Patents

Literature

243results about How to "Implement automatic filtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

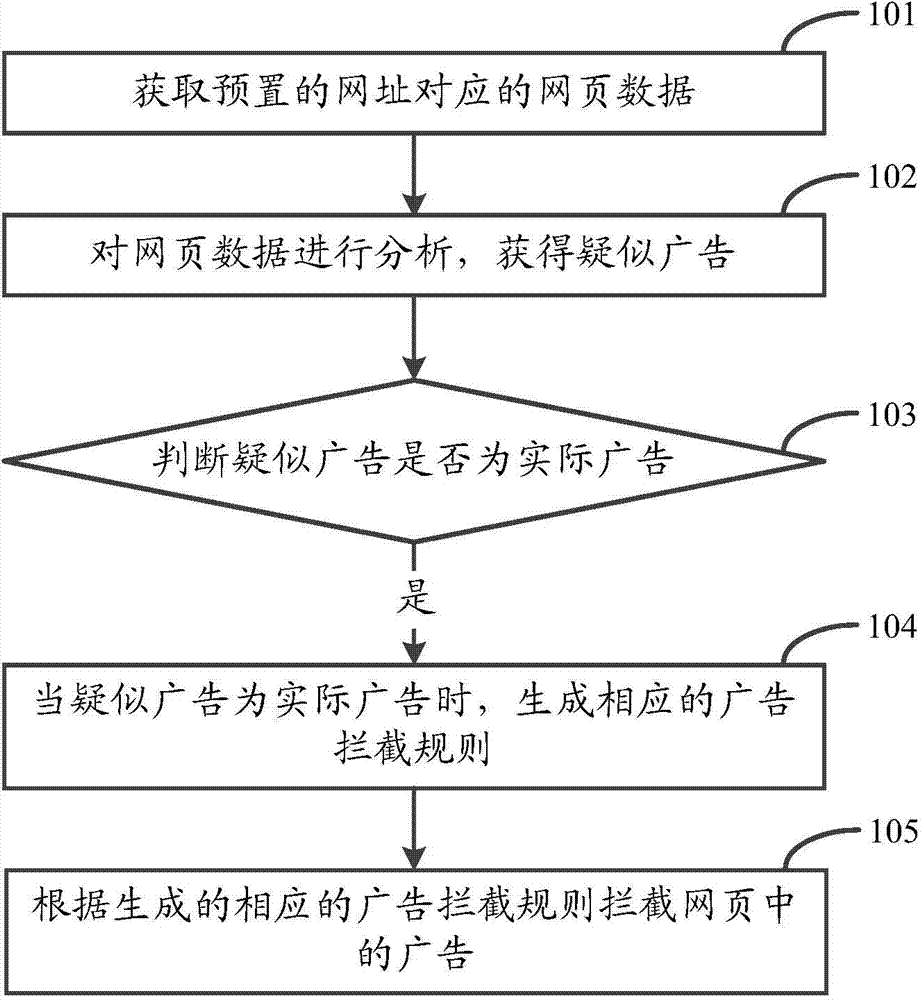

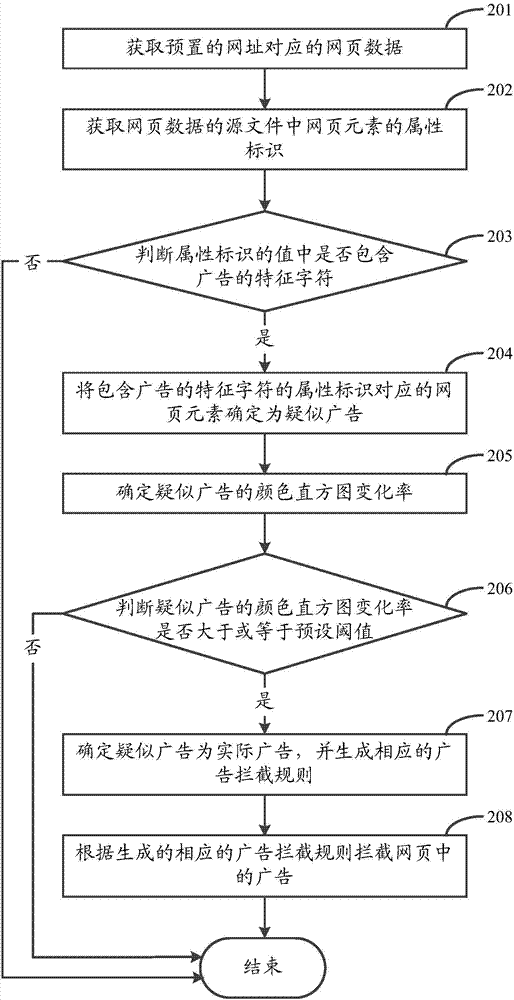

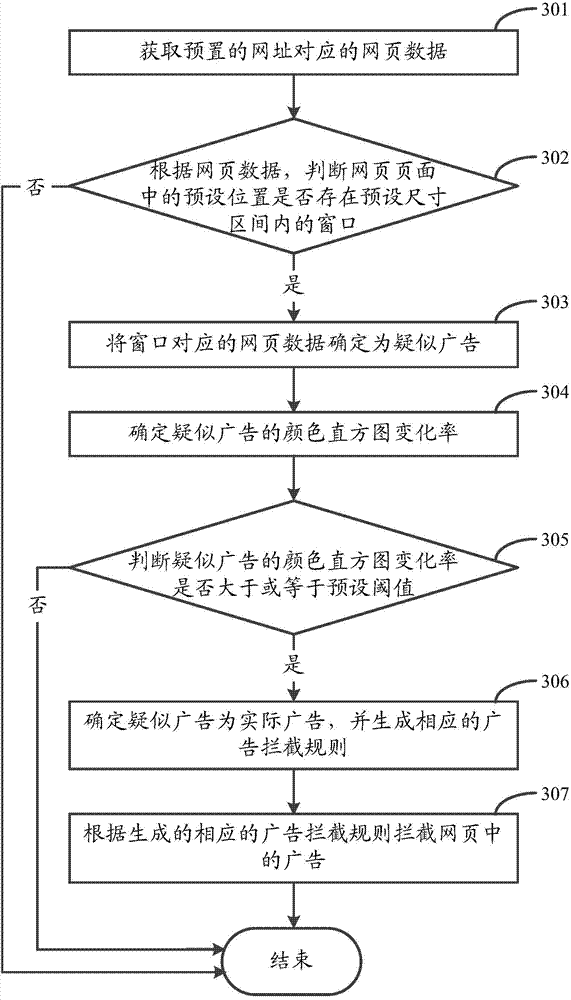

Method and device for intercepting advertisements in webpage

ActiveCN103886088AImplement automatic filteringQuick identificationComputer security arrangementsCommerceWeb pageAd blocking

Owner:BEIJING KINGSOFT NETWORK TECH

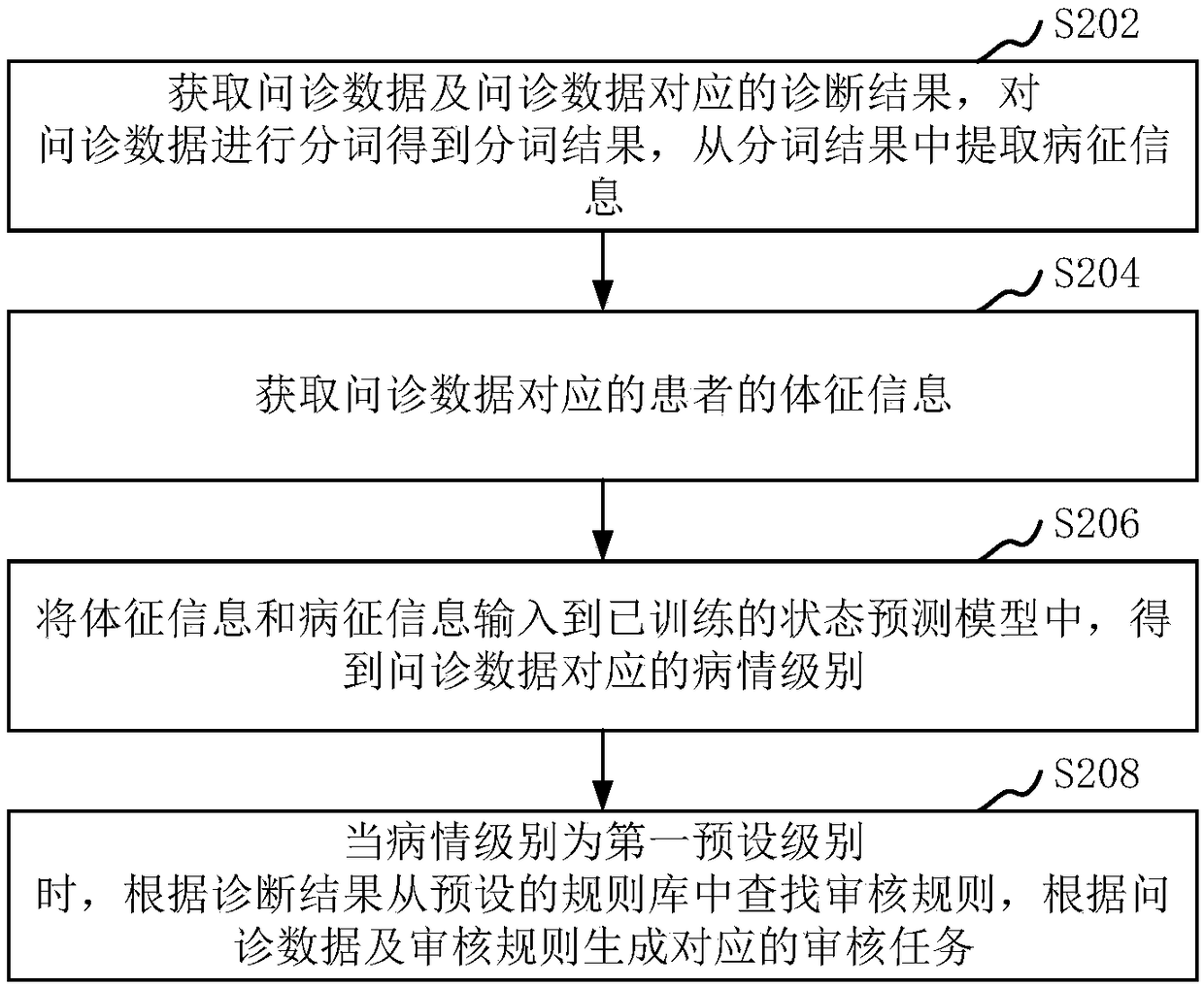

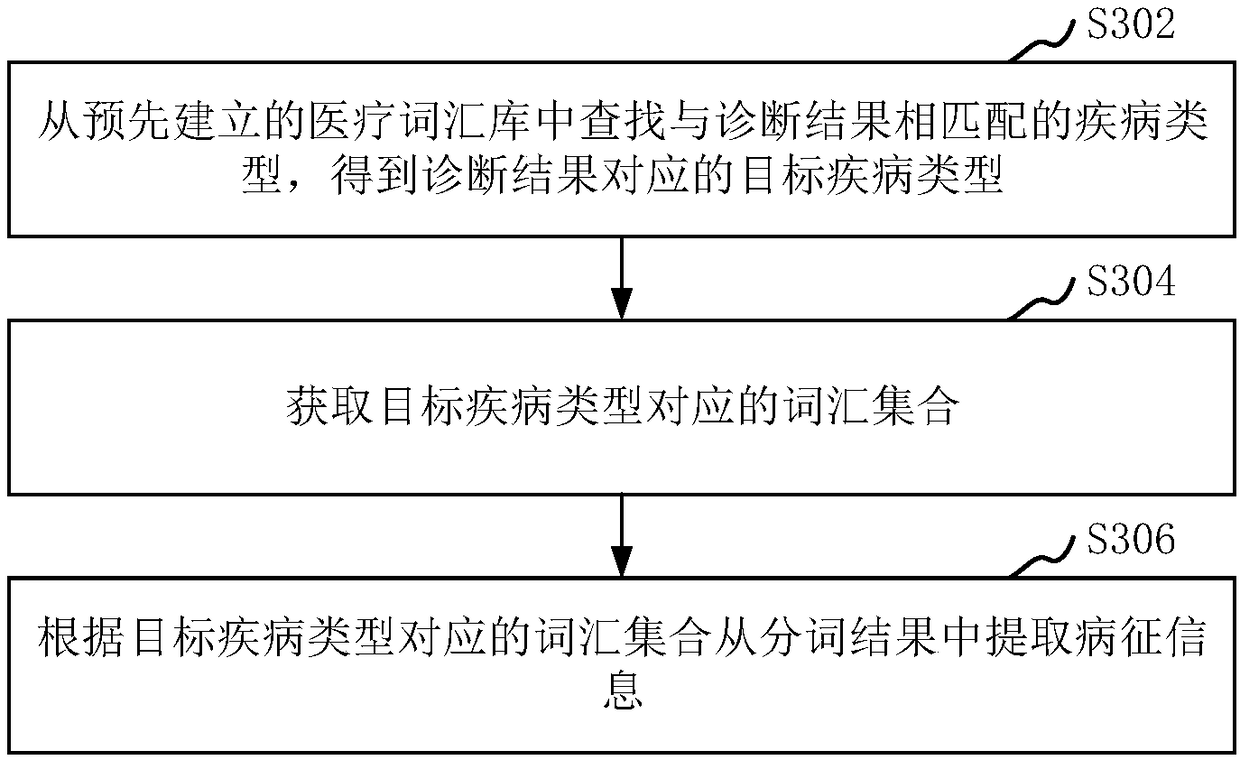

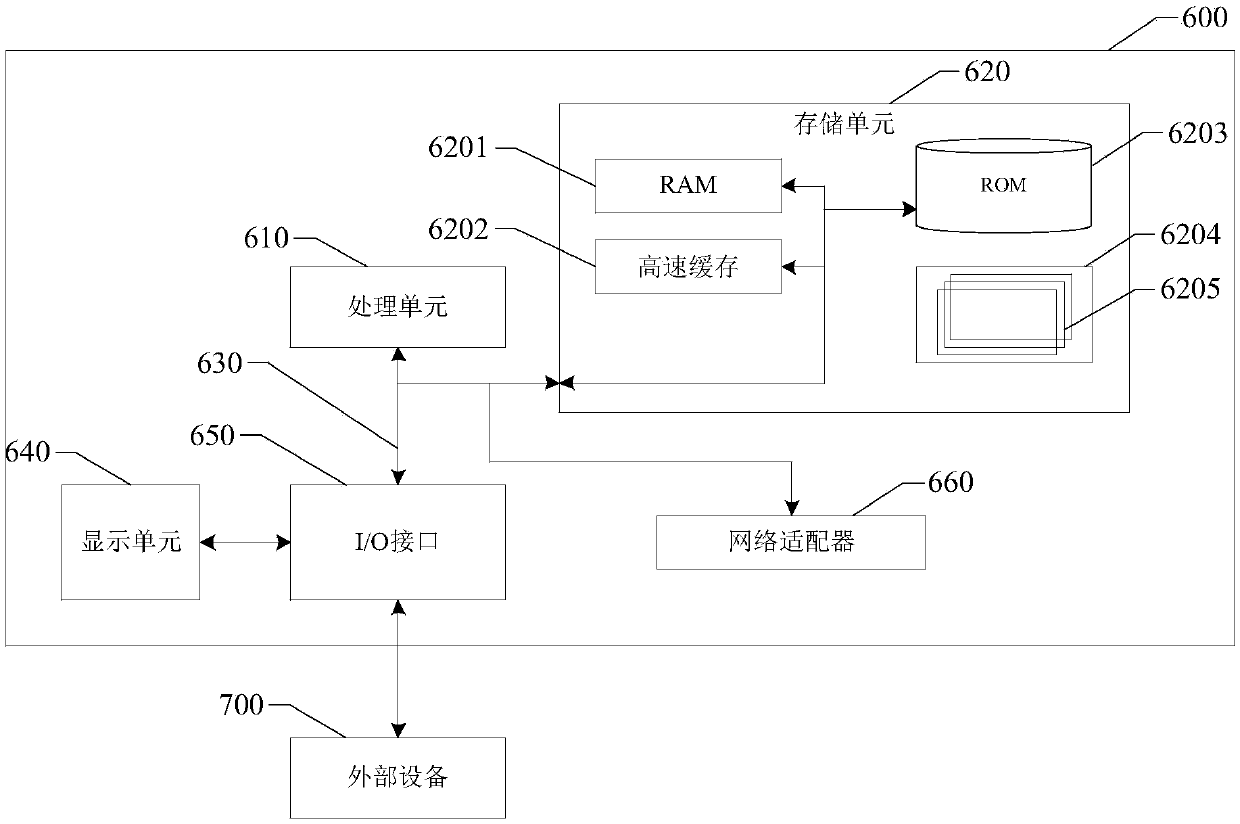

Interrogation data processing method and device, computer equipment and storage medium

ActiveCN108986908AImplement automatic filteringReduce missing checksMedical communicationSemantic analysisComputer engineeringComputer equipment

The invention relates to an interrogation data processing method and device, computer equipment and a storage medium. The method comprises that interrogation data and a diagnosis result correspondingto the interrogation data are obtained, the interrogation data is divided into words to obtain a word dividing result, and symptom information is extracted from the word dividing result; sign information of a patient corresponding to the interrogation data is obtained; the sign information and the symptom information are input to a trained condition level prediction model to obtain a condition level corresponding to the interrogation data; and when the condition level is a first preset level, a preset rule base is searched for a checking rule according to a diagnosis result, and a corresponding checking task is generated according to the interrogation data and checking rule. The method can be used to improve the interrogation data screening efficiency and reduce omission of interrogation data of severe illnesses.

Owner:PING AN MEDICAL TECH CO LTD +1

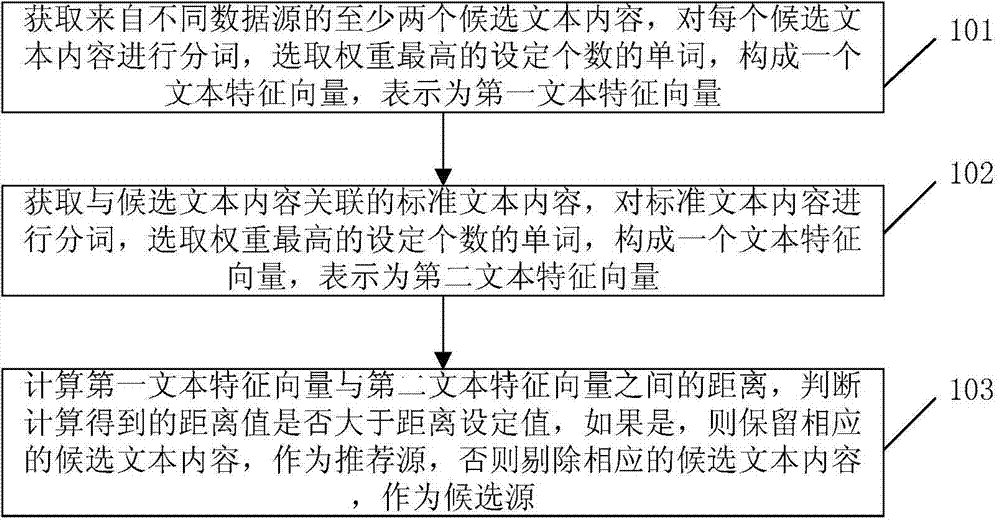

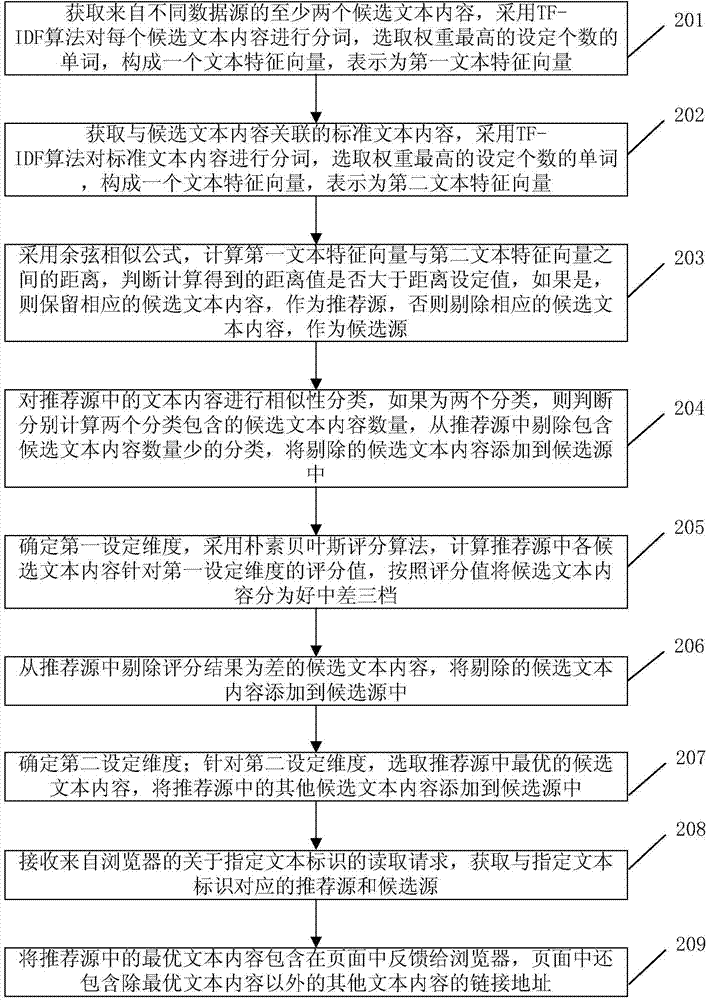

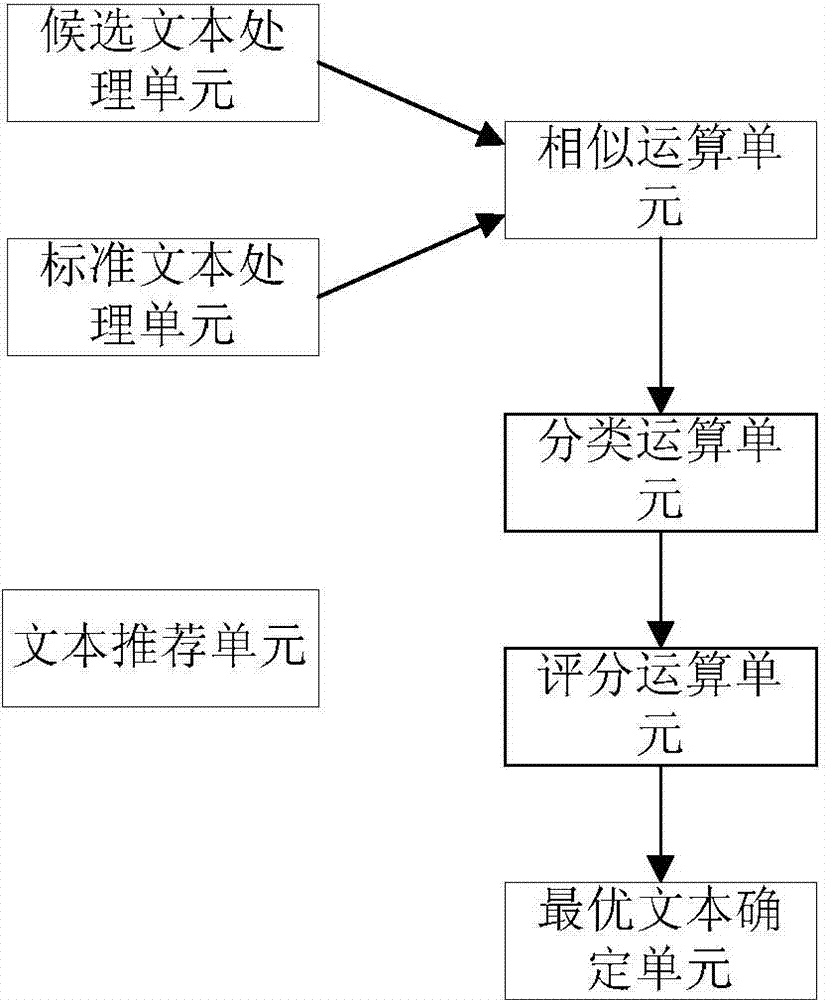

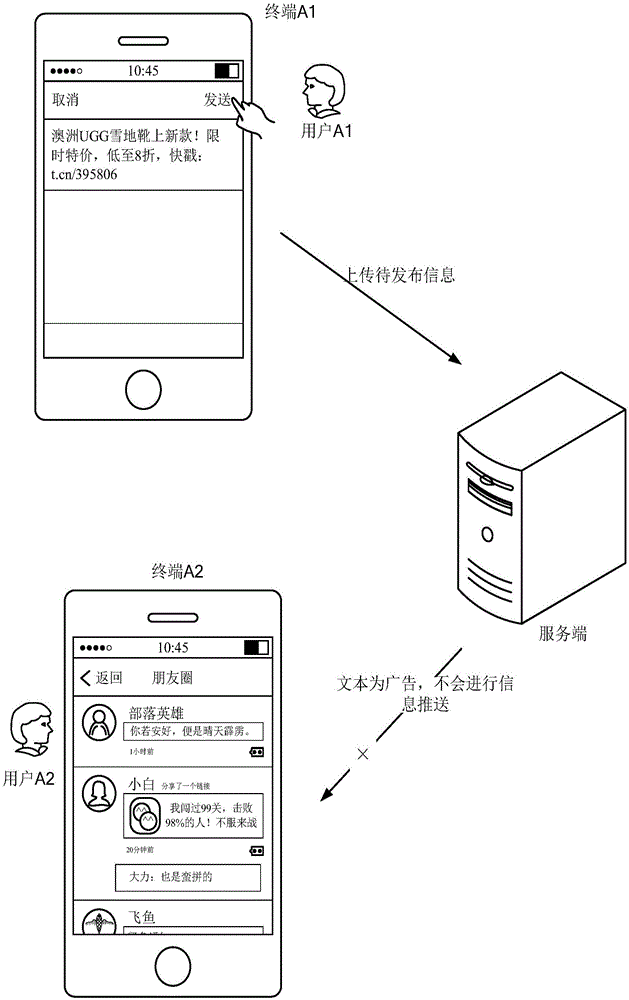

Method and device for screening text content

ActiveCN104850537AImplement automatic filteringEasy to operateSpecial data processing applicationsFeature vectorData source

