Patents

Literature

736results about How to "Not easy to block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

Efficient composite hydrate inhibitor

InactiveCN101074361AExtend build timeReduce generationDrilling compositionKinetic InhibitorEnvironmental chemistry

Owner:DONGGUAN UNIV OF TECH

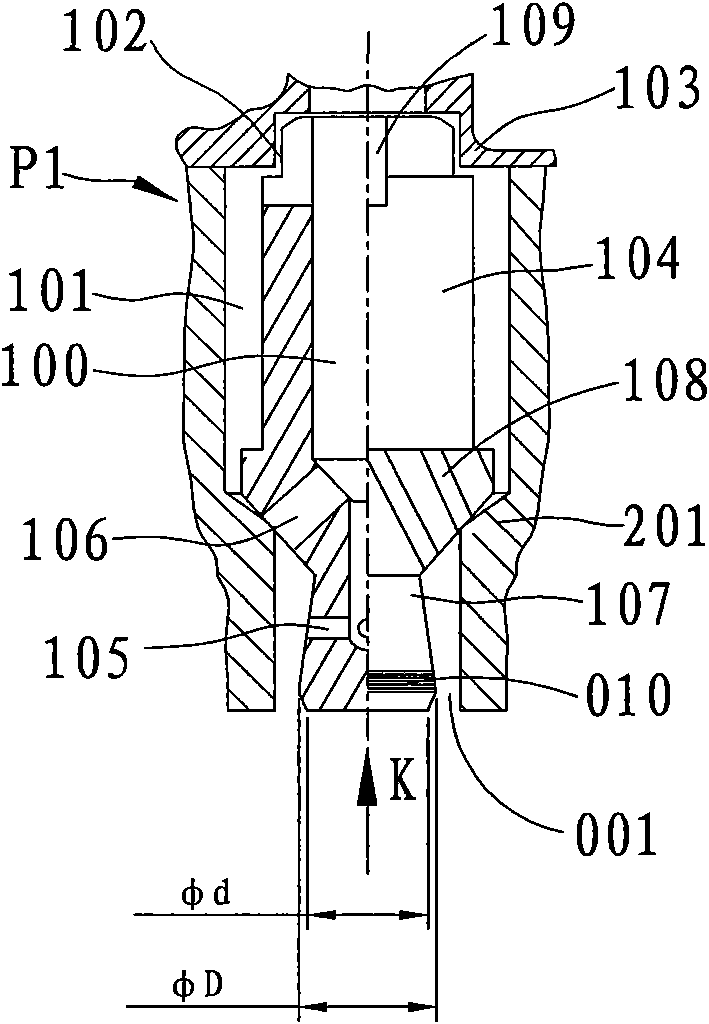

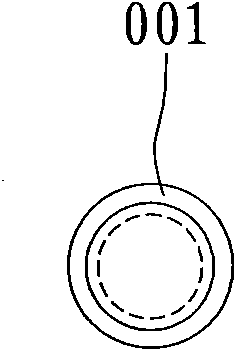

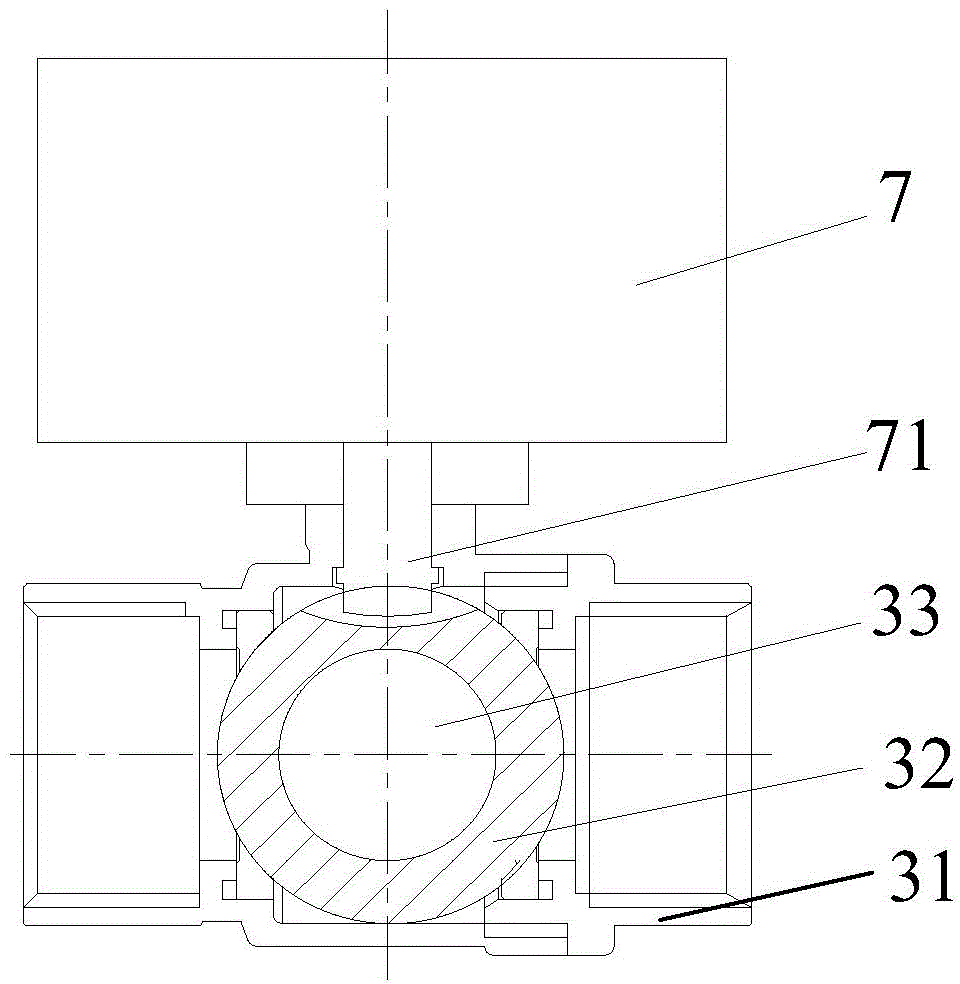

Rotary annular-seam spray nozzle and spraying device thereof

InactiveCN102039228AEasy ultra-fine atomizationUltra-fine atomization promotionSpray nozzlesLiquid spraying apparatusSpray nozzleFineness

The invention discloses a rotary annular-seam spray nozzle comprising a core seat, a rotary core and a rotary annular-seam spray hole, wherein a core cavity is arranged in the core seat, an inlet and an outlet which are communicated with the core cavity are arranged on the core seat, a core seat inlet is communicated with a pressure flow source, the rotary core can be sleeved into the core cavity in positioning and rotating modes and is concentric with the core cavity, a rotation-promoting flow path is arranged on the rotary core or / and the wall of the core cavity in order to mutually rotate the rotary core and the core cavity by using flow power, one end of the rotary core is penetrated into the core seat outlet, and the penetrating end forms the rotary annular-seam spray hole with the inner wall of the core seat outlet. The cross section of the spray hole of the rotary annular-seam spray nozzle is an annular seam, the annular seam and a diameter can be set to respectively and conveniently control the fineness and the flow of pressure spray and make liquid drop sizes more evenly and finely distributed. The rotary annular-seam spray nozzle has a self-cleaning function, is not easy to block and is in a self-closing dust-resisting type; the rotary annular-seam spray nozzle is arranged on a spray head body or the core seat of the rotary annular-seam spray nozzle is connected with the spray head body, the spray head body is communicated with the pressure flow source, and therefore, the spray device with the rotary annular-seam spray nozzle can be formed.

Owner:韩铁夫

Granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and preparation method thereof

ActiveCN102583659AReduce consumptionWith strengthWater/sewage treatmentElectrolysisChemical oxygen demand

The invention relates to a granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and a preparation method thereof. The grain size of the filler ranges from 1mm to 5mm, and iron powder, aluminium powder and graphite powder are mixed in a mass ratio of (2-6):(2-6):1 to perform granulation and then are sintered by being isolated from air, thus obtaining the filler. The micro-electrolysis filler is applicable to micro electronic treatment on acid sewage or base sewage. According to the invention, the efficiency of micro electrolysis on the sewage is high, a filling areais not easy to harden, and the period of back flushing is long. When the ternary micro-electrolysis filler is used for treating the sewage, CODcr (chemical oxygen demand) of the sewage can be reducedefficiently in a short time, and the biochemistry of the sewage can be improved. According to the invention, the raw materials are easy to obtain, the preparation process is simple, the problem of filler hardening of the conventional micro-electrolysis technology is solved, and the filler is applicable to treatment on the base sewage.

Owner:SHANDONG UNIV

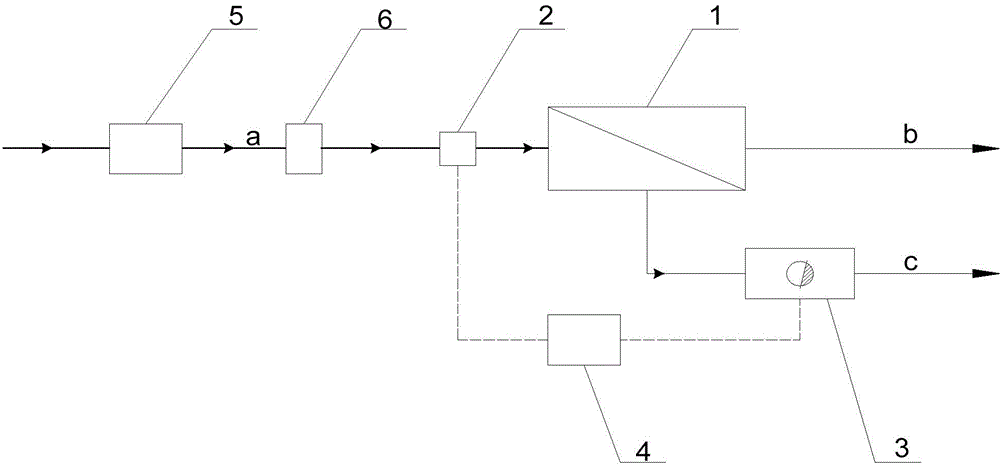

Reverse osmosis water purification machine and reverse osmosis water purification system

InactiveCN103951013AIncrease flushing powerReduce water yieldWater/sewage treatment bu osmosis/dialysisEngineeringStreamflow

The invention discloses a reverse osmosis water purification system which comprises a preprocessing device, a pressurizing device and a reverse osmosis membrane filtration device which are sequentially connected in series with a raw water passage, wherein a thick water branch and a clear water branch are arranged on the reverse osmosis membrane filtration device. The system also comprises a water quality detection device which is connected in series with the raw water passage, is arranged behind the preprocessing device and is used for detecting the TDS (total dissolved solid) value of raw water, an opening-adjustable flow valve arranged on the thick water branch, an adjusting device for adjusting the opening of the flow valve, and a controller for controlling the flow valve to keep first opening when the TDS value is not more than a preset value and controlling the flow valve to keep second opening when the TDS value is more than the preset value. According to the system, the waste of water resources can be effectively avoided and the service life of a reverse osmosis membrane can be effectively prolonged. The invention further discloses a reverse osmosis water purification machine provided with the reverse osmosis water purification system.

Owner:GREE ELECTRIC APPLIANCES INC

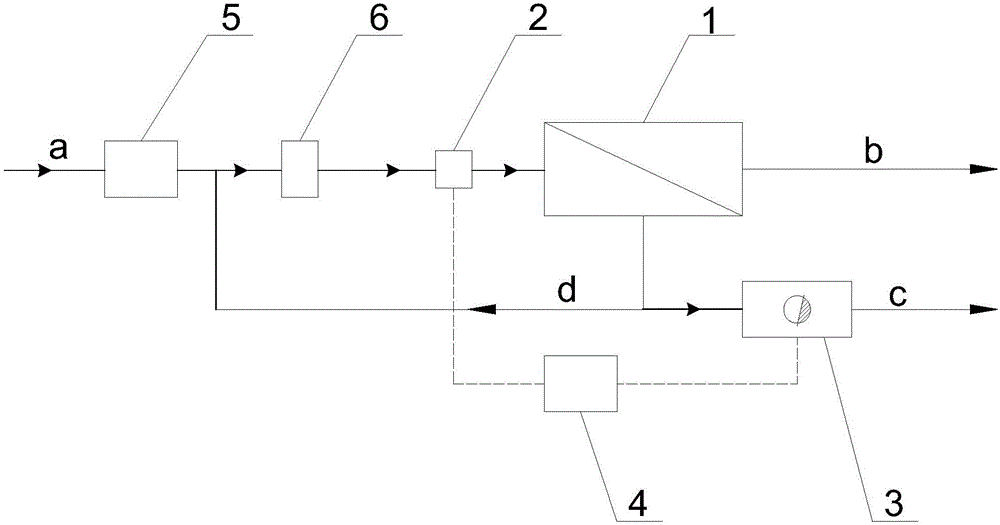

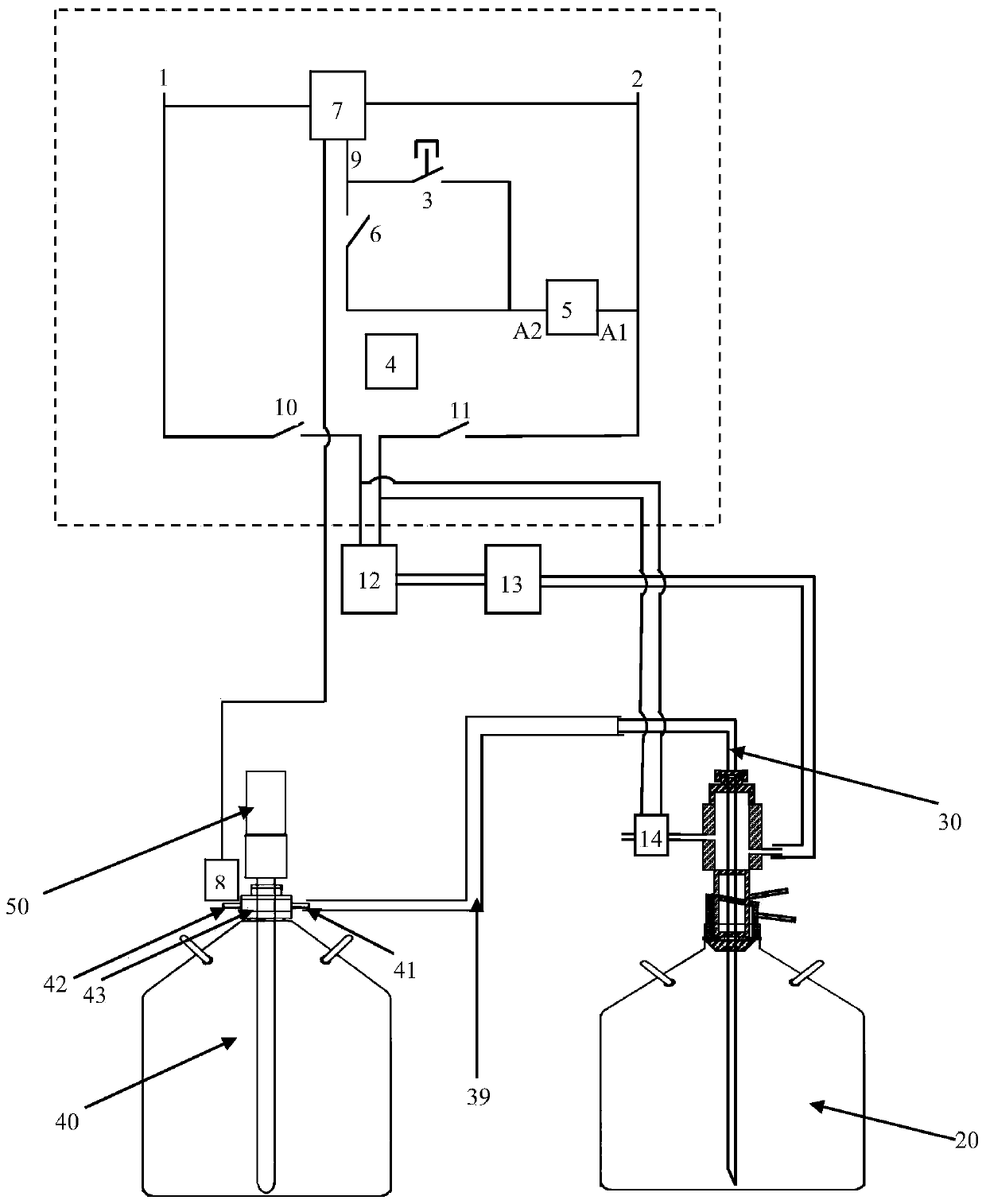

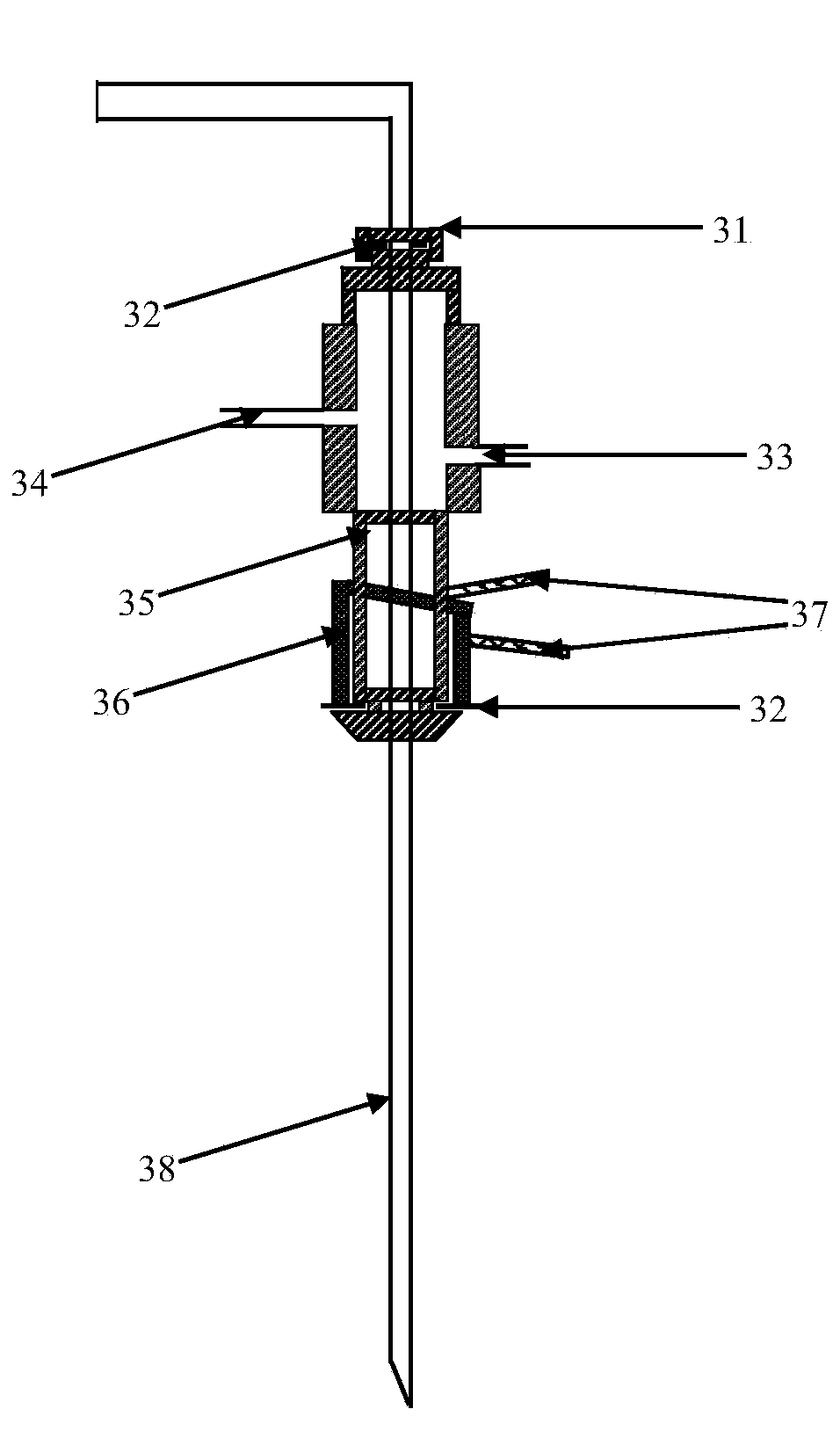

Water quality on-line detection method and system

ActiveCN101430312ANot easy to blockImprove reliabilityPreparing sample for investigationTesting waterOnline analysisWater velocity

The invention discloses a method for on-line detecting water quality, which comprises the following steps: a. sample collecting, wherein, water sample in the test environment is collected and delivered to pretreatment device; b, pretreatment, wherein, water sample flows out from an inlet tube into a water container after flowing through a filter screen, wherein, the angle formed between the water velocity attitude and the filter screen is an acute or a right angle; and c. measuring, wherein, the water sample to be tested is collected from the water container, and the water parameter is obtained by analyzing the test water sample to be tested. The invention also discloses a system for on-line detecting water quality. The invention has the advantages of continuous working, uneasy blockage, low cost, and the like, and the invention can be applied in various water sample on-line analysis.

