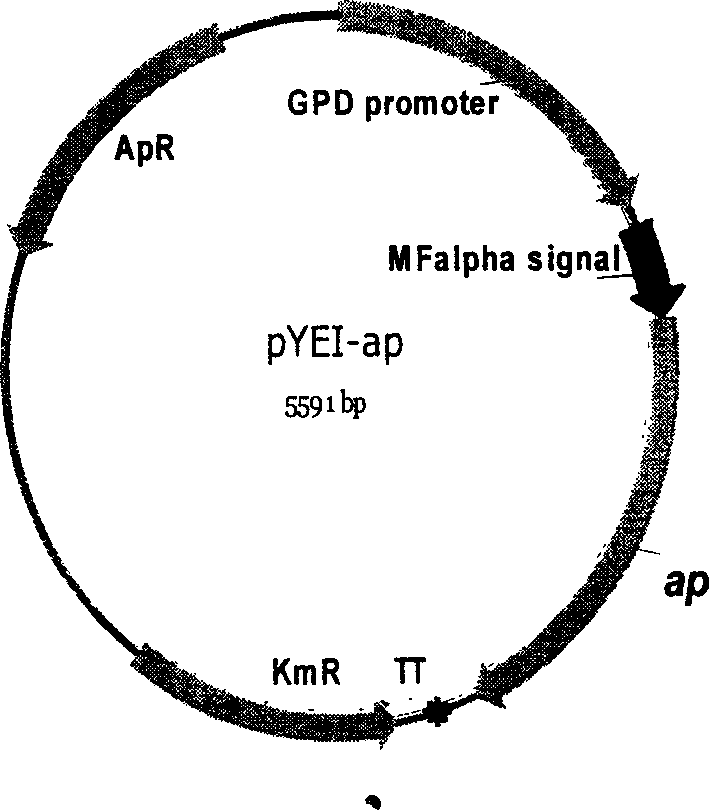

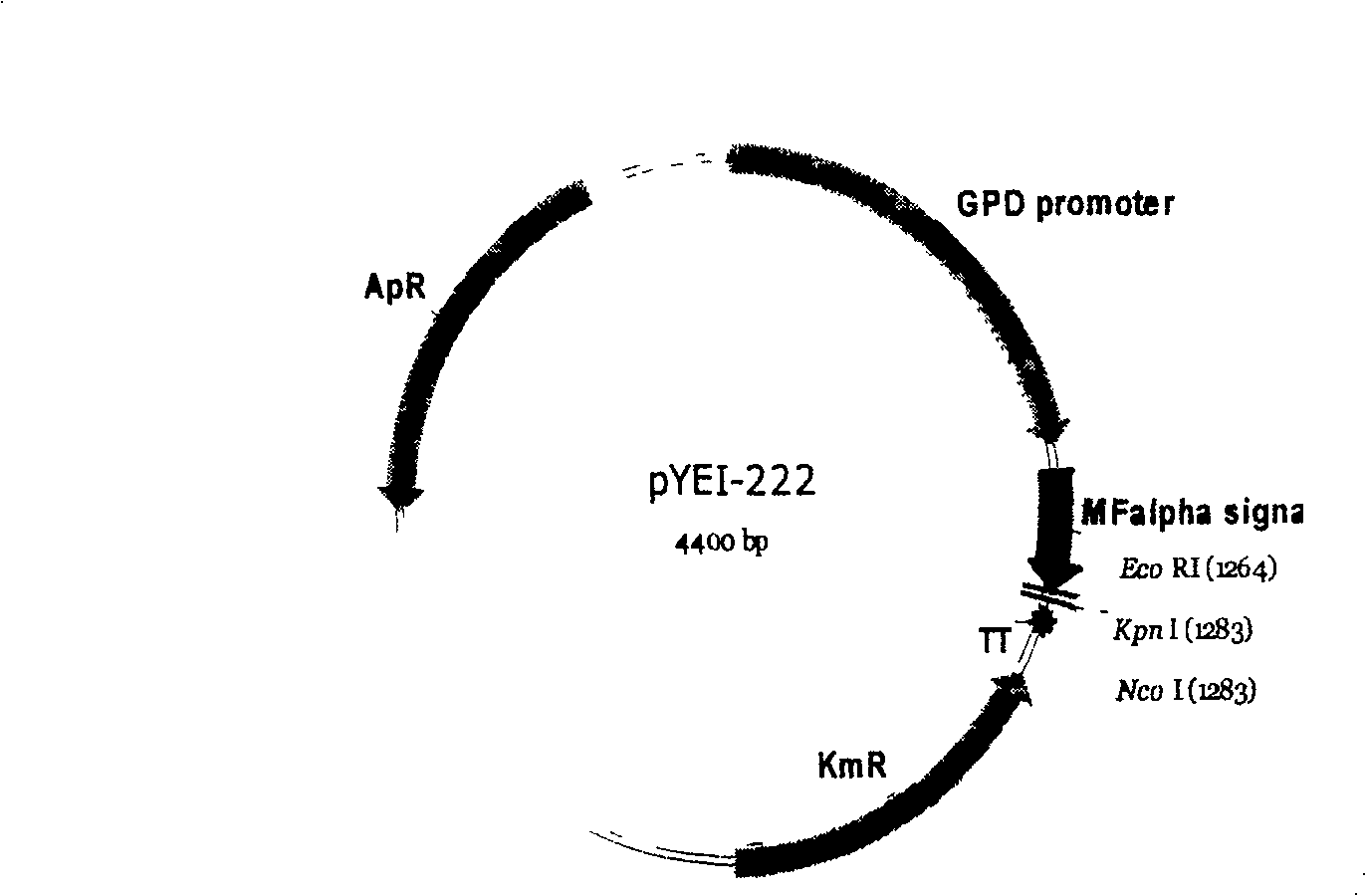

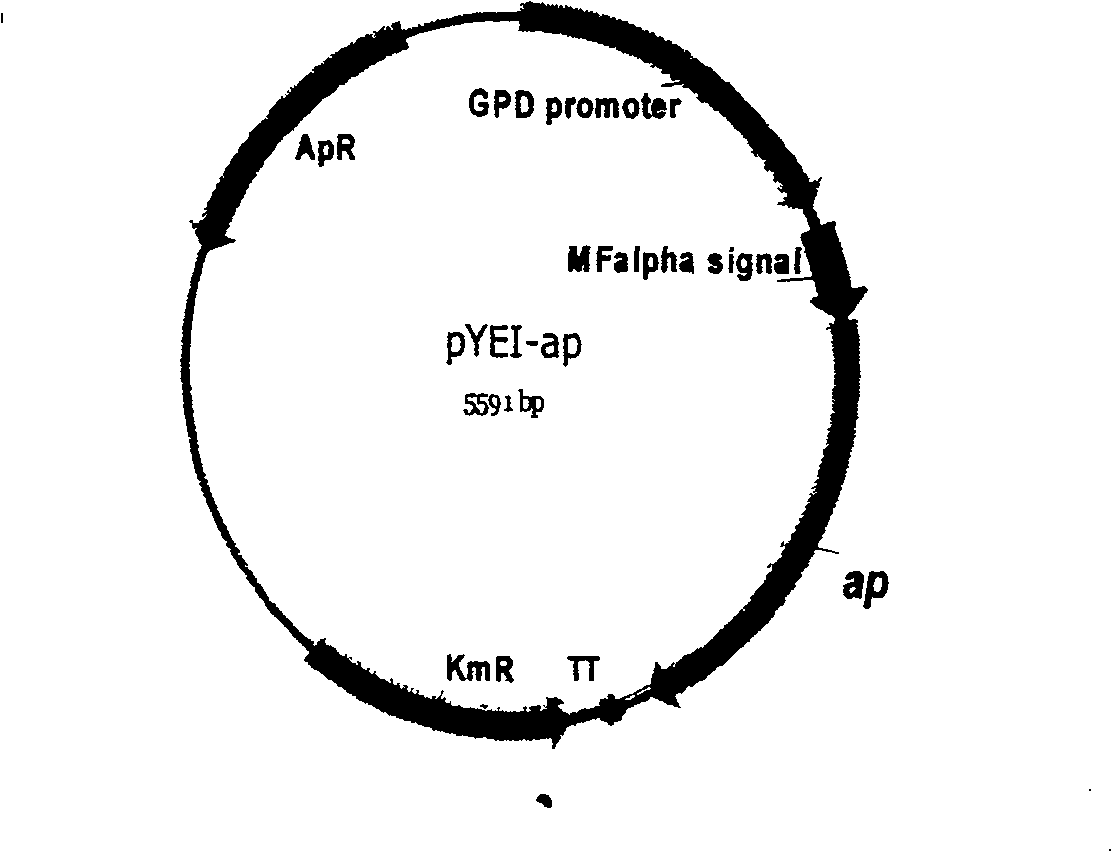

High fermentation rate type recombinant alcoholic fermentation yeast, the building and expression carrier thereof

InactiveCN1831110AIncrease profitShorten the fermentation cycleFungiHydrolasesBiotechnologyMicroorganism

The invention relates to recombination alcohol yeast and construction and the expression carrier it used. The invention supplies expression carrier of exogenous acid protease gene pYEI-222 and recombination particle of exogenous acid protease gene pYEI-ap. And the construction method of recombination alcohol yeast CCTCC M206009 and recombination alcohol yeast CCTCC M206009 that has high alcohol fermenting speed. It could be used to improve the alcohol yeast and alcohol industry.