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

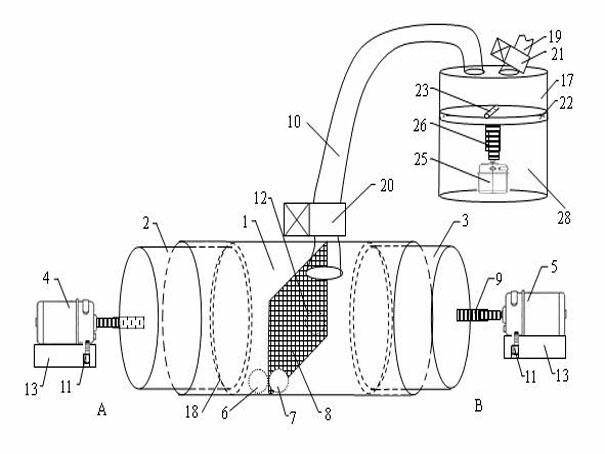

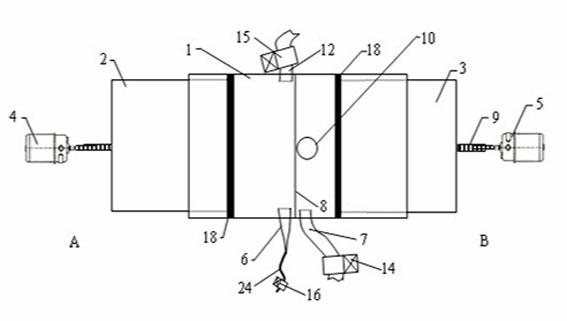

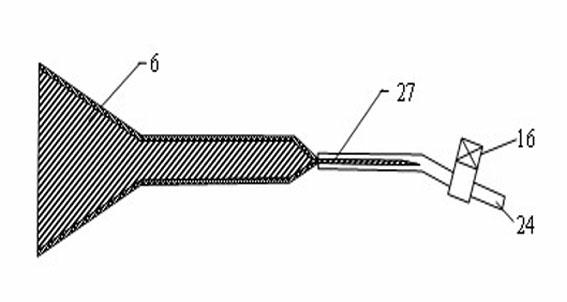

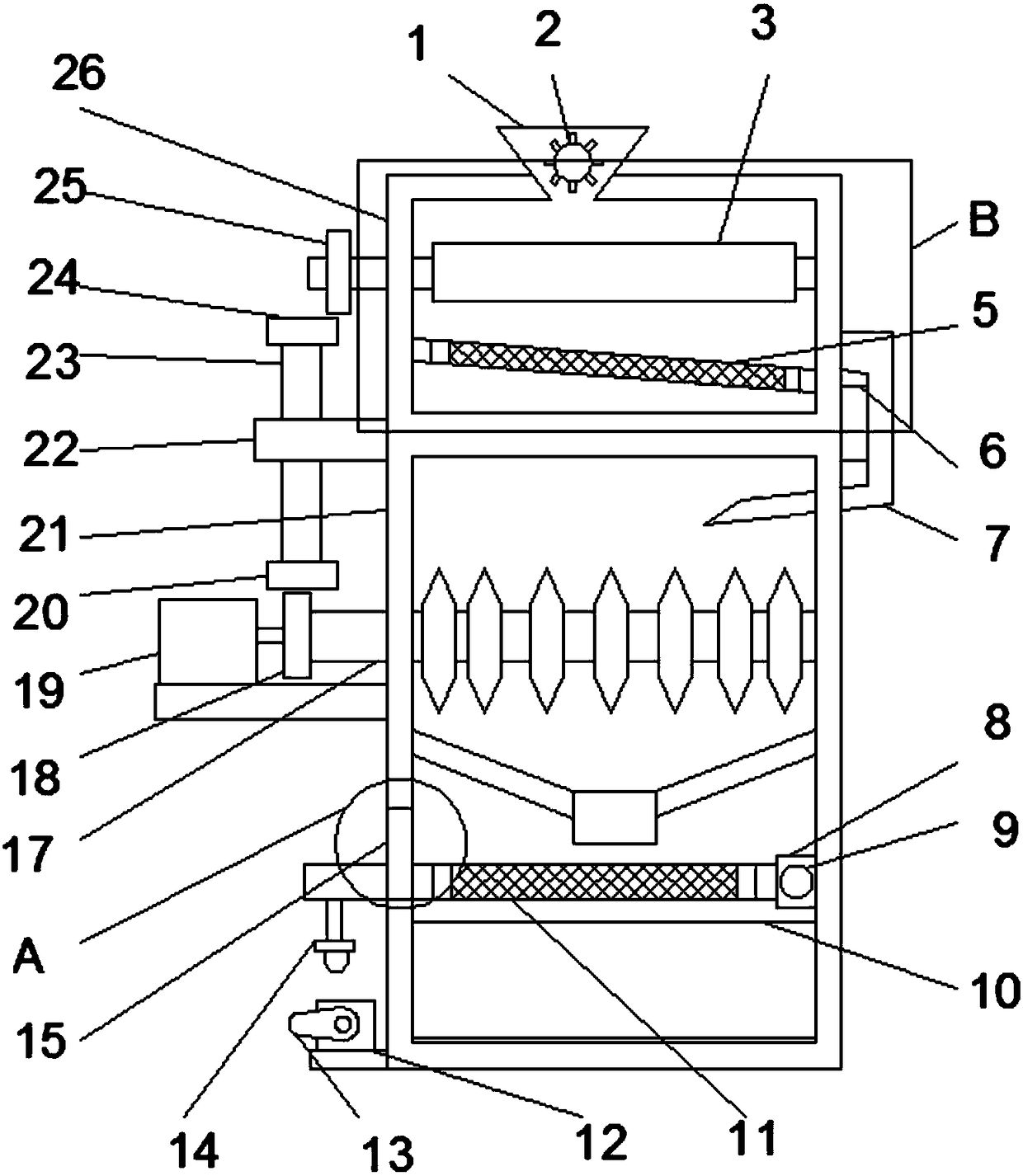

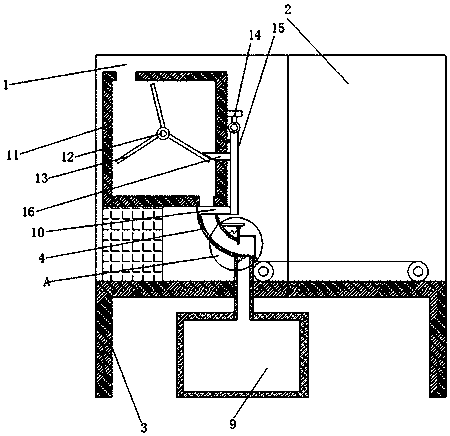

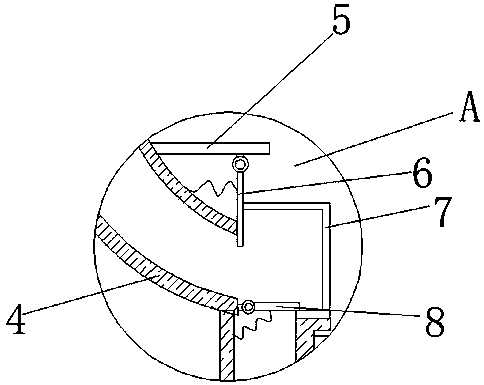

Sample introduction method and sample introduction device for microfluidics detection of fish-farming water environment

InactiveCN102495223AFully automatedMicrofluidic detection went wellMaterial analysisBiotechnologyMicrofluidics

The invention discloses a sample introduction method and a sample introduction device for microfluidics detection of a fish-farming water environment. Two ends of a tank body are respectively connected with an A end extrusion pump and a B end extrusion pump, and a 10 mum level filter screen is arranged in a space between the A end extrusion pump and the B end extrusion pump in a cavity of the tank body. A sample introduction channel is connected with a microfluidics device outside the tank body, the top of the tank body is connected with a magnetic stirring and pumping pressure conveying structure through a sample channel, an original water sample in the fish-farming water environment can be automatically and fully stirred, cluster materials including cenobium and the like in the water sample can be automatically dispersed, and extrusion pumps at two ends are respectively extruded according to a certain sequence. After the dispersed sample is automatically guided in through a push type sample introduction mode, the introduced sample is filtered, the processes from sample dispersing, sample filtering, sample introduction to the filter screen cleaning can be completed in a full automation mode, the microfluidics detection is guaranteed to be carried out smoothly, and the degree of automation is high.

Owner:JIANGSU UNIV

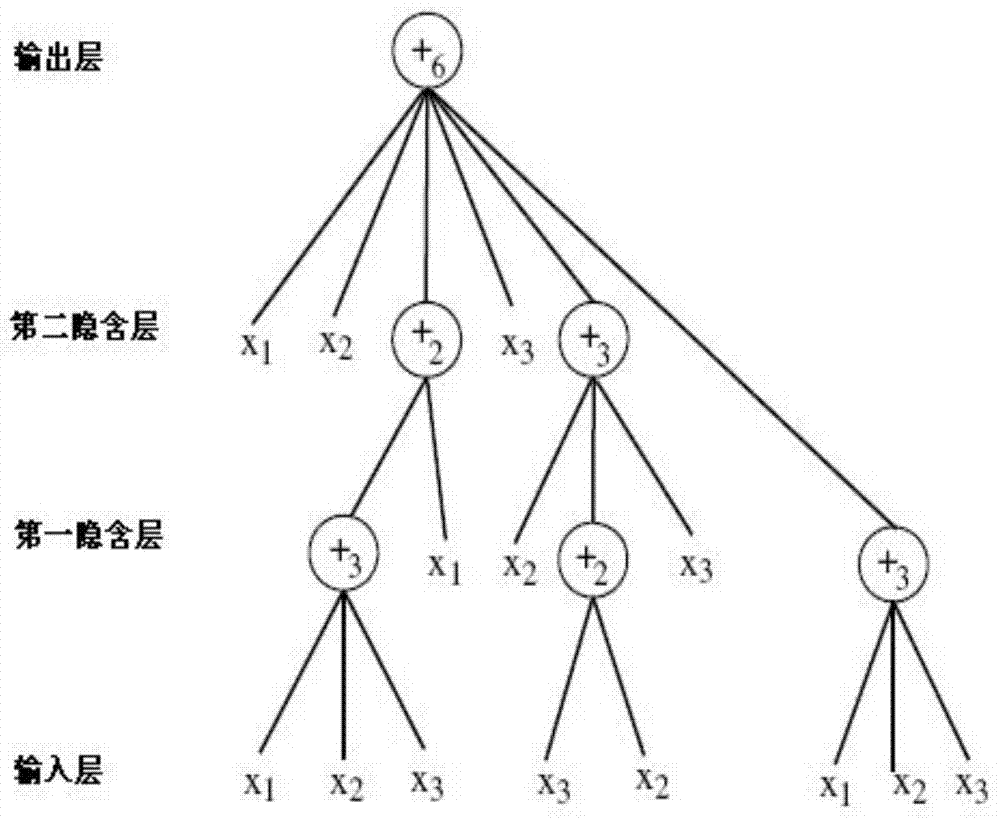

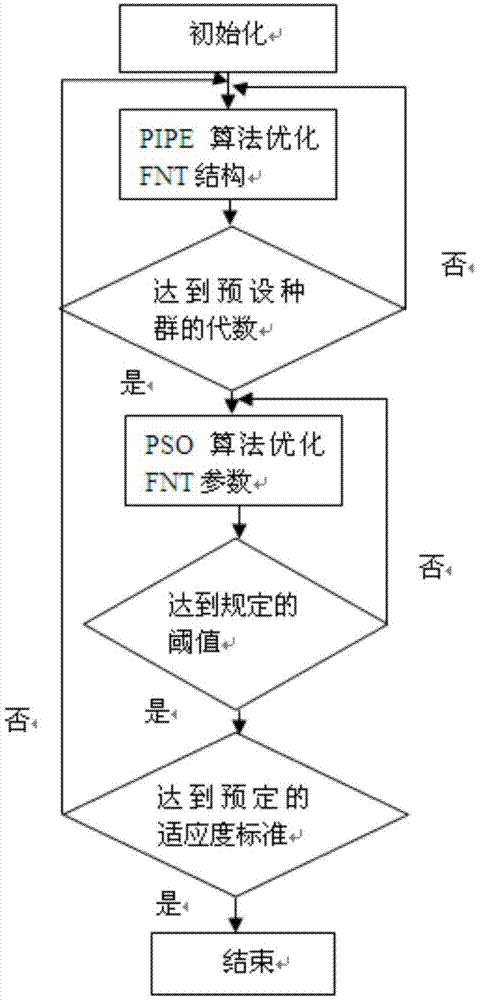

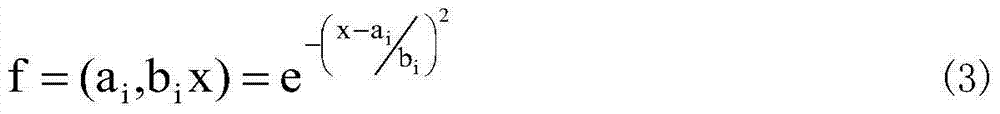

Industrial process modeling forecasting method oriented at flow object

InactiveCN104732067AImplement automatic filteringReduce restrictionsSpecial data processing applicationsData warehouseData set

The invention discloses an industrial process modeling forecasting method oriented at a flow object. The method comprises the following steps: building FNT models, extracting an industrial flow object original data set S from a data warehouse which has already been generated by the flow object, creating an initial species group of the FNT models, and customizing the individual numbers of the species group as required, wherein each individual represents an FNT model; utilizing the PIPE algorithm for optimizing FNT model structures, and adopting mean square errors or root-mean-square errors for fitness functions; utilizing the particle swarm optimization (PSO) algorithm for optimizing FNT model parameters; utilizing the FNT models for conducting modeling forecast for a flow object production process. According to the method, based on the flexible neural tree, an equation of variation tendency among measuring point data of the flow object is obtained, the industrial production process is simulated, based on relevant parameters of a current production state, production states in a period of time in the future are forecast, so that an enterprise is assisted and instructed for adjusting the production process parameters, and the production is guided for drawing on advantages and avoiding disadvantages in a microcosmic sense.

Owner:UNIV OF JINAN

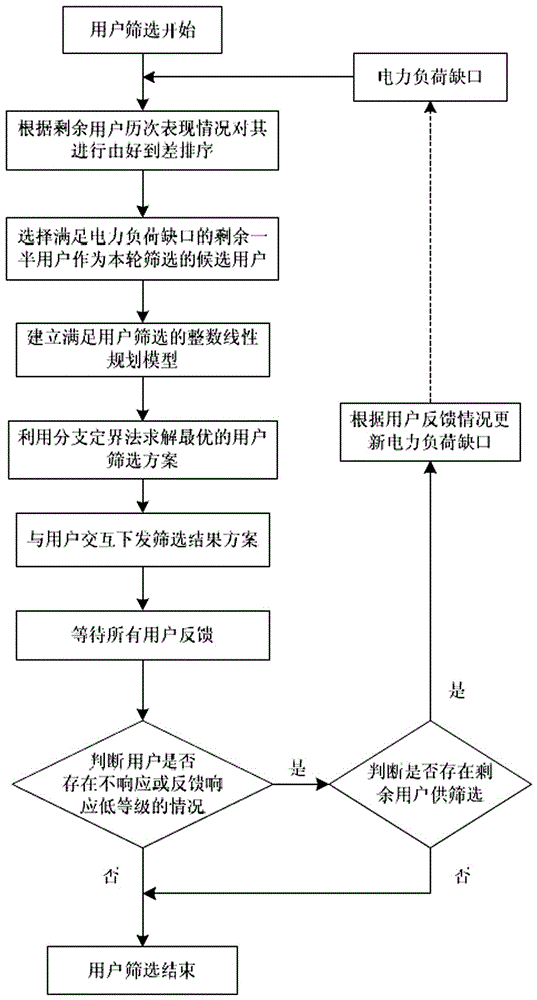

Method for automatically sorting demand response users

InactiveCN105096040AImprove performanceImprove creditResourcesPower userInteger linear programming model

The invention discloses a method for automatically sorting demand response users. Some users are selected from remaining response users as candidate sorting users of the round, and an integer linear planning model is established according to power load gap and load reduction capability of the candidate users. The solution is obtained through the branch and bound method to interact with users. Whether a next round of sorting is necessarily is determined according to feedback, and process is repeated until the power load gap defined by an upper-level system is met. The method adheres to the sorting principles of fairness, higher priority with higher creditability and maximally approaching the power load gap, and flexible interaction with power users and multiple rounds of dynamic sorting ensure matching level with the power load gap. Users are fairly selected to participate in demand response, the power user participation is improved, and the risk that real response capacity can not satisfy the expected power load gap capacity is reduced.