Owner:FOCUSED PHOTONICS +1

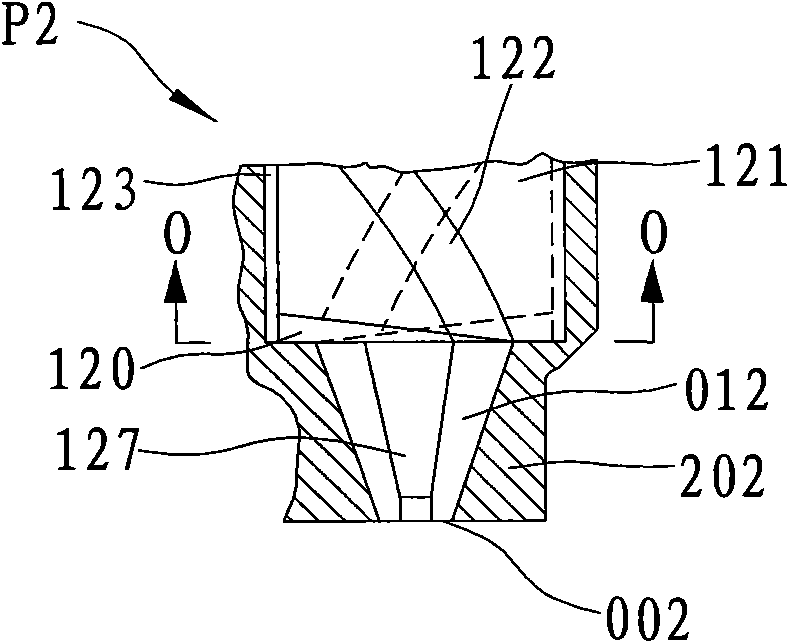

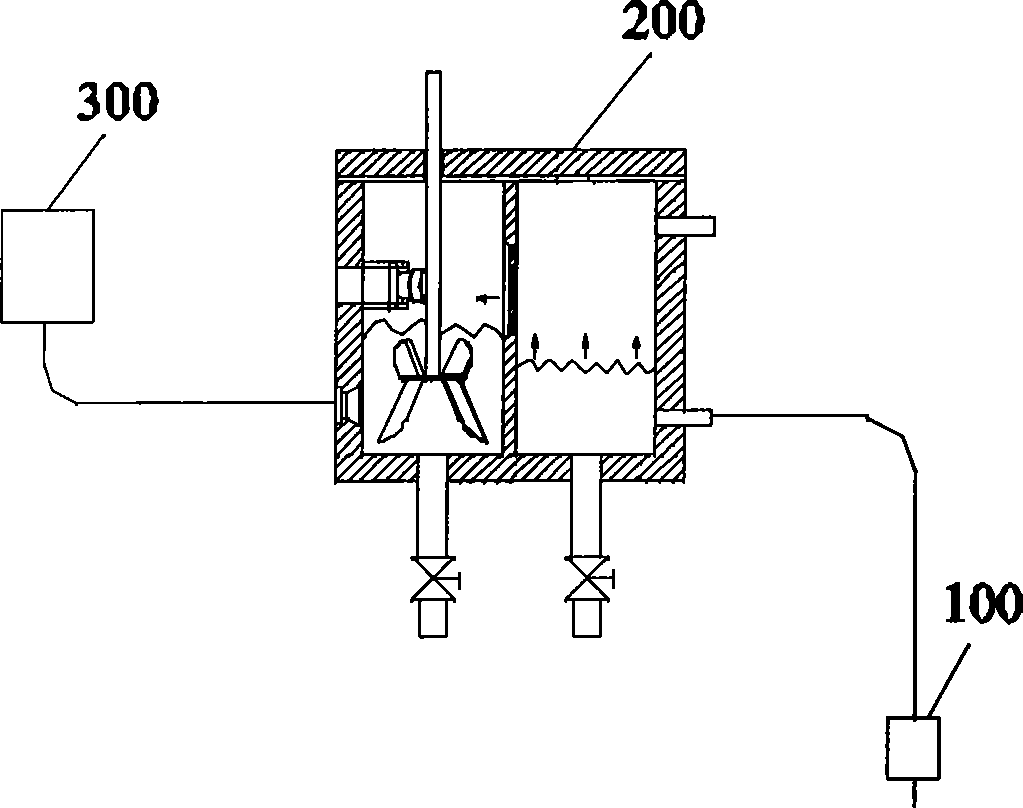

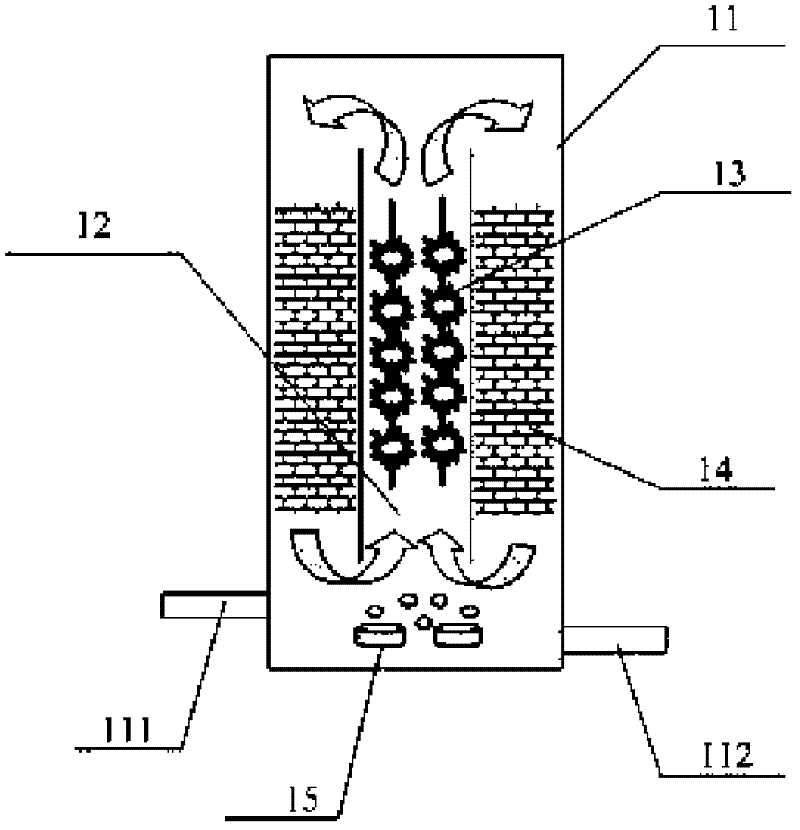

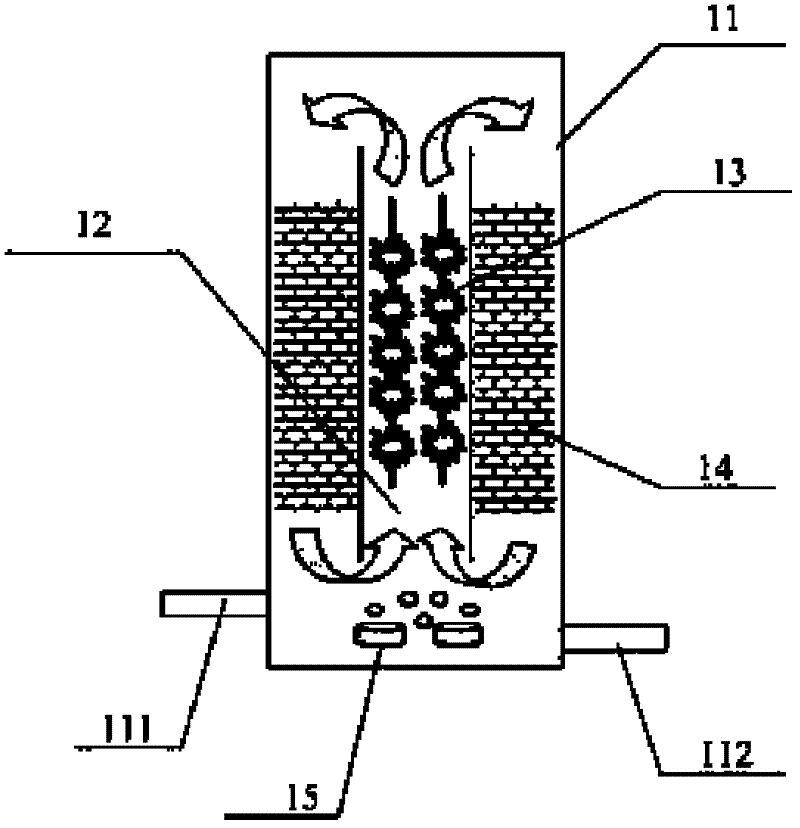

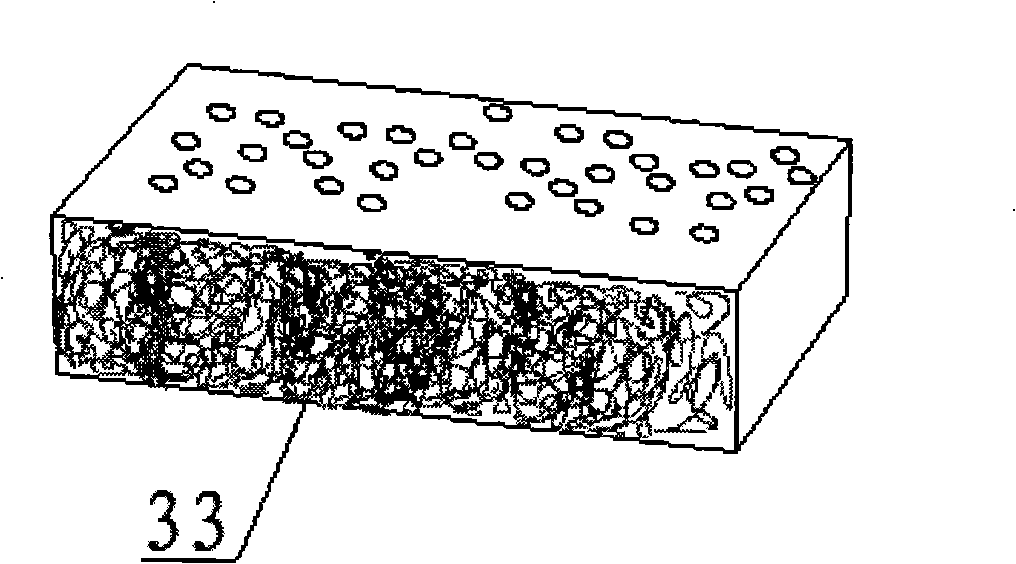

Biomembrane reactor, waste water treating system and method for treating waste water

ActiveCN102225803AReduce pollutant contentNot easy to blockTreatment using aerobic processesSustainable biological treatmentPromotion effectFilter material

The invention provides a biomembrane reactor, which comprises an outer cylinder with a water inlet and a water outlet provided at the bottom part; an inner cylinder arranged in the outer cylinder, two ends of the inner cylinder are communicated with the outer cylinder, the top of the inner cylinder is lower than the top of the outer cylinder; a filling material used for filling a bio-contact oxidation tank of the inner cylinder; a filter material used for filling the biological filter tank between the inner cylinder and the outer cylinder; an aeration apparatus provided at the bottom of the outer cylinder, the aeration apparatus is communicated with the inner cylinder. The invention provides a waste water treating system and a method for treating waste water. The biomembrane reactor provided in the invention has the functions of the bio-contact oxidation tank and the biological filter tank, waste water forms a circulation between the inner cylinder and the outer cylinder under the promotion effect of the aeration apparatus, and waste water passes through the filling material used for bio-contact oxidation tank and the filter material used for biological filter tank for a purifyingprocess, thereby the effect of treating waste water can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

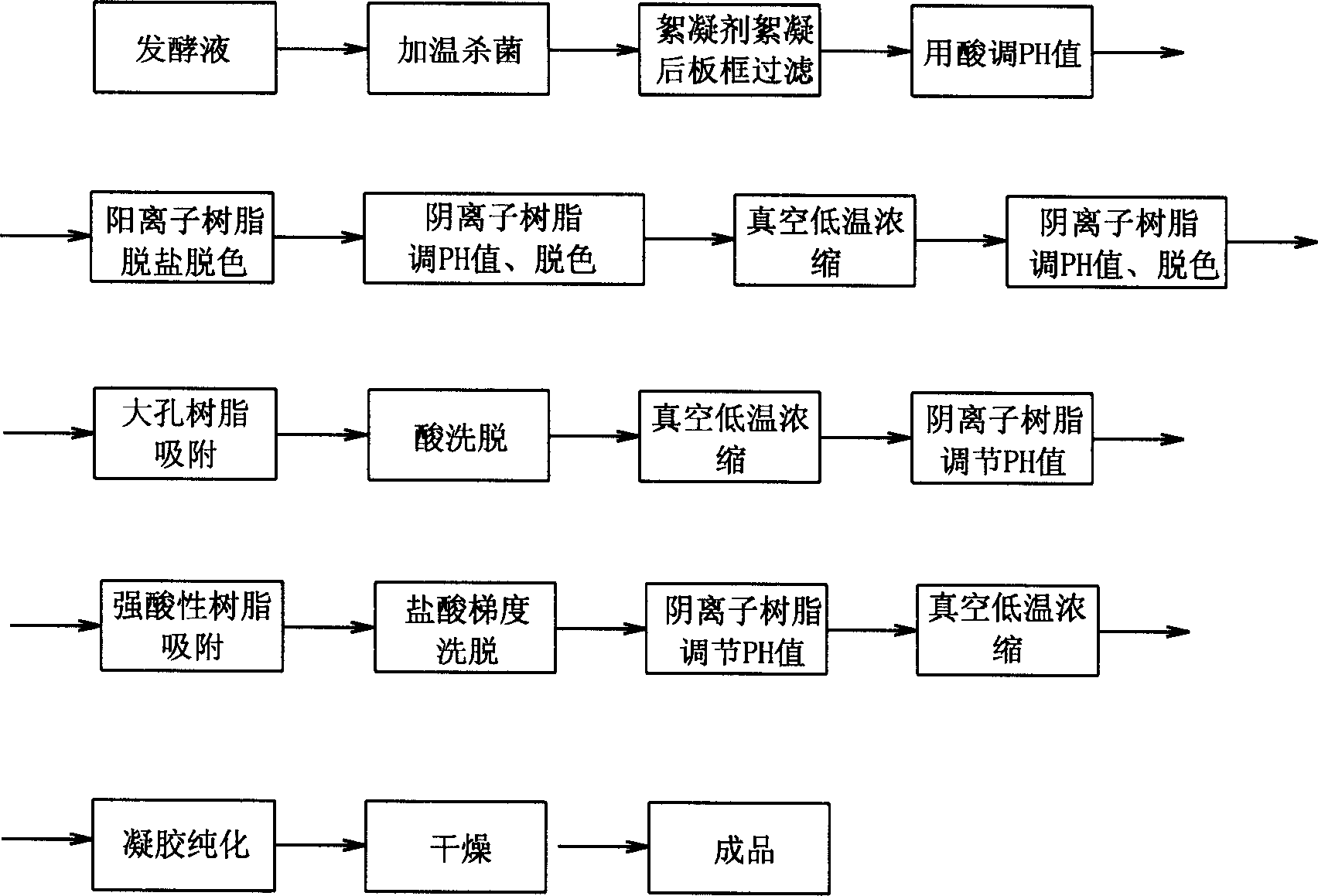

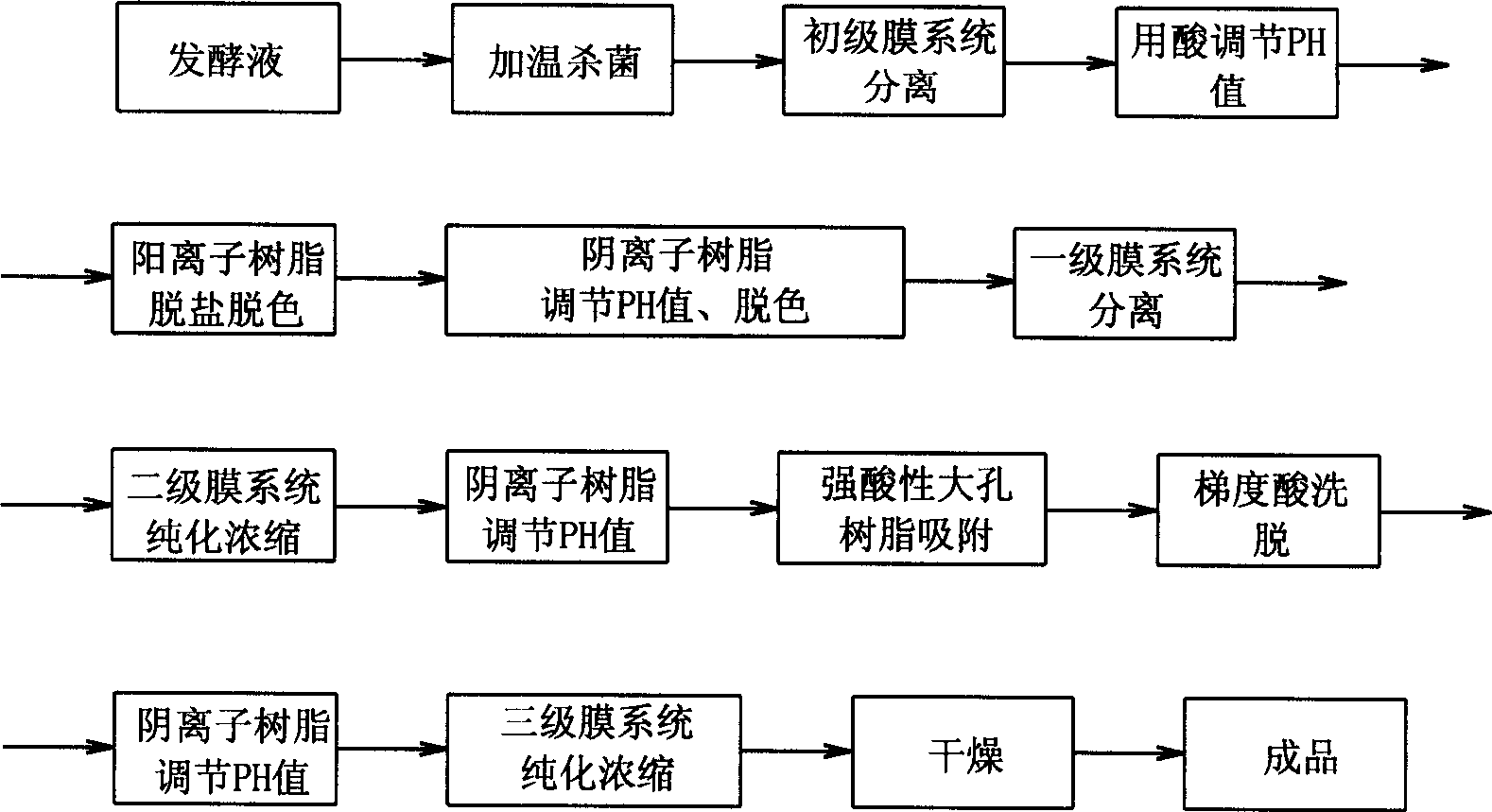

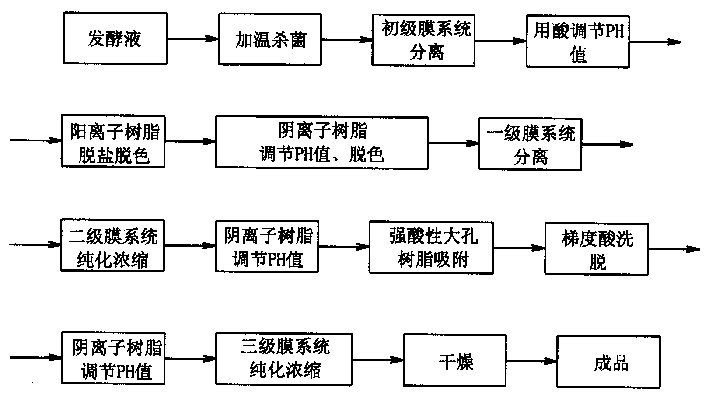

Method for preparing high-purity acarbose

InactiveCN1414003ARegeneration is easyNot easy to blockSugar derivativesSugar derivatives preparationAcarboseOrganic chemistry

A process for preparing high-purity Acarbose includes such steps as heating the fermented Acarbose liquid for sterilizing, primary membrane separation, cooling, regulating pH value, desalting and decolouring, regulating pH value, stage-one membrane separation, stage-2 membrane purifying, concentrating, regulating pH value, macroreticular resin adsorption, pickling, collecting high-purity (98%) solution of Acarbose, regulating pH value, stage-3 membrane purifying, concentrating and drying. Its advantages are high extraction rate, less environmental pollution and low cost.

