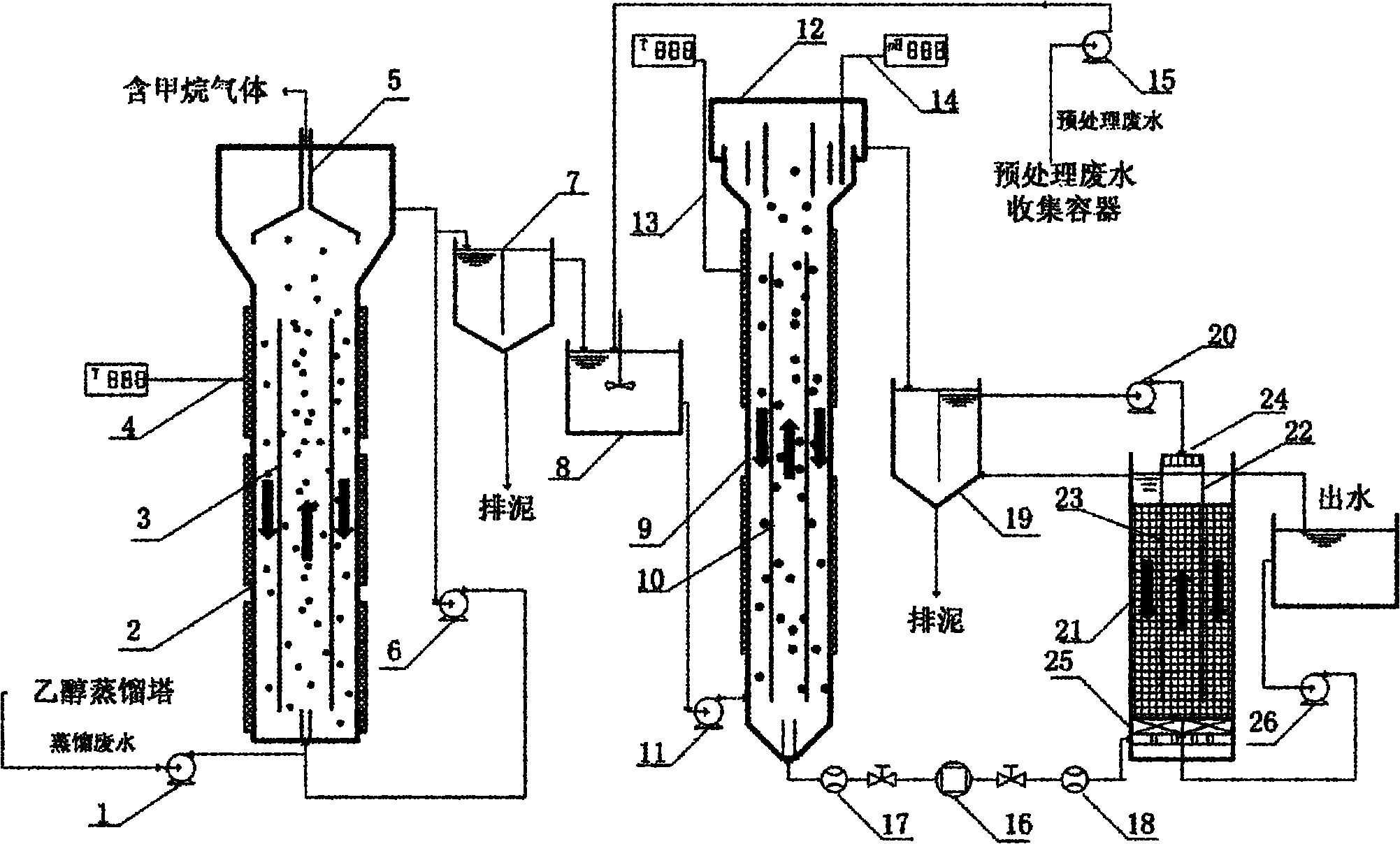

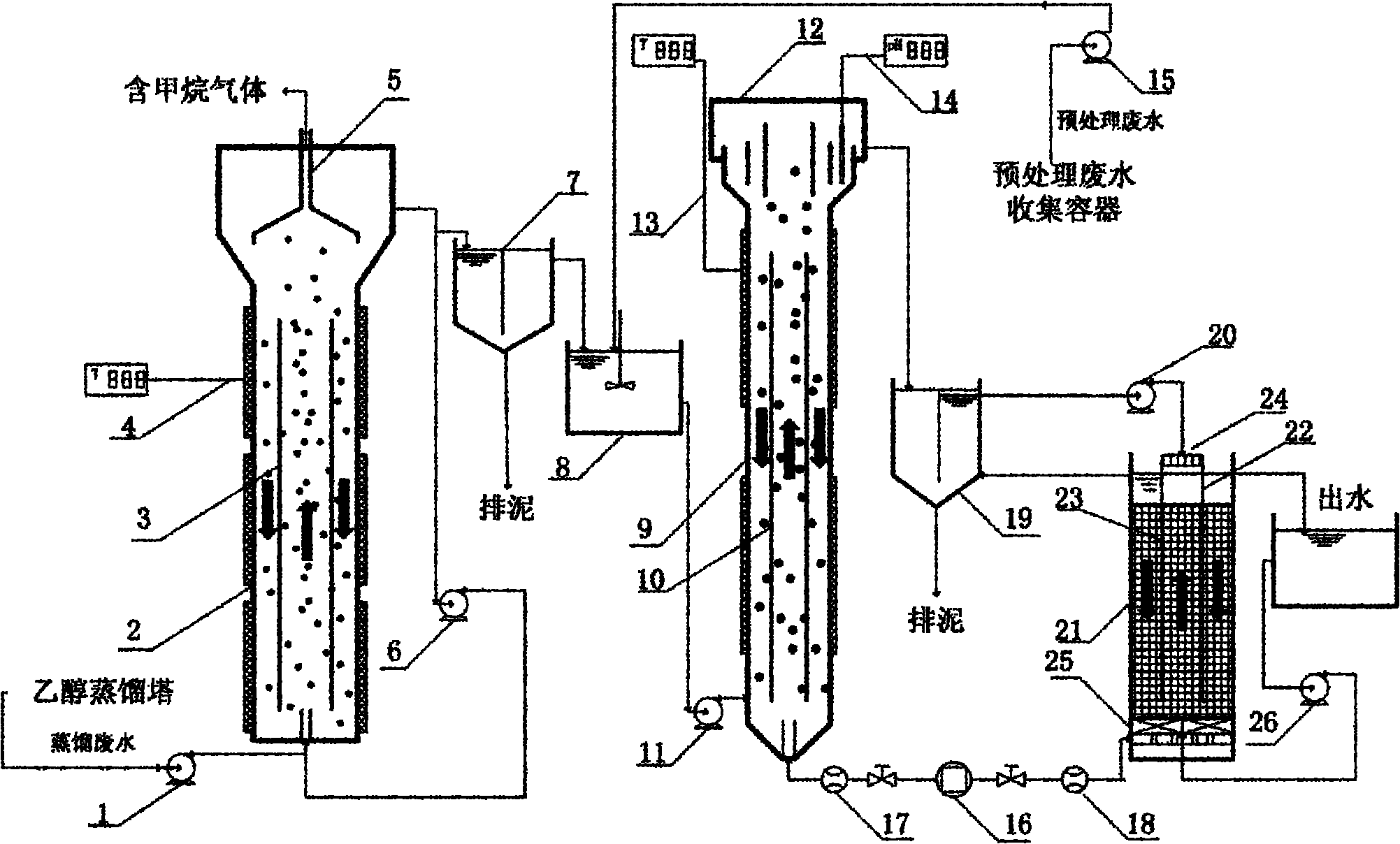

Integrated treating device and method of fuel ethanol distillation wastewater of corn straw and high ammonia nitrogen pretreatment wastewater

A technology for fuel ethanol and corn stalks, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of enhancing impact resistance, reducing impact, and operating flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] System startup: Connect 50% of the anaerobic activated sludge to the anaerobic fluidized bed reactor, add 10% of the reactor volume to the activated carbon carrier with a particle size of 0.8-1.3mm, the effective volume of the anaerobic reactor is 4L, and the outer shell The diameter is 80mm, the height is 880mm, the diameter of the guide tube is 55mm, and the height is 750mm. Keep the reactor temperature at 53-55°C, dilute 3-5 times the fuel ethanol distillation wastewater intermittently domesticated for 5 days, and then continuously feed water. The hydraulic retention time is 50-55h, and the liquid The upflow rate is 9.0m / h, the COD removal rate of the effluent is higher than 75%, the concentration of the influent is increased, and the activated sludge is enriched by gradient acclimatization. After 25 days of gradient acclimatization, the raw water is directly fed into the water. After 11 days of continuous operation, the immobilization of the biofilm film is completed....

Embodiment 2

[0032] The effective volume of the anaerobic fluidized bed bioreactor is 7L, the diameter of the outer shell is 100mm, the height is 1000mm, the diameter of the guide tube is 75mm, and the height is 800mm; Flow cylinder diameter 70mm, height 900mm; aerated biological filter bed effective volume 4.65L, shell