Owner:STATE GRID CORP OF CHINA +3

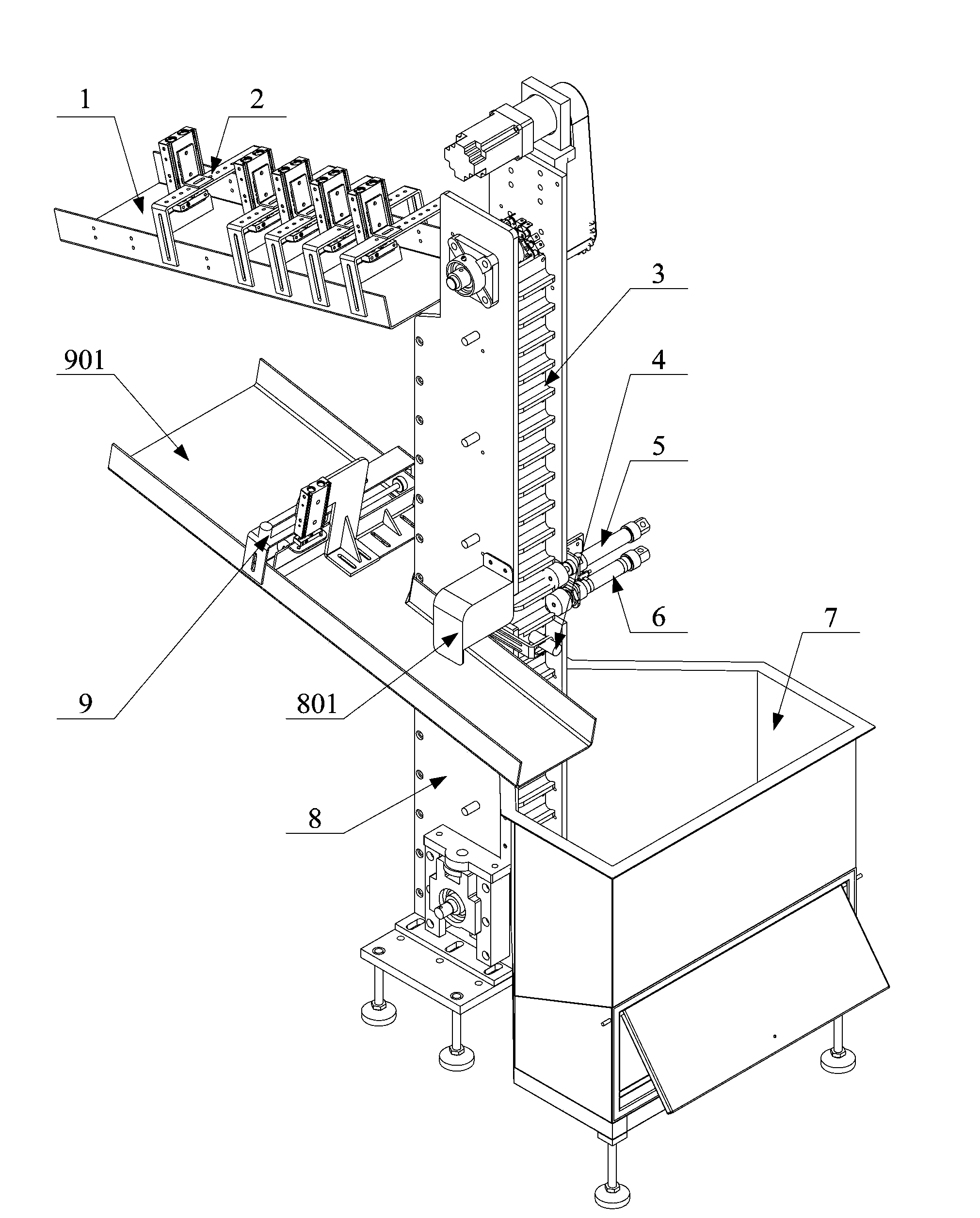

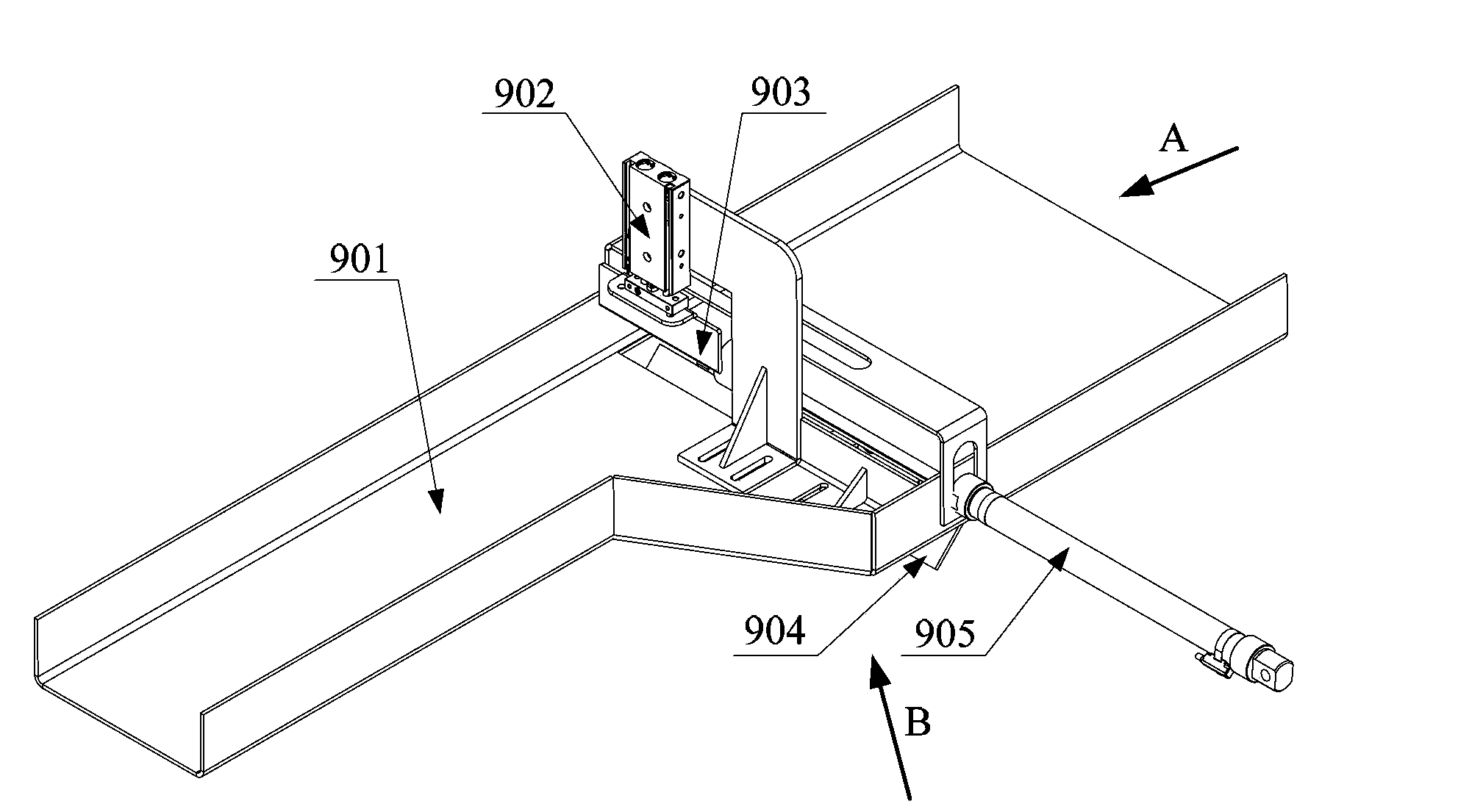

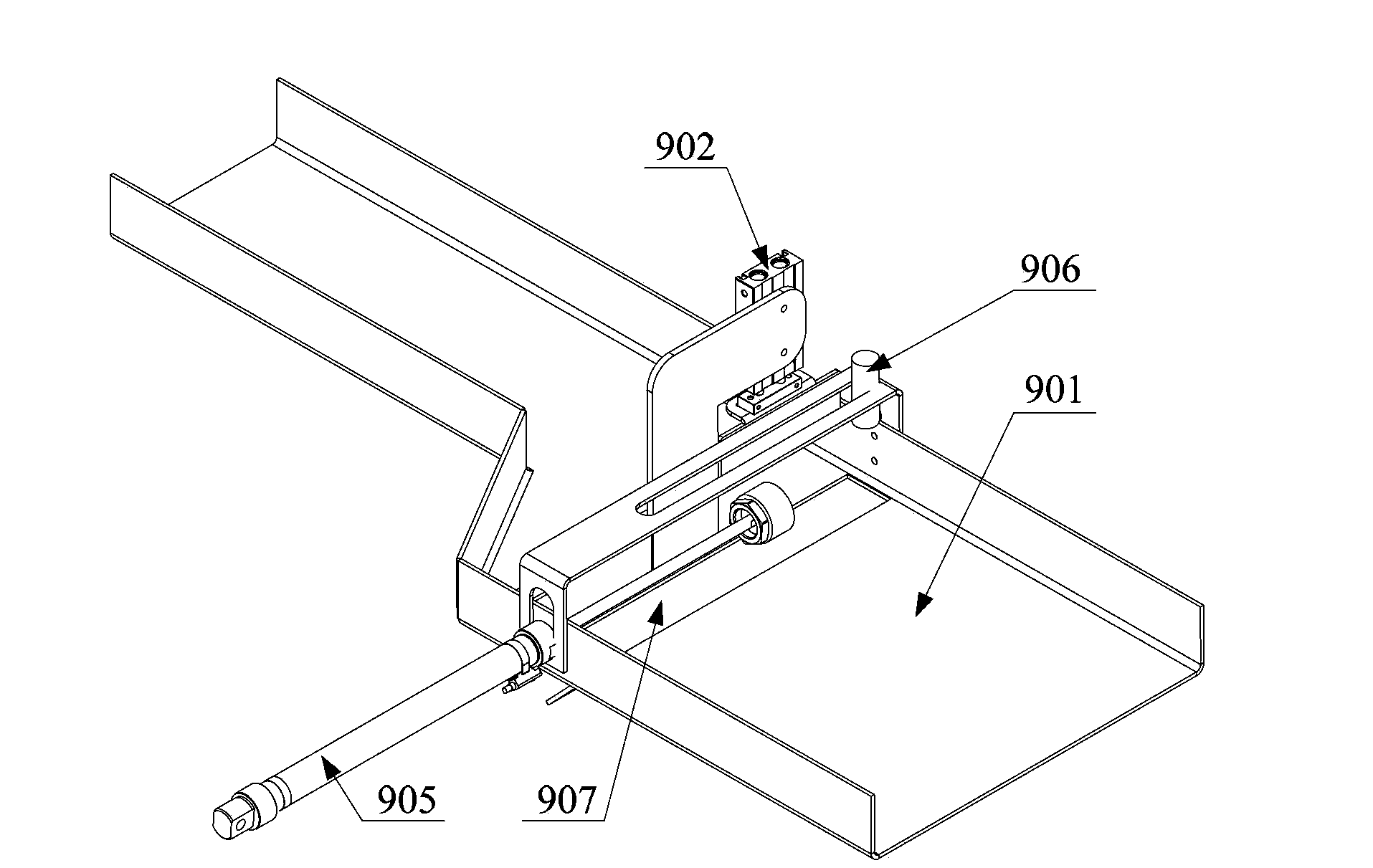

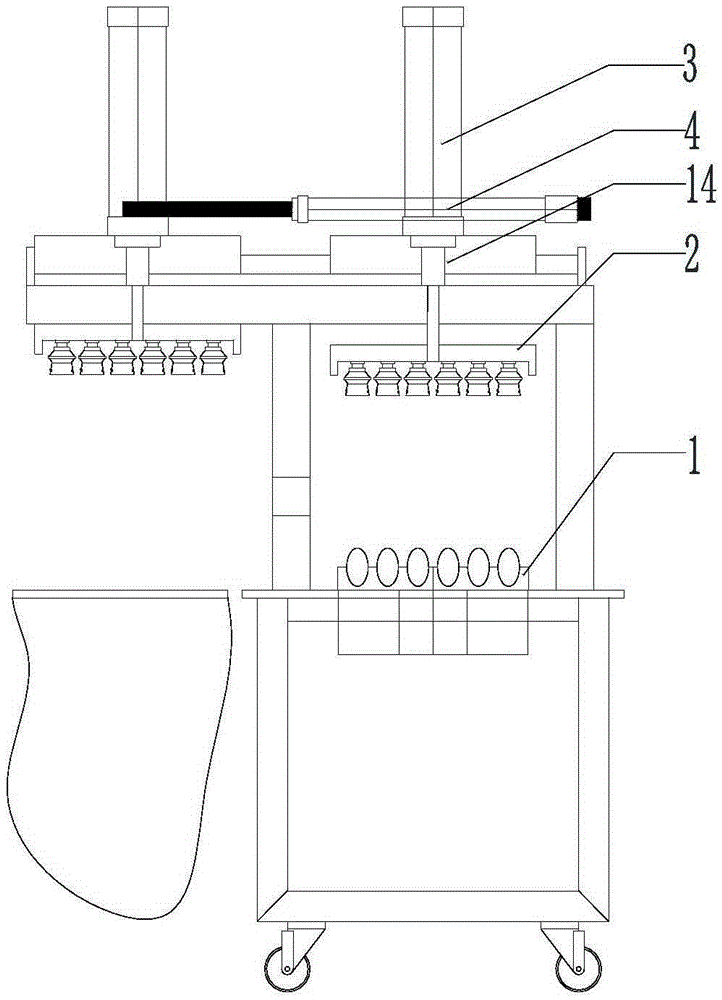

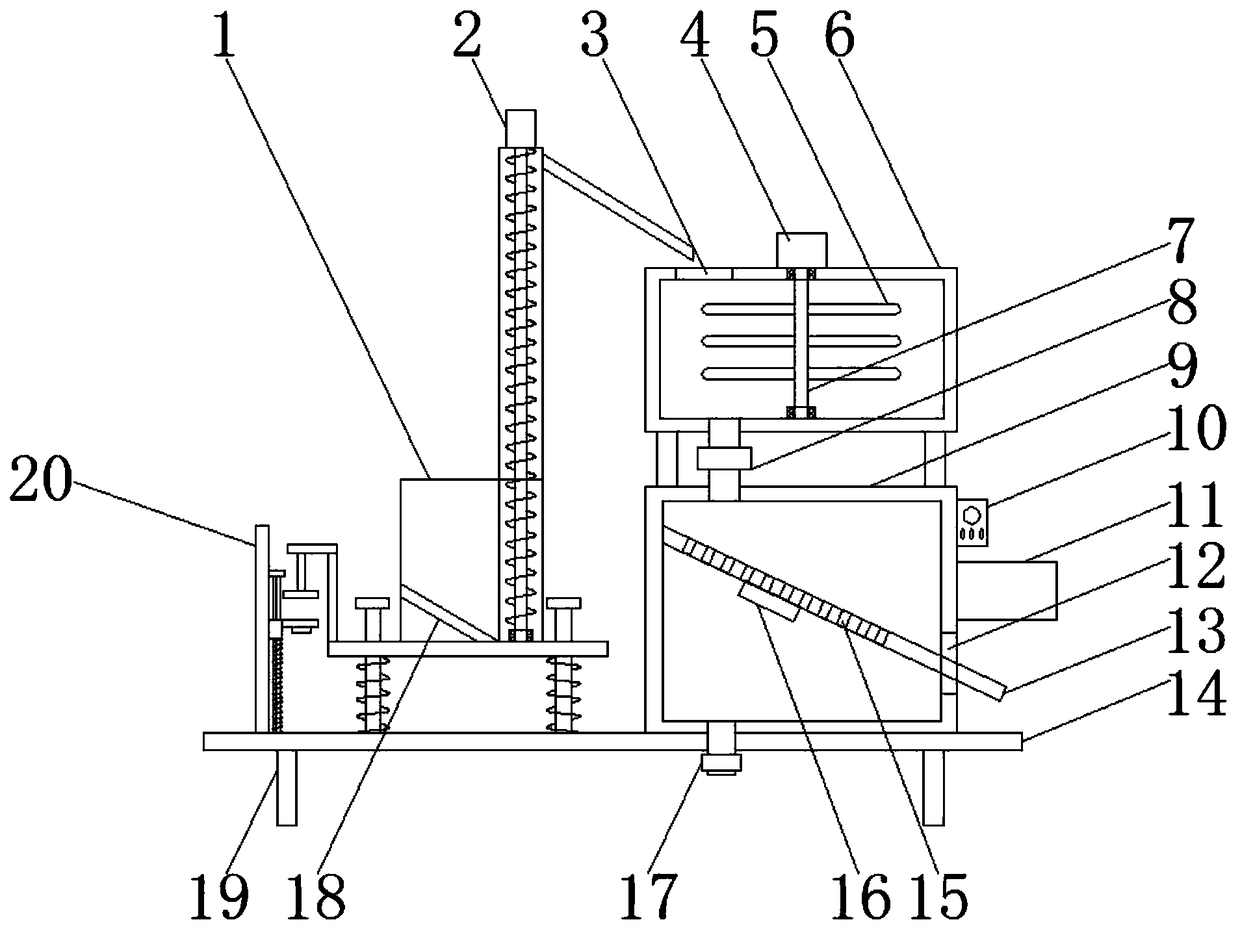

Feeding system

ActiveCN104139970AImplement automatic filteringAvoid manual screeningConveyor partsSignal onEngineering

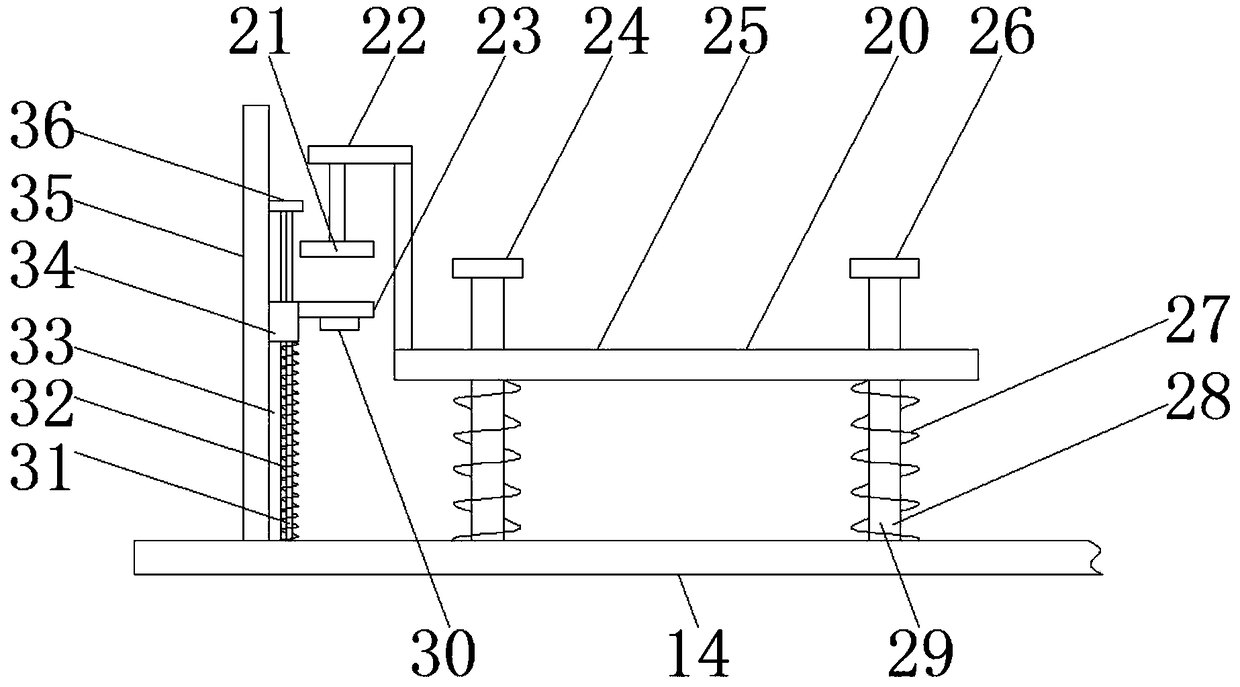

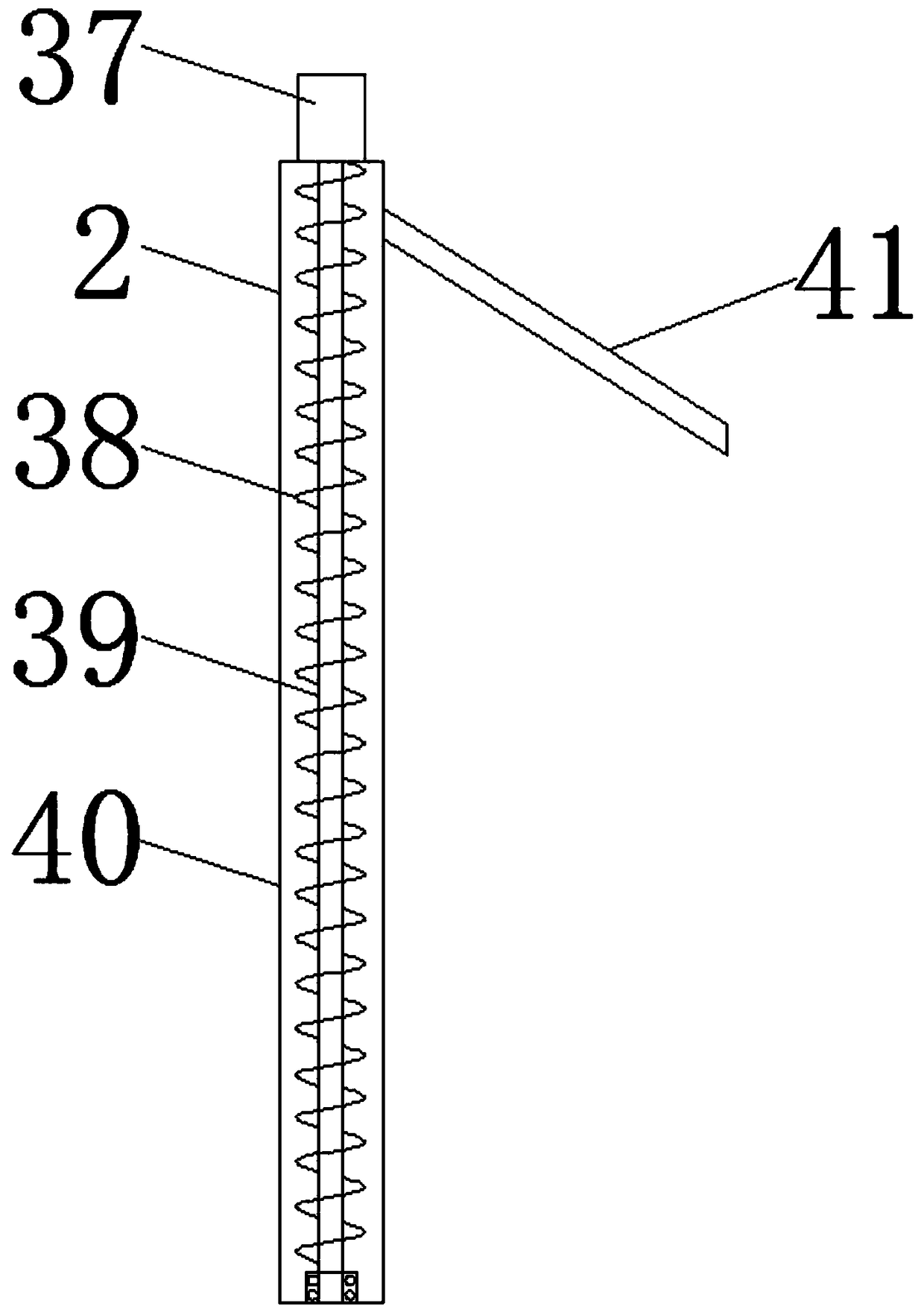

The invention provides a feeding system. The feeding device comprises a support, a hopper, a conveying device, a screening device, a first detection sensor and a first controller, wherein the hopper is connected with the support and is used for holding workpieces, the conveying device is arranged on the support and is used for conveying the workpieces in the hopper to machining equipment, the screening device is arranged on the support and is used for pushing the workpieces on the conveying device away from the conveying device, the first detection sensor is used for detecting whether one end of every workpiece on the conveying device needs to be machined or not and emitting a screening signal on not and is positioned in the downstream direction of the screening device or is arranged opposite to the screening device along the conveying direction of the conveying device, and the first controller is connected with the first detection sensor and is used for controlling the screening device to act after receiving the screening signal. The feeding system has the advantages that automatic workpiece screening is realized, manual work on workpiece screening is omitted, labor intensity is reduced for workers, production efficiency of the workpieces is improved, and demands on labor sources are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

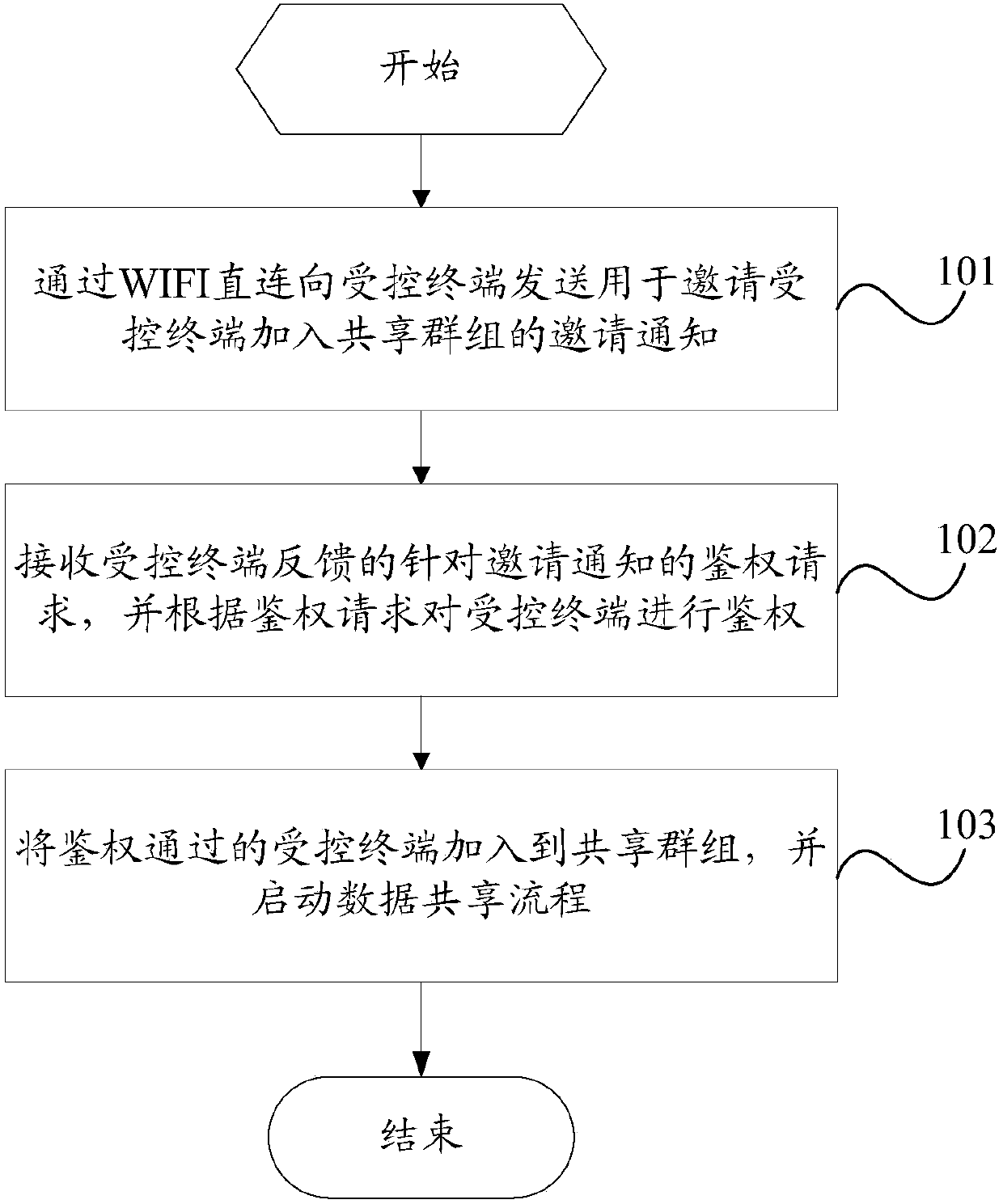

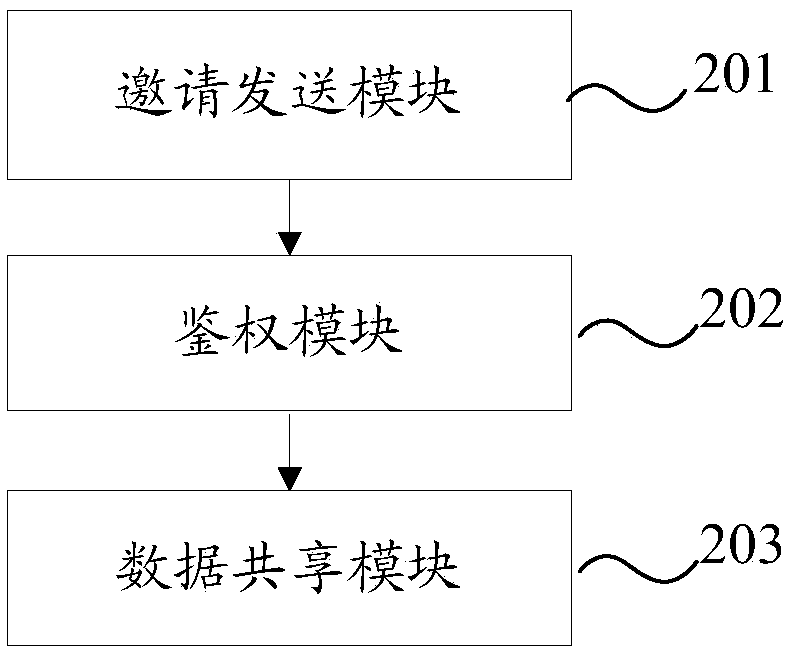

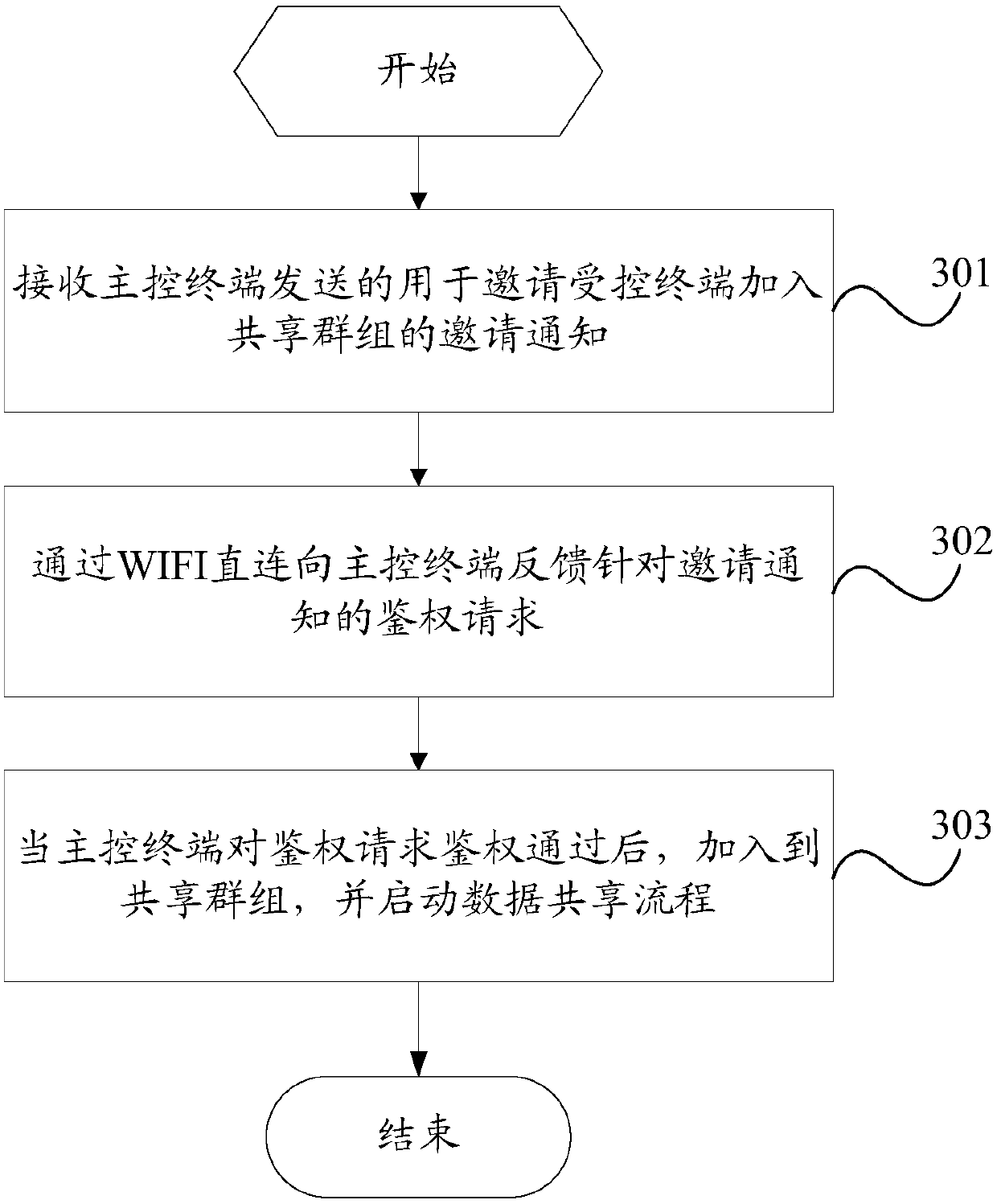

Data share method and device

InactiveCN107666669AImplement automatic filteringSolve the tediousness of manual screeningNetwork topologiesConnection managementData sharingInternet based

The invention provides a data share method and device. The method is applied to a main control terminal. The method includes sending an invitation notification used for inviting a controlled terminalto join a share group to the controlled terminal through WIFI direction connection; receiving an authentication request aiming at the invitation notification sent back by the controlled terminal and performing authentication on the controlled terminal according to the authentication request; joining the controlled terminal passing authentication into the share group and starting a data share flow.According to the invention, based on data share of IoT, defects in an internet based data share method are made up.

Owner:ZTE CORP

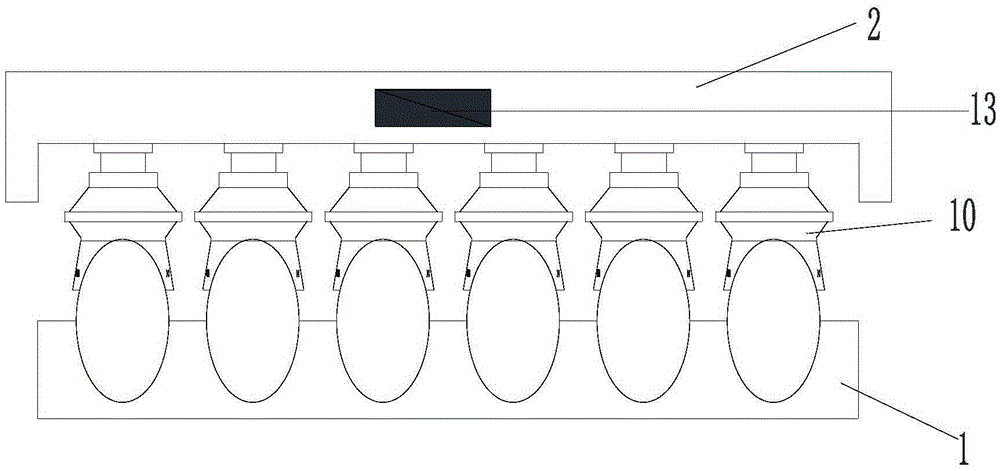

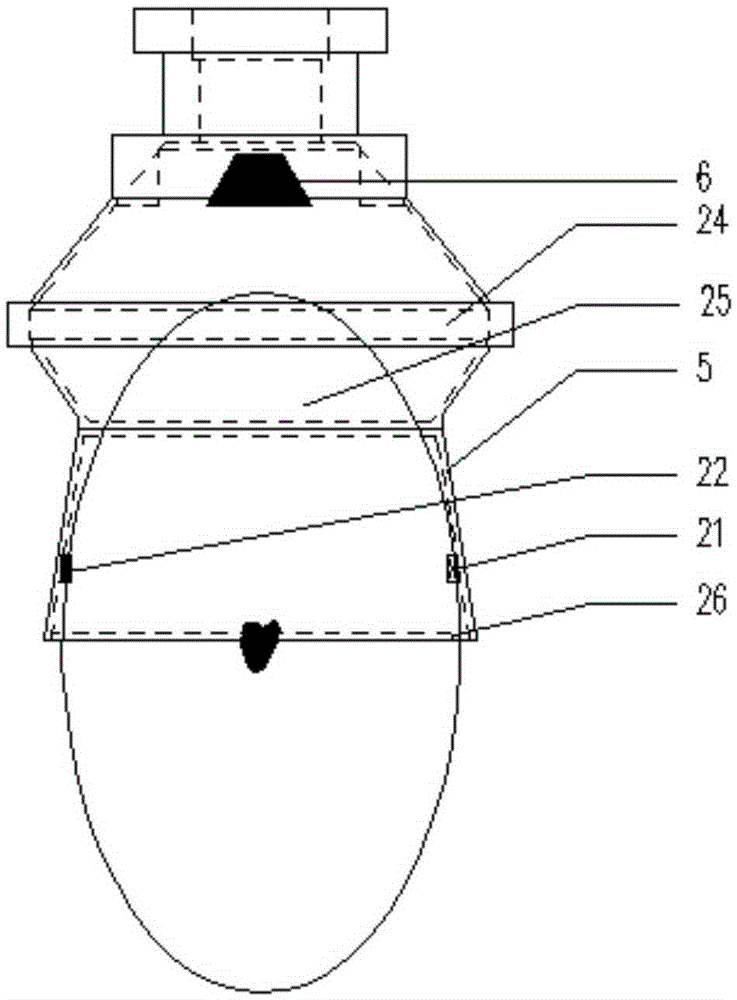

Hatching egg detector and hatching egg screening method

ActiveCN105265341AImplement automatic filteringReflection does not affectAvicultureLight reflectionScreening method

The invention discloses a hatching egg detector, which comprises a detection device, a tray and a separation lifting cylinder. The hatching egg detector is characterized in that the detection device comprises a plurality of detection heads and a processor. The detection heads are capable of emitting the light onto hatching eggs on the tray, detecting the light reflected by the hearts of the hatching eggs and then transmitting the detected information to the processor. The separation lifting cylinder is connected with the tray and is used for controlling the tray to move up and down. The entire detecting process is conducted based on the light reflection principle to detect the egg heart rate of hatching eggs. However, the light reflection effect is not affected by the ages of hatching eggs in days. The heart rate detection heads of the detection device are in direction contact with hatching eggs, while the contact parts thereof are accommodated in an inner space of the detection heads. A light emitting and receiving annunciator is arranged inside the inner space of the detection heads, so that the detection result of hatching eggs is not influenced by the external light. After the detection process, the detection result is transmitted to a negative pressure device by the processor. Therefore, hatching eggs can be automatically screened under the driving effect of the cylinder.