Owner:ZHEJIANG DONGLI INDAL

Zero discharge cooking fume purifier

InactiveCN101274189AHigh temperature resistantNot easy to blockCombination devicesDomestic stoves or rangesFiltrationMetallic materials

The invention provides a zero exhaust lampblack purification device, relating to an air purification device, in particular a lampblack purification device. Large and small oil drops and solid grains in the air are thoroughly filtrated by a filter screen and electrostatic dedusting, and bacteria and peculiar smell in the air are respectively killed and removed by an ultraviolet air purification device, thus achieving the object of high quality air purification. Better filtration and dedusting effect is obviously provided by adopting two filter plates compared with by adopting one filter plate; furthermore, when being required to be cleaned, one of the filter plates can be taken out for cleaning with few effects on the whole equipment. The filter screen shapes like a block and is formed by random staggering of metal wires; firstly, as being made of metal material, the filter screen has the advantages of high temperature resistance and long service life; secondly, the filter screen is formed by the random staggering of the metal wires with no filter hole as the existing filter screen has, thus being not easy to be blocked.

Owner:徐扬

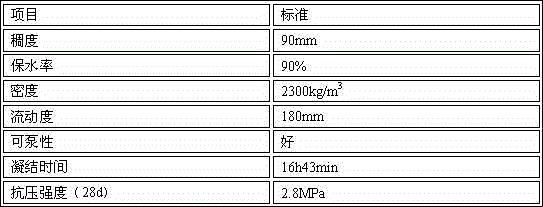

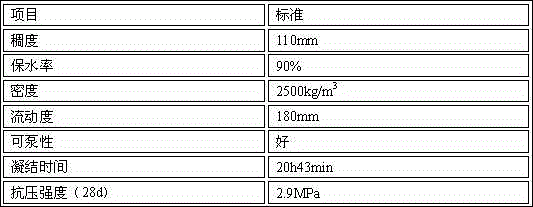

Synchronous grouting method for recycling large-diameter waste slurry generated during slurry shield

The invention provides a synchronous grouting method for recycling large-diameter waste slurry generated during slurry shield. The product per cubic meter is prepared from the following raw materials by weight: 100-180kg of cement, 50-120kg of slaked lime, 120-350kg of fly ash, 1300-1500kg of sand, 500-800kg of waste slurry, 0.5-2kg of water-retaining thickener, 0.5-2kg of water reducer, 0.5-2kg of retarder and 0.5-2kg of air entraining agent. The method has the advantages that expensive bentonite is unnecessary to be added, and about 100kg of bentonite is saved by mortar per cubic meter, thus effectively reducing the cost; the method has the advantages of good pumpability, water-retaining property, lubricating property, flowability, filling property and the like, and is used for fully utilizing the waste slurry.

Owner:CHINA RAILWAY 14TH BUREAU GRP LARGE SHIELD ENG CO LTD

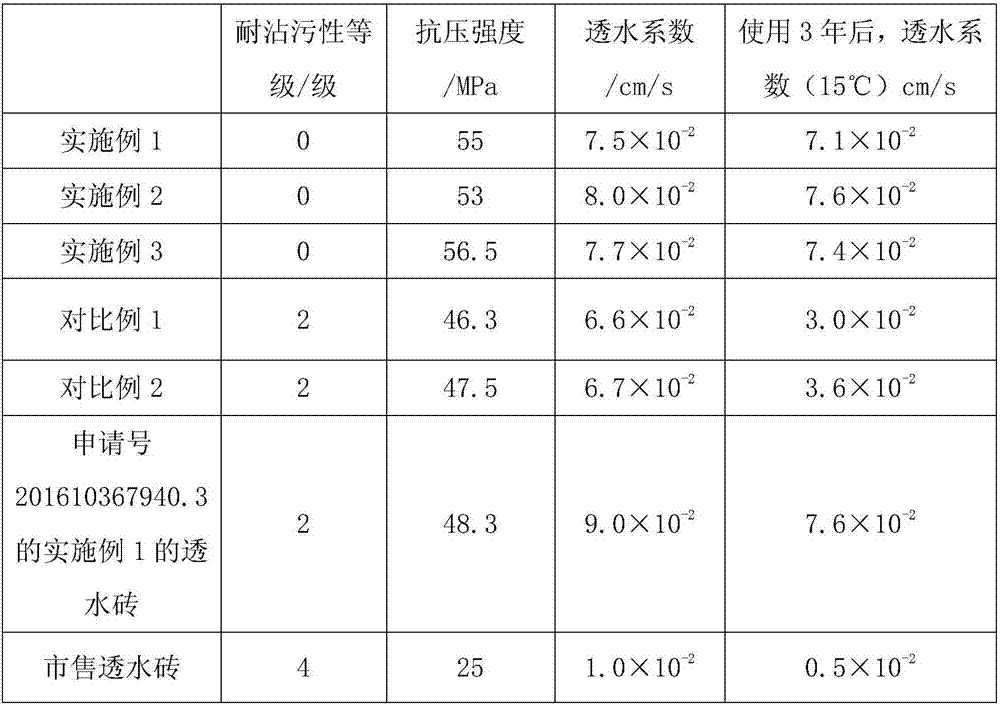

Anti-fouling and water-permeable brick with natural stone imitating effect and preparation method of anti-fouling and water-permeable brick

The invention provides an anti-fouling and water-permeable brick with a natural stone imitating effect and a preparation method of the anti-fouling and water-permeable brick. The anti-fouling and water-permeable brick comprises an anti-fouling and water-permeable surface layer and a water-permeable base layer, wherein the anti-fouling and water-permeable surface layer is prepared from raw materials in parts by mass as follows: 10-15 parts of cement, 0.5-2 parts of an aqueous adhesive, 65-75 parts of modified fine aggregate, 2-4.5 parts of water, 1.5-2 parts of a water-permeable agent and 3-8 parts of pigment; the water-permeable base layer is prepared from raw materials in parts by mass as follows: 15-25 parts of fly ash, 5-10 parts of cement, 10-20 parts of carbide slag, 5-15 parts of slag, 15-20 parts of construction waste, 2-4 parts of the water-permeable agent and 3-8 parts of water. A mass ratio of the anti-fouling and water-permeable surface layer to the water-permeable base layer is 1:(7.5-8.5), and the modified fine aggregate is prepared from one or more fine aggregate of granite debris, marble flakes, quartz sand and silica sand through modification. The anti-fouling and water-permeable brick has the advantages of being high in anti-fouling level, resistant to wear, good in water permeability, high in strength, low in cost and smooth in surface, achieving the attractive natural stone imitating effect and the like.

Owner:山东鑫旺节能建材有限公司

Device for preventing coal from burning spontaneously and rapidly extinguishing under coal mine and working method thereof

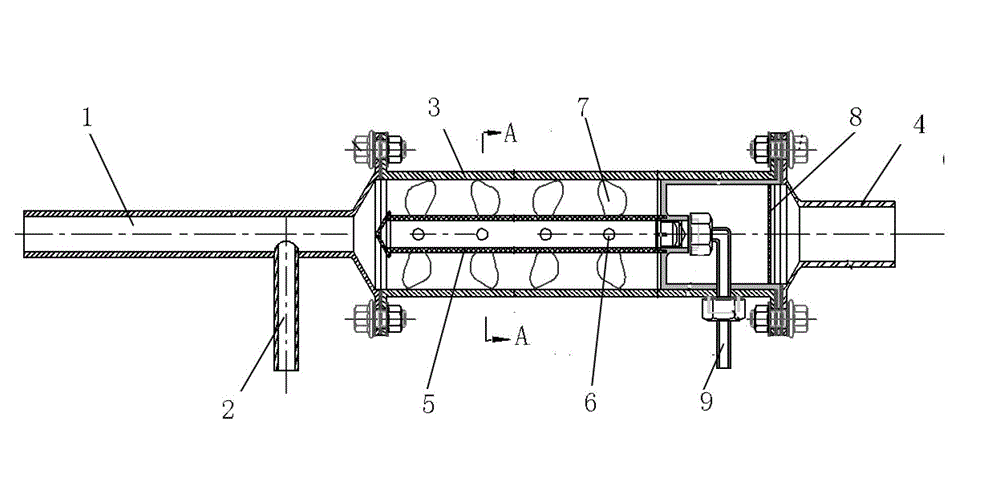

InactiveCN102979552APrevent spontaneous combustionAchieve fire extinguishingMixing methodsDust removalSpiral bladeEngineering

The invention discloses a device for preventing coal from burning spontaneously and rapidly extinguishing under a coal mine and a working method thereof. The device comprises a cylindrical foamed shell of which the two ends contract, wherein one end of the foamed shell is connected with a compressed air line; one side of the compressed air line is provided with a foam stock solution inlet; the other end of the foamed shell is connected with a foam output pipeline; 6-8 groups of spiral blades are arranged on a hollow shaft of an axis in the foamed shell at certain intervals; air outlet holes are formed among the spiral blades; included angles between the turning directions of the spiral blades and the axial direction of the hollow shaft are 45-60 degrees; each group of spiral blades has the same turning direction; and two adjacent groups of spiral blades have opposite turning directions. A mixture is foamed twice, so that the foaming times are raised to 50-150 times rapidly within a short period of time, and the aims of preventing and controlling spontaneous turning of coal and rapidly extinguishing are fulfilled.

Owner:SHANDONG UNIV OF SCI & TECH

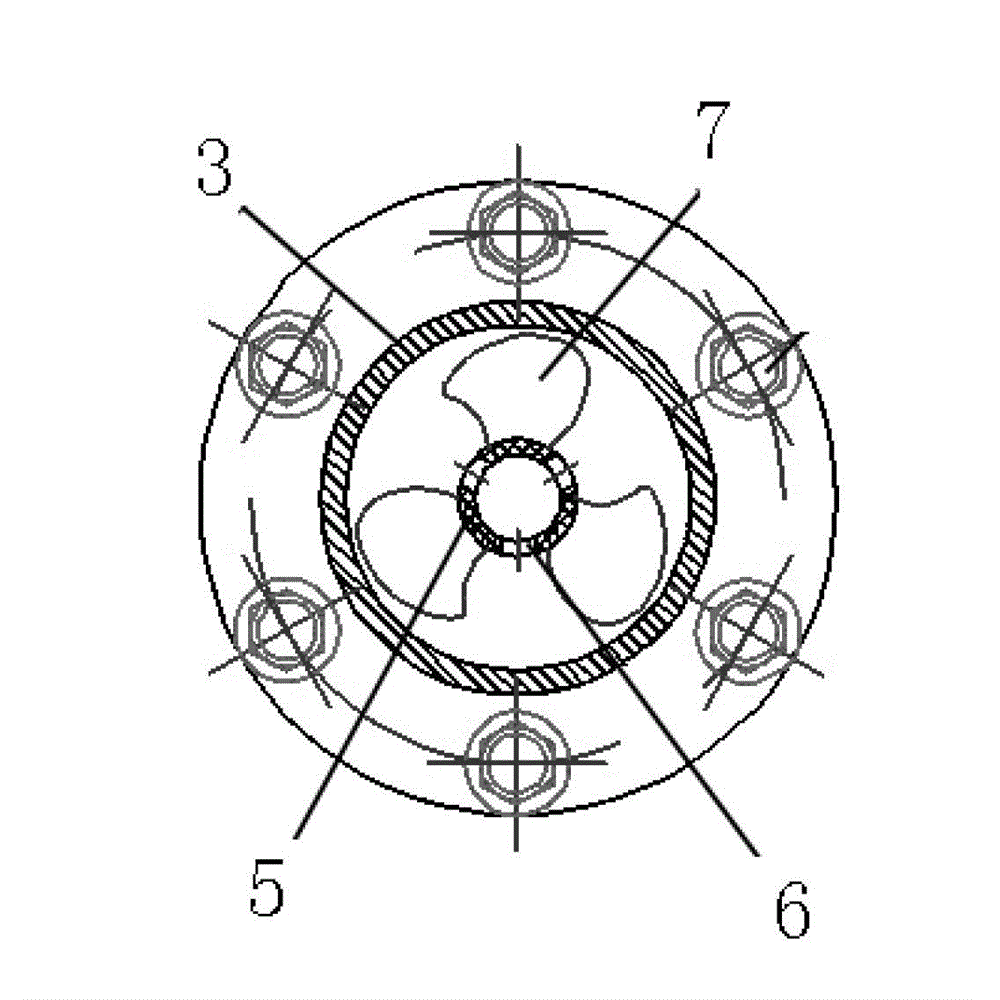

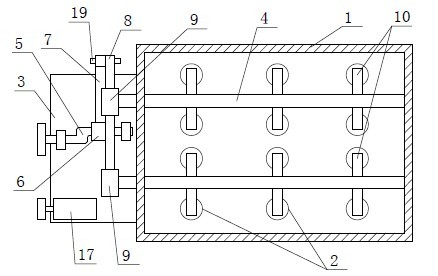

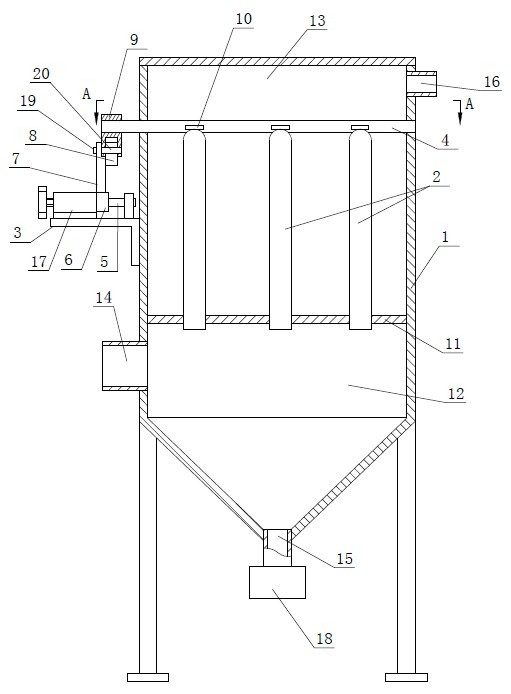

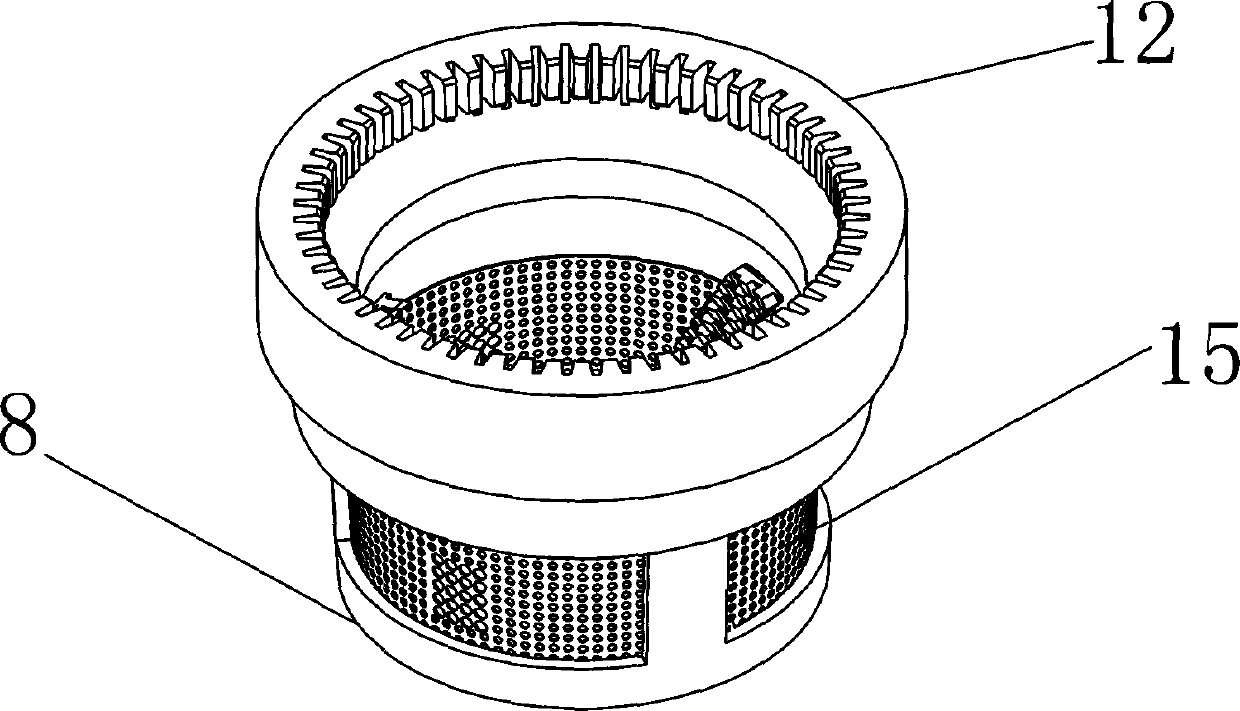

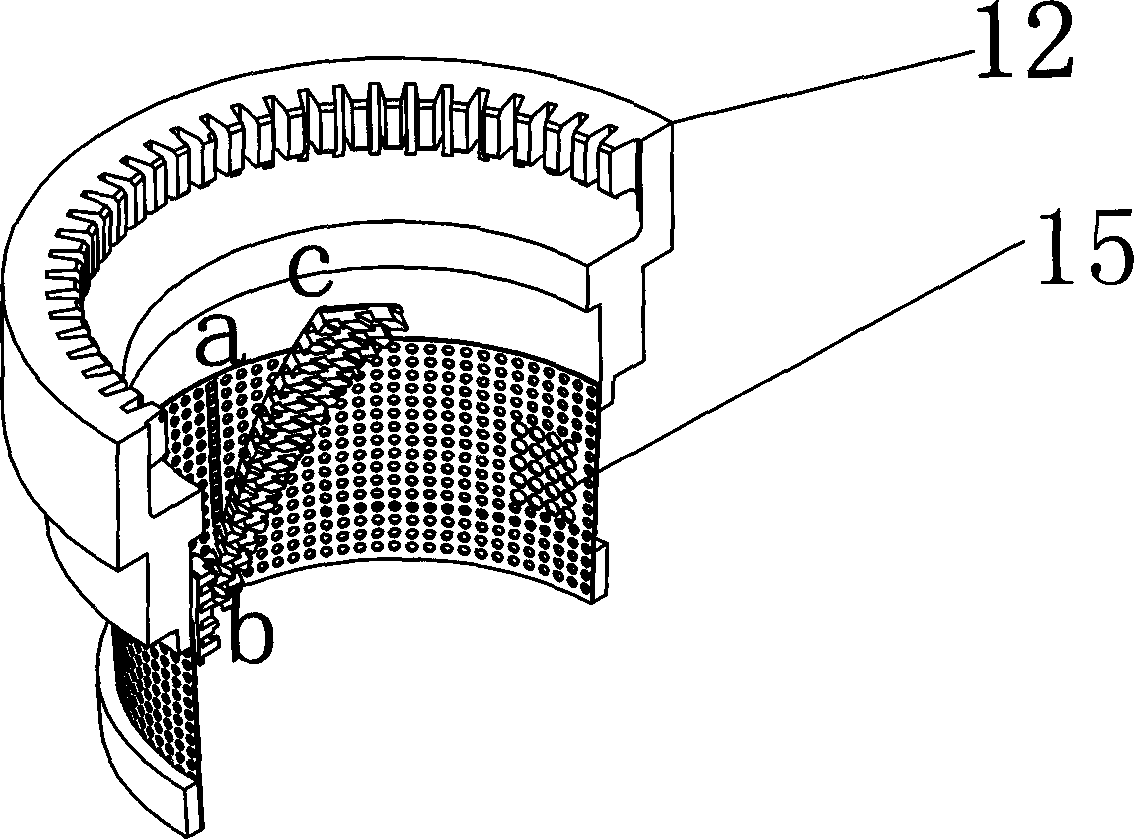

Bag-type dust collector

InactiveCN102430296AAvoid blocking flawsNot easy to accumulateDispersed particle filtrationBaghouseEngineering

The invention discloses a bag-type dust collector. The bag-type dust collector comprises a dust collector shell; dust collection bags are arranged in the dust collector shell; the upper part of the dust collector shell is provided with a swing device; and the upper ends of the dust collection bags are connected to the swing device. During dust collection, the dust collection bags swing along with the swing device, so dust cannot be adhered to the dust collection bags easily, the dust collection bags are not blocked easily and the dust collection efficiency can be improved conveniently.