Owner:JIANGNAN UNIV

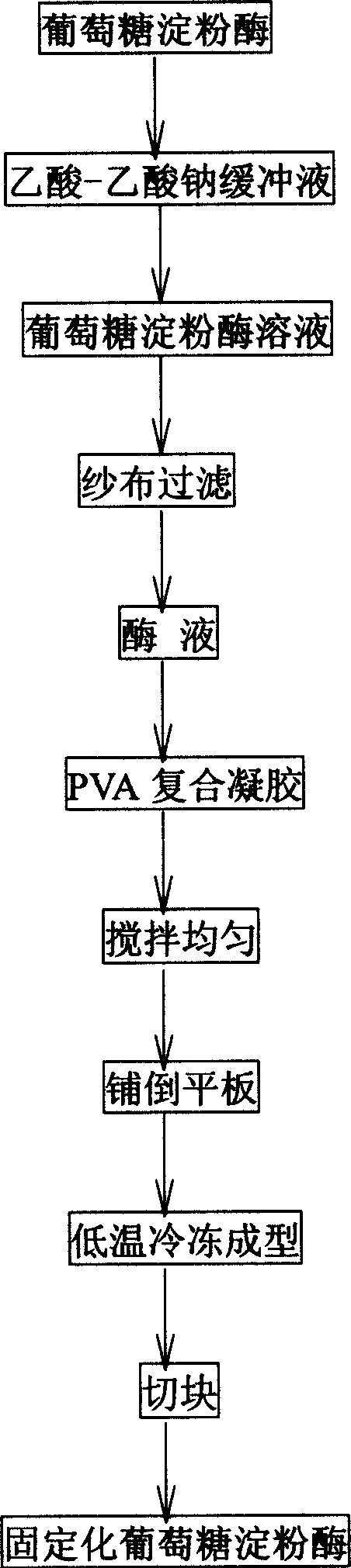

Immobilization glucose amylase products and method for immobilization of glucose amylase

InactiveCN1690200AHigh apparent enzyme activityEasy to operateOn/in organic carrierFood industryGram

The invention discloses an immobilization glucoamylase goods and a method of fixation of glucoamylase with polyvinyl alcohol composite gel. The immobilization glucoamylase goods is obtained from cryo-forming the mixture of polyvinyl alcohol composite gel and glucoamylase in low temperature. And the content of polyvinyl alcohol in polyvinyl alcohol composite gel is 8 to 15 percent(mass percent ), the concentration of glucoamylase is 8 to 15 percent(mass percent), Every 100ml composite gel can bear the weight of 0.5 to 1.5 gram of glucoamylase enzyme powder. The polyvinyl alcohol immobilizing glucoamylase goods has perfect mechanical capability, operating stabilization and has a good industrial application foreground. It can apply in alcohol industry, food industry, wine brewing, the finely processed of starch and starch stuff, analyzing and measuring, and other related ermentation industry.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Additive to low-alcohol or soft drinks and methods of conditioning drinks

InactiveUS20100112173A1High biological valueNice flavorFatty substance preservation using additivesAlcoholic beverage preparationAlcohol freeAntioxidant

The invention relates to the brewing and non-alcoholic industry and specifically for production of beer, low-alcohol and alcohol-free drinks The “Antioxilen” additive for beer, alcohol-free drinks contains an organic selenium compound—di-(3,4)-methyldipyrazolylselenide (DMDPS)—and also succinic acid and salts thereof (ammonium succinate or sodium succinate) as an antioxidant. The method of conditioning (enriching) drinks involves increasing biological value, improving quality and contributing antioxidant, antitoxic and hepatoprotective properties to drinks, i.e. protective properties for a human organism by adding the above additive to the finished product (drink). The additive is added in the form of a dry mixture or a solution. The invention allows for improving biological value of the product (drink), taste and useful properties thereof and also extending the “life” thereof.