diameter 130mm, height 390mm, guide cylinder diameter 70mm, height 360mm; anaerobic fluidized bed reactor inoculated with 40% anaerobic sludge, Dosing 7% activated carbon particles, inoculating 30% of aerobic sludge in the aerobic ascending loop reactor, adding 4% of activated carbon particles, inoculating 12% of aerobic sludge in the aerated biological filter bed, filling the height of the reactor with 75% of the thickness activated carbon, start the integrated device according to the method in Example 1.

[0033] Corn straw fuel ethanol distillation wastewater COD 24500-25000mg / L, ammonia nitrogen 50.3-55.5mg / L, pH 4.4-4.5; pretreatment wastewater COD 751-783mg / L, ammonia...

Embodiment 3

[0035]The effective volume of the anaerobic fluidized bed bioreactor is 10L, the diameter of the outer shell is 120mm, the height is 1080mm, the diameter of the guide tube is 80mm, and the height is 900mm; Flow cylinder diameter 80mm, height 1000mm; aerated biological filter bed effective volume 7.5L, shell diameter 150mm, height 450mm, diversion cylinder diameter 100mm, height 400mm; anaerobic fluidized bed reactor inoculated with 30% anaerobic sludge, Add 5% activated carbon particles, inoculate aerobic sludge with 20% of aerobic sludge in the aerobic ascending loop reactor, add 3% of activated carbon particles, inoculate 10% of aerobic sludge in the aerated biological filter bed, fill the reactor height with 70% thickness activated carbon, start the integrated device according to the method in Example 1.

[0036] Corn straw fuel ethanol distillation wastewater COD 15000-15500mg / L, ammonia nitrogen 38.1-40.5mg / L, pH 4.6-4.7; pretreatment wastewater COD 652-683mg / L, ammonia n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com