Large extraction high caving roof coal hydraulic support

A hydraulic support and top-coal caving technology, which is applied to the mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of low mechanical mining height of the top-coal caving support, influence on coal quality, waste of coal resources, etc., and achieve coal caving High recovery rate, good coal discharge effect, and small force on the coal machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

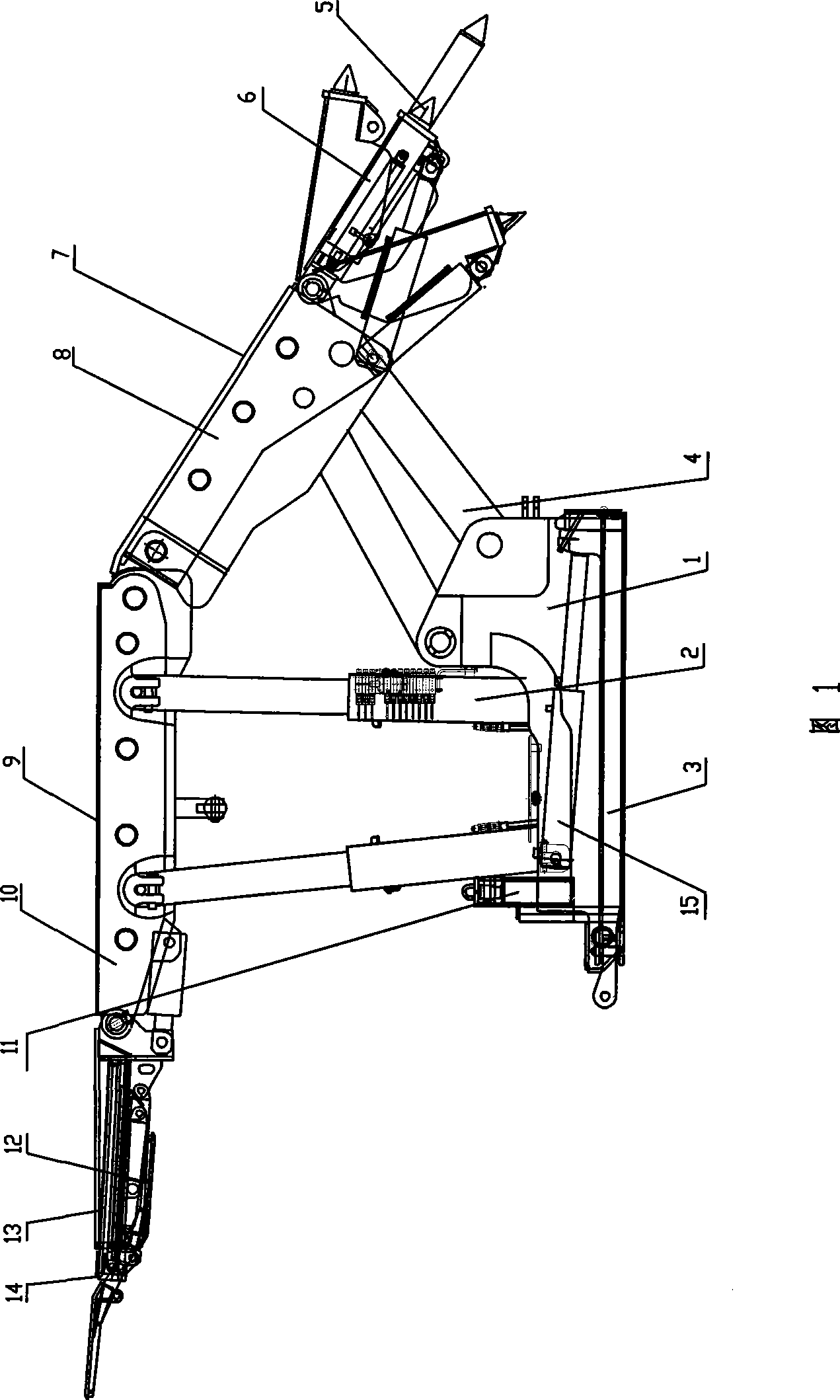

[0021] As shown in Figure 1, the hydraulic support for large mining and high coal caving of the present invention includes the base 1, the column 2, the top beam 9, the front beam 13 and the cover beam 7, the tail beam 6 and the inserting plate 5, the top The beam 9 is supported on the base 1 by four uprights 2, and the uprights are provided with alternate check valves to realize chain control and avoid crushing the support. The base 1 is a rigid split base, and the push rod 3 is located on the inner shelf of the base. The front end of the base is equipped with a bottom lifting device connected with a vertical bottom lifting jack 11. The bottom lifting device reduces the specific pressure at the front end of the base to ensure smooth movement. The key part of the frame, the middle of the base is connected with a horizontal moving jack 15, and the bottom lifting jack 11 and the moving jack 15 other ends act on the push rod 3 respectively. One end of the push rod 3 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com