Owner:HARBIN WEIKE BIOTECH DEV

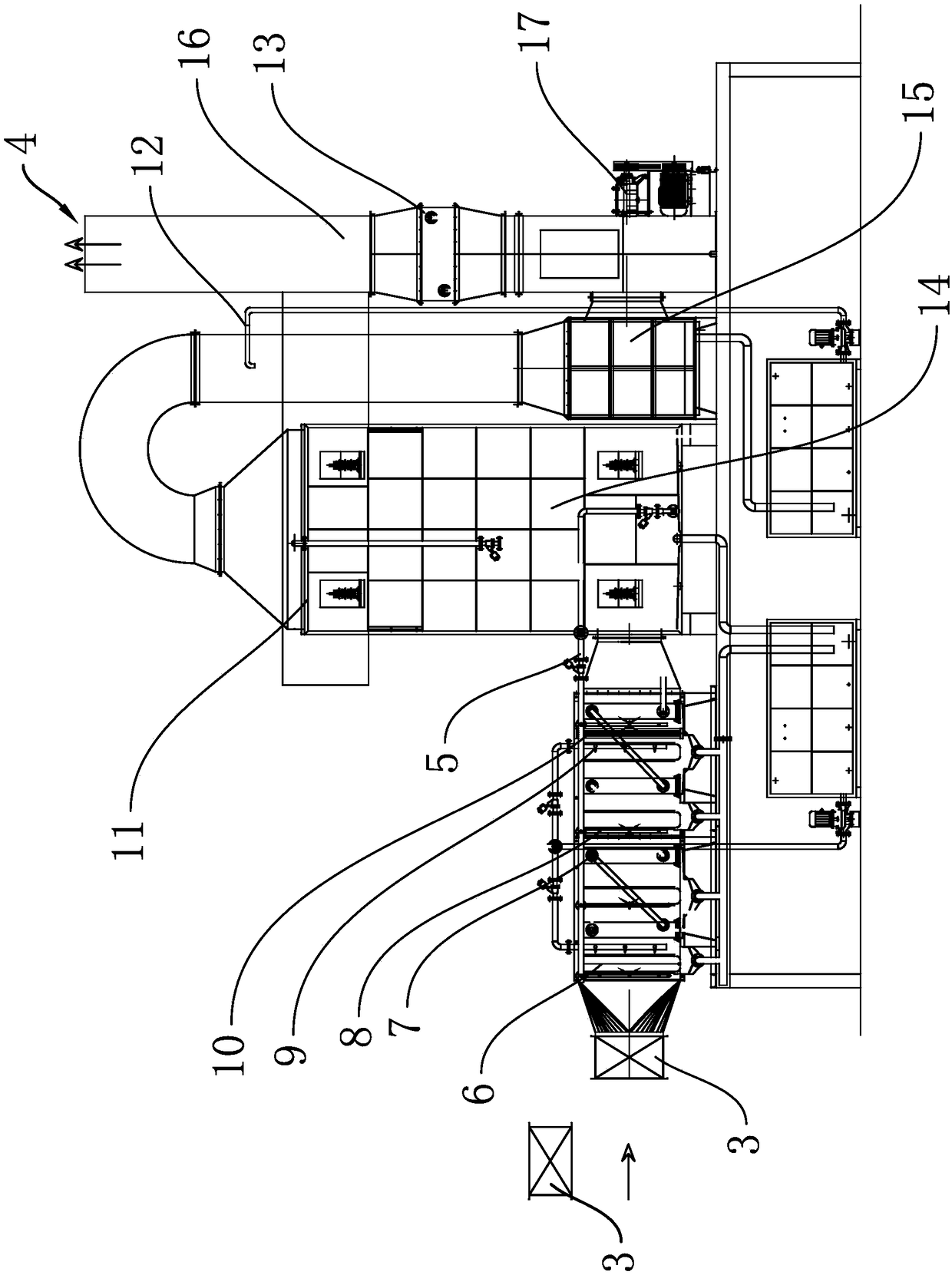

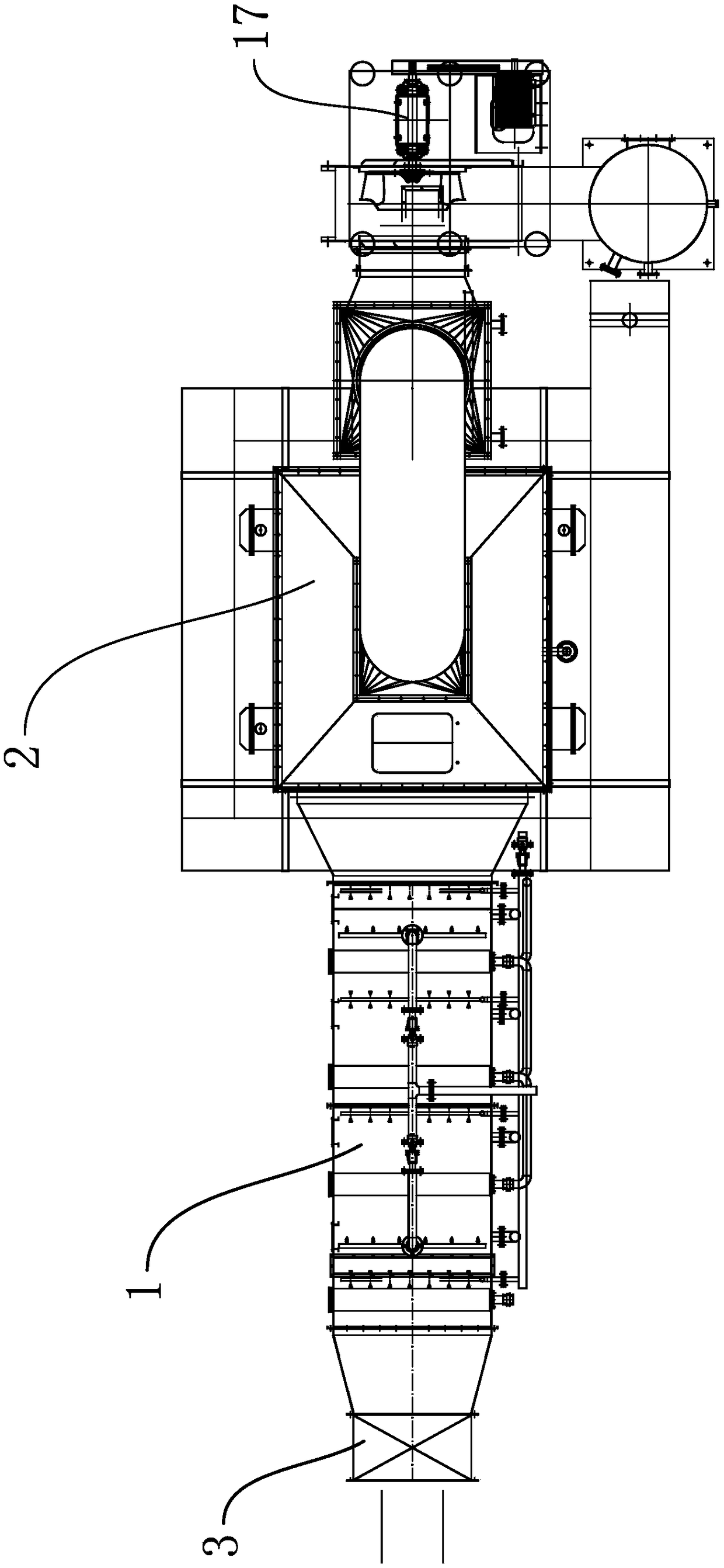

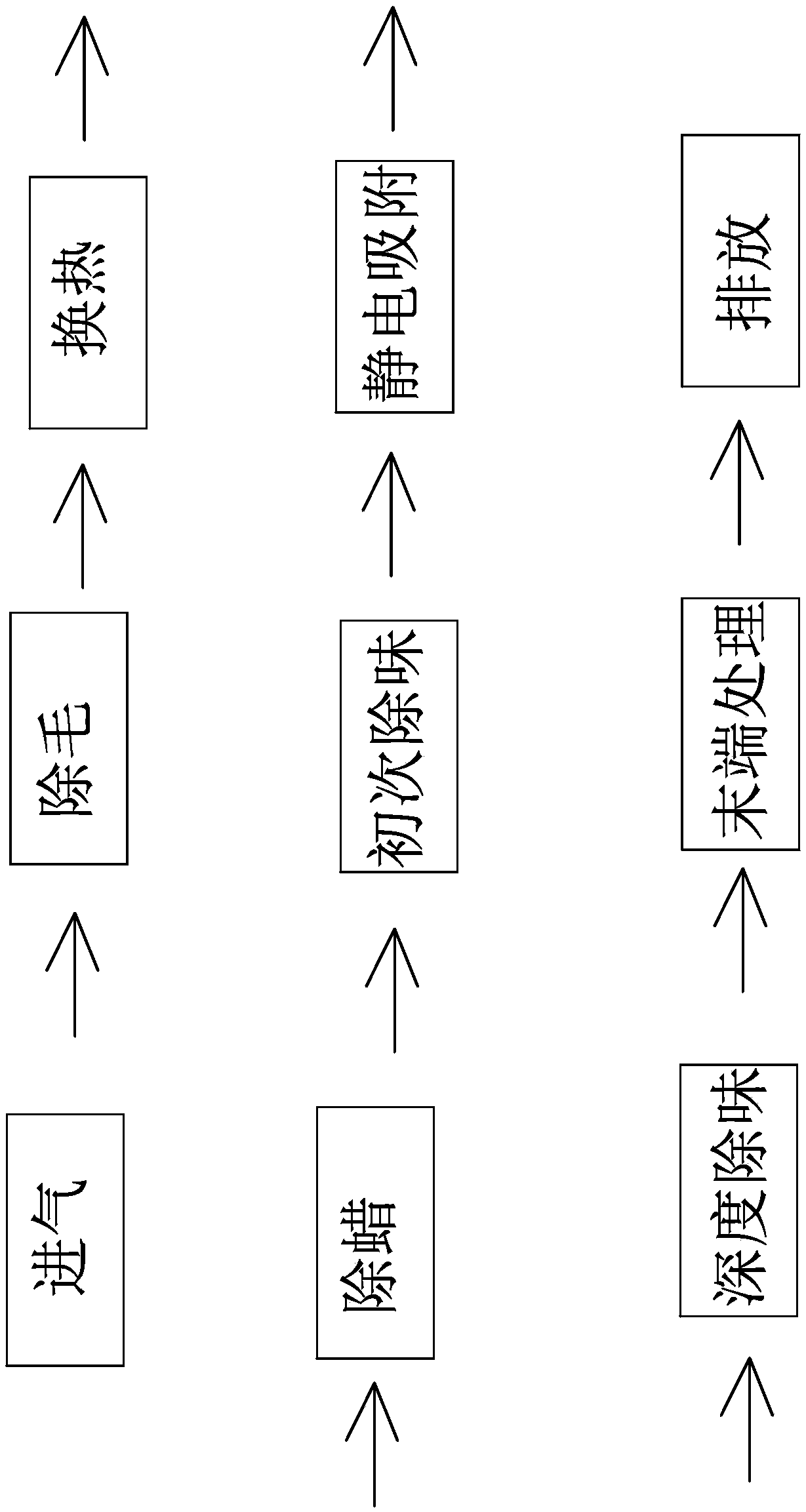

Atmospheric pollutant treatment technology

InactiveCN109225633AImplement automatic filteringGuaranteed uptimeElectrostatic separationMicro nanoParticulates

The invention relates to an atmospheric pollutant treatment technology which comprises the steps: A) gas feeding: inflating waste gas to be treated into a waste gas pretreatment device; B) flock removal: making the waste gas pass through an automatic flock removing mechanism to remove flocks in the waste gas; C) heat exchange: making the flock removed waste gas pass through a gas-liquid heat exchange mechanism to exchange heat with the gas-liquid heat exchange mechanism to reduce the temperature of the waste gas; D) wax removal: making the heat exchanged waste gas pass through a wax and impurity removing mechanism to remove wax in the waste gas; E) primary deodorization: making the wax removed waste gas pass through a primary microbubble deodorizing mechanism to primarily deodorize the waste gas; F) electrostatic adsorption: inflating the primarily-deodorized waste gas into a purifying tower from bottom to top and removing lamp black and particles in the waste gas through an electrostatic adsorption device; G) deep deodorization: making the electrostatically-adsorbed waste gas pass through a micro-nano bubble deep deodorizing mechanism from top to bottom to achieve deep deodorization; H) terminal treatment: making the deep-deodorized waste gas pass through a terminal white steam removing mechanism from bottom to top to remove white steam; I) discharge.

Owner:SUZHOU JINGTIAN AIREN ENVIRONMENTAL TECH CO LTD

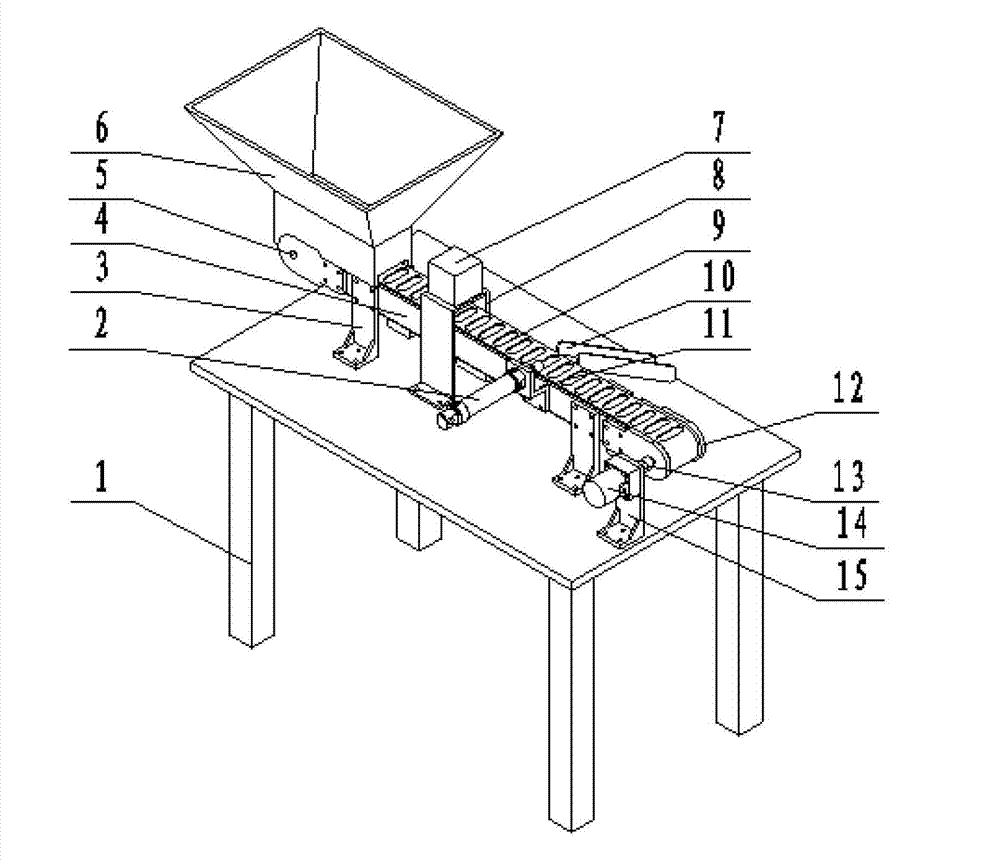

Automatic screening device for jujubes with different colors

The invention discloses an automatic screening device for jujubes with different colors. The automatic screening device comprises a working table, an air cylinder, a cross beam bracket, a cross beam, a rolling shaft, a hopper, a camera, a camera bracket, a transmission belt, a slide way, an air cylinder bracket, a rolling shaft bracket, a shaft coupler, a motor and a motor bracket, wherein the working table is placed on the ground; the cross beam bracket is mounted on the working table; the cross beam is mounted on the cross beam bracket; the air cylinder is fixed on the air cylinder bracket; the air cylinder bracket is mounted on the cross beam; the hopper is mounted on the cross beam; the camera is fixed on the camera bracket mounted on the working table; the slide way is mounted on the cross beam; the transmission belt is mounted on the rolling shaft; the rolling shaft is mounted on the rolling shaft bracket; the rolling shaft is connected with the motor through the shaft coupler; and the motor is fixed on the motor bracket. The device can automatically screen the jujubes with the different colors.

Owner:孙中国

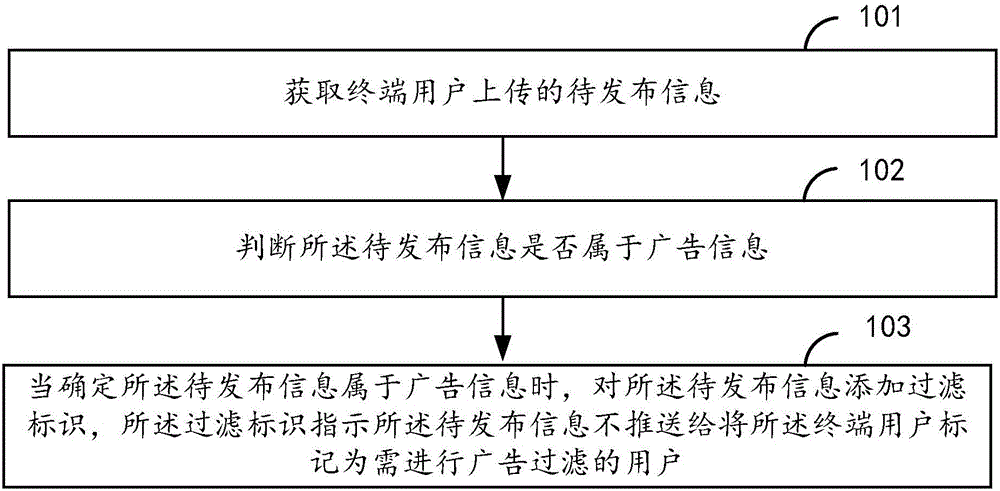

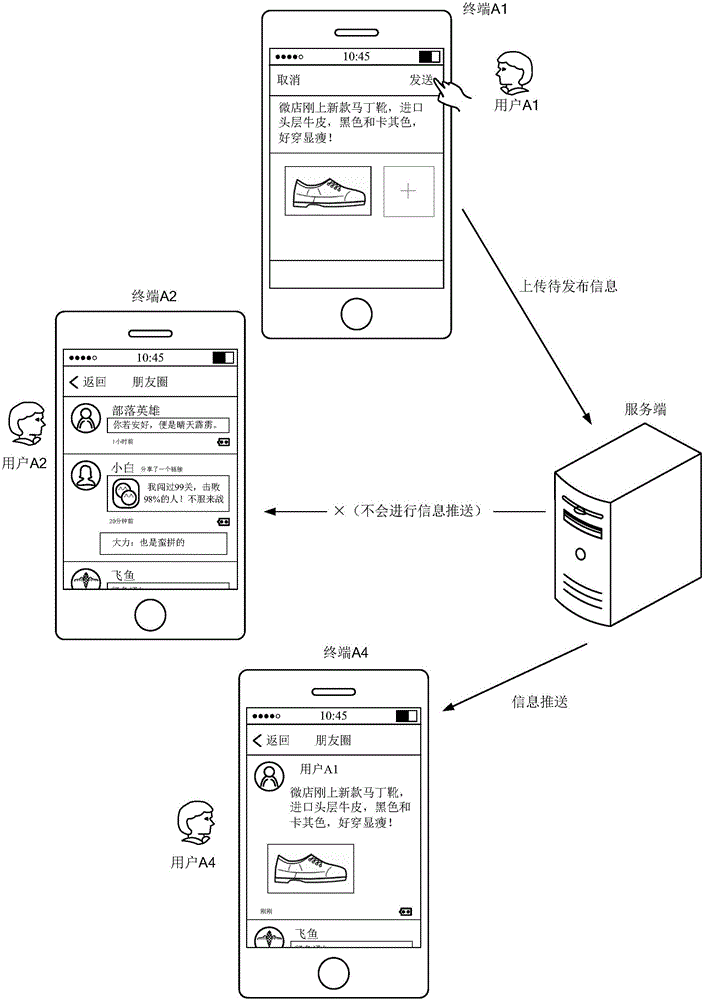

Method and device for filtering advertisement information

ActiveCN105787133AImplement automatic filteringImprove accuracyData processing applicationsWeb data retrievalEnd user

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

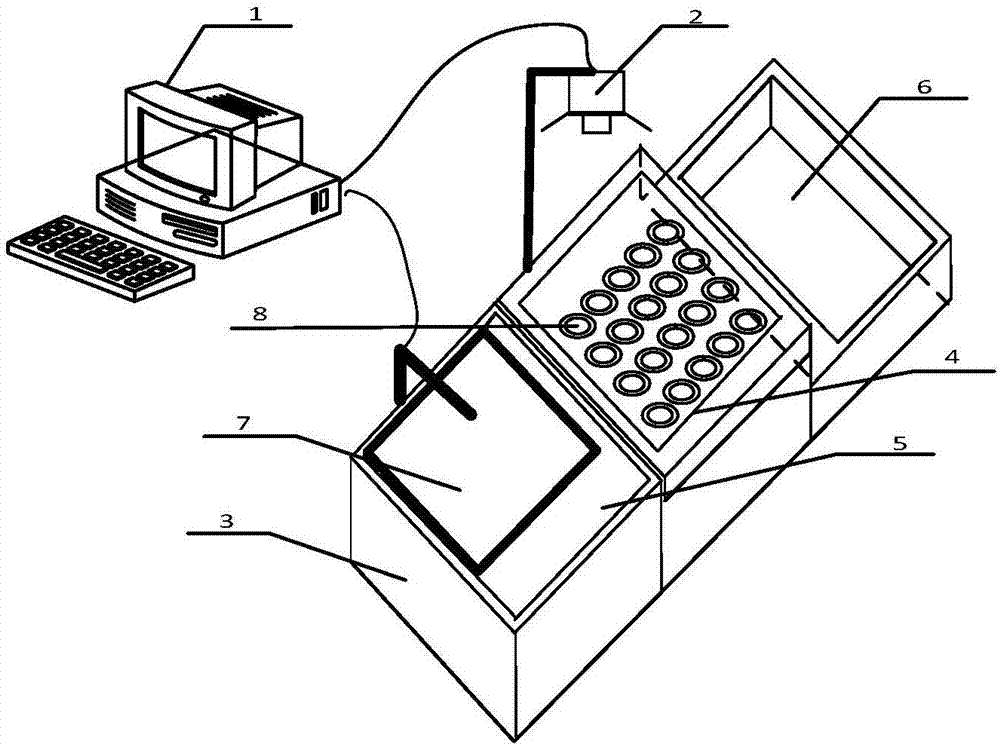

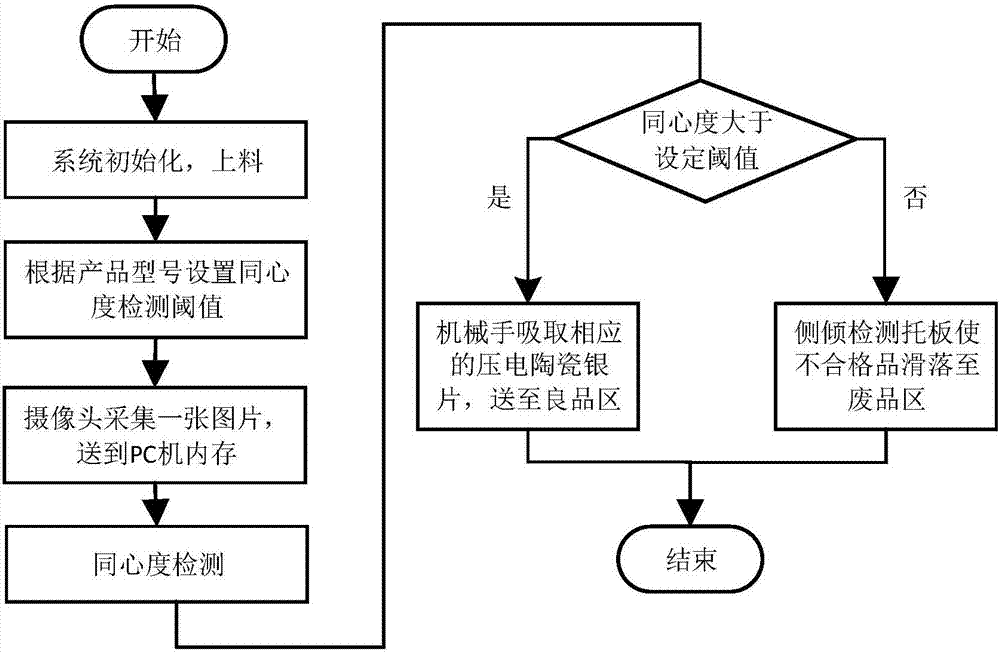

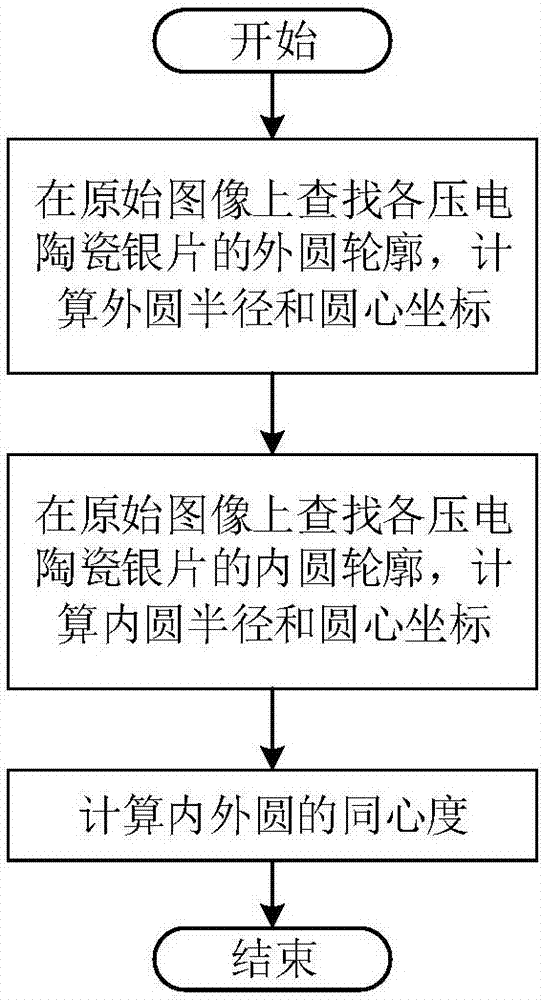

Automatic testing method for concentricity quality of piezoelectric ceramic silver plate and device

PendingCN107101598AEasy to operateImprove recognition accuracyUsing optical meansSilver plateEngineering

The invention discloses an automatic testing method for concentricity quality of a piezoelectric ceramic silver plate and a device. The method comprises the steps of acquiring a gray scale image by means of a camera, searching an external circle contour point set and an inner cycle contour point set of each piezoelectric ceramic silver plate in the image, performing circle curve fitting on the obtained point sets, calculating the circle centers and radiuses of the inner circle and external circle obtained through fitting, calculating concentricity of the inner circle and the external circle. The concentricity measured by each piezoelectric ceramic silver plate is compared with a preset concentricity threshold, and whether the piezoelectric ceramic silver plate is qualified or unqualified is determined one by one. After a system sets a quality threshold according to product type, adjustment of a random parameter is not required, and concentricity of the piezoelectric ceramic silver plates with different dimensions is measured automatically. The automatic testing method and the device have advantages of realizing high recognition accuracy, greatly improving automatic testing degree and improving production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