Owner:DOLYA VITAL MIKHAILOVICH

Method for production of bacillus licheniformis preparation by utilizing ethanol industrial yellow water

ActiveCN104004677AReduce manufacturing costExpand sourceBacteriaMicroorganism based processesBacillus licheniformisEcological environment

A method for production of a bacillus licheniformis preparation by utilizing ethanol industrial yellow water includes collection and treatment of the ethanol industrial yellow water, cultivation of bacillus licheniformis in the ethanol industrial yellow water, and receiving and preparation of bacillus licheniformis. The method for production of the bacillus licheniformis by utilizing the ethanol industrial yellow water not only can make full use of the ethanol industrial yellow water, reduce the treatment cost of the yellow water, optimize comprehensive utilization of the yellow water and improve the ecological environment, but also can expand sources of a nutrition substrate in a conventional bacillus licheniformis preparation production, lower the production costs and expand the application scope of bacillus licheniformis.

Owner:河南岐伯实业有限公司

Preparation method of fermentation-state manganese feed additive

ActiveCN104543401AReduce manufacturing costImprove resource utilizationAnimal feeding stuffChemical synthesisSlag

The invention relates to a preparation method of a fermentation-state manganese feed additive, which comprises the following steps: preparing a fermentation substrate from alcohol industry yellow water, bran coat, powder slag, corn flour and other industrial and agricultural byproducts, carrying out microbial screening and domestication culture to obtain a manganese-rich microbe, inoculating the manganese-rich microbe in the obtained fermentation substrate to perform fermentation, drying the fermentation material, pulverizing and packaging to obtain the product. Compared with the chemosynthetic organic-state manganese feed additive, the powder slag, bran coat, alcohol industry yellow water and other byproducts are used as the culture raw materials and substrate, thereby widening the resource utilization range and lowering the production cost of the manganese feed additive. The prepared fermentation-state manganese feed additive has more stable biological availability, and the absorptivity is 5.1 times of that of the inorganic manganese sulfate and 1.35 times of that of the amino acid chelated manganese.

Owner:河南岐伯实业有限公司

High fermentation rate type recombinant alcoholic fermentation yeast, the building and expression carrier thereof

InactiveCN100422308CIncrease profitShorten the fermentation cycleFungiHydrolasesGeneFermentation rate

The invention relates to recombination alcohol yeast and construction and the expression carrier it used. The invention supplies expression carrier of exogenous acid protease gene pYEI-222 and recombination particle of exogenous acid protease gene pYEI-ap. And the construction method of recombination alcohol yeast CCTCC M206009 and recombination alcohol yeast CCTCC M206009 that has high alcohol fermenting speed. It could be used to improve the alcohol yeast and alcohol industry.

Owner:JIANGNAN UNIV

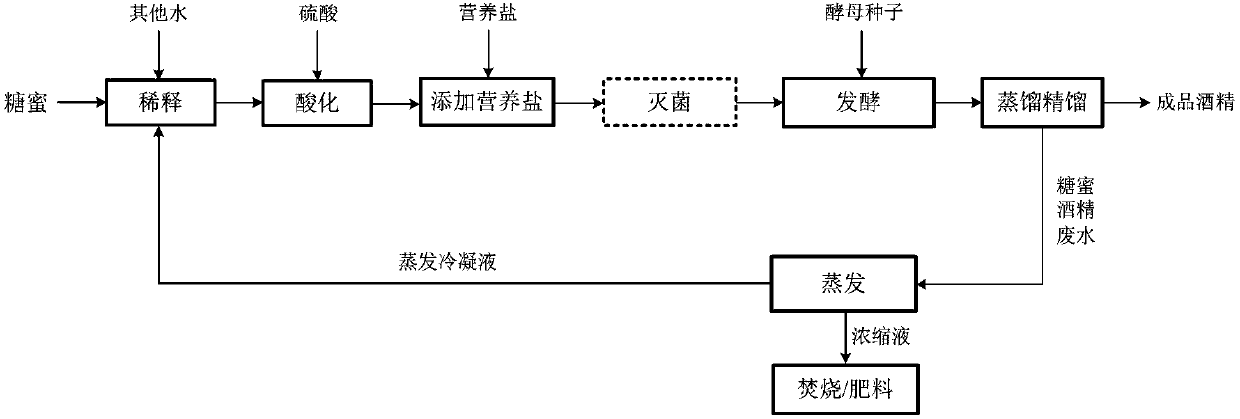

Process for recycling molasses alcohol wastewater evaporation and condensation liquid in alcohol fermentation

The invention discloses a process for recycling molasses alcohol wastewater evaporation and condensation liquid in alcohol fermentation, and belongs to the field of alcohol fermentation and alcohol industrial wastewater comprehensive utilization. By recycling the molasses alcohol wastewater evaporation and condensation liquid, the load capacity of the aerobic digestion section is reduced, the occupied area, that is, fixed investment and operating cost of the aerobic digestion section are reduced; the wastewater discharge amount is reduced, and meanwhile lots of water resources are saved.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com