Alcohol vinasse waste slag treatment system and treatment method

A treatment system and technology of distiller's grains, applied in the field of waste residue treatment system, can solve the problems of waste of available resources, unusable waste residue, no use of waste residue, etc., and achieve the effect of reasonable structure, good effect of pressing and dehydration, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, a distiller's grain waste residue treatment system, which is composed of a classifier, a screw press, a drying device and a molding machine;

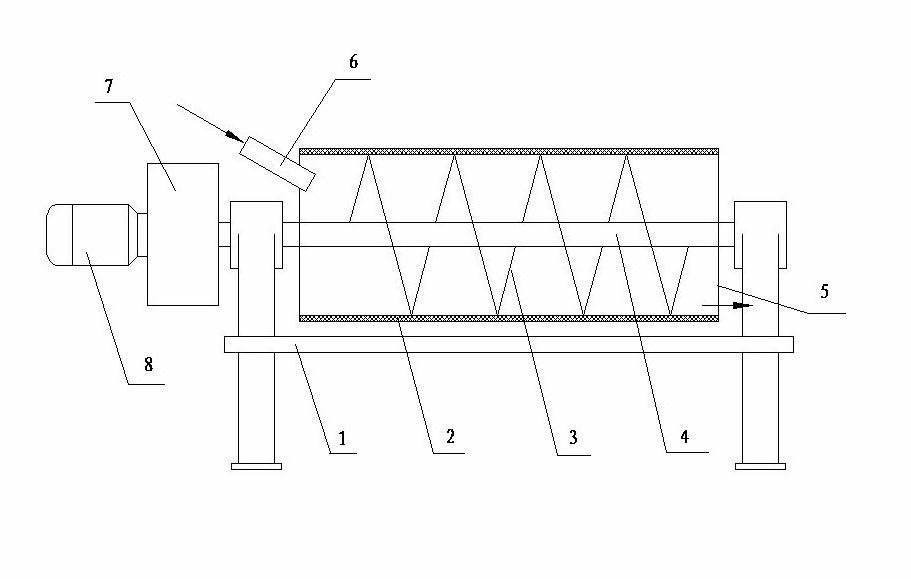

[0036] refer to figure 1, the grading separator grading separator includes a separation frame 1, a motor 8, a separation cylinder 2 and a main shaft 4 are arranged on the separation frame 1, and the motor 8 is connected with the main shaft 4 through a reducer 7; the separation The cylinder 2 is a screen-type separation cylinder, the separation cylinder 2 is fixed on the main shaft 4, the main shaft 4 passes through the separation cylinder 2 and is connected to the separation frame 1 through bearings, and the main shaft 4 in the separation cylinder 2 is fixed A separation screw 3 is provided, and a number of through holes are arranged on the separation screw 3. The separation screw 3 is also fixed on the separation cylinder 2, and a feed pipe 6 is connected to one side of the separation cylinder 2, and a feed pipe 6 ...

Embodiment 2

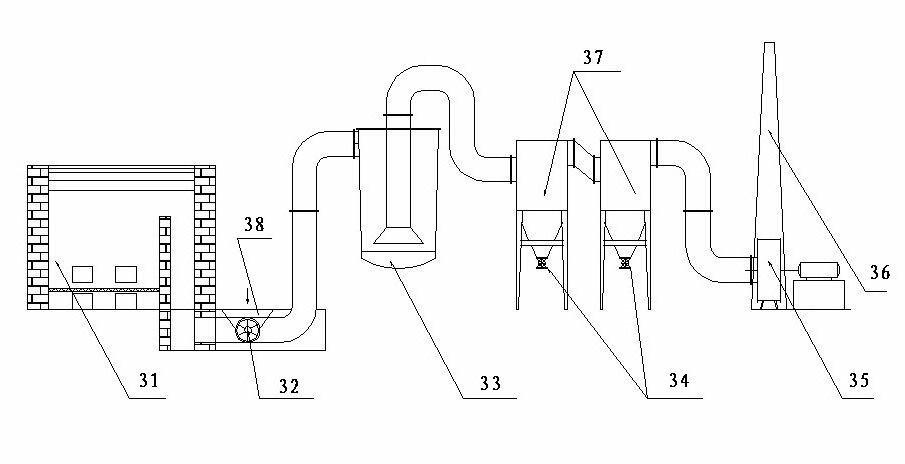

[0040] Embodiment 2, with reference to image 3 , In the distiller's grain waste treatment system described in Example 1: in the drying device, the cyclone dust collector 37 is a multi-tube cyclone dust collector, and the cyclone dust collector 37 is two sets, which are connected in series on the pipeline.

Embodiment 3

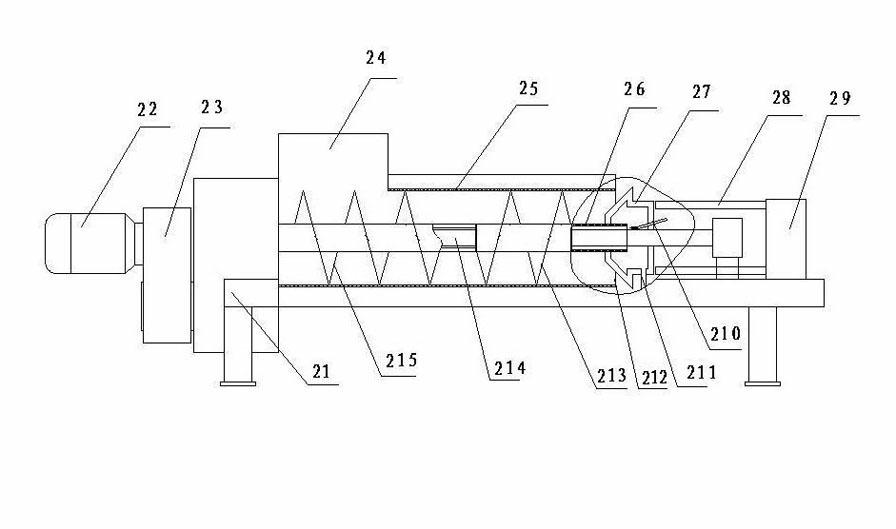

[0041] Embodiment 3, in the distiller's grain waste treatment system described in Embodiment 1 or 2: in the screw press, a flushing pipe 210 leading into the cavity is also provided on the pressing part 27 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com