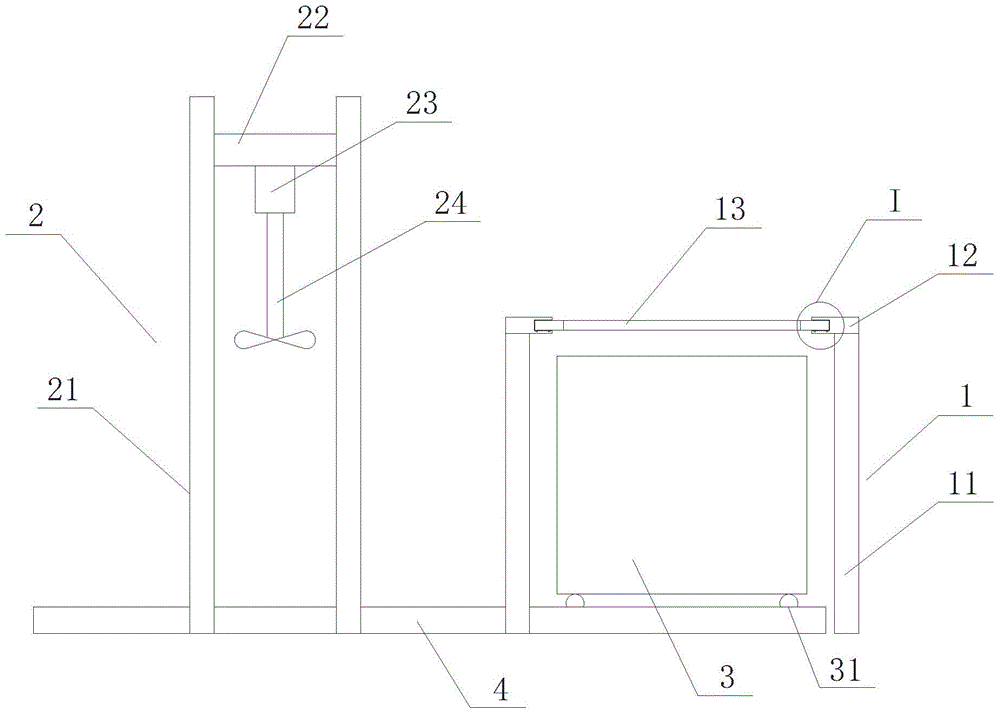

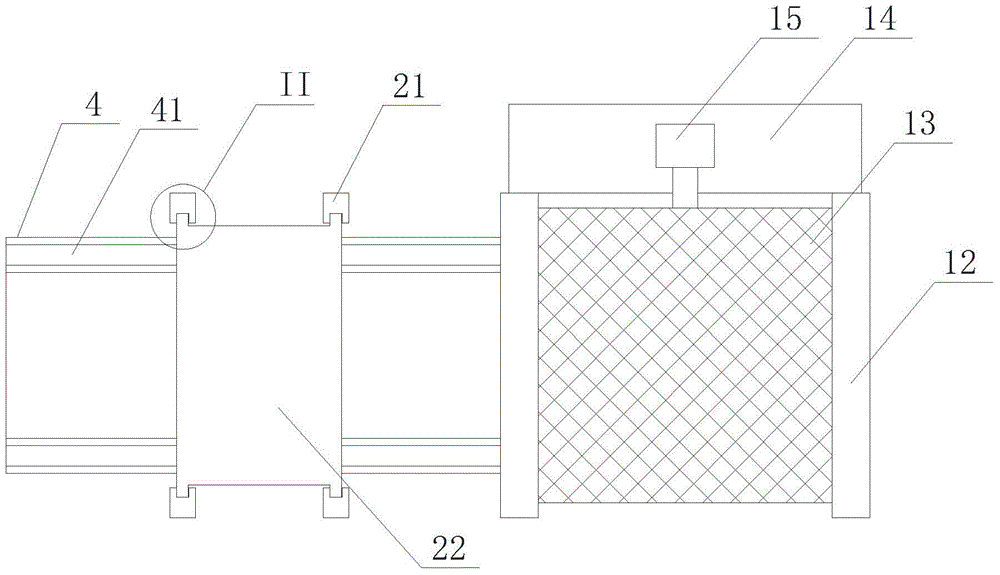

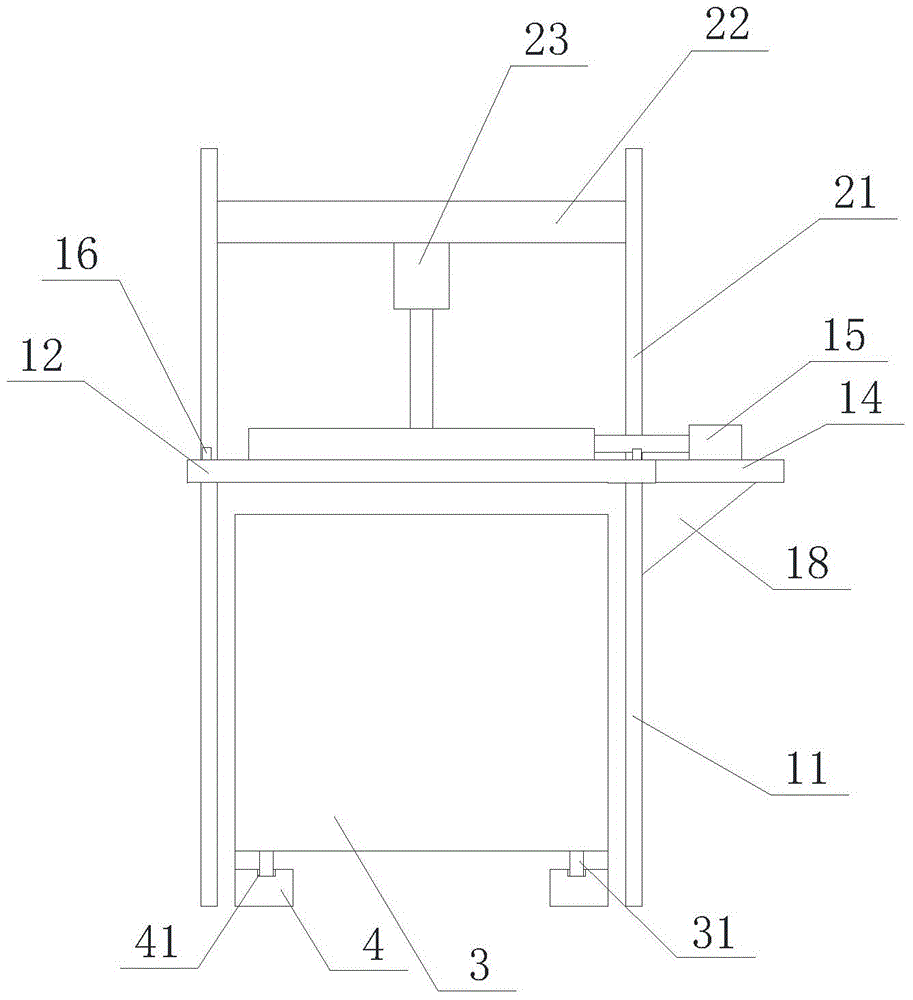

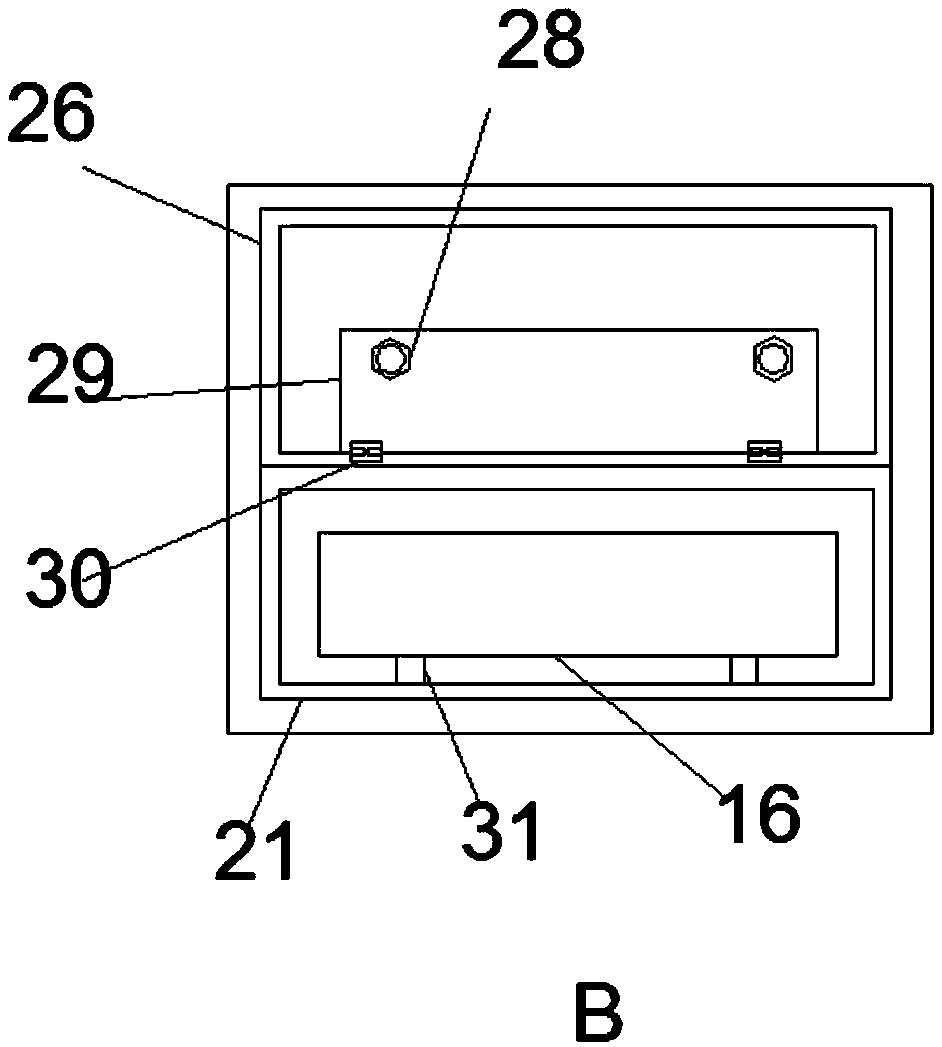

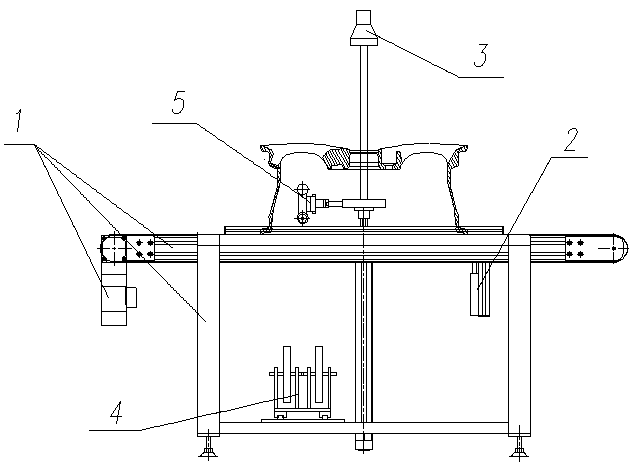

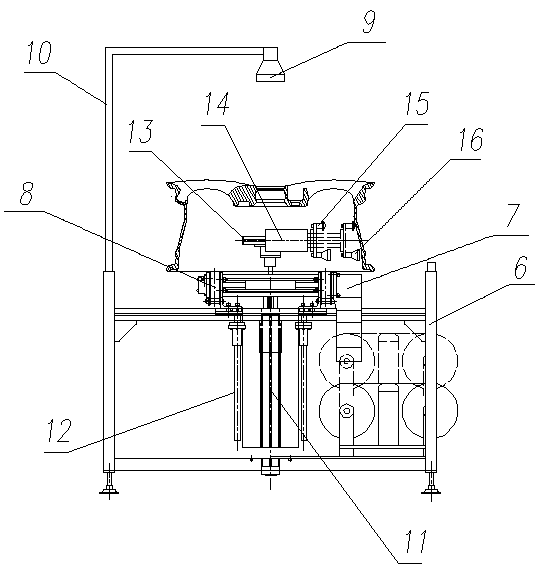

Automatic screen stirring device

The invention provides an automatic screen stirring device which is even in stirring and capable of lowering labor intensity and increasing glaze slip attaching force. The automatic screen stirring device comprises a screen device, a stirring device body, a material containing box and a pair of sliding rails. The sliding rails are provided with sliding grooves respectively. Wheels matched with the sliding grooves are arranged on the two sides of the bottom of the material containing box respectively. The screen device comprises a screen support, an air cylinder, a screen, an air cylinder fixing plate and a pair of parallel screen fixing frames. The screen fixing frames are arranged on the screen support. Drawing and inserting grooves are formed in the opposite faces of the screen fixing frames. The air cylinder fixing plate is arranged at one ends of the screen fixing frames. The stirring device body comprises a sliding plate, a motor, a stirrer and four vertically-arranged height adjusting rails. The labor intensity is lowered, automatic stirring is achieved, the mixing uniformity and attaching force of glaze slip are improved, and the one-time pass percent of products is increased.

Owner:YANGZHOU JIAZHONG MACHINERY

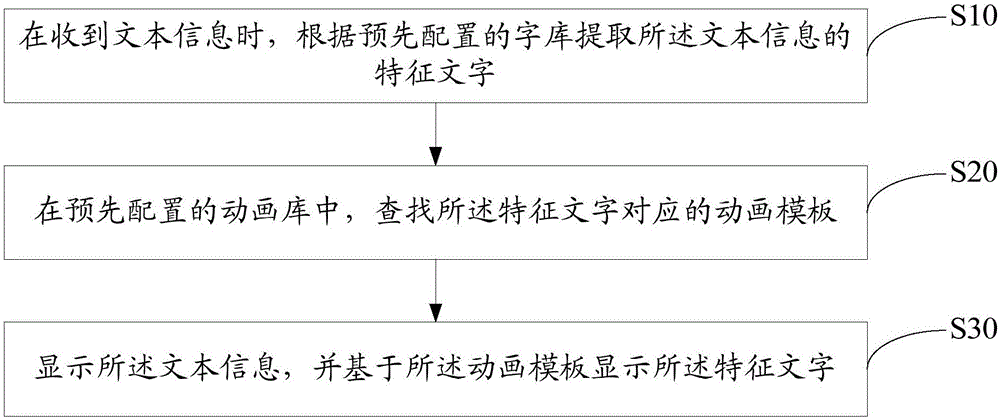

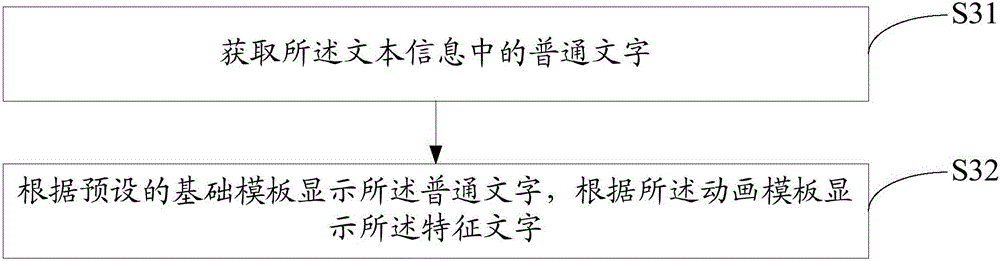

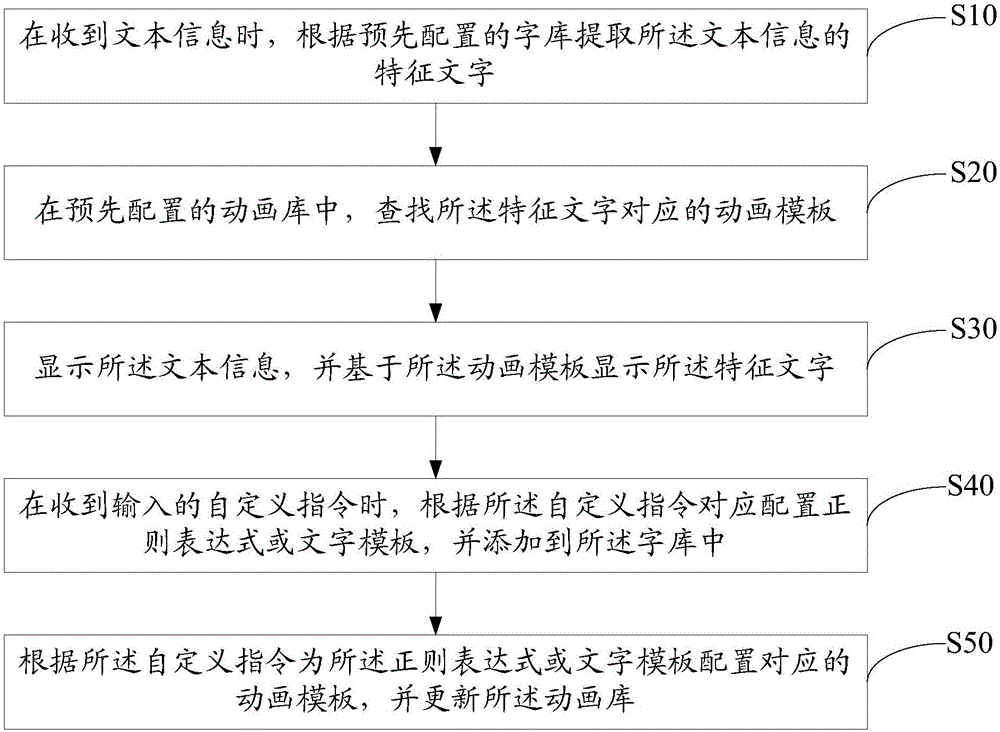

Text display method and device

InactiveCN106649209AImplement automatic filteringImprove reading experienceNatural language data processingSpecial data processing applicationsText displayAnimation

The invention discloses a text display method. The text display method includes the steps that when text information is received, characteristic characters of the text information are extracted according to a pre-configured character library; in a pre-configured animation library, animation templates corresponding to the characteristic characters are found; the text information is displayed, and the characteristic characters are displayed based on the animation templates. The invention also discloses a text display device. By means of the text display method and device, the visual interestingness is enhanced, and reading experiences of a user are improved.

Owner:SHENZHEN TINNO WIRELESS TECH

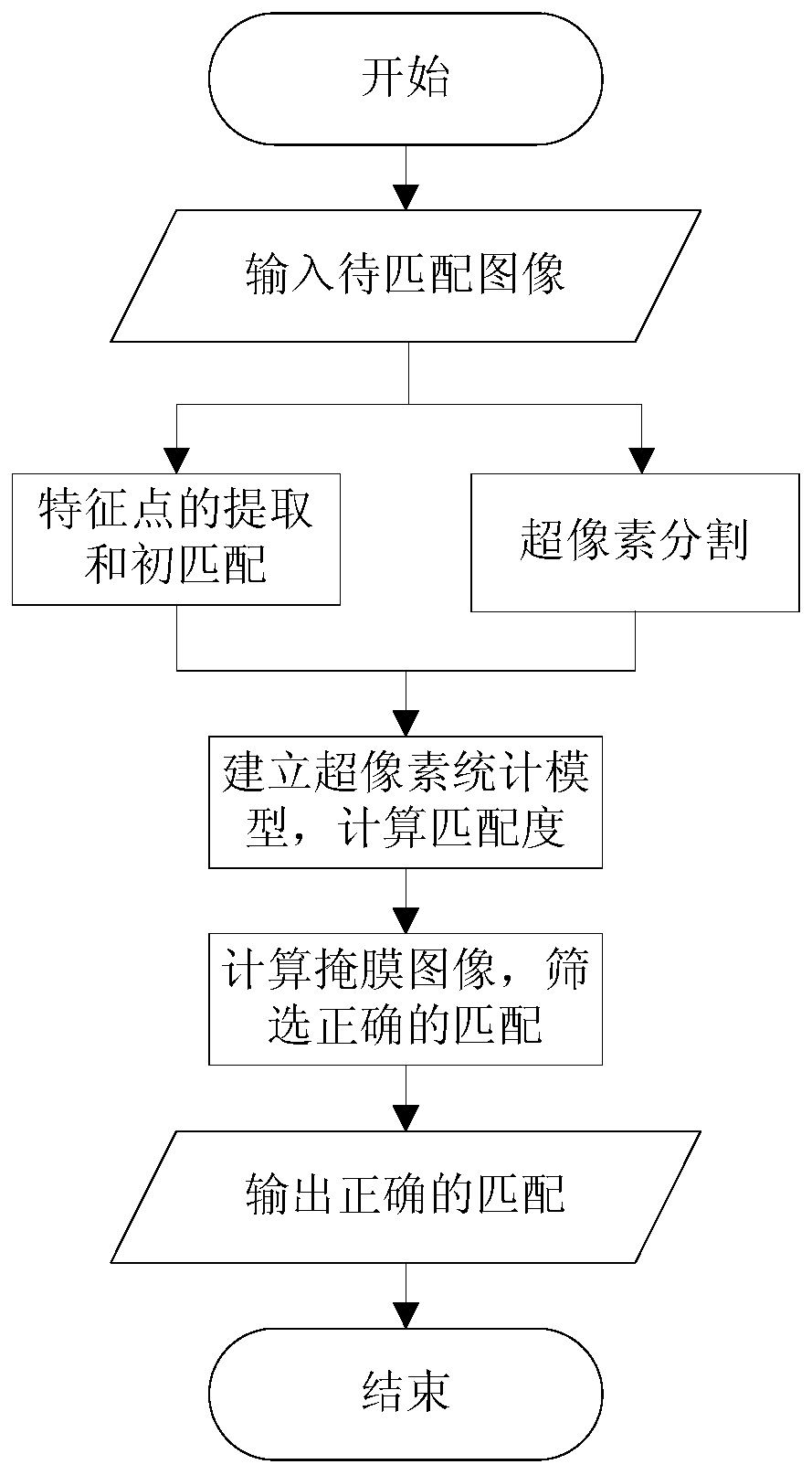

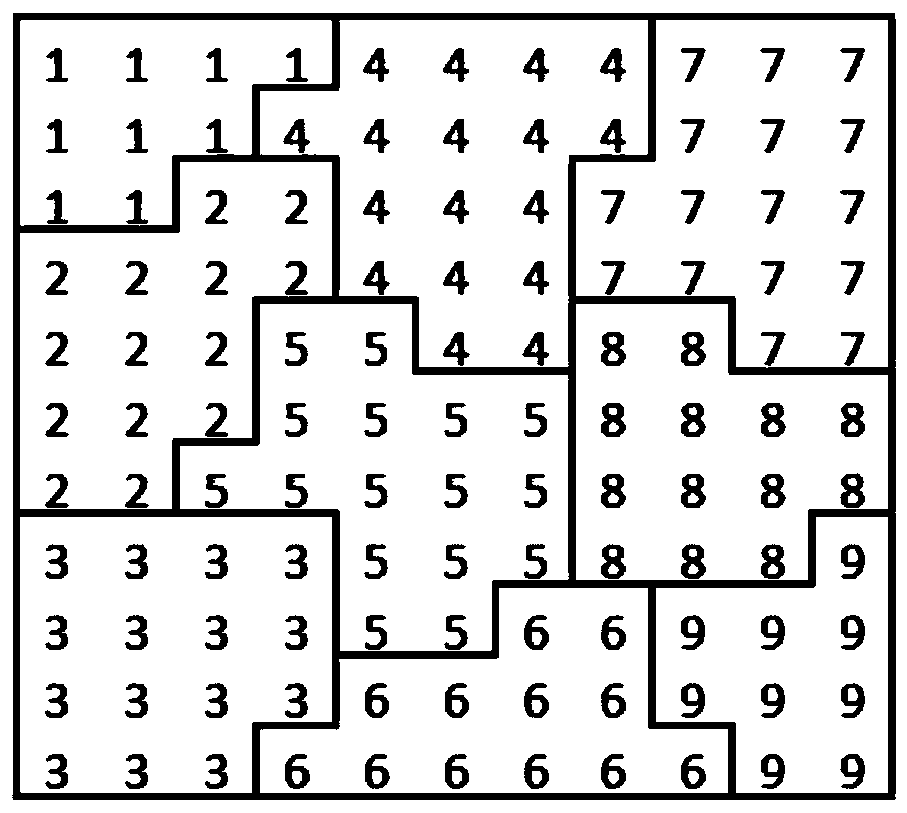

A false matching removal method based on superpixel motion statistics

ActiveCN109949348AImprove accuracy and stabilityScreening results are accurateImage analysisCharacter and pattern recognitionMesh gridFeature extraction

The invention discloses a false matching removal method based on superpixel motion statistics. The method comprises the following steps: carrying out feature extraction, description and matching on two images to be matched; Segmenting the to-be-matched images I1 and I2 by using an improved superpixel segmentation algorithm to obtain two superpixel mark graphs; And establishing a superpixel motionstatistical model based on the superpixel marker map, and realizing automatic screening of registration feature points of the non-rigid deformation image through the model. According to the method, asuper-pixel segmentation strategy is adopted to replace simple rectangular grid division, super-pixel blocks obtained through segmentation are tightly connected in space, colors and textures in singlesuper-pixel blocks are kept consistent, a segmentation result better follows the moving edge of an object, and therefore it is guaranteed that feature points in super-pixels have the same or consistent moving tendency.