Owner:潍坊华星机械有限公司

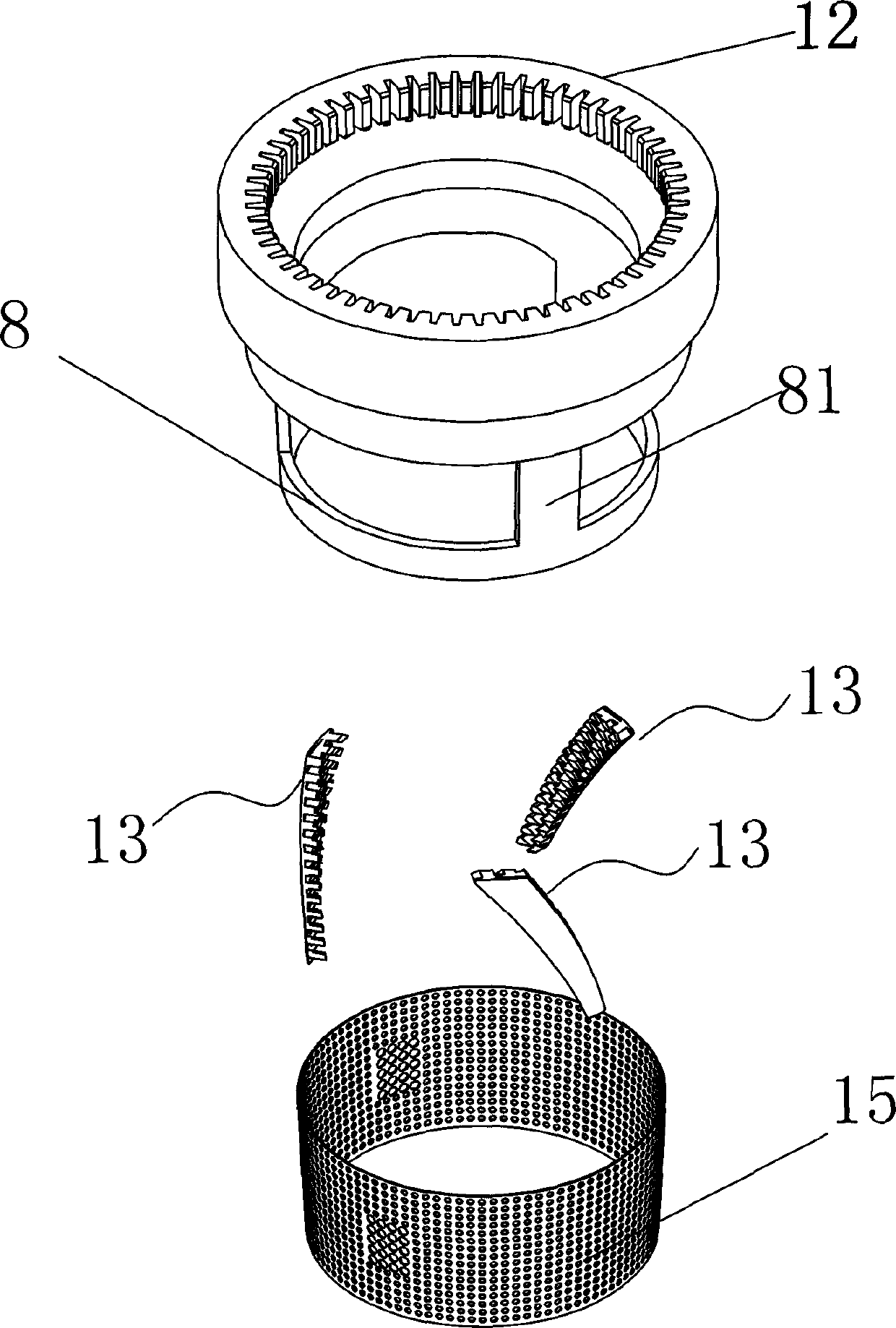

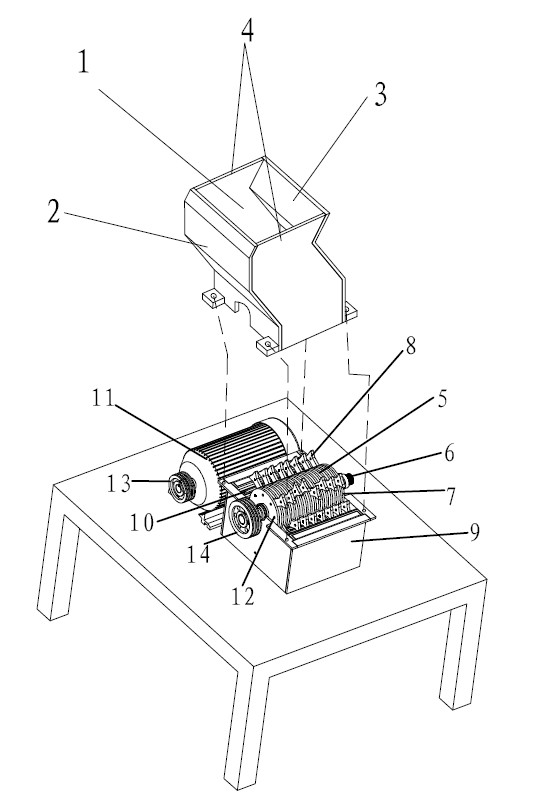

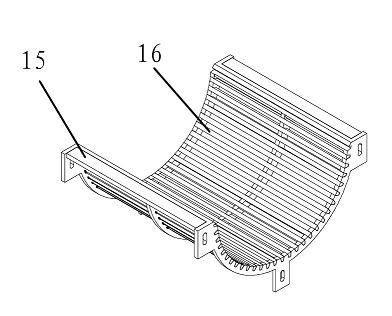

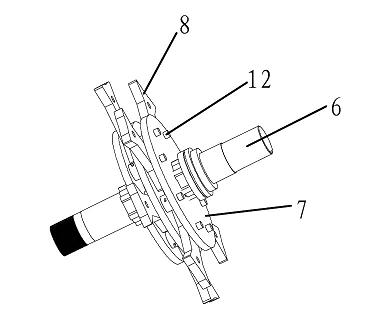

Filter screen mechanism and fruit and vegetable squeezing and grinding machine using same

The invention belongs to the field of a fruit and vegetable machine and particularly discloses a filter screen mechanism for a fruit and vegetable squeezing and grinding machine. The filter screen mechanism comprises an upper filter screen and a lower filter screen; a middle ring screen is also arranged between the upper filter screen and the lower filter screen; the middle ring screen is fixedly provided with a shielding ring; the shielding ring is provided with a plurality of notches; the notches are positioned in a mesh region of the middle ring screen; and the aperture of each mesh of the middle ring screen is respectively greater than those of each mesh of the upper filter screen and each mesh of the lower filter screen. The invention also discloses the fruit and vegetable squeezing and grinding machine utilizing the filter screen mechanism, which comprises the filter screen mechanism and a screw drive mechanism. The screw drive mechanism comprises a screw and a center shaft; the center shaft is connected with the screw; the screw is connected with a motor shaft; the screw is a spinning-cone-shaped sphere with a small upper part and a big lower part; the outer surface of the sphere is provided with a helix-shaped convex strip; the center shaft of the screw is coincided with a center shaft of the upper filter screen; gaps are formed between the edge of the screw and the inner walls of the upper filter screen, the middle ring screen and the lower filter screen; and fruits rotate along with the screw in the gaps to be processed. The filter screen mechanism and the fruit and vegetable squeezing and grinding machine have the advantage of multiple functions.

Owner:杭州富阳正易工贸有限公司

Waste lead acid battery crusher

InactiveCN101797526ANot easy to blockImprove work efficiencyLead-acid accumulatorsReclaiming serviceable partsCrusherMechanical field

The invention relates to a waste lead acid battery crusher, belonging to the mechanical field. The crusher comprises a feed port, a crushing bin, a filtering device and a discharging port, wherein the inside of the crushing bin is provided with a crushing hammer, the feed port is arranged on the upper part of the crushing bin, the discharging port is arranged on the lower part of the crushing bin, the filtering device is arranged between the crushing hammer and the discharging port; the crushing hammer comprises a rotation shaft, a hammer carrier and a hammer body; and the rotation shaft penetrates through the crushing bin, the hammer carrier is arranged on the rotation shaft, the center of the hammer carrier is positioned on the central axis of the rotation shaft, the hammer carrier is perpendicular to the rotation shaft, the hammer carrier is provided with a hammer shaft, and the hammer body is arranged on the hammer shaft. The device of the invention has simple structure, low cost, long service life, low maintenance cost, less procedures, simple process and good crushing effect.

Owner:ZHEJIANG HUITONG POWER

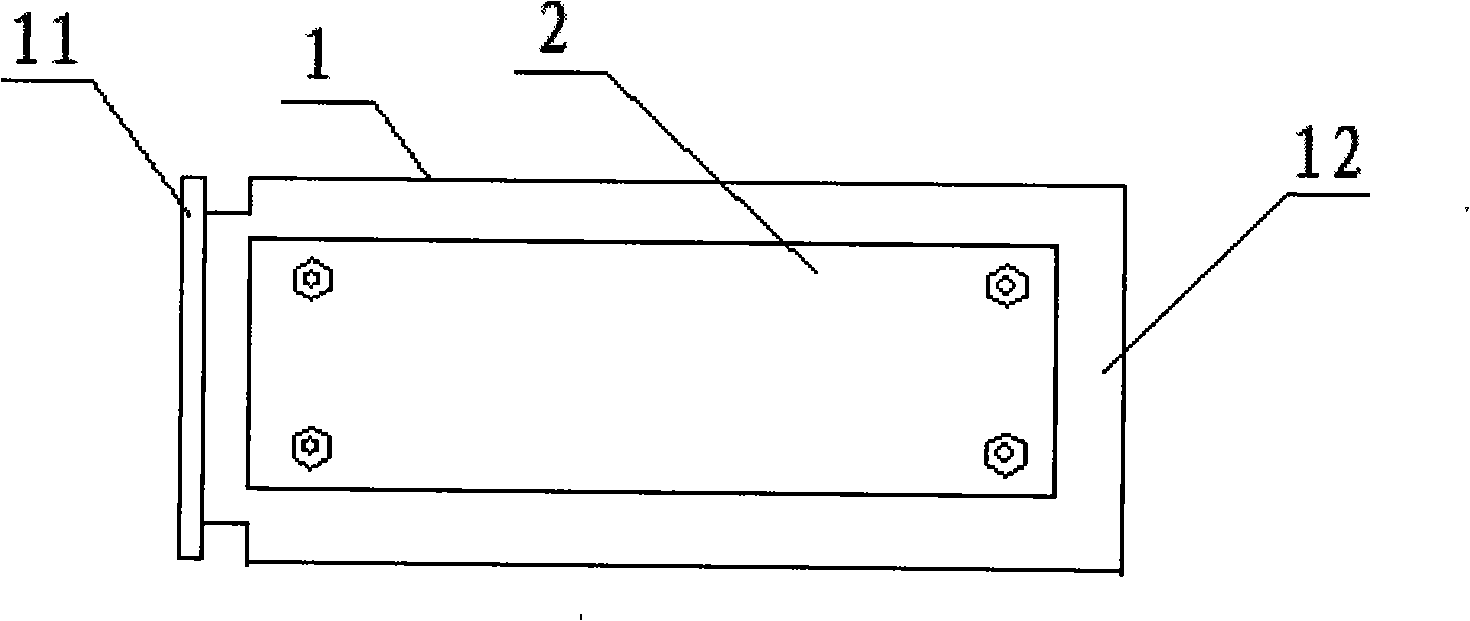

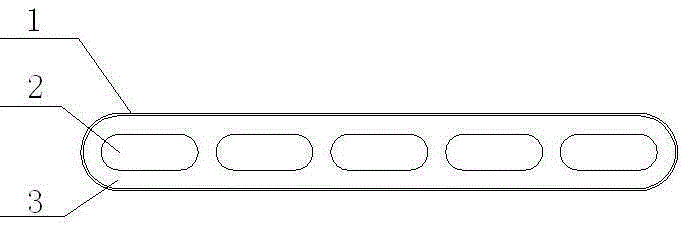

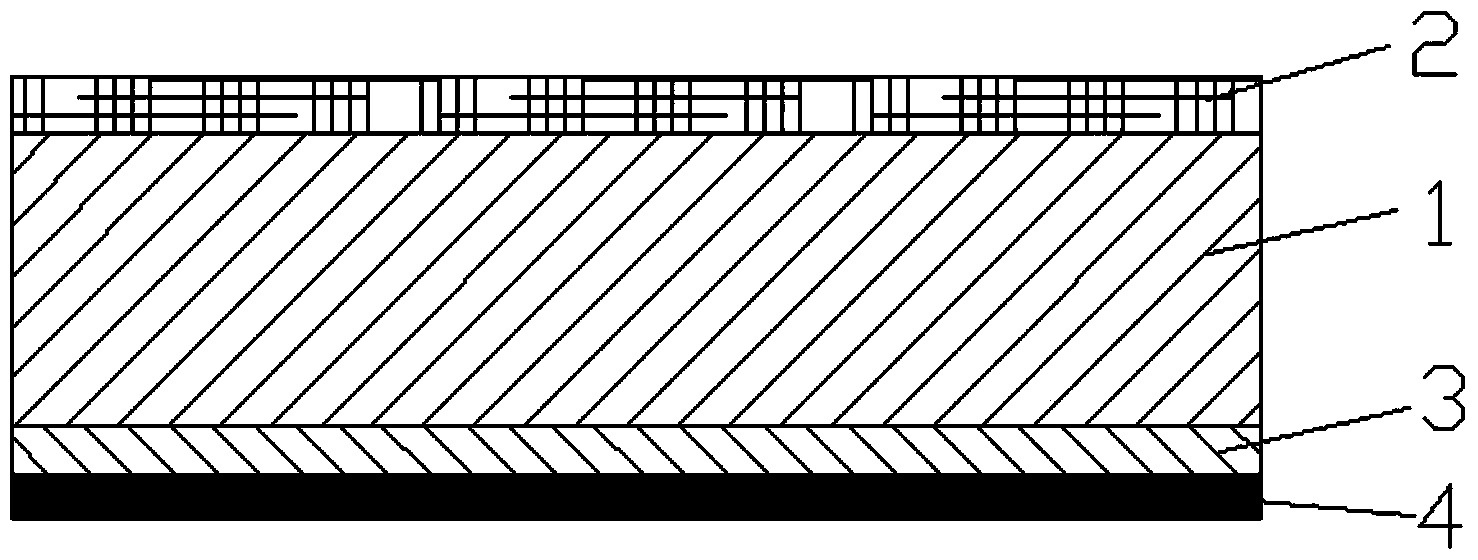

Diatomite-based low-cost ecological environment-friendly type flat ceramic membrane and preparation method thereof

ActiveCN105413484ALow priceLow costMembranesSemi-permeable membranesWater processingCeramic membrane

The invention discloses a diatomite-based low-cost ecological environment-friendly type flat ceramic membrane. The diatomite-based low-cost ecological environment-friendly type flat ceramic membrane comprises a ceramic flat support body and a separating layer membrane coated an outer surface of the ceramic flat support body, the water outlet holes are arranged in the ceramic flat support body; an integral body of the ceramic flat support body is a flat plate, and each corner angle of the flat plate is designed as round corner. The invention also provides a preparation method of the diatomite-based low-cost ecological environment-friendly type flat ceramic membrane, which comprises the steps of preparation of a ceramic flat membrane support body and preparation of a separating flat ceramic membrane. The raw materials have the advantages of low cost and no toxicity, the ceramic membrane is the ecological environment-friendly type filter membrane, is easily decomposed after being discard, and secondary pollution on environment cannot be generated. The ceramic membrane has wide utilization scope, can be used for water processing and gas processing, and especially used for processing and purifying harmful gas due to indoor decoration and processing outdoor environment gas PM2.5.

