Immobilization glucose amylase products and method for immobilization of glucose amylase

A technology of glucoamylase and amylase enzymes, applied in biochemical equipment and methods, fixed on/in organic carriers, enzymes, etc., can solve the problems of poor carrier strength, easy rupture, enzyme molecule leakage, and glucoamylase immobilization It can achieve the effect of high apparent enzyme activity and good operability due to the lack of chemical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

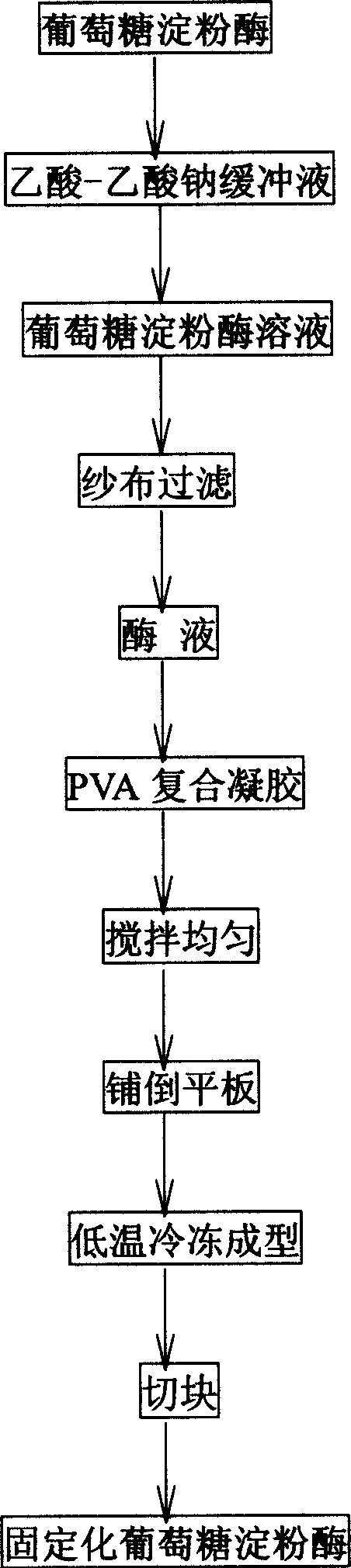

[0016] Take 50 mL of polyvinyl alcohol composite gel (containing dextran-40) with a concentration of 8%, and mix it with 5 mL of 10% glucoamylase (Wuxi Genenco Biological Engineering Co., Ltd., 50,000 units) enzyme solution ( Glucoamylase was dissolved with acetic acid-sodium acetate buffer solution of pH 4.6, filtered through multiple layers of gauze), mixed, stirred evenly, poured into a 20cm plate with a thickness of 3-4mm, and frozen at -24°C for 48 hours , take out after forming and thaw naturally, cut into small pieces of 3mm×3mm×3mm.

[0017] use Na 2 S 2 o 3 Standard solution titration (QB 1805.2-93 standard) was used to measure the activity of immobilized glucoamylase. At the same time, the starch hydrolysis experiment was carried out in batches, the DE value was determined, and the glucose content was determined by potassium ferricyanide titration. The results showed that the apparent enzyme activity of the immobilized glucoamylase was 1558u / g·dry·gel, the recove...

Embodiment 2

[0020] Repeat Example 1, with the following differences: use 50mL concentration of 10% polyvinyl alcohol composite gel, mix with 5mL concentration of 10% glucoamylase enzyme solution at room temperature, the apparent enzyme of the resulting immobilized glucoamylase The activity is 1480u / g·dry·gel.

[0021] Compared with Comparative Example A, due to the lower porosity and smaller pore size of the carrier, the continuous hydrolysis operation performance is slightly worse, and the production cost is also increased.

Embodiment 3

[0023] Repeat Example 1, with the following differences: the use of concentration is 10% polyvinyl alcohol composite gel 50mL, mixed with 10% glucoamylase enzyme solution at room temperature with 5mL concentration, stirred evenly, poured into a petri dish, thickness 1mm, Then freeze at -24°C for 48 hours, and cut into strips of 3mm×6mm after being shaped. The results showed that the apparent activity of the immobilized glucoamylase was 2573.6u / g·dry·gel, and the recovery rate of the enzyme activity was 51.2%.

[0024] Compared with "Example 1", its operability is worse than that of the granular immobilized enzyme, and it is easy to cause the enzyme molecule to fall off during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com