Owner:TIANJIN UNIV

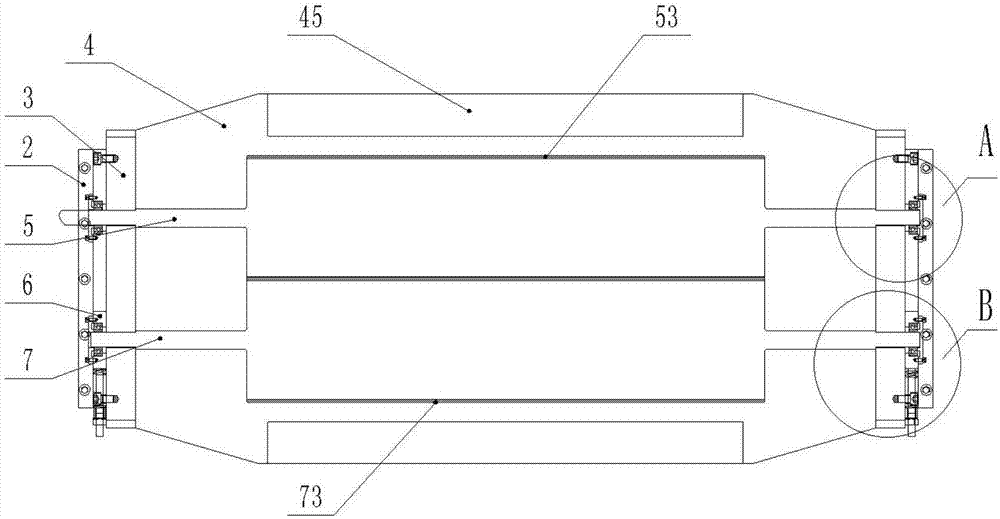

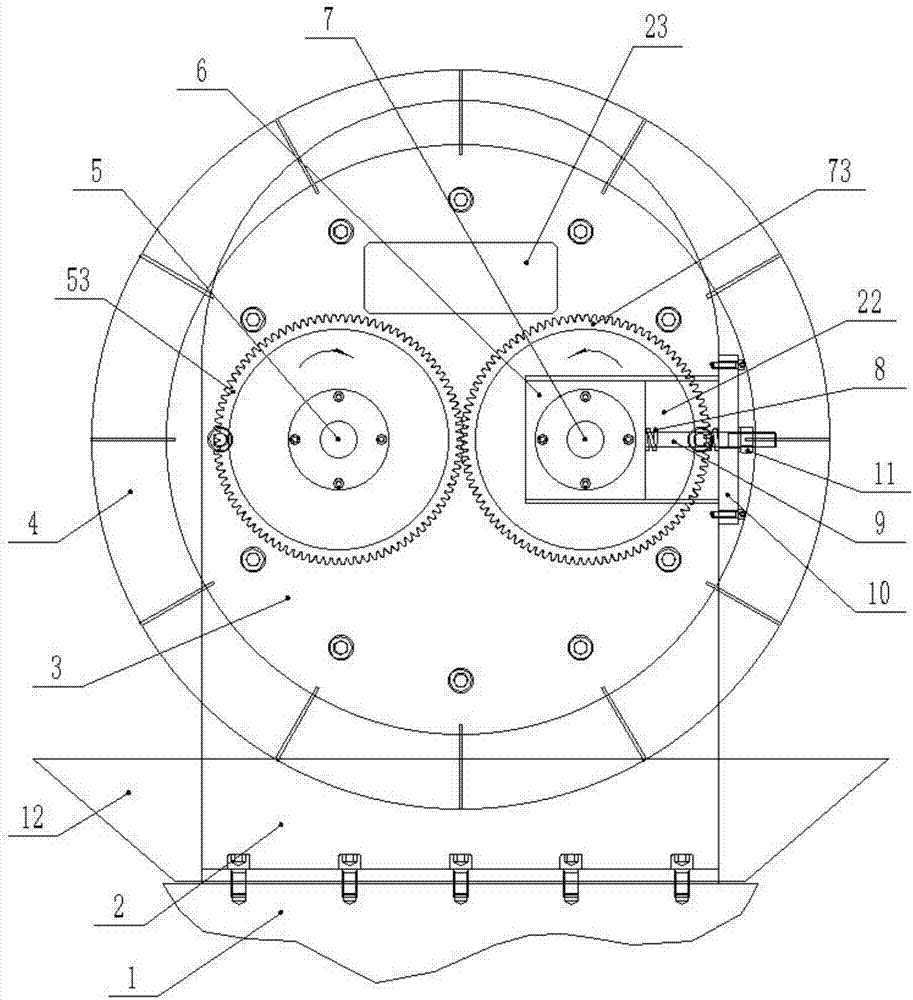

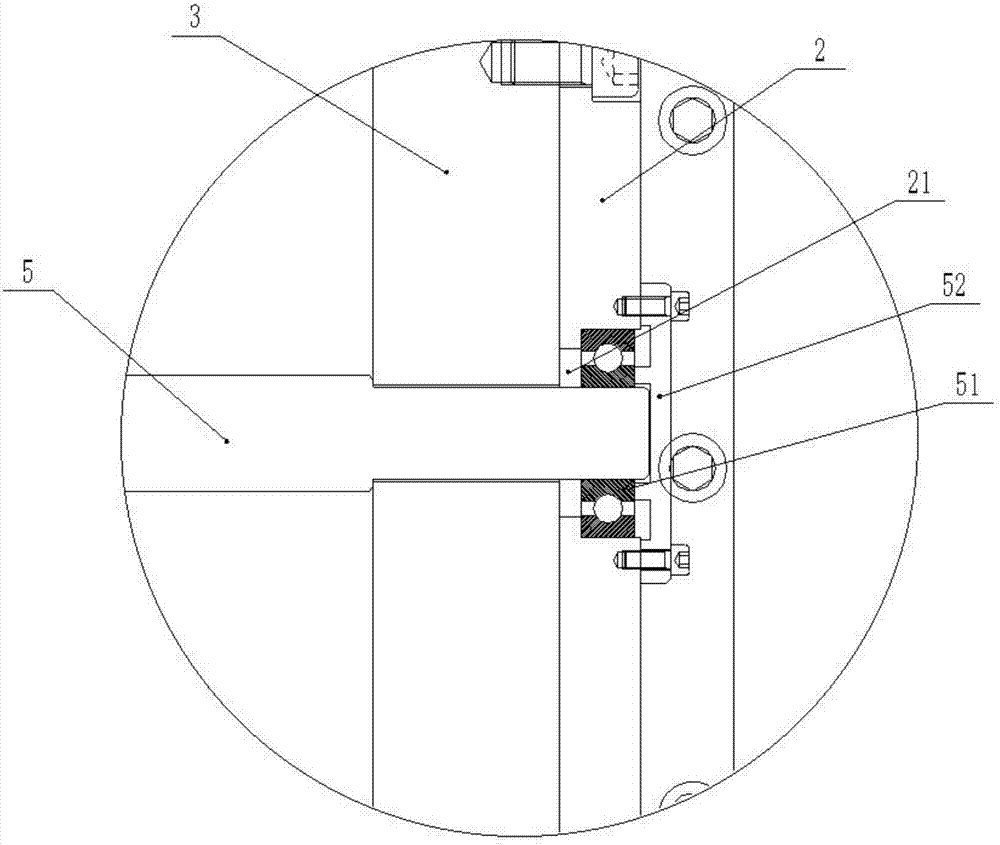

Full-automatic two-way airtightness detection device

InactiveCN103335796AImplement automatic filteringCompact structureMeasurement of fluid loss/gain rateEngineeringAir tightness

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

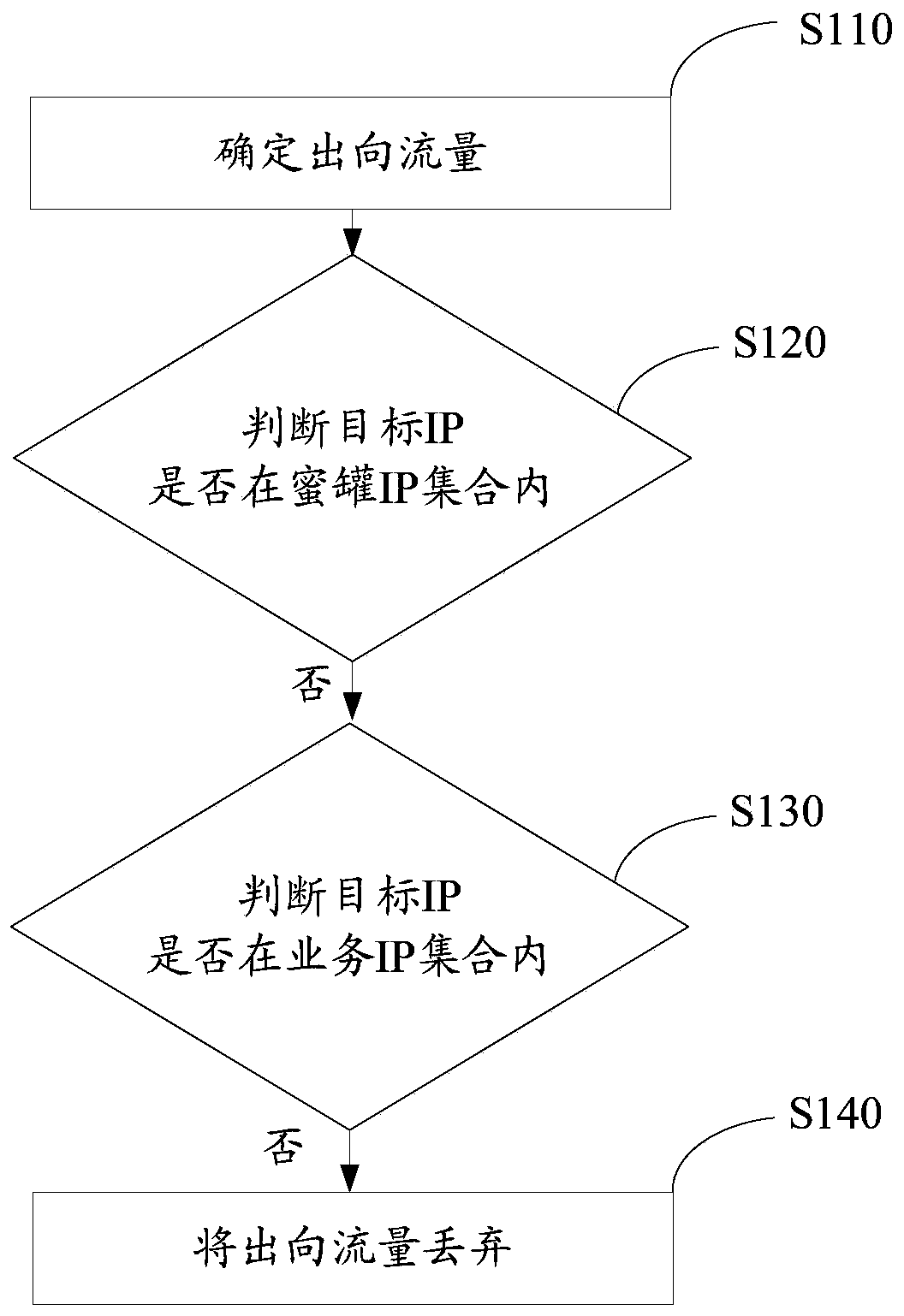

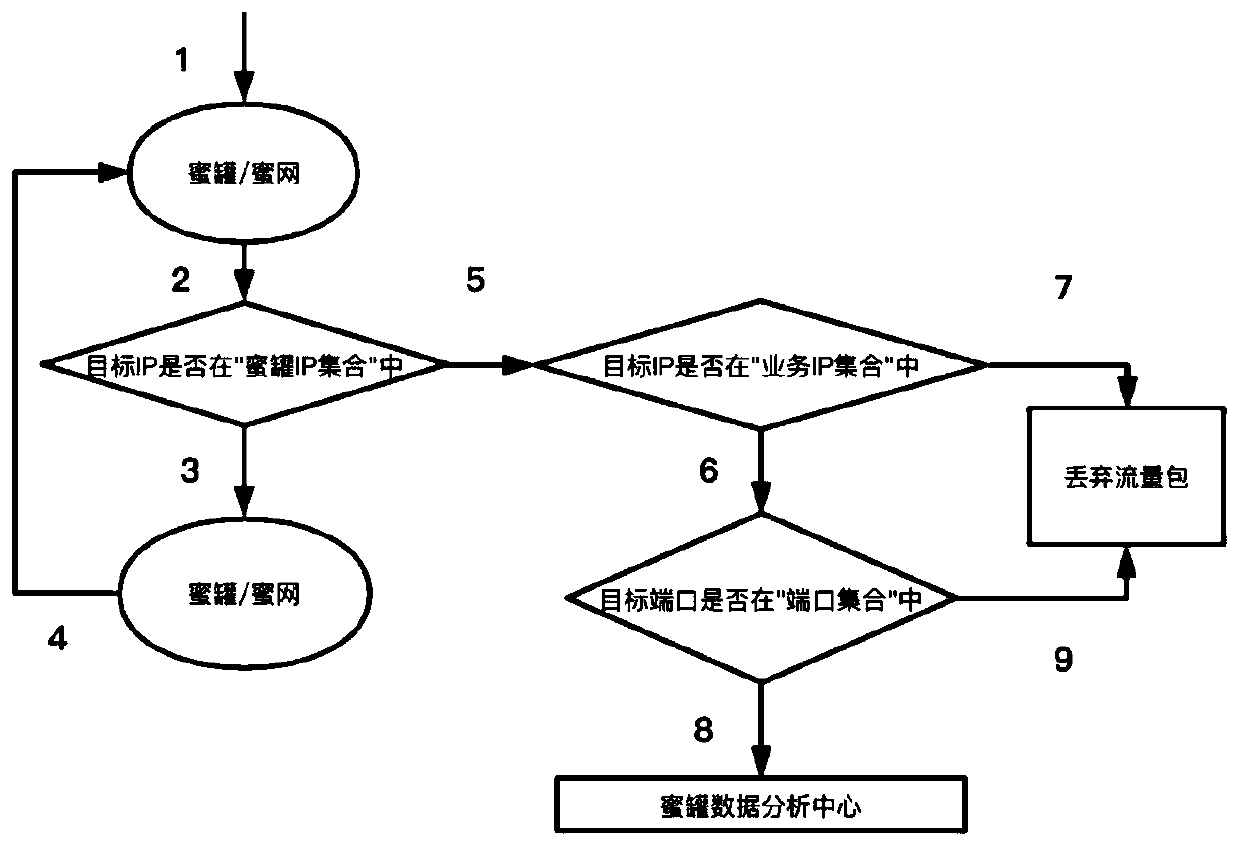

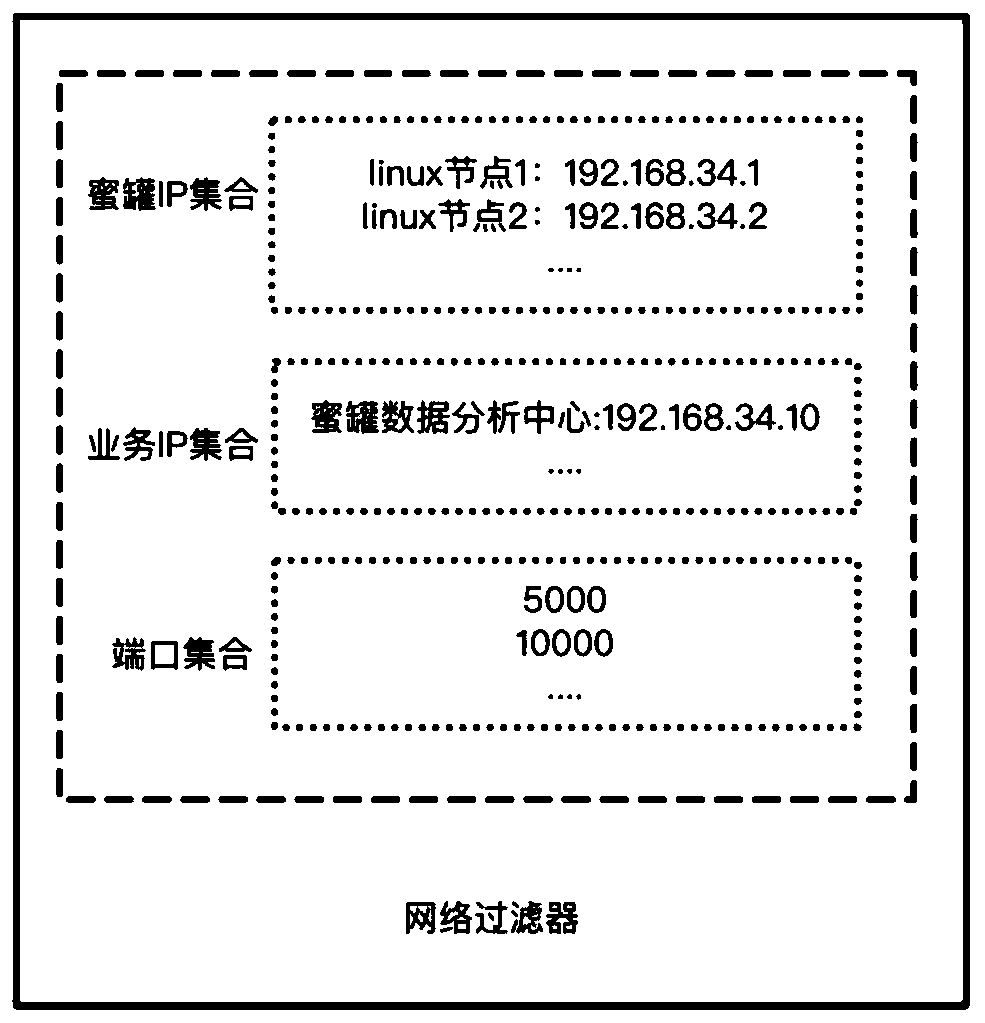

System-level honeypot network isolation system based on linux network filter

The invention provides a system-level honeypot network isolation system based on a linux network filter, and relates to the technical field of network security, and the corresponding method comprisesthe steps: determining outgoing flow which comprises a target IP; judging whether the target IP is in the honeypot IP set or not; if not, judging whether the target IP is in the service IP set or not;and if not, discarding the outgoing flow. The technical problem that for an existing honeypot, the risk that a service system is invaded exists, and normal service safety is threatened is solved.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

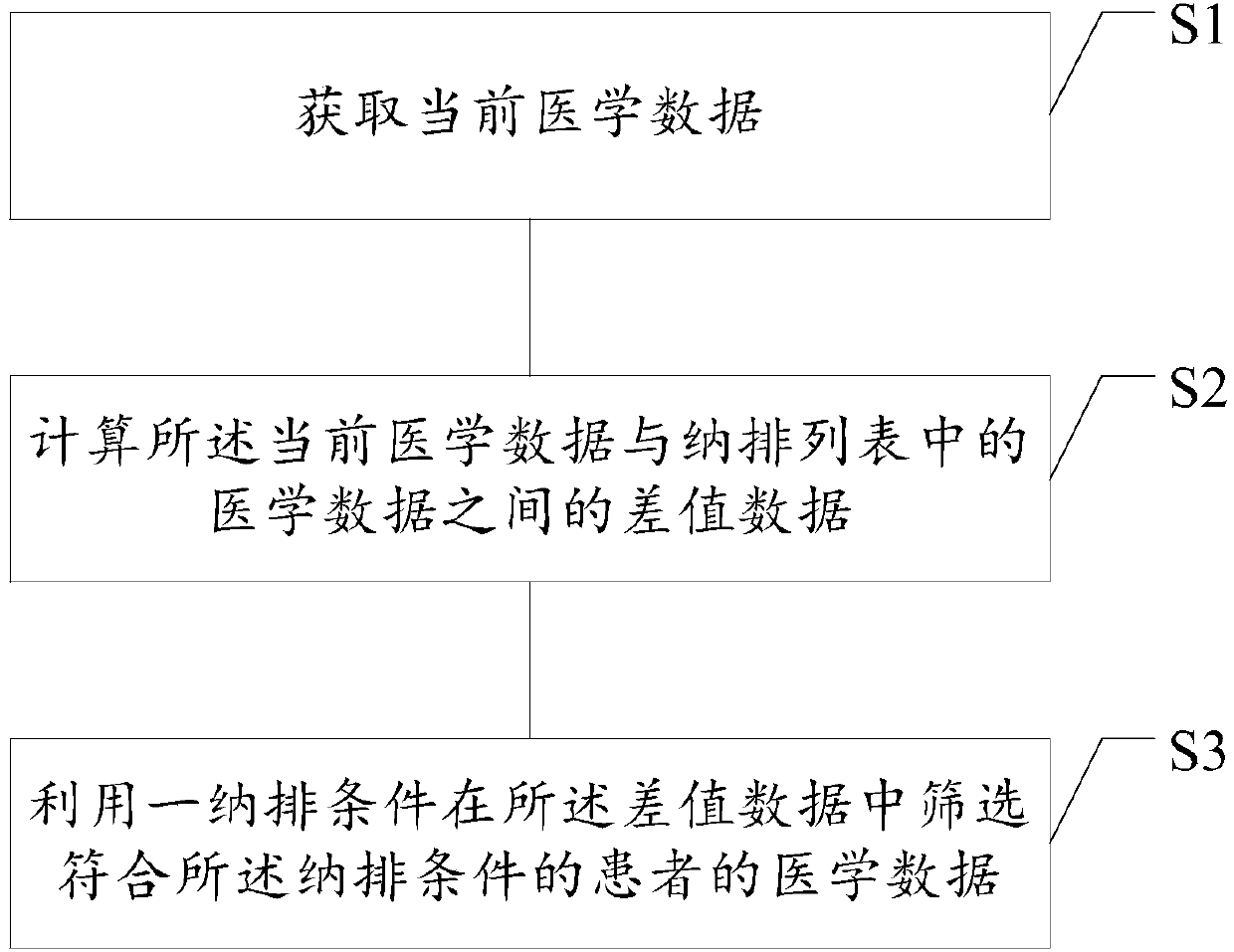

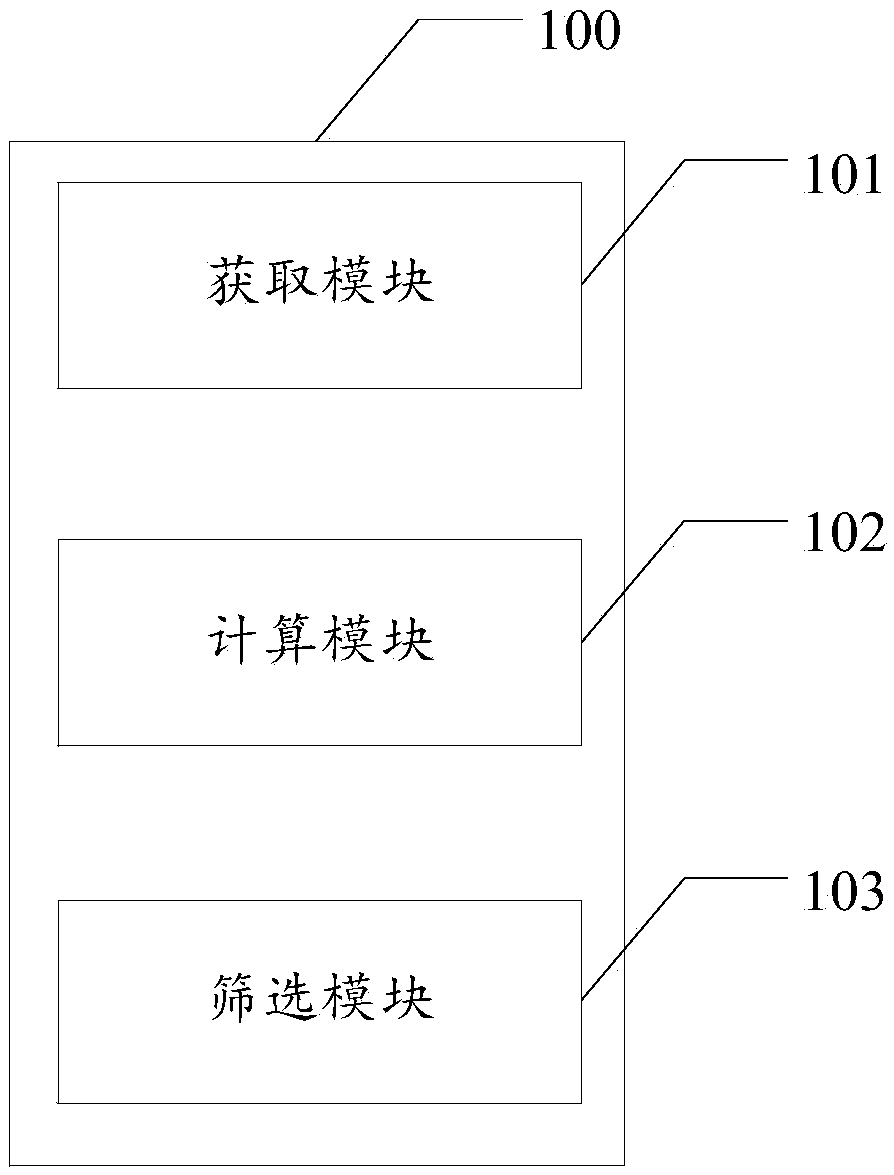

A patient data screening method and device, a storage medium and an electronic apparatus

ActiveCN107657991AGuaranteed accuracyImplement automatic filteringMedical data miningPatient-specific dataScreening methodPatient data

The invention relates to the technical field of data processing, in particular to a patient data screening method and device, a storage medium and an electronic apparatus. The method comprises the steps of: acquiring current medical data; calculating difference value data between the current medical data and medical data in an inclusion / exclusion list; using an inclusion / exclusion condition to screen out medical data of patients meeting the inclusion / exclusion condition in the difference value data. The method and the device guarantee the accuracy of medical data of patients obtained through screening, achieve automatic screening of medical data of patients, increase screening efficiency and greatly reduce screening cost.

Owner:YIDU CLOUD (BEIJING) TECH CO LTD

Crushing equipment for attapulgite

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

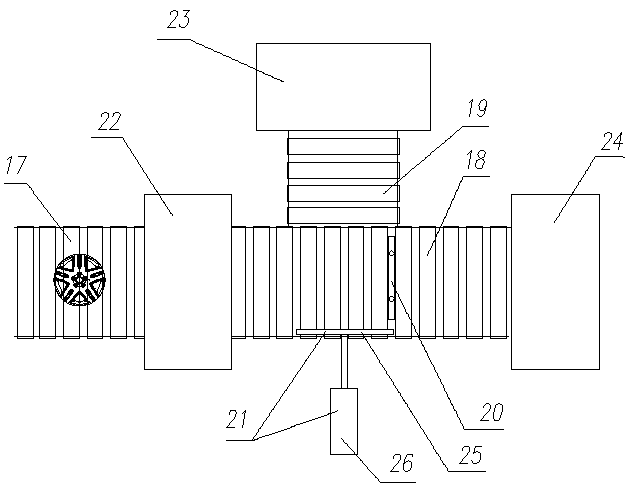

Automatic labelling equipment for hub, and production line

PendingCN110481923AImplement automatic filteringReduce participationImage analysisConveyorsProduction lineLabelling

The invention relates to the technical field of hub packaging, and specifically relates to automatic labelling equipment for a hub, and a production line. A conveying mechanism conveys the hub to a camera-shooting identification module, and the type of the hub is judged; a printer is capable of printing many types of bar-code labels or two-dimensional code labels; the bar-code labels or the two-dimensional code labels can be automatically printed according to a wheel type; and the bar-code labels or the two-dimensional code labels can be automatically bonded at specific positions according tothe wheel type. Automatic identification for the wheel type, automatic printing for the labels, and automatic bonding for the labels are realized, and personnel participation is reduced, so that the production efficiency is increased, and the generation of customer complaints is reduced.