Owner:安徽名创新材料科技有限公司

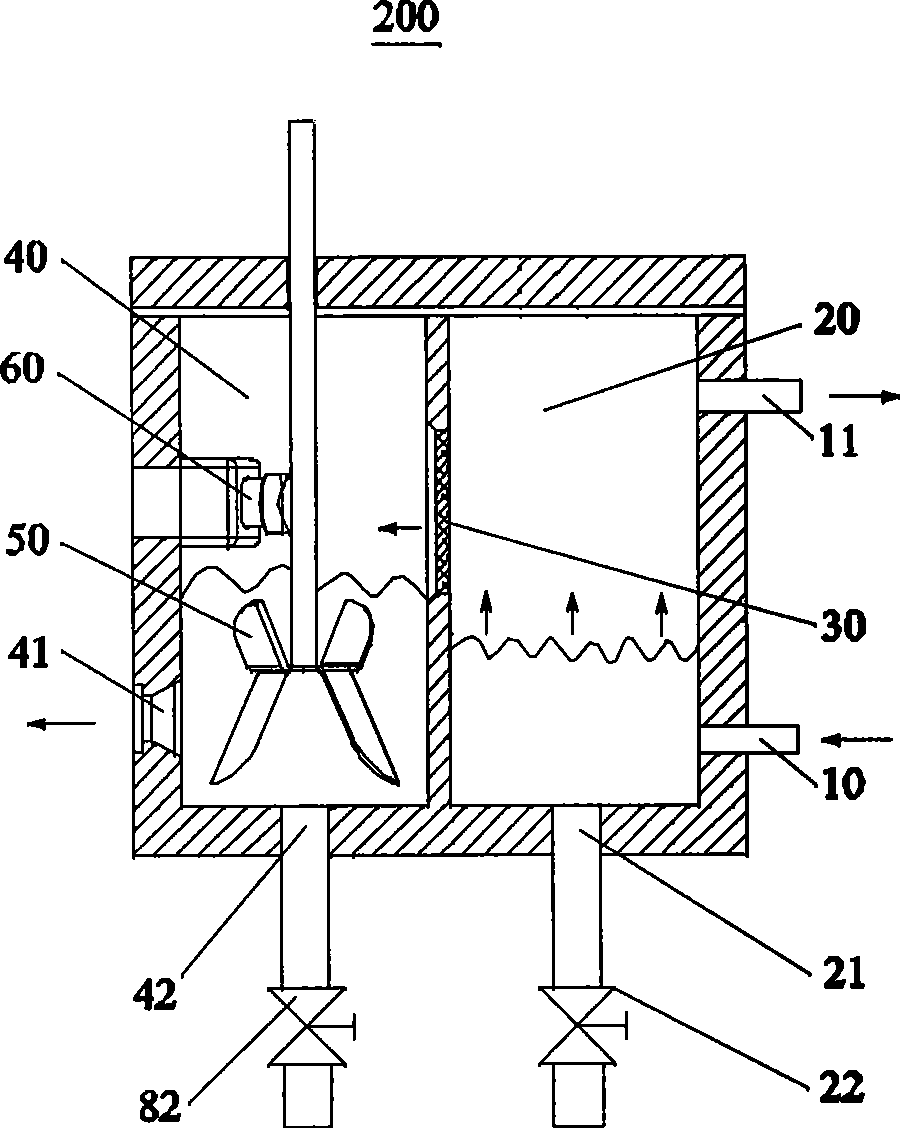

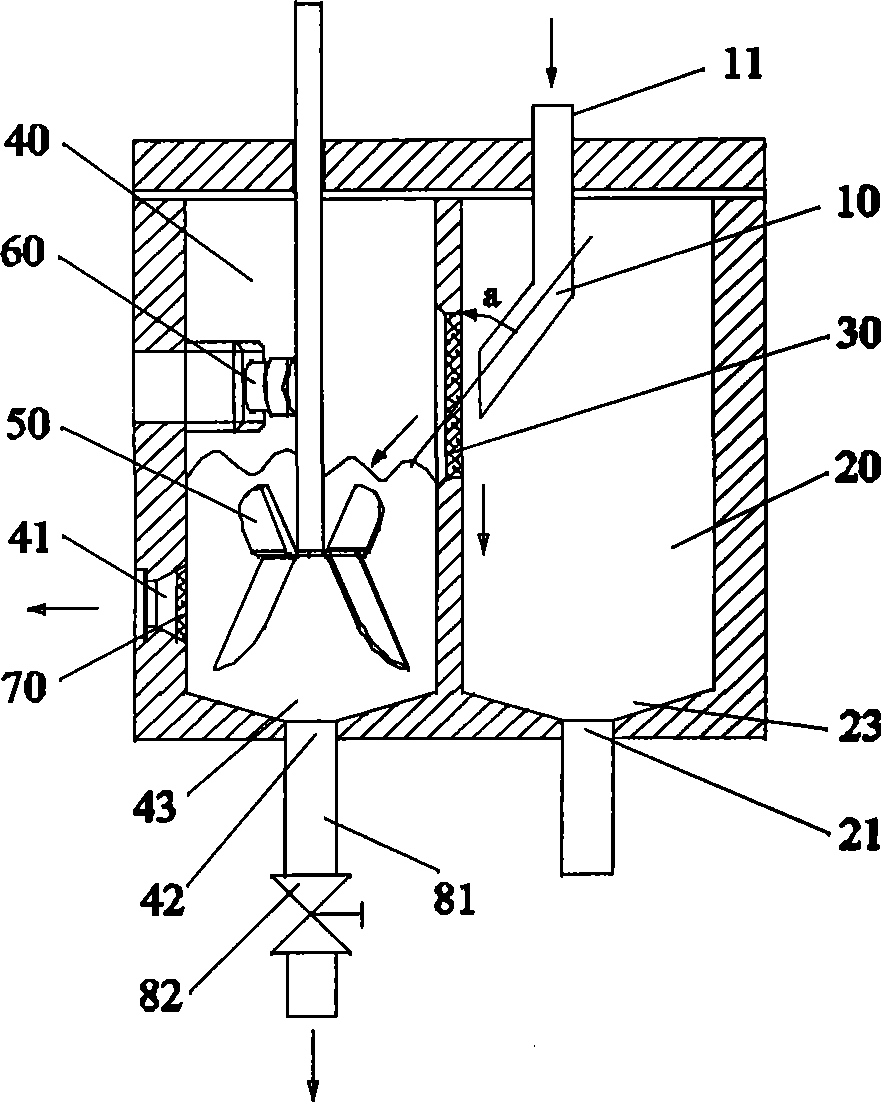

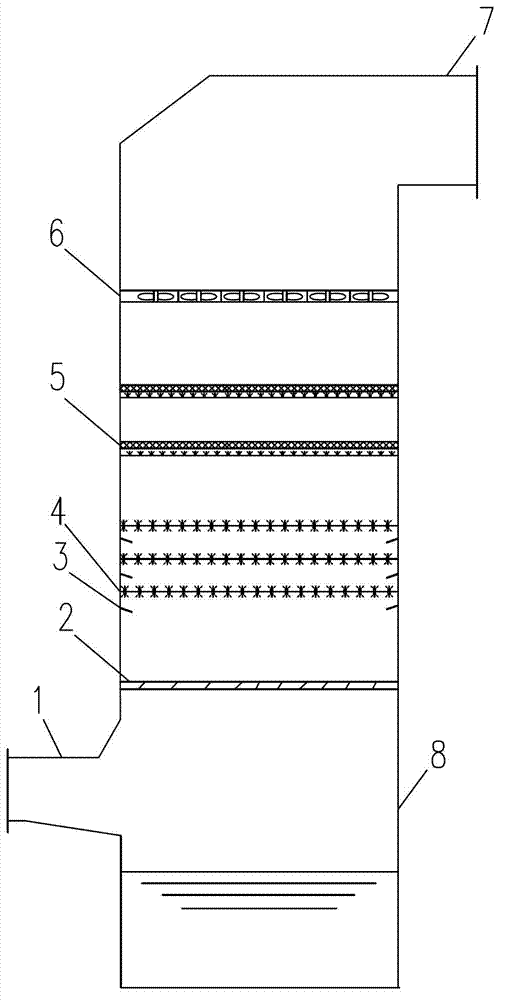

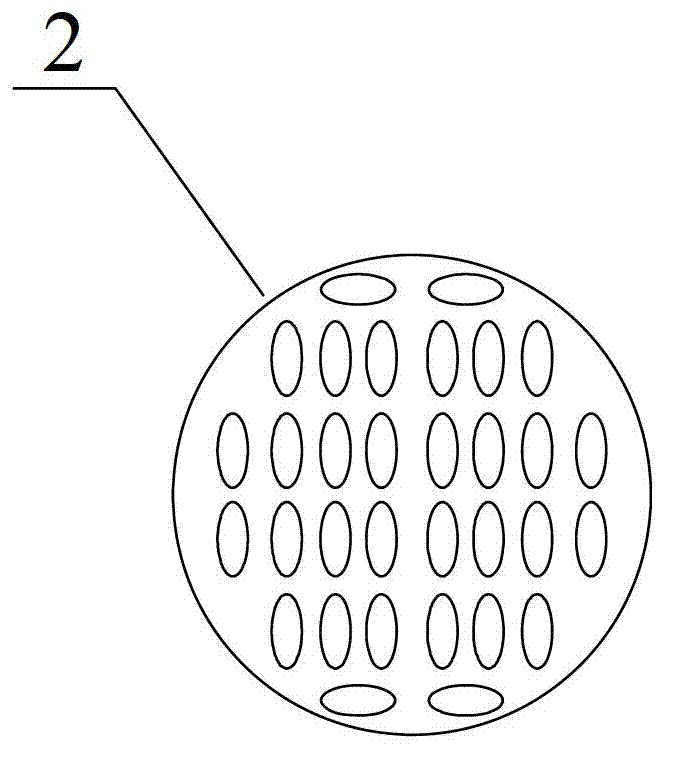

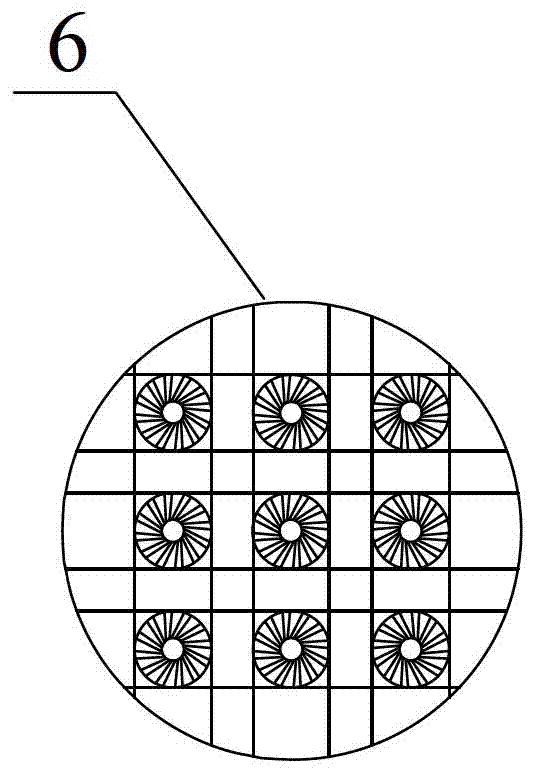

High-quality spray absorber for wet flue gas desulfurization

ActiveCN102764582AOvercomes easy crystallization and scalingNot easy to blockDispersed particle separationGypsumSulfur dioxide

The invention discloses a high-quality spray absorber for wet flue gas desulfurization. The absorber comprises an absorber cylinder body which is provided with a flue gas inlet channel and a flue gas outlet channel. A perforated screen plate, flue gas redistribution rings, slurry spray devices, a demister and a rotating-stream plate device are arranged horizontally from bottom to top between the flue gas inlet channel and the flue gas outlet channel. Inner side edges of the flue gas redistribution rings are in an undulate or serrated shape, and the rotating-stream plate device is composed of a plurality of evenly-distributed independent rotating-stream plate separators. According to the high-quality spray absorber for wet flue gas desulfurization, the problem of no flue gas flowing above the absorber close to the flue gas inlet section is solved, the phenomenon of the easy crystallization and scaling of the area is overcome, gas-liquid contact area is maximized, absorption reaction is effective, and the absorber is applicable to desulfurization of flue gas with high sulfur dioxide content. 'fog-drop particles' carried in the flue gas are eliminated to the maximum extent, chimney 'rain' phenomena are reduced greatly, and the content of fog-drop particles can achieve 60 milligrams / nanometer3. The absorber is wide in applicable range, and can be used for wet flue gas desulfurization in a double-alkali way, an acetylene sludge way, a lime-gypsum way and the like.

Owner:武汉华德环保工程技术有限公司

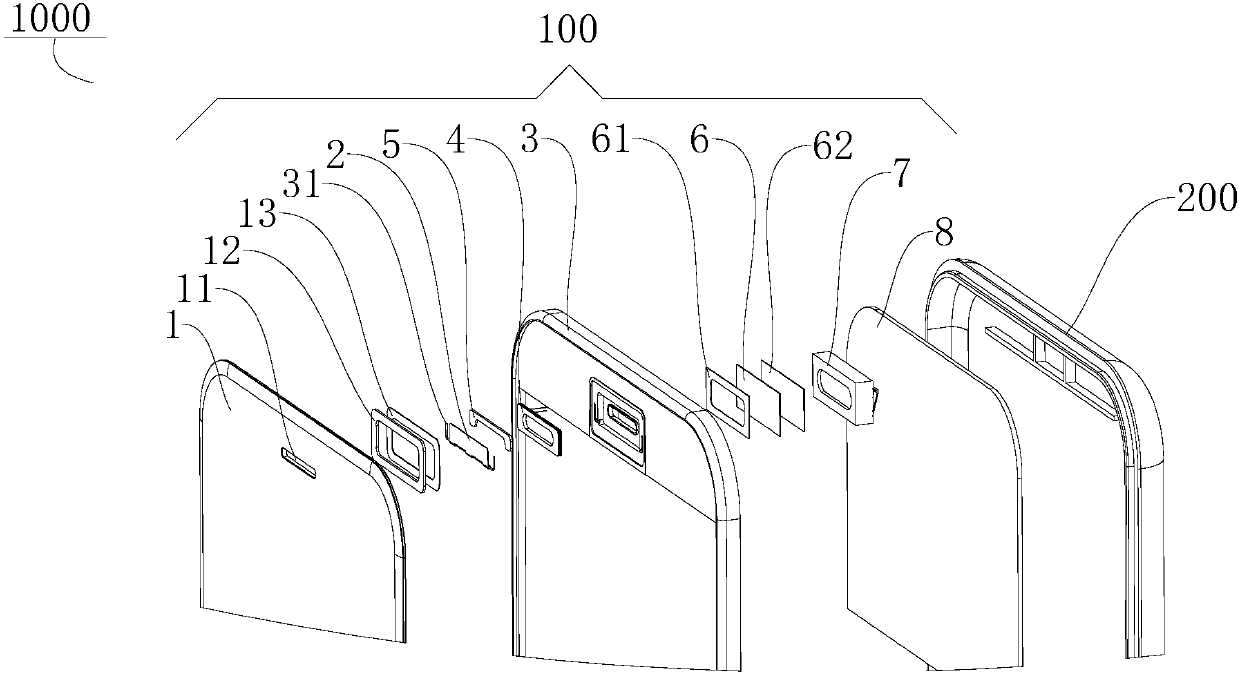

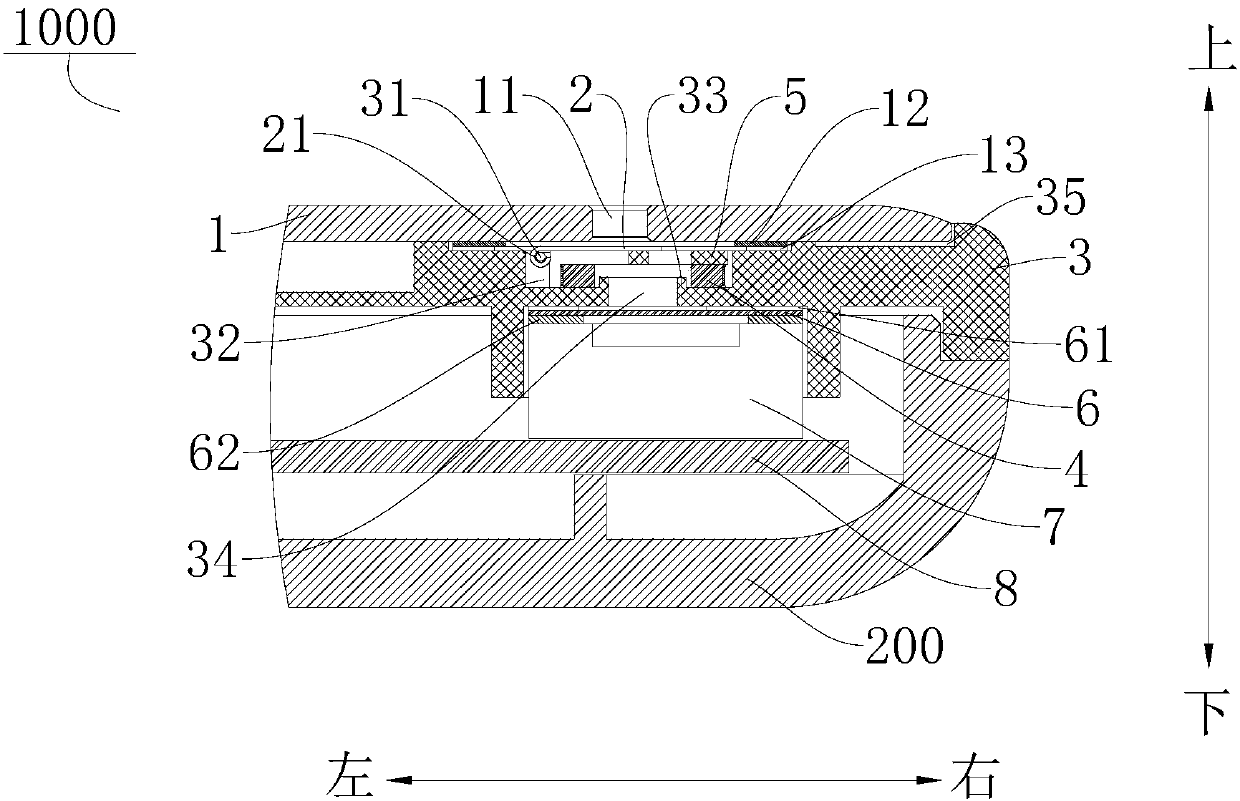

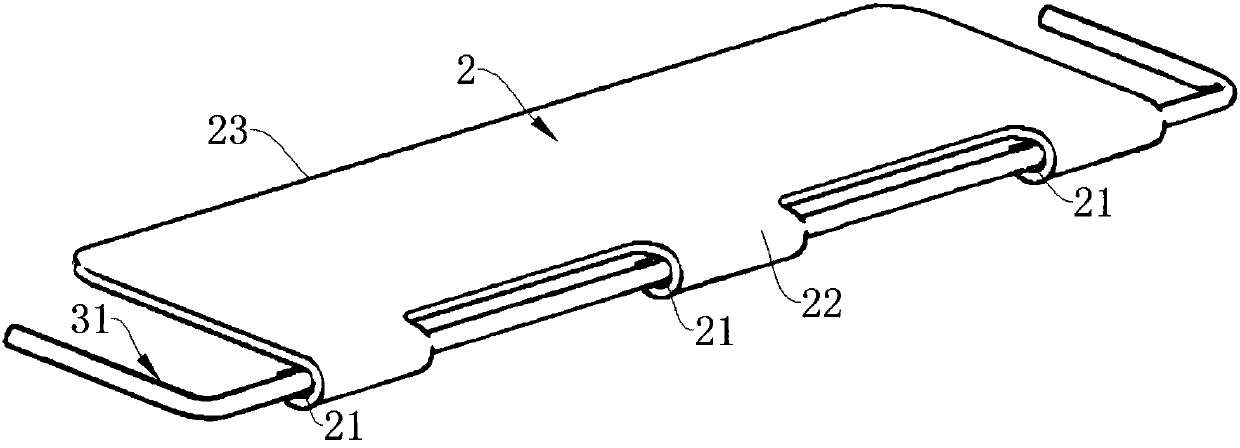

Terminal housing assembly, terminal and terminal control method

The invention discloses a terminal housing assembly, a terminal and a terminal control method; the terminal housing assembly comprises the following units: a middle frame with a sound hole; a cover plate arranged on the middle frame and provided with a sound through hole matched with the sound hole; a metal decoration arranged between the middle frame and the cover plate, wherein one end of the metal decoration is pivoted on the middle frame so as to open or close the sound through hole; a coil arranged between the metal decoration and the middle frame, and used for forming a magnetic field soas to drive the metal decoration for opening the sound through hole; an elastic support member arranged between the coil and the metal decoration and used for driving the metal decoration to close the sound through hole. According to the housing assembly, the coil can form the magnetic field so as to drive the metal decoration to rotate, thus opening the sound through hole on the cover plate; themetal decoration can close the sound through hole under the support member elastic force effect, thus preventing dusts or particles from blocking the sound through hole, and ensuring the output soundquality.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

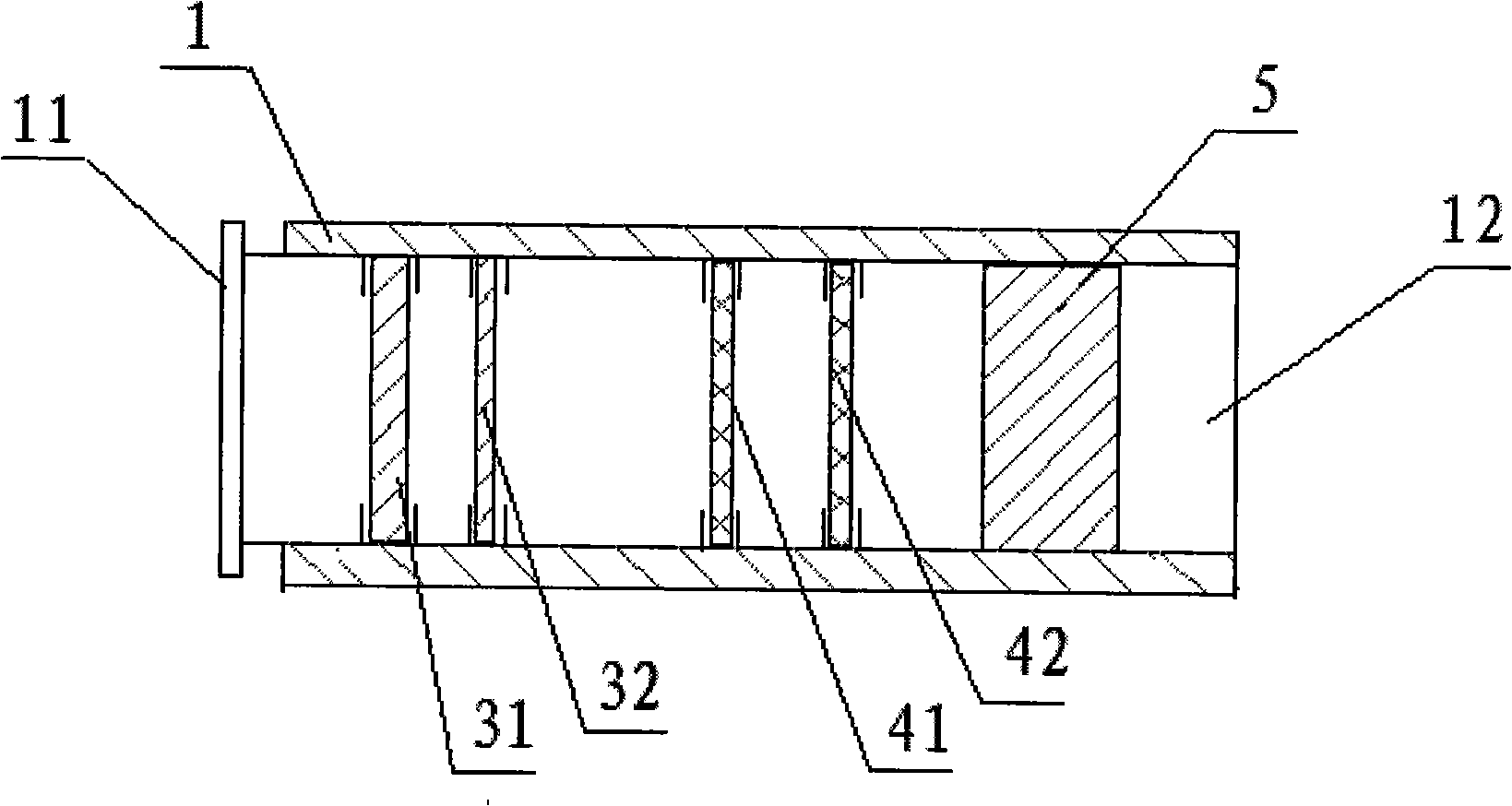

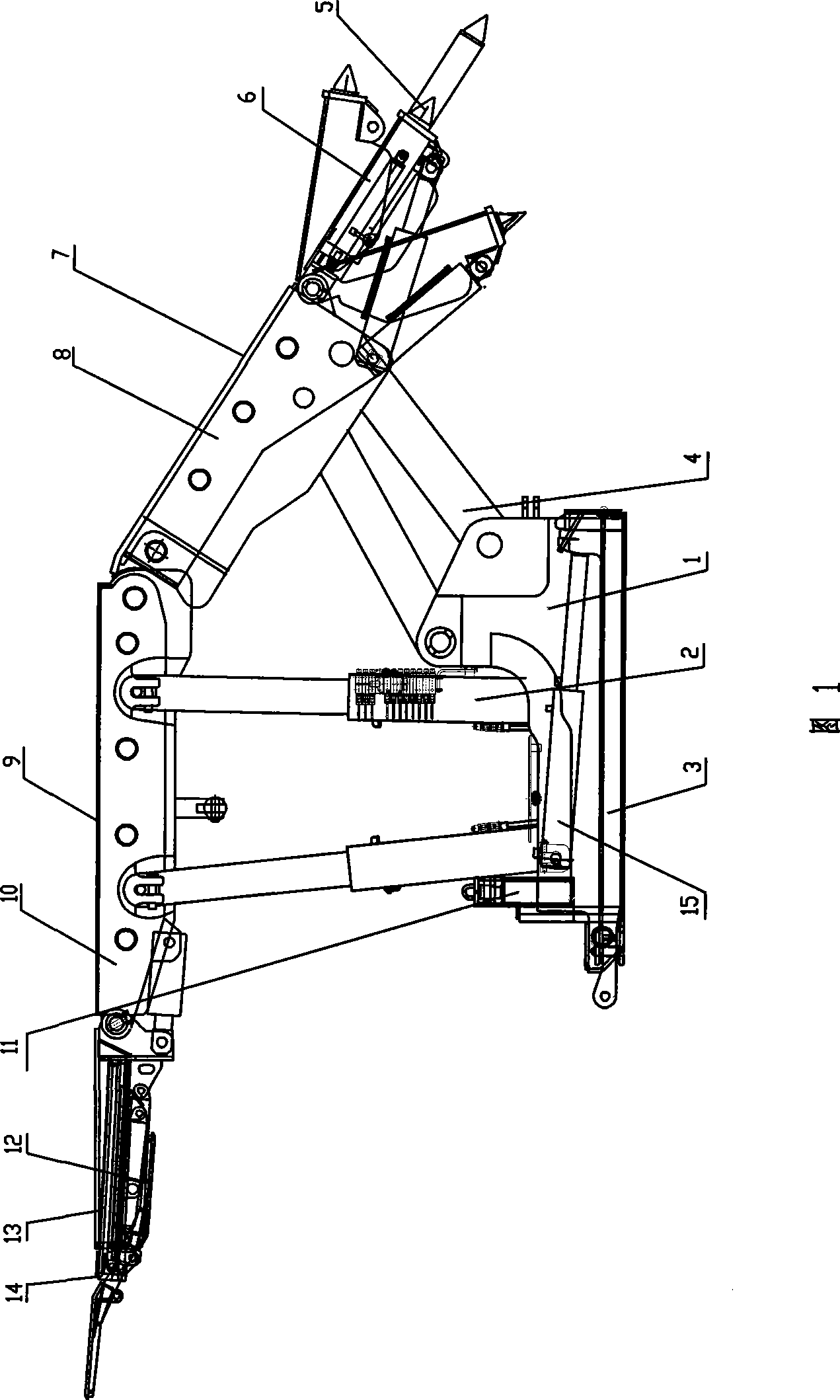

Large extraction high caving roof coal hydraulic support

InactiveCN101440711ACoal position is lowHigh coal recovery rateMine roof supportsSpelunkingArchitectural engineering

The invention relates to a top coal caving hydraulic bracket with large mining height. The hydraulic bracket comprises a base, upright posts, a top beam, a front beam, a shield beam, a tail beam and an insertion plate; the top beam is supported on the base through four upright posts; the front beam and the shield beam are hinged with the front end and the rear end of the top beam respectively; the shield beam is also connected with a connecting rod; the front part of the front beam is provided with a telescopic beam which is connected with the front beam through a telescopic beam jack; the front end of the telescopic beam is hinged with the rear part of a protective plate; one end of a protective plate jack is connected with the telescopic beam; the other end pf the protective plate jack is connected with the tail part of the protective plate; the front end of the tail beam is hinged with the shield beam; the other end of the tail beam is connected with the shield beam through a tail beam jack; and the insertion plate is positioned in the inside of the tail beam. The hydraulic bracket has the advantages that the hydraulic bracket has large mining height and high working resistance, can realize top coal caving and can also realize overall height mining once when the thickness of the coal is 4.5 meters.

