Extraction method of defatted wheat germ protein

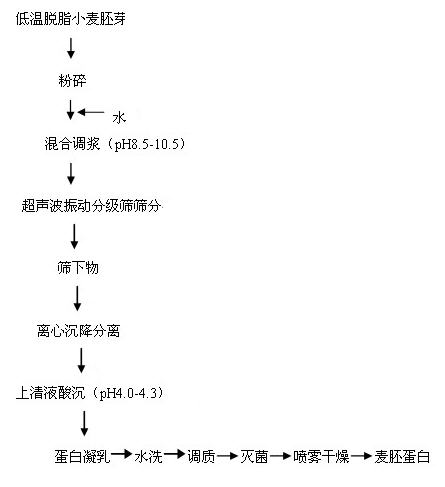

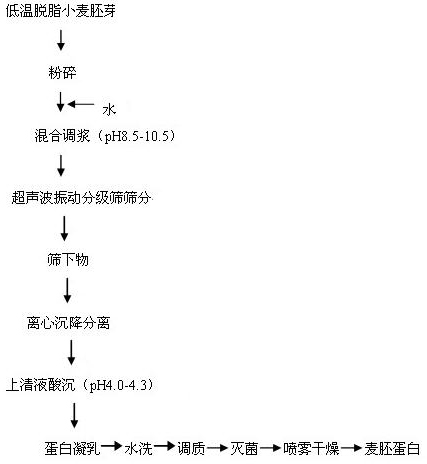

A technology of wheat germ protein and extraction method, which is applied in the fields of application, food preparation, food science, etc., can solve the difference between powder diameter-thickness ratio and shape coefficient, increase the flour content of coarse-grade products, and increase the coarse-grained product content of fine-grained products and other issues, to achieve the effect of improving the purity and yield, improving the comprehensive utilization rate, and facilitating the promotion of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using 1000g of commercially available low-temperature defatted wheat germ as a raw material, pulverize it with a traditional Chinese medicine grinder for 20 seconds, stir the powder into a uniform wheat germ slurry according to the mass ratio of the obtained defatted wheat germ powder to water 1:30, adjust the pH to 9.5, Stir for 20 minutes, pass through 100 mesh, 200 mesh, and 325 mesh ultrasonic vibrating sieves for wet sieving, and spray evenly on the vibrating sieve with water with a flow rate of 2.0 L / min, and the sieving time is 20 minutes. Test and calculate with conventional method, the defatted wheat germ protein content is 40.35 ± 1.54% (on a dry basis) in the final sieve that obtains, and the balance is carbohydrate and ash, and the defatted wheat germ protein loss in the sieve is about Accounting for 5%-10% of the total protein of defatted wheat germ as raw material, the sieve can be used to prepare wheat germ dietary fiber.

Embodiment 2

[0027] Using 1000g of commercially available low-temperature defatted wheat germ as a raw material, pulverize it with a traditional Chinese medicine grinder for 15 seconds, stir the powder into a uniform wheat germ slurry according to the mass ratio of the obtained defatted wheat germ powder to water 1:10, adjust the pH to 10.0, Stir for 30 minutes, then pass through 100 mesh, 200 mesh, and 325 mesh ultrasonic vibrating sieves for wet sieving, and spray evenly in the vibrating sieve with water with a flow rate of 1.5L / min. The sieving time is 30 minutes, and the final sieved The lower matter was centrifuged in a refrigerated centrifuge for 20 minutes at a speed of 5000rmp, and the resulting supernatant was adjusted to a pH of 4.0 with 1mol / L HCl to obtain a protein precipitate, which was then treated with soft water at a mass ratio of 1.5:1 between water and protein precipitate. Wash and adjust the pH to 7.0 with 1.0mol / L NaOH, heat the obtained protein curd to 85°C, and steril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com