Owner:CITIC DICASTAL

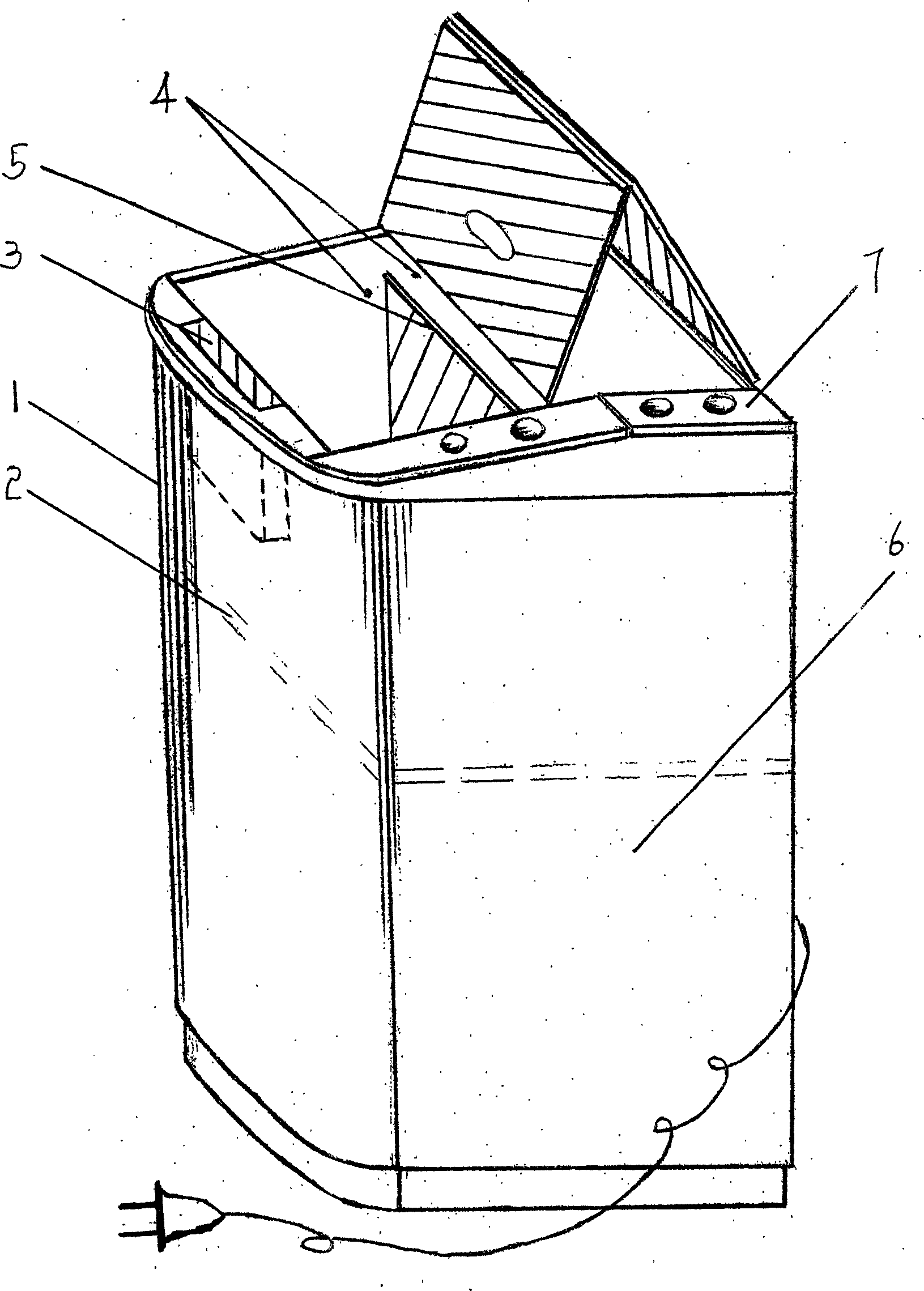

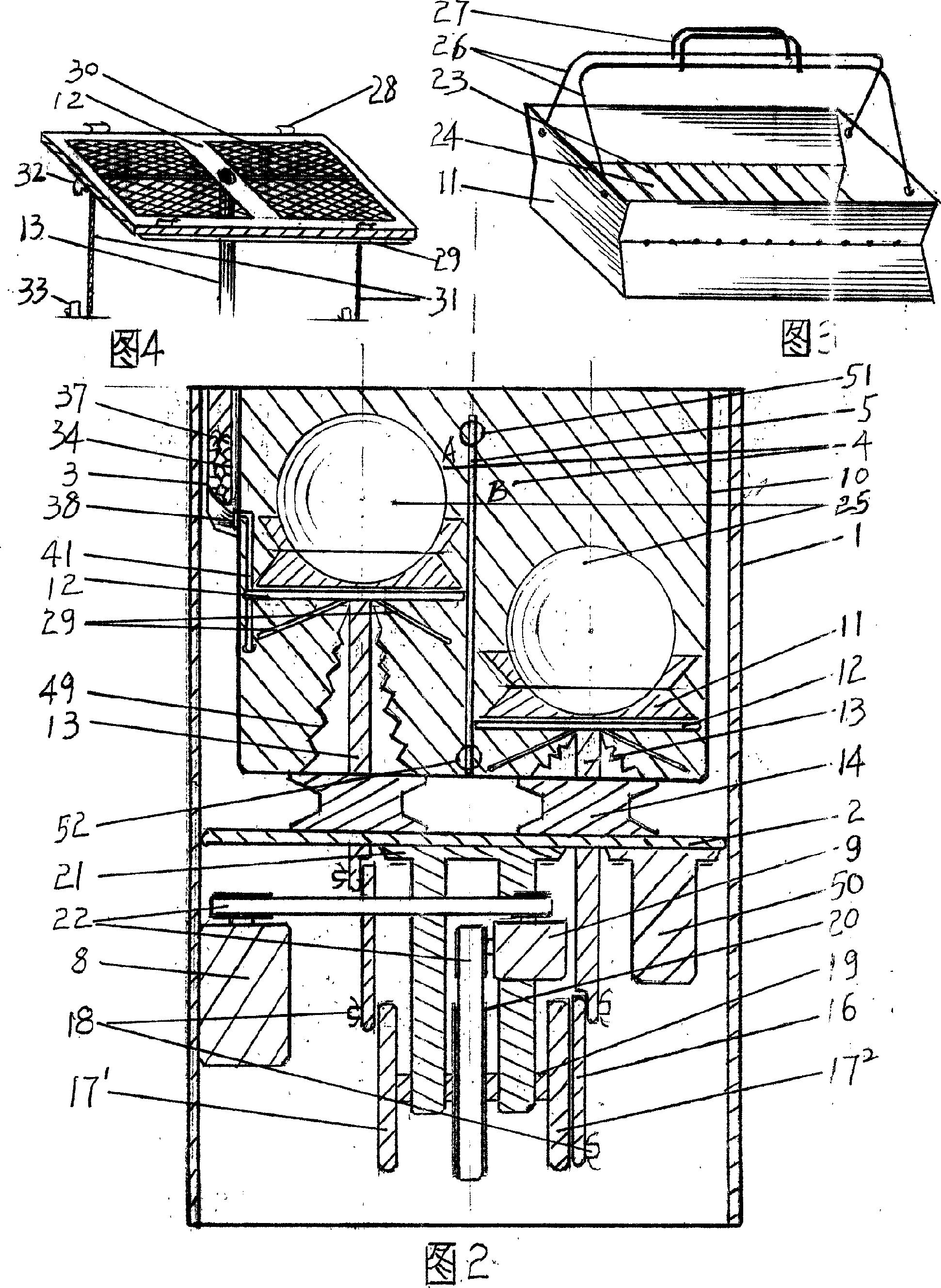

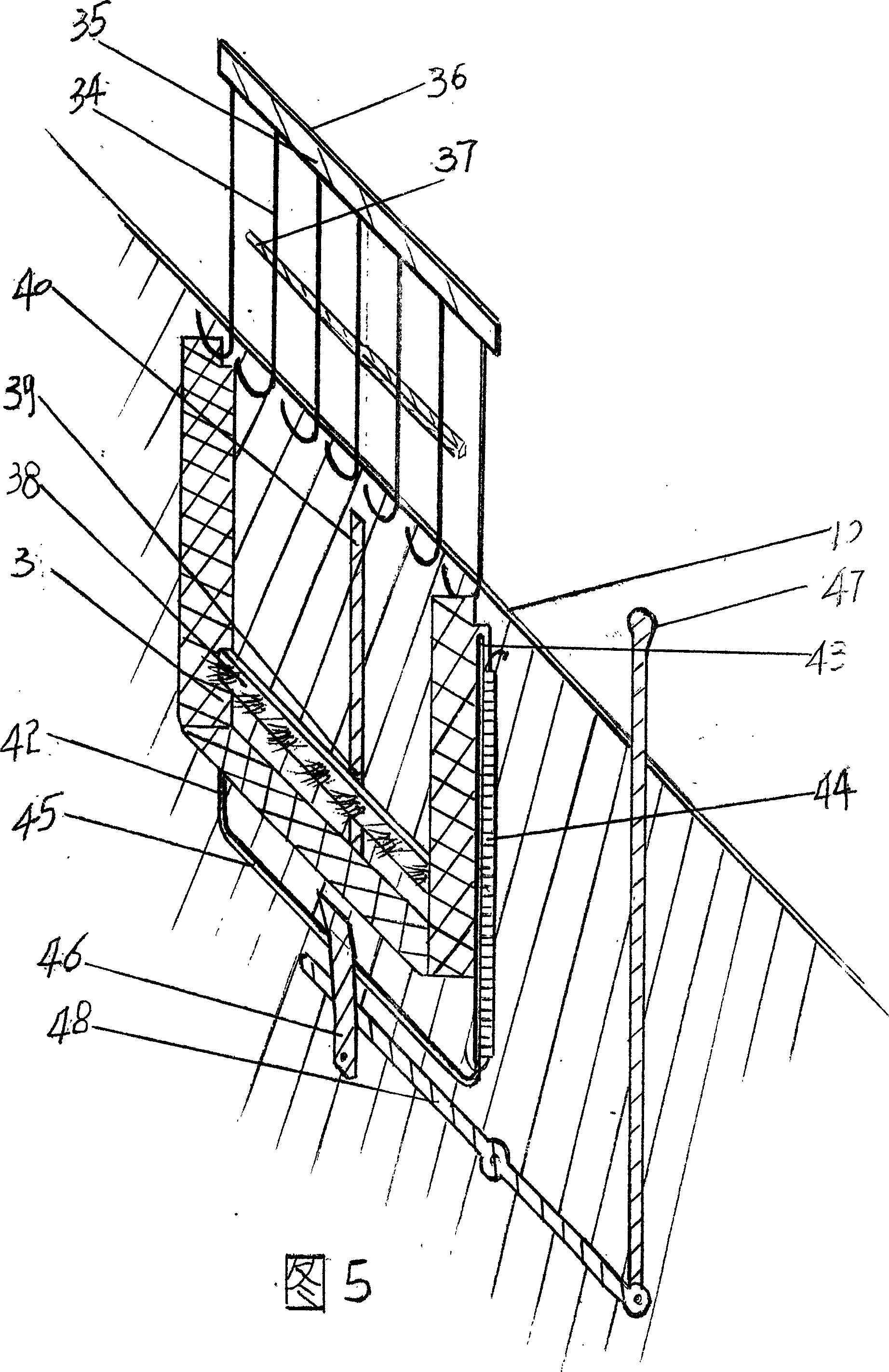

Fully-automatic submersible panting type multi-cylinder dish-washing machine

The present invention provides a full-automatic vertically-soaked multitub disk-washer. In the containing cavity of machine body interior the partions are vertically set, said containing cavity can be divided into several water tubs, in every water tub interior a movable frame for supporting dish basket is set, a movable bar positioned on the axis of water tub is passed through the bottom of water tub and is connected with motor by means of driving device, the rotation of motor can be used for driving dish basket by means of driving device and making it be up-down reciprocally moved so as to attain the goal of cleaning dishes. Said dish-washer also is equipped with the components of washing frequency regulator and float water-level detector, etc.

Owner:施兆登

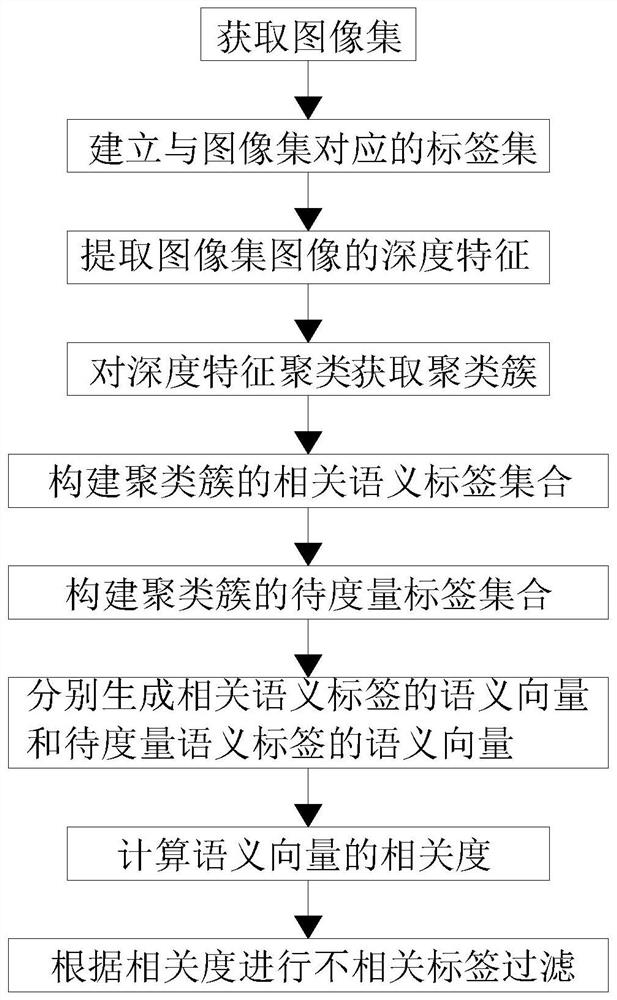

Irrelevant label filtering method based on depth feature clustering and semantic measurement

ActiveCN112232374ASimple structureReasonable designCharacter and pattern recognitionNeural architecturesSemantic vectorSample graph

The invention discloses an irrelevant label filtering method based on depth feature clustering and semantic measurement. The method comprises the following steps: 1, acquiring an image set by a sensor; 2, establishing a label set corresponding to the image set; 3, extracting depth features of the images in the image set; 4, clustering the depth features to obtain a cluster; 5, constructing a related semantic label set of the clustering cluster; 6, constructing a to-be-measured label set of the clustering cluster; 7, generating a semantic vector; 8, calculating the relevancy of the semantic vectors; and 9, filtering the irrelevant labels according to the relevancy. According to the method, the clustering cluster is obtained by clustering huge sample image data and used for pre-classifying the sample image data, the clustered sample image data is analyzed, higher effectiveness and correctness are achieved, meanwhile, relevancy measurement is conducted on label semantics, and therefore automatic filtering of irrelevant labels is achieved, and the filtering accuracy is improved, the generalization and robustness of the deep network can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Material crushing and screening device

InactiveCN107297241AImprove crushing effectTurn over to achieveSievingScreeningFree fallingGear wheel

The invention discloses a material crushing and screening device, which comprises two side plates, wherein the side plates are symmetrically arranged on a workbench; a cylinder cover is fixedly connected with the side plates; two ends of a roller movably sleeve the cylinder cover; the roller comprises a turnover plate and a screening mesh; an installation hole and a slideway are processed in each side plate; a baffle plate is fixed at the outer side of each slideway; a driving shaft is arranged in the installation hole and matched with a rolling bearing and a bearing cover plate; a driving gear is processed on the driving shaft; a slide block is located in each slideway; a driven shaft is arranged between the slide blocks and matched with a rolling bearing I and a bearing cover plate I; a driven gear is processed on the driven shaft; one end of an adjusting screw rod is fixed on each slide block and the other end extends out of the baffle plate and is screwed with an adjusting nut; a pressure spring also sleeves each adjusting screw rod; the roller rotates and passes through the turnover plate to continuously take materials to a high place for free falling; and the driving shafts drive the driven shaft to rotate, and the materials are ground into powder and screened through the screening mesh under the grinding action of meshed driving gears and driven gear, so that the material crushing and screening device is compact in structure, suitable for grinding of various materials and good in universality.

Owner:舟山市敏瑞科技咨询有限公司

Automatic machining device for rail accessories

ActiveCN107553194AImplement automatic filteringReduce processing timeOther manufacturing equipments/toolsMetal working apparatusMachining timeRaw material

The invention discloses an automatic machining device for rail accessories. The automatic machining device comprises a base; a conveying chamber and a machining chamber are arranged on the base; the machining chamber is internally provided with a cutting device, a perforating device and a grooving device; a supporting plate is arranged in the position, inside the conveying chamber, on the base; astorage box is arranged on the supporting plate, the upper portion of the storage box is provided with a feeding inlet, and the lower portion of the storage box is provided with a discharging outlet;a rotary shaft is arranged in the storage box, and three rotating plates are uniformly welded to the rotary shaft in the circumferential direction at equal intervals; a fixed plate is arranged on oneside wall of the storage box, and the lower portion of the fixed plate is connected with a connection rod through a rotary shaft; the bottom of the connection rod is provided with a discharging baffle, and the discharging baffle is located below the discharging outlet; a push rod is welded to the middle of the connection rod, the end, away from the connection rod, of the push rod penetrates through the storage box, and the end, stretching into the storage box, of the push rod is in an arc shape; and a discharging pipe is arranged below the discharging outlet. According to the automatic machining device for the rail accessories, raw materials are screened in the machining and feeding processes, so that the time for machining waste is shortened, and the machining efficiency is improved.

Owner:安徽浦进轨道装备有限公司

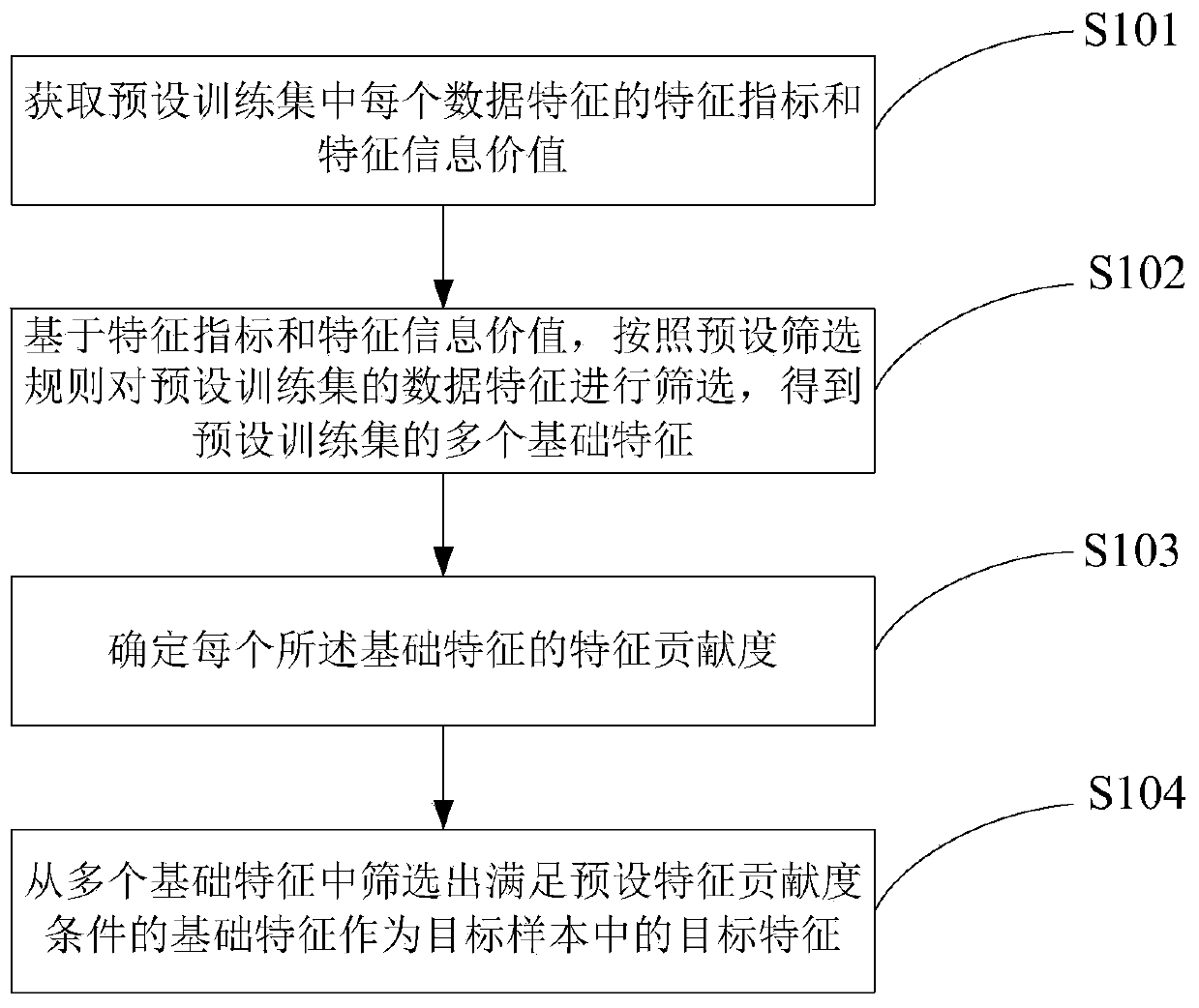

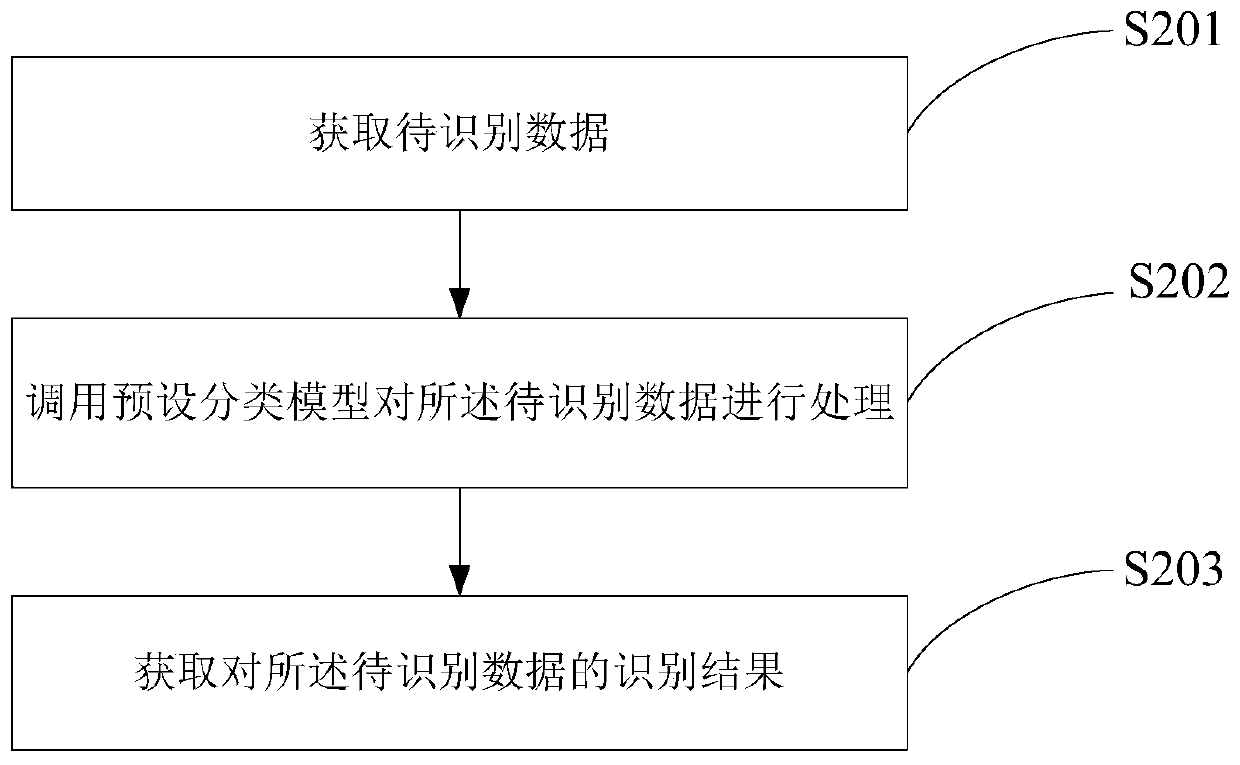

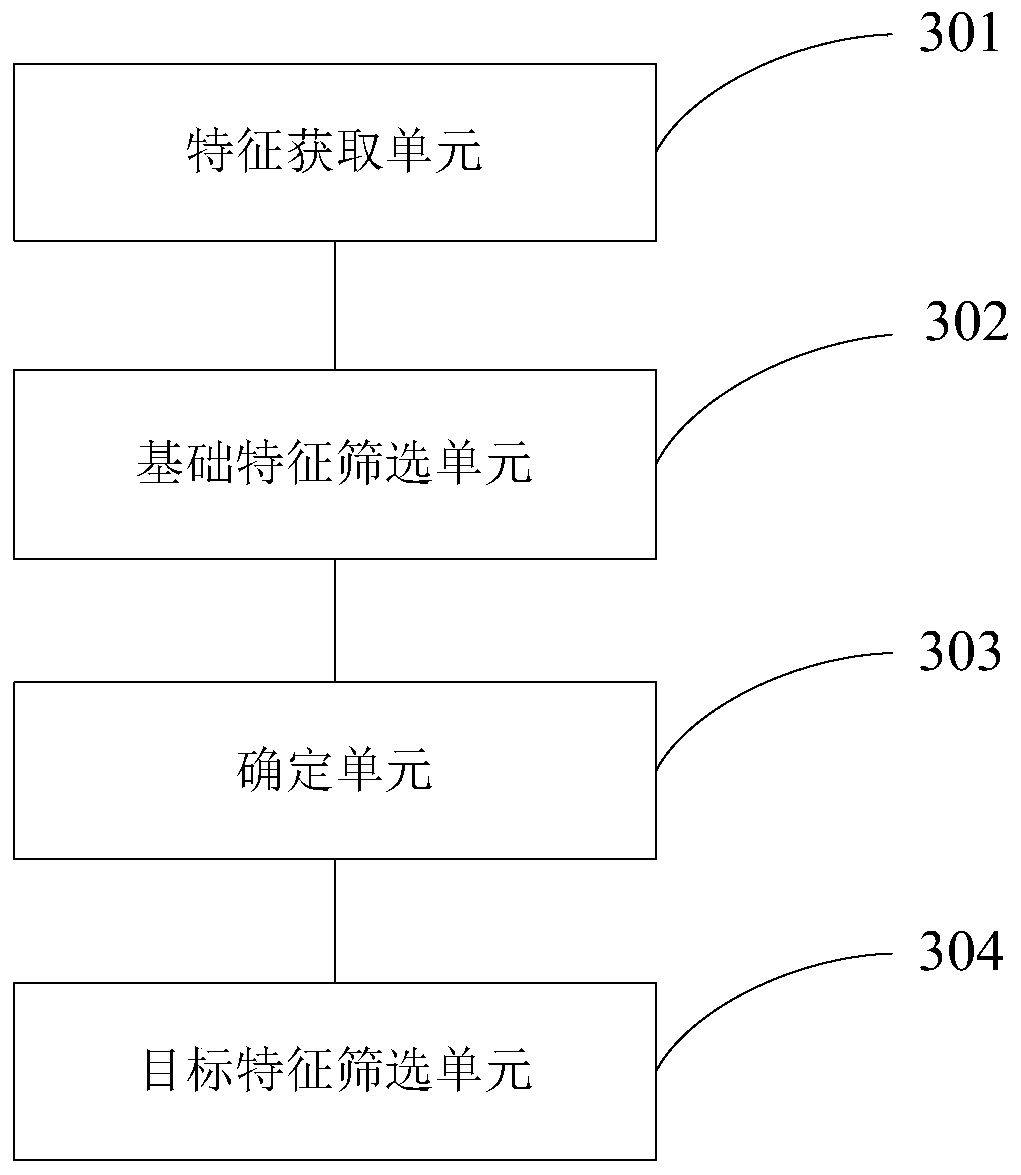

Sample generation method, classification model training method, recognition method and corresponding devices

PendingCN111476296AImprove training efficiencyReduce processingCharacter and pattern recognitionEngineeringData mining

The invention discloses a sample generation method, a classification model training method, a recognition method and corresponding devices. The method comprises the steps: during the generation of samples of a classification model, carrying out the preliminarily screening of the data features in a preset training set based on feature indexes and feature information values to obtain a plurality ofbasic features; reducing the data processing amount during classification model training; then, based on the feature contribution degree of each basic feature, screening out the basic features meetinga preset feature contribution degree condition from the plurality of basic features to serve as target features in the target sample so as to further reduce the data processing amount of classification model training, and generating a classification model based on the target features and the target data corresponding to the target features in the preset training set and the preset verification set. Therefore, automatic screening of the data is realized, and the data processing amount is small, so the manpower and time are greatly saved, and the training efficiency of the classification modelis improved.