Owner:ZAOZHUANG MINING GRP CO LTD

Preparation method of polyacrylonitrile-based precursor

ActiveCN105671668AGuaranteed filtering effectNot easy to blockMonocomponent synthetic polymer artificial filamentWet spinning methodsSolventItaconic acid

The present invention relates to a preparation method of a polyacrylonitrile-based precursor, and mainly solves the problems that in the prior art bubbles in a material sprayed out by a filter cannot be completely eliminated, spinnability is poor, wire broken rate is high, and a carbon fiber precursor obtained by spinning is low in strength and unstable in performance. The preparation method well solves the problems, and the preparation method includes the following steps: 1) solvent dimethyl sulfoxide, first monomer acrylonitrile, a second monomer itaconic acid and initiator azodiisobutyronitrile are polymerized to obtain a spinning stock solution, and a high performance polyacrylonitrile copolymer spinning stock solution is obtained by filtering after demonomerisation and defoaming of the spinning stock solution; nascent fiber is obtained by jet extrusion and consolidation forming; and a high-performance polyacrylonitrile carbon fiber precursor is obtained by drawing, water washing, oiling, compacting by drying, steam stretching, heat-setting and collection of the nascent fiber; and the method can be used for the industrial production of the carbon fiber precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

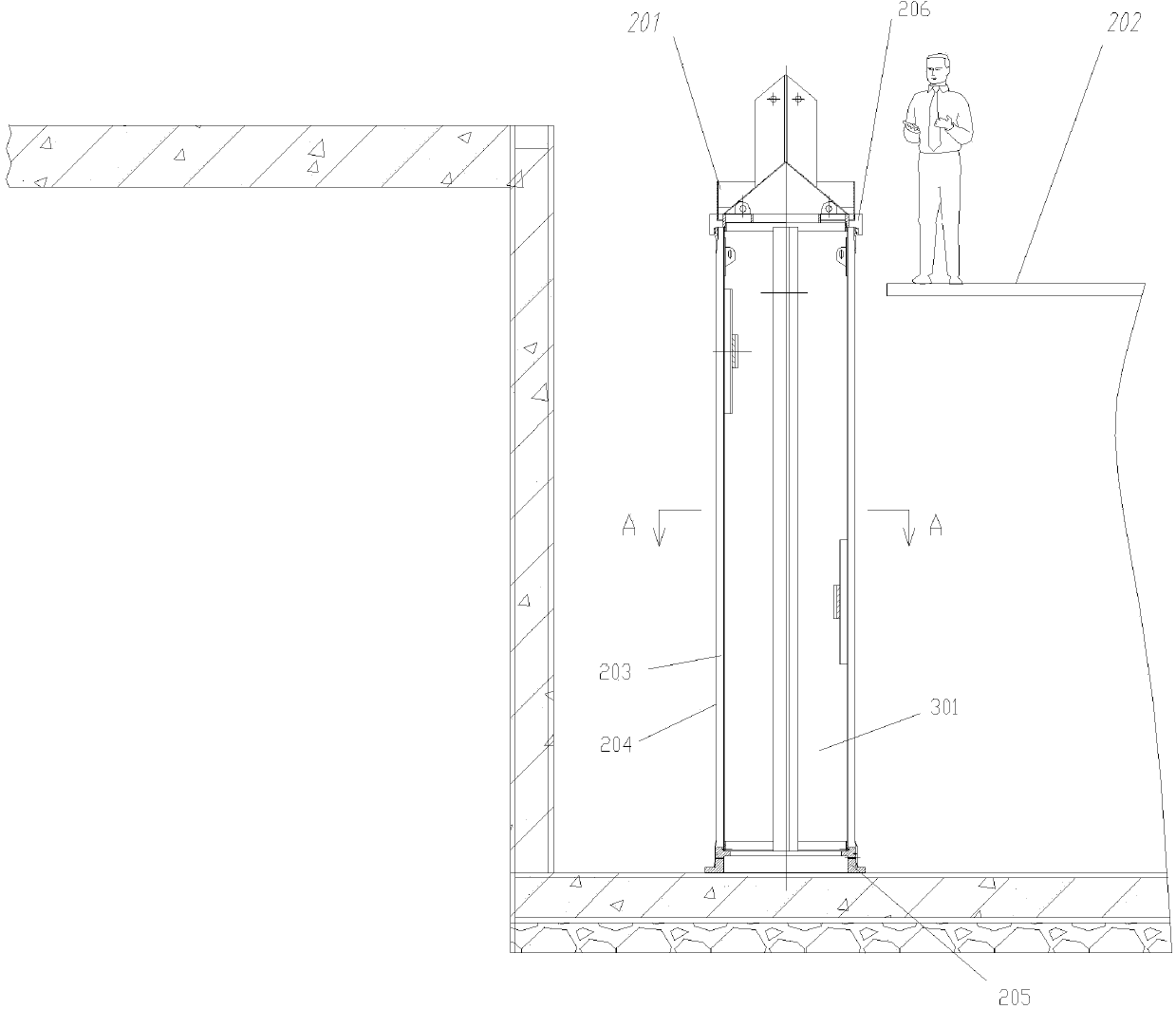

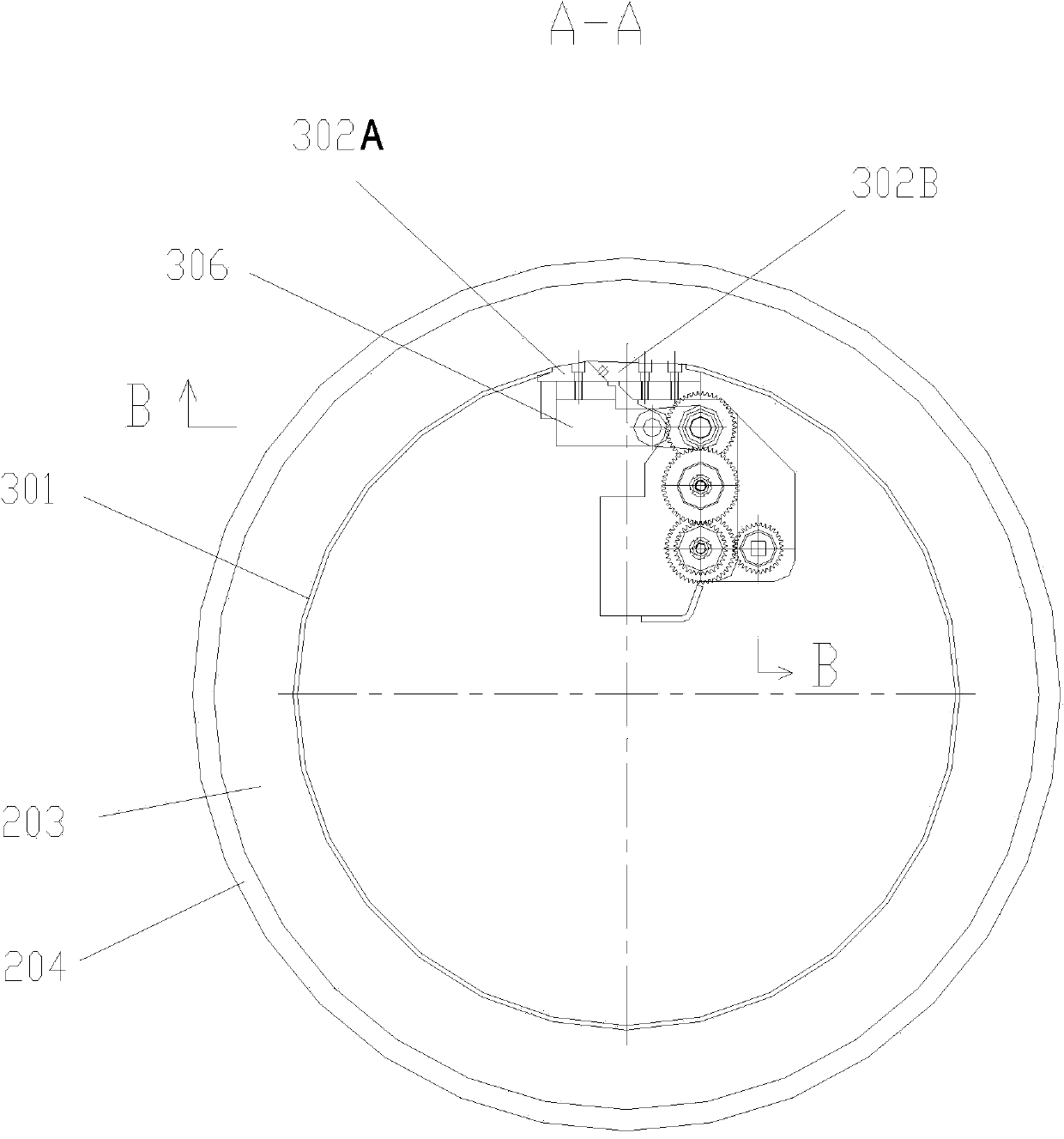

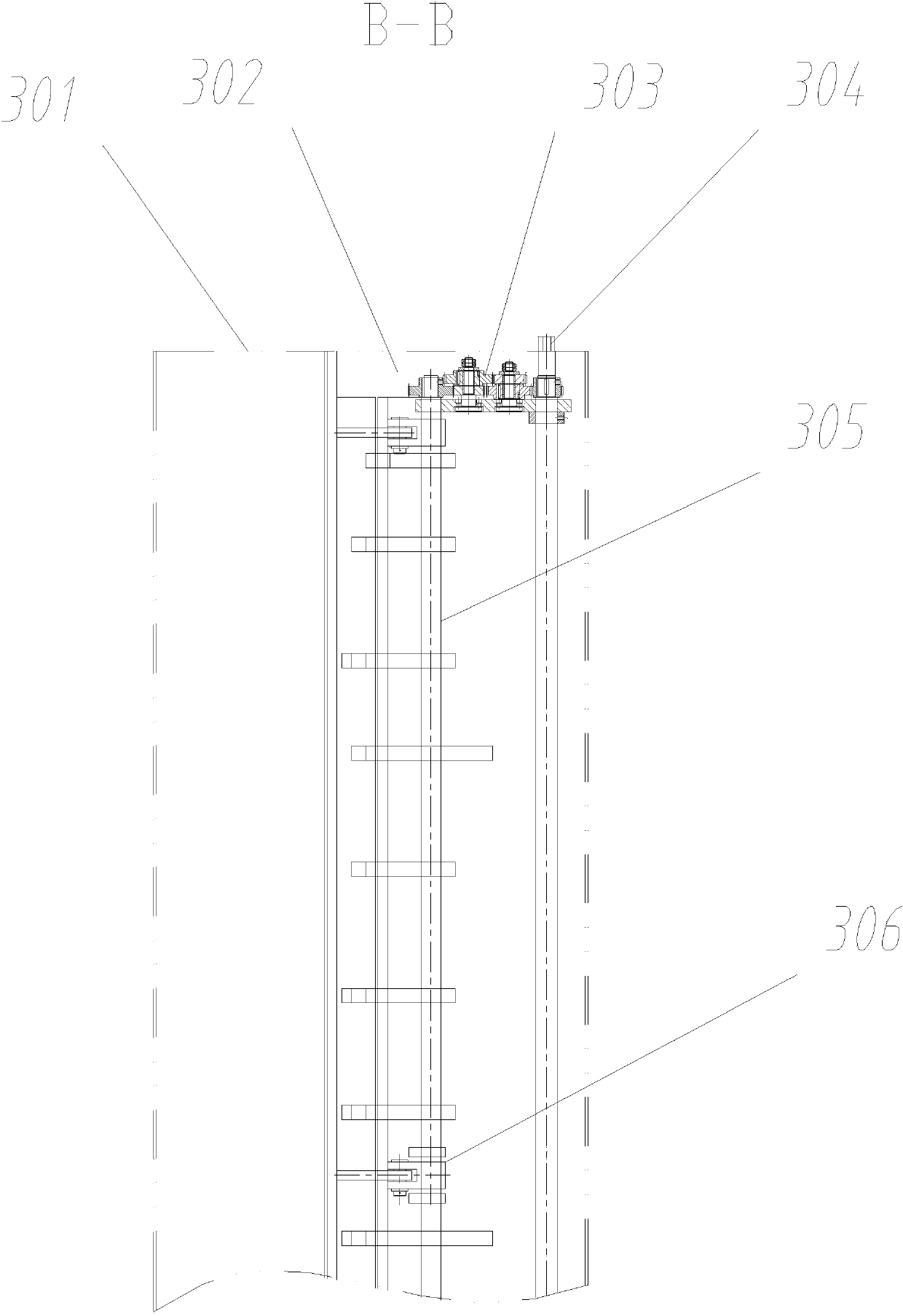

Vertical machining device and method for small-caliber PCCP

ActiveCN104191519AImprove locking effectIncrease torqueLapping machinesCeramic shaping apparatusGear wheelDrive shaft

The invention discloses a vertical machining device and method for a small-caliber PCCP. The vertical machining device and method are suitable for small-caliber pipes, operation is convenient, and the sealing effect is good. The vertical machining device comprises a vertical inner die, an outer die and a pouring device. The inner die is provided with an axial straight slit penetrating through the inner die in the height direction, and two slit openings of the straight slit are fixedly connected with a movable door plate and a driven door plate respectively. The inner die is internally provided with a stretching and contracting device which comprises a drive shaft, a driven shaft, a support, a reduction gear set and at least three movable door plate driving mechanisms. According to the vertical machining device and method for the small-caliber PCCP, the stretching and contracting device and a locking device having the heights basically identical with the height of the inner die are used, wherein the heights of the stretching and contracting device and the locking device can be slightly smaller than the height of the inner die when being applied, and the stretching and contracting device is large in torque, high in evenness of force transmitted out from the driven shaft with the same rigidity and good in movement speed and synchronism. The locking device is transmitted through a screw rod, drives a sliding plate in linear movement and achieves locking of the movable door plate in the stretched state through a wedge mechanism.

Owner:JIANGSU JIANGYANG BUILDING MATERIAL MACHINERY

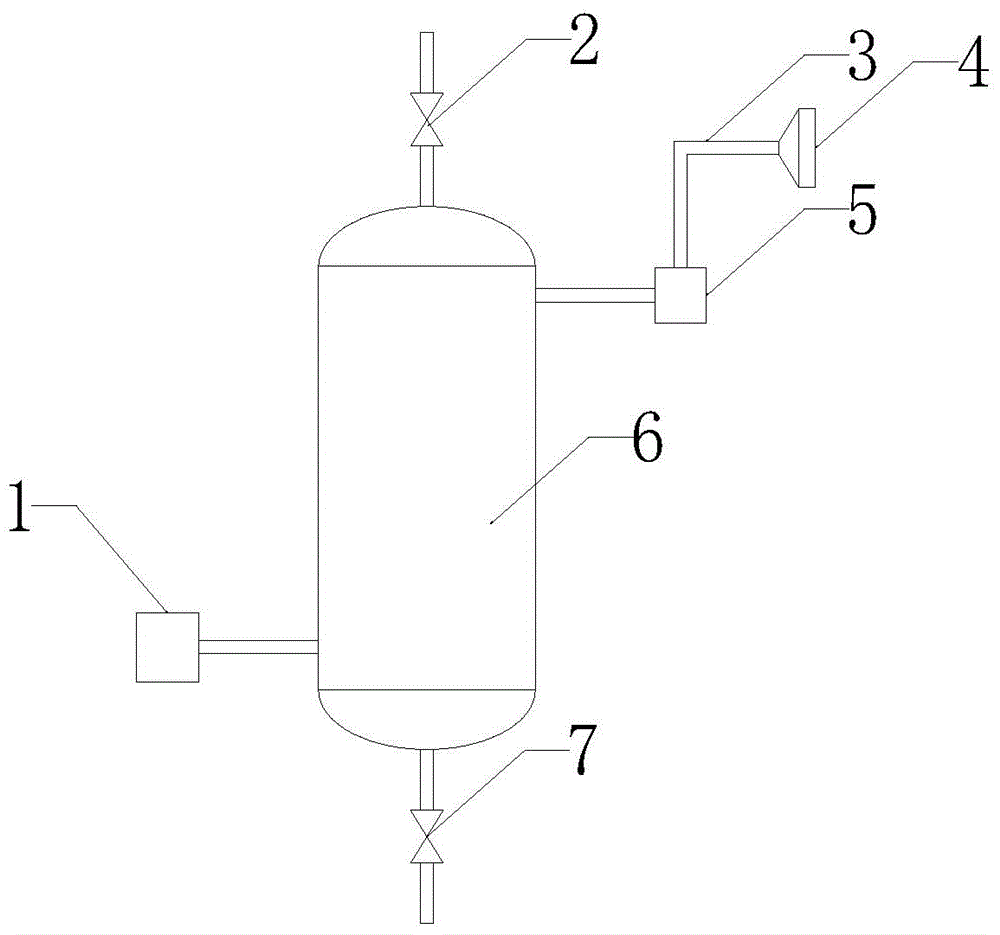

Portable liquid nitrogen filling device with automatic stopping function for high-purity germanium detector

ActiveCN103742783ANot easy to blockCompact structureContainer discharging methodsContainer filling under pressureAutomatic controlContactor

The invention discloses a portable liquid nitrogen filling device with an automatic stopping function for a high-purity germanium detector. The portable liquid nitrogen filling device comprises a temperature measuring unit, an automatic control unit and a liquid nitrogen filling unit, wherein the automatic control unit comprises a 220V power supply, a start button, an alternating-current contactor, a temperature controller and an electromagnetic valve; the electromagnetic valve is arranged on an exhaust pipe of a liquid nitrogen pump; the two input ends of the electromagnetic valve are connected with an L phase and an N phase of the 220V power supply respectively through a contact KM2 and a contact KM3 of the alternating-current contactor; the electromagnetic valve is in a shut-down state when the output voltages of the contact KM2and the contact KM3 are switched on and is in a turn-on state when the voltages are switched off. By adopting the portable liquid nitrogen filling device, a temperature monitoring function is realized, the liquid nitrogen pump stops automatically when a Dewar tank is full of liquid nitrogen and the automatic control unit is irreversible when the temperature is higher than a set threshold value, so that the function of unattended operation is realized in a liquid nitrogen filling process.

