Preparation method of selenium yeast feed additive

A feed additive, yeast selenium technology, applied in animal feed, animal feed, application and other directions, can solve problems such as water pollution, and achieve the effects of improving efficiency, high absorption rate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

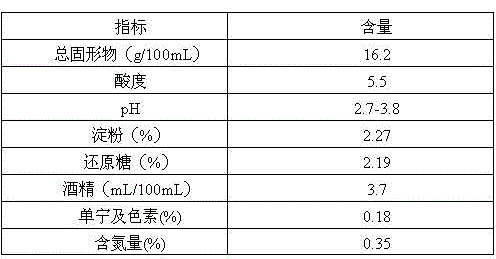

Image

Examples

Embodiment 1

[0039] Embodiment 1: a preparation method of yeast selenium feed additive, at first, mix solid raw material and liquid raw material to obtain fermentation substrate, then inoculate yeast in it and carry out fermentation, after the fermentation is finished, the material obtained is dried, packaged promptly makes product, wherein the yeast is a yeast with strong selenium-enriching ability obtained through screening and domestication, and the preparation method of the yeast selenium feed additive comprises the following specific steps:

[0040] 1. Processing of fermentation raw materials

[0041] The fermentation raw materials used in the present invention include solid raw materials and liquid raw materials.

[0042] 1.1. Treatment of solid raw materials

[0043] The solid raw materials include selenium raw materials, bran, rice bran and corn flour, wherein the selenium raw material is sodium selenite; the bran is wheat bran, air-dried basis, and the crude protein content is 15...

Embodiment 2

[0066] Embodiment 2: a preparation method of yeast selenium feed additive, at first, solid raw material and liquid raw material are mixed to obtain fermentation substrate, then yeast is inoculated therein and fermented, and after the fermentation is finished, the material obtained is dried and packaged to obtain product, wherein the yeast is a yeast with strong selenium-enriching ability obtained through screening and domestication, and the preparation method of the yeast selenium feed additive comprises the following specific steps:

[0067] 1. Processing of fermentation raw materials

[0068] The fermentation raw materials used in the present invention include solid raw materials and liquid raw materials.

[0069] 1.1. Treatment of solid raw materials

[0070] The solid raw materials include selenium raw materials, bran, rice bran and corn flour, wherein the selenium raw material is sodium selenite; the bran is wheat bran, air-dried basis, and the crude protein content is 1...

Embodiment 3

[0093] Embodiment 3: A preparation method of a yeast selenium feed additive, firstly, mixing solid raw materials and liquid raw materials to obtain a fermentation substrate, then inoculating yeasts therein for fermentation, drying and packaging the obtained materials after the fermentation is complete product, wherein the yeast is a yeast with strong selenium-enriching ability obtained through screening and domestication, and the preparation method of the yeast selenium feed additive comprises the following specific steps:

[0094] 1. Processing of fermentation raw materials

[0095] The fermentation raw materials used in the present invention include solid raw materials and liquid raw materials.

[0096] 1.1. Treatment of solid raw materials

[0097] The solid raw materials include selenium raw materials, bran, rice bran and corn flour, wherein the selenium raw material is sodium selenite; the bran is wheat bran, air-dried basis, and the crude protein content is 15.3%; prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com