Owner:度小满科技(北京)有限公司

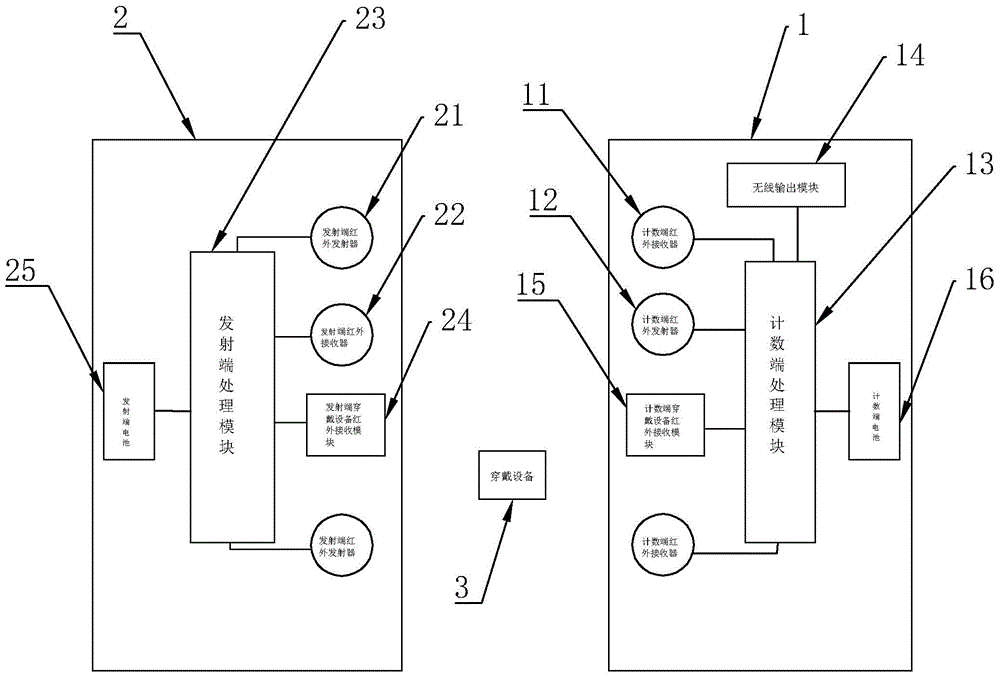

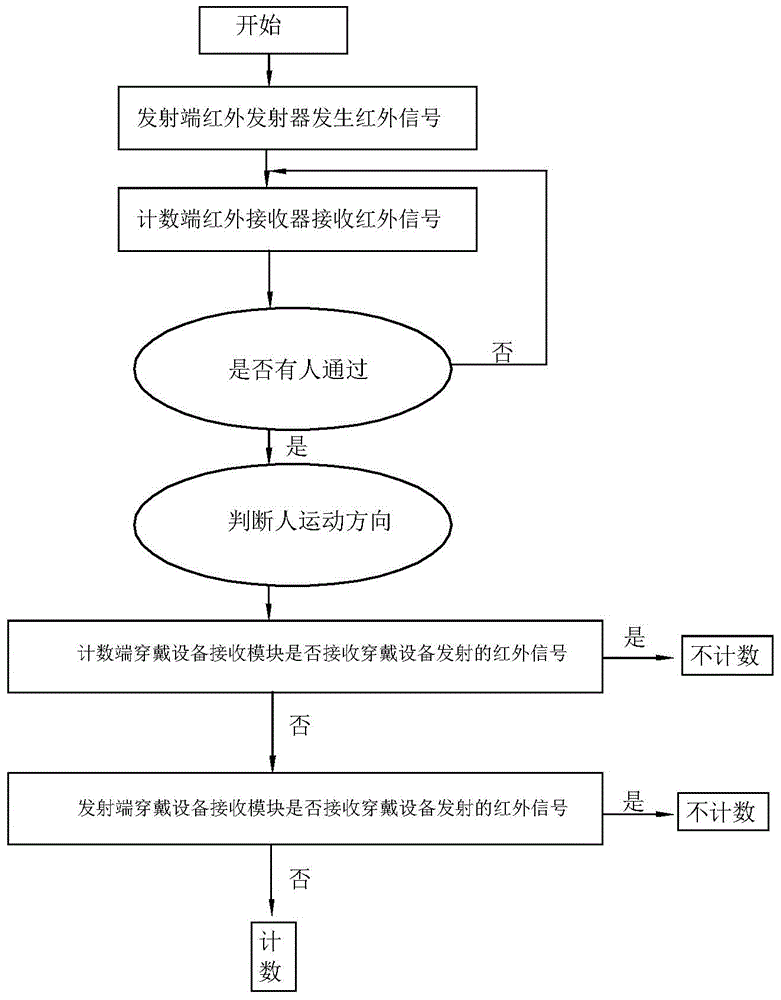

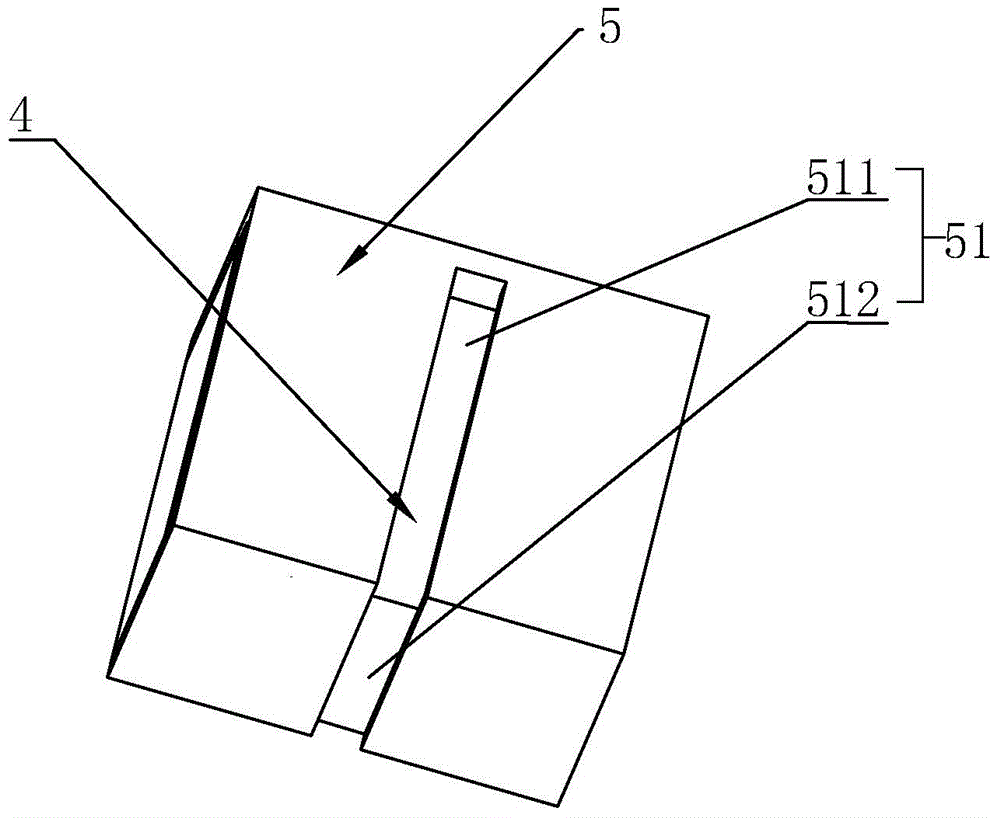

An infrared passenger flow volume counter

ActiveCN105117765ADisadvantages of implementing automatic deletionImplement automatic filteringCounting mechanisms/objectsVIT signalsInfrared emitter

The invention discloses an infrared passenger flow volume counter. The main points of the technical scheme are that an infrared counting terminal, an infrared transmitting terminal and a wearable device are comprised; when infrared rays are shielded, a counting terminal processing module carries out infrared signal acquisition on a counting terminal wearable device infrared reception module; when acquired infrared signals are in accordance with infrared signals sent by the wearable device, the present counting operation is paused; when the acquired infrared signals are not in accordance with infrared signals sent by the wearable device, the counting terminal processing module generates counts, and meanwhile, the counting terminal processing module will control a counting terminal infrared emitter to transmit infrared signals to a transmitting terminal infrared receiver. When the infrared signals acquired by a transmitting terminal processing module are in accordance with the infrared signals transmitted by the wearable device, response will be given, and then the counting terminal processing module will automatically delete counting data generated at that time, thereby realizing identification without counting personnel and avoiding disadvantages of automatic deleting of real passenger flow data by an infrared passenger flow volume counter. The accurate passenger flow counting is realized.

Owner:温州亿通自动化设备有限公司

Automatic sand sieving device for construction material production

InactiveCN108855880AAffect the screening effectImplement automatic filteringSievingRotary stirring mixersArchitectural engineeringBuilding material

Owner:张孝法

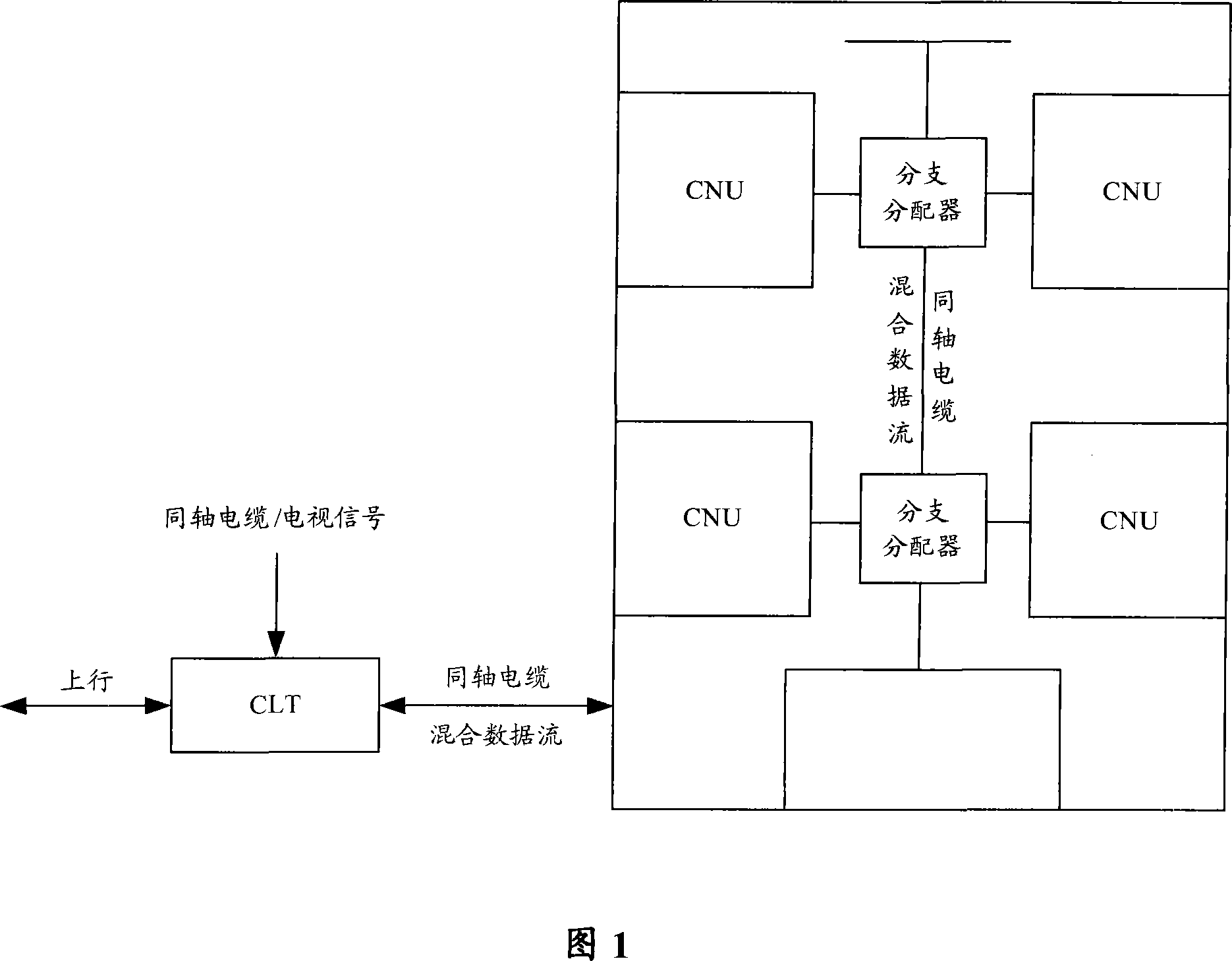

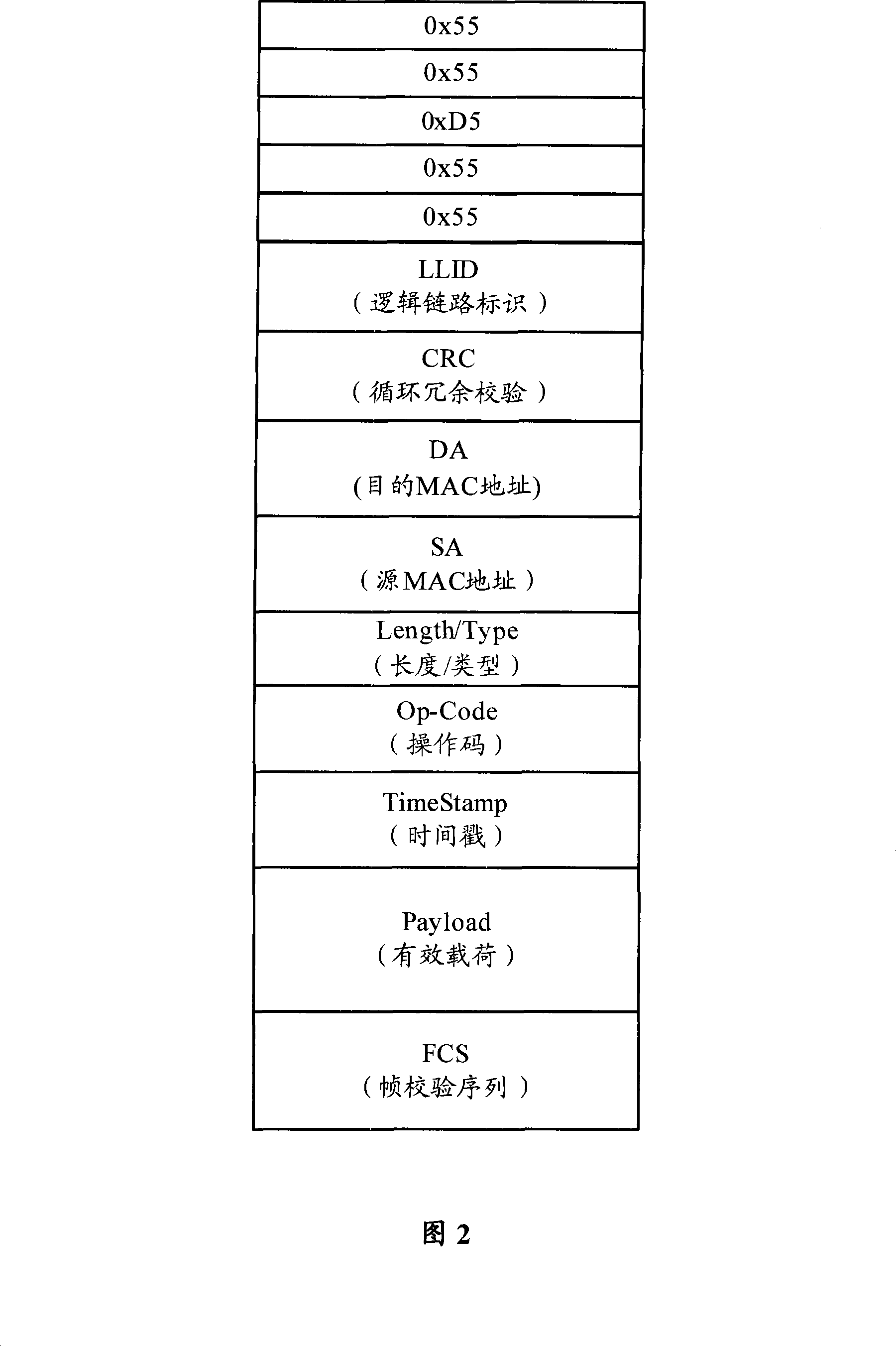

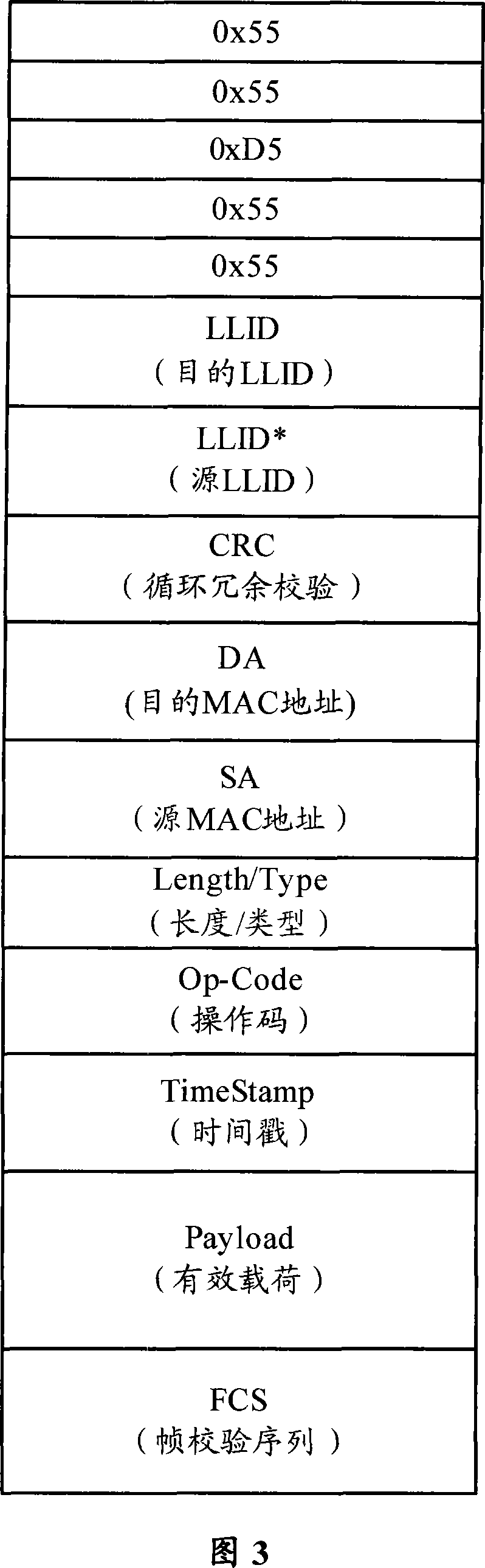

Method and apparatus for echo wave filtering in EOC system

InactiveCN101110611AImplement automatic filteringTwo-way loud-speaking telephone systemsLine-transmissionFiltrationEthernet

The present invention discloses a back wave filtration method in an EOC system including procedures below: A target LLID and a source LLID in a received message are acquired. The message is judged according to the source LLID and the target LLID. As an equipment corresponding to the target LLID comprises a principal equipment and the source LLID does not correspond to the principal equipment, the message is processed or discarded. The present invention also discloses a network equipment for back wave filtration in an EOC system. The present invention realizes back wave data filtration with a network equipment in a coaxial Ethernet system by adding a source LLID and a target LLID into a message.

Owner:NEW H3C TECH CO LTD

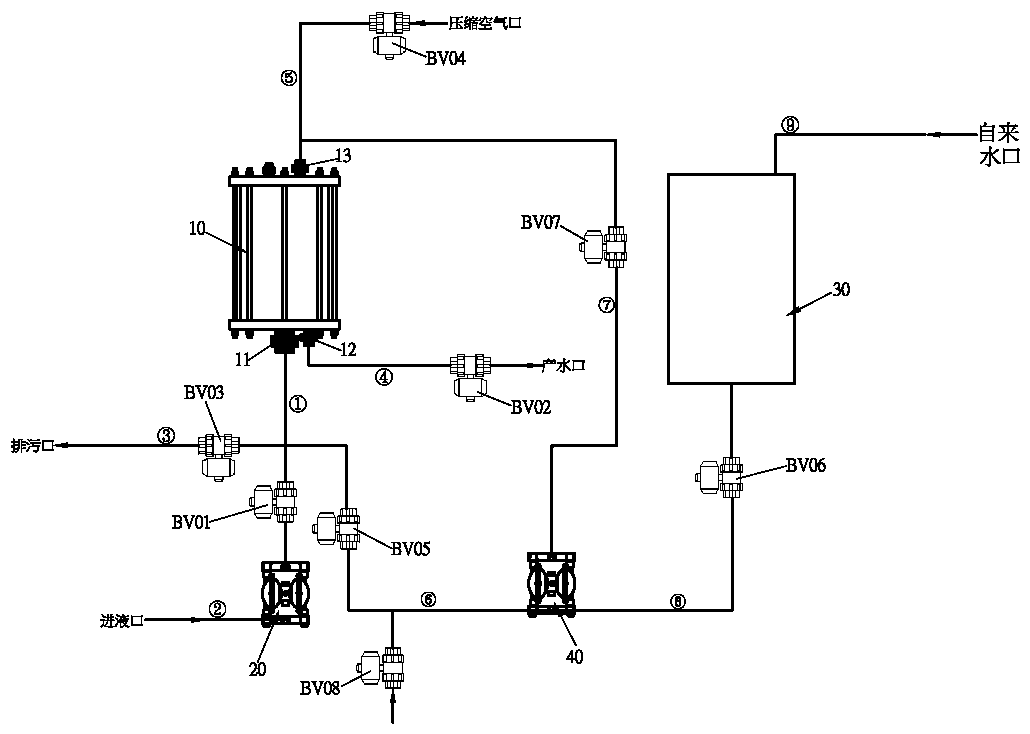

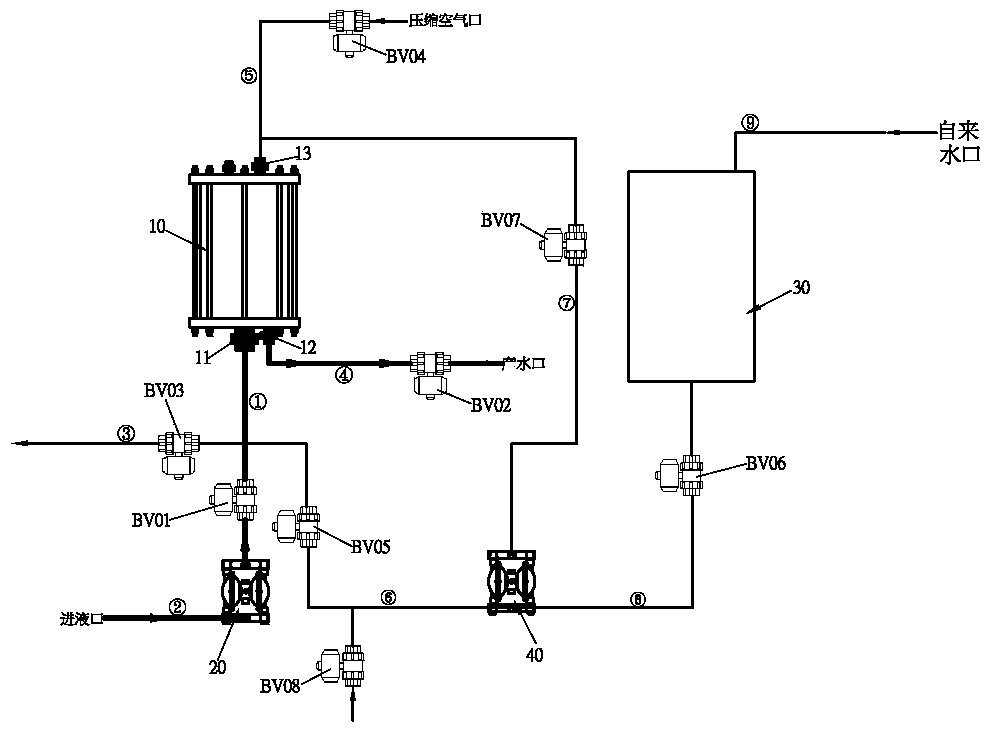

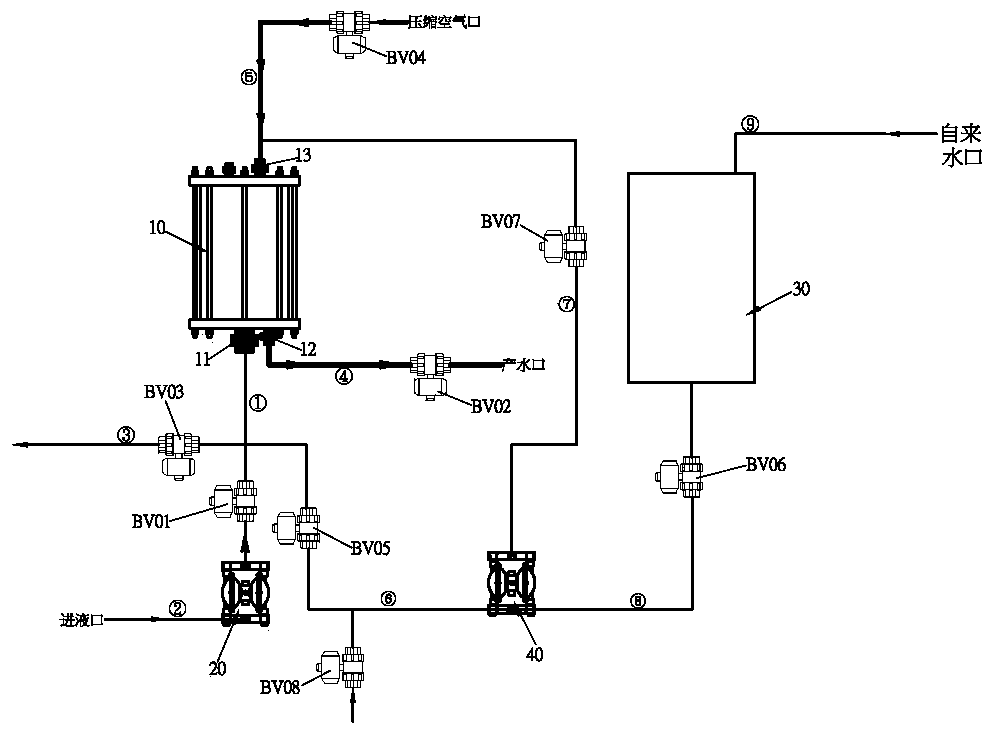

PCB (polychlorinated biphenyl) smear removal drug liquid filtration recycling equipment and smear removal drug liquid filtration recycling method thereof

PendingCN108245985AReduce pressure on environmental protectionImplement automatic filteringFiltration circuitsPolychlorinated biphenylFiltration

The invention discloses PCB smear removal drug liquid filtration recycling equipment and a smear removal drug liquid filtration recycling method thereof. The equipment comprises a filtration film assembly, a filtration pump, a washing barrel, a washing pump, a liquid inlet, a sewage draining outlet, a water production port, an air compressed port and a running water port. Automated filtration andsmear removal are achieved through arrangement and mutual cooperation of the components. Automated washing is achieved mainly through arrangement and mutual cooperation of the filtration film assembly, the filtration pump, the washing barrel, the washing pump and valves. Washing is performed through circulation washing by adopting a drug preparation, and running water washing effectively guarantees smear stuck to the filtration assembly is removed clearly. In this way, the filtration film assembly can achieve the effect of repeated cyclic using without being replaced, and the replacement costis saved.

Owner:GUANGDONG VICDI TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com