Owner:NORTHWEST INST OF NUCLEAR TECH

Porous carbon material and its preparation method

The invention discloses a porous carbon material and its preparation method. The preparation method provided by the invention successively comprises steps of: raw material and auxiliary material selection, pulverization, spheroidization, grading, burdening, mixing, molding, roasting and the like. Green petroleum coke and green pitch coke are creatively used as raw materials. A filtration materialprepared after spheroidization of a green coke powder has large contractility, high strength, uniform pore distribution, smooth pore path, high filtration precision and good transmissivity, is not easy to block during the purification process, is easy to regenerate, and has long service life. The porous carbon material prepared in the invention can be widely used as a filtration material, a thermal insulation material, a conductance electrode and the like.

Owner:ZIGONG YUXING CARBON PRODS

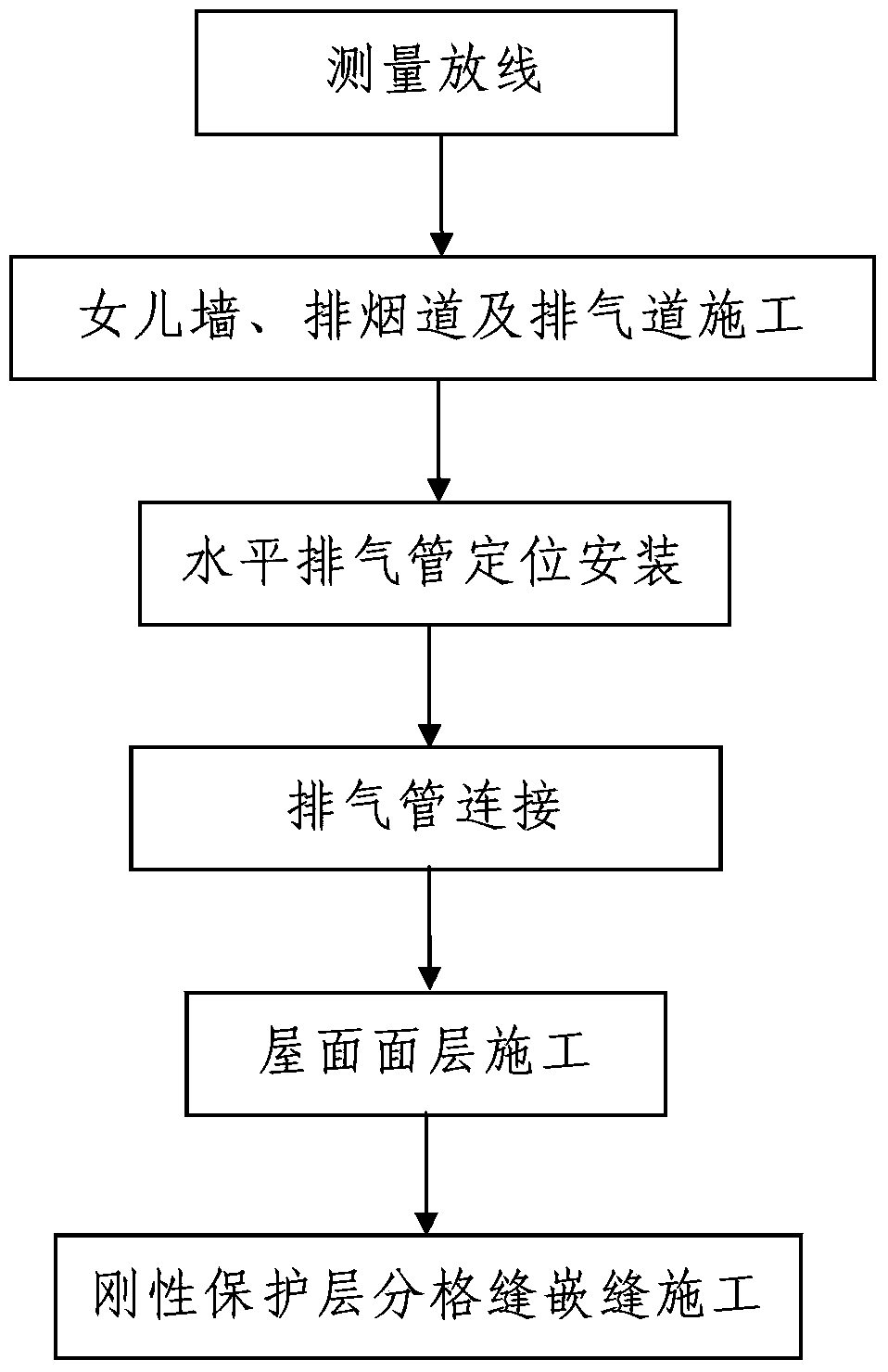

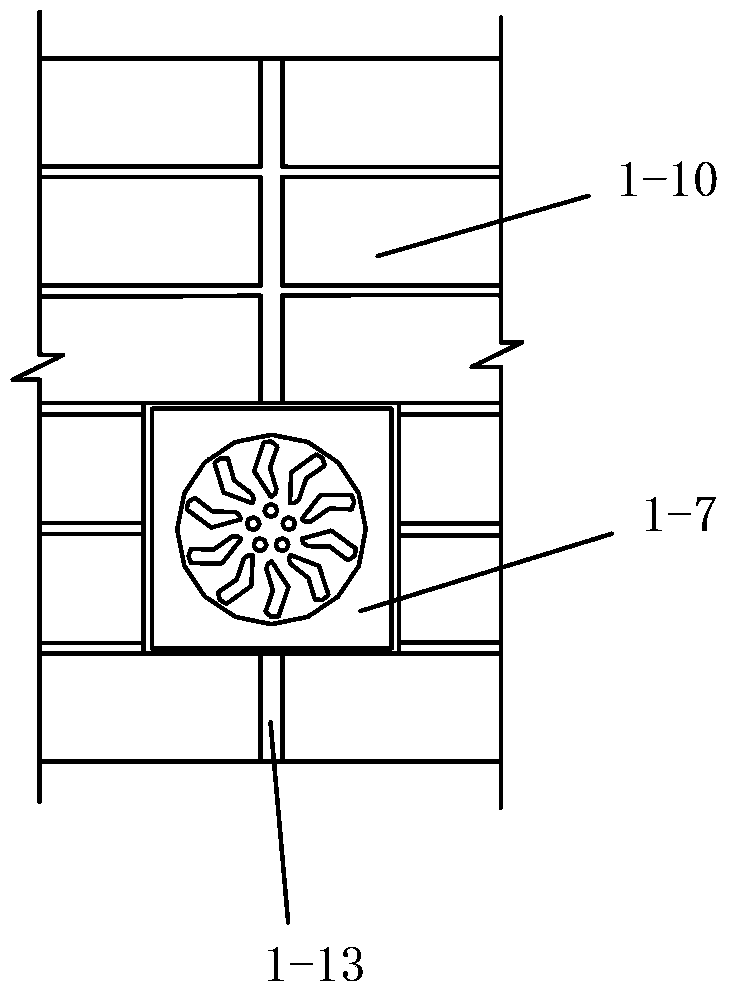

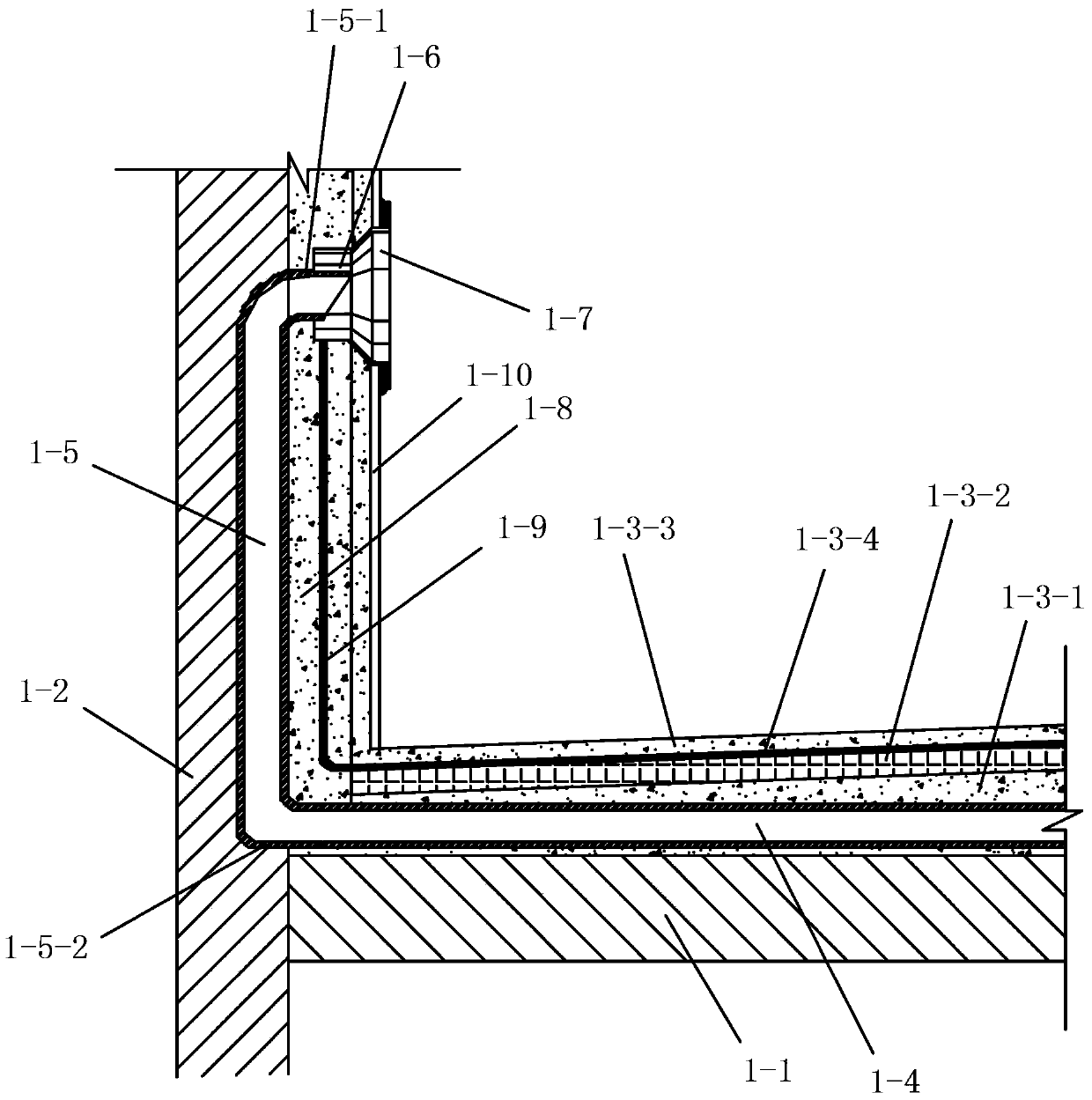

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

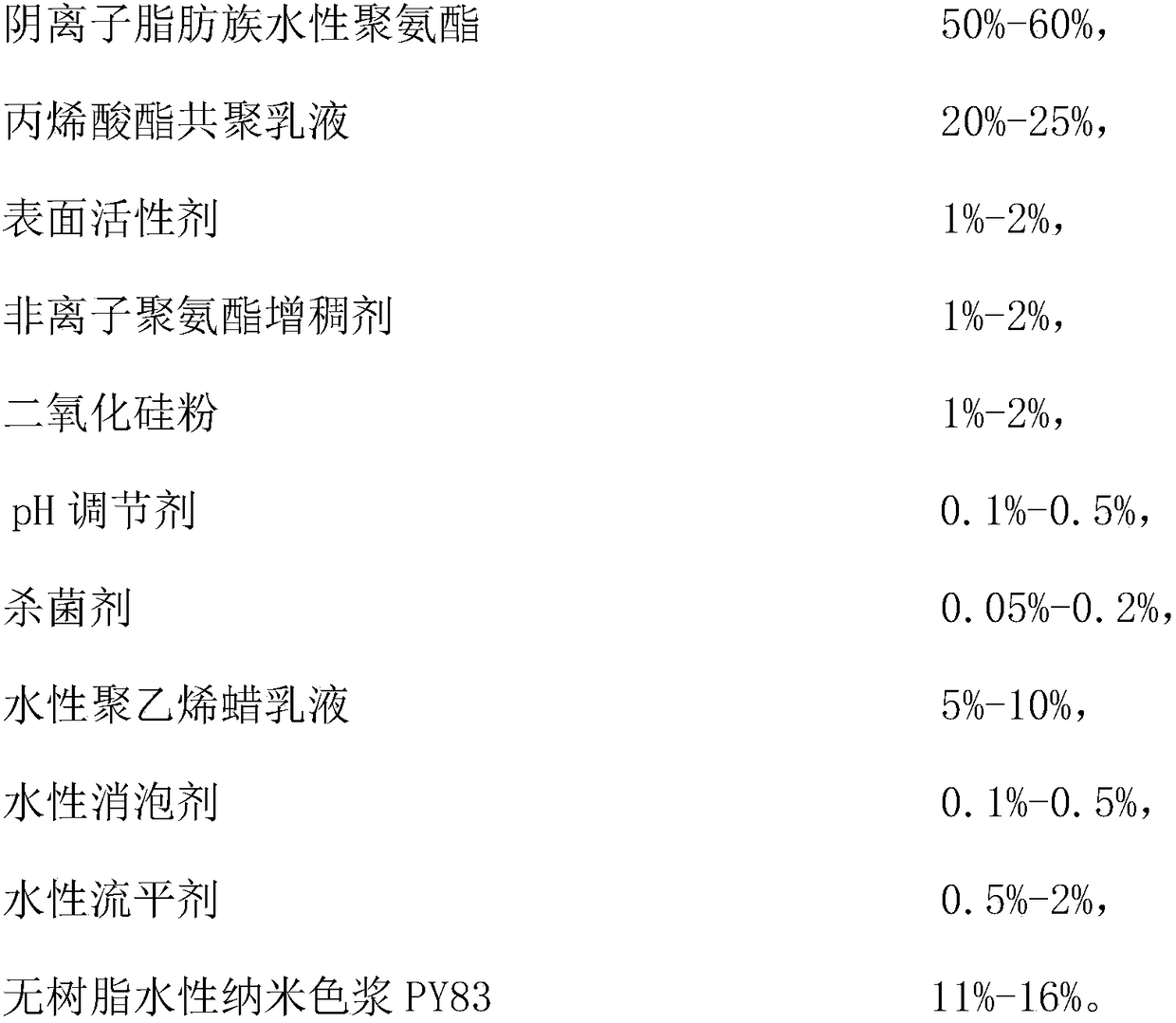

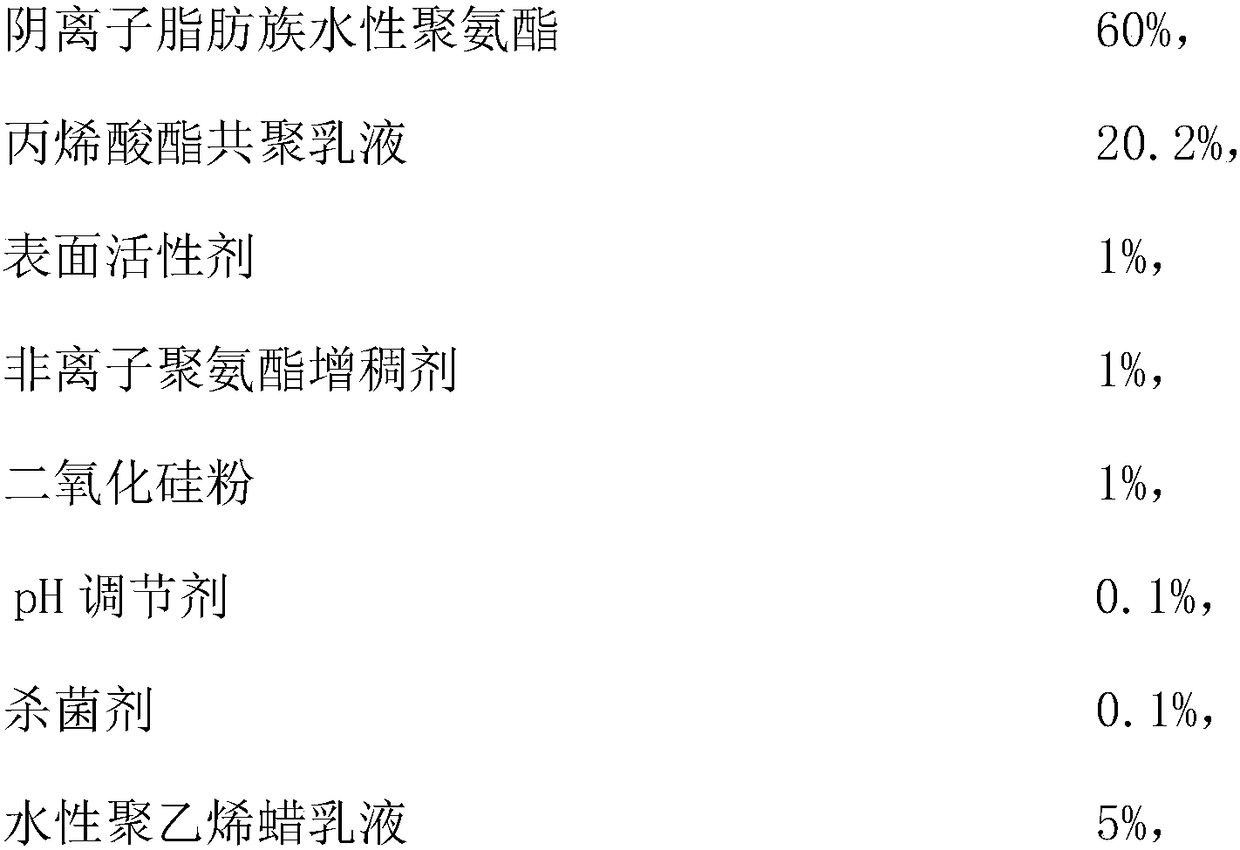

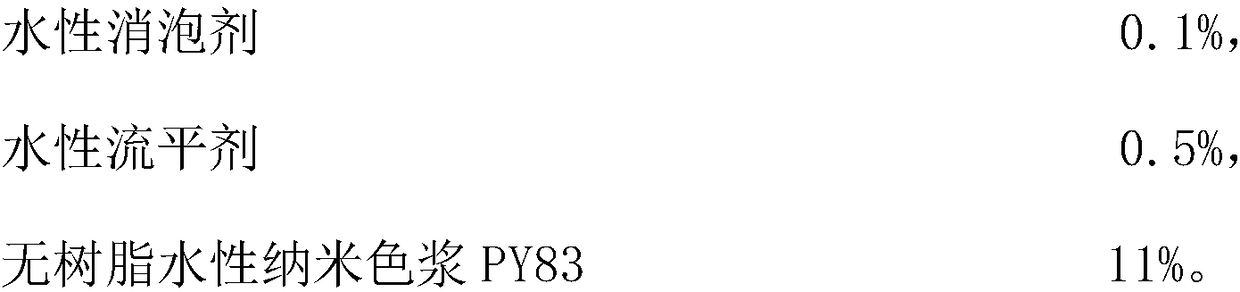

Water-based gravure yellow ink for soft PVC decoration film, and preparation method thereof

The invention relates to a water-based gravure yellow ink for a soft PVC decoration film. The water-based gravure yellow ink comprises, by mass, 50-60% of anionic aliphatic waterborne polyurethane, 20-25% of an acrylate copolymer emulsion, 1-2% of a surfactant, 1-2% of a nonionic polyurethane thickener, 1-2% of silica powder, 0.1-0.5% of a pH adjuster, 0.05-0.2% of a bactericide, 5-10% of an aqueous polyethylene wax emulsion, 0.1-0.5% of an aqueous defoamer, 0.5-2% of an aqueous leveling agent and 11-16% of a resin-free aqueous nanometer color paste PY83. The invention also provides a preparation method of the aqueous gravure yellow ink. The ink has the advantages of good resolubility, no clogging, good adhesion to a substrate, no after-tack, few bubbles in the use process, convenience inpackaging and construction, high bonding strength, and excellent resistance to yellowing and weathering; and the preparation method has the advantages of simplicity, easiness in control, no grinding process, and improvement of the production efficiency.

