Waste lead acid battery crusher

A crusher and waste lead-acid technology, applied in the field of machinery, can solve the problems of complex process and expensive equipment, and achieve the effects of simple process, long service life and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

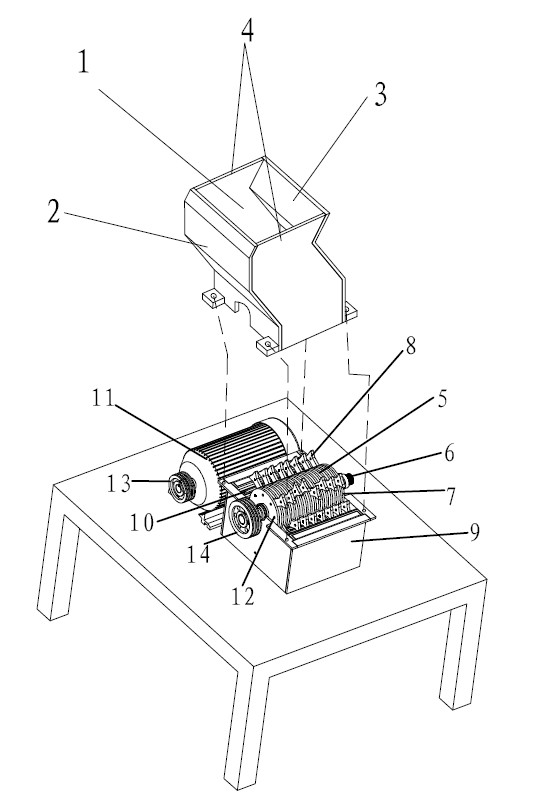

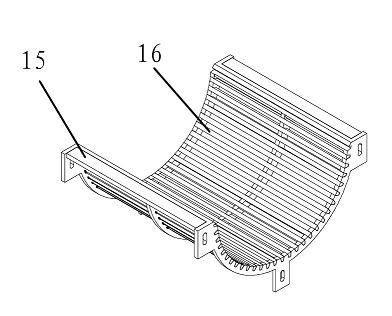

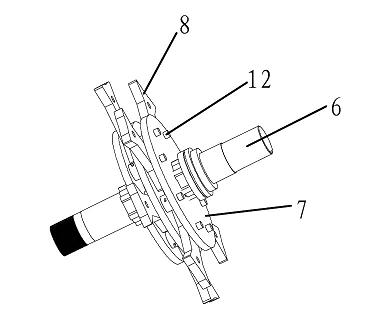

[0032] A waste lead-acid battery crusher, comprising a feed port 1, a crushing bin 9, a filter device 10, a discharge port and a motor 11, the feed port 1 is located above the crushing bin 9, and includes a substantially Z-shaped The front side plate 2 and the rear side plate 3 of the type also include the side plate 4 on which the front side plate 2 and the rear side plate 3 are installed; the crushing chamber 9 is provided with a breaking hammer 5, and the breaking hammer 5 includes a rotating shaft 6, a hammer plate 7 and hammer body 8, the rotating shaft 6 runs through the crushing bin 9, seventeen hammer plates 7 are arranged on the rotating shaft 6 and the hammer plates 7 are fixed by splines, the center of the hammer plate 7 is at the At the central axis of the rotating shaft 6 and the hammer disc 7 is perpendicular to the rotating shaft 6, the hammer discs 7 are relatively fixed by positioning clip springs, and eight hammer shafts are evenly arranged along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com