Owner:中山创美涂料有限公司

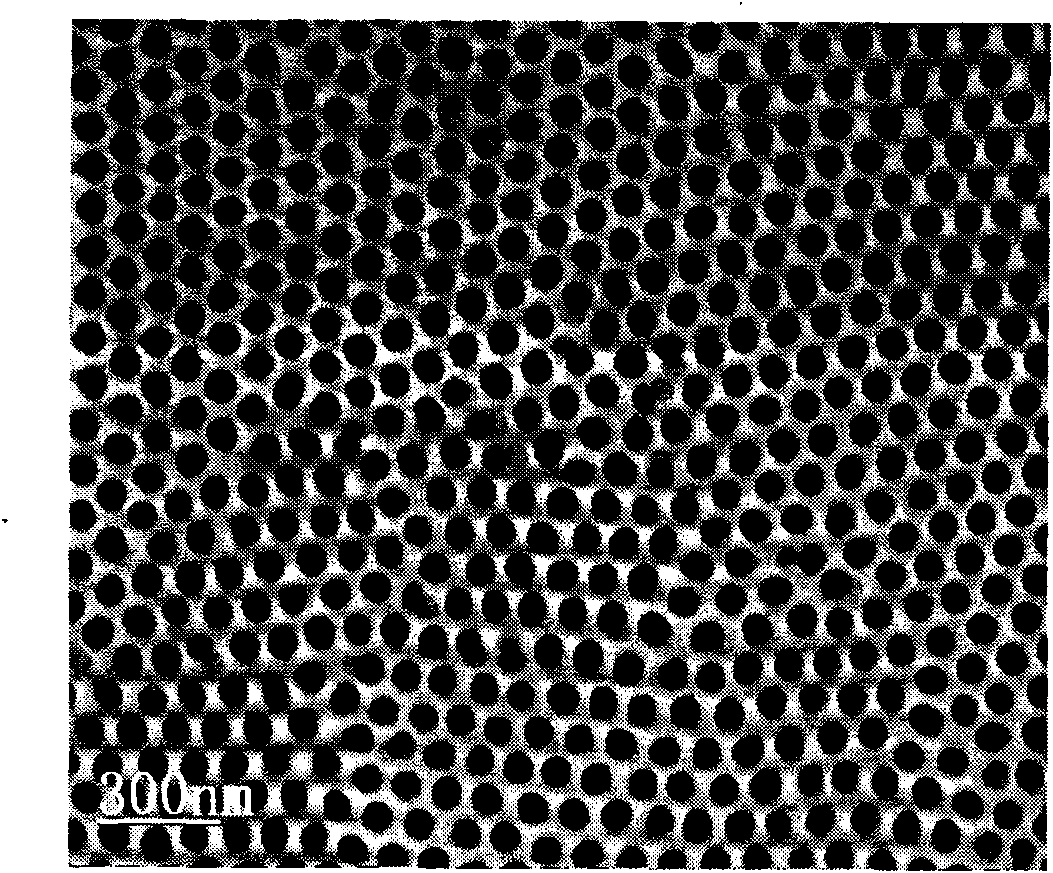

Method for preparing zinc oxide nanowire array based on coordination chemical reaction theory

InactiveCN101624208ASmooth inputOvercoming rateNanostructure manufactureZinc oxides/hydroxidesChemical reactionFilling rate

A chemical preparation method (coordination reaction method) for preparing ZnO nanowire array which is based on coordination chemical reaction theory and used in porous anode aluminum oxide template is disclosed. The reactant of the method is dissoluble zinc salt added with aqueous ammonia, but different from the direct deposition method, the product of the preceding reaction Zn(OH)2 is not directly deposited on the pore channel of the aluminum oxide template but is subject to coordination reaction to be precursor---zinc ammonium coordinate, and crystallizing ions in the form of precursor is conveyed into the pore channel of the aluminum oxide template; the precursor is subject to hydrolysis reaction and is converted into Zn(OH)2 in the pore channel of the aluminum oxide template to be deposited; then, Zn(OH)2 is baked to be the target product ZnO in the end. The ZnO nanowire prepared by the method of the invention has high pore channel filling rate and continuous, compact and filled line, and when using high quality aluminum oxide template, the ZnO nanowire array is regular and uniform.

Owner:TIANJIN UNIV

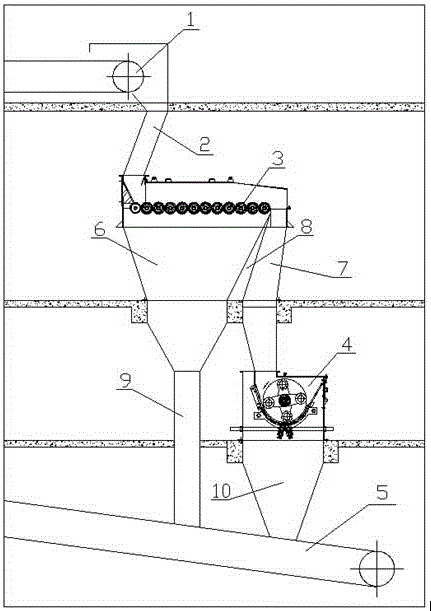

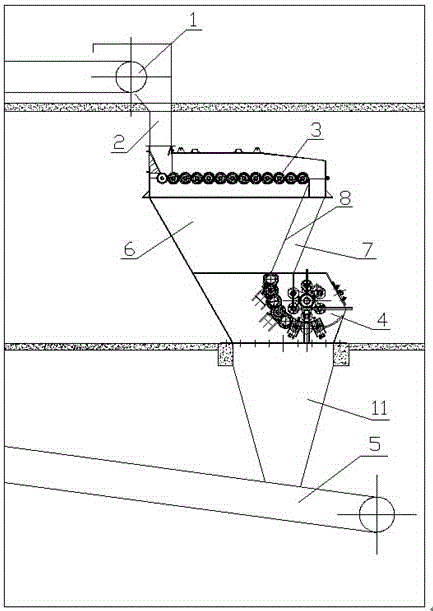

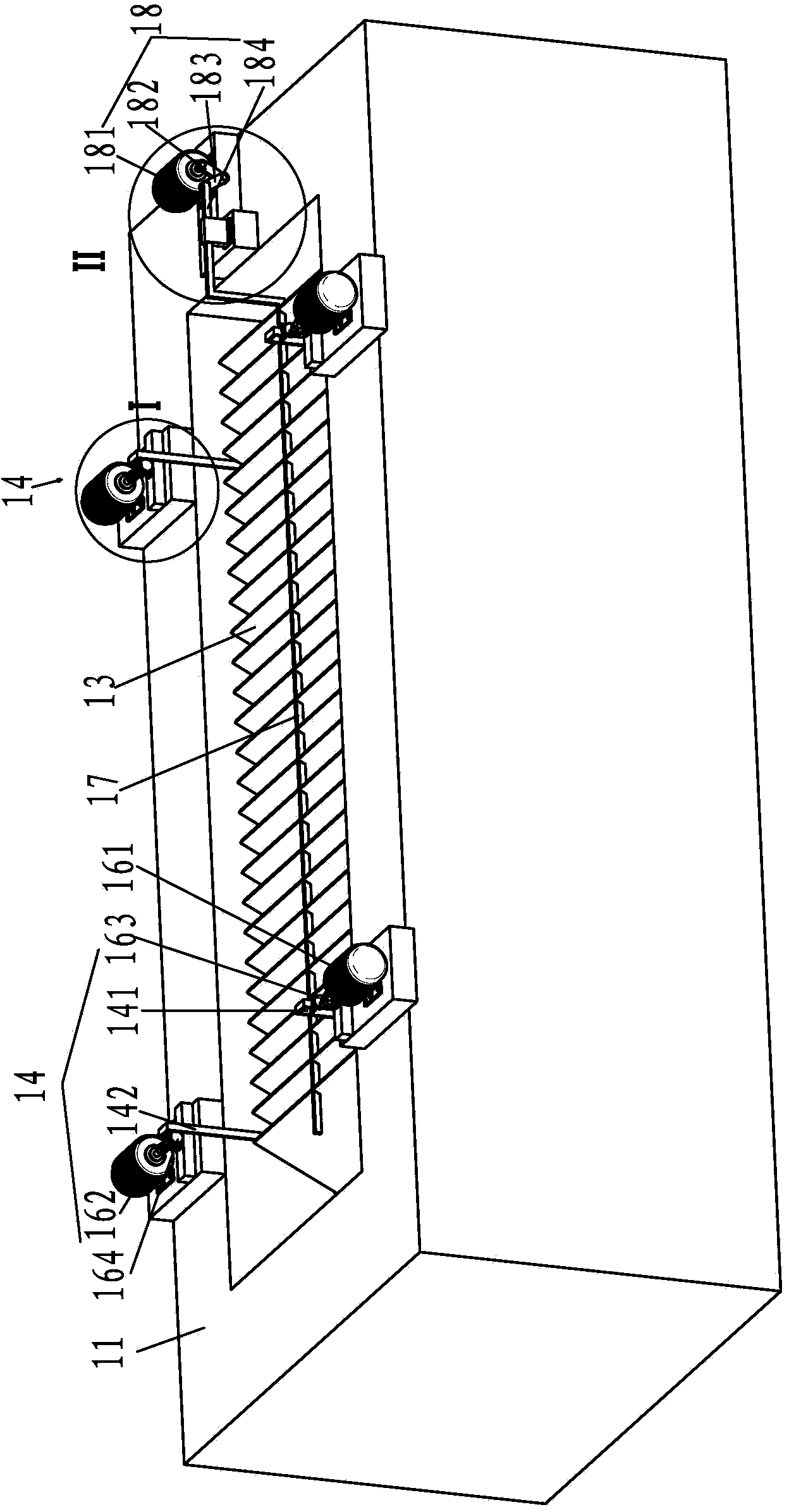

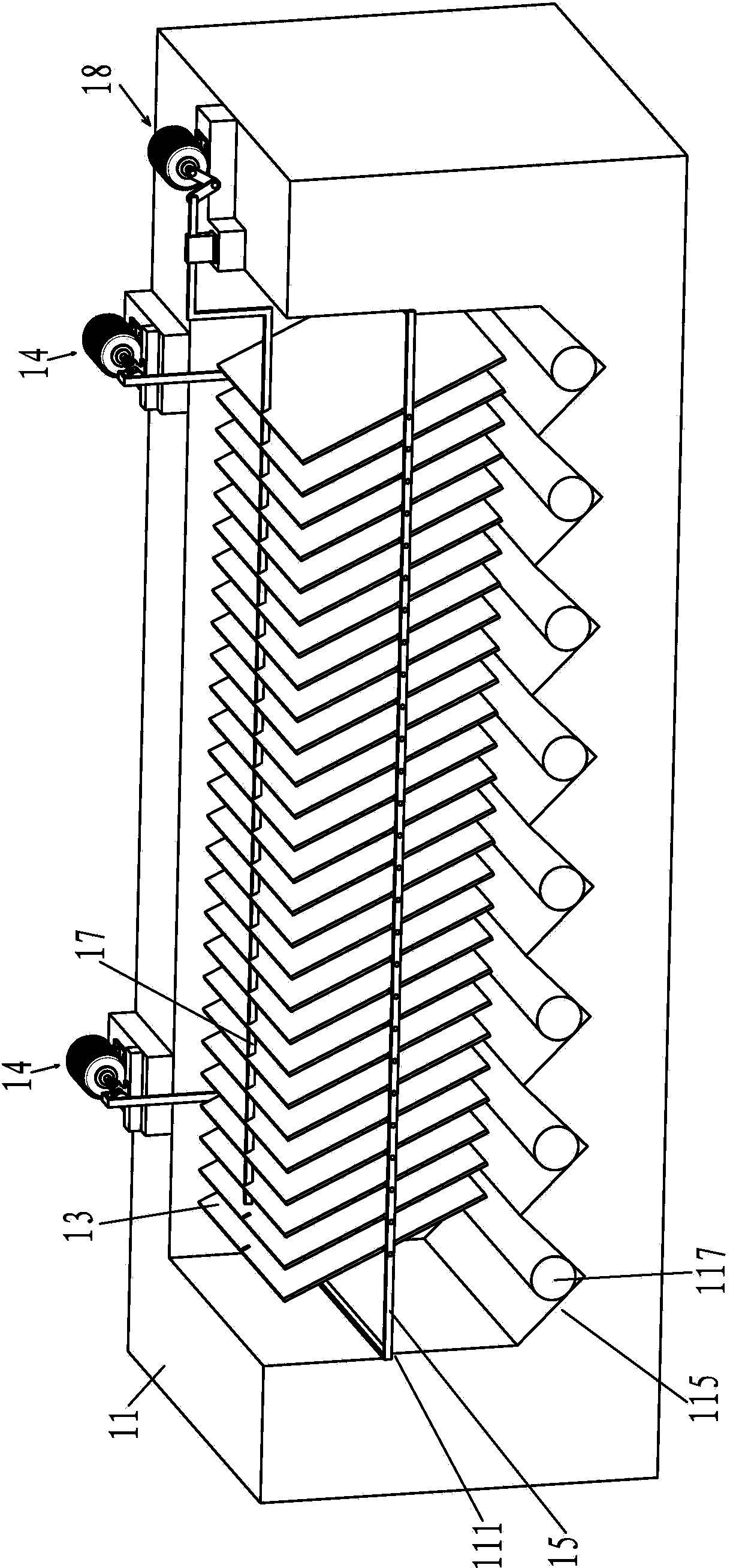

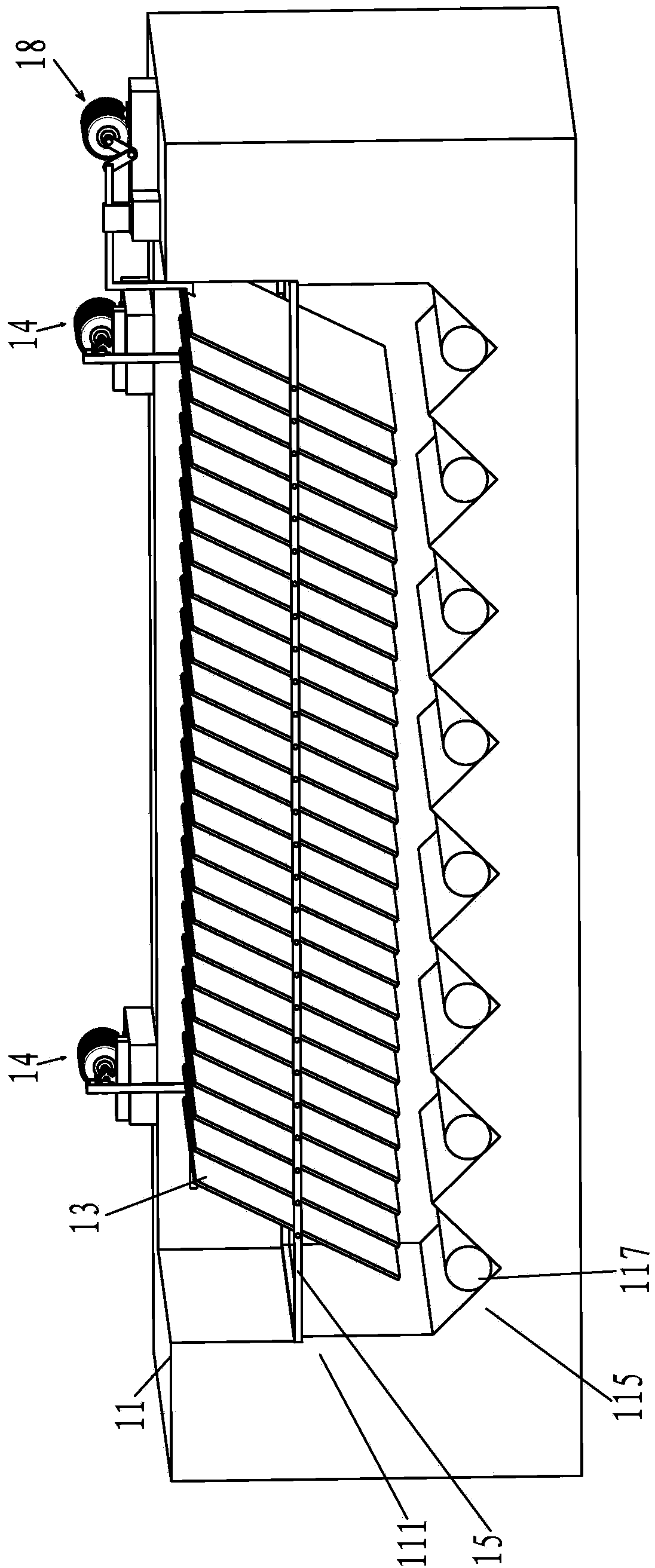

Floor-type screening and crushing device

InactiveCN106334617AIncrease the screening areaImprove screening effectGrain treatmentsScreening effectEngineering

The invention discloses a floor-type screening and crushing device. A material supply belt conveyor (1) is connected with a feed inlet of a screening machine (3) through a material supply guide tube (2). A qualified material outlet of the screening machine (3) is connected with an inlet of a funnel-shaped discharge tube (6). An unqualified material outlet of the screening machine (3) is connected with a discharge outlet of a crushing machine (4) through an unqualified material discharge tube (7). The funnel-shaped discharge tube (6) and the unqualified material discharge tube (7) are partitioned through a partition baffle (8). The big-end-up funnel-shaped discharge tube is adopted for being connected with the qualified material outlet of the screening machine, the height of the funnel-shaped discharge tube is in direct proportion to the screening capacity and the floor height, large-grain-diameter unqualified materials mixed at the qualified material outlet of the screening machine can be subjected to secondary screening and crushing, and the screening area is enlarged. The floor-type layout is adopted, so that the installing space is narrowed; and coal materials collide with the walls of guide tubes under the effect of gravity, repeated screening and crushing are achieved, and the screening effect is good.

Owner:马琳

Leak-proof color-changeable adsorption cotton

ActiveCN104383898AAvoid spillingAdjust in timeWater cleaningGeneral water supply conservationSurface layerChange color

The invention relates to the field of materials, and particularly relates to leak-proof color-changeable adsorption cotton which comprises a surface layer, a color-changeable layer and an oil holding layer, wherein the oil holding layer is positioned between the surface layer and the color-changeable layer; a leak-proof layer is arranged outside the color-changeable layer; the oil-holding layer is a coarse polypropylene fiber melt-blowing layer, the surface layer is a fine polypropylene fiber melt-blowing layer, and the color-changeable layer is a color-changeable oil absorption material layer. The leak-proof color-changeable adsorption cotton is high in oil holding rate and convenient to use, and can change color along with oil absorption amount.

Owner:FUYANG AOHONG FIBER PROD CO LTD

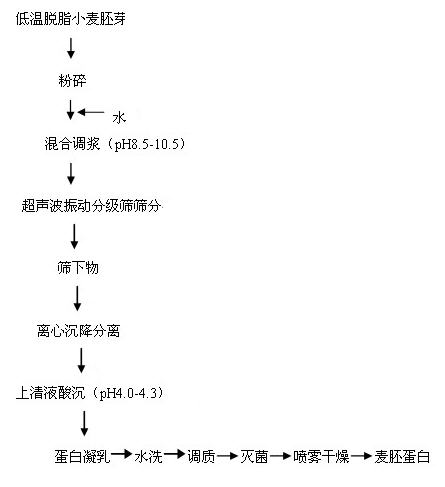

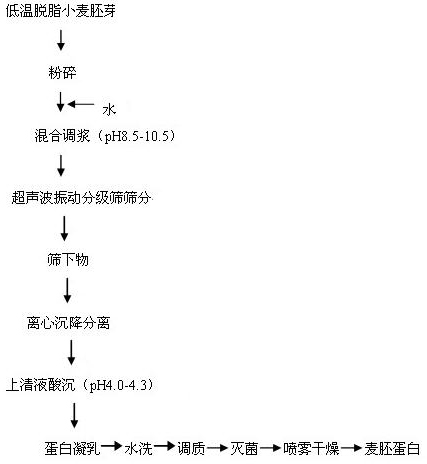

Extraction method of defatted wheat germ protein

ActiveCN102669404AImprove screening efficiencyNot easy to blockFood preparationProtein proteinChemistry

The invention discloses an extraction method of defatted wheat germ protein. The extraction method includes crushing low-temperature defatted wheat germs to make even wheat germ slurry, using an ultrasonic vibration classifying screen for wet screening, subjecting screening product to centrifugal settling separation and acid precipitation to obtain protein precipitate, and subjecting the protein precipitate to washing, modifying, sterilizing and drying to obtain the finished wheat germ protein. Compared with the prior art, the extraction method has the advantages that screening efficiency is high, meshes are less easy to block, power consumption is low and the like. By the extraction method, protein dissolution quantity can be increased, protein purity and yield can be increased, the protein is fine in dispersiblity, emulsibility, foamability, water retention and oil retention, the primary concentration of the protein can be achieved, and wheat germ dietary fiber, high-added-value product, can further be obtained from oversize product, and accordingly comprehensive utilization rate of the wheat germs is increased. In addition, the extraction method has low requirement for production equipment, is simple in process sequence and is convenient for industrial popularization.

Owner:JIANGNAN UNIV

Inclined plate sedimentation tank

InactiveCN103520963AAvoid cloggingImprove sedimentation efficiencySedimentation settling tanksMechanical engineeringSedimentation

Provided is an inclined plate sedimentation tank. The inclined plate sedimentation tank comprises a sedimentation tank body and a plurality of inclined plates arranged to be parallel to each other at intervals in the sedimentation tank body. A fixing table is arranged in the inner sides of the sedimentation tank body. A frame is arranged on the fixing table. Two ends of each of the inclined plates are respectively hinged with two sides of the frame along the width direction. The top of each inclined plate is connected with a pulling rod. The extension direction of the pulling rod is the arrangement direction of the inclined plates. Vibration devices are arranged on the frame. The inclined plate sedimentation tank can avoid obstruction of the inclined plates when the sedimentation efficiency is raised.

Owner:烟台亿源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com